Page 1

Data Sheet

Sight glass

Type LLG 185 - 1550

For industrial and marine refrigeration installations.

LLG are sight glasses in ductile steel which

meets the strictest requirements on industrial

and marine refrigeration installations.

The sight glasses are oered in 3 dierent

versions:

• with welding nipples (LLG)

• with stop valves equipped with caps (LLG S)

• with stop valves and sight adapter in acrylic

glass ready for insulation on site (LLG SF)

The range of sight glasses is based on 3 basic

sight glasses: LLG 185, LLG 335 and LLG 740.

The other standard lengths are combined by

using variations of basic glass lengths.

LLG produce sucient ow areas to secure the

highest possible degree of synchronous

operation, and have a specially hardened

reection glass for quick reading. The front and

the base frame are mounted together from the

front with countersunk allen screws. This

ensures easy insulation on site as well as easy

inspection and service, if any.

All sight glasses are equipped as standard with

a built-in safety system (non return device). If a

glass is damaged, the pressure of the

refrigerant will activate the safety system and

refrigerant loss will be limited to an absolute

minimum.

AI176286432251en-000701

Page 2

Sight glass, Type LLG 185 - 1550

Features

• Refrigerants

◦ Applicable to HCFC, HFC and R717 (Ammonia).

• Temperature range:

◦ –10/+100 °C (–14/+212 °F) or

◦ –50/+30°C (–58/+86°F)

• Maximum operating pressure

◦ 25 bar g (363 psi g)

• Equipped with boron silicate glass, hardened by an accurately controlled heat treatment process

• Classication: CRN, EAC etc.

To get an updated list of certication on the products please contact your local Danfoss Sales Company.

Product specication

Technical data

Refrigerants

Applicable to HCFC, HFC and R717 (Ammonia). For further information please see installation instruction for LLG.

Flammable hydrocarbons are not recommended. For further information please contact your local Danfoss Sales

Company.

Temperature range

The sight glasses are applicable to the above mentioned refrigerants within the temperature range of:

• –10/+100°C (+14/+212°F) for the LLG types with safety system with welding nipples and the LLG S types with

safety system with stop valves.

• –50/+30°C (–58/+86°F) for the LLG SF types with safety system with stop valves and sight adapter (acrylic glass)

and the LLG F types with safety system and sight adapter (acrylic glass).

Pressure range

All LLG types are designed for:

Max. operating pressure 25 bar g (363 psi g)

Strength test: 50 bar g (725 psi g)

Leakage test: at 25 bar g (363 psi g)

Design

Glass

LLG's are equipped with a boronsilicate glass, hardened by an accurately controlled heat treatment process. All

glasses are according to DIN 7081.

Gaskets

The glasses are equipped with a special nonasbestos carbon compound gasket which provides superior mechanical

characteristics and a long time guarantee against service leakage.

Connectors

LLG 590, LLG 995, LLG 1145 and LLG 1550 are joined together by 2 basic LLG’s by means of a connector. The

connector holds the two basic glasses together by means of screws and guiding pins, which ensures a rigid

construction.

Stop Valves/Nipples

The glasses are connected to the refrigeration system by means of welding nipples or stop valves. Which ever

system is used, the nipples or stop valves are screwed into a ange, which is located in the correct position and

subsequently tightened with a seal gasket and 4 screws.

Installation

Install the glasses on a bracket using the 4 screws supplied with the glass.

© Danfoss | Climate Solutions | 2021.02 AI176286432251en-000701 | 2

Page 3

1

2 3

LLG

4

Danfoss

148H21

1234Separator/ Intermediate cooler

Purge valve

Oil charging valve

Oil vessel

Sight glass, Type LLG 185 - 1550

Use the threaded holes on the back of the frame to mount the glass on a bracket (not of Danfoss supply). Always

connect the piping after mounting on the bracket. Please note the importance of a minimum of stress in the sight

glasses from the connected pipes. Please also make sure that there is sucient space behind the the sight glasses to

ensure proper insulation, service and inspection, etc.

For installations below –10 °C (+14 °F) it is recommended to add the sight adapter to enable reading after insulation

has been applied. For installations below –10 °C (+14 °F) in R717 plants it is recommended to use an oil column as

described in the following pages. There will be no formation of bubbles or ice build-up in oillled sight glasses,

which may be the case in the refrigerant-lled glasses.

The sight glasses are designed to withstand high internal pressures. However, the piping system in general should

be designed to avoid liquid traps and reduce the risk of hydraulic pressure caused by thermal expansion.

NOTE:

The LLG sight glass can only be placed in CE approved applications with the stop valves in front.

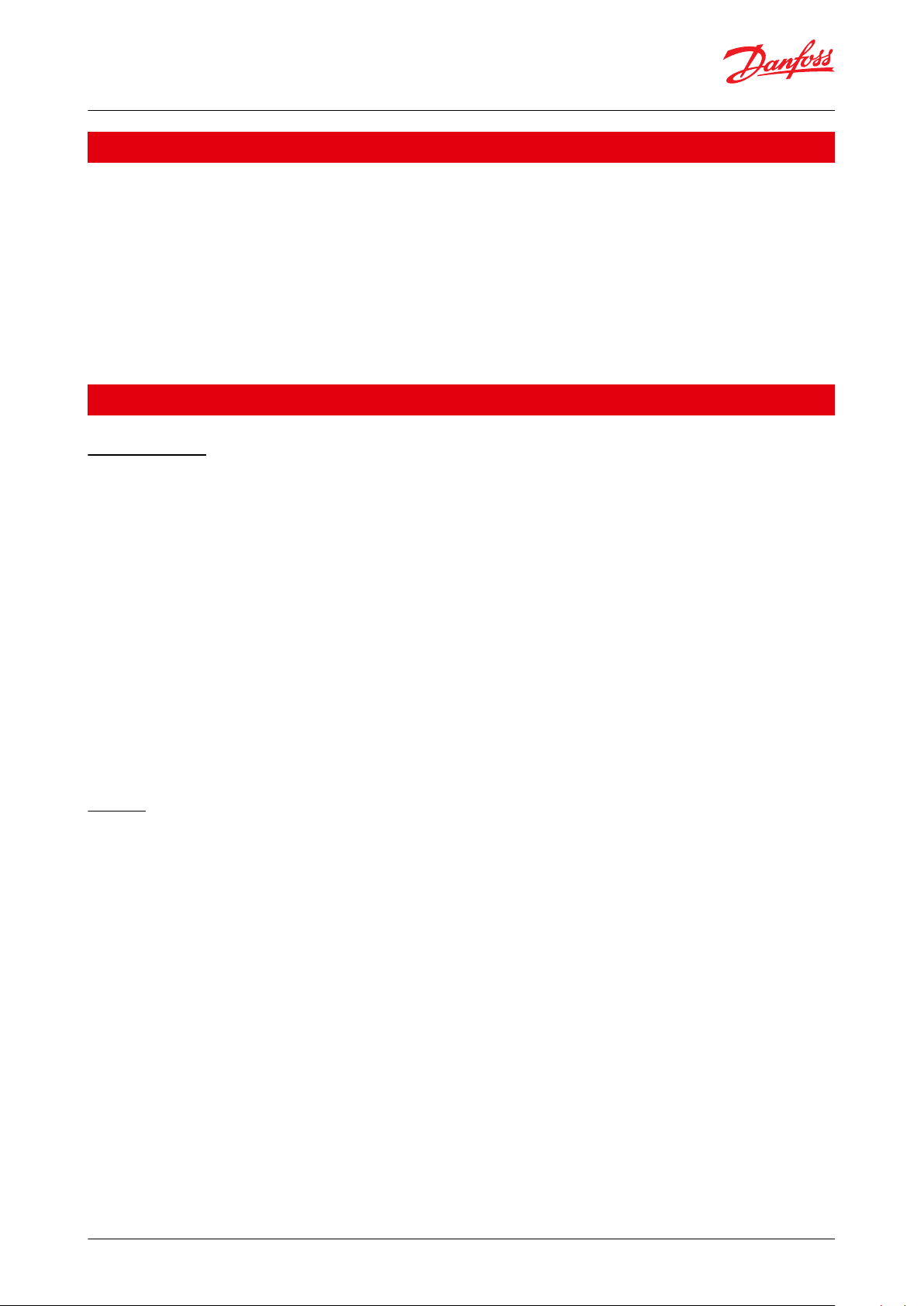

Frostproof sight glasses

Example 1

Refrigerant: R717 (ammonia)

Temperature: Recommended for temperatures below –10 °C (+14 °F).

The principle shown in Figure 1 can be used in connection with low temperature liquid separators or intermediate

coolers when the refrigerant is R717 (ammonia). As the liquid level in the R717 separator varies the oil level will

change simultaneously.

Figure 1: Working principle of sight glass

Oil changing

The system is charged with synthetic oil type SHC 226 with a specic weight, diering from that of R717, and (h)

must be multiplied by approximately 1.35 (the ratio of density oil to density R717) to calculate H.

Charge the oil vessel (volume approximate 10 litres) to a level just below the lower balancing pipe (A) through the

oil charging valve. Close the oil charging valve.

The oil will show in the sight glass at a level equal to the level in the oil vessel. When R717 is lled into the separator

or intermediate cooler it will enter the oil vessel and press down the oil surface.

The R717 will also rise into the upper balance pipe (B) to a level equal to the level in the separator or intermediate

cooler. As the oil surface in the oil vessel is pressed down, the oil will rise into the sight glass.

NOTE:

It is important to use an oil which is not likely to mix with R717. The oil must have a high viscosity index to ensure

easy owing at low temperatures. Mobil SHC 226 of the synthetic polyalphaolen type has proven suitable for this

purpose.

© Danfoss | Climate Solutions | 2021.02 AI176286432251en-000701 | 3

Page 4

1

2

3

4 5

6

Danfoss

148H20

1

23456

Separator pressure P

0

Uninsulated

Bypass

Oil charging valve

Purge valve

Oil vessel

P

0

H

ρ

g

Separator pressure – [N/m2]

R717 liquid level, see g. 2 – [m]

R717 density – [kg/m3]

Acceleration due to gravity 9.81 – [m/s2]

Sight glass, Type LLG 185 - 1550

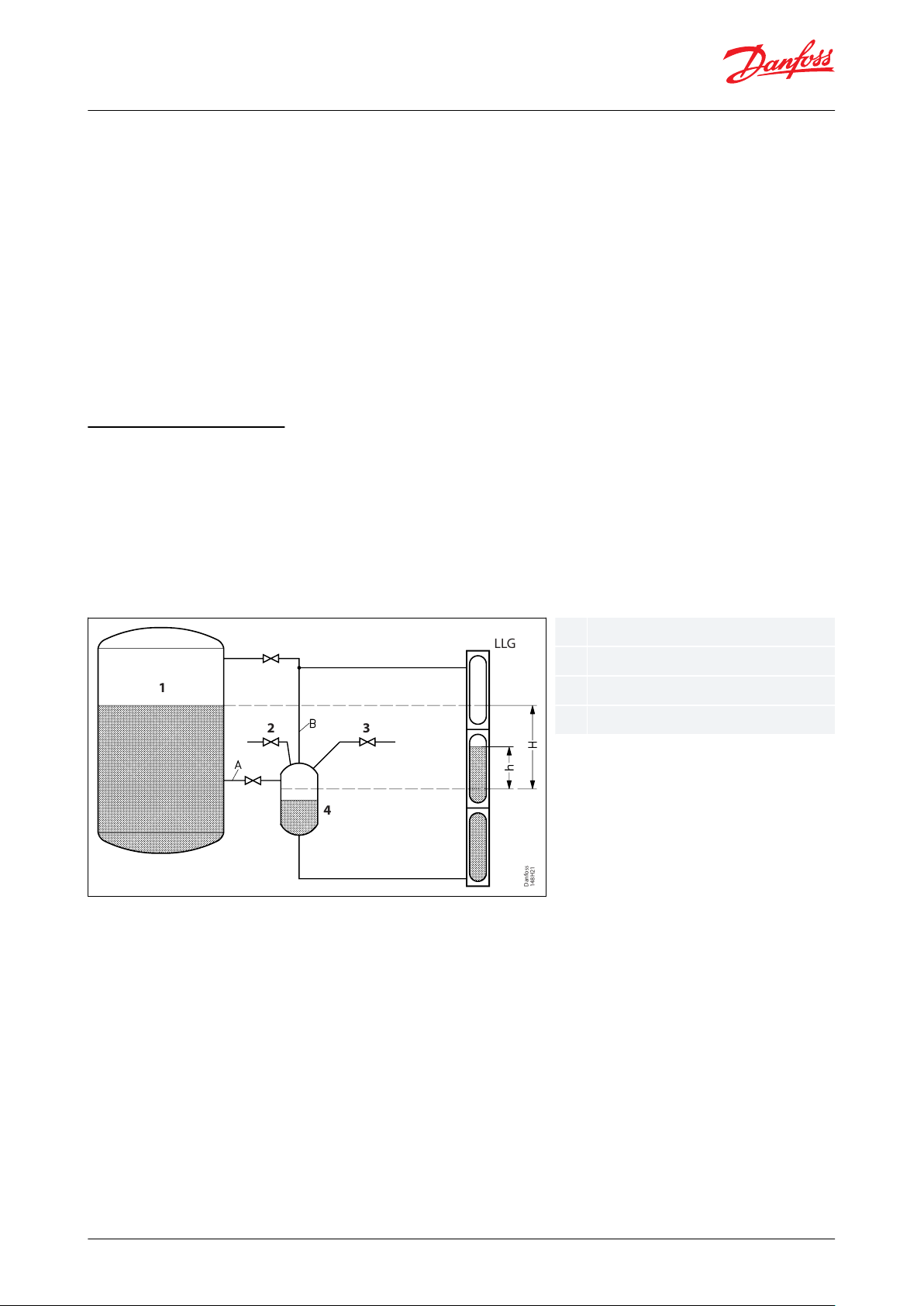

Example 2

Refrigerant: R717 (ammonia)

Temperature: Recommended for temperatures below –10 °C (+14 °F).

Figure 2 shows a frostproof sight glass for an R717 liquid separator which is placed above ground level. The

arrangement is called a Hampsonmeter.

Due to the evaporation taking place in the uninsulated balance pipe (ND 80/3 in.) the pressure in this pipe will be

equal to P1 = P0 + H × ρ × g.

Figure 2: Frostproof sight glass

Oil Charging

The pressure will act on the oil surface in the oil vessel and cause the oil to rise in the sight glasses which are

installed in a length of e.g. 2 in. pipe, the top of which is connected to the top of the separator which is at pressure

P0.

The oil will rise to a level h and H can then be calculated by multiplying h by 1.35 (the ratio of density oil to density

R717).

Charge the oil vessel through the oil charging valve to a level of approximately ¾ of full level. The level will show in

the lower sight glass.

Take care that the volume of the oil vessel is sucient to allow the oil to rise into the sight glasses. When the system

is operating keep the bypass valve closed.

NOTE:

It is important to use an oil not likely to mix with R717, and having a high viscosity index to ensure easy oil

movements at low temperatures. Mobil SHC 226 of the synthetic polyalphaolen type has proven suitable for this

purpose.

© Danfoss | Climate Solutions | 2021.02 AI176286432251en-000701 | 4

Page 5

Danfoss

148H16

Danfoss

148H17

No.

Part

Material

DIN

ISO

ASTM

1

Front frame

Steel

RSt. 37.2, 17 100

Fe 360 B, 630

Grade C, A 283

2

Back frame

Steel

RSt. 37.2, 17 100

Fe 360 B, 630

Grade C, A 283

3

Sight glass

Glass4Gasket

Non-asbestos

5

Protective coating for sight glass

Non-asbestos

6

Sight adapter

PMMA-acrylic

8

Connecting piece

Steel

RSt. 37.2, 17 100

Fe 360 B, 630

Grade C, A 283

10

O‑ring

Cloroprene (Neoprene)

14

Flange

Steel

RSt. 37.2, 17 100

Fe 360 B, 630

Grade C, A 283

15

Balls

Stainless steel

18

Welding nipple

Steel

RSt. 37.2, 17 100

Fe 360 B, 630

Grade C, A 283

19

Stop valve (SNV-ST

(1)

)

Steel

Sight glass, Type LLG 185 - 1550

Material specication

Figure 3: LLG

Table 1: Material specication

Figure 4: LLG S and LLG SF

(1)

(1)

See Technical data for SNV-ST valves.

See Technical data for SNV-ST valves.

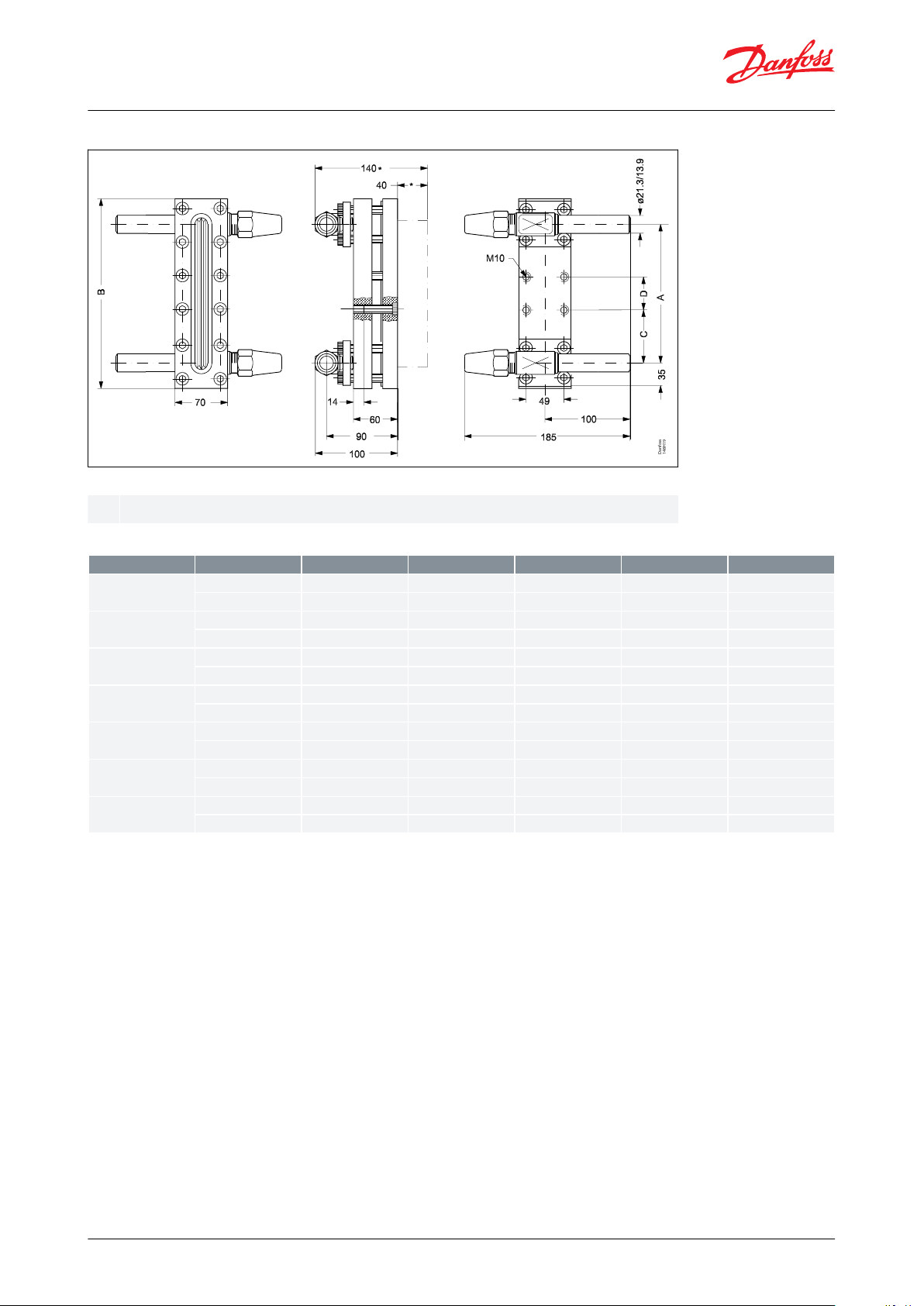

Dimensions and weights

Figure 5: LLG

© Danfoss | Climate Solutions | 2021.02 AI176286432251en-000701 | 5

Page 6

*

Danfoss

148H19

Only for LLG SF with sight adapter

Type

UnitABCD

Weight

LLG 185

mm

185

2556948

4.2 kg

(1)

in7¼102¾2

5.8 kg

(2)

LLG 335

mm

335

4056342

7.5 kg

(1)

in

13¼162½1¾9.2 kg

(2)

LLG 590

mm

590

660

69 + 63

48 + 42

13.2 kg

(1)

in

23¼262¾ + 2½

2 + 1¾

15.1 kg

(2)

LLG 740

mm

740

8106342

16.5 kg

(1)

in

29¼322½1¾18.5 kg

(2)

LLG 995

mm

995

1065

69 + 63

48 + 42

22.5 kg

(1)

in

39¼422¾ + 2½

2 + 1¾

24.7 kg

(2)

LLG 1145

mm

1145

12156342 + 42

25.7 kg

(1)

in4547¾2½1¾ + 1¾

28.0 kg

(2)

LLG 1150

mm

1550

16206342

33.5 kg

(1)

in6163¾2½1¾

36.1 kg

(2)

Sight glass, Type LLG 185 - 1550

Figure 6: LLG S and LLG SF

Table 2: LLG 185 - 1550

(1)

(1)

Type LLG

Type LLG

(2)

(2)

Type LLG S and LLG SF

Type LLG S and LLG SF

NOTE:

• Specied weights are approximate values only

• LLG 740 consist of one back piece and 2 front sight glasses.

© Danfoss | Climate Solutions | 2021.02 AI176286432251en-000701 | 6

Page 7

Valve type

LLG

Sight glass

Nominal size in mm

Combined by:

185

DN 185

335

DN 335

590

DN 590

LLG 185 + LLG 335

740

DN 740

LLG 740 consist of one back piece and 2 front sight glasses

995

DN 995

LLG 185 + LLG 740

1145

DN 1145

LLG 335 + LLG 740

1550

DN 1550

LLG 740 + LLG 740

Equipment

-

Safety system and welding nipples

F

Safety system and sight adapter

S

Safety system and stop valves (SNV-ST)

SF

Safety system, stop valves (SNV-ST) and sight adapter

Length

Type

Code no.

mm

in

1857¼LLG 185

2512+049

335

13¼

LLG 335

2512+050

590

23¼

LLG 590

2512+051

740

29¼

LLG 740

2512+052

995

39¼

LLG 995

2512+053

1145

45

LLG 1145

2512+054

1550

61

LLG 1550

2512+055

Length

Type

Code no.

mm

in

185

7¼

LLG 185 S

2512+056

335

13¼

LLG 335 S

2512+057

590

23¼

LLG 590 S

2512+058

740

29¼

LLG 740 S

2512+059

995

39¼

LLG 995 S

2512+060

1145

45

LLG 1145 S

2512+061

1550

61

LLG 1550 S

2512+062

Sight glass, Type LLG 185 - 1550

Ordering

How to order

The table below is used to identify sight glasses required.

NOTE:

The type codes only serve to identify the sight glasses, some of which may not form part of the standard product

range.

For further information please contact your local Danfoss Sales Company.

Type codes

Example for type codes: LLG 740 SF

Table 3: Type codes

Sight glasses - LLG

Table 4: With safety system and welding nipples

Sight glasses - LLG S

Table 5: With safety system and stop valves (SNV-ST)

© Danfoss | Climate Solutions | 2021.02 AI176286432251en-000701 | 7

Page 8

Length

Type

Code no.

mm

in

185

7¼

LLG 185 F

2512+078

335

13¼

LLG 335 F

2512+079

590

23¼

LLG 590 F

2512+080

740

29¼

LLG 740 F

2512+081

995

39¼

LLG 995 F

2512+082

1145

45

LLG 1145 F

2512+083

1550

61

LLG 1550 F

2512+084

Length

Type

Code no.

mm

in

185

7¼

LLG 185 SF

2512+066

335

13¼

LLG 335 SF

2512+067

590

23¼

LLG 590 SF

2512+068

740

29¼

LLG 740 SF

2512+069

995

39¼

LLG 995 SF

2512+070

1145

45

LLG 1145 SF

2512+071

1550

61

LLG 1550 SF

2512+072

File name

Document type

Document topic

Approvals Authority

MD 033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

MD 033F0686.AH

Manufacturers Declaration

PED

Danfoss

RMRS 19.10327.266

Marine - Safety

Certicate

RMRS

TSSA CRN.0F2997.7123456890YTN

Pressure - Safety

Certicate

CRN

TSSA

Sight glass, Type LLG 185 - 1550

Sight glasses for insulating - LLG F

Table 6: With safety system and sight adapter

Sight glasses for insulating - LLG SF

Table 7: With safety system, stop valves (SNV-ST) and sight adapter

IMPORTANT:

Where products need to be certied according to specic certication societies or where higher pressures are

required, the relevant information should be included at the time of order.

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 8: LLG 185 and LLG 1550

© Danfoss | Climate Solutions | 2021.02 AI176286432251en-000701 | 8

Page 9

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI176286432251en-000701 | 9

Loading...

Loading...