Page 1

Danfoss Link™ Dynamic Boiler Relay

Installation Guide

Danfoss Heating

Page 2

Installation Guide Danfoss Link™ DBR

UK

UK

NL

FR

Hearby, Danfoss A/S declares that the radio equipment type Danfoss Link DBR is in compliance

with directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address, http://

heating.danfoss.co.uk

Danfoss can accept no responsibility for possible errors in catalogues, brochures, and other printed

material. All trademarks in this material are property of the respective companies. Danfoss and the

Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2

VIIOS202 © Danfoss 07/2017

Page 3

Table of Contents

Introduction.................................................. 4

Installation ................................................... 4

Installation in application with bypass valve using AVDO....... 5

Mounting .................................................... 6

Wiring ....................................................... 7

Adding the device ............................................ 7

Congure Danfoss Link™ DBR ................................. 8

Congure the DBR Operation Mode........................... 9

Congure the DBR Settings .................................. 10

Perform network test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Factory reset ................................................ 11

Status indicator.............................................. 11

Technical specications...................................... 12

Disposal instructions ........................................ 12

Important information

For safety reasons the heating system must have a bypass

function. This is either built into the boiler or it must be

installed in the system.

Demount other heating control timers in the installation or

they will interfere with the Danfoss Link™ heating control

algorithm. If weather compensation is present it should be set

to constant comfort.

Electric heating devices are not supported.

VIIOS202 © Danfoss 07/2017

3

Page 4

Installation Guide Danfoss Link™ DBR

UK

NL

Introduction

The Danfoss Link™ Dynamic Boiler Relay (DBR) is an electronic

FR

device for turning gas and oil boilers ON/OFF depending on

heat demand.

The Danfoss Link™ DBR must in applications with bypass valve

such as AVDO, be installed in combination with the ESM-11

temperature sensor (included inside the box) for turning the

boiler ON/OFF based on heating demand and water temperature in return pipe for running the system at optimal energy

efficiency.

This pack includes:

1 x Danfoss Link™ Dynamic Boiler Relay

1 x ESM-11 Temperature Sensor

Installation

The Danfoss Link™ wireless system’s transmission range is sucient for most applications; however each building has dierent

obstacles aecting communication and maximum transmission

distance. If communication problems occur Danfoss suggests

that accessories would be required to support the system, such

as repeaters.

In exceptional cases the wireless system may not be suitable for

your installation.

Be aware that installation and placement must be

according to local building regulations.

4

VIIOS202 © Danfoss 07/2017

Page 5

UK

Condensing

Boiler

Bypass

Valve

(AVDO)

Dynamic Boiler

Relay (DBR)

ESM-11

Temperature

Sensor

70C

70C

50C

50C

Condensing

Boiler

Bypass

Valve

(AVDO)

Dynamic Boiler

Relay (DBR)

ESM-11

Temperature

Sensor

70C

70C

50C

50C

Condensing

Boiler

Dynamic Boiler

Relay (DBR)

70C

70C

50C

50C

Bypass

Valve

(AVDO)

ESM-11

Temperature

Sensor

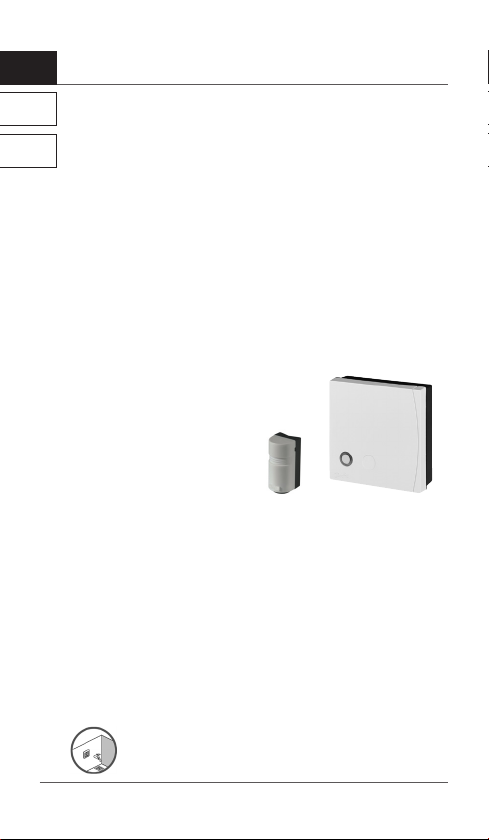

Installation in application with bypass valve

using AVDO

In installations with bypass using AVDO, remember to mount

and wire the ESM-11 Temperature Sensor included in the pack.

Note:

· The ESM-11 Temperature Sensor needs to b e mounted on the

return pipe.

·Mount t he ESM-11 Tempe rature Sensor in the bypass circuit

(gure 1) and not outside of the circuit (gure 2). Pay at tention

that the ESM -11 must be o utside the circuit of an e ventual storage tank

Figure 1

Figure 2

VIIOS202 © Danfoss 07/2017

NL

FR

5

Page 6

Installation Guide Danfoss Link™ DBR

UK

NL

The Danfoss Link™ DBR is not recommended in application

FR

without bypass valve. Install Danfoss Link™ DBR together with

e.g. AVDO bypass valve.

If boiler has internal bypass valve and installed with weather

compensation, the Danfoss Link™ DBR can be installed without

the Return Sensor, in operation mode “On when Heat Demand”

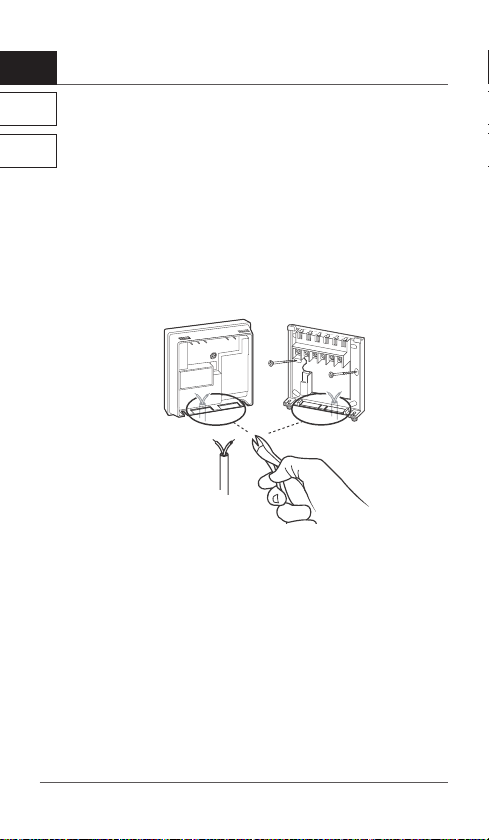

Mounting

Note:

The Danfoss Link™ DBR must be mounted on a at surface.

For mounting the temperature sensor correctly on the pipe

please see enclosed installation guide for ESM-11 Temperature

Sensor.

6

VIIOS202 © Danfoss 07/2017

Page 7

UK

UK

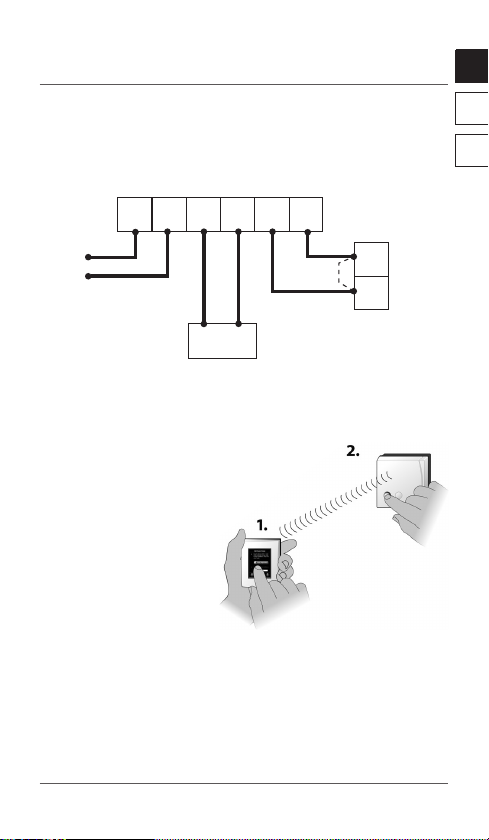

Wiring

Danfoss Link™ DBR

Electronics

Remove

1NL 234

230 V AC

ESM-11

Note: Refer to boiler manufacturer’s manual for wiring connections

to the boiler.

jumper

if tted

T

T

Boiler ON/OFF

terminals

Adding the device

The process of adding the D anfoss Link™ DBR

to a system is performed on the Danfoss

Lin k™ CC.

Note that the Danfoss Link™ DBR

must be added as a Service

Device.

When adding, press and

release the install button,

and observe that the LED

gives a fast green ash.

If adding is successful the LED turns green permanently.

For further information, see the D anfoss Link™ CC instruction

manual.

NL

FR

Note: If adding the D anfoss Link™ DBR to the Danfoss Link™ CC is

unsuccessful, make sure th e right Danfoss Link™ CC software

version is applied. Correct ver sion: 4.1.0 or higher.

VIIOS202 © Danfoss 07/2017

7

Page 8

Installation Guide Danfoss Link™ DBR

UK

NL

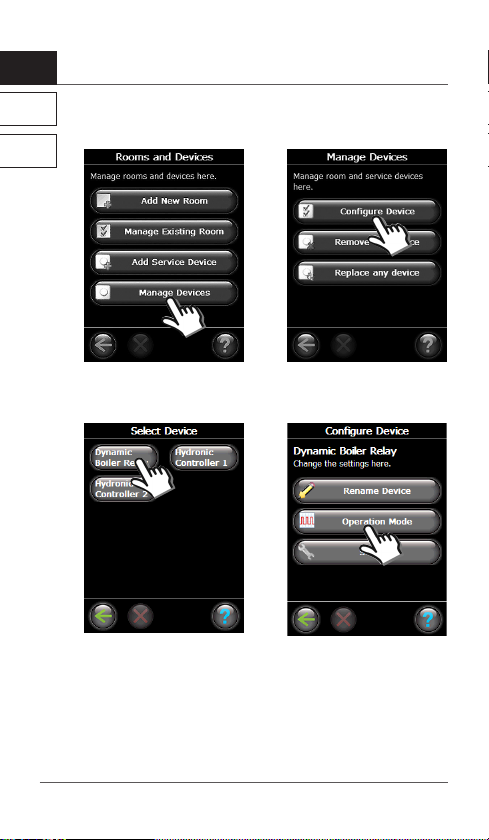

Congure Danfoss LinkTM DBR

FR

Select “Manage Devices” in

“Rooms and Devices”.

Select Device to congure Select operation mode

8

VIIOS202 © Danfoss 07/2017

Select “Congure Device”.

according to the application

Page 9

UK

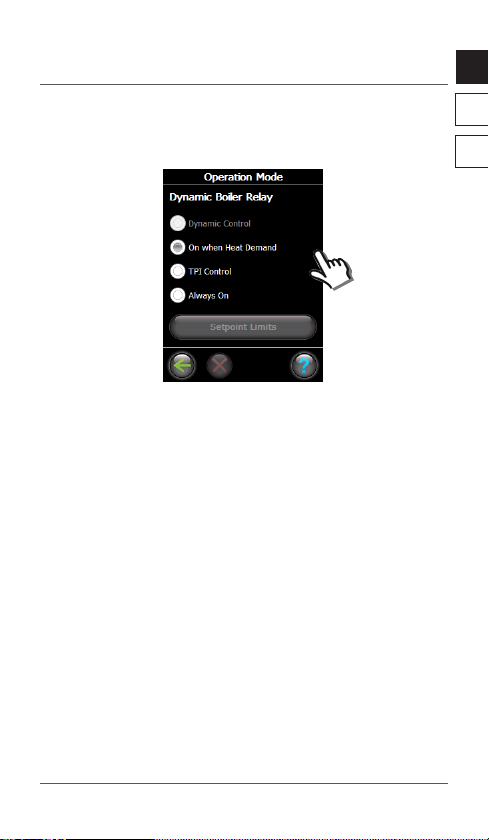

Congure the Danfoss LinkTM DBR Operation

Mode

Dynamic Control (Recommended)

When Dynamic Control is selected, the on/o cycles are determined by the heat demand in the rooms and the temperature

of the return pipe into the boiler to optimize energy savings.

Recommended in systems with bypass in heating circuit, such

as AVDO valve. It is possible to adjust the Setpoint Limits in

this mode. Dynamic Control only possible to select with ESM11 sensor mounted on return pipe

On when Heat Demand

The boiler is only ON when there is heat demand from a

reference room in the system. Recommended for modulating boilers and non-condensing boilers.

TPI (Time Proportional Interval)

A duty cycle is calculated and used to control the boiler.

Select ‘Cycle Time’ in Settings.

NL

FR

VIIOS202 © Danfoss 07/2017

9

Page 10

UK

Installation Guide Danfoss Link™ DBR

NL

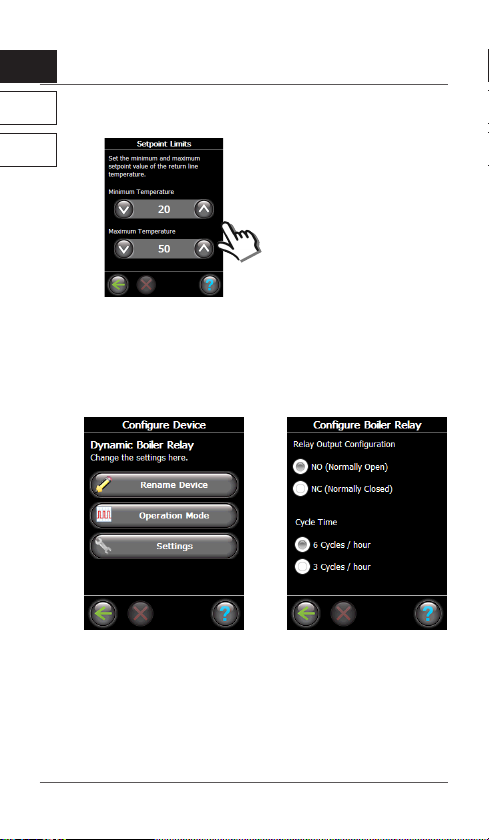

Setpoint Limits

FR

The recommended Maximum Temperature is below 54 degrees to

ensure maximum eciency with condensing boilers.

If Maximum Temperature is set too low, there is a risk of not reaching

the desired temperature.

Congure the Minimum

Temperature and Maximum

temperature for Return Line

setpoint temperatures for

Danfoss Link™ DBR here.

(Note: You can only set these

setpoint limits within the

Dynamic mode.)

Congure settings of the Danfoss LinkTM DBR

Relay Output Conguration

NO (Normally Open) and NC (Normally Closed)

Cycle time

• 6 cycles/hour is recommended for condensing non-modulating gas boilers.

• 3 cycles/hour is recommended for condensing non-modulating oil boilers.

10

VIIOS202 © Danfoss 07/2017

Page 11

UK

Perform network test

Once the Danfoss Link™ DBR and all other devices in the system

have been registered and the Danfoss Link™ CC is placed in

its nal position, perform a network test (see

separate Danfoss Link™ CC manual).

Note: If the connection to the Danfoss Link™ CC is

lost for more than 1½ hour, the Danfoss Link™

DBR will go into safety mode. In this mode the

boiler will be turned ON continuously.

Factory reset

Turn o the power to the device, then press and hold the install

button in front of the device for approx. 5 sec. while the power

is switched on again. The button must be held until LED gives a

red ash.

Status indicator

Green LED OFF Relay OFF/Standby

Green LED ON Relay ON/Heating

Green LED fast ash Adding or link test

Green LED short ash Ready for adding

Red LED slow ash Adding not OK

Link test not OK

Safe State Active

NL

FR

VIIOS202 © Danfoss 07/2017

11

Page 12

Installation Guide Danfoss Link™ DBR

UK

NL

Technical specications

FR

Operation voltage 230 V AC, 50 Hz

Standby consumption 1.6 W

Load

Rated impulse voltage 2.5 kV

Switching Type 1B

Regulation ON/OFF

Ambient temperature 0˚ to +45˚C

Transmission frequency Wireless Z-wave 868.42 MHz

Transmission range in

normal buildings

Transmission power Max. 1 mW

Pollution situation Degree 2

Ball pressure test 75˚C

Software classication Class A

Software version 4.1.0 or higher

IP class 40

Dimensions 84 × 84 × 30 mm

3 amps resistive

1 amp inductive

Up to 30 m

Disposal instructions

12

VIIOS202 © Danfoss 07/2017

Page 13

VIIOS202 © Danfoss 07/2017

13

Page 14

Installatiehandleiding Danfoss Link™ DBR

UK

NL

NL

Inhoudsopgave

Inleiding................................................... 15

FR

Installatie ............................................... 15

Installatie in een toepassing met een AVDO-bypassklep ..16

Montage .................................................. 17

Bedrading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Het apparaat toevoegen .................................. 18

Danfoss Link™ DBR congureren ............................. 19

Danfoss Link™ DBR-bedrijfsmodus congureren.............. 20

De instellingen van het Danfoss Link™ DBR congureren ..... 21

Netwerktest uitvoeren .................................... 22

Terugzetten naar fabrieksinstellingen..................... 22

Statusindicator .......................................... 22

Technische specicaties................................... 23

Instructies voor verwijdering.............................. 23

Belangrijke informatie

Om veiligheidsredenen moet het verwarmingssysteem zijn

voorzien van een bypassfunctie. Deze functie is ingebouwd in

de cv-ketel of moet worden geïnstalleerd in het systeem.

Demonteer eventuele andere verwarmingsregelingstimers in de

installatie. Als u dit niet doet, zullen ze het algoritme van de Danfoss

Link™-verwarmingsregeling verstoren. Als er een weersafhankelijke

regeling beschikbaar is, moet u die instellen op constant comfort.

Elektrische verwarmingstoestellen worden niet ondersteund.

14

VIIOS202 © Danfoss 07/2017

Page 15

UK

Inleiding

Het Danfoss Link™ dynamische ketelrelais (DBR) is een elektronisch

component die de gas- en stookolieketels in- en uitschakelt op basis

van de warmtevraag.

Het Danfoss Link™ DBR moet in toepassingen met een

bypassklep, zoals AVDO, worden geïnstalleerd met de

ESM-11-temperatuursensor (opgenomen in de doos) om de

cv-ketel in en uit te schakelen op basis van de warmtevraag en

de watertemperatuur in de retourbuis, om het systeem zo

energie-eciënt mogelijk te laten werken.

Dit pakket bestaat uit:

1 Danfoss Link™ dynamisch ketelrelais

1 ESM-11-temperatuursensor

Installatie

Het transmissiebereik van het draadloze Danfoss Link™-systeem

is groot genoeg voor de meeste toepassingen; elk gebouw kent

echter andere obstakels die de communicatie en de maximale

transmissieafstand kunnen beïnvloeden. Danfoss beveelt aan

om bij communicatieproblemen accessoires te gebruiken om

het systeem te ondersteunen, zoals signaalversterkers, de RU.

In uitzonderlijke gevallen kan het zijn dat het draadloze systeem

niet geschikt is voor uw installatie.

NL

FR

De installatie en plaatsing moeten voldoen aan

de lokale bouwvoorschriften.

VIIOS202 © Danfoss 07/2017

15

Page 16

UK

HR-ketel

Bypassklep

(AVDO)

Dynamisch

ketelrelais

(DBR)

ESM-11

Temperatuursensor

70 °C

70 °C

50 °C

50 °C

HR-ketel

Bypassklep

(AVDO)

Dynamisch

ketelrelais

(DBR)

ESM-11

Temperatuursensor

70 °C

70 °C

50 °C

50 °C

HR-ketel

Dynamisch

ketelrelais (DBR)

70 °C

70 °C

50 °C

50 °C

Bypassklep

(AVDO)

ESM-11

Temperatuursensor

Installatiehandleiding Danfoss Link™ DBR

NL

Installatie in een toepassing met een

AVDO-bypassklep

FR

In installaties met een AVDO-bypassklep moet u niet vergeten

om de bij het pakket geleverde ESM-11-temperatuursensor

te monteren en te bedraden.

Let op:

· De E SM-11-temperatuur sensor moet op de r etourbuis worde n

gemonteerd.

· Mo nteer de ESM-11-temp eratuursensor i n het bypasscircui t

(afbeel ding 1) en niet buiten he t circuit (afbeeld ing 2). Let op!

De sensor n iet op de centrale re tour plaatsen wa nneer er een

indirect gestookte boiler in het systeem zit.

Afbeelding 1

Afbeelding 2

16

VIIOS202 © Danfoss 07/2017

Page 17

UK

NL

Het wordt niet aanbevolen het Danfoss Link™ DBR te gebruiken in

toepassingen zonder bypassklep. Installeer het Danfoss Link™ DBR

in combinatie met, bijvoorbeeld, een AVDO-bypassklep.

Als de cv-ketel is uitgerust met een interne bypassklep en werkt op

basis van een weersafhankelijke regeling, kunt u het Danfoss Link™

DBR zonder retoursensor installeren, in de bedrijfsmodus “Aan

bij warmtevraag”. Bij deze instelling kijkt de regeling niet naar

de retoursensor.

Montage

Let op:

De Danfoss Link ™ DBR moet op een vlakke ondergrond worden

gemonteerd.

Raadpleeg de bijgesloten installatiegids van de ESM-11-temperatuursensor voor de juiste montage van de temperatuursensor op de retour.

FR

VIIOS202 © Danfoss 07/2017

17

Page 18

Installatiehandleiding Danfoss Link™ DBR

UK

NL

Bedrading

FR

Elektronica van het

Danfoss Link™

DBR

1NL 234

Verwijder de

doorverbinding

indien aanwezig.

230 V AC

ESM-11

Let op: Raadpleeg het bedienings- en installatievoorschrift van de

ketelfabrikant voor de bedradingsaansluitingen naar de ketel.

T

T

Aan-uitklemmen

van ketel

(kamerthermo-

staataansluiting)

Het apparaat toevoegen

Het toevoegen van het Danfoss Link™ DBR aan

het systeem gebeurt via de D anfoss Link™ CC.

Het Danfoss Link™ DBR moet

worden toegevoegd als een

Servicecomponent.

Tijdens het toevoegen

moet de installatieknop

kort ingedrukt worden; kijk

gelijktijdig of de groene led

snel gaat knipperen.

Als het toevoegen geslaagd

is, brandt de groene led

permanent.

Zie de instructiehandleiding van de Danfoss Link™ CC voor meer

informatie.

Let op: Als het niet gel ukt is om het Danfoss Link™ DBR a an de Danfoss

Link™ CC toe te voegen, mo et u controleren of de correc te softwareversie van d e Danfoss Link™ CC gebruikt is. Res et eventueel

de DBR en prob eer het opnieuw. Correcte ve rsie: 4.1.0 of hoge r.

18

VIIOS202 © Danfoss 07/2017

Page 19

UK

Danfoss Link™ DBR congureren

Selecteer “Componenten beheren” in “Ruimtes en apparaten”.

Selecteer de component

die u wilt congureren.

Selecteer “Component

congureren”.

Selecteer de bedrijfsmodus

op basis van de toepassing.

NL

FR

VIIOS202 © Danfoss 07/2017

19

Page 20

UK

Installatiehandleiding Danfoss Link™ DBR

NL

Danfoss Link™ DBR-bedrijfsmodus

congureren

FR

Dynamische regeling (aanbevolen)

Wanneer Dynamische regeling is geselecteerd, worden de

aan/uit-cycli bepaald door de warmtevraag in de ruimtes en

de temperatuur van de retour naar de cv-ketel, zodat optimale

energiebesparingen kunnen worden behaald.

Aanbevolen in systemen met een bypass zoals de AVDO-klep.

In deze modus kunt u de setpointlimieten, max. en min. retourtemperatuur aanpassen. Dynamische regeling kan alleen

geselecteerd worden als de ESM-11 sensor gemonteerd is op de

retourleiding.

Aan bij warmtevraag

De ketel staat alleen aan wanneer een referentieruimte in het

systeem warmte vraagt. Aanbevolen voor niet-condenserende

ketels.

TPI (tijdklokinterval)

Om de ketel te sturen wordt een werkcyclus berekend en gebruikt.

Selecteer “Cyclustijd” in Instellingen.

20

VIIOS202 © Danfoss 07/2017

Page 21

UK

Setpointlimieten

Hier congureert u de

minimale en de maximale

setpointtemperatuur voor

de retour.

(Let op: u kunt deze setpointlimieten alleen in de Dynamische

modus instellen.)

De aanbevolen maximumtemperatuur bedraagt minder dan 54 graden

met het oog op maximale eciëntie van condenserende ketels.

Wanneer een te lage maximumtemperatuur wordt ingesteld, bestaat

het risico dat de ketel de gewenste temperatuur niet bereikt.

De instellingen van het Danfoss Link™ DBR

congureren

Relaisuitgang conguratie

NO (normaal open) en NC (normaal gesloten)

Cyclustijd

• 6 cycli per uur worden aanbevolen voor condenserende

niet-modulerende gasgestookte cv-ketels.

• 3 cycli per uur worden aanbevolen voor condenserende

niet-modulerende oliegestookte cv-ketels. En trage systemen

met bijvoorbeeld vloerverwarming als hoofdverwarming.

NL

FR

VIIOS202 © Danfoss 07/2017

21

Page 22

Installatiehandleiding Danfoss Link™ DBR

UK

NL

Netwerktest uitvoeren

Zodra het Danfoss Link™ DBR en alle andere

FR

systeemcomponenten zijn geregistreerd en

de Danfoss Link™ CC op de uiteindelijke locatie

gemonteerd is, voert u een netwerktest uit

(zie de afzonderlijke handleiding van de

Danfoss Link™ CC).

Let op: Als de verbinding met de Danfoss Link™ CC

langer dan 1,5 uur verbroken is, zal het

Danfoss Link™ DBR naar de veiligheidsmodus gaan. In deze modus zal de ketel continu AAN staan,

begrensd op zijn maximaal ingestelde retourtemperatuur.

Terugzetten naar fabrieksinstellingen

Schakel de stroom naar de component uit, houd de installatieknop

aan de voorzijde van het toestel ingedrukt en schakel de stroom weer

in; laat de knop niet los! De knop moet ingedrukt gehouden worden

tot de rode led knippert.

Statusindicator

Groene led UIT Relais uit/stand-by

Groene led AAN Relais aan/verwarming

Groene led knippert snel Toevoegen of verbindingstest

Groene led knippert kort Klaar om toe te voegen

Rode led knippert

langzaam

Toevoegen niet gelukt

Verbindingstest niet geslaagd

Veiligheidsstatus actief

22

VIIOS202 © Danfoss 07/2017

Page 23

UK

NL

Bedrijfsspanning 230 V AC, 50 Hz

Verbruik in stand-by 1,6 W

Belasting

Nominale impulsspanning 2,5 kV

Schakeling Type 1B

Regeling AAN/UIT

Omgevingstemperatuur 0 tot +45 °C

Transmissiefrequentie Draadloze Z-wave 868,42 MHz

Transmissiebereik in

normale gebouwen

Transmissievermogen Max. 1 mW

Verontreinigingsgraad Niveau 2

Druktest kogel 75 °C

Softwareclassicatie Klasse A

Software Versie 4.1.0 of hoger

Beschermingsgraad IP 40

Afmetingen 84 × 84 × 30 mm

3 A resistief

1 A inductief

Tot 30 m

Instructies voor verwijdering

FR

VIIOS202 © Danfoss 07/2017

23

Page 24

Manuel d’installation Danfoss Link™ DBR

UK

NL

Sommaire

Introduction................................................. 25

FR

Installation .................................................. 25

Installation dans une application avec une vanne

de bipasse AVDO ............................................ 26

Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Câblage ..................................................... 28

Ajout de l’appareil........................................... 28

Conguration du Danfoss Link™ DBR ........................... 29

Conguration du mode de fonctionnement DBR ............. 30

Conguration des réglages DBR.............................. 29

Test du réseau............................................... 32

Restauration des réglages par défaut......................... 32

Indicateur d’état............................................. 32

Caractéristiques techniques.................................. 33

Instructions pour la mise au rebut............................ 33

Informations importantes

Pour des raisons de sécurité, le système de chauage doit disposer

d’une vanne de décharge. Elle doit être intégrée à la chaudière ou

installée dans le système.

Démontez les autres programmateurs de commande du chauage

présents dans l’installation car ils risquent de créer des interférences

avec l’algorithme de commande du chauage Danfoss Link™.

Si un régulateur en fonction de la température extérieureest

installé, il doit être réglé sur confort constant.

Les dispositifs de chauage électriques ne sont pas pris en charge.

24

VIIOS202 © Danfoss 07/2017

Page 25

Manuel d’installation Danfoss Link™ DBR

UK

Introduction

Le Danfoss Link™ DBR (relais de chaudière dynamique) est un électronique appareil servant à allumer et à éteindre les chaudières à gaz

ou à oul, en fonction de la demande de chauage.

Le Danfoss Link™ DBR doit être installé dans des applications avec

vanne de bipasse telle que AVDO, en combinaison avec la sonde de

température ESM-11 (inclus dans la boîte) an d’allumer et éteindre

la chaudière en fonction de la demande de chauage et de la température d’eau dans la conduite de retour an d’optimiser l’ecacité

énergétique du système.

Ce pack comprend:

1 x relais de chaudière dynamique Danfoss Li nk™,

1 x sonde de température ESM-11.

Installation

La portée d’émission du système sans l Danfoss Link™ est susante

pour la plupart des applications. Chaque bâtiment présente

néanmoins des obstacles diérents qui aectent la communication

et la distance maximale de transmission. En cas de problèmes de

communication, Danfoss recommande d’installer des accessoires

pour assister le système, par exemple des répéteurs.

Dans des cas exceptionnels, le système sans l peut ne pas convenir

à votre installation.

NL

FR

N’oubliez pas que l’installation et le choix de l’emplacement

doivent respecter les réglementations locales relatives à la

construction.

VIIOS202 © Danfoss 07/2017

25

Page 26

Manuel d’installation Danfoss Link™ DBR

Chaudière à

condensation

Vanne de

bipasse

(AVDO)

Relais de chaudière

dynamique (DBR)

ESM-11

Sonde de température

70°C

70°C

50°C

50°C

Chaudière à

condensation

Vanne de

bipasse

(AVDO)

Relais de chaudière

dynamique (DBR)

ESM-11

Sonde de température

70°C

70°C

50°C

50°C

Chaudière à

condensation

Relais de chaudière

dynamique (DBR)

70°C

70°C

50°C

50°C

Vanne de

bipasse

(AVDO)

ESM-11

Sonde de température

UK

NL

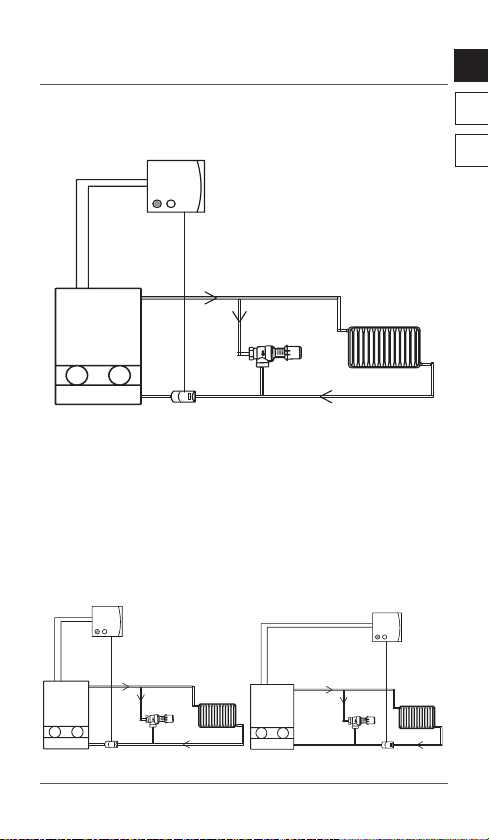

Installation dans une application avec

une vanne de bipasse AVDO

FR

Pour les installations avec bipasse AVDO, n’oubliez pas de monter et

de raccorder la sonde de température ESM-11 incluse dans le pack.

Remarque :

· La so nde de températu re ESM-11 doit être mo ntée sur la conduite

de retour.

· Mo ntez la sonde de temp érature ESM-11 dans le circuit de bi passe

(gure 1) et non en d ehors du circuit (gu re 2). Faites attentio n que

ESM-11 doit être à l’exté rieur du circuit d ’un éventuel réser voir de

stockage.

Figure 1

Figure 2

26

VIIOS202 © Danfoss 07/2017

Page 27

Manuel d’installation Danfoss Link™ DBR

UK

NL

Le Danfoss Link™ DBR n’est pas conseillé dans une application

sans vanne de bipasse. Installez le Danfoss Link™ DBR avec par

ex. une vanne de bipasse AVDO.

Si la chaudière possède une vanne de bipasse interne et une

régulation en fonction de l’extérieur, le Danfoss Link™ DBR peut

être installé sans sonde de retour, en mode de fonctionnement

«Activé si demande de chauage».

Montage

Remarque :

Le Danfoss Link ™ DBR doit être monté sur une surface plane.

Veuillez consulter le guide d’installation pour sonde de

température ESM-11 en annexe an de monter la sonde

de température correctement.

FR

VIIOS202 © Danfoss 07/2017

27

Page 28

Manuel d’installation Danfoss Link™ DBR

UK

NL

Câblage

FR

Électronique

Danfoss Link™

DBR

1NL 234

Enlevez le

cavalier s’il

est installé

230 V AC

ESM-11

Remarque : reportez-vous au manuel du fabricant de la chaudière pour

les raccordements à la chaudière.

T

T

Bornes ON/OFF

de la chaudière

Ajout de l’appareil

L’ajout du D anfoss Link™ DBR à un système

s’eectue depuis le Da nfoss Link™ CC.

Notez que le D anfoss Link™ DBR doit

être ajouté en tant qu’appareil de

service.

Lors de l’ajout, appuyez sur

le bouton d’installation, puis

relâchez-le. Vériez que le

voyant émet un clignotement

vert rapide.

Si l’ajout est réussi, le voyant

reste vert en continu.

Pour de plus amples informations, consultez le mode d’emploi

du Danfoss Link™ CC .

Remarque: si l’ajout du D anfoss Link™ DBR sur le Danfoss Link™ CC

28

échoue, véri ez que la version du logi ciel du Danfoss

Link™ CC appliquée e st correcte. Version correcte :

4.1.0 ou supérieure.

VIIOS202 © Danfoss 07/2017

Page 29

Manuel d’installation Danfoss Link™ DBR

UK

Conguration du Danfoss Link™ DBR

Sélectionnez Gérer les unités

locales dans Pièces et unités

locales.

Sélectionnez le dispositif à

congurer.

Sélectionnez Congurer l’unité.

Sélectionnez le mode

de fonctionnement selon

l’application.

NL

FR

VIIOS202 © Danfoss 07/2017

29

Page 30

Manuel d’installation Danfoss Link™ DBR

UK

NL

Conguration du mode de fonctionnement

du Danfoss LinkTM DBR

FR

Contrôle dynamique (conseillé)

Lorsque le contrôle dynamique est sélectionné, les cycles allumés/

éteints sont déterminés par la demande de chaleur dans les pièces

et par la température de la conduite de retour dans la chaudière

an d’optimiser les économies d’énergie.

Recommandé pour les systèmes avec bipasse dans le circuit de

chauage tel que la vanne AVDO. Il est possible d’ajuster les

limites de la température de consigne dans ce mode. Le contrôle

dynamique n’est possible que si une sonde ESM-11 est montée sur

la conduite retour

Activé si demande de chauage

La chaudière n’est en marche que lorsqu’une pièce de référence

du système émet une demande de chaleur. Cette conguration

est recommandée pour les chaudières à marche modulée et les

chaudières sans condensation.

TPI (période du mode chrono-proportionnel)

Un cycle d’utilisation est calculé et sert à commander la chaudière.

Sélectionnez Durée du cycle dans Réglages.

30

VIIOS202 © Danfoss 07/2017

Page 31

Manuel d’installation Danfoss Link™ DBR

UK

Limites de la température de

consigne

Congurez ici la température

minimum et maximum des

températures de consigne de

la conduite de retour pour le

Danfoss Link™ DBR.

(Remarque: vous pouvez

uniquement régler ces limites

de température de consigne en

mode dynamique.)

La température maximale recommandée se situe sous les 54 degrés an

de garantir une ecacité maximale des chaudières à condensation.

Si la température maximale dénie est trop basse, la température

désirée pourrait ne pas être atteinte.

Conguration des réglages

du Danfoss LinkTM DBR

Conguration du relais de sortie

NO (normalement ouverte) et NF (normalement fermée)

Durée du cycle

• 6 cycles/heure sont recommandés pour les chaudières à gaz,

à condensation et à marche non modulée.

• 3 cycles/heure sont recommandés pour les chaudières à oul,

à condensation et à marche non modulée.

VIIOS202 © Danfoss 07/2017

NL

FR

31

Page 32

Manuel d’installation Danfoss Link™ DBR

UK

NL

Test du réseau

Une fois le Danfoss Link™ DBR et tous les autres

FR

appareils du système enregistrés et lorsque le

Danfoss Link™ CC est à son emplacement nal,

testez le réseau (voir le manuel Danfoss Link™ CC

spécique).

Remarque: si la connexion au Danfoss Link™ CC

est perdue pendant plus d’une heure

et demie, le Danfoss Link™ DBR passe

en mode de sécurité. Sous ce mode,

la chaudière reste activée en continu.

Restauration des réglages par défaut

Coupez l’alimentation du dispositif, puis appuyez sur le bouton

d’installation à l’avant du dispositif pendant 5 secondes environ

tandis que l’alimentation est rétablie. Le bouton doit rester

enfoncé jusqu’à ce que le voyant émette un clignotement rouge.

Indicateur d’état

Voyant vert éteint Relais désactivé/Veille

Voyant vert en continu Relais activé/Chauage

Clignotement vert rapide Ajout ou test de liaison

Clignotement vert court Prêt pour l’ajout

Clignotement rouge lent Ajout non eectué

Test de liaison non eectué

Mode de sécurité activé

32

VIIOS202 © Danfoss 07/2017

Page 33

Manuel d’installation Danfoss Link™ DBR

UK

Caractéristiques techniques

Tension de fonctionnement 230 V CA, 50 Hz

Consommation en veille 1,6W

Charge

Tension d’impulsions

nominale

Commutation Type 1B

Régulation ON/OFF

Température ambiante 0˚ à +45˚C

Fréquence de transmission Z-Wave sans l 868,42 MHz

Portée d’émission dans des

bâtiments normaux

Puissance de transmission 1 mW max.

Degré de pollution Degré 2

Essai à la bille 75˚C

Classe du logiciel Classe A

Version Software

Classe IP 40

Dimensions 84 × 84 × 30 mm

résistive : 3 A

inductive :1 A

2,5 kV

Jusqu’à 30m

4.1.0 ou supérieure

Instructions pour la mise au rebut

NL

FR

VIIOS202 © Danfoss 07/2017

33

Page 34

Installation Guide Danfoss Link™ DBR

34

VIIOS202 © Danfoss 07/2017

Page 35

VIIOS202 © Danfoss 07/2017

35

Page 36

Danfoss A/S

Heating Solutions

Haarupvaenget 11

8600 Silkeborg

Denmark

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

013R9624 VII OS202 © Danfoss 07/2017

Loading...

Loading...