Page 1

Data sheet

Danfoss Leanheat® Monitor

A web-based SCADA software application hosted in Microsoft Azure

Description

Leanheat® Monitor

Danfoss Leanheat® Monitor is a web -based SCADA

(Supervisory Control And Data Acquisition)

software application hosted in Microsoft Azure

for district heating systems.

Leanheat® Monitor is built on strong bases of

already established Danfoss solutions with new

and improved features for remote monitoring,

control and optimization of your district heating.

A reliable and stable software solution brings you

a cost effective and energy efficient management

and lays the foundations for a connected future

of your district energy system.

Leanheat® Monitor is offered as a hosted SaaS

solution. This means that Danfoss takes care of all

maintenance, backup and securit y updates of the

system.

Customers can access the system from any

internet connected PC or mobile device.

The user of Leanheat® Monitor can remote control

and monitor the parameters settings in the

controllers and monitor actual, reference and

historical values of sensors and energy

consumption meters connec ted to the controllers.

© Danfoss | 2021.09

AI260030799383en-000401| 1

Page 2

Data sheet Leanheat® Monitor

User benefits

The advantages of Leanheat® Monitor are among

others:

Customized for district energy Modern web-based solution

Danfoss Leanheat® Monitor is tailored specifically

for district energy systems. Every function is

designed to simplify your daily tasks and ensure

that your system operates with improved control

and better efficiency.

This can be achieved by providing you with a

better system overview by dashboards and

customizable KPI widgets, with predefined alarms

and report templates, functions like virtual

measurements and group settings. At the same

time you can fully customize it to the specific

needs of your district energy utility.

•

Improve your network control and

management with actionable information

insights

•

Faster and more efficient management of your

daily tasks with easy to use reporting and

alarming as well as functions like easy

commissioning, group settings

• Easy integration of new devices

•

Danfoss district energy and app experts

available for support

•

Faster and more efficient management of your

daily tasks

Being a web-based solution hosted in Microsoft

Azure, Danfoss Leanheat® Monitor can never be

outdated, as the regular improvements and

upgrades are instantly available and provided to

you. The online system can be accessible from

everywhere using a standard web browser on

desktop or mobile devices. At the same time it

provides efficient protec tion for all interfaces and

stores data with the trusted security mechanism

ensuring all your data stays safe and secure.

•

Always up to date – the latest version is

automatically available for your use

• Clear and customizable user interface

•

Access from anywhere and from any device

(mobile, desktop compatible)

•

Trusted security mechanisms for safe and

secured data storage.

Open, connected and transparent

Benefit from open communication and data

interfaces. Besides wide range of Danfoss

products, you can easily integrate devices from

other (third party) providers providing the devices

that can communicate over modbus RTU/TCP.

Collected data can also be made available for

other business (e.g. billing) and operational

systems (optimizers, energy management ...).

•

Connect with any device using standard

Modbus communication

•

Easy integration with business intelligence

and optimization solutions using API

• Part of Danfoss Leanheat® software suite

Always up to date Lower your investment cost

Your investment will never be outdated.

We are dedicated to constantly improve and

upgrade the solution and will provide you with

the access to all the latest features and

improvements.

Safe and secure Team of experts at your service

Operate with more control and better efficiency

The software was developed with a special

attention on your daily tasks and our dedication

to simplify them to save your time.

Get a better overview of your system with

improved alarming features and reporting.

And with easier commissioning, group settings,

etc. you are now able to manage your daily

business in a faster and more efficient way.

Using the Danfoss Leanheat® Monitor subscription

model (Software as a Service) will result in:

•

Lower total cost of ownership and

improved return on investment

•

Reduced IT investments and maintenance

costs using Software as a Service

•

No local IT infrastructure and knowledge

required

•

Unlocking your resources to focus on your

primary business

2 | © Danfoss | 2021.09

Your data will stay safe and secure as Danfoss

Leanheat® Monitor provides protection for all

interfaces and stores data with the trusted security

mechanisms.

Leanheat® Monitor is hosted in highly secure

modern data centers located within the EU. Data

within Leanheat® Monitor is processed, stored and

secured in compliance with EU regulations.

Benefit from our know-how database, access to

online and on-site trainings, online video guides,

support forums and engineers.

This will result in your improved per formance and

overall satisfaction.

AI260030799383en-000401

Page 3

Data sheet Leanheat® Monitor

Application Leanheat® Monitor automatically adapts its user

interface to fit the application in the controller.

For ECL Comfort 296 and 310 controllers Leanheat®

Monitor can automatically detect the correct

application. However, for some older controllers

it is necessary to select the correct application

during commissioning.

The following controller applications are

supported:

• ECL Comfort 310 controller

• Please see ‘List of application keys

supported by Leanheat® Monitor’.

Go to: https://www.danfoss.com

In the ‘Service and support’ menu select

‘Documentation’ > ‘Data sheets’ and

search for the literature number.

(AI13148 6467165)

• OPR0020 Controller

• Firmware R9 and newer

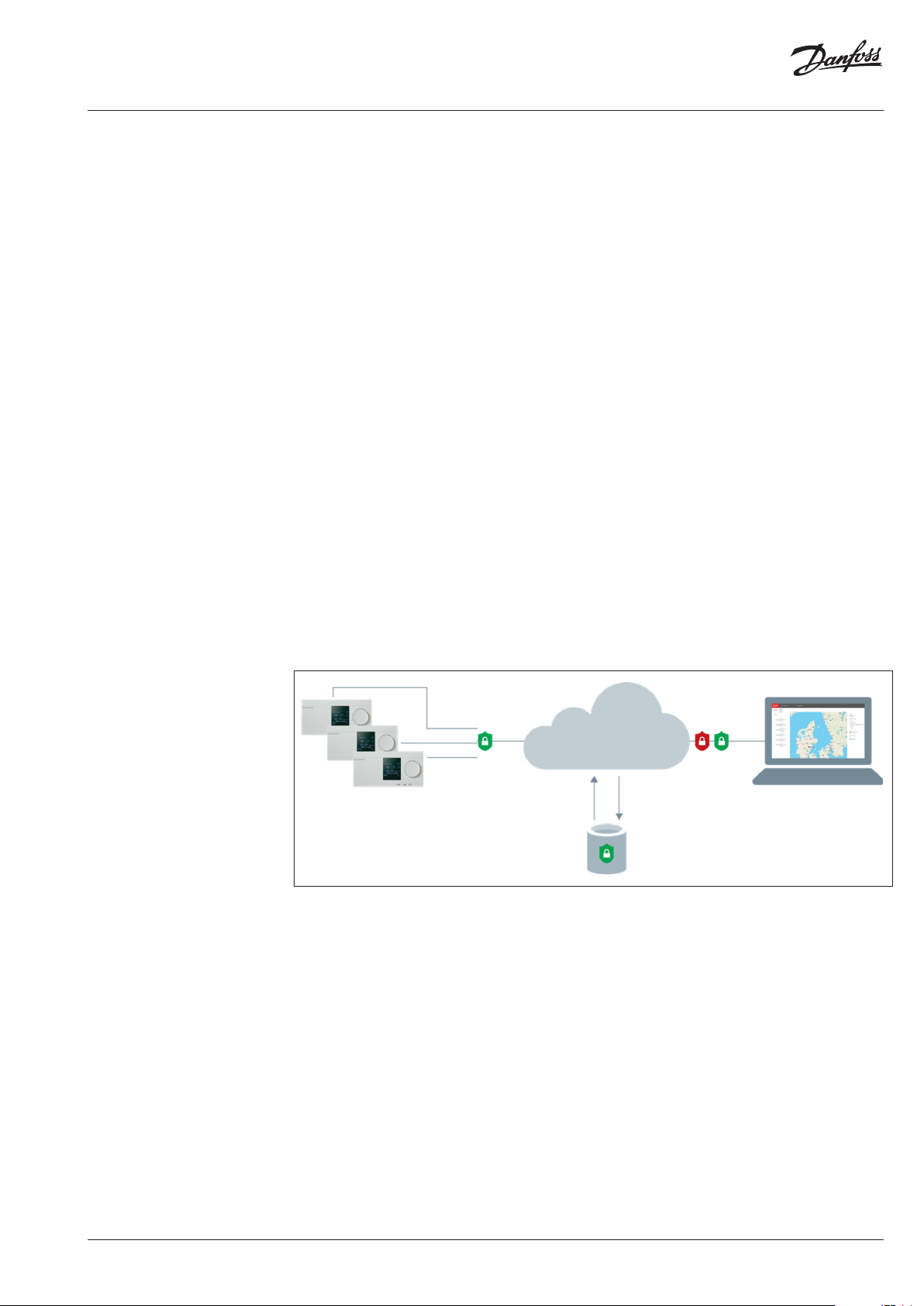

Below is an example of Leanheat® Monitor

configured with ECL Comfort 310 electronic

controllers connected over TCP. This is the

recommended connection method for controllers

to Leanheat® Monitor, as this avoids running any

IT infrastructure locally at the customer’s site.

In this case, Leanheat® Monitor and the controllers

communicate via Modbus/TCP over a secure

encrypted connection.

As an option the ECL Apex 20 controller can be

integrated into Leanheat® Monitor to remote

control and monitor the district heating utility or

boiler house.

This requires a system integrator to develop a

customized application for the ECL Apex 20

controller. A special Modbus adapter sof tware also

has to run in the same subnet as the ECL Apex 20

either on a PC or a hardware gateway that supports

this option.

AI260030799383en-000401

© Danfoss | 2021.09 | 3

Page 4

Data sheet Leanheat® Monitor

Application

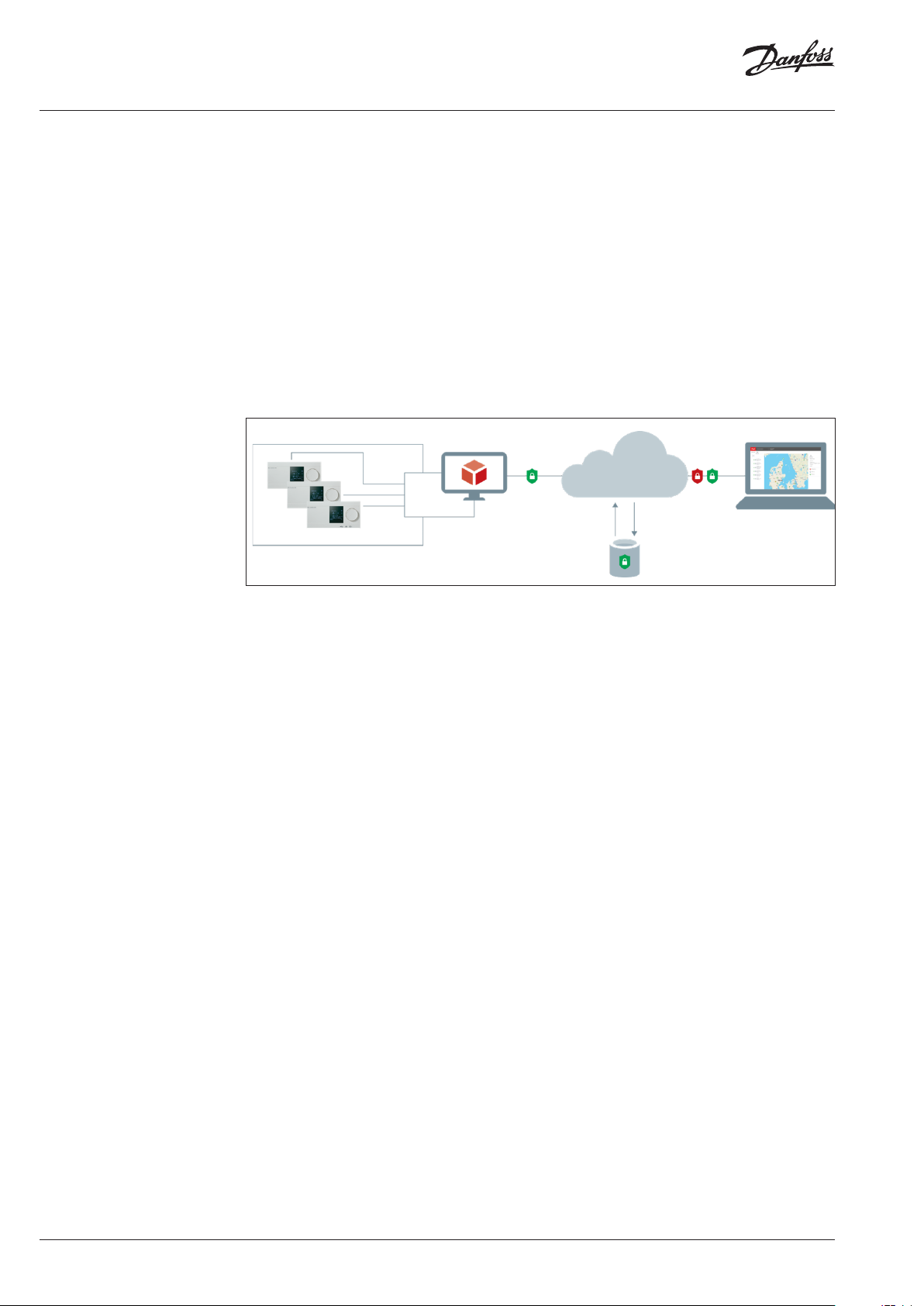

Below is an example of connecting controllers on

a closed network (e.g. a serial to Leanheat®

Monitor). In this case, the controllers can be

connected through a local OPC-UA server or if

they communicate over Modbus RTU/TCP they

can be connected through a Modbus adapter

software that does not require an OPC server.

Leanheat® Monitor includes two light-weight

software gateways that must be installed in the

same network as the devices or OPC server is

located. One gateway is for OPC UA

communication and the other for direct Modbus

communication.

The communication bet ween the controllers and

the OPC-UA server can be any protocol supported

by the controllers, server, and network, e.g.

Modbus/RS485, Modbus/TCP or LON.

Languages

The following languages are supported by the

graphical user interface of Leanheat® Monitor:

• English

• German

• Danish

• Dutch

• Turkish

• Russian

• Slovenian

• Swedish

• Chinese

• Lithuanian

• Polish

4 | © Danfoss | 2021.09

AI260030799383en-000401

Page 5

Data sheet Leanheat® Monitor

Supported controllers

Supported application keys

The following controllers are supported by

Leanheat® Monitor:

• Danfoss ECL Comfort 296 electronic

controllers

• Danfoss ECL Comfort 310 electronic

• controllers

• Danfoss ECL Comfort 310B electronic

• controllers

• NOPRO OPR0020 electronic controller (via

• built-in OPC-UA server)

• Danfoss ECL APEX 20 free programmable

• controller (via Modbus adapter software)

• Any third party controller supporting

Modbus RTU/TCP communication

Please see data sheet ‘List of application keys

supported by Leanheat® Monitor’

(AI13148 6467165).

Note:

When connecting through an OPC-UA server, the

server must also supp ort the relevant applications

for the controllers to be supported by Leanheat®

Monitor.

An example is when a Modbus-RS485 subnet of

ECL controllers or OPR0020 controllers, or a mix

hereof, is connected to Leanheat® Monitor via this

OPC-UA server.

Supported energy meters

(M-bus)

Data communication

Please see data sheet ‘Energy meters supported

by Danfoss SCADA solutions and ECL Comfort

296/310’ (AI150386468396).

Please be aware that battery operated energy

meters are not recommended, because the data

communication will shorten the battery lifetime.

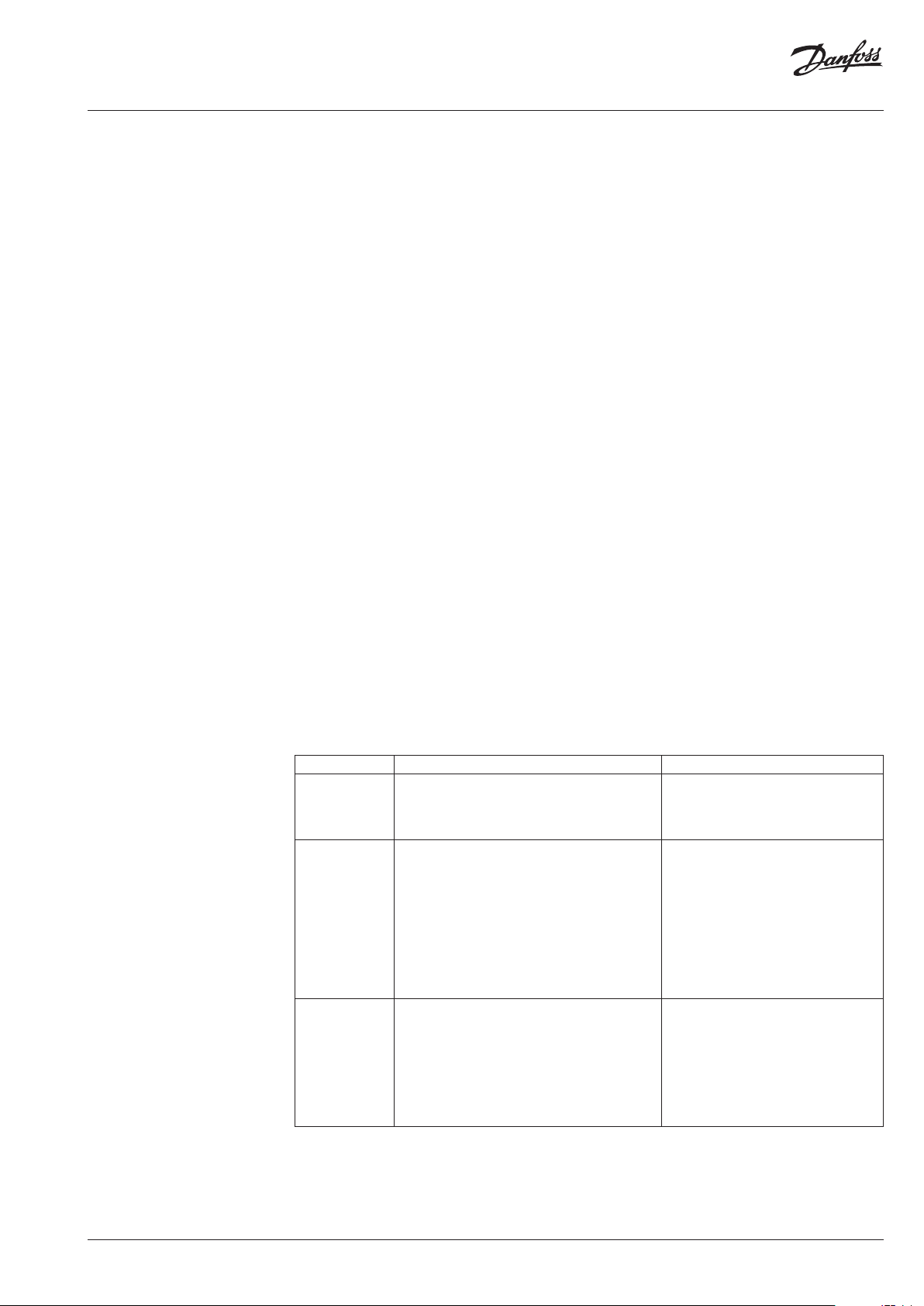

The options for data communication between

controllers and server are listed below.

Typ e Description Remarks

Direct

Via OPC-UA

Via Modbus

RTU/TCP

ECL Comfort 296/310 controllers connected

directly to Leanheat® Monitor using the

ethernet connection on the controller to

connect directly over the internet.

Intended for connecting existing serial

networks to Leanheat® Monitor. In this case,

the Leanheat® Monitor software gateway

must be installed alongside the OPC UA server

to facilitate secure communication to

Leanheat® Monitor.

Intended for connecting existing Modbus

RTU/TCP network s and third party devices to

Leanheat® Monitor. In this case, the Leanheat®

Monitor Modbus adapter software has to be

installed either on a PC or a hardware gateway

that supports i t. The Modbus adapter soft ware

facilitates secure communicati on to Leanheat®

Monitor.

It is highly recommended to enable

encryption in the controller settings

in order to secure the transmission of

data end-to-end.

In that case, Leanheat® Monitor will

handle security from the OPC UA

server and to Leanheat® Monitor.

Security and reliability of the net work

below the OPC UA server is not

managed by Leanheat® Monitor.

Performance of Leanheat® Monitor

may be degraded due to technical

limitations of the OPC UA server and

underlying controller network.

In that case, Leanheat® Monitor will

handle security from the devices and

to Leanheat® Monitor. Security and

reliability of the Modbus network is

not managed by Leanheat® Monitor.

Performance of Leanheat® Monitor

may be degraded due to the

underlying controller network.

AI260030799383en-000401

© Danfoss | 2021.09 | 5

Page 6

Data sheet Leanheat® Monitor

Ordering Please contact your local Danfoss sales company.

Technical data For further information on technical data, please go to:

https://www.danfoss.com

In the ‘Service and support’ menu select ‘Documentation’ > ‘Manuals & guides’

and search for the literature number.

https://www.danfoss.com/en/service-and-support/documentation/

Typ e Description Literature no.

Instructions/

Operating

guide

Service

guide

Operating

guide

System requirements Requirements to the client computer accessing Leanheat® Monitor:

Operating system Windows 10 (any version) or newer.

CPU Modern dual-core processor, e.g. Intel Core i5 or

RAM 2GB of free memory.

Free disc space 500MB

Internet connection A stable always-on internet connection is

Backup and security Since Leanheat® Monitor is offered as a hosted

ECL Comfort 210 / 296 / 310, communication

description

ECL Comfort 296 / 310 controllers

Modbus networking guide

Connection of ECL Comfor t 296 / 310 controller

to wireless network (WLAN)

similar.

required for the Leanheat® Monitor software

gateway to transmit data to Leanheat® Monitor.

solution, Danfoss ensures that the transmitted

data is securely encrypted, stored, and backed

up.

Danfoss strongly recommends that customers

keep all software up to date including their

operating system on all systems connected to

the internet.

AQ074886472234

AX236986479687

AQ070386470176

Note:

Performance may be impacted by other software and/or tasks running on the same PC as the OPC

server and the Leanheat® Monitor software OPC gateway.

If the above specifications are adhered to, and performance is lacking, make sure that the PC is not

being used for additional workloads.

Requirements to Leanheat® Monitor software OPC gateway:

The Leanheat® Monitor software OPC gateways

is designed to be installed on the same PC as

the OPC server is running on.

Web browser Latest version of

• Google Chrome

• Mozilla Firefox

• Microsoft Edge

• Opera

• Safari

Danfoss always recommends keeping your

browser up to date.

6 | © Danfoss | 2021.09

AI260030799383en-000401

Page 7

Data sheet Leanheat® Monitor

System requirements Requirements to the ECL Comfort 296/310 controllers:

Controller software ECL Comfort 296 / ECL Comfort 310 controllers must be

software version 1.11 (or newer).

If it is version 1.11 – 1.30 then it will automatically be

updated by the application key to at least version 1.30.

If it is older than version 1.11 then it cannot be used for

Leanheat® Monitor.

Application key software 1.04 (or newer)

ECA 30 Remote Control (optional) 1.30 (or newer)

Requirements to the NOPRO OPR0020 controller:

Controller software NOPRO OPR0020 controllers must be software version

R9 (or newer).

Technical literature and

additional information

Please go to:

https://www.danfoss.com

In the ‘Service and support’ menu select ‘Documentation’ > ‘Data sheets’

and search for the literature number.

https://www.danfoss.com/en/service-and-support/documentation/

Typ e Description Literature no.

Appendix to

data sheets

Appendix

to data

sheet on

Leanheat®

Monitor

For further information on supported application keys please visit http://danfoss.com

In the ‘Products’ menu select ‘Climate Solutions for heating’ >‘Electronic Controls > Leanheat® Monitor

> Documents

https://www.danfoss.com/en/products/dhs/electronic-controls/electronic-controllers-and-applicationkeys/leanheat-monitor/

Energy meters supported by Danfoss SCADA

solutions, Leanheat® M onitor and ECL Comfort

296 / 310

List of application keys supported by

Leanheat® Monitor

AI150386468396

AI131486467165

AI260030799383en-000401

© Danfoss | 2021.09 | 7

Page 8

Data sheet Leanheat® Monitor

Leanheat® Monitor

main functionalities

Dashboard

• Dashboard

• Maps

• Smart groups

• Flow diagrams

• Heatmeter support

• Readings

• Device table

• Graphs

• Alarms

• Reporting

• Mobile version

• API

8 | © Danfoss | 2021.09

• This is a landing page after the user enters

the application.

• With different widgets that are available, it

represents the current district heating

system status as:

* Communication status

* Current system power (production,

consumption, losses)

* Alarms and warnings status

* …

• It is fully flexible, so users can place the

widgets, set them up with parameters,

define size and position.

• Dashboard of the Leanheat® Monitor can

be placed on one or multiple pages.

AI260030799383en-000401

Page 9

Data sheet Leanheat® Monitor

Maps

• Pins on the map representing device

location and status (based on the color of

the pin).

• Users can access the device by clicking on

the pin.

• Users can navigate around the map or use

the zoom function.

• For the map “Open street map” is used. It

is connected directly to the map service,

so the map is always up to date.

AI260030799383en-000401

© Danfoss | 2021.09 | 9

Page 10

Data sheet Leanheat® Monitor

Smart groups

• In order to have better presentation and

easier access to devices, the user is able to

create smart groups.

• Groups can be created based on different

criteria:

* Device name

* Device location

* Device tag

* …

Flow diagrams

• Smart groups can be used as a selection of

devices presented in the list and map.

• They can also be used for the selection of

devices when the user is creating a report,

alarm rule, executing bulk operation, etc.

• Represents physical installation on the

field.

• All components are drawn in the diagram,

which is equipped with live sensors data

and other active components data, e.g.

pumps, valves, actuators, etc.

• The refresh rate of data on the diagram is

10 seconds.

• Flow diagrams for Danfoss ECL controllers

with the standard application are

pre-created and stored in the diagram

library.

10 | © Danfoss | 2021.09

AI260030799383en-000401

Page 11

Data sheet Leanheat® Monitor

Heat meter support

Readings

• In case that energy meters are connected

to the ECL Comfort controller, those are

represented in Leanheat® Monitor without

any manual intervention.

• There are two places for the energy

meters. The first place is next to the flow

diagram on the right-hand side. In this

case the refresh period is the same as for

the flow diagram data, 10 seconds.

The second place is in the database, where

data together with controller sensor data

is stored every 15 minutes.

• Heat meter data can be presented in the

readings table and graph or used in the

reports, alarming, etc.

AI260030799383en-000401

• All sensor and energy meter data are

stored in the database every 15 minutes.

• Those data can be represented in the

“Readings table”, where users have an

option to select, which sensors they would

like to include and for which period. Users

can choose one of the predefined periods,

like today, one week, one month, one

quarter, one year, or define a custom

period.

• If the user wants to use the same selection

in the future a preset function can be used.

• Data can be exported in a CSV file directly

from the readings table.

© Danfoss | 2021.09 | 11

Page 12

Data sheet Leanheat® Monitor

Device table

Graphs

• Is a table that represents selected sensors

for multiple devices in order to compare

the values (e.g. flow temperature, return

temperature, …)

• Users can select devices manually or use

smart filters.

• Sensors can also be selected manually, or

presets can be used.

• Devices can be sorted based on a

particular sensor, selected by the user.

12 | © Danfoss | 2021.09

• All sensor and energy meter data are

stored in the database every 15 minutes.

• Those data can be represented in a graph

where users have an option to select

which sensors they would like to include

and for which period. Users can choose

one of the predefined periods, like today,

one week, one month, one quarter, one

year or define a custom period.

• If the user wants to use the same selection

in the future a preset can be created.

• The graph can be exported as a picture in

PNG or PDF format.

AI260030799383en-000401

Page 13

Data sheet Leanheat® Monitor

Alarms

• Leanheat® Monitor supports three types

of Alarms:

• The first type is “Threshold alarms” which

is based on periodically stored data. Users

select the sensor and define threshold

values for it.

• The second supported type is “Controller

alarms”. That means that alarm logic is in

the controller, but the user can make

settings from the Leanheat® Monitor.

• The third type is “Offline alarms“ which

tells the user when communication

between the controller and Leanheat®

Monitor is interrupted.

• For all types, users can define controllers

for which a particular Alarm rule is

applied, optional Alarm recipients,

schedule, and optional delays (occurrence

and notification).

Graphs

• All data stored in a database can be

exported by using the Reports

functionality. For that purpose, “Reports

definitions editor” should be used.

• The user defines, period, controllers,

sensors and other data that will be

included in the report.

• Reports can be executed manually or by

the schedule.

• Reports can be sent to specified recipients

or only generated and available for the

manual download.

AI260030799383en-000401

© Danfoss | 2021.09 | 13

Page 14

Data sheet Leanheat® Monitor

Mobile version (PWA)

14 | © Danfoss | 2021.09

• If the user accesses the application with a

mobile device, the resolution of that

device is automatically recognized and the

mobile version of Leanheat® Monitor

opens.

• Not all the functionalities are available in

the mobile version, but when using it

users can still connect new controllers, see

the flow diagrams, alarms, documents or

remotely change controller settings.

• Users can always decide to switch to the

desktop version manually.

AI260030799383en-000401

Page 15

Data sheet Leanheat® Monitor

API

• API offers access to data in the Leanheat®

Monitor database for the Danfoss

optimization software suite and 3rd party

applications.

• In an opposite direction, optimization

applications or 3rd party applications can

write calculated setpoints or any other

values directly to the controller.

• Detailed API documentation is available in

order to integrate 3rd party application.

AI260030799383en-000401

© Danfoss | 2021.09 | 15

Page 16

Data sheet Leanheat® Monitor

16 | © Danfoss | DCS-SGDPT/DK | 2021.09

AI260030799383en-000401

Loading...

Loading...