Page 1

Technical Information

LDU20/24

Closed Circuit Axial Piston Transmission

www.danfoss.com

Page 2

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

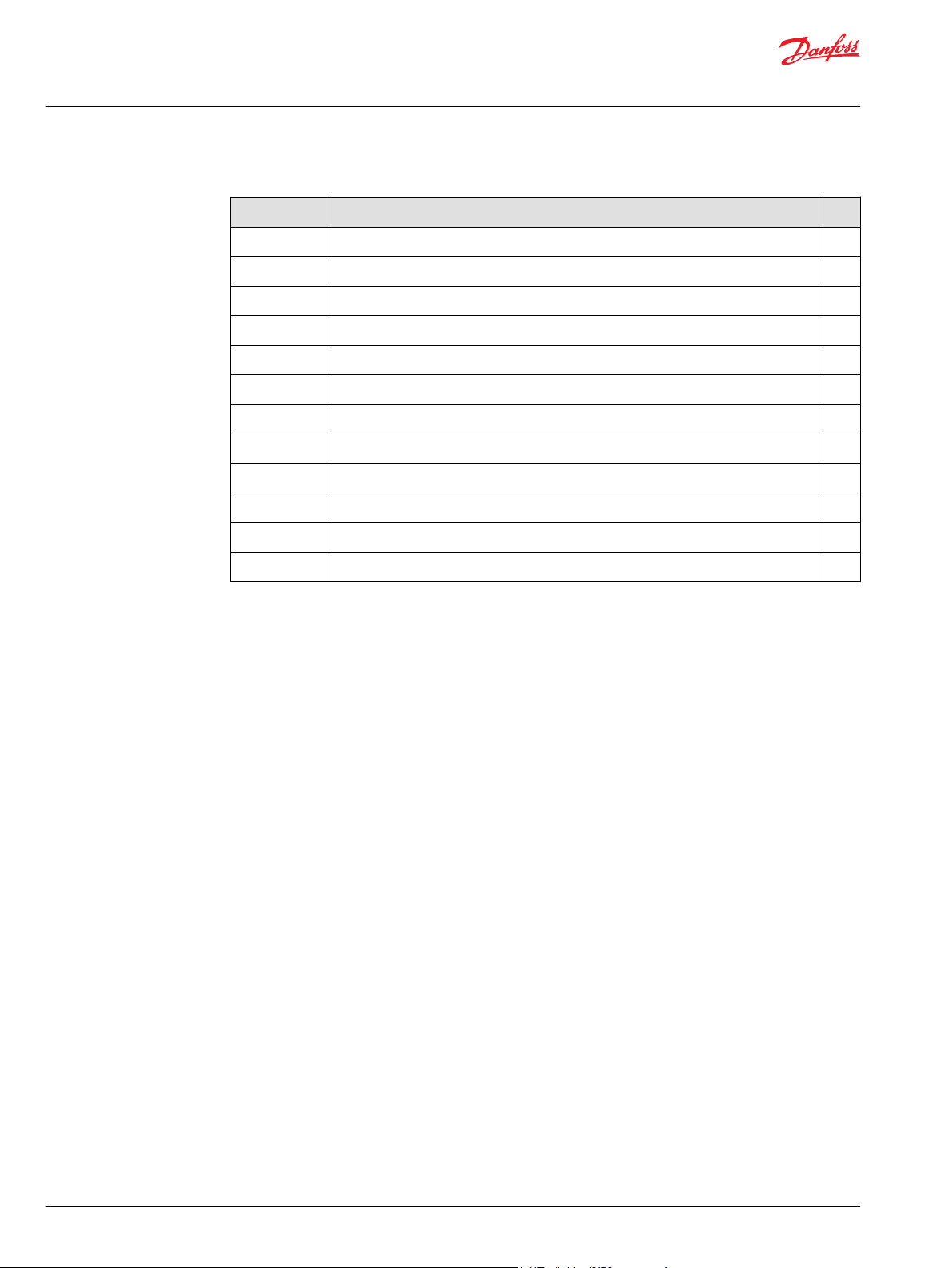

Revision history Table of revisions

Date Changed Rev

May 2021 Added Size 24 0301

January 2021 Minor update in Physical Properties 0208

December 2020 Minor correction 0207

Novemebr 2020 Minor update 0206

June 2020 Changed document number from 'BC00000192' and 'L1124546' to 'BC152886483777' 0205

April 2019 Fixed Control Handle Requirements 0103

April 2018 Minor update 0102

June 2016 Converted to New Danfoss layout 0101

December 2014 Converted to DITA CMS AD

March 2013 Paint and Tag AC

March 2011 2nd edition AB

January 2011 First edition AA

2 | © Danfoss | May 2021 BC152886483777en-000301

Page 3

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Contents

General description

Basic Design........................................................................................................................................................................................4

Key Features....................................................................................................................................................................................... 4

Typical Applications........................................................................................................................................................................ 4

Schematic diagram..........................................................................................................................................................................4

Technical Specification

Physical properties...........................................................................................................................................................................5

Operation Parameters.....................................................................................................................................................................5

Fluid Specifications..........................................................................................................................................................................6

Operations

Check / High Pressure Relief Valve ............................................................................................................................................7

Bypass Function................................................................................................................................................................................8

CPRV (Charge Pressure Relief Valve)..........................................................................................................................................9

Control............................................................................................................................................................................................... 10

Direct Displacement Control................................................................................................................................................10

Control Handle Requirements ............................................................................................................................................ 10

Operating Parameters

Overview........................................................................................................................................................................................... 11

Input Speed......................................................................................................................................................................................11

System Pressure..............................................................................................................................................................................11

Input Power......................................................................................................................................................................................11

Charge Pressure..............................................................................................................................................................................11

Case pressure...................................................................................................................................................................................12

Viscosity.............................................................................................................................................................................................12

Temperature.................................................................................................................................................................................... 12

System Design Parameters

Filtration System ............................................................................................................................................................................13

Filtration............................................................................................................................................................................................ 14

Charge Filtration....................................................................................................................................................................... 14

Suction Filtration.......................................................................................................................................................................14

Independent Braking System....................................................................................................................................................15

Fluid Selection.................................................................................................................................................................................15

Reservoir............................................................................................................................................................................................15

Case Drain.........................................................................................................................................................................................15

Charge Pump...................................................................................................................................................................................15

Bearing Loads and Life.................................................................................................................................................................16

Applications with External Shaft Loads............................................................................................................................16

Input Shaft...................................................................................................................................................................................17

Shaft Torque Rating and Spline Lubrication...................................................................................................................18

Shaft Availability and Torque Ratings...............................................................................................................................18

Sizing Equations............................................................................................................................................................................. 19

Model Code

Model Code: A - H.......................................................................................................................................................................... 20

Model Code: J - M...........................................................................................................................................................................21

Model Code: N - Z...........................................................................................................................................................................22

Installation Drawings

Shaft Availability and Torque Ratings: Input Shaft/PTO Shaft.......................................................................................23

Shaft Availability and Torque Ratings: Output Shaft........................................................................................................ 24

Installation Drawings LDU20/24...............................................................................................................................................25

Center section: Option A.............................................................................................................................................................27

Center section: Option B............................................................................................................................................................. 28

Center section: Option F..............................................................................................................................................................29

Center section: Option H.............................................................................................................................................................30

©

Danfoss | May 2021 BC152886483777en-000301 | 3

Page 4

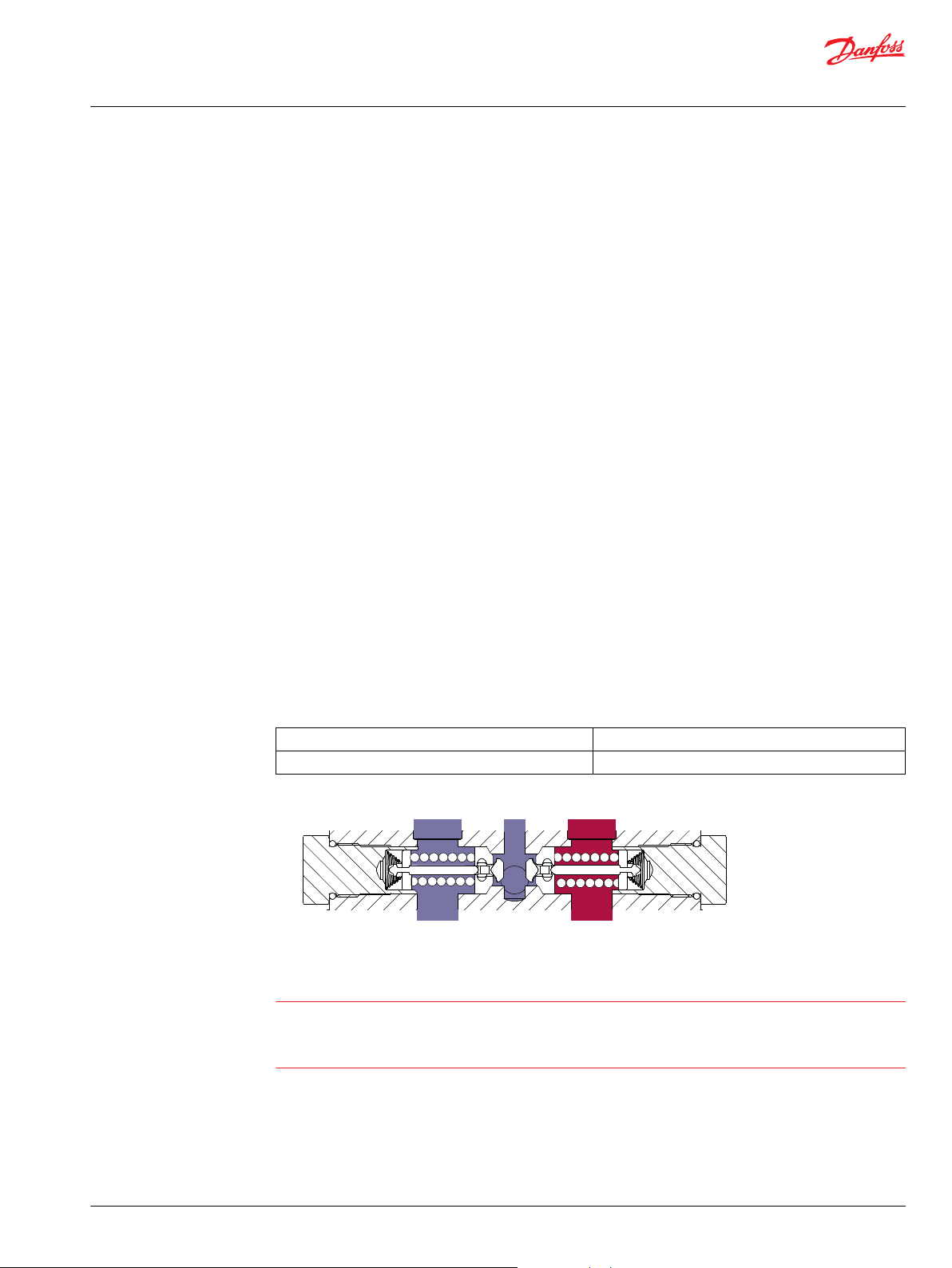

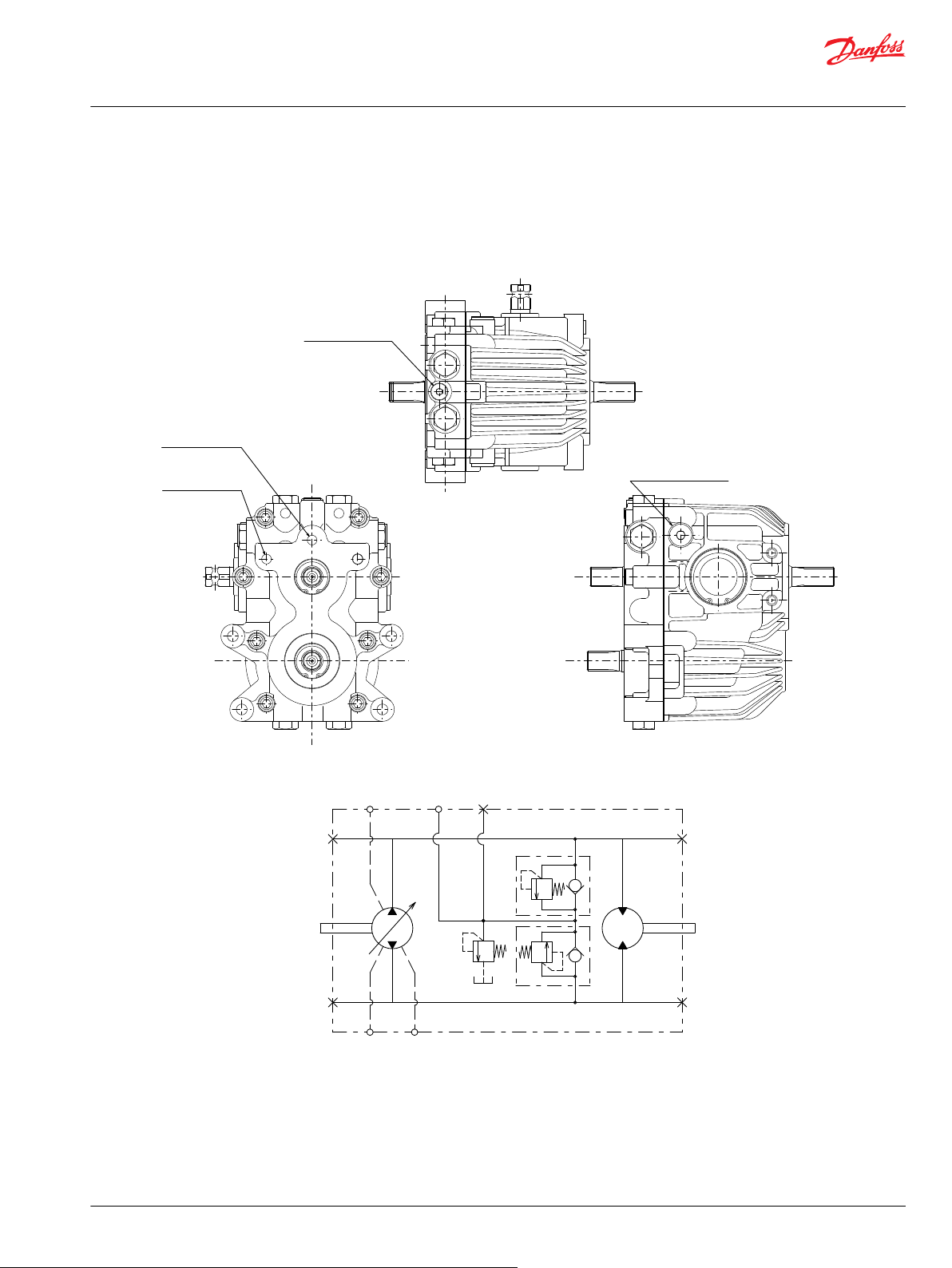

MA1

MB1

MA2

MB2

L1

L2

L3

S

M3

P400004

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

General description

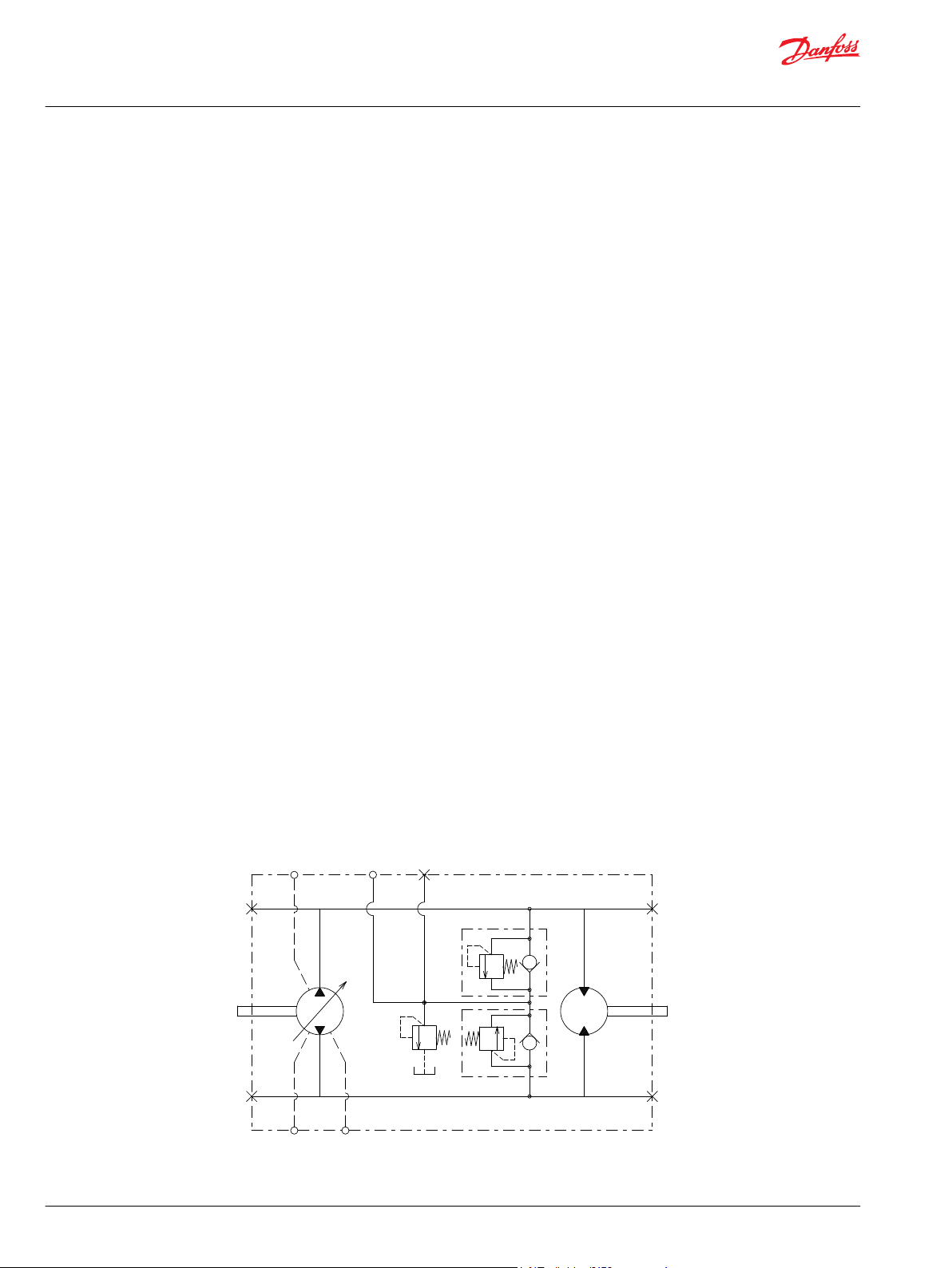

Basic Design

LDU20/24 is a kind of U-style HST hardware, including a closed circuit variable displacement piston pump

with DDC (Direct displacement control) and a fixed motor. LDU20/24 is specially designed with optimized

performance, size, and cost, in order to fulfill the demand of the mobile applications marketplace. This

document provides the detailed specifications and features for LDU20/24.

Key Features

Easy to use design as Complete Hydrostatic Transmission package for Turf care machines & Compact

•

Utility Tractors up to 26 kw[35 PS]

Compact design

•

U-style layout in One housing with Z-shaft configuration

•

Require external charge

•

Bypass valve to allow the vehicle to be towed

•

Same shaft center distance as BDU21 85mm…Between pump and motor shaft

•

Same drive line design is available between BDU21 and LDU20/24

•

Best in class Efficiency by Female Piston & Male slipper design…Can reach approximately 80% overall

•

efficiency

Longer life kit, Higher Duty Cycle capability in the most compact design in this class of HST

•

Low trunnion operating force

•

Serviced by a Worldwide Network of Danfoss

•

Typical Applications

Schematic diagram

Compact utility tractor

•

Turf care

•

Small agricultural machinery

•

4 | © Danfoss | May 2021 BC152886483777en-000301

Page 5

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

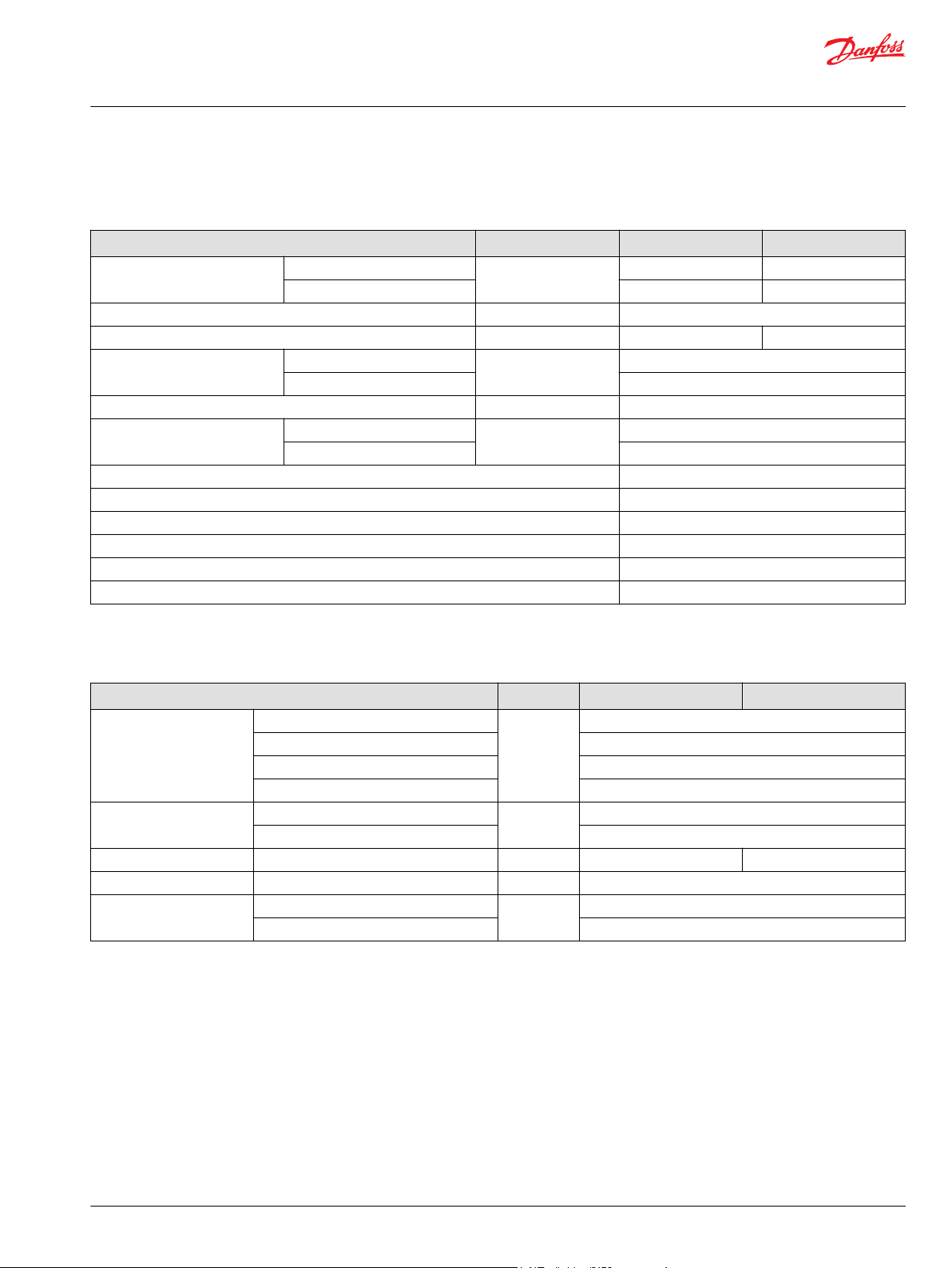

Technical Specification

Physical properties

Features Units LDU20 LDU24

Displacement

Recommended charge pump displacement for external charge supply cm3/rev [in3/rev] 6 [0.37]

Torque at maximum displacement (theoretical)

Mass moment of inertia of

rotating components

Weight dry kg [lb] 14.1 [31.1]

Oil volume

Installation See Installation Drawings on page 25-30

Rotation Clockwise or Counterclockwise

Ports (ISO 11926-1) See Installation Drawings on page 25-30

Input shafts and PTO shafts See Installation Drawings on page 23

Output shaft See Installation Drawings on page 24

Control type DDC

1

Max Swash angle is 18 deg.

Pump side

Motor side 20 [1.22] 24 [1.46]

Pump side

Motor side 0.000928 [0.000683]

Case only

With passage 1.2 [0.32]

1

cm3/rev [in3/rev]

N•m/bar [lbf•in/1000 psi]

kg•m2 [slug•ft2]

liter [US gal]

0-20 [0-1.22] 0-24 [0-1.46]

0.32 [195.2] 0.38 [234.2]

0.000936 [0.000693]

1.1 [0.28]

Operation Parameters

Features Units LDU20 LDU24

Minimum for external charge supply

Input speed

System pressure

Input power Maximum kw [PS] 22 [30] 26 [35]

Charge pressure Minimum bar [psi] 5 [73]

Case pressure

Minimum for full performance 1300

Rated 3400

Maximum 3800

Maximum working pressure

Maximum pressure 345 [500]

Rated

Maximum 3 [43.5]

min-1 (rpm)

bar [psi]

bar [psi]

500

300 [4350]

1 [14.5]

©

Danfoss | May 2021 BC152886483777en-000301 | 5

Page 6

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

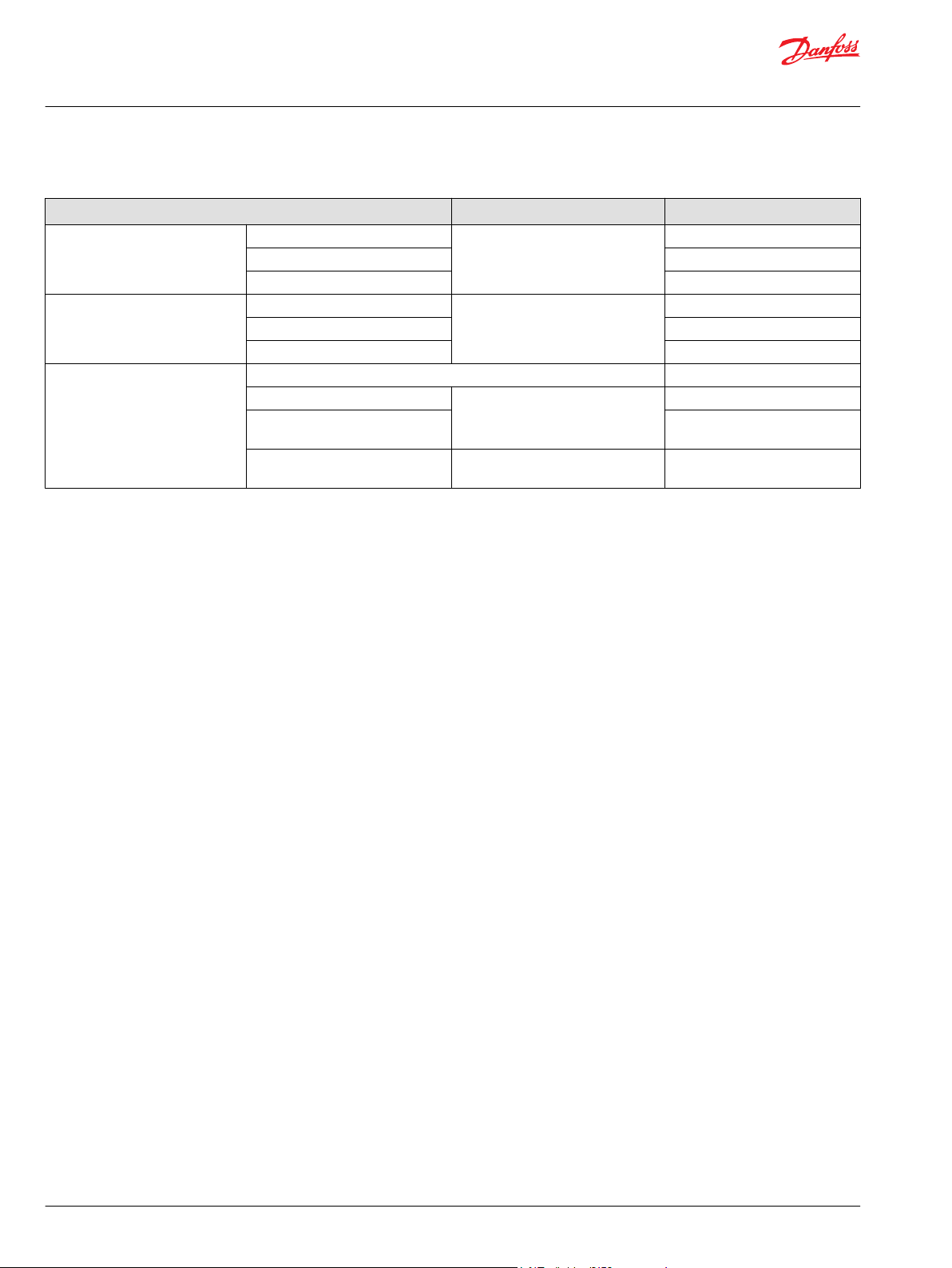

Technical Specification

Fluid Specifications

Features Units LDU20/24

Viscosity

Temperature

Filtration

(recommended minimum)

Minimum

Recommended range 12-60 [66-280]

Maximum 1600 [7500]

Minimum

Recommended range +82 [+180]

Maximum +104 [+220]

Cleanliness per ISO 4406 22/18/13

Efficiency (charge pressure filtration)

Efficiency (suction and return line

filtration)

Recommended inlet screen mesh

size

mm2/sec. [ SUS]

Degrees C [Degrees F]

β-ratio

µm 100-125

7 [49]

-40 [-40]

β15-20=75(β10≥10)

β15-20=75(β10≥10)

6 | © Danfoss | May 2021 BC152886483777en-000301

Page 7

P400005

C

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Operations

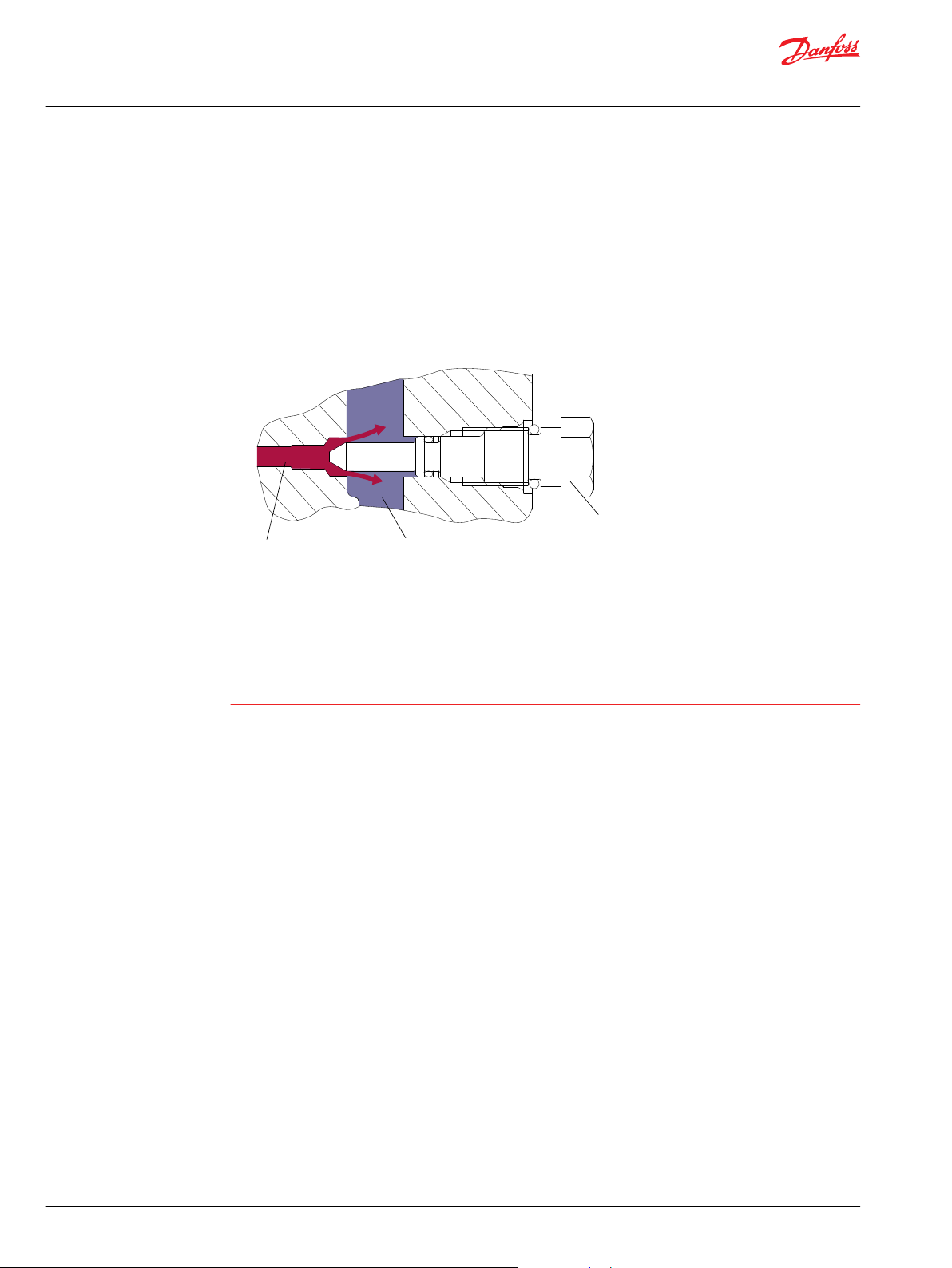

Check / High Pressure Relief Valve

LDU20/24 is equipped with a combination high pressure relief and charge check valve. The high-pressure

relief function is a dissipative (with heat generation) pressure control valve for the purpose of limiting

excessive system pressures. The charge check function acts to replenish the low-pressure side of the

working loop with charge oil. Each side of the transmission loop has a dedicated HPRV valve that is nonadjustable with a factory set pressure. When system pressure exceeds the factory setting of the valve, oil

is passed from the high pressure system loop, into the charge gallery, and into the low pressure system

loop via the charge check.

The order code allows for different pressure settings to be used at each system port. HPRV valve with

orifice is available to gain wider neutral dead-band. When HPRV valves with orifice are used, it is only for

High pressure ports when vehicle goes in reverse. The system pressure order code for transmissions with

only HPRV is a reflection of the HPRV setting.

The system pressure order code for transmissions configured with pressure limiter and HPRV is a

reflection of the pressure limiter setting.

Check/High pressure relief valve with orifice

As an option, LDU20/24 offers Check / HPRV with an orifice produce a larger neutral deadband.

In some applications, it is desirable to use Check / HPRV with an orifice to expand null dead band, which

would help provide a larger margin of safety for vehicle movement in neutral and provide easier

adjustment of the vehicle linkage for machine neutral. The orifice connects the working loop, which is a

main hydraulic circuit, to a charge circuit. It always allows some internal leakage to ensure the expanding

null dead band around neutral position of control shaft. However, it decreases the volumetric efficiency,

particularly at high system pressure in the working loop. Check / HPRV with an orifice has possibility to

increase downhill creap. It is recommended to install the orifice in a specific working loop, which is

pressurized when the vehicle moves in reverse.

The HPRV are set at the following flow rates

Check/HPRV without orifice 5 l/min [1.3 US gal/min]

Check/HPRV with orifice 17 l/min [4.5 US gal/min]

Caution

HPRV´s are factory set at a low flow condition. Any application or operating condition which leads to

elevated HPRV flow will cause a pressure rise with flow above a valve setting. Consult factory for

application review.

©

Danfoss | May 2021 BC152886483777en-000301 | 7

Page 8

System Pressure

Bypass Valve

System Pressure

P400006

C

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Operations

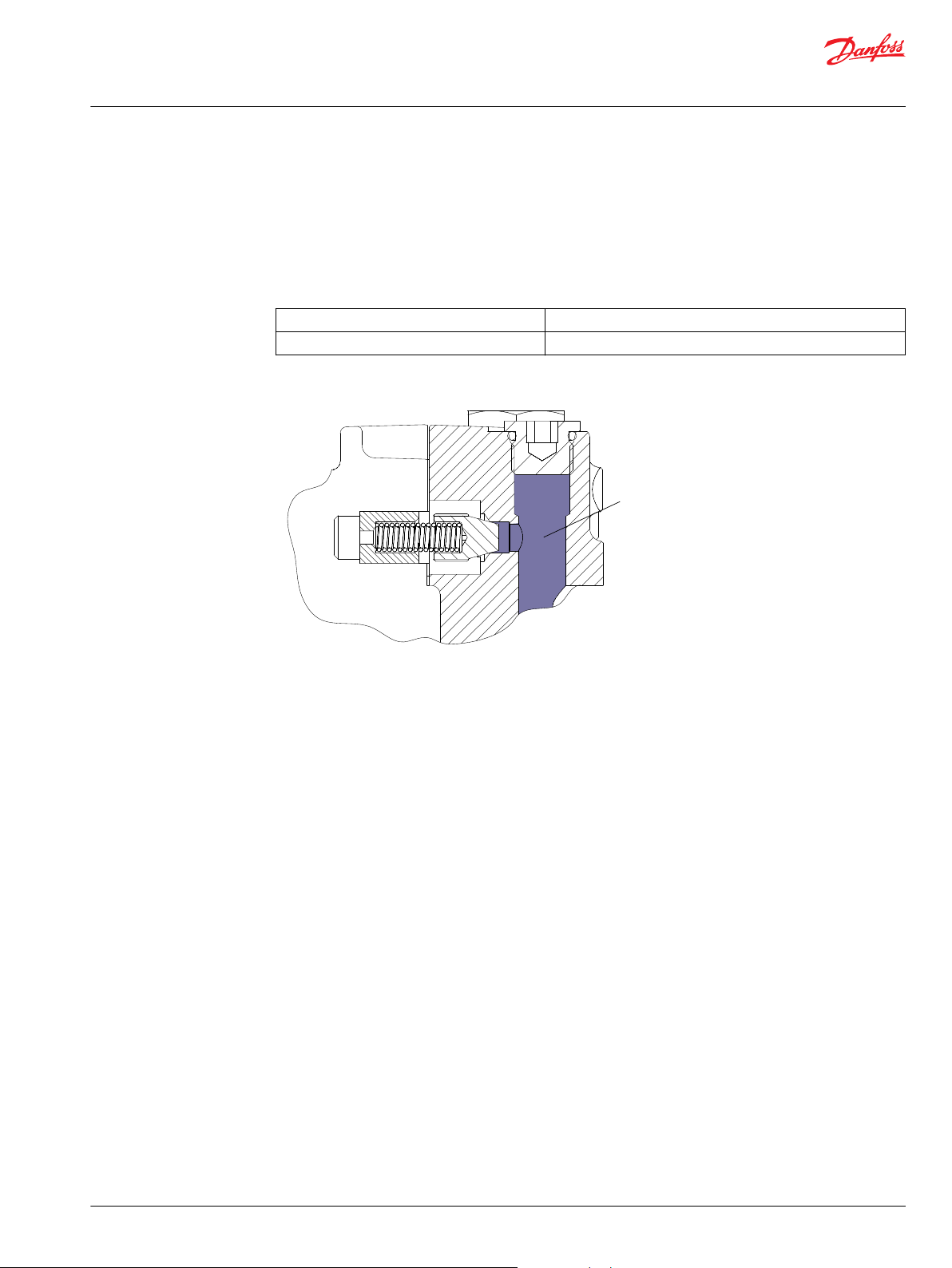

Bypass Function

The LDU20/24 contains a dedicated bypass valve option. The bypass function is activated when the

bypass valve is mechanically backed out 3 full turns (maximum). The bypass function allows a machine or

load to be moved without rotating the pump shaft or prime mover. In some applications, it is desirable to

bypass the fluid around the variable displacement pump when pump shaft rotation is unachievable or

undesired. To illustrate, an inoperable vehicle may need to be moved to the service or the repair location,

or winched onto a trailer without operating the prime mover. Thus, LDU20/24 is designed with the

bypass function as an option.

Bypass Function

Caution

Excessive speed or extended movement will damage the transmission.

Avoid excessive speeds and extended load/vehicle movement. Do not move the load or vehicle more

than 20 % of maximum speed or for longer than 3 minutes. When the bypass function is no longer

needed, reseat the bypass valve to the normal operating position.

8 | © Danfoss | May 2021 BC152886483777en-000301

Page 9

Charge Flow

P400007

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Operations

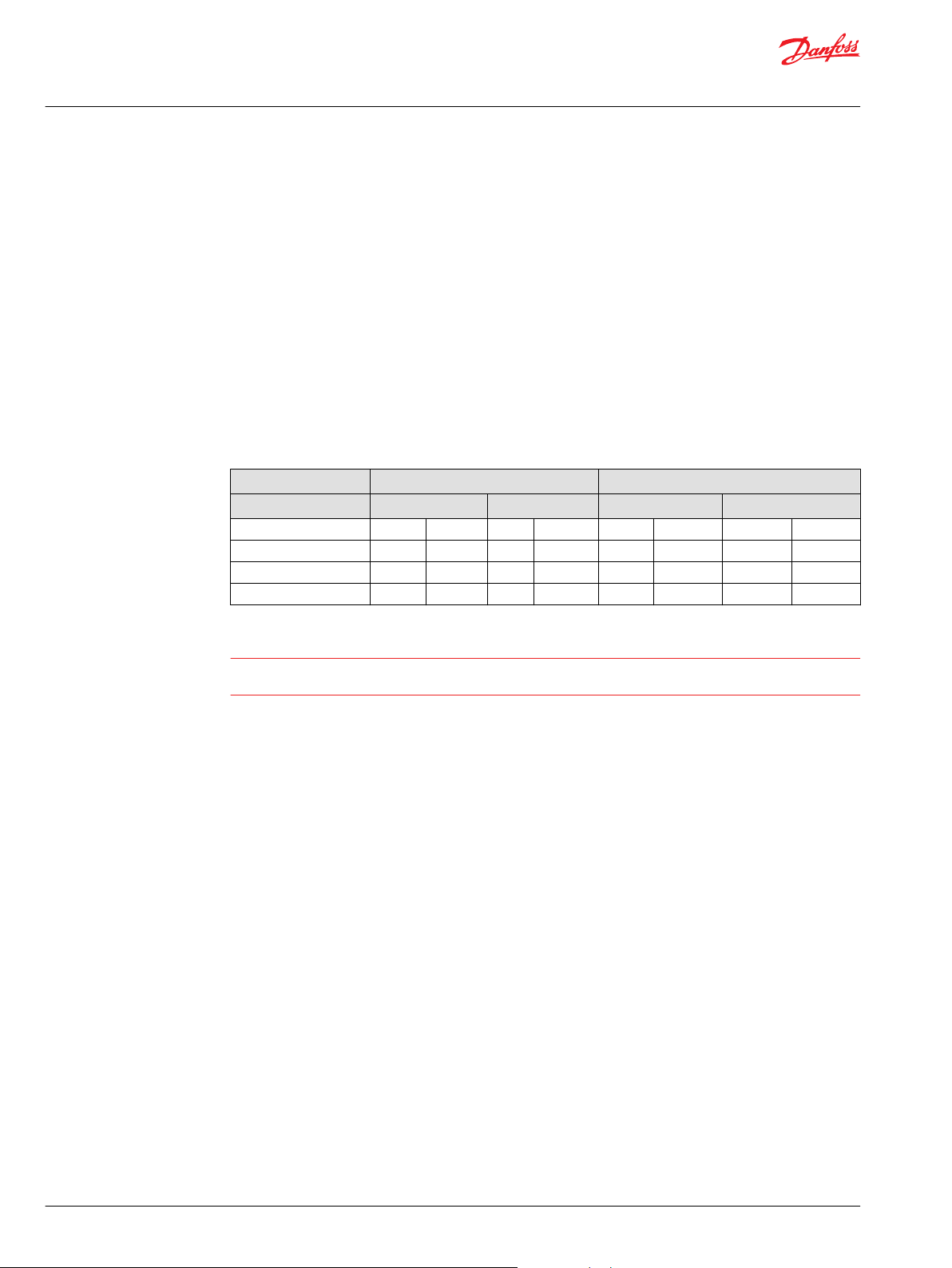

CPRV (Charge Pressure Relief Valve)

The charge pressure relief valve maintains charge pressure at a designated level above case pressure. The

charge pressure relief valve is a direct acting poppet valve which opens and discharges fluid to the HST

case when pressure exceeds a designated level. For external charge flow the CPRV is set according to

below table. The charge pressure relief valve setting is specified on the model code of the transmission.

Charge Pressure Relief Valve settings for external charge supply

LDU 20/24 10.8 [2.9]

Charge Pressure Relief Valve Function

Flow l/min [US gal/min]

©

Danfoss | May 2021 BC152886483777en-000301 | 9

Page 10

W

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Operations

Control

Direct Displacement Control

The LDU20/24 features Direct Displacement Control (DDC) .The swashplate angle is set directly by a

control lever or linkage attached directly to the swashplate trunnion. Control lever movement changes

the speed and rotating direction of the motor by increasing or decreasing the swashplate angle.

The control input shaft is configurable on both of left and right hand side of the LDU20/24.

Control Handle Requirements

Maximum allowable trunnion torque is 79.1 N•m [700 lbf•in]. The approximate torque necessary to rotate

the control arm at 300 bar system operating pressure and 3000 rpm is 25 N•m with the standard

valveplate. Minimum torque necessary to hold the swashplate at a zero angle for neutral is 2.3 N•m [20

in•lbf ]. The actual value will vary due to the influence of pump operating conditions. For mating

dimensions, see Installation Drawings LDU20/24 on page 25.

Input shaft rotation CW CCW

Trunnion location Right Left Right Left

Trunnion rotation CW CCW CW CCW CW CCW CW CCW

Output rotation CCW CW CW CCW CW CCW CCW CW

High pressure port MA MB MB MA MB MA MA MB

Low pressure port MB MA MA MB MA MB MB MA

Warning

With no external forces applied to the swashplate trunnion, internal hydraulic forces may not return the

swashplate to the neutral position under all conditions of operation.

10 | © Danfoss | May 2021 BC152886483777en-000301

Page 11

W

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Operating Parameters

Overview

This section defines the operating parameters and limitations for LDU20/24 with regard to input speeds

and pressures. For actual parameters, refer to Operating Parameters in the Technical Specifications

section.

Input Speed

Minimum speed is the lowest input speed recommended during engine idle condition. Operating below

minimum speed limits pump’s ability to maintain adequate flow for lubrication and power transmission.

Rated speed is the highest input speed recommended at full power condition. Operating at or below

this speed should yield satisfactory product life.

Maximum speed is the highest operating speed permitted. Exceeding maximum speed reduces product

life and can cause loss of hydrostatic power and braking capacity. Never exceed the maximum speed

limit under any operating conditions.

Operating conditions between rated speed and maximum speed should be restricted to less than full

power and to limited periods of time. For most drive systems, maximum unit speed occurs during

downhill braking or negative power conditions.

Warning

System Pressure

Input Power

Unintended vehicle or machine movement hazard.

Exceeding maximum speed may cause a loss of hydrostatic drive line power and braking capacity. You

must provide a braking system, redundant to the hydrostatic transmission, sufficient to stop and hold the

vehicle or machine in the event of hydrostatic drive power loss.

System pressure is the differential pressure between system ports A & B. It is the dominant operating

variable affecting hydraulic unit life. High system pressure, which results from high load, reduces

expected life. Hydraulic unit life depends on speed and normal operating—or weighted average—

pressure that you can only determine from a duty cycle analysis.

Maximum Working Pressure is the highest recommended Application pressure. Maximum working

pressure is not intended to be a continuous pressure. Propel systems with Application pressures at, or

below, this pressure should yield satisfactory unit life given proper component sizing.

Maximum pressure (peak) is the highest intermittent pressure allowed under any circumstances.

Applications with applied pressures between rated and maximum require factory approval with

complete application, duty cycle, and life expectancy analysis.

All pressure limits are differential pressures referenced to low loop (charge) pressure. Subtract low loop

pressure from gauge readings to compute the differential.

Maximum continuous input power is the highest recommended input power to HST excluding PTO

output power.

Charge Pressure

An internal charge relief valve regulates charge pressure. Charge pressure maintains a minimum pressure

in the low side of the transmission loop. Charge pressure is the differential pressure above case pressure.

Minimum charge pressure is the lowest pressure safe working conditions allow in the system.

©

Danfoss | May 2021 BC152886483777en-000301 | 11

Page 12

C

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Operating Parameters

Case pressure

Under normal operating conditions, the rated case pressure must not be exceeded. During cold start case

pressure must be kept below maximum intermittent case pressure. Size drain plumbing accordingly.

Caution

Possible component damage or leakage

Operation with case pressure in excess of stated limits may damage seals, gaskets, and/or housings,

causing external leakage. Performance may also be affected since charge and system pressure are

additive to case pressure.

Viscosity

Maintain fluid viscosity within the recommended range for maximum efficiency and bearing life.

Minimum viscosity should only occur during brief occasions of maximum ambient temperature and

severe duty cycle operation. Maximum viscosity should only occur at cold start. Limit speeds until the

system warms up. Refer to Fluid Specifications on page 6

Temperature

1. Maintain fluid temperature within the limits shown in the table.

Minimum

temperature

Maximum

temperature

2. Measure maximum temperature at the hottest point in the system.

Refer to Fluid specifications for specifications.

3. Ensure fluid temperature and viscosity limits are concurrently satisfied.

relates to the physical properties of the component materials. Cold oil will not

affect the durability of the components, however, it may affect the ability of

the transmission to provide flow and transmit power.

is based on material properties. Don’t exceed it.

12 | © Danfoss | May 2021 BC152886483777en-000301

Page 13

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

System Design Parameters

Filtration System

To prevent premature wear, ensure that only clean fluid enters the hydrostatic transmission circuit. A

filter capable of controlling the fluid cleanliness to ISO 4406, class 22/18/13 (SAE J1165) or better, under

normal operating conditions, is recommended.These cleanliness levels cannot be applied for hydraulic

fluid residing in the component housing/case or any other cavity after transport.

Filtration strategies include suction or pressure filtration. The selection of a filter depends on a number of

factors including the contaminant ingression rate, the generation of contaminants in the system, the

required fluid cleanliness, and the desired maintenance interval. Filters are selected to meet the above

requirements using rating parameters of efficiency and capacity.

Filter efficiency can be measured with a Beta ratio1 (βX). For simple suction-filtered closed circuit

transmissions and open circuit transmissions with return line filtration, a filter with a β-ratio within the

range of β

and closed circuits with cylinders being supplied from the same reservoir, a higher filter efficiency is

recommended. This also applies to systems with gears or clutches using a common reservoir. For these

systems, a charge pressure or return filtration system with a filter β-ratio in the range of β

10) or better is typically required.

Because each system is unique, only a thorough testing and evaluation program can fully validate the

filtration system. Please see Design Guidelines for Hydraulic Fluid Cleanliness Technical Information,

BC152886482150 for more information.

= 75 (β10 ≥ 2) or better has been found to be satisfactory. For some open circuit systems,

35-45

= 75 (β10 ≥

15-20

Cleanliness level and βx-ratio

Cleanliness per ISO 4406 22/18/13

Filtration

(recommended

minimum)

Efficiency (charge pressure filtration) β

Efficiency (suction and return line filtration) β

Recommended inlet screen mesh size 100 – 125 µm

= 75 (β10 ≥ 10)

15-20

= 75 (β10 ≥ 2)

35-45

1

Filter βx-ratio is a measure of filter efficiency defined by ISO 4572. It is defined as the ratio of the number of particles greater than a

given diameter (“x” in microns) upstream of the filter to the number of these particles downstream of the filter.

©

Danfoss | May 2021 BC152886483777en-000301 | 13

Page 14

P400009

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

System Design Parameters

Filtration

Charge Filtration

The pressure filter is remotely mounted in the circuit after the charge pump, as shown in the

accompanying illustration.

Filters used in charge pressure filtration circuits must be rated to at least 34.5 bar [500 psi] pressure.

Danfoss recommends locating a 100 - 125 µm screen in the reservoir or in the charge inlet line when

using charge pressure filtration.

A filter bypass valve is necessary to prevent damage to the system. In the event of high pressure drop

associated with a blocked filter or cold start-up conditions, fluid will bypass the filter. Avoid working with

an open bypass for an extended period. We recommend a visual or electrical bypass indicator. Proper

filter maintenance is mandatory.

Charge filtration

Suction Filtration

The suction filter is placed in the circuit between the reservoir and the inlet to the charge pump as shown

in the accompanying illustration.

Suction filtration

14 | © Danfoss | May 2021 BC152886483777en-000301

Page 15

W

C

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

System Design Parameters

Independent Braking System

Vehicle propel applications may require a provision for non-linear control input to reduce control

sensitivity near neutral. Damping or frictional forces may be necessary to produce the desired control

feeling.

These units do not include any neutral centering device for the swashplate. It is necessary to provide a

force in the machine’s control system that will hold the swashplate at the desired angle. A “ fail safe

“ which will return the swashplate to the neutral in the event of linkage failure is recommended.

Warning

Unintended vehicle or machine movement hazard.

The loss of hydrostatic drive line power, in any mode of operation (forward, neutral, or reverse) may cause

the system to lose hydrostatic braking capacity. You must provide a braking system, redundant to the

hydrostatic transmission, sufficient to stop and hold the vehicle or machine in the event of hydrostatic

drive power loss.

Fluid Selection

Ratings and performance data are based on operating with hydraulic fluids containing oxidation, rust

and foam inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear,

erosion, and corrosion of the components.

Reservoir

Case Drain

Caution

Never mix hydraulic fluids of different types.

The hydrostatic system reservoir should accommodate maximum volume changes during all system

operating modes and promote de-aeration of the fluid as it passes through the tank.

A suggested minimum total reservoir volume is 5⁄8 of the maximum charge pump flow per minute with a

minimum fluid volume equal to ½ of the maximum charge pump flow per minute. This allows 30 seconds

fluid dwell for removing entrained air at the maximum return flow. This is usually adequate to allow for a

closed reservoir (no breather) in most applications.

Locate the reservoir outlet (charge pump inlet) above the bottom of the reservoir to take advantage of

gravity separation and prevent large foreign particles from entering the charge inlet line. A 100-125 µm

screen over the outlet port is recommended.

Position the reservoir inlet (fluid return) to discharge below the normal fluid level, toward the interior of

the tank. A baffle (or baffles) will further promote de-aeration and reduce surging of the fluid.

A case drain line must be connected to one of the case outlets to return internal leakage to the system

reservoir. Use the higher of the outlets to promote complete filling of the case. Since case drain fluid is

typically the hottest fluid in the system, it is a good idea to return this flow to the reservoir via the heat

exchanger

Charge Pump

Charge flow requirements for the LDU20/24 should be equivalent to a 6-8cc/rev charge pump,

depending on pump input speed. Charge flow must not exceed 30 l/min.

©

Danfoss | May 2021 BC152886483777en-000301 | 15

Page 16

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

System Design Parameters

Bearing Loads and Life

Bearing life is a function of speed, system pressure, charge pressure, and swashplate angle, plus any

external side or thrust loads. The influence of swashplate angle includes displacement as well as

direction. External loads are found in applications where the pump is driven with a side/thrust load (belt

or gear) as well as in installations with misalignment and improper concentricity between the pump and

drive coupling. All external side loads will act to reduce the normal bearing life of a pump. Other life

factors include oil type and viscosity.

Applications with External Shaft Loads

LDU20/24 is designed with bearings that can accept some external radial and thrust loads. When external

loads are present, the allowable radial shaft loads are a function of the load position relative to the

Housing surface, the load orientation relative to the internal loads, and the operating pressures of the

hydraulic unit. In applications where external shaft loads cannot be avoided, the impact on bearing life

can be minimized by proper orientation of the load. Optimum pump orientation is a consideration of the

net loading on the shaft from the external load, the pump rotating group.

In applications where the pump is operated such that nearly equal amounts of forward vs. reverse

•

swashplate operation is experienced; bearing life can be optimized by orientating the external side

load at 90° or 270° such that the external side load acts 90° to the rotating group load (for details see

drawing below).

In applications where the pump is operated such that the swashplate is predominantly (> 75 %) on

•

one side of neutral (ie vibratory, conveyor, typical propel); bearing life can be optimized by

orientating the external side load generally opposite of the internal rotating group load. The direction

of internal loading is a function of rotation and which system port has flow out.

LDU20/24 is designed with bearings that can accept some thrust load such that incidental thrust

•

loads are of no consequence. When thrust loads are anticipated the allowable load will depend on

many factors and it is recommended that an application review be conducted.

Contact Danfoss for a bearing life review if external side loads are present.

Thrust loads should be avoided. Contact factory in the event thrust loads are anticipated.

16 | © Danfoss | May 2021 BC152886483777en-000301

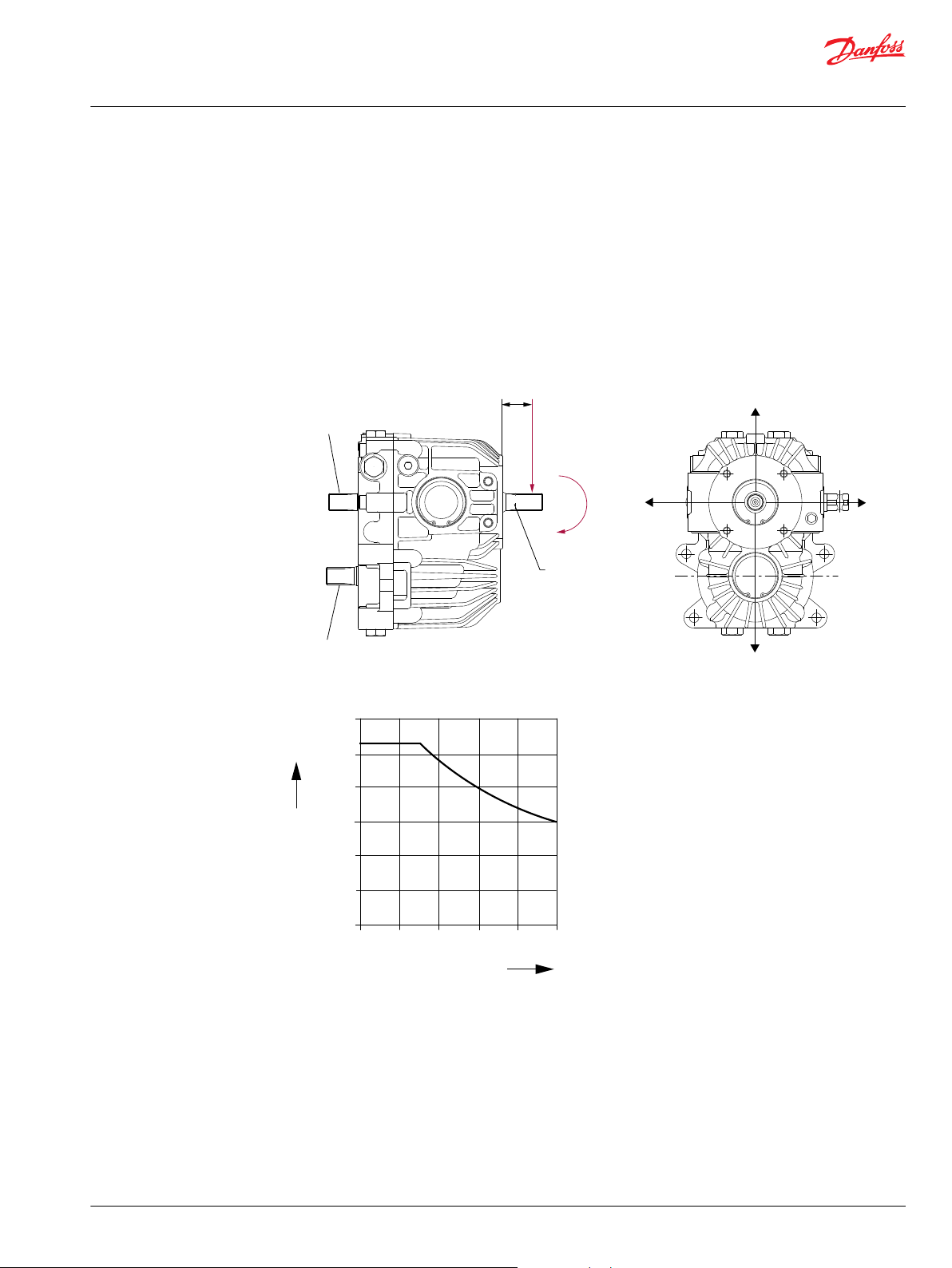

Page 17

270° Re90° Re

0° Re

180° Re

Output shaft

PTO shaft

Input shaft

L

Re

Me

P400010

1200

1000

800

600

400

200

Re N

0 10 20 30 40 50

distance (L) mm

P400011

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

System Design Parameters

Input Shaft

The maximum allowable radial load (Re) is based on the maximum external moment (Me) and the

distance (L) from the mounting flange to the load. It is shown in the chart below.

Re = Me / L

Me Shaft moment

L Flange distance

Re External force to the shaft

Danfoss recommends clamp-type couplings for applications with radial shaft loads

Contact your Danfoss representative for an evaluation of unit bearing life if you have continuously

applied external loads exceeding 25 % of the maximum allowable radial load (Re) or the pump

swashplate is positioned on one side of center all or most of the time.

PTO shaft, Output shaft

Avoid any load in either direction.

©

Danfoss | May 2021 BC152886483777en-000301 | 17

Page 18

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

System Design Parameters

Shaft Torque Rating and Spline Lubrication

Maximum torque ratings are based on torsional fatigue strength considering 100.000 full load reversing

cycles. However, a spline running in oil-flooded environment provides superior oxygen restriction in

addition to contaminant flushing. The rated torque of a flooded spline can increase to that of the

maximum published rating. A flooded spline would be indicative of a pump driven by a pump drive or

plugged into an auxiliary pad of a pump.

Maintaining a spline engagement at least equal to the Pitch Diameter will also maximize spline life. Spline

engagements of less than ¾ Pitch Diameter are subject to high contact stress and spline fretting.

Shaft Availability and Torque Ratings

Alignment between the mating spline’s pitch diameters is another critical factor in determining the

operating life of a splined drive connection. Plug-in, or rigid spline drive installations can impose severe

radial loads on the shaft. The radial load is a function of the transmitted torque and shaft eccentricity.

Increased spline clearance will not totally alleviate this condition; BUT, increased spline clearance will

prevent mechanical interference due to misalignment or radial eccentricity between the pitch diameters

of the mating splines. Maximize spline life by adding an intermediate coupling between the bearing

supported splined shafts.

18 | © Danfoss | May 2021 BC152886483777en-000301

Page 19

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

System Design Parameters

Sizing Equations

The following equations are helpful when sizing hydraulic transmissions. Generally, the sizing process is

initiated by an evaluation of the machine system to determine the required transmission speed and

torque to perform the necessary work function. Refer to Selection of drive line components,

BC157786484430, for a more complete description of hydrostatic drive line sizing.

Based on SI units Based on US units

Input torque Nm [lbf•in]

Input power kW [hp]

Output

torque

Output

power

Where;

V

gp

V

gm

Δ

p

η

mp

η

mm

η

tp

η

tm

p

HD

p

ND

n

p

n

m

Nm [lbf•in]

kW [hp]

Pump displacement per rev. cm3 [in3]

Motor displacement per rev. cm3 [in3]

pHD – pND bar [psi]

Pump Mechanical-hydraulic (Torque) efficiency

Motor Mechanical-hydraulic (Torque) efficiency

Pump Overall efficiency

Motor Overall efficiency

High pressure bar [psi]

Low pressure bar [psi]

Input speed

Output speed

©

Danfoss | May 2021 BC152886483777en-000301 | 19

Page 20

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Model Code

Model Code: A - H

A - Displacement

Code Description

20D Displacement: 20 cc/rev / Block type : standard Block

24D Displacement: 24 cc/rev / Block type : standard Block

B - Rotation

Code Description

L Left hand side viewing from input shaft (CCW)

R Right hand side viewing from input shaft (CW)

C - Valve Plate

Code Description

A Standard

D - Control Arm Position

Code Description

L Left hand side viewing from input shaft (pump located upside)

R Right hand side viewing from input shaft (pump located upside)

E - Control Arm Configuration

Code Description

S Square

F - Pump Shaft Configuration (Input Shaft/PTO Shaft)

Code Description

JJ JIS 14T (Input) / JIS 14T (PTO)

AA ANSI 16/32-13T (Input) / ANSI 16/32-13T (PTO)

H - Output Shaft Configuration)

Code Description

J JIS 14T

A ANSI 16/32-13T

20 | © Danfoss | May 2021 BC152886483777en-000301

Page 21

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Model Code

Model Code: J - M

J - Centersection Configuration

Code Description

Drain port: 9.8mm on centersection

Charge port : 9.8mm on centersection

Without Bypass valve With Bypass valve on left

A X

B X

F X

H X

(A)

Connect charge inlet and drain line directly from LDU20 centersection with trans axle. See Installation Drawings

on page 27-30 for detail.

valve

(A)

(A)

Drain port: 3/4-16 drain port on housing

Charge port : 9/16-18 on centersection

Without Bypass valve With Bypass valve on left

side

K - Charge Pump Displacement

Code Description

N None

L - Charge Relief Setting

Code Description

07 7 bar at 10.8 l/min [102 psi at 2.9 US gal/min]

M - Bypass Valve

Code Description

N None

C w/Bypass Valve Left hand side

©

Danfoss | May 2021 BC152886483777en-000301 | 21

Page 22

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Model Code

Model Code: N - Z

N - Check & Relief Valve Side A

P - Check & Relief Valve Side B

The following two tables are used to selection for ports “A” and “B”

(Orifice must not be used for both side (A or B))

**N

14N

17N

21N

23N

25N

28N

30N

32N

34N

00N

1

Duty cycle analysis and Factory approval is needed. See Maximum Pressure in System Pressure on page 11.

**A

14A

17A

21A

25A

Check & Relief valve without orifice

140 bar [2030 psi]

175 bar [2538 psi]

210 bar [3045 psi]

230 bar [3285 psi]

250 bar [3625 psi]

280 bar [4060 psi]

300 bar [4351 psi]

1

325 bar [4713 psi]

1

345 bar [5003 psi]

Poppet type check valve

Check & Relief valve with orifice (∅0.85)

140 bar [2030 psi]

175 bar [2538 psi]

210 bar [3045 psi]

250 bar [3625 psi]

Y - Special Hardware Features

Code Description

NNN Housing Configuration : Standard

Z - Paint and Tag

Code Description

NNN No Paint (corrosion protection), Danfoss Logo

NAN No Paint (corrosion protection), Daikin Logo

BNN Black Paint, Danfoss Logo

BAN Black Paint, Daikin Logo

22 | © Danfoss | May 2021 BC152886483777en-000301

Page 23

[

0.778

]

±0.039

±0.039

±0.02

∅

19.75

0

-0.15

∅

19.75

0

-0.15

212

±1

30

±0.5

22

±0.5

34

±1

[

8.346

]

[

1.339

]

[

0.866

]

±0.02

[

1.181

]

-0.006

0

[

0.778

]

-0.006

0

Spline data

Number of teeth : 14

Module : 1.25

Pressure angle : 20°

Pitch diameter : 17.5

Addendum modification

Coefficient : 0.8

Involute spline

Per : JIS D 2001 CLASS a

Spline data

Number of teeth : 14

Module : 1.25

Pressure angle : 20°

Pitch diameter : 17.5

Addendum modification

Coefficient : 0.8

Involute spline

Per : JIS D 2001 CLASS a

full spline length

full spline length

P400012

±0.039

±0.02

[

7.913

]

[

0.787

]

Spline data

Number of teeth : 13

Pitch fraction : 16/32

Pressure angle : 30°

Pitch diameter : 20.638 [0.8125

]

Type of fit : Fillet root side

Per : ANSI B92.1-1970 CLASS

5

Spline data

Number of teeth : 13

Pitch fraction : 16/32

Pressure angle : 30°

Pitch diameter : 20.638 [0.8125

]

Type of fit : Fillet root side

Per : ANSI B92.1-1970 CLASS

5

∅

21.72

201

±1

20

±0.5

20

33

±1

±0.5

±0.09

∅

21.72

±0.09

±0.039

±0.02

[

1.299

]

[

0.787

]

±0.0035

[

0.855

]

±0.0035

[

0.855

]

full spline length full spline length

P400013

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Installation Drawings

Shaft Availability and Torque Ratings: Input Shaft/PTO Shaft

Input shaft/PTO Shaft

Option Spline

Torque Rating

N•m [lbf•in]

Rated Torque Maximum Torque

JJ 14 teeth, 1.25 module (Input) 122 [1080] 314 [2779]

14 teeth, 1.25 module (PTO) 89 [788] 310 [2743]

©

Danfoss | May 2021 BC152886483777en-000301 | 23

Option Spline

Torque Rating

N•m [lbf•in]

Rated Torque Maximum Torque

AA 13 theeth, 16/32 pitch (Input) 106 [938] 245 [2168]

13 theeth, 16/32 pitch (PTO) 106 [938] 226 [2000]

Page 24

21.5

±0.5

37

±1

∅

19.75

0

-0.15

±0.02

[

0.846

]

±0.039

[

1.457

]

[

0.778

]

-0.006

0

Spline data

Number of teeth : 14

Module : 1.25

Pressure angle : 20°

Pitch diameter : 17.5

Addendum modification

Coefficient : 0.8

Involute spline

Per : JIS D 2001 CLASS a

full spline length

P400014

∅

21.72

20 full spline length

±0.5

±0.09

36

±1

Spline data

Number of teeth : 13

Pitch fraction : 16/32

Pressure angle : 30°

Pitch diameter : 20.638 [0.8125

]

Type of fit : Fillet root side

Per : ANSI B92.1-1970 CLASS

5

±0.02

[

0.787

]

±0.039

[

1.417

]

±0.0035

[

0.855

]

P400015

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Installation Drawings

Shaft Availability and Torque Ratings: Output Shaft

Output Shaft

Option Spline

Torque Rating

N•m [lbf•in]

Rated Torque Maximum Torque

J 14 teeth, 1.25 module 87 [770] 310 [2743]

Option Spline

Torque Rating

N•m [lbf•in]

Rated Torque Maximum Torque

A 13 teeth, 20mm pitch 106 [938] 226 [2000]

24 | © Danfoss | May 2021 BC152886483777en-000301

Page 25

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ][ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

[ ]

Charge gage (inlet) port "M3"

Port ISO 11926-1, 9/16-18

System B gage port "MB1"

Port ISO 11926-1, 3/4-16

System A gage port "MA1"

Port ISO 11926-1, 3/4-16

1.063

0.787

0.551

0.768

±0.003

±0.001

±0.008

±0.005

M8x1.25 Thread

16 [0.63] Min thread depth

[ ]

[ ]

[ ]

0.63

±0.003

0.394

0.965

R0.2

[ ]

4.280

[ ]

27

1.063

27

14

20

108.7 Max

∅

19.5

±0.08

∅

16

±0.08

R5

±0.13

10

±0.25

24.5

±0.2

Case drain port "L2"

Port ISO 11926-1, 3/4-16

High pressure

relief valve B

+0.0024

0.669

-0.0016

5.89

+0.0018

0

M10X1.5 Thread

CCW CW

18 [0.71] Min

Thread depth

X4

±0.016

18° MAX DISP.

18° MAX DISP.

95.6

57.5

42

2X 17

+0.06

-0.04

4X 45°

149.6

166.52 Max

55

+0.046

0

23.8

±0.4

1.654

3.764

2.264

[ ]

6.556

[ ]

2.165

[ ]

0.937[ ]

±0.016

23.8

±0.4

0.937[ ]

CW

Charge inlet port "S"

∅

9.8

±0.1

±0.0028

±0.002

+0.0014

0

±0.1

Depth 11

±0.004

±0.004

85

±0.07

102.8

±0.05

102.8

122

167.65

Max

69.15

Max

95.2 Max

86.2 Max

46 46

±0.05

∅

10

+0.036

0

1.811

±0.002

1.811

[ ]

4.047

4.803

6.600

[ ]

2.722

[ ]

3.394

[ ]

0.292

[ ]

2.286

[ ]

0.381

3.748

[ ]

95.2 Max

86.2 Max

3.394

[ ]

3.748

[ ]

3.346

4.047

0.394

[ ]

0.433

[ ]

0.386

[ ]

0.197

0

+0.016

163.52 Max

5

+0.4

0

40

6.438

[ ]

1.016

[ ]

CCW

CW

Case drain port "L3"

Control Arm Location (R)

See Model Code (Page 22)

∅

9.8

±0.1

±0.004

0.386

[ ]

∅

90

R11.5

R15

P400016

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Installation Drawings

Installation Drawings LDU20/24

©

Danfoss | May 2021 BC152886483777en-000301 | 25

Input shaft rotation CW CCW

Trunnion location Right

Trunnion rotation CW CCW CW CCW

Output rotation CCW CW CW CCW

High pressure port MA MB MB MA

Low pressure port MB MA MA MB

Page 26

[ ]

[ ]

[ ]

[ ]

[0.433 ]

System A gage port "MA2"

Port ISO 11926-1, 3/4-16

Control Arm Location (R)

System B gage port "MB2"

Port ISO 11926-1, 3/4-16

0.787

1.063

27

[ ]

1.063

27

20

Case drain port "L1"

Port ISO 11926-1, 3/4-16

High pressure

relief valve A

2.264

57.5

Approx.

center of

gravity

42

84.6

1.654

3.3

[ ]

CW

CCW

±0.008

±0.008

±0.008 ±0.008

71

±0.2

80

±0.2

25

±0.2

49

±0.2

4X ∅11

+0.38

-0.05

29.9

0.8

2.795

[ ]

3.15

[ ]

±0.008

±0.008

71

±0.2

80

±0.2

2.795

[ ]

3.15

[ ]

+0.015

-0.002

1.929

[ ]

0.984

[ ]

1.2

[ ]

0.03

[ ]

See Model Code (Page 22)

P400017

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Installation Drawings

26 | © Danfoss | May 2021 BC152886483777en-000301

Page 27

[

0.386

]

∅

9.8

±0.1

±0.004

[

0.386

]

∅

9.8

±0.1

±0.004

Case drain port "L3"

Charge inlet port "S"

Charge gage (inlet) port "M3"

Port ISO 11926-1, 9/16-18

Case drain port "L1, L2"

Port ISO 11926-1, 3/4-16

MA1

MB1

MA2

MB2

L1

L2

L3

S

M3

P400018

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Installation Drawings

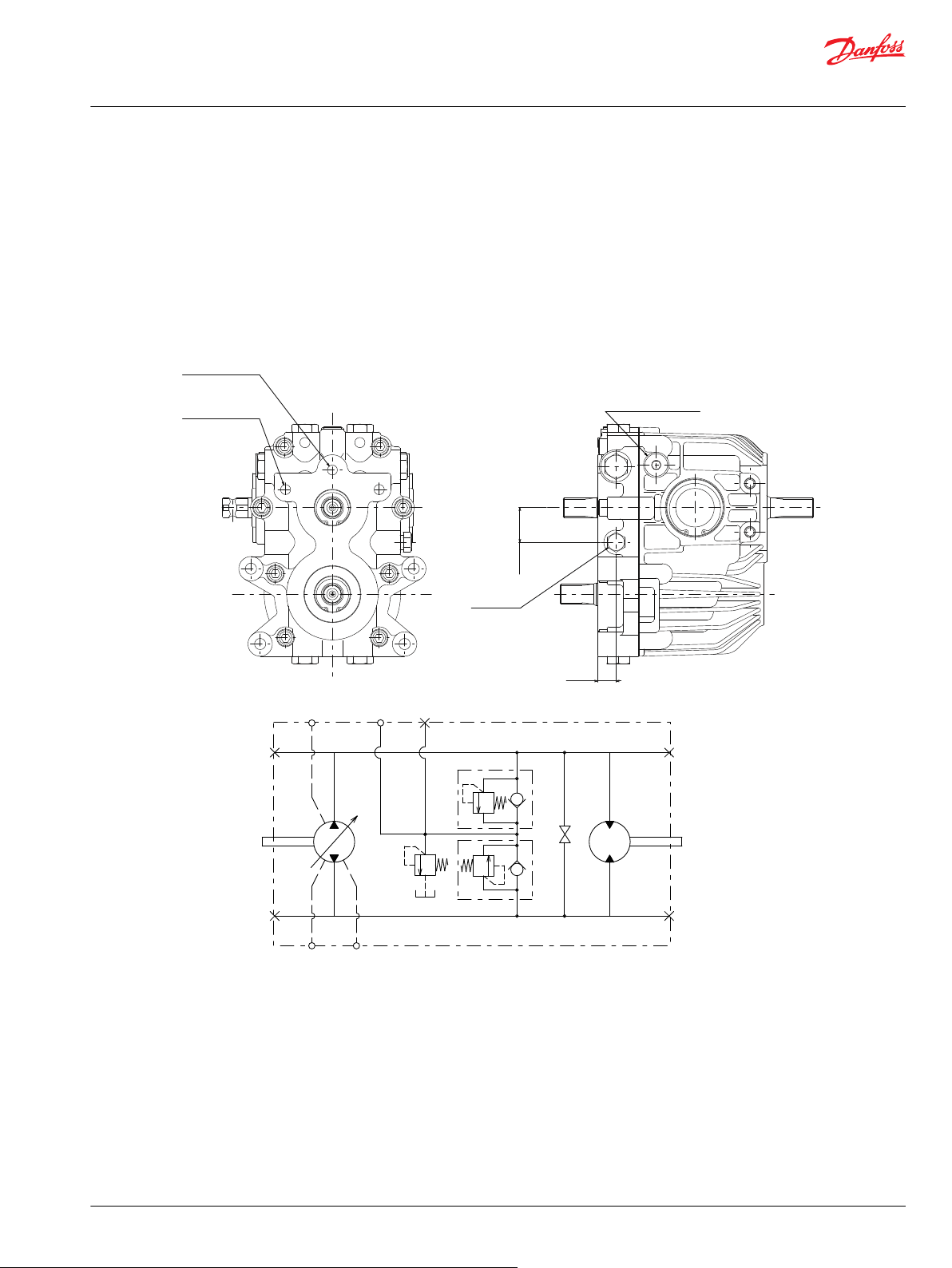

Center section: Option A

Drain port: 9.8mm on centersection

Charge port: 9.8mm on centersection

©

Danfoss | May 2021 BC152886483777en-000301 | 27

Page 28

[

2.854

]

72.5

[

2.854

]

72.5

[

3.047

]

77.4

Charge inlet port "M3"

Port ISO 11926-1, 9/16-18

Case drain port "L1, L2"

Port ISO 11926-1, 3/4-16

MA1

MB1

MA2

MB2

L1

M3

L2

P400019

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Installation Drawings

Center section: Option B

Drain port: 3/4-16 on Housing.

Charge port: 9/16-18 on centersection

28 | © Danfoss | May 2021 BC152886483777en-000301

Page 29

Bypass valve

[

0.386

]

∅

9.8

±0.1

±0.004

[

0.386

]

∅

9.8

±0.1

±0.004

Case drain port "L3"

Charge inlet port "S"

[

1.339

]

34

[

0.709

]

(

17mm external hex

)

Torque 12 N•m [

9 lbf

•ft]

18

MA1

MB1

MA2

MB2

L1 L2

L3 M3S

Case drain port "L1, L2"

Port ISO 11926-1, 3/4-16

P400020

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Installation Drawings

Center section: Option F

Drain port: 9.8mm on centersection

Charge port: 9.8mm on centersection With Bypass valve

©

Danfoss | May 2021 BC152886483777en-000301 | 29

Page 30

[

]

Bypass valve

Case drain port "L1, L2"

Port ISO 11926-1, 3/4-16

Charge inlet port "M3"

Port ISO 11926-1, 9/16-18

0.709

18

1.339

34

[

]

MA1

MB1

MA2

MB2

L1 L2

M3

P400021

Technical Information

LDU20/24 Closed Circuit Axial Piston Transmission

Installation Drawings

Center section: Option H

Drain port: 3/4-16 on Housing

Charge port: 9/16-18 on centersection With Bypass valve

30 | © Danfoss | May 2021 BC152886483777en-000301

Page 31

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | May 2021 BC152886483777en-000301

Loading...

Loading...