Page 1

Data Sheet

Thermostat

Type KP

The KP Thermostats are single-pole, doublethrow (SPDT) temperature-operated electric

switches.

They can be connected directly to a singlephase AC motor of up to approx. 2 kW or

installed in the control circuit of DC motors and

large AC motors.

The KP Thermostats are used for regulation, but

can also be seen in safety monitoring systems.

They are available with vapour charge or with

adsorption charge. With vapour charge the

dierential is very small. The KP Thermostats

with adsorption charge are widely used to give

frost protection.

Features

• Wide regulating range

• Can be used for deep freeze, refrigeration and

air conditioning plant

• Welded bellows elements mean increased

reliability

• Small dimensions. Easy to install in

refrigerated counters or cold rooms

• Ultra-short bounce times. This gives long

operating life, reduces wear to a minimum

and increases reliability

• Standard versions with changeover switch.

Possible to obtain opposite contact function

or to connect a signal

• Electrical connection at the front of the unit.

◦ Facilitates rack mounting

◦ Saves space

• Suitable for alternating and direct current

• Cable entry of soft thermoplastic for cables

from 6 to 14 mm diameter

• Extensive and wide range

AI203586420959en-000801

Page 2

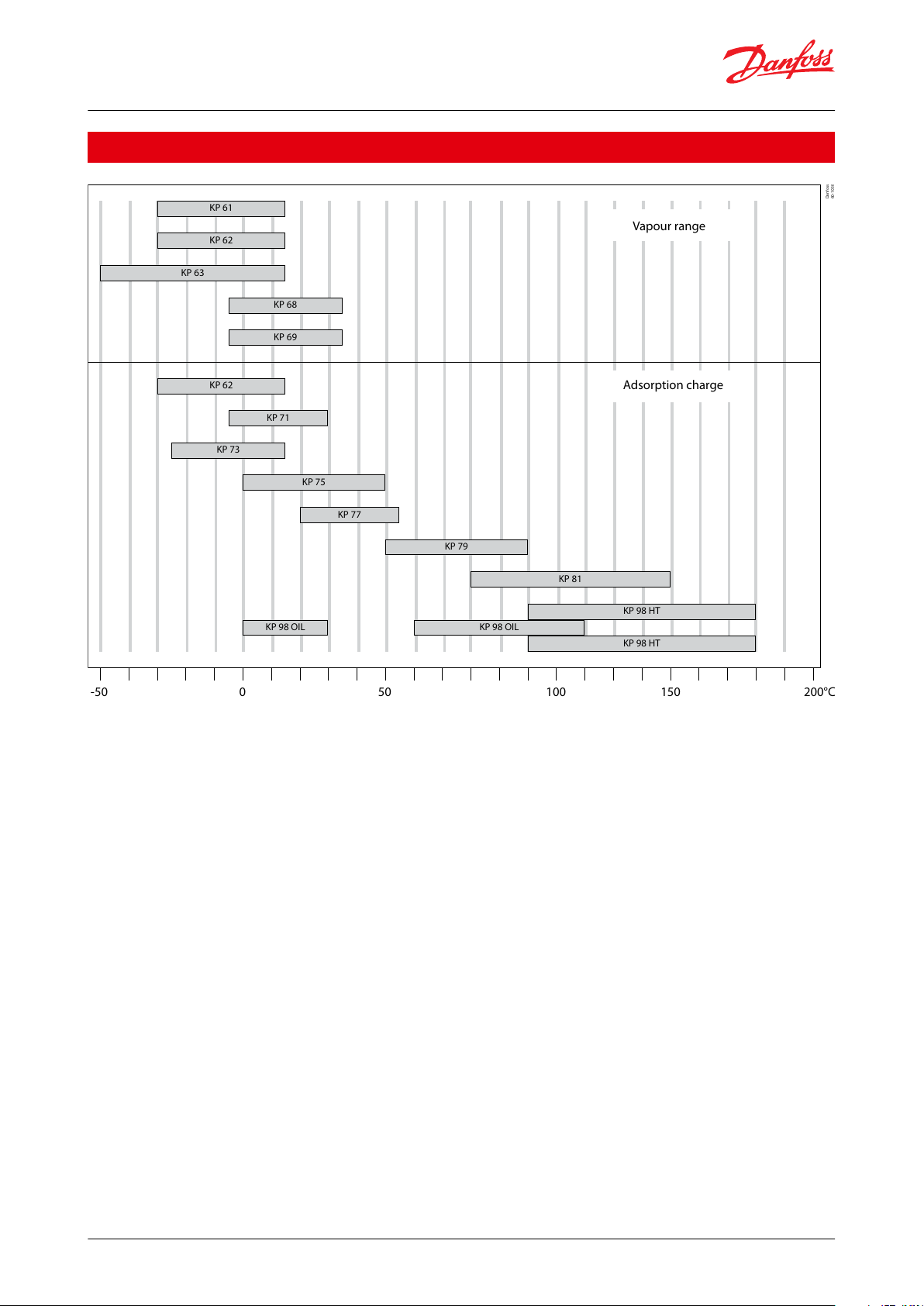

KP 63

KP 68

KP 69

KP 62

KP 71

KP 73

KP 75

KP 77

KP 79

KP 81

KP 98 HT

KP 98 HT

KP 98 OILKP 98 OIL

Vapour range

Adsorption charge

KP 61

KP 62

-50 50 100 150 200°C0

Danfoss

60-1038

Thermostat, Type KP

Portfolio overview

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 2

Page 3

Features

Description

Ambient temperature

-40 – 65 °C (80 °C for max. 2 hours)

Switch

Single-pole, double-throw (SPDT) changeover switch

Contact load

Alternating current

AC1 =16 A, 400 V

AC3 = 16 A, 400 V

Direct current

DC13: 12 W, 220 V control current

Wire dimensions

solid / stranded

0.75 – 2.5 mm

2

exible, without ferrules

0.7 – 2.5 mm

2

exible, with ferrules

0.5 – 1.5 mm

2

Tightening torque

max. 2 Nm

Rated impulse voltage

4 kV

Pollution degree

3

Short circuit protection, fuse

16 A

Insulation

400 V

Enclosure

IP30 / IP44

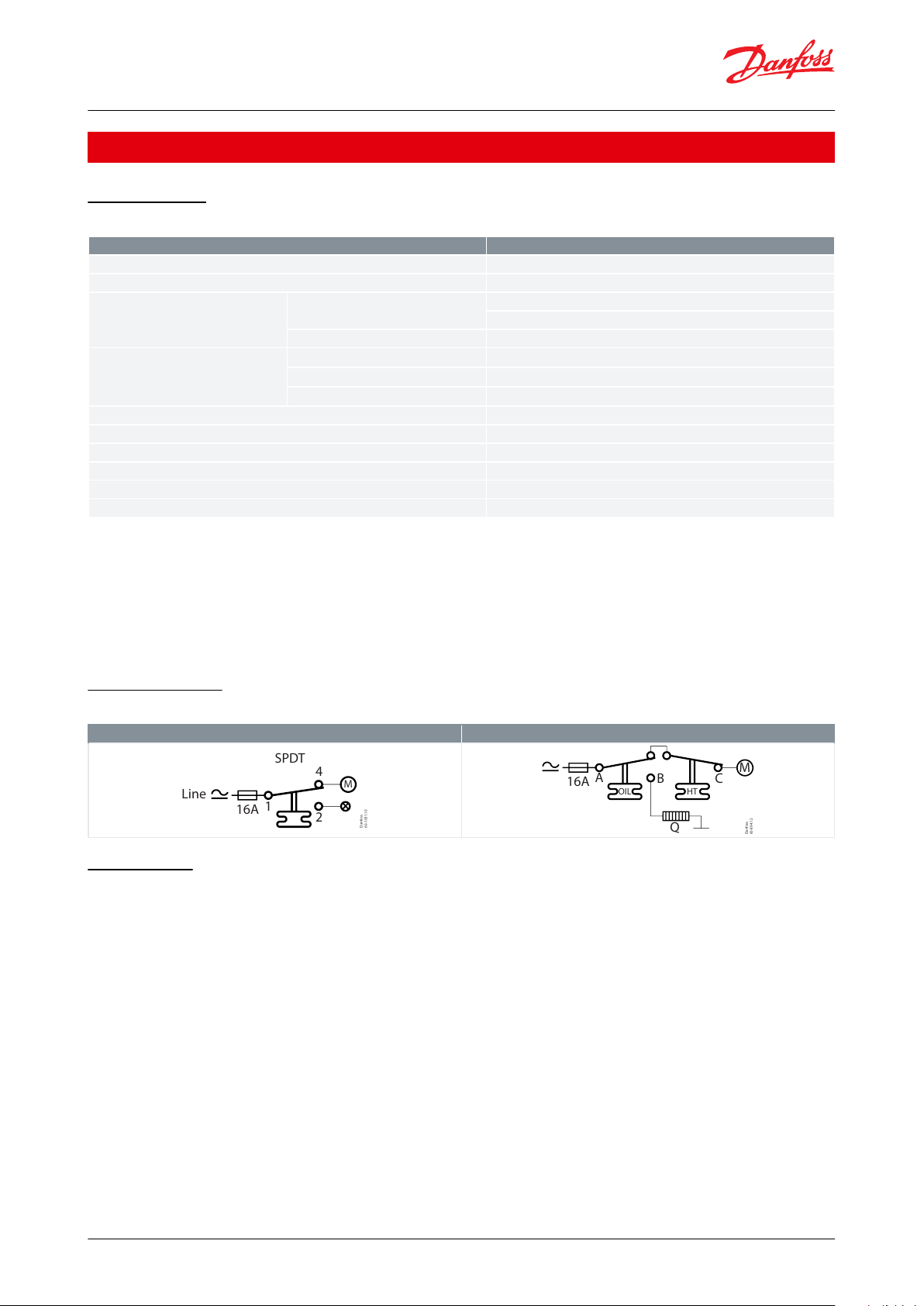

KP temperature control

KP 98

Line

SPDT

16A

1

2

4

M

Danfoss

60-894.12

M

HTOIL

16A

A

Q

B C

Thermostat, Type KP

Product specication

Technical data

Table 1: Technical data

Cable connection

Cable entry for cables 6 – 14 mm dia. A Pg 13.5 screwed cable entry can be used for 6 – 14 mm dia. cables. With 8 –

16 mm cables a standard Pg 16 screwed cable entry can be used.

Enclosure IP30 to EN 60529 / IEC 529

This grade of enclosure is obtained when the unit is mounted on a at surface or bracket. The bracket must be xed

so that all unused holes are covered.

Contact systems

Table 2: Contact systems

Terminology

Dierential

The dierential is the dierence between the make and break temperatures. A dierential is necessary for

satisfactory automatic operation of the plant.

Mechanical dierential (intrinsic dierential)

The mechanical dierential is the dierential set by the dierential spindle.

Operating dierential (thermal dierential)

The operating dierential is the dierential the plant operates on. Operating dierential is the sum of the

mechanical dierential and the dierential produced by the time constant.

Reset

1. Manual reset:

Units with manual reset can only be restarted after the reset button has been activated. On min. reset units the set

value is equal to the cut-out value for falling temperature. On max. reset units the set value is equal to the cut-out

value for rising temperature.

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 3

Page 4

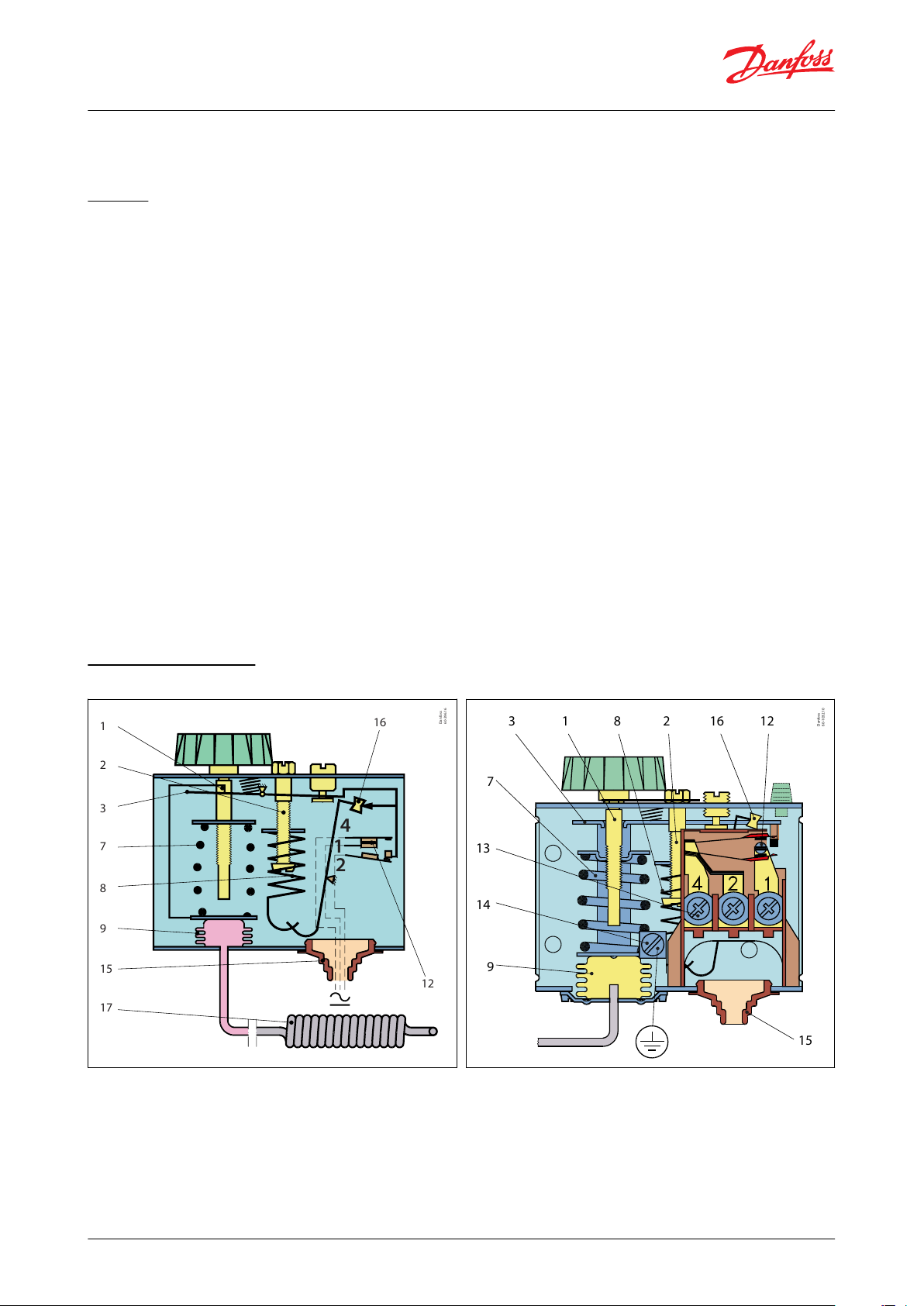

1

2

3

7

8

9

15

17

12

16

4

1

2

Danfoss

60-296.16

Danfoss

60-1032.10

15

12162813

7

9

13

14

Thermostat, Type KP

2. Automatic reset:

These units are automatically reset after operational stop.

Setting

Thermostats with automatic reset

Set the upper activating temperature on the range scale.

Set the dierential on the "DIFF" scale. The temperature setting on the range scale will then correspond to the

temperature at which the refrigeration compressor will be started on rising temperature. The compressor will be

stopped when the temperature has fallen in relation to the dierential setting.

Note that the dierential depends on the range setting. Therefore, the dierential scale must only be used as

guideline.

If with low stop temperature settings the compressor will not stop, check whether the dierential is set at too high a

value!

Thermostats with minimum reset

Set the stop temperature on the range scale. The dierential is a xed setting.

The compressor can be restarted by pressing the “Reset button” after the temperature on the thermostat sensor has

risen by a value equal to the xed dierential setting.

Thermostats with maximum reset

Set the stop temperature on the range scale. The dierential is a xed setting.

The compressor can be restarted by pressing the “Reset button” after the temperature on the thermostat sensor has

fallen to a value equal to the xed dierential setting.

Design and function

Figure 1: Key sketch of KP thermostat

Figure 2: KP thermostat

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 4

Page 5

Danfoss

60-904.12

17

Danfoss

60-272.12

17

Danfoss

60-1037

17

Danfoss

60-1033.10

17

Danfoss

60-370.16

OIL

17 17

Max. reset

18512161183

7

10

15 13 11

9

14

Danfoss

60-421.13

KP 98

123789121314151617Temperature setting spindle

Dierential setting spindle

Main arm

Main spring

Dierential spring

Bellows

Switch

Terminals

Earth terminal

Cable entry

Tumbler

Sensor

Thermostat, Type KP

Figure 3: Adsorption charge

Figure 4: Vapour charge

Figure 5: Adsorption charge

Figure 6: Vapour charge

The switch in the KP has a snap-action function and the bellows move only when the cut-in or cut-out value is

reached.

The design of the KP thermostats aords the following advantages:

• High contact load

• Ultra-short bounce time

• Vibration resistance up to 4 g

• In the range 0 – 1000 Hz

• Long mechanical and electrical life

Figure 7: KP thermostat, dual type

Figure 8: KP 98

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 5

Page 6

19

17

9

Danfoss

60-910.10.20

91719

Bellows element

Sensor (bulb)

Capillary tube

13579101112131415161718Temperature setting spindle, OIL

Main arm

Temperature setting spindle, HT

Main spring

Bellows

Capillary tube, OIL

Capillary tube, HT

Switch

Terminals

Earth terminal

Cable entry

Tumbler

Sensor (bulb)

Locking plate

Thermostat, Type KP

Dual thermostat KP 98 is used to provide protection against excessively high discharge gas temperature and to

ensure a suitable oil temperature in the compressor.

To avoid the temperature of the hot gas exceeding the maximum permissible value during extreme operating

conditions (low evaporating pressure, high condensing pressure, high suction vapour superheat) a KP 98

thermostat can be used on the high temperature side (HT). If the temperature of the hot gas becomes too high the

refrigerant will break down and the compressor discharge valve will become damaged.

The risk is greatest in refrigeration systems that operate on a high compression ratio (e.g. in systems with NH3 or

R22) and in applications with hot gas bypass.

This unit has two separate thermostat functions. The HT sensor that controls the discharge gas temperature is tted

on the discharge tube immediately after the compressor.

For larger compressors, the sensor can be built into the discharge line.

The OIL sensor that controls the oil temperature is located in the compressor oil sump.

Charges

1. Vapour charge

Figure 9: Vapour charge

Here the interdependence between the pressure and temperature of saturated vapour is utilized, i.e. the element is

charged with saturated vapour plus a small amount of liquid.

The charge is pressure-limited; a further increase in pressure after evaporation of all the liquid in the sensor (17) will

only result in a small pressure increase in the element.

This principle can be utilized in thermostats for low temperature, etc. where evaporation must be able to take place

from the free liquid surface in the sensor (within the operating range of the thermostat), and where at the same

time, the bellows must be protected against deformation when kept at normal ambient temperatures. Since the

pressure in the element depends on the temperature at the free liquid surface, the thermostat must always be

placed so that the sensor is colder than the rest of the thermostatic element.

The evaporated liquid will recondense at the coldest point, i.e. the sensor. Thus, as intended, the sensor becomes

the temperature-controlling part of the system.

NOTE:

When the sensor is coldest, the ambient temperature has no eect on regulating accuracy.

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 6

Page 7

19

17

9

Danfoss

60-909.10.20

91719

Bellows element

Sensor (bulb)

Capillary tube

Danfoss

60-298.15.10

44

84

14

61

M4 (8 - 32 UNC)

18

18

25.4

13

23

32

8

64

Ø5

Ø5

44

122

61

27

51

14.5

35

49

25.4

M4(8 - 32 UNC)

18

25.4

Ø5

Thermostat, Type KP

2. Adsorption charge

Figure 10: Adsorption charge

In this case the charge consists partly of a superheated gas and partly of a solid having a large adsorption surface.

The solid is concentrated in the sensor (17) and it is therefore always the sensor that is the temperature-controlling

part of the thermostatic element.

The sensor can be placed warmer or colder than thermostat housing and capillary tube, but variations from 20 °C

ambient temperature will inuence the scale accuracy.

Dimensions [mm] and weights [kg]

Figure 11: KP 61 – 81

Figure 13: KP 98

Figure 12: Mounting holes (back of KP)

Figure 14: Mounting holes (back of KP)

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 7

Page 8

11

16

6.2

40

5.5

25.4

ø3.45

ø5

79.5

91.5

4

11

25.4

28.6

ø5

25.4

71.1

15

15

12

12

39

24.5

16.5

12.5

Danfoss

60-299.12.12

A

KP 61, KP 63,

KP 69

B

KP 61, KP 63

C1

KP 62, KP 68,

C2

KP 62

9.5

70

30

40 25

78

Danfoss

60-300.15.11

16

170

D2

KP 73

E2

KP 71

E3

KP 77, KP 73,

KP 75, KP 77,

KP 98

D1

KP 73,

KP 79,

KP 81

E1

KP 73

F

KP 75

9.5

9.5

10

115

85 85

95

125

25

ø5

50

40

6.4

Thermostat, Type KP

Figure 15: Wall bracket

Figure 17: Thermostat sensor types A, B and C

Figure 16: Angle bracket

Figure 18: Thermostat sensor types D, E and F

Net weight

• KP 61 - 81: approx. 0.4 kg

• KP 98: approx. 0.6 kg

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 8

Page 9

Charge

Type

Bulb type

Regulating

range

Dierential ∆t

Reset

Max. bulb

temp.

Capillary tube

length

Code no.

Lowest tem‐

perature

Highest tem‐

perature

[°C]

[°C]

[°C]

[°C]

[m]

Vapour

(1)

KP 61A-30 – 15

5.5 – 23

1.5 – 7

aut.

1202060L110066

KP 61A-30 – 15

5.5 – 23

1.5 – 7

aut.

1205060L110166

KP 61B-30 – 13

4.5 – 23

1.2 – 7

aut.

1202060L110266

KP 61B-30 – 15

5.5 – 23

1.5 – 7

aut.

120

2

060L110366

(3)

KP 61B-30 – 15

5.5 – 23

1.5 – 7

aut.

120

2

060L112866

(3) (4)

KP 61A-30 – 15

Fixed 6

Fixed 2

min.

1205060L110466

KP 61B-30 – 15

Fixed 6

Fixed 2

min.

1202060L110566

KP 62

C 1

-30 – 15

6.0 – 23

1.5 – 7

aut.

120–060L110666

KP 63A-50 – 10

10.0 – 70

2.7 – 8

aut.

1202060L110766

KP 63B-50 – 10

10.0 – 70

2.7 – 8

aut.

1202060L110866

KP 68

C 1

-5 – 35

4.5 – 25

1.8 – 7

aut.

120–060L111166

KP 69B-5 – 35

4.5 – 25

1.8 – 7

aut.

1202060L111266

Adsorbtion

(2)

KP 62

C 2

-30 – 15

5.0 – 20

2.0 – 8

aut.

80

–

060L111066

(3) (4)

KP 71

E 2

-5 – 20

3.0 – 10

2.2 –9

aut.

802060L111366

KP 71

E 2

-5 – 20

Fixed 3

Fixed 3

min.

802060L111566

KP 73

E 1

-25 – 15

12.0 – 70

8.0 – 25

aut.

802060L111766

KP 73

D 1

-25 – 15

4.0 – 10

3.5 – 9

aut.

802060L111866

(3)

KP 73

D 1

-25 – 15

Fixed 3.5

Fixed 3.5

min.

802060L113866

KP 73

D 2

-20 – 15

4.0 – 15

2.0 – 13

aut.

553060L114066

KP 73

D 1

-25 – 15

3.5 – 20

3.25 – 18

aut.

802060L114366

KP 75F0 – 35

3.5 – 16

2.5 – 12

aut.

1102060L112066

KP 75

E 2

0 – 35

3.5 – 16

2.5 – 12

aut.

1102060L113766

KP 77

E 3

20 – 60

3.5 – 10

3.5 – 10

aut.

1302060L112166

KP 77

E 3

20 – 60

3.5 – 10

3.5 – 10

aut.

1303060L112266

KP 77

E 2

20 – 60

3.5 – 10

3.5 – 10

aut.

1305060L116866

KP 79

E 3

50 – 100

5.0 – 15

5.0 – 15

aut.

1502060L112666

KP 81

E 3

80 – 150

7.0 – 20

7.0 – 20

aut.

2002060L112566

KP 81

E 3

80 – 150

Fixed 8

Fixed 8

max.

2002060L115566

KP 98

E 2

OIL: 60 – 120

OIL: Fixed 14

OIL: Fixed 14

max.

150

1

060L113166

E 2

HT: 100 – 180

HT: Fixed 25

HT: Fixed 25

max.

250

2

Thermostat, Type KP

Ordering

Table 3: Standard thermostat type KP

(1)

(1)

Bulb must always be placed colder than the thermostat housing and capillary tube. The thermostat will then regulate independent of ambient

Bulb must always be placed colder than the thermostat housing and capillary tube. The thermostat will then regulate independent of ambient

temperature.

temperature.

(2)

(2)

Bulb can be placed warmer or colder than thermostat housing and capillary tube, but variations from 20 °C ambient temperature will inuence

Bulb can be placed warmer or colder than thermostat housing and capillary tube, but variations from 20 °C ambient temperature will inuence

the scale accuracy.

the scale accuracy.

(3)

(3)

With manual switch, not isolating switch.

With manual switch, not isolating switch.

(4)

(4)

Panel mounting model with top plate.

Panel mounting model with top plate.

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 9

Page 10

Thermostat bulb types

Description

A

Danfoss

60L8012

Straight capillary tube

B

Danfoss

60L8032

ø9.5 × 70 mm remote air coil

C

Danfoss

60L8013

C1: ø40 × 30 mm air coil

C2: ø25 × 67 mm air coil

(integral with thermostat)

D

Danfoss

60L8012

D1: ø10 × 85 mm double contact remote bulb

D2: ø16 × 170 mm double contact remote bulb

NOTE:

Cannot be used in sensor (bulb) pocket

E

Danfoss

60L8008

E1: ø6.4 × 95 mm remote bulb

E2: ø9.5 × 115 mm remote bulb

E3: ø9.5 × 85 mm remote bulb

F

Danfoss

60L8018

ø25 × 125 mm remote duct coil

Thermostat, Type KP

Table 4: Thermostat bulb types

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 10

Page 11

Document name

Document type

Document topic

Approval authority

060-9638.AA

Manufacturers Declaration

China RoHS

Danfoss

060-9650.AD

EU Declaration

LVD/RoHS

Danfoss

BV 02281-J0 BV

Marine - Safety Certicate

BV

BV SMS.W.II-2179-B.0

Marine - Manufacturing Permission

BV

CCC 2003010305069849

Electrical - Safety Certicate

CCC

DNV GL TAA000026F

Marine - Safety Certicate

DNV GL

LR 17-20046

Marine - Safety Certicate

LR

RINA ELE-086320XG-001

Marine - Safety Certicate

RINA

UL E31024

Electrical - Safety Certicate

UL

Thermostat, Type KP

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 5: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 11

Page 12

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI203586420959en-000801 | 12

Loading...

Loading...