Fitters notes Thermostats

Contents Page

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

KP thermostat with air sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Thermostats with automatic reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Thermostats with maximum reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Thermostats with minimum reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Test of contact function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

KP 98 dual thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

The correct thermostat for your refrigeration system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Vapour charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Absorption charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Low voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Placing of surplus capillary tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Thermostats with vapour charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Thermostats

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 27

Notes

28 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Fitters notes Thermostats

Installation

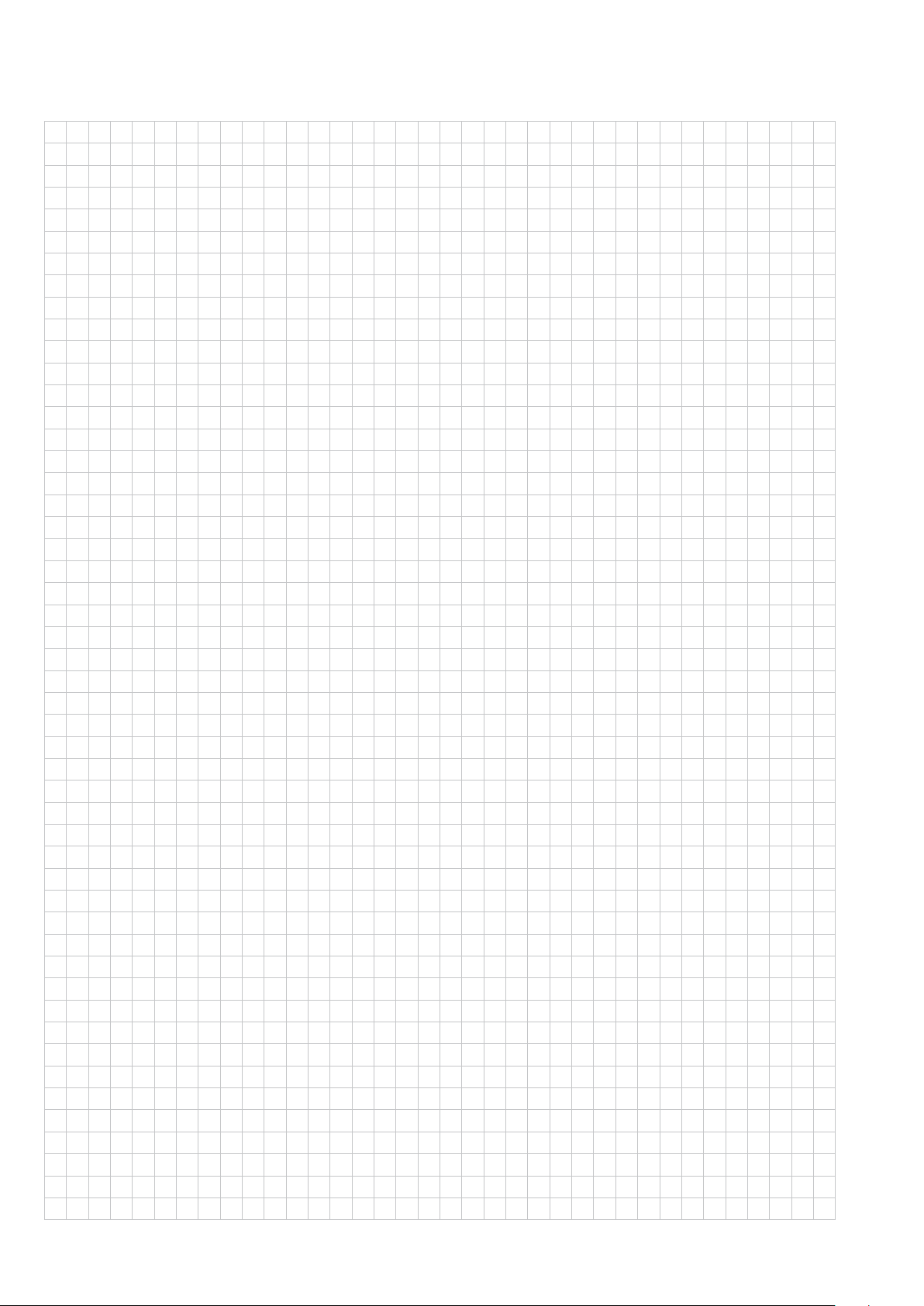

If the risk of water droplets or water spray is

present, t a top plate. The plate increases the

grade of enclosure to IP 44 and is suitable for all

KP thermostats. The top plate must be purchased

separately (Code no.: for single unit, 060-109766;

for dual unit, 060-109866).

To obtain IP 44, cover all holes in the backplate of

the thermostat.

If the unit is to be used in dirty conditions or

where it might be exposed to heavy spray it

should be tted with a protective cap. The

cap can be used together with either an angle

bracket (060-105666) or a wall bracket (060-

105566).

Aj0_0001

Thermostats

KP thermostat with air sensor

Aj0_0002

If the unit risk being exposed to heavy water

inuence a better grade of enclosure can be

achieved when mounting the product in a special

IP 55 enclosure

The IP 55 enclosure is available for both single

unit (060-033066) and dual unit (060-035066).

Ak0_0020

Remember that the dierential is aected by

air circulation around the sensor. Insucient air

circulation can increase the dierential by 2-3°C.

Place the room thermostat so that air is able to

ow freely around the sensor. At the same time,

ensure that the sensor is not exposed to draughts

from doors or radiation from the evaporator

surface.

Never place the thermostat directly on a cold

wall; this increases the dierential. Instead,

mount the unit on an insulating plate.

Aj0_0003

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 29

Fitters notes Thermostats

KP thermostat with air sensor

(cont.)

Setting

Thermostats with

automatic reset

When placing the sensor: Remember that air

must be able to circulate freely around the

sensor. With control from, for example, return

air temperature, the sensor must not touch the

evaporator.

KP thermostat with cylindrical sensor

There are three ways of securing the sensor:

1) The pipe.

2) Between evaporator ns.

3) In a pocket.

Always set the highest temperature on the range

scale. Then set the dierential on the DIFF scale.

The temperature setting on the range scale

then corresponds to the temperature at which a

refrigeration compressor will be started on rising

temperature. The compressor will stop when the

temperature corresponds to the value set on the

DIFF scale.

For pre-setting of vapour charged thermostats,

the graph curves stated in the customer

instruction sheet should be used.

If the compressor will not stop when it is set for

low stop temperatures: Check to see whether

the dierential has been set at too high a value.

Ah0_0006

When using a pocket: Always use heat-conductive compound (code no. 041E0110) to ensure

good contact between sensor and medium.

Aj0_0004

Aj0_0005

Thermostats with

maximum reset

Set the highest temperature = stop temperature

on range scale.

The dierential setting is xed. When the temperature on the thermostat sensor corresponds

to the dierential setting, the system can be

restarted by pressing the "Reset" button.

Thermostats with

minimum reset

Set the lowest temperature = stop temperature

on range scale.

The dierential setting is xed.

When the temperature around the thermostat

sensor has risen to the dierential setting, the

compressor can be restarted by pressing the

“Reset” button.

Aj0_0006

30 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Fitters notes Thermostats

Setting example

Test of contact function

The temperature in a deep freeze room is to be

controlled by a thermostat that closes a solenoid

valve. The system is of the pump-down type and

is stopped via a low-pressure control.

Here, the pressure control must not be set to

cut out at a pressure lower than necessary.

At the same time, it must cut in at a pressure

corresponding to the cut-in temperature of the

thermostat.

Example:

Deep freeze room with R404A

Room temperature: –20°C

Thermostat cut out temperature: –20°C

Thermostat cut in temperature: –18°C

Pressure control cut out

pressure: 0.9 bar (–32°C)

Pressure control cut in

pressure: 2.2 bar (–18°C)

Thermostats

Aj0_0007

When the electrical leads are connected, the

contact function can be tested manually.

Depending on the sensor temperature and

the thermostat setting, the test device must

be pressed up or down. Any reset mechanism

becomes inoperative during the test.

Use the test device at top left.

KP 98 dual thermostat

Aj0_0009

Warning!

The contact function on a KP

single thermostat must never

be tested by activating the

device on the righthand side. If this warning

is ignored, the thermostat might go out of

adjustment. In the worst case, function can be

impaired.

Use the test device on the lefthand side to

test function on rising oil temperature and the

test device at bottom right to test function on

rising pressure gas temperature.

Aj0_0010

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 31

Fitters notes Thermostats

The correct thermostat for

your refrigeration system

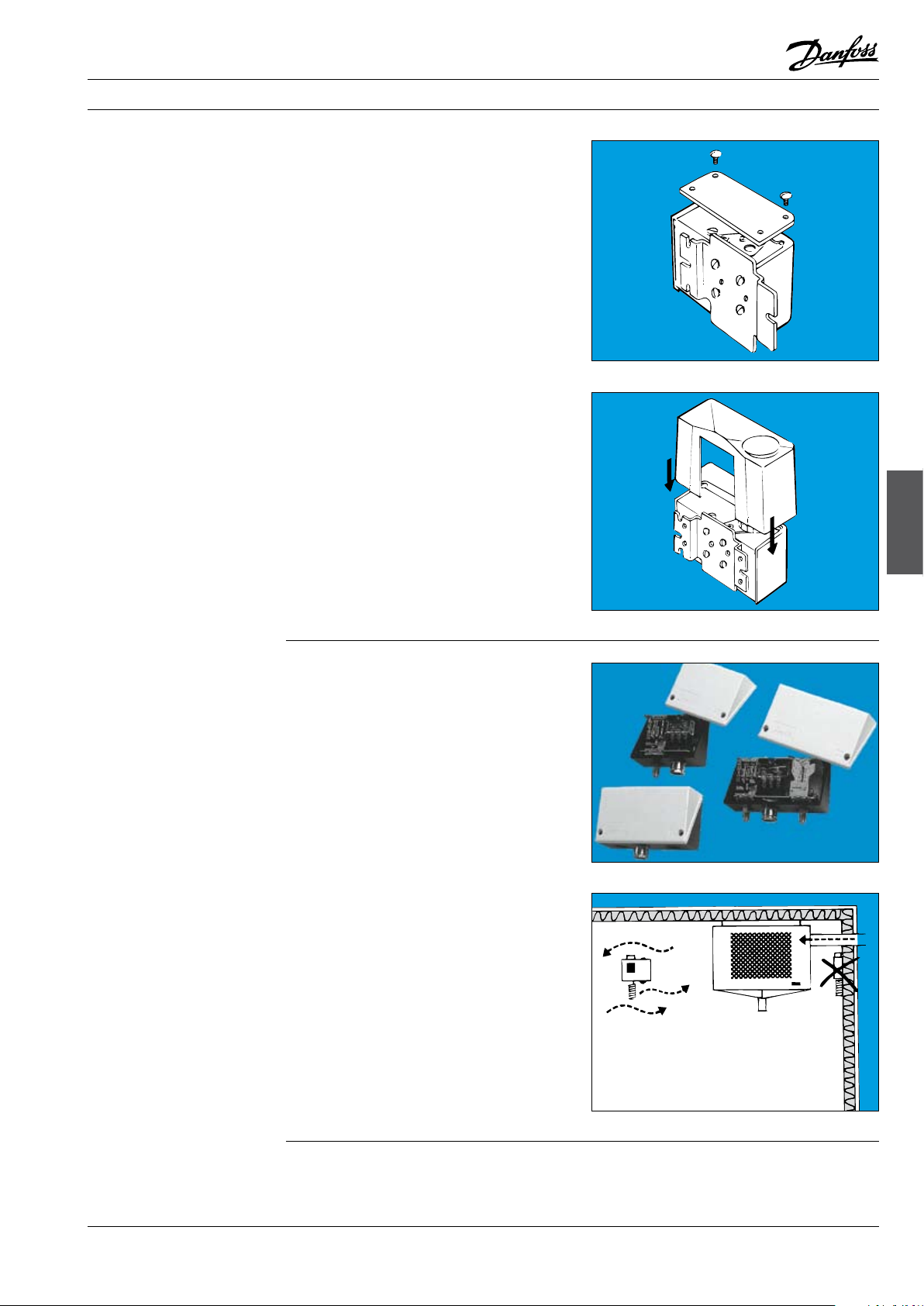

Vapour charge

Absorption charge

A thermostat must contain the correct charge, as

described below.

Low temperatures, coldest bellows, not enclosure-sensitive.

Thermostat with air coil: On gradual temperature

rise and fall (less than 0.2K/min), e.g. in large,

sluggish cold rooms containing many items, KP

62 with vapour charge is recommended.

High temperatures, enclosure-sensitive. Bellows

colder or warmer.

Thermostat with air coil: On fast changes in

temperature (more than 0.2K/ min), e.g. in

smaller cold rooms where the produce turnover

rate is high, KP 62 with absorption charge is

recommended.

Straight

capillary tube

60I8012

Remote air coil

60I8032

Vapour charge

Air coil

(integral with

thermostat)

60I8013

Double contact

remote bulb

60I8017

Cylindric

remote bulb

60I8008

Low voltage

For systems where KP is activated occasionally

(alarm) and for systems where KP is the signal

source for PLC, etc. (low voltage): Use KP with

gold contacts; these give good contact at low

voltages.

Absorption charge

Aj0_0012

Air coil

(integral with

thermostat)

60I8013

Remote air coil

(for duct mounting)

60I8018

32 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Fitters notes Thermostats

Placing of surplus

capillary tube

Thermostats with

vapour charge

Dual thermostat KP 98:

Surplus capillary tube can fracture if vibration

occurs and might lead to loss of thermostat

charge. It is therefore very important that the

following rules be observed:

When mounting direct on compressor:

Secure the capillary tube so that the

compressor/thermostat installation vibrates as

a whole. Surplus capillary tube must be coiled

and bound.

Other types of mounting: Coil surplus capillary

tube into a loose loop. Secure the length of

capillary tube between compressor and loop

to the compressor.

Secure the length of capillary tube between

loop and thermostat to the base on which the

thermostat is mounted.

Never locate a KP thermostat with vapour charge

in a room where the temperature is or can be

lower than that in the cold room.

Aj0_0017

Thermostats

Never allow the capillary tube from a KP

thermostat to run alongside of a suction line in a

wall entry.

Aj0_0014

Aj0_0015

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 33

Loading...

Loading...