Danfoss

60-1416.10

Danfoss

60-1416.10

Danfoss

60-1416.10

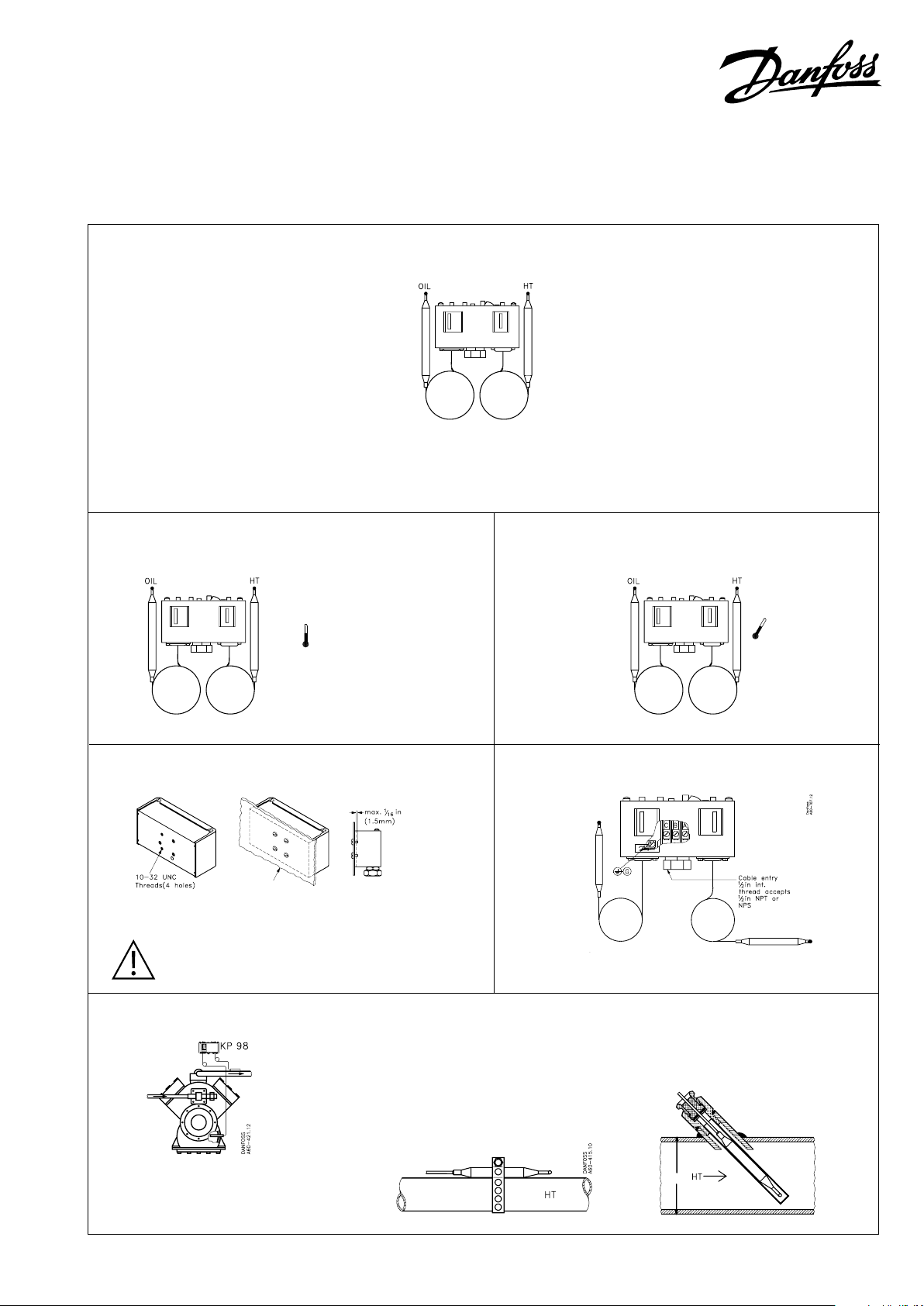

Installation guide

Thermostat

Type KP 98 (cross ambient)

060R9749

Oil temp. High temp.

(OIL) bulb (HT) bulb

KP 98 man. (OIL)/man.(HT) rese t

Note:

Code no. stamped on top of control.

Ambient temperatures Max. bulb temperatures

min. -40 °F (-40 °C)

max. 150 °F ( 65 °C)

(175 °F (80 °C) for max. 2 hours)

max. 300 °F (150 °C)

060R9749

max. 480 °F (250 °C)

Enclosure Cable entry

~ NEMA 1

Danfoss

60-786.12

CAUTION:

The mounting panel must be plane to avoid

damage of control.

Mounting

Mount OIL temperature bulb in compressor

crankcase and the HT bulb on/in discharge line

as shown.

Small pipe size Large pipe size

OD > 3.5 in.

Danfoss

60-1419.10

O.D.

© Danfoss A/S (RC-MDP / jmn), 2014-08 DKRCC.PI.CA0.A6.22 / 520H8513 1

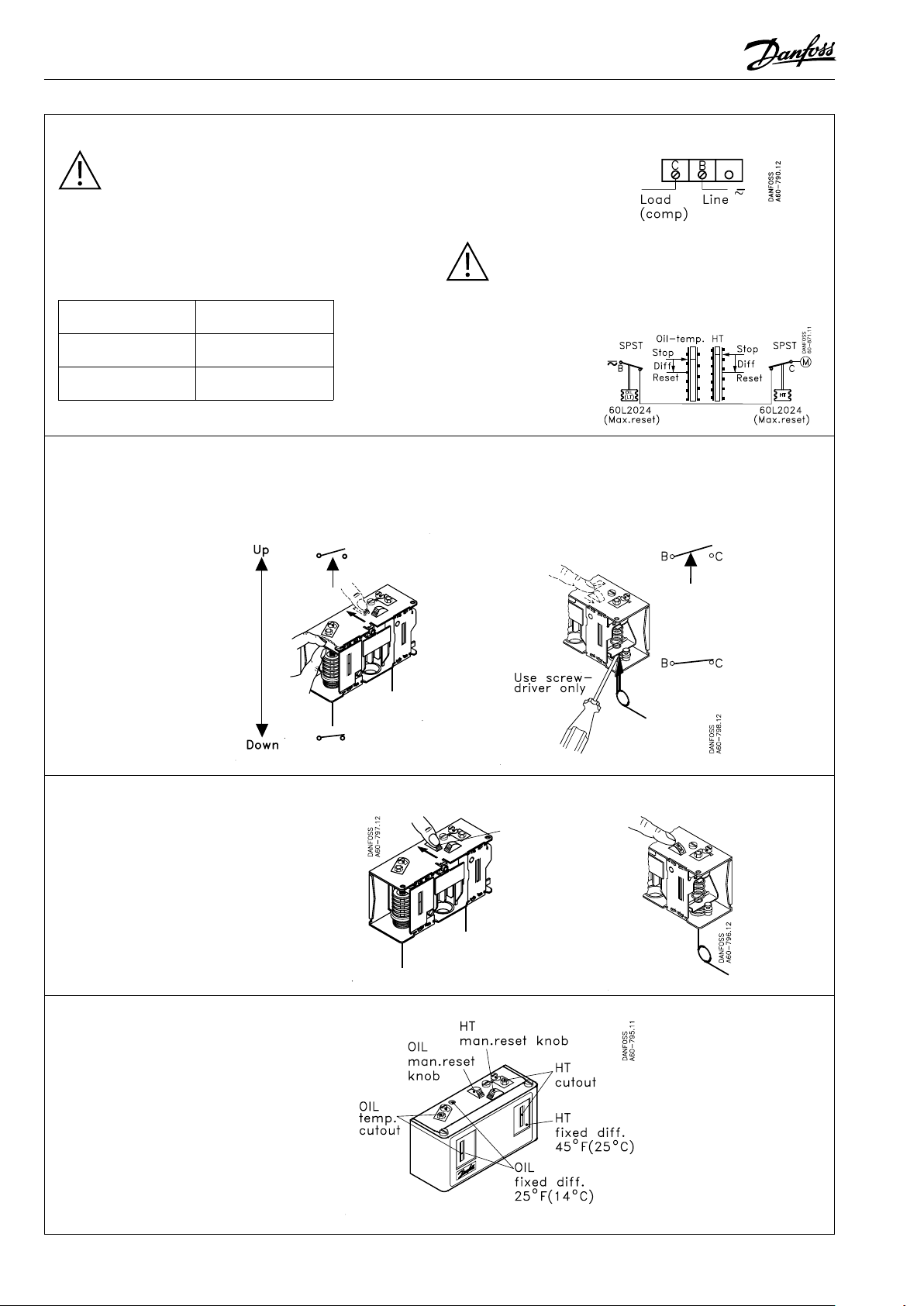

Wiring

CAUTION: disconnect power supply

before wiring connections are made

to avoid possible electrical shock or

damage to equipment.

All wiring should conform to the National

Electrical Code and local regulations.

Contact load ratings

120 V a.c. 16 FLA, 96 LRA

240 V a.c. 8 FLA, 48 LRA

240 V d.c. 12 W pilot duty

See label inside cover.

Manual tripping

(Electrical contacts/wiring test)

OIL side HT side

B

SPST

Terminal block

CAUTION: Use terminal screws furnished in the

contact block. Use tightening torque 20 lb. in. (2.3 Nm).

Use copper wire only.

B-C open on oil temperature rise

B-C open on discharge

temperature rise

A is not used

See label for current

wiring inside cover.

C

Contact positionContact position

TRIP

use FINGERS ONLY!

(Do NOT use screwdriver)

Manual reset

To resume control operation after safety

cut-out, push man. reset knob as indicated

Note:

OIL/HT man. reset is possible only after oil

or discharge temperature is equal to or has

dropped below cut-in value.

Adjustment spindle(s) location

Contact position

Danfoss

60-801.13

Contact position

C

B

OIL

reset

HT

man. reset

KP 98 A. MAN./MAN. RESET

2 DKRCC.PI.CA0.A6.22 / 520H8513 © Danfoss A/S (RC-MDP / jmn), 2014-08

Danfoss

60-1417.10

Danfoss

60-1418.10

Setting

Oil temp. (OIL) side setting High temp. (HT) side setting

1. Adjust range spindle to

desired CUT-OUT value

(max. allowable

oil temp.)

2. Dierential (DIFF.)

is xed 25 °F (14 °C)

Value printed on

scale plate

CUT OUT minus DIFFERENTIAL equals CUT OUT minus DIFFERENTIAL equals

CUT-IN CUT-IN

Example: Example:

CUT-OUT – DIFF. = CUT-IN CUT-OUT - DIFF. = CUT-IN

200 °F – 25 °F = 175 °F 325 °F - 45 °F = 280 °F

(93 °C) (14 °C) (79 °C) (163 °C) (25 °C) (138 °C)

OIL temp.

scale

Cut out

Di.

1. Adjust range spindle to

desired CUT-OUT value

(max. allowable

discharge temp.)

2. Dierential (DIFF.)

is xed 45 °F (25 °C)

Value printed on

scale plate

HT

scale

Cut out

Di.

Note:

CUT-OUT = compressor cut-out

CUT-IN = compressor cut-in

Adjustment

Danfoss

60-802.12

Note:

Remove lockplate before adjustment.

Replace lockplate after adjustment (if desired).

3 DKRCC.PI.CA0.A6.22 / 520H8513 © Danfoss A/S (RC-MDP / jmn), 2014-08

Loading...

Loading...