Installation Guide

Infocal 9

Energy calculator

for heating and cooling applications

www.danfoss.com

Installation Guide Infocal 9

2 | © Danfoss | Energy Meters | 2020.11 BC266538737985en-010201

Installation Guide Infocal 9

1. Installation

1.1. Preparation

Only qualified personnel may install the equipment, following the requirements listed in this document.

More detailed instructions can be found on www.heating.danfoss.com.

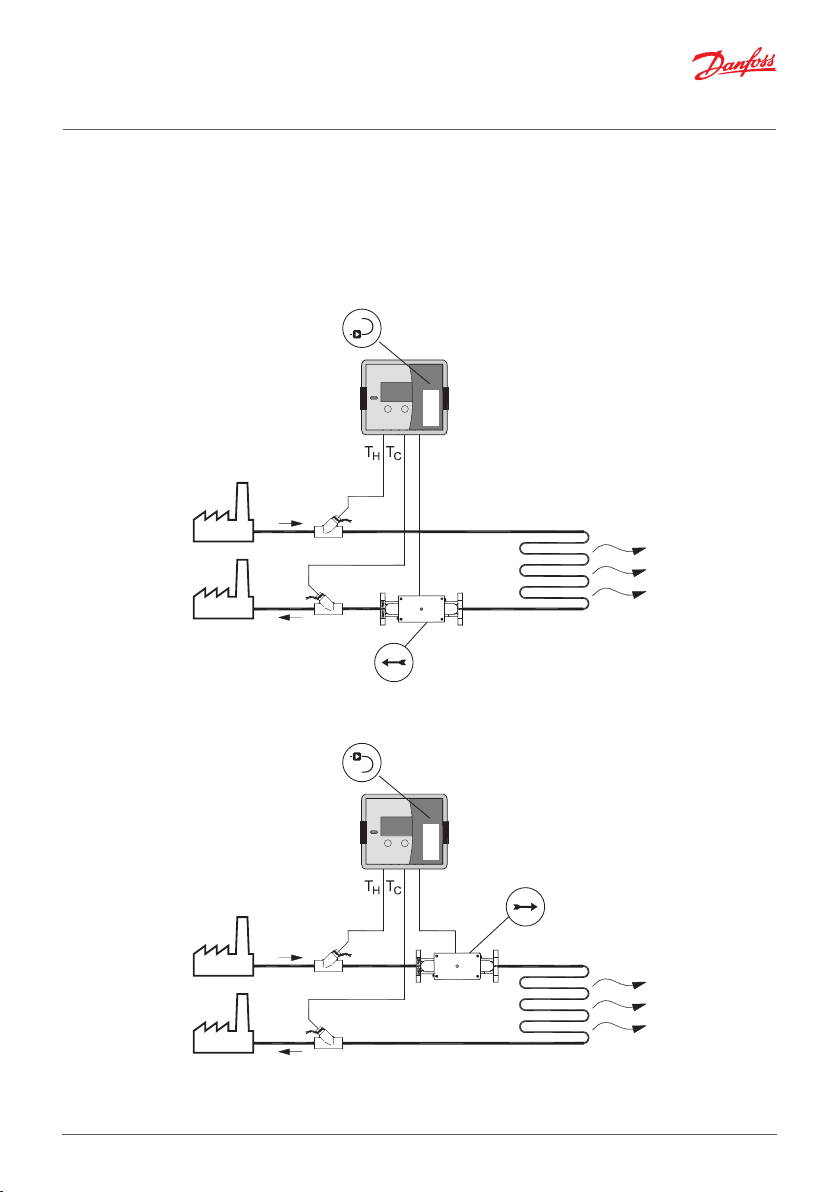

1.2. Identification of installation: Return or Supply pipe flow meter/sensor installation

Flow direction

Flow meter/sensor installed in return pipe

Flow direction

Flow meter/sensor installed in supply pipe

BC266538737985en-010201 © Danfoss | Energy Meters | 2020.11 | 3

Installation Guide Infocal 9

Seal

ocket

1.3. Installation of temperature sensors

Handle the temperature sensors carefully! The sensor cables are fitted with coloured type labels:

• Red (TH): sensor in supply pipe

• Blue (TC): sensor in return pipe

Make sure the sensors are mounted symmetrically (both directly immersed, or both installed in a pocket).

The maximum cable length is 10 m. The connecting cables must not be shortened or extended. The free

temperature sensors can be installed in a ball valve or adapter or in a conformity tested pocket for this type

of sensor. Ensure that the temperature sensors are permanently connected during operation.

For installation in a ball valve or adapter, a 4-piece coupling set is enclosed in a separate bag. See procedure

under item 1…5 on the right. Insert an O-ring in the sensor hole using the mounting pin supplied.

If the sensor is installed in a pocket, it must be inserted as far as the bottom of the pocket and then secured.

The pockets are best installed in T-pieces with a 45° or 90° angle. The tip of the pocket must point in the opposite direction to the direction of flow and must be located in the middle of the pipe. Temperature sensors

must be sealed after installation in the pockets.

The operation of any violation of this guidance will result in immediate invalidation of the factory

warranty and verification.

Seal

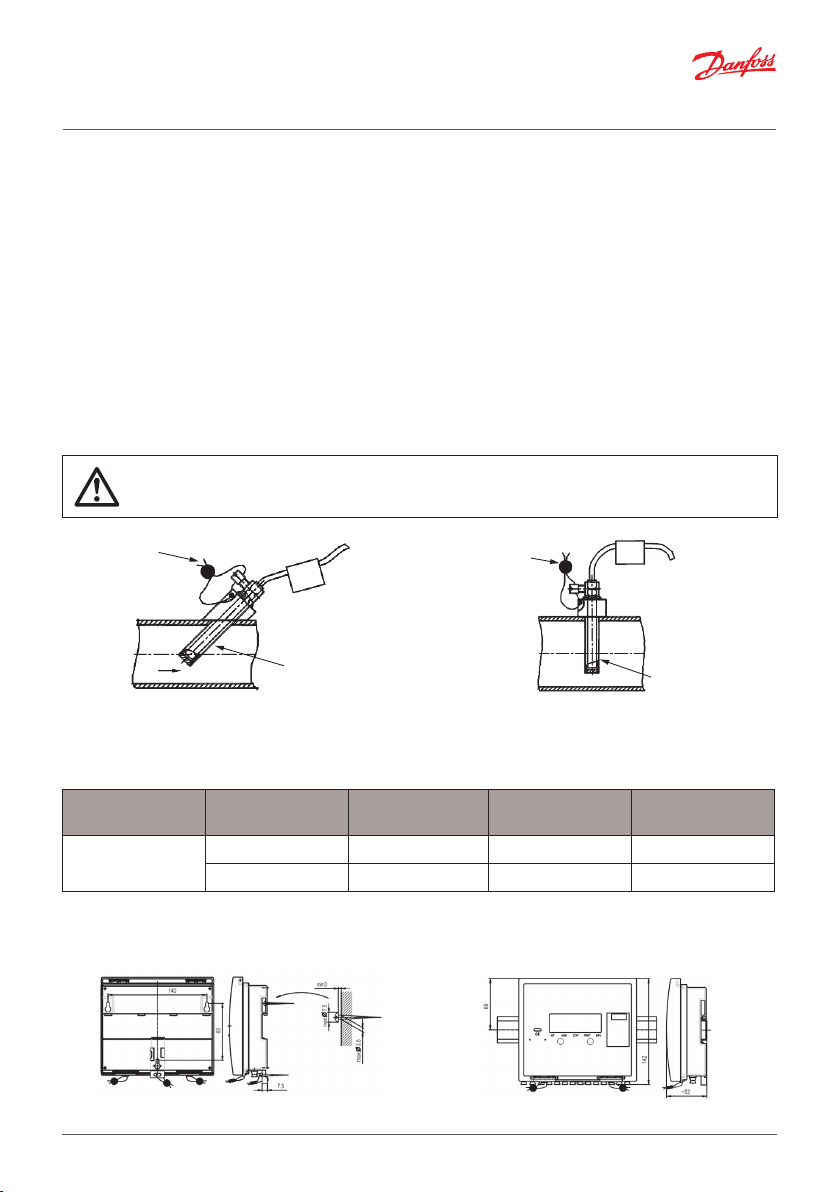

a) angled 45°

Pocket

b) perpendicular

P

Installation recommendations for pocket temperature sensors with permanently connected signal leads.

Temperature sensor cables should be connected to terminals as shown in below table:

Calculator type Sensor marking

Heating or

Heating/cooling

Red T

Blue T

Wiring 2-wire

sensor

(5-6) T

Hot

(7-8) T

Cold

Wiring 4-wire

sensor

(1/5-6/2) Supply pipe

Hot

(3/7-8/4) Return pipe

Cold

Installation

position

1.4. Mounting and sealing of calculator

On the wall:

4 | © Danfoss | Energy Meters | 2020.11 BC266538737985en-010201

On standard DIN-rail:

Installation Guide Infocal 9

w

brown

1.5. Flow meter or flow sensor connection

For connection of flow meter/sensor to energy calculator Infocal 9 it is important to know in which pipe

(supply –q1 or return – q2) this flow meter/sensor will be installed:

Flow sensor in return pipe

Infocal 9 terminal

External 3.6 V* 9(+U)

Flow pulse 52 (q2+)

Ground 11 (q2-)

Wiring to flow meter SONO 3500 CT:

SONO 3500 CT in

supply pipe

Infocal 9 terminal

56 (flow pulse) 10 (q1+)

57 (ground) 11 (q1-)

Flow sensor in supply pipe

External 3.6 V* 9(+U)

Flow pulse 10 (q1+)

Ground 11 (q1-)

*only if external supply for flow meter/sensor is needed.

Infocal 9 terminal

SONO 3500 CT in

return pipe

Infocal 9 terminal

56 (flow pulse) 52 (q2+)

57 (ground) 11 (q2-)

Wiring to flow sensor SonoSensor 30:

SonoSensor 30 in

supply pipe

Infocal 9 terminal

18 (flow pulse) 10 (q1+)

19 (ground) 11 (q1-)

SonoSensor 30 in

return pipe

Infocal 9 terminal

18 (flow pulse) 52 (q2+)

19 (ground) 11 (q2-)

Wiring to flow sensor SONO 1500 CT:

SONO 1500 CT in

return pipe

Infocal 9 terminal

Vcc (brown)* 9 (+U)

Pulse (white) 52 (q2+)

GND (blue) 11 (q1-)

white

blue

yello

BC266538737985en-010201 © Danfoss | Energy Meters | 2020.11 | 5

Installation Guide Infocal 9

SONO 1500 CT in supply pipe Infocal 9 terminal

Vcc (brown)* 9 (+U)

Pulse (white) 10 (q1+)

GND (blue) 11 (q1-)

*connect only if SONO 1500 CT with external supply.

Maximum permissible pulse input frequency and minimal permissible pulse duration.

Number of Pulse inputs 2

Measurement unit m³

Pulse value Configurable by control buttons

Min. pulse duration

Max. permissible pulse frequency

Pulse type Passive pulses

Sensor cable length Max. 10 m

Cable type Shielded twisted pair cable

5ms

100ms for combination with SonoSensor 30

60Hz

5Hz for combination with SonoSensor 30

Note:

In order to avoid any noise interference keep safety distance of 5cm between mains and pulse cable on

installation site

Note:

Recommendation is to use 0.75mm shielded cables for pulse and mains power connection.

2. Electrical wiring

Electrical wiring diagram with 2-wire temperature sensors

q1 - pulse input signal from flow meter in supply pipe

q2 - pulse input signal from flow meter in return pipe

q3, q4 - pulse inputs from water meters

T1 - temperature sensor in supply pipe

T2 - temperature sensor in return pipe

Note: Only required for selected calculator type should be connected

6 | © Danfoss | Energy Meters | 2020.11 BC266538737985en-010201

Installation Guide Infocal 9

Electrical wiring diagram with 4-wire temperature sensors

q1 - pulse input signal from flow meter in supply pipe

q2 - pulse input signal from flow meter in return pipe

q3, q4 - pulse inputs from water meters

T1 - temperature sensor in supply pipe

T2 - temperature sensor in return pipe

Note: Only required for selected calculator type should be connected

Calculator

Terminal Marking Description

9 +U +3,6V power supply (only if mains supply)

11 -q1 Ground for 1-st flow sensor (-)

10 +q1 Pulse input signal from flow meter in supply pipe

11 -q2 Ground for flow sensor

52 +q2 Pulse input signal from flow meter in return pipe

11 -q3 Ground for 3-rd flow sensor (-)

53 +q3 Pulse input signal from 3-rd flow sensor (+)

11 -q4 Ground for 4-th flow sensor (-)

54 +q4 Pulse input signal from 4-th flow sensor (+)

5 T1 Current terminal for 1-st temperature sensor “+I”

1 T1 Voltage terminal for 1-st temperature sensor “+U”

2 T1 Voltage terminal for 1-st temperature sensor “-U”

6 T1 Current terminal for 1-st temperature sensor “-I”

50 Shield terminal (for 1-st temperature sensor etc.)

7 T2 Current terminal for 2-nd temperature sensor “+I”

3 T2 Voltage terminal for 2-nd temperature sensor “+U”

4 T2 Voltage terminal for 2-nd temperature sensor “-U”

8 T2 Current terminal for 2-nd temperature sensor “-I”

50 Shield terminal (for 2-nd temperature sensor etc. )

BC266538737985en-010201 © Danfoss | Energy Meters | 2020.11 | 7

Installation Guide Infocal 9

Communication modules

Terminal Marking Description

76 Current output ground (-)

77 Iout1 1-st current output (+)

78 Iout2 2-st current output (+)

79 Pulse output ground (-)

80 Puls1 1-st pulse output (+)

81 Puls2 2-st pulse output (+)

24, (73) BUS M-Bus interface L1 signal (M-Bus , CL – -CL or RS232 – Rx (input))

25, (74) BUS M-Bus interface L2 signal (M-Bus , CL – +CL or RS232 – Tx (output))

75 BUS Ground for RS-232 interface “GND”

Power supply

To ensure constant pulse read out, recommended is connecting ground terminal 26 of 230V AC module with

terminal 11 of Infocal 9. Infocal 9 with battery is not affected.

Terminal Marking Description

26 Main ground

27 0 Neutral

28 L Mains power supply (230V AC)

3. Commissioning

3.1. Bleeding

1. Bleed the system until the flow rate display is steady.

2. Make sure no error codes are displayed.

3. Check the display for a plausible indication of flow rate and temperatures.

8 | © Danfoss | Energy Meters | 2020.11 BC266538737985en-010201

Installation Guide Infocal 9

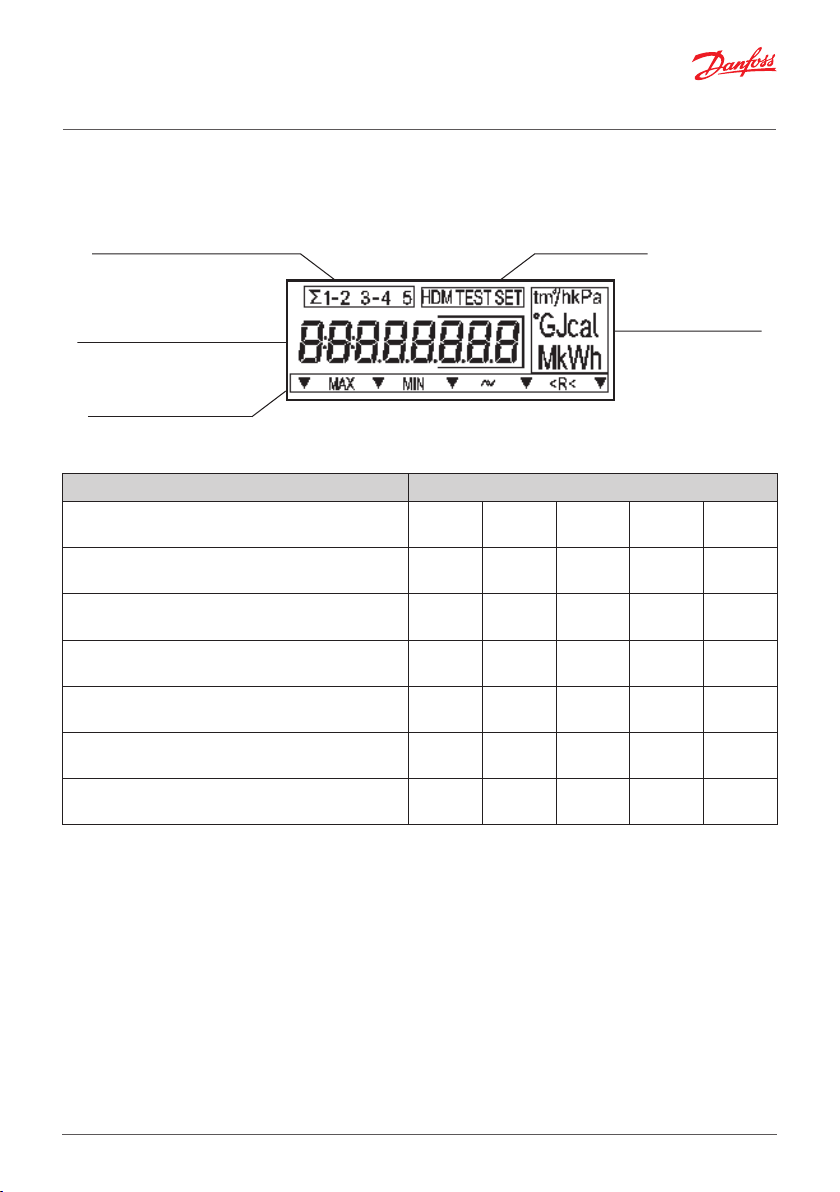

Parameter and group numbers Operation mode

Measurement units

V

L1 L2 L3 L4 L5

4. Display function overview

4.1. Display symbols description

alues

Group of parameters

4.2. Menu structure

Parameters shown Identification symbols

Integral values

Instantaneous parameters values (L2) L1

Set day parameters and archive data values (L3) L1 L2

Printing reports by standard printer (L4) L1 L2 L3

Configuration settings parameters (L5) L1 L2 L3 L4

Parametrization (configuration) mode (SET) L1 L2

Test mode (TEST) L1 L2

Note: More detailed display description is available for download from www.danfoss.com.

L1

L2 L3 L4 L5

L2

L3 L4 L5

L3

TEST

L3

TEST

L3

L4 L5

L4

L4 L5

L4 L5

L5

L5

BC266538737985en-010201 © Danfoss | Energy Meters | 2020.11 | 9

Installation Guide Infocal 9

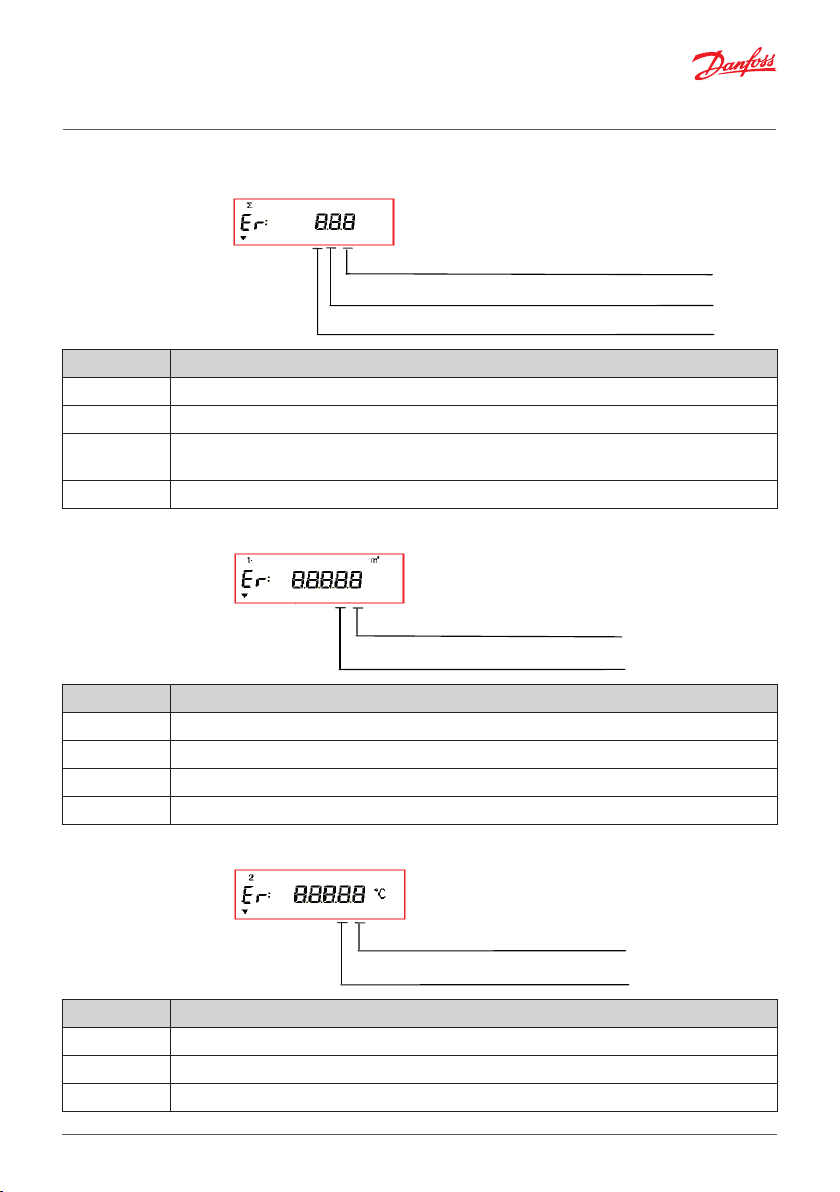

4.3. Error codes check

The calculator continuously analyzes operational modes, diagnoses and informs of errors in system.

General errors:

1-st heang system operaon error

2-nd heang system operaon error

Calculator error

Error display Error description

ErΣ: 0 No error. Normal mode.

ErΣ: 1 Warning! Estimated battery lifetime less than 6 months.

ErΣ: 5

ErΣ: 8 Flow or temperature sensor error.

Status of flow sensors:

Flow rate outside designated limits or temperature difference is under programmed

minimum allowed value (only when energy calculation algorithm “2 – special” is applied).

Status of flow sensor q1

Status of flow sensor q2

Display Description

Er1: 0 No error. Normal mode.

Er1: 2 Flow rate is under programmed minimum allowed value

Er1: 4 Flow rate exceeds programmed maximum allowed value.

Er1: 8 Sensor failure (broken connection or disconnected power supply.

Status of flow

temperature sensors:

Status of sensor Θ1

Status of sensor Θ2

Display Description

Er2: 0 No error. Normal mode.

Er2: 1 Temperature difference is under programmed minimum allowed value.

Er2: 8 Sensor failure (open circuit or short circuit).

10 | © Danfoss | Energy Meters | 2020.11 BC266538737985en-010201

Installation Guide Infocal 9

5. Disposal

This symbol on the product indicates that it will not be treated as household waste.

It must be handed over to the applicable take-back scheme for the recycling of electrical and electronic equipment. For more detailed information about the recycling

of this product, please contact your local municipal office.

Item Material Disposal

Battery

PCBA with display

Other plastic parts PC, PPS, PEI, TPE Plastic recovery

D-cell lithium/thionyl chloride

3.5 g lithium

Coppered epoxy laminate components

soldered on, PC, TPE

Approved deposit for lithium

batteries

Electronic waste

6. Local Importer name and address

For goods delivered to UK, importer name and address is:

Danfoss Ltd.

Oxford Road

UB9 4LH Denham

UK

BC266538737985en-010201 © Danfoss | Energy Meters | 2020.11 | 11

12 | © Danfoss | Energy Meters | 2020.11 BC266538737985en-010201

Loading...

Loading...