Page 1

www.danfoss.com/ir

Application Handbook

Industrial Refrigeration

Ammonia and CO2 Applications

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 1

Page 2

Application Handbook Industrial Refrigeration ammonia and CO2 applications

2 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 3

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Content Page

Introduction ................................................................................................................................................................................... 3

1.1 Refrigerants ............................................................................................................................................................................. 4

1.2 Refrigerant feed to the evaporator ............................................................................................................................................ 6

1.3 One-stage systems ................................................................................................................................................................... 8

1.4 Two-stage/multistage systems .................................................................................................................................................. 9

1.5 Cascade systems .................................................................................................................................................................... 12

1.6 Transcritical systems .............................................................................................................................................................. 13

Compressor controls ..................................................................................................................................................................... 18

2.1 Reverse flow control ............................................................................................................................................................... 19

2.2 Suction pressure control ......................................................................................................................................................... 20

2.3 Compressor capacity control ................................................................................................................................................... 21

2.4 Discharge Temperature Control with Liquid Injection ................................................................................................................ 24

2.5 Economizer damper ................................................................................................................................................................ 26

2.6 Summary ............................................................................................................................................................................... 27

Condenser controls ....................................................................................................................................................................... 28

3.1 High-pressure float valve operation ......................................................................................................................................... 28

3.2 Low-pressure float valve operation .......................................................................................................................................... 29

3.3 Air-cooled condensers............................................................................................................................................................. 29

3.4 Evaporative condensers .......................................................................................................................................................... 33

3.5 Water-cooled condensers ........................................................................................................................................................ 36

3.6 Summary ............................................................................................................................................................................... 38

Liquid level regulation ................................................................................................................................................................... 39

4.1 High-pressure liquid level regulation system (HP LLRS) ............................................................................................................. 41

4.2 Low-pressure liquid level regulation system (LP LLRS) .............................................................................................................. 47

4.3 Summary ............................................................................................................................................................................... 52

Evaporator controls ...................................................................................................................................................................... 53

5.1 Temperature controls ............................................................................................................................................................. 54

5.2 Liquid supply control............................................................................................................................................................... 58

5.3 Injection with a solenoid valve (EVRA) ..................................................................................................................................... 65

5.4 Injection with a pulse width modulation AKV(A) valve............................................................................................................... 65

5.5 Risers .................................................................................................................................................................................... 68

5.6 Defrost methods .................................................................................................................................................................... 73

5.7 Summary ............................................................................................................................................................................... 90

Oil systems .................................................................................................................................................................................. 92

6.1 Oil cooling controls ................................................................................................................................................................. 93

6.2 Oil differential pressure controls .............................................................................................................................................. 98

6.3 Oil recovery system .............................................................................................................................................................. 102

6.4 Summary ............................................................................................................................................................................. 106

Safety systems ........................................................................................................................................................................... 107

7.1 Pressure relief devices .......................................................................................................................................................... 107

7.2 Pressure and temperature limiting devices ............................................................................................................................. 110

7.3 Liquid level safety devices ..................................................................................................................................................... 111

7.4 Refrigerant detection ............................................................................................................................................................ 112

Refrigerant pump controls........................................................................................................................................................... 116

8.1 Pump protection with differential pressure control .................................................................................................................. 117

8.2 Pump bypass flow control ..................................................................................................................................................... 120

8.3 Pump pressure control .......................................................................................................................................................... 122

8.4 Summary ............................................................................................................................................................................. 123

Others ....................................................................................................................................................................................... 124

9.1 Filter driers in fluorinated systems ......................................................................................................................................... 124

9.2 Water removal for CO2 systems ............................................................................................................................................ 126

9.3 Water removal for ammonia systems ..................................................................................................................................... 128

9.4 Air purging systems .............................................................................................................................................................. 130

9.5 Heat recovery systems.......................................................................................................................................................... 135

Using CO2 in refrigeration systems ............................................................................................................................................ 136

10.1 CO2 as a refrigerant ........................................................................................................................................................... 137

10.2 Comparision of line sizings in CO2 systems ........................................................................................................................... 138

10.3 -Subcritical CO2 systems ..................................................................................................................................................... 145

10.4 Special considerations for CO2 refrigeration systems ............................................................................................................. 153

10.5 Conclusion ......................................................................................................................................................................... 157

10.6 Safety and gas detection ..................................................................................................................................................... 159

10.7 Gas detection ..................................................................................................................................................................... 159

10.8 Pressure control CO2 systems ............................................................................................................................................. 161

10.9 Cascade system controls ..................................................................................................................................................... 163

10.10 Control methods for hot gas defrosting .............................................................................................................................. 164

10.11 Oil in CO2 systems ............................................................................................................................................................ 171

10.12 Water in CO2 Systems ....................................................................................................................................................... 174

Transcritical CO2 systems ......................................................................................................................................................... 179

11.1 Explanation of the transcritical cycle. ................................................................................................................................... 179

11.2 Typical CO2 transcritical system types .................................................................................................................................. 184

11.3 CO2 in Industrial refrigeration ............................................................................................................................................. 190

11.4 Industrial CO2 transcritical systems. .................................................................................................................................... 193

11.5 Defrosting of industrial pump-circulated transcritical systems ................................................................................................ 209

11.6 Oil management ................................................................................................................................................................. 211

11.7 Oil return ........................................................................................................................................................................... 212

11.8 Heat recovery ..................................................................................................................................................................... 217

11.9 Design pressure and safety ................................................................................................................................................. 223

Heat exchangers ...................................................................................................................................................................... 225

12.1 Heat transfer fundamentals ................................................................................................................................................. 230

12.2 Plate heat exchangers ......................................................................................................................................................... 237

12.3 Installation of heat exchangers ............................................................................................................................................ 242

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 1

Page 4

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Foreword:

Some of the solutions presented here might be subject to special requirements in local laws and legislation and Danfoss has made no verification of such

and expressly disclaims any compliance there with. A

licensed and skilled professional engineer should always be consulted when designing, using, making or

selling any device or equipment to ensure compliance with applicable laws and standards.

Refrigeration systems and methods of operating the

same may be subject to intellectual property rights

in some jurisdictions. A licensed attorney should always be consulted when designing, using, making or

selling any such system, methods or equipment to

ensure freedom to operate.

Danfoss shall have no liability or obligation to indemnify or hold harmless for any claims, legal proceedings, losses, actions, damages, suits, judgments, liabilities, and expenses, including attorneys’ fees, arising from any information provided in this document,

or arising out of the modification or combination of

any Danfoss product or system with any third party

equipment, materials or intellectual property.

All diagrams and drawings are included as principle

sketches and for illustration purposes only. All

Danfoss products and pipe lines etc. should be dimensioned according to the actual capacity and temperature range they are to be used at.

Any information, including, but not limited to information on selection of product, its application or

use, product design, weight, dimensions, capacity or

any other technical data in this document shall be

considered informative, and is only binding if and to

the extent, explicit reference is made in a quotation

or order confirmation by Danfoss. Danfoss reserves

the right to alter its products without notice.

This document itself, all text, diagrams. drawings

and all trademarks in this material are property of

Danfoss A/S or Danfoss group companies. Danfoss

and the Danfoss logo are trademarks of Danfoss A/S.

All rights reserved.

2 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

www.danfoss.com\ir

Page 5

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Introduction

The refrigeration systems and their applications described in this guide are all vapour compression refrigeration systems.

the refrigerant to condense and release heat. When

the refrigerant is fully condensed, it is expanded to

lower the pressure, the evaporation pressure, corresponding to a saturation temperature that is low

Vapour compression refrigeration systems utilise the

heat absorbed or released in a phase change, the latent heat, of refrigerants. The boiling temperature

enough for the refrigerant to absorb heat from the

cooled environment, thus evaporating, and the processes repeat themselves.

changes with the pressure of the refrigerant.

The refrigerant is pressurised at different pressure

levels, evaporation pressure levels and condensation

pressure levels, to absorb heat from the heat source

(cold room) and release heat to the heat sink (ambient), thus the refrigerant acts as a heat transport

media. The refrigerant is evaporated and absorbs

heat from the environment that is to be cooled.

Once the refrigerant is evaporated, it is compressed

to a higher pressure level, where the saturation tem-

To visualise the processes, a log(p)-h diagram is

shown in Figure 1.1. The log(p)-h diagram shows the

thermodynamic properties of a refrigerant. It is used

for representing refrigeration cycles by plotting in

state points from the refrigeration cycle. It can also

be used for reading values for the state points in a

refrigeration cycle. The log(p)-h diagram has been

created with the Danfoss calculation tool Coolselector2.

perature is higher than the ambient temperature for

Figure 1.1: Log(p)-h diagram for one-stage ammonia system

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 3

Page 6

Application Handbook Industrial Refrigeration ammonia and CO2 applications

A simple one-stage ammonia refrigeration cycle is

shown in the log(p)-h diagram above. In this example, the evaporation temperature is -10°C and the

condensation temperature is 35°C.

The bell shape seen in the diagram is the two-phase

area of the refrigeration and the horizontal lines inside the bell shape represent the evaporation ((4) to

1.1 Refrigerants

The refrigerant is the medium that transports energy

from the evaporator to the condenser. Different refrigerants have different thermodynamic properties,

such as latent heat, density, critical point etc. Different refrigerants also have different safety precautions, environmental impacts and regulations to be

taken into account when designing a refrigeration

system.

The most common refrigerants used in industrial systems are:

(1)) and the condensation ((2) to (3)). The area to the

left of the bell shape is the liquid phase, while the

area to the right of the bell shape is the vapour/gas

phase. In the gas phase, the pressure is increased

from (1) to (2) - this is the vapour compression. From

(3) to (4), the refrigerant liquid is expanded to the

evaporation pressure level.

Ammonia is toxic and flammable (in certain concentrations), so proper safety precautions must be

taken when handling large amounts of ammonia.

1.1.2 Carbon dioxide (CO

) – R744

2

CO2 is a non-toxic (in small concentrations), nonflammable substance that is present in the atmosphere. CO2 has become more popular in recent years

as CFC refrigerants have been phased out, especially

in smaller systems and as a secondary refrigerant in

commercial applications.

Ammonia – R717

Carbon dioxide (CO

Halocarbons – CFCs, HCFCs and HFCs

Hydrocarbons – HCs

) – R744

2

Safety systems, such as safety relief valves and gas

detectors are described in chapter 7.

1.1.1 Ammonia - R717

Ammonia is a natural refrigerant with the chemical

composition NH3. Ammonia is inexpensive, easy to

manufacture and has a high amount of latent heat,

which is why it is a very commonly used refrigerant

in industrial applications. At ambient conditions,

20°C and 1 atm, ammonia is lighter than air. Additionally, ammonia has no ozone depletion potential

(ODP) and no global warming potential (GWP).

Ammonia’s operational area as a refrigerant ranges

from around -40°C of evaporation temperature and

up. Ammonia is not compatible with copper, so steel

components should be used.

The challenges regarding CO2 are the high pressure

for condensation/recuperating and the low critical

temperature, requiring transcritical operation with

warm ambient temperatures. CO2 can be dangerous

when leaking, as it is not self-alarming like ammonia.

Large concentrations of CO2 can cause dizziness and,

in the most extreme cases, death. The other side of

CO2’s high pressure is that it is very efficient at low

temperatures, making it a good refrigerant for freezing applications. However, CO2’s triple point at -

56.6°C/5.1 bar abs is the lower limit for its use.

1.1.3 Halocarbons – CFCs, HCFCs and HFCs

Halocarbons are made by replacing one or more hydrogen atoms with halogens in methane and ethane

molecules.

Three classes of these exists: CFCs (chlorofluorocarbons), HCFCs (hydrochlorofluorocarbons) and HFCs

(hydrofluorocarbons). These refrigerant classes are

known for:

CFCs: All hydrogen atoms are substituted by either

chloride or fluoride, e.g. R11. These are very stable

4 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 7

Application Handbook Industrial Refrigeration ammonia and CO2 applications

compounds with a long lifetime. CFCs are non-toxic

and non-flammable refrigerants. However, these refrigerants have been phased out because they contribute to the breakdown of the ozone layers in the

Earth’s stratosphere when they are leaked.

HCFCs: At least one hydrogen atom is present in

these molecules, e.g. R22, which is used to replace

R12. These components are less stable and have

shorter lifetimes, thus they are less harmful regarding ozone layer depletion and global warming potential. HCFCs are being phased out by some countries.

HFCs: These halocarbons do not contain either chlorine or bromine, e.g. R134a, and are therefore not

ozone depleting. However, they do still have a high

GWP and are therefore on a phasedown. The properties of R134a are close to R12, and therefore

R134a can normally replace R12 in new and existing

systems. Many new blends are entering the market

at the present time though. However, due to the relatively high GWP compared to natural refrigerants,

there is a risk that these will be phased out in the future.

1.1.4 Hydrocarbons – HCs

Hydrocarbons have become very common in domestic refrigeration applications. Hydrocarbons are flammable and explosive, but in small systems the charge

is typically too low to pose any risk, and these systems are typically hermetic. Isobutane - R600a is a

hydrocarbon refrigerant which is used in domestic

applications. R290 – propane – is used in some larger

chillers but is yet to be seen in large-scale industrial

applications.

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 5

Page 8

Application Handbook Industrial Refrigeration ammonia and CO2 applications

1.2 Refrigerant feed to the evaporator

There are two common ways that refrigerant is fed

to the evaporator in a vapour compression refrigeration system, which are presented in the following

paragraphs.

1.2.1 Direct expansion system (DX)

After expansion, the liquid/vapour mixture of refrigerant is fed directly to the evaporator. The refrigerant is then fully evaporated, so that only the vapour

phase is present at the evaporator outlet. To ensure

that no liquid is present in the suction line, the refrigerant vapour is superheated (the actual temperature is above saturation) in the evaporator before

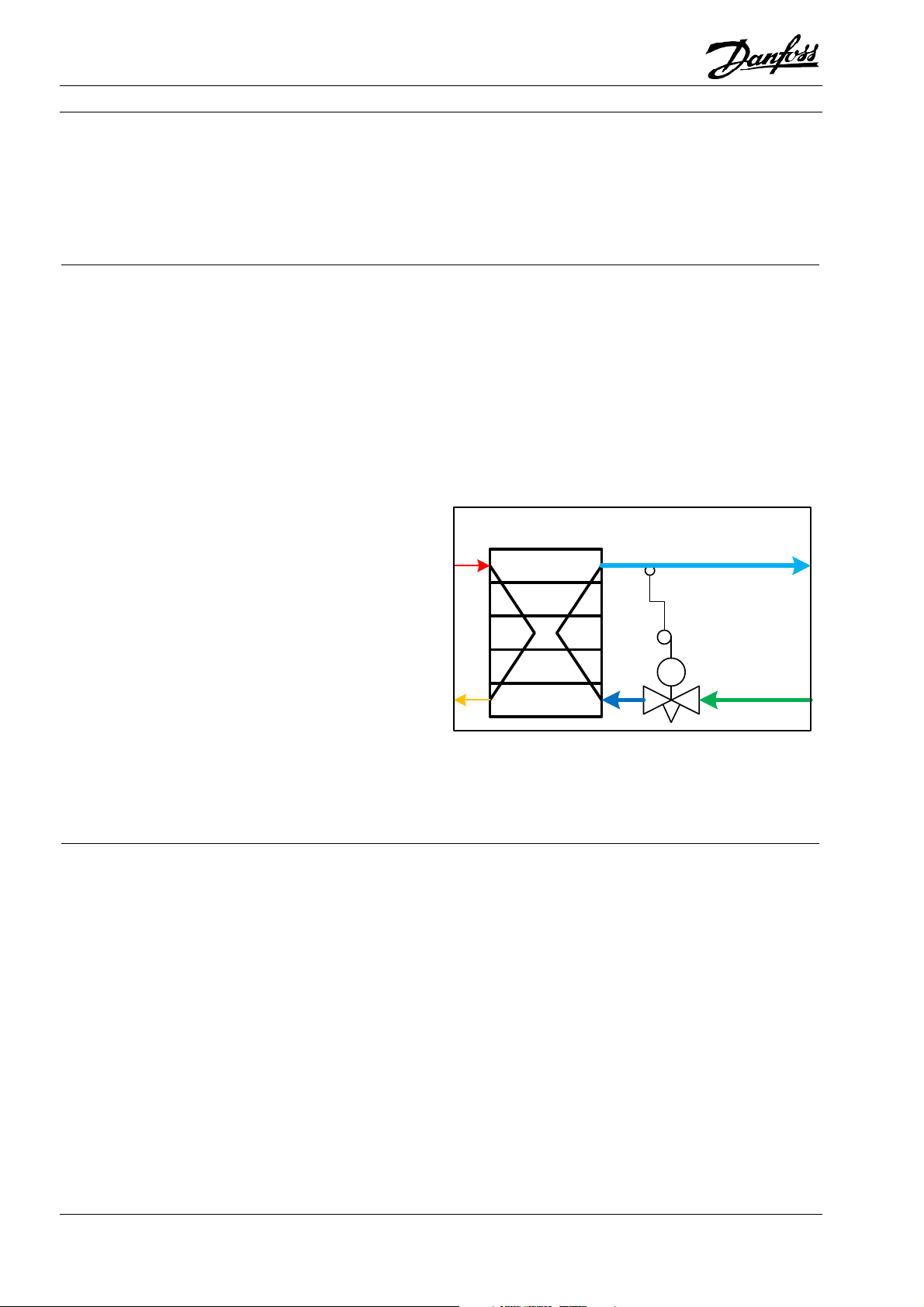

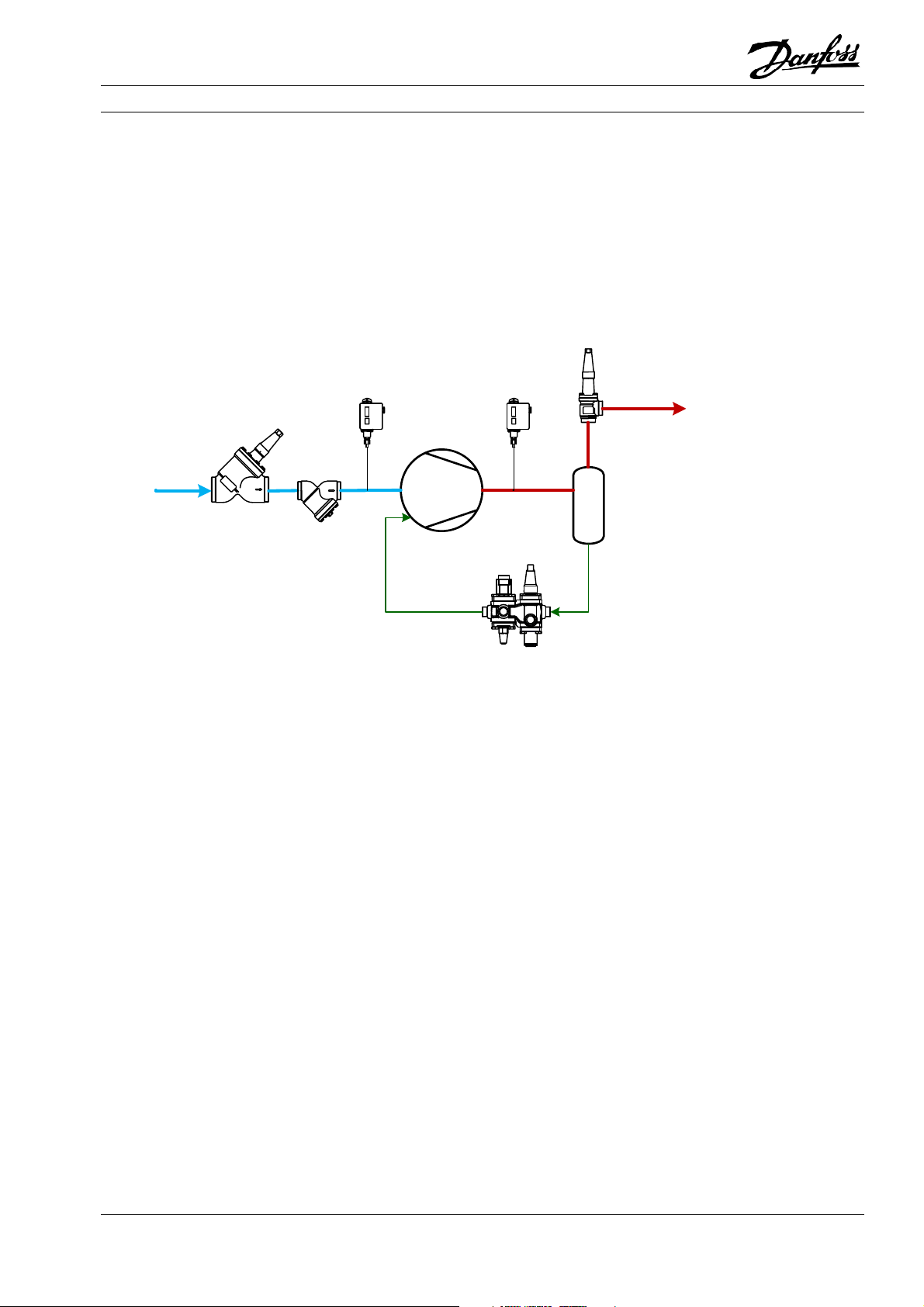

A sketch of a direct expansion evaporator is shown

in Figure 1.2. The evaporator is depicted as a plate

heat exchanger, with the cooled product on the left

side and the refrigerant on the right side. The thermostatic expansion valve is regulated based on the

superheat measured on the suction line (line to compressor).

being fed to the compressor.

Figure 1.2: Direct expansion evaporator

An expansion valve is controlled by the superheat.

This is either done by a thermostatic expansion valve

DX Evaporator

or an electronic expansion valve.

To Compressor

By keeping a constant level of superheat at the evaporator outlet, the expansion valve feeds the right

flow of refrigerant to the evaporator according to

the cooling load.

A certain level of superheat should ensure that only

refrigerant vapour is fed to the compressor suction.

Liquid droplets in the suction will cause liquid hammering in the compressor.

TC

From Receiver

NOTE: A thermostatic expansion valve can only keep

a constant superheat, rather than a constant evapo-

rating temperature.

6 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 9

Application Handbook Industrial Refrigeration ammonia and CO2 applications

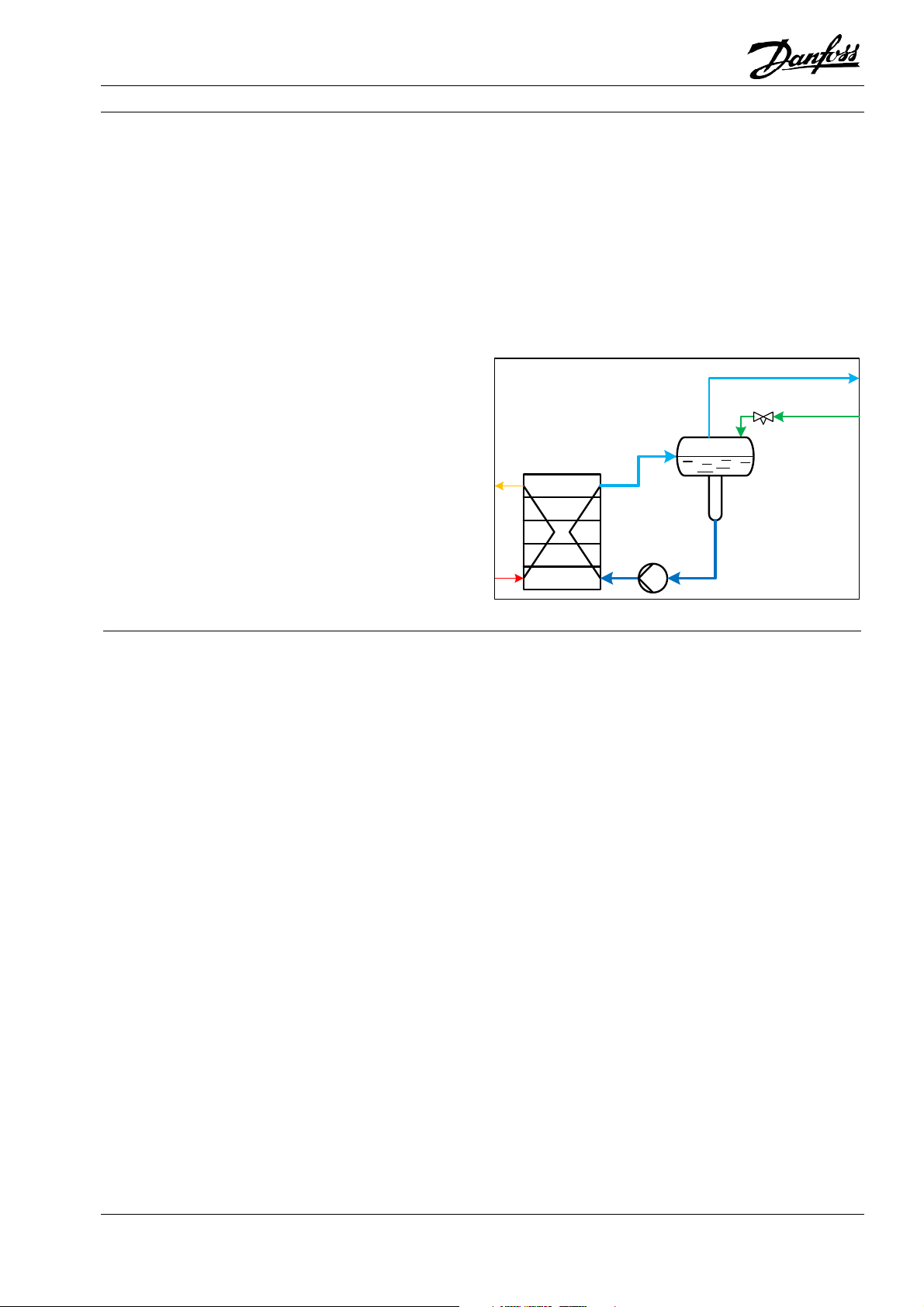

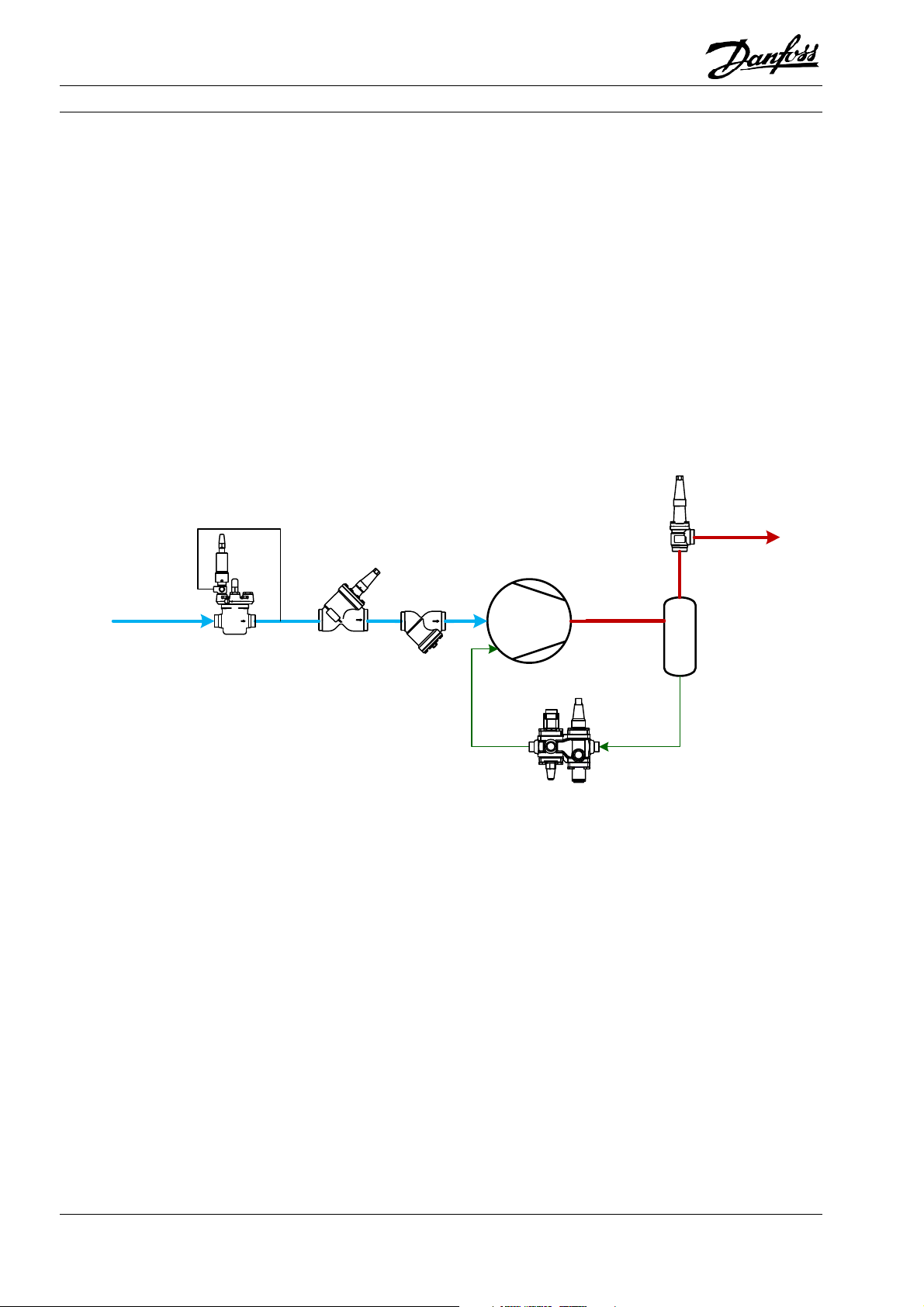

1.2.2 Circulated system (flooded system)

In circulated systems, the liquid/vapour mixture of

refrigerant is separated after the expansion in a sep-

A circulation system is therefore more efficient than

a corresponding DX system.

aration vessel. The saturated liquid phase of the refrigerant is pumped, or driven by gravity, into the

evaporator and is partially evaporated, so that a liquid/vapour mixture of the refrigerant is present at

the evaporator outlet. In the separator vessel, only

the saturated vapour will be fed to the compressor,

while the saturated liquid is circulated through the

A sketch of a flooded evaporator is shown in Figure

1.3. The evaporator type is the same as in Figure 1.2.

For the flooded evaporator, the pump is shown, but

it would be left out if it were a thermosyphon evapo-

rator driven by gravity.

Figure 1.3: Pumped flooded evaporator

evaporator.

As the evaporator does not need to superheat the

suction vapour, the entire surface is used for evaporation, making the flooded evaporator much more

efficient. Furthermore, creating superheat in a DX

Flooded

Evaporator

evaporator requires a higher temperature difference

and thus the evaporating temperature in a flooded

evaporator can be closer to the product temperature, allowing for a more efficient refrigeration system

To Compressor

From Receiver

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 7

Page 10

Application Handbook Industrial Refrigeration ammonia and CO2 applications

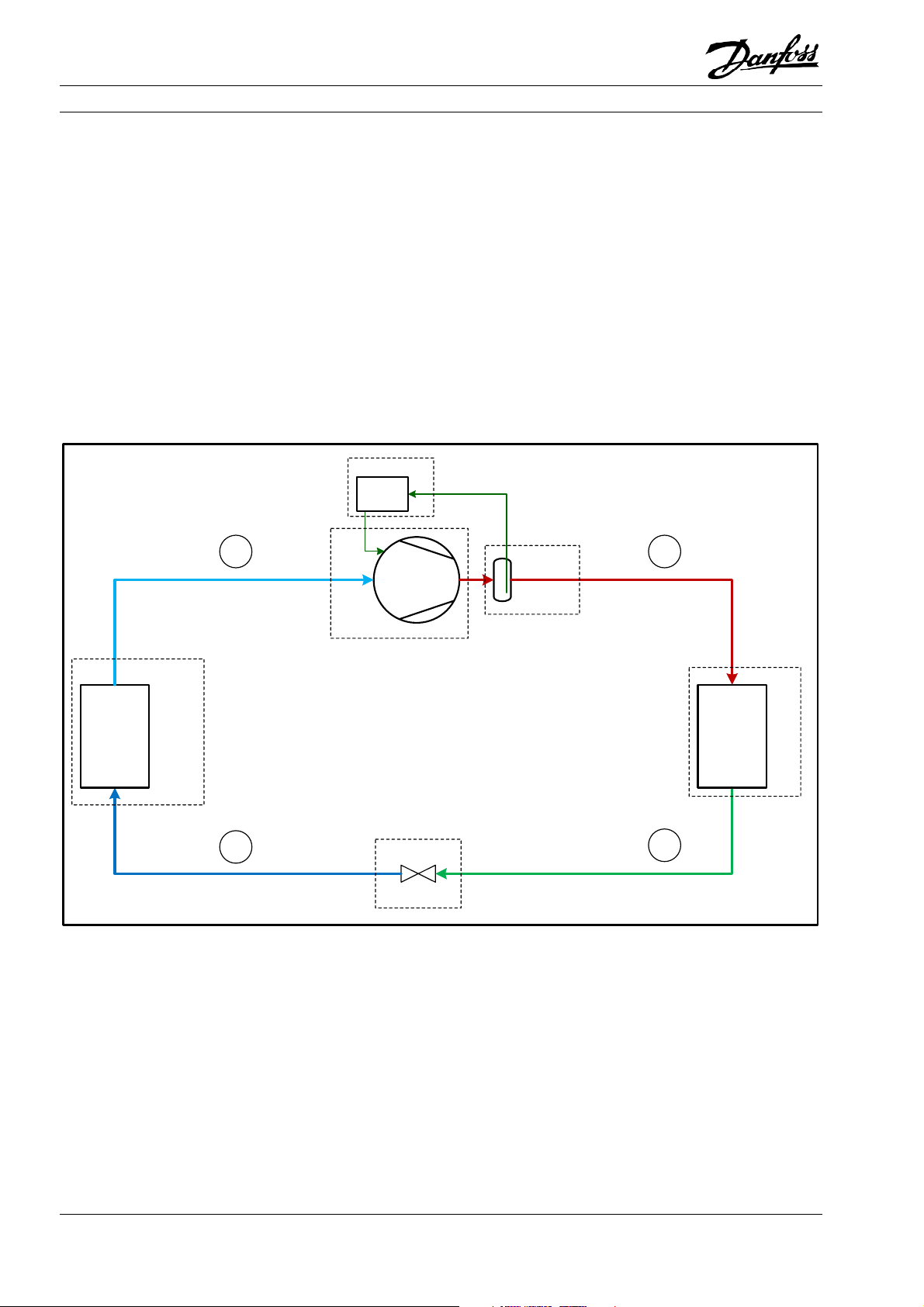

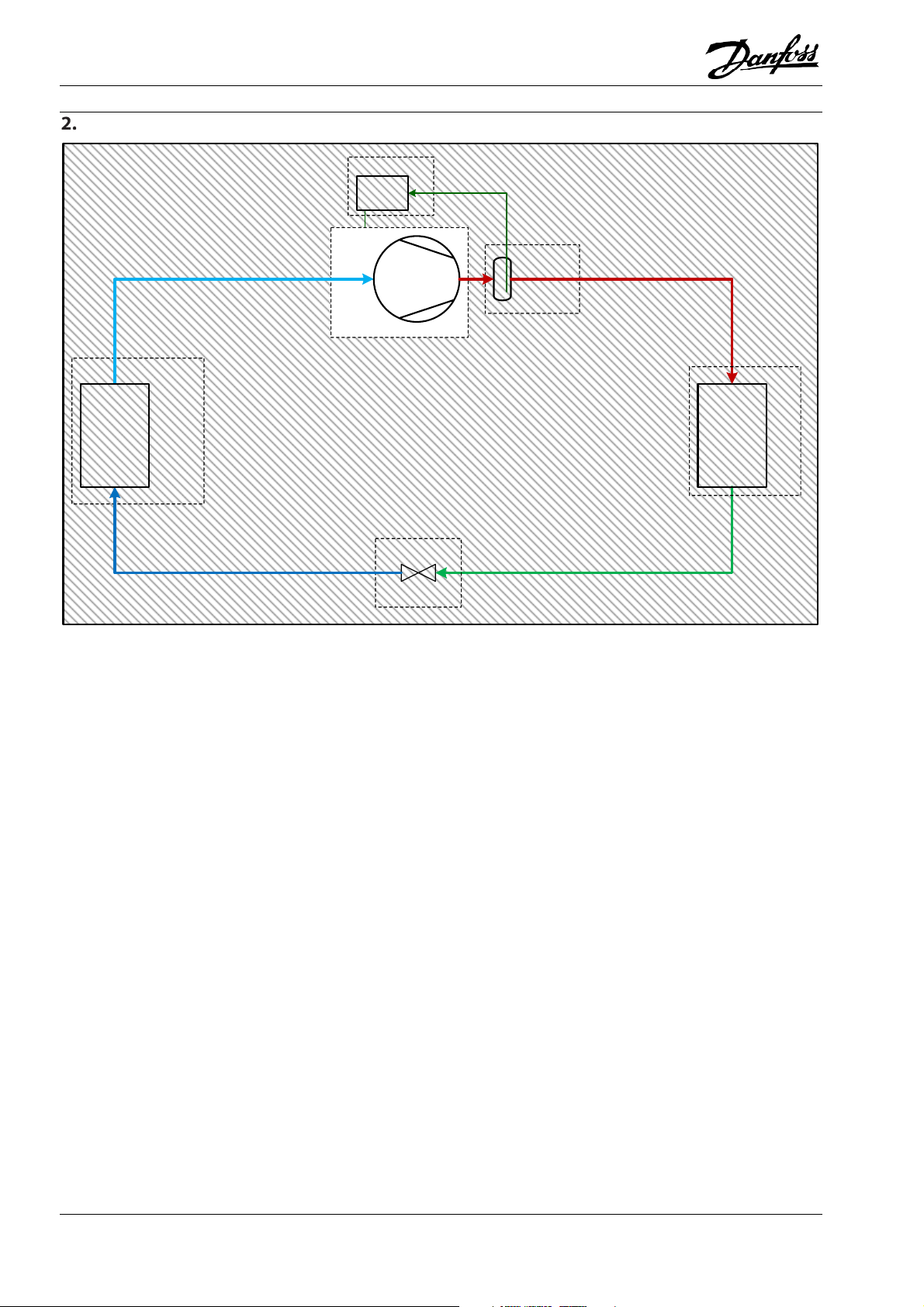

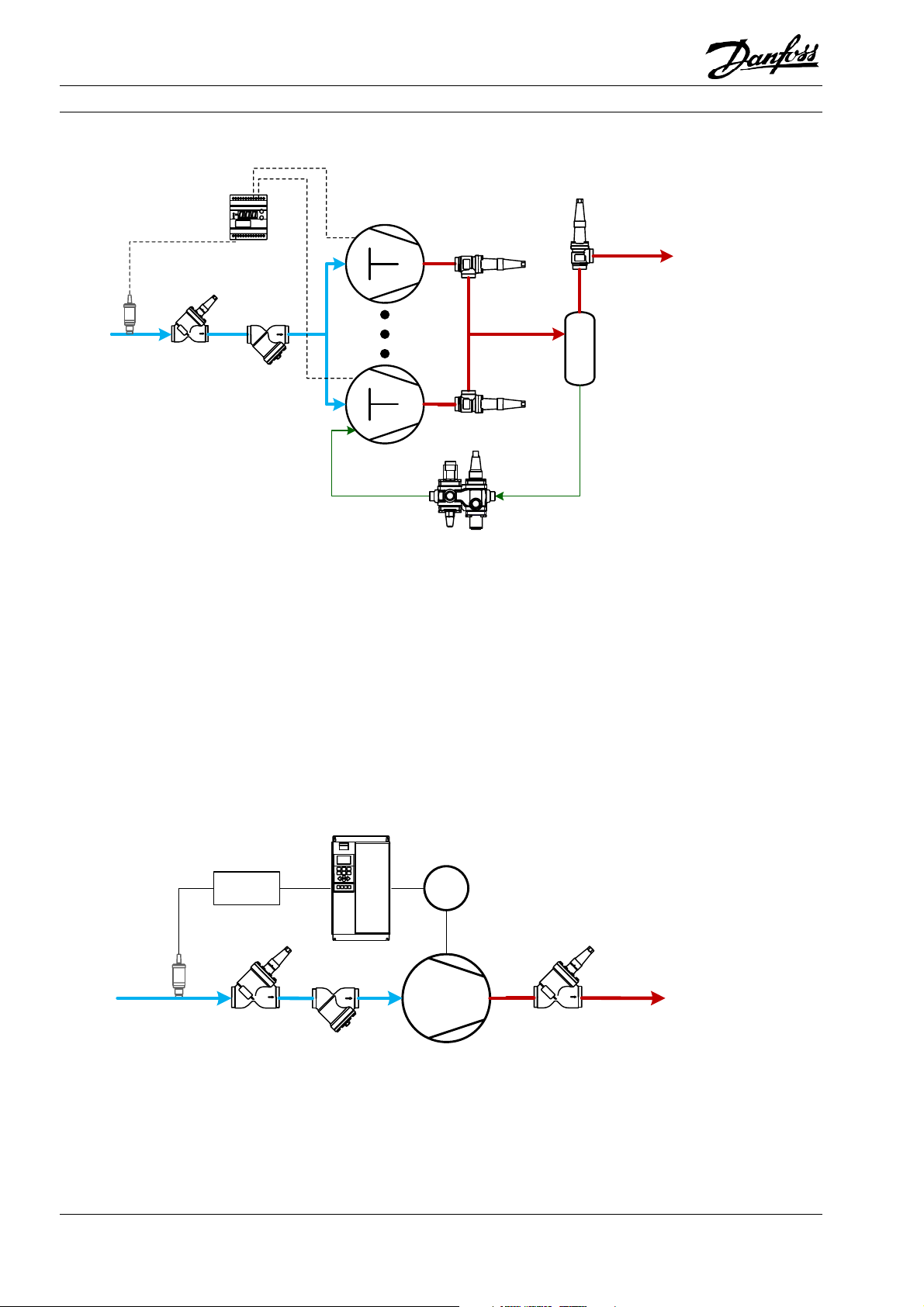

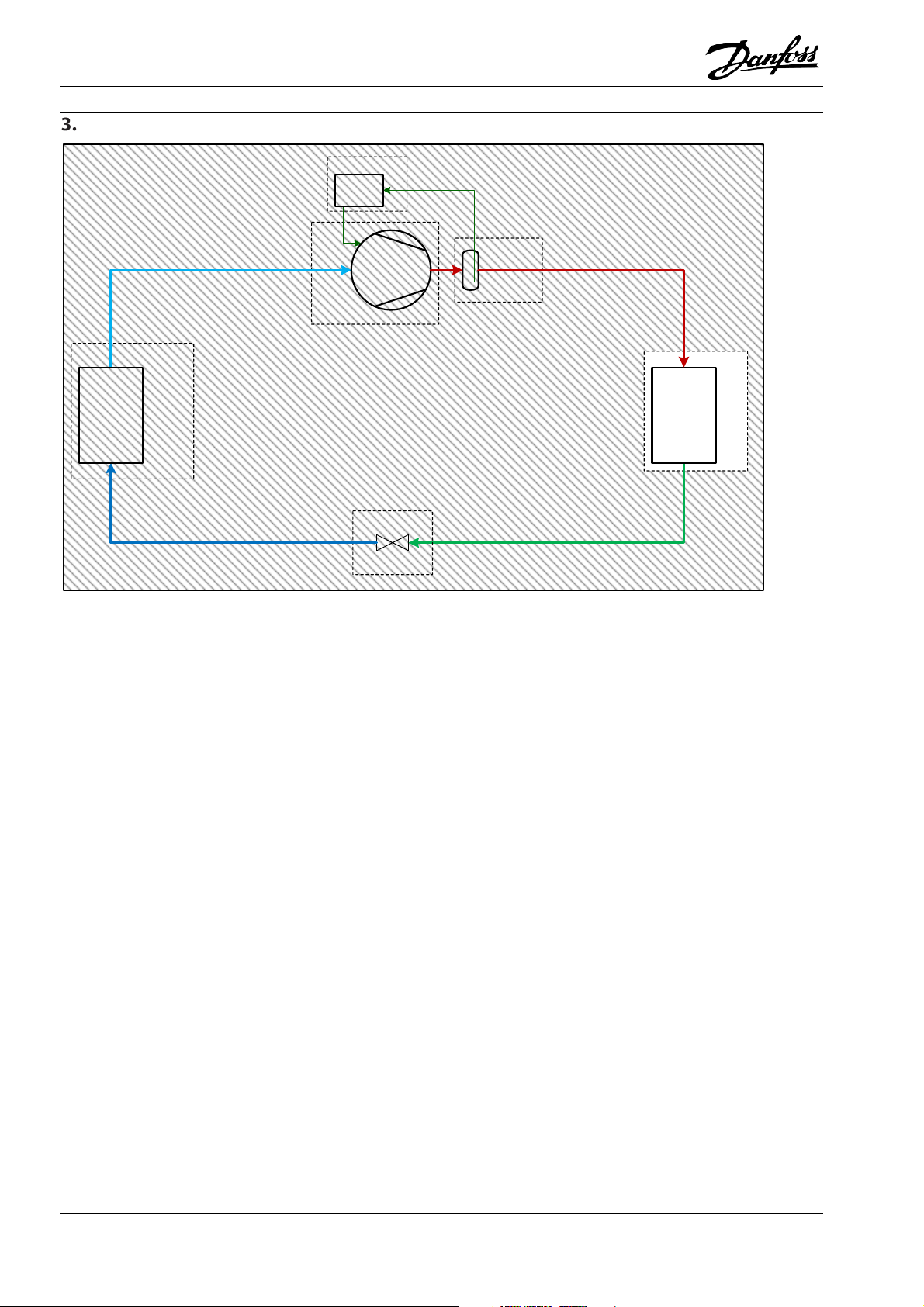

1.3 One-stage systems

One-stage or single-stage refrigeration systems are

refrigeration systems where the compression from

low pressure to high pressure is done in one stage. A

one-stage refrigeration system with the most basic

components is shown in

Figure 1.4.

Neither the evaporator nor the condenser is specified as a specific type, but rather represent the general concept of evaporation and condensation. Both

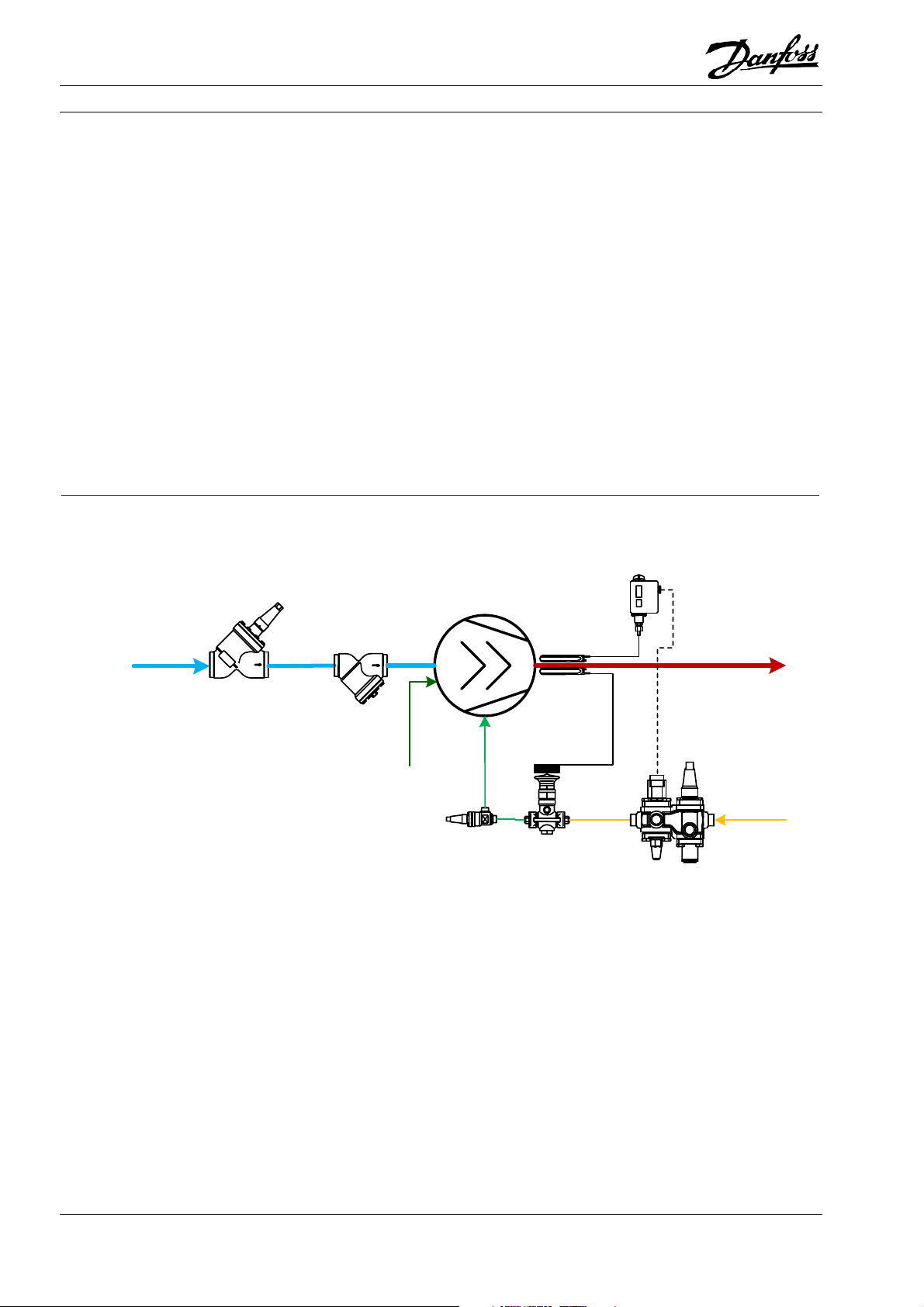

Figure 1.4: System diagram for a one-stage system

Oil Cooler

1 2

can be constructed and controlled in a number of

ways. A log(p)-h diagram for a one-stage system can

be seen in Figure 1.1. The numbers shown in

Figure 1.4 corresponds to the numbers shown for

the state points in the log(p)-h diagram.

Oil Separator

Compressor

Evaporator

4

Expansion valve

3

Condenser

8 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 11

Application Handbook Industrial Refrigeration ammonia and CO2 applications

1.4 Two-stage/multistage systems

A two-stage or multistage refrigeration systems are

refrigeration systems with two or more stages of vapour compression.

Industrial two-stage refrigeration systems usually

have inter-stage cooling between compression

stages to cool the discharge gas from the first compression stage.

By cooling the discharge gas from the low-pressure

compressor, excessively high discharge temperatures from the high-pressure compressor are

avoided. The cooling in the inter-stage cooler is supplied by expanding some of the liquid refrigerant

from the condenser to the intermediate pressure,

where some of it evaporates in the process of cooling the LP compressor discharge gas. The gas mixed

from cooled LP compressor discharge gas, refrigerant flashed and refrigerant evaporated is passed to

the HP compressor.

Two or more stages of vapour compression are used

when there is a large difference between the evaporating and condensing temperature, which often results in compression ratios that are too high for the

compressors or results in other undesirable operat-

ing conditions. Additionally, the desire for another

temperature level or efficiency considerations may

result in a two-stage system being chosen over a sin-

gle stage.

It is therefore suitable to have two or more stages of

compression to have the compressors operating at

their optimal compression ratio, and within their op-

eration limits.

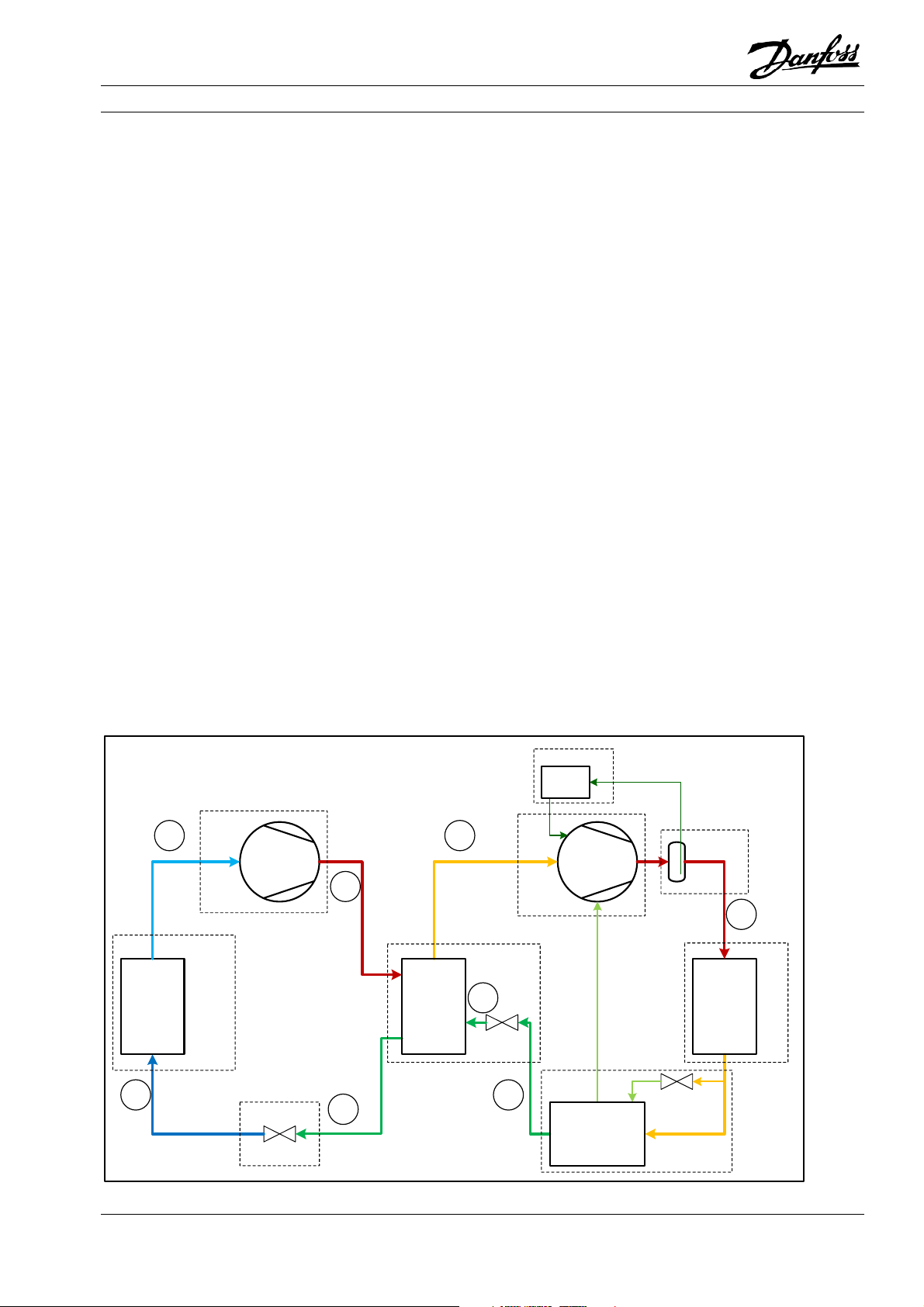

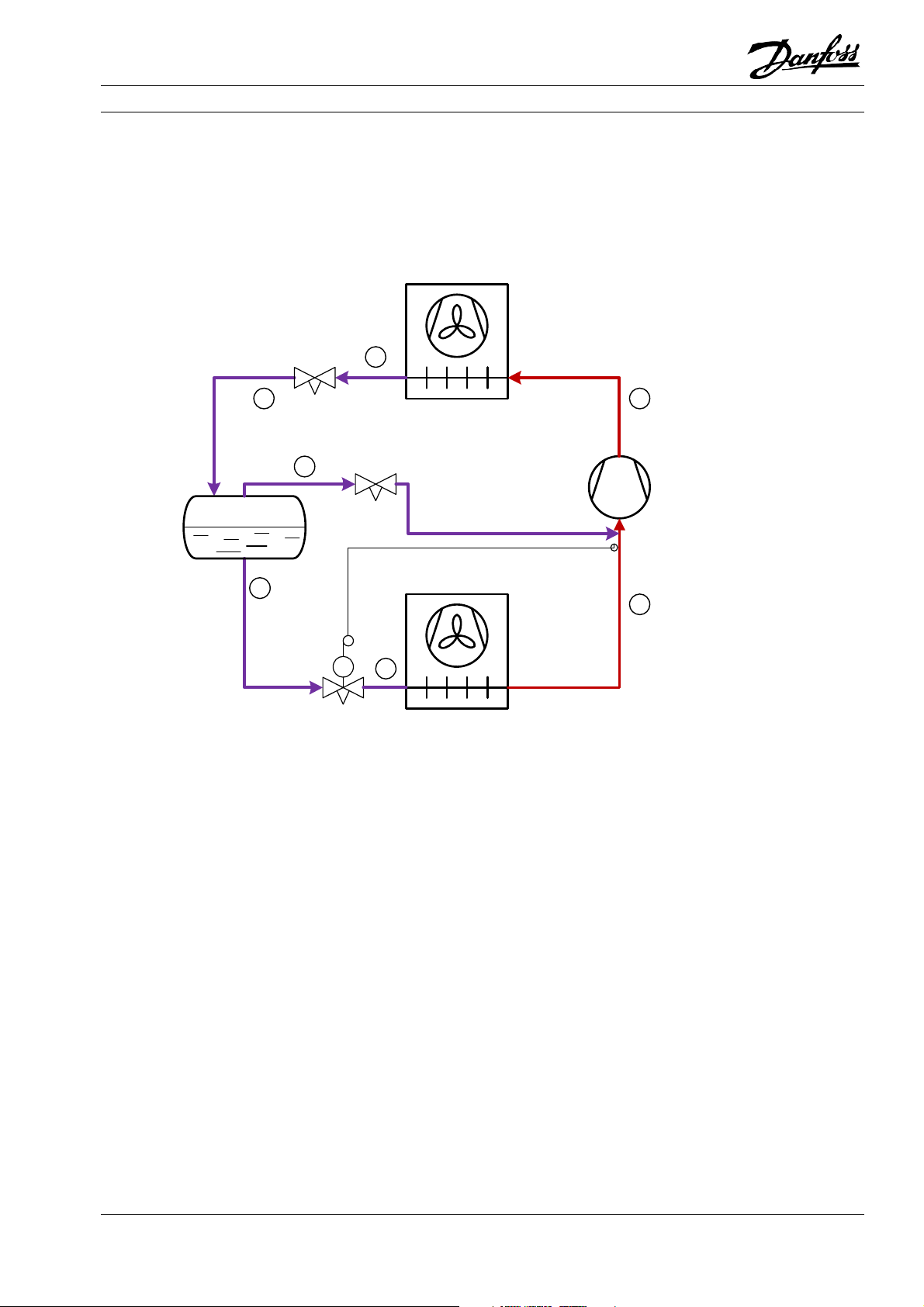

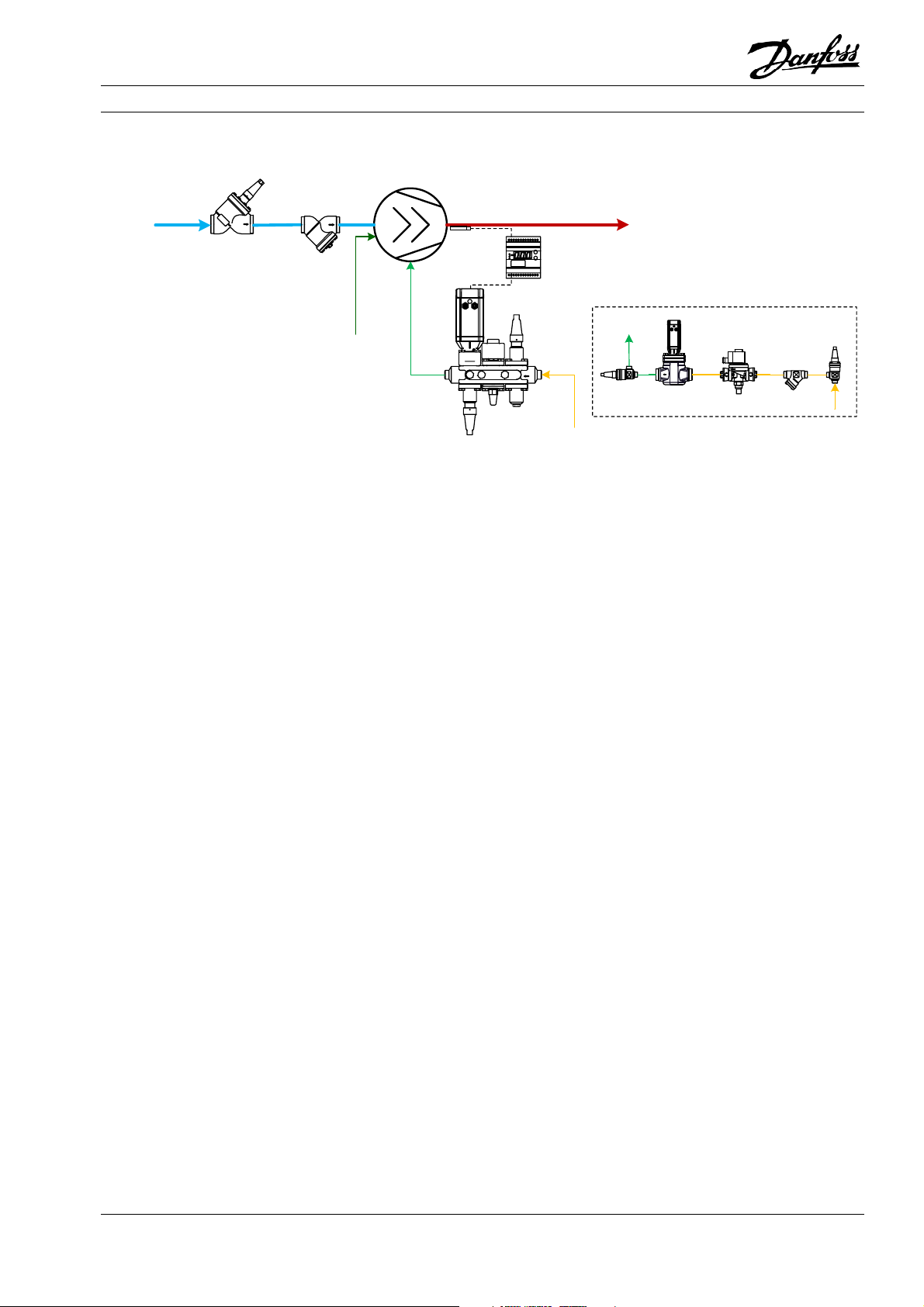

A system sketch of a two-stage refrigeration system

is shown in Figure 1.5. The figure is shown with an

inter-stage cooler and economiser. An economiser

like the one shown in the system diagram is used for

subcooling the refrigerant after the condenser by by-

passing and flashing some refrigerant. The bypassed

refrigerant is evaporated and fed to an economiser

port in the high-pressure compressor which can in-

crease the capacity and/or the efficiency of the sys-

tem. The LP compressor may also have an econo-

miser, but it is not shown here.

Figure 1.5: System diagram for two-stage system

LP Compressor

1

2

Evaporator

8

Expansion valve

7

3

HP Compressor

Inter-stage coole r

6

5

Oil Cooler

Oil Separator

4

Condenser

Economizer

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 9

Page 12

Application Handbook Industrial Refrigeration ammonia and CO2 applications

A log(p)-h diagram for the two-stage system is

shown in Figure 1.6. The numbering in Figure 1.5 follows the numbering of the state points shown in the

log(p)-h diagram. It should be noted that the evaporation temperature is -30°C and the condensation

temperature is kept at 35°C, as for the example for

the one-stage system. It should be noted how the in-

temperature from the high-pressure compression

stage. If no inter-stage cooling was used, the line (1)

to (2) would be extended and end on the same horizontal level as (4), but shifted to the right, thus increasing the discharge temperature to around

160°C, which is not acceptable (primarily for oil considerations).

ter-stage cooler helps to keep a low discharge gas

Figure 1.6: Log(p)-h diagram for two-stage ammonia system

(5)

(4)

(7)

(8)

(2)

(6)

(3)

(1)

10 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 13

Application Handbook Industrial Refrigeration ammonia and CO2 applications

In the above Log(P)-H diagram, the economiser is

not shown. The economiser port is a port in screw

compressors that allows access to the compression

chamber after the suction port has closed. As such, if

a high enough pressure is applied to the economiser

port, an additional refrigerant flow can be added to

This is utilised with the economiser, which is a heat

exchanger that further cools the liquid from the con-

denser. To do this, a little of the condenser liquid

flow is flashed to a lower pressure/temperature,

where it is evaporated to cool the remaining liquid.

That modifies the Log(P)-H diagram a little:

the compressor without affecting the suction flow.

Figure 1.7: Log(p)-h diagram for two-stage ammonia system with economizer on the high stage

Low-stage compression from (1) to (2), de-superheating in the inter-stage cooler from (2) to (3) and

initial high-stage compression from (3) to (4) is the

same as in the non-economized system. The discharge from the high-stage compressor (6) is condensed from (6) to (7) as before. After the condenser

(7), a small amount of refrigerant is flashed to a

lower temperature (8), where it is evaporated and

added to the partially compressed suction gas of the

high-stage compressor. The resulting mixture is (5),

which is compressed together to the final discharge

the remaining liquid from (7) to (9). It is noteworthy

that the liquid flashed to the intermediate tempera-

ture is further to the left than it would have been

without the economizer, thus the enthalpy differ-

ence from (10) to (3) is bigger and that increases the

compressor’s cooling capacity. The power consump-

tion is increased as well, because there is an addi-

tional mass flow that needs to be compressed, but

the overall effect – depending on the operating con-

ditions – is a higher cooling capacity and, usually, a

higher COP.

at (6). The evaporative capacity is used to sub-cool

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 11

Page 14

Application Handbook Industrial Refrigeration ammonia and CO2 applications

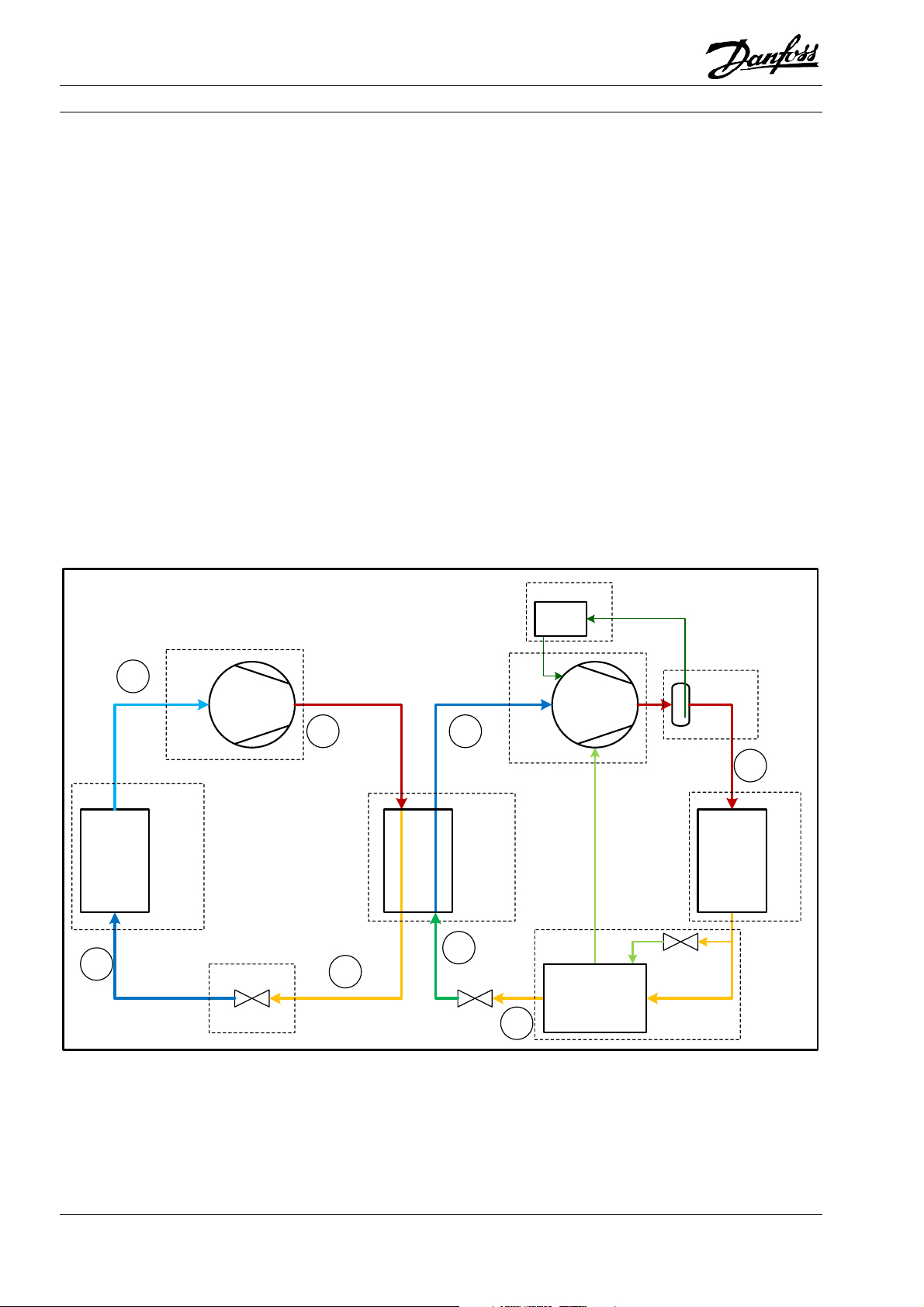

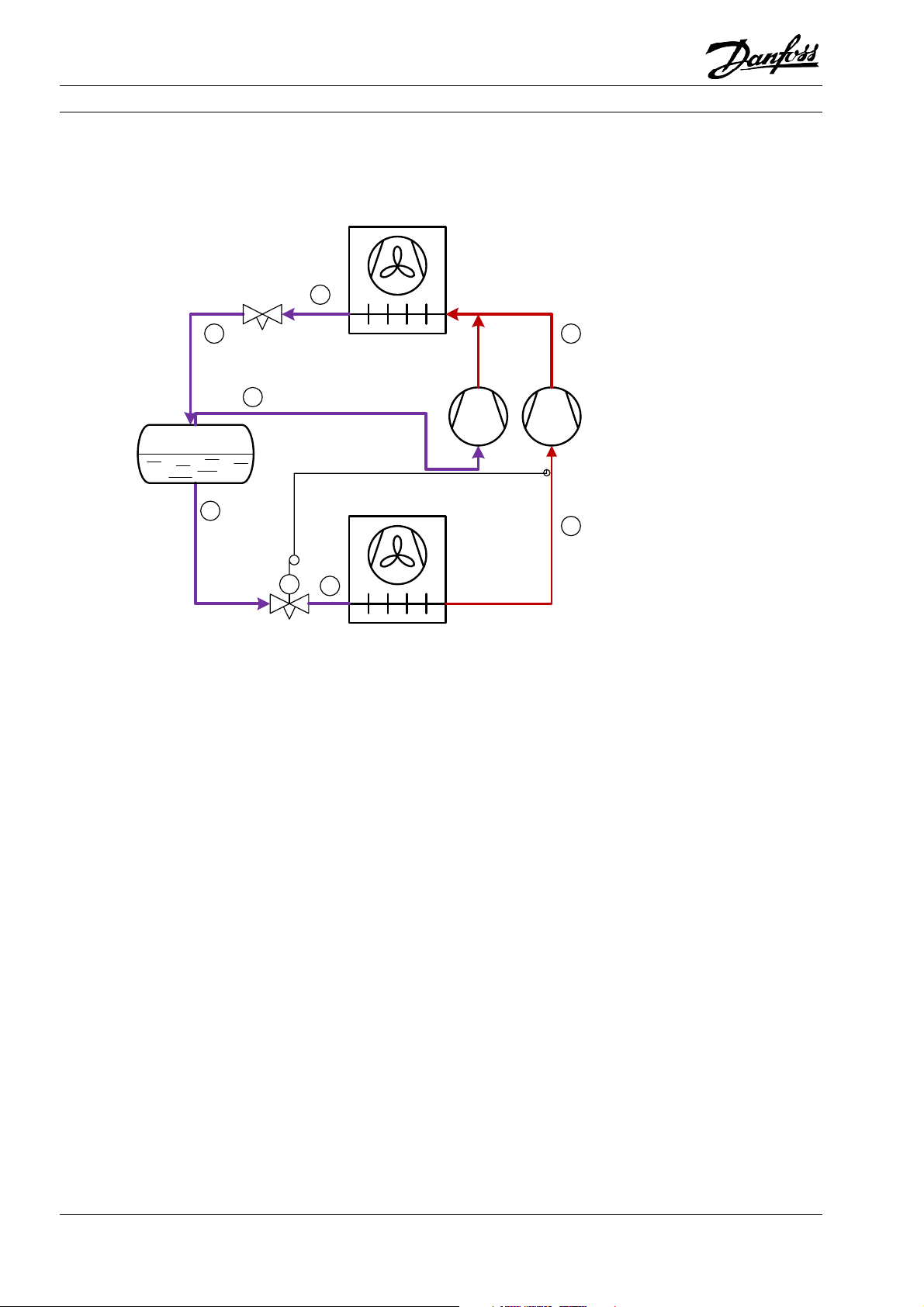

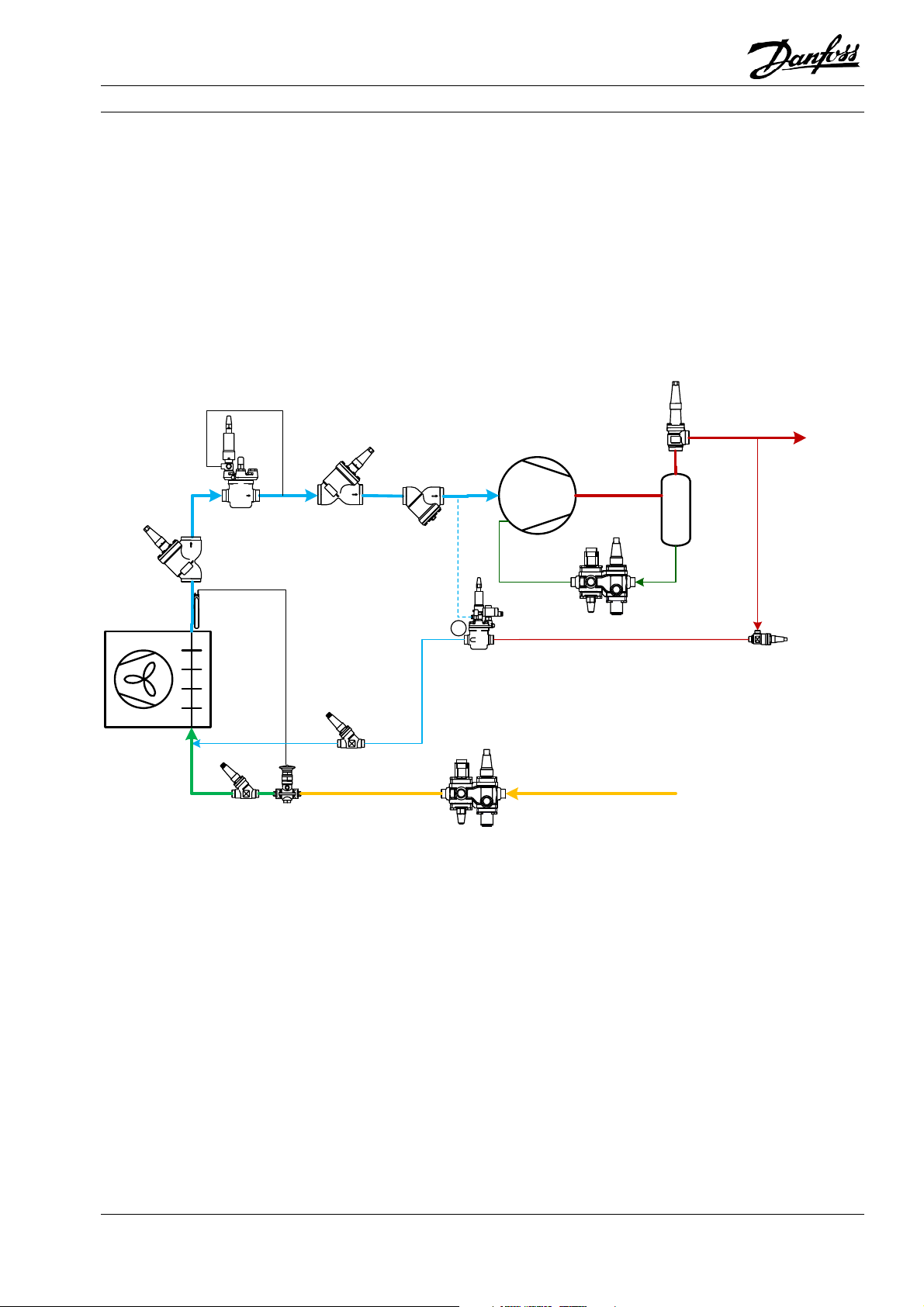

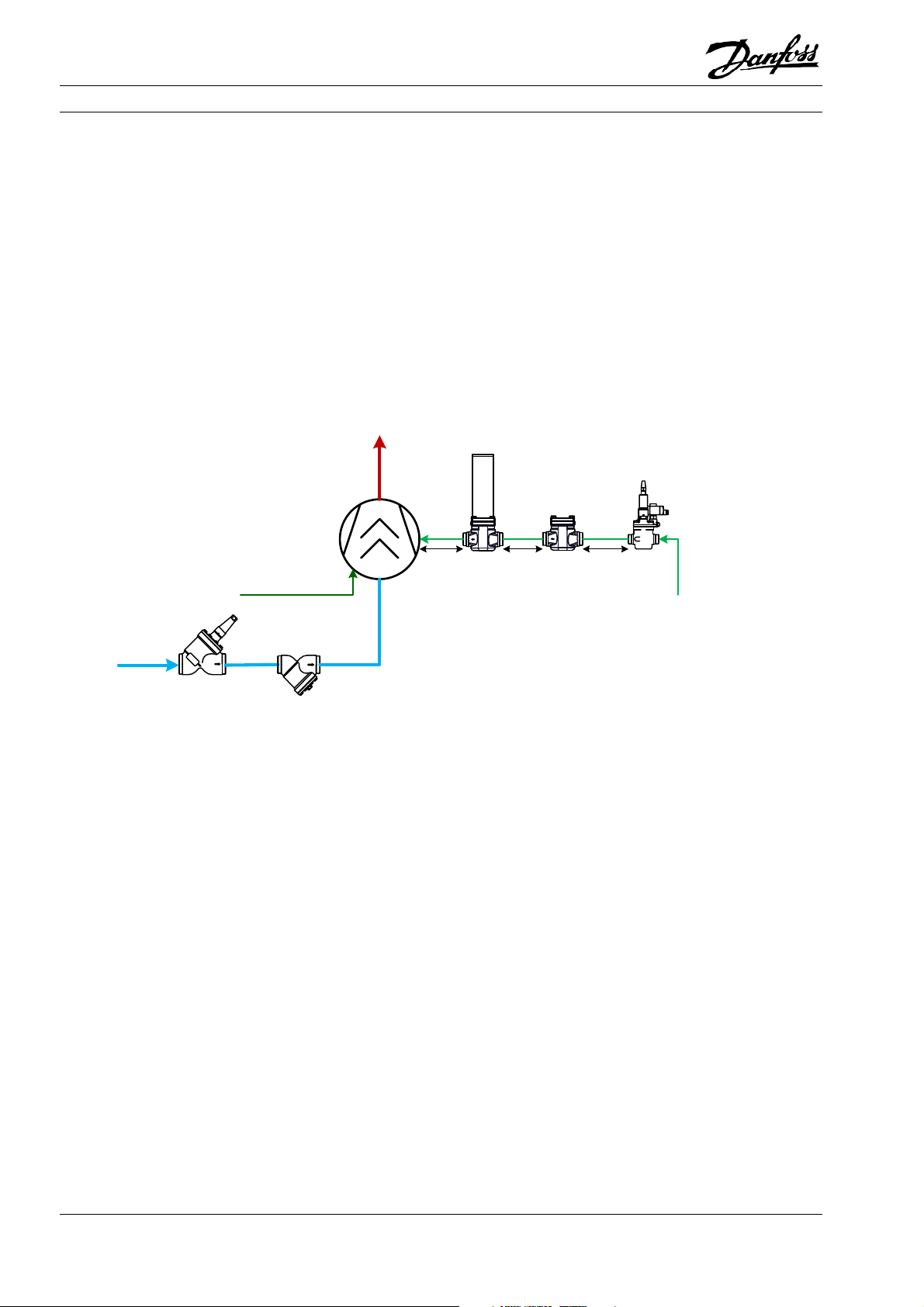

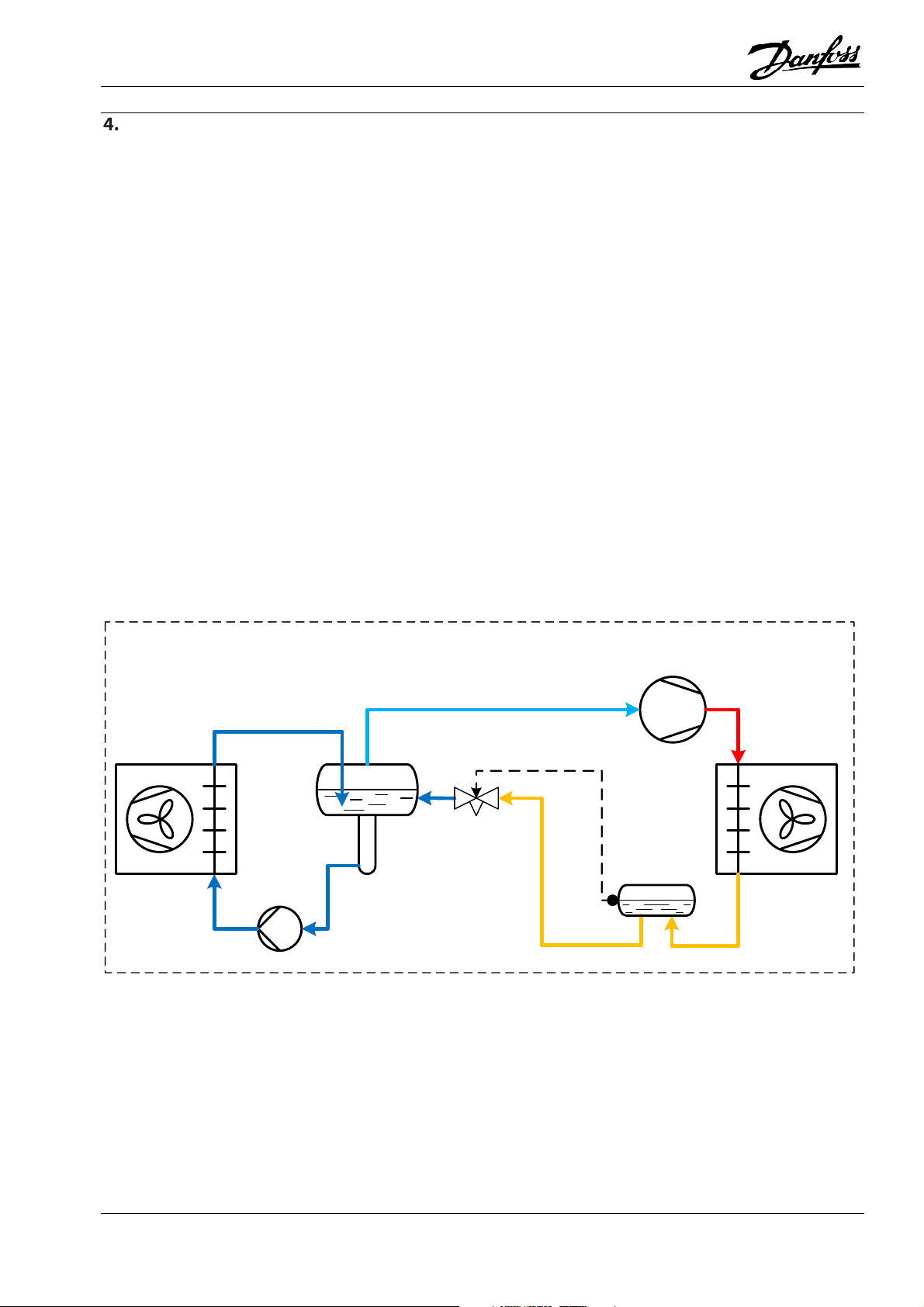

1.5 Cascade systems

A cascade system consists of two separate refrigeration circuits. The separate refrigeration circuits are

connected by a heat exchanger, which acts as a condenser for the low-temperature circuit and an evaporator for the high-temperature circuit.

The refrigerants for the two circuits can be different

and optimised for each circuit. For example, the refrigerant for the high-temperature circuit could be

ammonia, and the refrigerant for the low-temperature circuit could be CO2.

A CO2/ammonia system needs a smaller charge of

ammonia and proves to be more efficient in lowtemperature refrigeration than a similar two-stage

ammonia system.

Figure 1.8: Cascade system diagram

A system diagram for a cascade system is shown in

Figure 1.8. The cascade system diagram is somewhat

similar to the two-stage system, where the interstage cooler is replaced by a cascade cooler, thus

making two closed cycles. A cascade system is usually more complex than a two-stage system, but it

offers some benefits. CO2 is very efficient down to

very low evaporating temperatures where ammonia‘s efficiency drops, while ammonia can condense

at relatively low pressure against warm ambient

temperatures, where CO2 has to go transcritical

where the efficiency drops. So, choosing CO2 in the

LP circuit and ammonia in the HP circuit allows for

the best of both worlds.

Oil Cooler

LP Compressor

1

2

Evaporator

4

Expansi on valve

3

5

HP Compressor

Cascade cooler

8

7

Oil Separator

6

Condenser

Economizer

12 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 15

Application Handbook Industrial Refrigeration ammonia and CO2 applications

1.6 Transcritical systems

The properties of CO2 make it necessary to operate

the system in a different way. The ‘critical point’ –

the top of the bell-shaped two-phase area – is at

31°C / 72.8 bara. In areas/periods where the ambient temperature is low, CO2 can be operated with

condensing below the critical point. In that case the

cycle is, in principle, the same as for other refrigerants (different pressures and enthalpies), but if the

ambient temperature is relatively high, it is no

longer possible to condense in the traditional way.

Figure 1.9: Log(p)-h diagram for transcritical CO2 system

Above the critical point, the refrigerant is called a

transcritical fluid. The transcritical fluid does not

condense, but rather displays a gradual change of

density as it is cooled. In a traditional condensing

process, the condensing temperature defines the

pressure, but in the transcritical fluid there is no

such connection. Thus, the gas cooling pressure

(equal to compressor discharge pressure) needs to

be controlled.

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 13

Page 16

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Evaporation takes place from (4) to (1) and

compression from (1) to (2) as in other refrigeration

systems. From (2) to (3) is the ‘gas cooling’ process

that replaces the condensing process. Point (3) is

defined by the outlet temperature of the gas cooler

– here set to 40°C – and the pressure that is

controlled by the expansion device that expands to

(4). The actual pressure in the gas cooler is based on

an analysis of the cycle. Consider a case where the

gas cooler outlet is at 40°C, but different pressures

are controlled. The corresponding cycles are as

shown below:

Figure 1.10: Log(p)-h diagram for a transcritical CO2 system at different gas cooler pressures

The cooling capacity of the system is the enthalpy

difference between points (1) and (4) multiplied by

the mass flow. The necessary compression power is

the enthalpy difference between points (2) and (1)

(horizontally) multiplied by the mass flow. The COP

of the system is thus (H1-H4)/(H2-H1), which is independent of the mass flow. It can be seen that if the

pressure is varied up (red) or down (blue), both the

cooling capacity and power consumption change.

Calculating the COP along the (red) temperature

curve, it can be found to have a maximum at a specific pressure, which for 40°C works out to be 102.4

bar. Mapping this maximum COP across different gas

cooler exit temperatures has resulted in a curve that

expresses the best pressure for a given gas cooler

exit temperature. This curve has been implemented

in the Danfoss EKC 326 controller.

Controlling the gas cooler pressure with the expansion device results in a problem. Since it is intended

that the low-pressure side be supplied with the right

amount of liquid – especially with DX operation of

the low-pressure evaporators – it is simply not possible to have an expansion valve serve both purposes

at once.

14 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 17

Application Handbook Industrial Refrigeration ammonia and CO2 applications

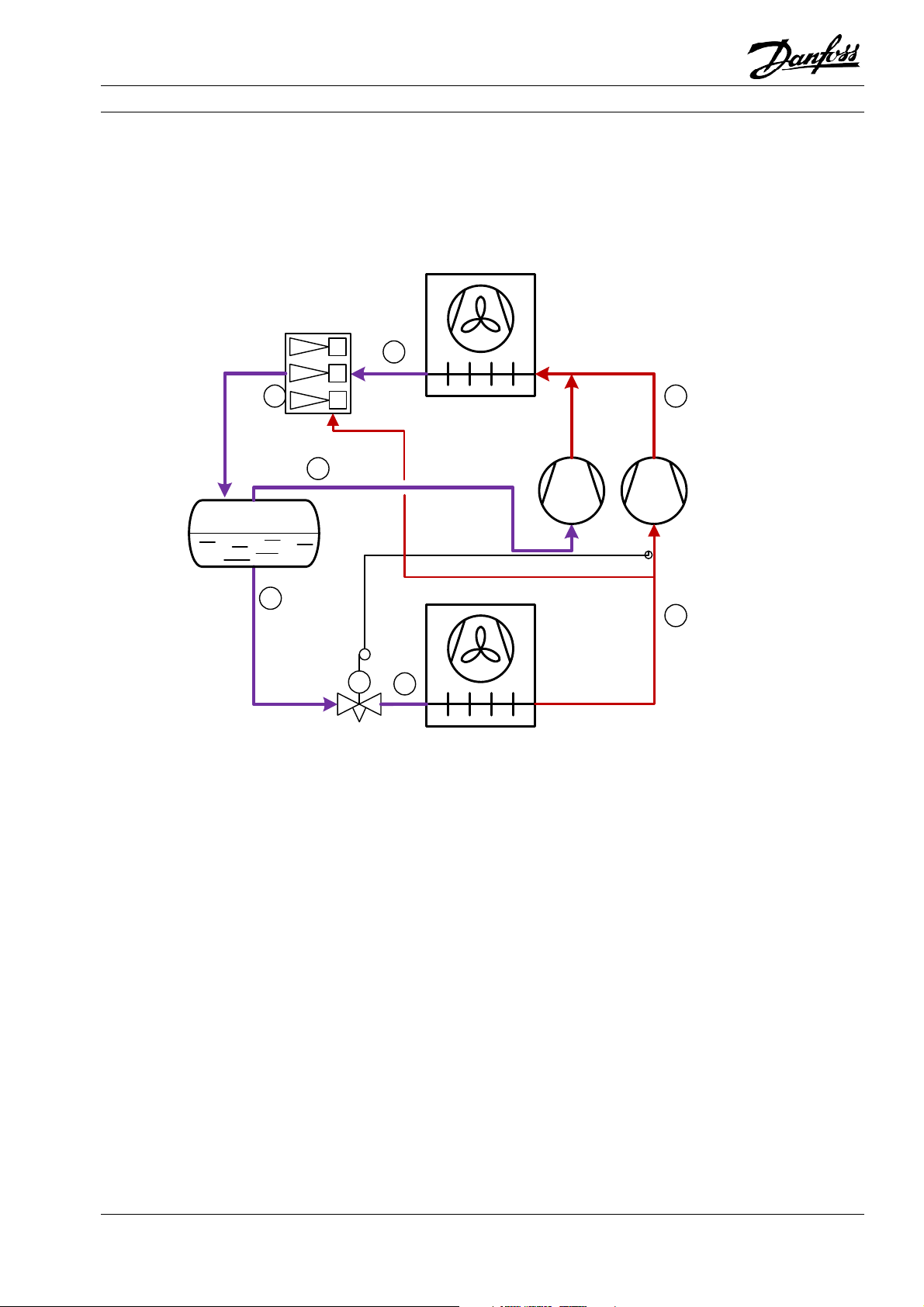

The solution is to make an intermediate stop in the

form of a receiver. The transcritical fluid is flashed

from the gas cooler exit through the high-pressure

valve into the receiver. In the receiver, the gas and

the evaporators as necessary, while the gas part is

reduced in pressure and fed to the compressor’s suc-

tion line, thereby controlling the pressure in the re-

ceiver.

liquid part is separated, the liquid part is flashed to

Figure 1.11: Transcritical CO2 system with intermediate pressure receiver

3

4

5

Receiver

Gas cooler

2

6

1

TC

7

Figure 1.12: Log(p)-h diagram for a transcritical CO2 system with intermediate pressure receiver

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 15

Page 18

Application Handbook Industrial Refrigeration ammonia and CO2 applications

This process can be optimised. The gas from the receiver is reduced in pressure to the compressor suction, however it is possible to take advantage of the

compressor to compress this gas to gas cooler pressure with a higher efficiency due to the higher suc-

tion pressure. This is called parallel compression.

higher pressure in the receiver to employ another

Figure 1.13: Transcritical CO2 system with parallel compression

3

4

5

Receiver

6

Gas cooler

2

1

TC

7

Figure 1.14: log(P)-h diagram for a transcritical CO2 system with parallel compression

16 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 19

Application Handbook Industrial Refrigeration ammonia and CO2 applications

One further optimisation for CO2 transcritical systems is the use of ejectors. Ejectors utilise the power

in the expansion from gas cooler pressure to lift a

gas flow to a higher pressure. One of several differ-

ent ways of employing this is to lift part of the suction gas from the low-stage compressor to the suction of the parallel compressor, resulting in an efficiency gain.

Figure 1.15: Transcritical CO2 system with parallel compression and gas ejectors

3

4

5

Receiver

Gas cooler

2

6

1

TC

7

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 17

Page 20

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Compressor controls

Oil Cooler

Oil Separator

Compressor

Evaporator

Expansion valve

The compressor is the “heart” of the refrigeration

system. It has two basic functions:

Maintain the pressure in the evaporator so that the

liquid refrigerant can evaporate at the required temperature.

Compress the refrigerant so that it can be condensed at a higher temperature.

Condenser

If the compressor capacity is greater than the de-

mand, the evaporating pressure and temperature

will be lower than that required, and vice versa.

Additionally, the compressor should not be allowed

to operate outside of the approved operation enve-

lope for the mechanical safety of the compressor

and operational safety of the entire system.

The basic function of compressor control, therefore,

is to adjust the capacity of the compressor to the actual demand of the refrigeration system so that the

required evaporating temperature can be maintained.

18 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 21

Application Handbook Industrial Refrigeration ammonia and CO2 applications

2.1 Reverse flow control

Reverse flow and condensation of refrigerant during

stand-still from the condenser to the oil separator

and the compressor should be avoided at all times.

For piston compressors, reverse flow can result in

liquid hammering. For screw compressors, reverse

Application Example 2.1.1: Reverse flow control

RT 1A RT 5A

Compressor

From evaporator/

liquid separator

SVA

FIA

flow can cause reversed rotation and damage to the

compressor bearings. To avoid this reverse flow, it is

necessary to install a check valve on the outlet of the

oil separator.

SCA

To condenser

Oil

Separator

ICFS

ICFE

The stop check valve SCA can function as a check

valve when the system is running and can also shut

off the discharge line for service as a stop valve. This

combined stop/check valve solution is easier to install and has lower flow resistance compared to a

normal stop valve plus check valve installation.

When selecting a stop check valve, it is important to:

Select a valve according to the capacity and not the

pipe size.

Consider both the nominal and part-load working

conditions. The velocity in the nominal condition

should be close to the recommended value, while at

the same time, the velocity in the part-load condition should be higher than the minimum recommended velocity.

ICFF

ICFO

ICF

Pressure switches RT 1A and RT 5A are shown in the

suction line and discharge line of the compressor. It

is important to have pressure switches to cut-out or

cut-in operation if the pressure fluctuates outside

the operational range in the suction and discharge

line. Not all compressors are delivered with built-in

controls and safety switches, therefore the RT 1A

and RT 5A are shown. The pressure switches are not

shown for all application examples, but they should

always be present in the system. Often these

switches are part of the compressor package.

For details on how to select valves, please refer to

the product catalogue and use the Danfoss software

tool Coolselector2 for sizing the valve according to

the system capacity.

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 19

Page 22

Application Handbook Industrial Refrigeration ammonia and CO2 applications

2.2 Suction pressure control

During start-up or after defrosting, the suction pressure needs to be controlled, otherwise it may be too

high, and the compressor motor will be overloaded.

The electric motor for the compressor may be damaged by this overloading.

There are two ways to overcome this problem:

Start the compressor at part load. The capacity control methods can be used to start the compressor at

part load, e.g. unload part of the pistons for multi-

Application example 2.2.1: Crankcase pressure control

CVC

piston reciprocating compressors, or bypass some

suction gas for screw compressors with slide valves,

etc.

Control the suction pressure for reciprocating com-

pressors. By installing a back pressure-controlled

regulating valve in the suction line, which will not

open until the pressure in the suction line drops be-

low the set value, suction pressure can be kept un-

der a certain level.

SCA

To condenser

Compressor

From evaporator/

liquid separator

ICS

SVA

In order to control the suction pressure during startup, after defrosting, or in other cases when the suction pressure may be too high, the pilot-operated

servo valve (ICS) with the back pressure controlled

pilot valve (CVC) is installed in the suction line. The

Oil

Separator

FIA

ICFS

ICFE

ICFF

ICFO

ICF

ICS will not open until the downstream suction pres-

sure falls below the set value of the pilot valve (CVC).

In this way, the high-pressure vapour in the suction

line can be released into the compressor gradually,

which ensures a manageable capacity for the com-

pressor motor.

20 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 23

Application Handbook Industrial Refrigeration ammonia and CO2 applications

2.3 Compressor capacity control

The compressor in a refrigeration system is normally

selected to be able to satisfy the highest possible

cooling load. However, the cooling load during normal operation is usually lower than the design cooling load. This means that it is always necessary to

control the compressor capacity so that it matches

the actual cooling load. There are several common

ways to control the compressor capacity:

2.3.1 Step control

This means to unload cylinders in a multi-cylinder

compressor, to open and close the suction ports of a

screw compressor, or to start and stop some compressors in a multi-compressor system. This system

is simple and convenient. Furthermore, efficiency

decreases very little during part-load by step control,

although this regulation is by nature coarser than

many other regulation types. It is especially applicable to systems with several multi-cylinder reciprocating compressors.

2.3.2 Slide valve control

The most common device used to control the capacity of a screw compressor is the slide valve. The action of the oil-driven slide valve allows part of the

suction gas to avoid being compressed. The slide

valve permits a smooth and continuous modulation

of capacity from 100% down to 10%, but the efficiency drops at part load, usually quite significantly.

2.3.3 Variable speed control

This solution is applicable to all kinds of compressors

and is efficient. A two-speed electric motor or a frequency converter can be used to vary the speed of

the compressor. The two-speed electric motor regulates the compressor capacity by running at the high

speed when the cooling load is high (e.g. cooling

down period) and at the low speed when the cooling

load is low (e.g. storage period). The frequency converter can vary the rotation speed continuously to

satisfy the actual demand. The frequency converter

observes limits for min. and max. speed, temperature and pressure control, protection of compressor

motor as well as current and torque limits. Frequency converters offer a low start-up current. Variable speed control usually has little impact on the efficiency of the compressor and is thus a very popular

control. In some cases, the range of allowed RPM of

the compressor is not enough to cover the desired

range of capacities, so often variable speed control is

combined with step control.

2.3.4 Hot gas bypass

This solution is applicable to compressors with fixed

capacities and more typical for commercial refrigeration. In industrial refrigeration systems it is used as a

safety measure to avoid an excessively low suction

pressure when there is a sudden drop in cooling

load. To control the refrigeration capacity, part of

the hot gas flow in the discharge line is bypassed

into the low-pressure circuit. This works as a fast response to a sudden drop in cooling load, thus adding

extra cooling load to the system when the compressor is ramping down. This generally decreases the efficiency of the system.

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 21

Page 24

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Application example 2.3.1: Step control of compressor capacity

Compressor

pack

EKC 331

AKS 33

FIA

From evaporator/

liquid separator

SVA

A step control solution for compressor capacity can

be achieved by using a step controller, e.g. Danfoss

EKC 331. EKC 331 is a four-step controller with up to

four relay outputs. It controls the loading/unloading

of the compressors/pistons or the electric motor of

the compressor according to the suction pressure

SCA

To condenser

Oil

Separator

ICFO

ICFE

SCA

SCA

ICFS

ICFF

ICF

signal from a pressure transmitter, e.g. Danfoss AKS

33. Based on a neutral zone control, EKC 331 can

control a pack system with up to four equally sized

compressor steps or, alternatively, two capacity-con-

trolled compressors (each with one unload valve).

Application example 2.3.2: Variable speed capacity control

VLT

Controller

AKS 33

FIA

From evaporator/

liquid separator

22 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

SVA

M

Compressor

SVA

To oil separator

Page 25

Application Handbook Industrial Refrigeration ammonia and CO2 applications

The VLT frequency converter is controlled by a controller module that adjusts the control signal to the

converter from an input signal from a pressure

transmitter, e.g. AKS 33. The controller module can

be either a Danfoss AK-CC or a PLC/OEM module.

The VLT frequency converter can also receive the

signal from the pressure transmitter and work without a separate controller.

Application example 2.3.3: Hot gas bypass

CVC

ICS

SVA

SVA

FIA

Frequency converter control offer the following advantages:

Energy savings

Improved control and product quality

Noise reduction

Longer lifetime

Simplified installation

Easy-to-use complete control of the system

SCA

Compressor

ICFS

ICFE

CVC

EVM

1

ICFO

ICFF

ICF

To condenser

Oil

Separator

SVA

Evaporator

SVA

TEA

ICFE

ICFO

Hot gas bypass can be used in specific cases to compensate for a suddenly reduced cooling load. Normally in industrial refrigeration plants, the compressors will be speed controlled or step controlled.

These controls can, however, be too slow in reacting

in cases where there is a sudden drop in cooling

load. This sudden drop will initially cause the compressor to decrease the suction pressure. Hot gas bypass can be used as a fast response to a sudden decrease in cooling load, which will prevent the suction

pressure from dropping too low. The hot gas is bypassed to the evaporator until the compressor has

ramped down to match the reduced cooling load.

ICS SVA

ICFS

From receiver

ICFF

ICF

Hot gas bypass is energy inefficient and should not

be used as a primary solution to “control” the compressor, but rather as a safety measure to avoid excessively low suction pressure.

The pilot-operated servo valve ICS (1) with a CVC pilot valve is used to control the hot gas bypass flow

according to the pressure on the suction line. The

CVC is a back-pressure controlled pilot valve which

opens the ICS (1) and increases the flow of hot gas

when the suction pressure is below the set value. In

this way, the suction pressure ahead of the compressor is kept constant, and thus the refrigeration capacity satisfies the actual cooling load.

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 23

Page 26

Application Handbook Industrial Refrigeration ammonia and CO2 applications

2.4 Discharge Temperature Control with Liquid Injection

Compressor manufacturers generally recommend

limiting the discharge temperature below a certain

value to prevent overheating of the compressor and

its parts, prolonging their life and preventing the

breakdown of oil at high temperatures.

There are several ways to reduce the discharge tem-

perature. One way is to install water-cooled heads in

reciprocating compressors. Another method is liquid

injection, which involves liquid refrigerant from the

outlet of the condenser or receiver being injected

into the suction line, the intermediate cooler beReferring to the log p-h diagram in chapter 1, it can

be seen that the discharge temperature may be high

tween compressors, or the side port of the screw

compressor.

when:

the compressor runs with high pressure differential.

the compressor receives highly superheated suction

vapour.

the compressor runs with capacity control by hot gas

bypass.

Application example 2.4.1: Liquid injection with thermostatic injection valve

Screw compressor

RT 107

From evaporator/

liquid separator

SVA

FIA

Oil injection

When the discharge temperature rises above the set

value of the thermostat RT 107, RT 107 will energize

the solenoid valve ICFE which will start liquid injection into the side port of the screw compressor. The

To oil

Separator

ICFS

ICFE

SVA

TEAT

ICFO

ICFF

From

receiver

ICF

thermostatic injection valve (TEAT) controls the in-

jected liquid flow according to the discharge temper-

ature, which prevents the discharge temperature

from rising further.

24 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 27

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Application example 2.4.2: Liquid injection with motor valve

Screw compressor

To oil

Separator

From evaporator/

liquid separator

SVA

FIA

AKS 21

EKC 361

ICAD

Oil injection

ICM

An electronic solution for liquid injection control can

be achieved with the motorized valve ICM. An AKS

21 temperature sensor will register the discharge

temperature and transmit the signal to the temperature controller EKC 361.

ICFS

ICFO

ICFE

ICF

ICFS

ICFF

From

receiver

SVA

ICAD

ICM

Single component solution

EVRA

The EKC 361 controls the ICAD actuator which adjusts the opening degree of the ICM motor valve in

order to limit and maintain the required discharge

temperature.

SVA

FIA

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 25

Page 28

Application Handbook Industrial Refrigeration ammonia and CO2 applications

2.5 Economizer damper

An economizer is used to increase system capacity

and efficiency.

Pulsations need to be dampened to avoid compo-

nent damage. Correct and well considered dimen-

sioning of economizer lines is necessary to reduce

However, pulsations from the compressor are trans-

ferred into the economizer line which damages components and leads to valve chattering. The pulsations will lead to increased maintenance costs and

downtime if they are not taken care of.

pulsations. The Danfoss Eco-Damper combines three

components into a high-impact solution which re-

duces pulsations significantly and ensures high oper-

ational reliability thanks to its solid design. The

Danfoss Eco-Damper is based on the Danfoss ICV

platform.

Application example 2.5.1: Economizer line pulsation damping solution

To oil

Separator

Screw compressor

Max 150 mm

Oil injection

Max 150 mm Max 150 mm

ICD ICC

EVMCVP

ICS

From economizer

vessel

From evaporator/

liquid separator

SVA

FIA

The Danfoss Eco-damper solution consists of 3 components. The Eco-damper (ICD), the Eco-check valve

(ICC) and a standard control valve, e.g. an ICS servo

valve with CVP, constant pressure pilot valve, and

the EVM solenoid valve. The combination shown in

the application example can dampen the pulsations

by up to 80% and prevent premature failure of economizer components and reduce system downtime.

The Eco-damper solution unit has a unique broadband damping effect in the 100-500 Hz working

range.

Support on pipe segments is essential to reduce the

pulsations and thus reduce vibrations induced by the

pulsations. Therefore, each pipe segment between

the components in the Eco-damper solution must be

fixed to a pipe support element which can absorb

the pulsations. The tube on the Eco-damper (ICD)

must also be fixed to a pipe support element that

can absorb the pulsations.

The ICD Eco-damper comes with an integrated

strainer, and is applicable for ammonia systems,

along with R134a and R407C systems.

The ICC Eco-check valve has a solid design and is fully

opening at low differential pressure to prevent oscil-

lating movements. The ICC Eco-check valve is appli-

cable for ammonia, CO2 and HFC systems.

For less severe or occasional pulsation issues, the ro-

bust Eco-check valve (ICC) and the control valve can

be used without an Eco-damper (ICD). Note! In this

case, the pulsations from the compressor eco-port

will not be damped.

It is recommended to have a maximum pipe length

of 150 mm between the individual components and

between the ICD and the economizer port in the

compressor.

26 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 29

Application Handbook Industrial Refrigeration ammonia and CO2 applications

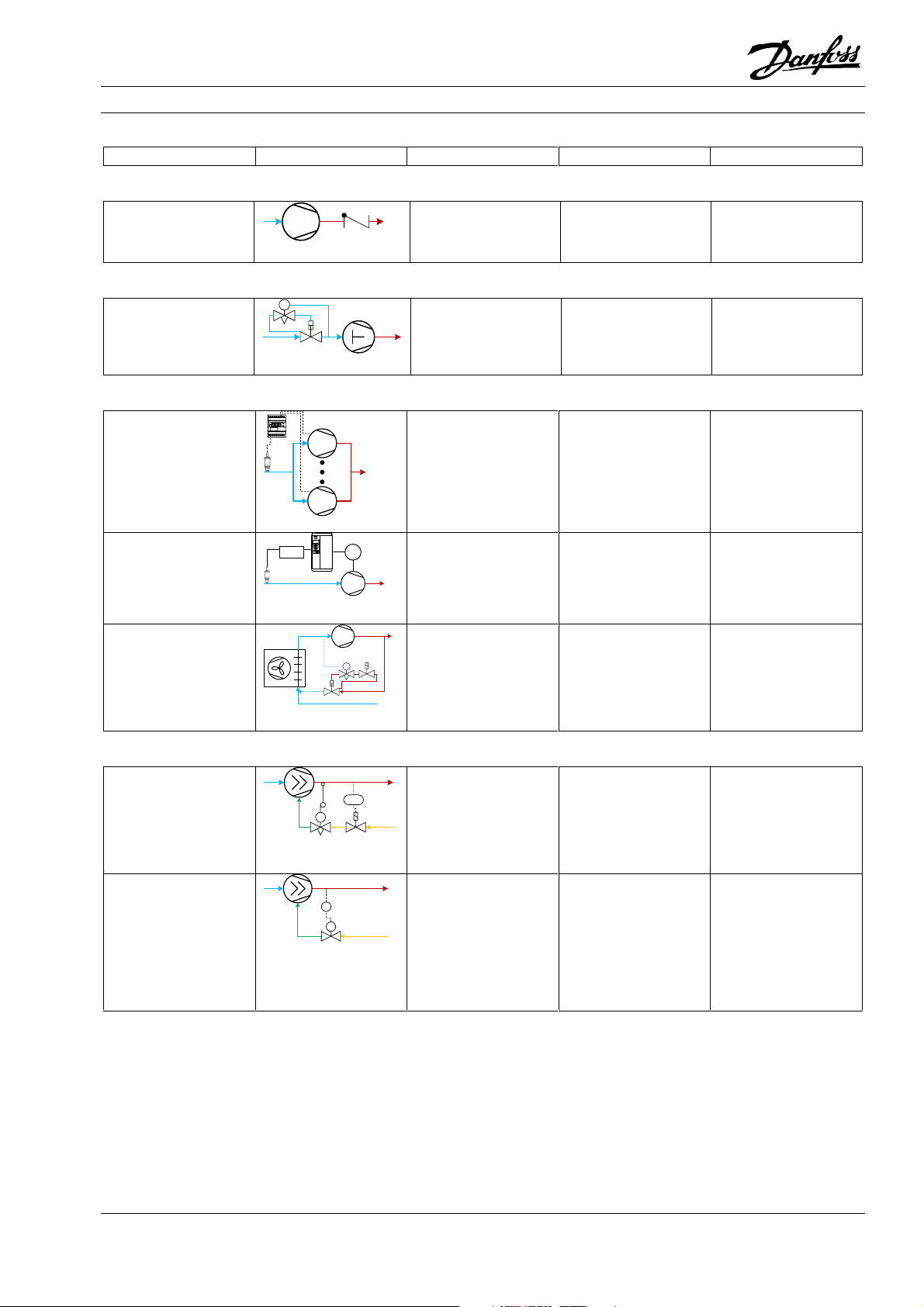

2.6 Summary

Solution Application Benefit Limitations

Reverse Flow Control – see section 0

Reverse flow control with

SCA

Applicable to all

refrigeration plants.

Crankcase Pressure Control – see section 2.2

Crankcase pressure

control with ICS and CVC

PC

Applicable to

reciprocating

compressors, normally

used for small and

medium systems.

Compressor Capacity Control – see section 2.3

Step control of

compressor capacity with

EKC 331 and AKS 33

Compressor variable

speed capacity control

Hot gas bypass using ICS

and CVC

Controller

M

PC

Applicable to multicylinder compressor,

screw compressor with

multiple suction ports,

and systems with several

compressors running in

parallel.

Applicable to all

compressors with the

ability to run at reduced

speed.

Applicable to

compressors with fixed

capacities. Used as safety

measure against

excessively low suction

pressure

Discharge Temperature Control with Liquid Injection – see section 0

Simple.

Easy to install.

Low flow resistance.

Simple and reliable.

Effective in protecting

reciprocating

compressors on start-up

or after hot gas defrost.

Simple.

Almost as efficient at part

load as at full load.

Low start-up current

Energy savings

Lower noise

Longer lifetime

Simplified installation

Fast response to sudden

drops in cooling load. The

hot gas can help the oil

return from the

evaporator.

Causes constant pressure

drop in the discharge

line.

Causes constant pressure

drop in the suction line.

The control is not

continuous, especially

when there are only a few

steps. Fluctuations in the

suction pressure.

Compressor must be

suited for reduced speed

operation.

Should not be used as

primary compressor

capacity control. Energy

inefficient.

Mechanical solution for

liquid injection with TEAT,

EVRA(T) and RT

Electronic solution for

liquid injection control

with EKC 361 and ICM/ICF

Applicable to systems

TSHL

TC

where the discharge

temperatures may run

too high.

Simple and effective.

Injection of liquid

refrigerant may be

dangerous to the

compressor. Not as

efficient as intermediate

cooler.

Applicable to systems

TC

M

where the discharge

temperatures may run

too high.

Flexible and compact.

Possible to monitor and

control remotely.

Not applicable to

flammable refrigerants.

Injection of liquid

refrigerant may be

dangerous to the

compressor. Not as

efficient as intermediate

cooler.

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 27

Page 30

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Condenser controls

Oil Cooler

Oil Separator

Compressor

Evaporat or

Expansi on valve

In areas where there are large variations in ambient

air temperatures and/or load conditions, it is necessary to control the condensing pressure to prevent it

from falling too low. Excessively low condensing pressures result in there being insufficient pressure differential across the expansion device and the evaporator not being supplied with enough refrigerant. It

means that condenser capacity control is mainly

used in the temperate climate zones and to a lesser

degree in subtropical and tropical zones.

The basic idea of condensing capacity control is to

control the condenser capacity when the ambient

temperature is low, so that the condensing pressure

is maintained above the minimum acceptable level

and to keep the condensing pressure as low as possible for optimal efficiency. This condensing capacity

control is achieved either by regulating the flow of

circulating air or water through the condenser, or by

reducing the effective heat exchanger surface area.

Different solutions can be designed for different

types of condensers:

Air cooled condensers

Condenser

Condenser installation depends on the way injection

to the low-pressure side of the refrigeration system

is controlled. Note that the terms ‘high-pressure

float valve operation’ and ‘low-pressure float valve

operation’ refer to the mode of operation, not spe-

cifically the use of a float valve. Both operation

modes can be achieved by using level

switches/transmitters and a normal expansion valve.

3.1 High-pressure float valve operation

High-pressure float valve operation is expansion of

the liquid immediately after the condenser. Any vari-

ation in the charge volume due to variations in ca-

pacity must be handled at the low-pressure side, e.g.

in a liquid separator. Since the flow after the expan-

sion valve is two-phase, it is not suitable for distribu-

tion to more than one location and thus it is primar-

ily used in systems with only one low-pressure sepa-

rator, such as a chiller unit.

High-pressure float valves are usually mounted im-

mediately after the condenser and, as such, pose no

special problems with regard to condenser installa-

tion.

Evaporative condensers

Water cooled condensers

28 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 31

Application Handbook Industrial Refrigeration ammonia and CO2 applications

3.2 Low-pressure float valve operation

Low-pressure float valve operation controls the expansion of the condensed liquid to keep a given level

in one or more low-pressure separators. Any varia-

3.3 Air-cooled condensers

An air-cooled condenser consists of tubes mounted

within a fin block. The condenser can be horizontal,

vertical or V-shaped. The ambient air is drawn across

the heat exchanger surface with axial or centrifugal

fans.

3.3.1 Step control of air-cooled condensers

This method utilizes a step controller to control the

air flow in the air-cooled condenser by switching the

fans on or off according to a condensing pressure

signal.

tion of the charge volume due to variations in capacity must be handled on the high-pressure side, e.g. in

a receiver.

To ensure proper functioning of a condenser in a

low-pressure float valve system, the installation

must be correct.

Air-cooled condensers are used on industrial refrigeration systems where the relative air humidity is

high. Air-cooled condenser application examples are

depicted below as low-pressure float valve operation.

Controlling the condensing pressure for air-cooled

condensers can be achieved in the following ways:

A pressure transmitter, e.g. Danfoss AKS 33,

measures the condensing pressure and sends a signal to a step controller, e.g. Danfoss EKC 331, which

controls the switching of the fans according to the

pressure signal.

3.3.2 Fan speed control of air-cooled condensers

This method of condenser fan control is mainly used

when a reduction in noise level is desired due to environmental concerns.

3.3.3 Area control of air-cooled condenser

For area control of air-cooled condensers, a receiver

is required. This receiver must have sufficient volume to be able to accommodate the variations in

the amount of refrigerant in the condenser.

There are two ways this condenser area control can

be done:

The main valve ICS combined with the constant pressure pilot CVP-H (high-pressure) mounted in the discharge line on the inlet side to the condenser and

ICS combined with a differential pressure pilot CVPP

mounted in the pressure equalization line between

the discharge line and the receiver. In the pipe between the condenser and the receiver, a stop-check

valve SCA is mounted to prevent liquid migration

from the receiver to the condenser.

For this type of installation, Danfoss frequency converter VLT can be used.

Main valve ICS combined with the constant pressure

pilot CVP-H mounted in the pipe between the condenser and the receiver and an ICS combined with a

differential pressure pilot CVPP mounted in the pressure equalization line between the discharge line

and the receiver. This method is mainly used in commercial refrigeration.

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 29

Page 32

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Application Example 3.3.1: Air flow control of air-cooled condenser with step controller EKC 331

EKC 331

AKS 33

From

discharge line

SVA

LLG

SVA

To oil cooler

EKC 331 is a four-step controller with up to four relay outputs. It controls the switching of the fans according to the condensing pressure signal from a

pressure transmitter AKS 33.

Based on neutral zone control, EKC 331 can control

the condensing capacity so that the condensing pressure is maintained above the required minimum

level.

The bypass pipe (thin red line) where SVA is installed

is an equalizing pipe, which helps balance the pressure in the receiver with the inlet pressure of the

condenser so that the liquid refrigerant in the condenser can be drained into the receiver.

It is important to account for the pressure drop in

the condenser when designing the piping from the

condenser to the receiver. The pressure at the outlet

of the condenser can be lower than the pressure in

the receiver, which will restrict the flow to the receiver. Using a drop leg between the condenser and

Condenser

SVA

SNV

SFASFA

DSV

Receiver

SCA

To expansion device

h

Liquid trap

Priority for oil cooler

receiver with a liquid trap at the bottom will allow

the build-up of liquid in the drop leg. The liquid col-

umn in the drop leg will provide a positive pressure

to counter the pressure drop in the condenser. The

height of the drop leg must be larger than the pres-

sure loss in the condenser, expressed in metres of

liquid. In some installations, EKC 331T is used. In this

case, the input signal could be from a PT 1000 tem-

perature sensor, e.g. AKS 21. The temperature sen-

sor is usually installed in the outlet of the condenser.

Note! The EKC 331T + PT1000 temperature sensor

solution is not as accurate as the EKC 331 + pressure

transmitter solution, because the condenser outlet

temperature may not entirely reflect the actual con-

densing pressure due to the liquid subcooling or the

presence of incondensable gasses in the refrigera-

tion system. If the subcooling is too low, flash gas

may occur when the fans start.

30 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 33

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Application Example 3.3.2: Fan speed control of air-cooled condenser

VLT

From

discharge line

AKS

SVA

LLG

SVA

To oil cooler

The VLT frequency converter is controlled by the

condensing pressure signal from a pressure transmitter, e.g. Danfoss AKS 33, on the discharge line. The

VLT frequency converter adjusts the speed of the

fans in the air-cooled condenser according to the signal from the pressure transmitter.

Frequency converter control offers the following advantages:

Energy savings

Improved control and product quality

Noise reduction

Longer lifetime

Simplified installation

Condenser

SVA

SNV

Receiver

To expansion device

SFASFA

DSV

SCA

h

Liquid trap

Priority for oil cooler

It is important to account for the pressure drop in

the condenser when designing the piping from the

condenser to the receiver. The pressure at the outlet

of the condenser can be lower than the pressure in

the receiver, which will restrict the flow to the receiver. Using a drop leg between the condenser and

receiver, with a liquid trap at the bottom, will allow

the build-up of liquid in the drop leg. The liquid column in the drop leg will provide a positive pressure

to counter the pressure drop in the condenser. The

height of the drop leg must be greater than the pressure loss in the condenser, expressed in metres of

liquid.

Easy-to-use complete control of the system

© Danfoss A/S (RC-MDP/MWA), 2020-10 AB13778641621700-000702 31

Page 34

Application Handbook Industrial Refrigeration ammonia and CO2 applications

Application Example 3.3.3: Area control of air-cooled condenser (for cold climates)

CVP

Suction

line

SVA

LLG

To oil cooler

ICS

SVA

ICS

CVPP

SVA

SVA

SFASFA

SNV

DSV

Receiver

To expansion device

Condenser

h

SCA

Liquid trap

Priority for oil cooler

This regulating solution maintains the pressure in

the receiver at a sufficiently high level during low

ambient temperatures.

The ICS pilot-operated servo valve in the discharge

line opens when the discharge pressure reaches the

set pressure on the CVP pilot valve and closes when

the pressure drops below the set pressure of the

CVP pilot valve.

The ICS pilot-operated servo valve with the CVPP

constant differential pressure pilot in the pressure

equalization line (thin red line) maintains sufficient

pressure in the receiver.

The SCA stop-check valve ensures increased condenser pressure by liquid back-up within the condenser.

This requires a sufficiently large receiver. The SCA

stop-check valve also prevents liquid flow from the

receiver back into the condenser when the latter is

colder during compressor shut-down periods.

It is important to account for the pressure drop in

the condenser when designing the piping from the

condenser to the receiver. The pressure at the outlet

of the condenser can be lower than the pressure in

the receiver, which will restrict the flow to the re-

ceiver. Using a drop leg between the condenser and

receiver, with a liquid trap at the bottom, will allow

the build-up of liquid in the drop leg. The liquid col-

umn in the drop leg will provide a positive pressure

to counter the pressure drop in the condenser. The

height of the drop leg must be greater than the pres-

sure loss in the condenser, expressed in metres of

liquid.

32 AB13778641621700-000702 © Danfoss A/S (RC-MDP/MWA), 2020-10

Page 35

Application Handbook Industrial Refrigeration ammonia and CO2 applications