Page 1

Indoor Cable Floor Heating Systems

Indoor Cable Floor

Heating Systems

Application manual

Intelligent solutions

with lasting effect

Visit devi.com

Page 2

Page 3

Index

Our quality management

system

and compliances

Along with full compliance with EU

directives and product approvals

ISO 9001 TS 16949

ISO 14001 PED

Let DEVI do the work

1. DEVI electrical heating systems 4

2. Application Briefing 5

2.1 General information 5

3. Product overview 6

3.1. Cables 6

3.2 Mats 6

3.3 Thermostats 7

4. Heating systems in floor

constructions 9

4.1. Comfort Floor Heating 9

4.2. Total (Direct) floor heating 13

4.3. Accumulating heating via

electrical floor heating system 18

5. Electrical heating system floor

constructions 21

5.1. Cable heating in thick concrete

floor construction 21

5.2. Electrical heating system in

thin floor construction 25

5.3. Heating in wooden floors 30

Appendixes 48

A.1. C-C distance and

corresponding output W/m² 48

A.2. Fitting 49

A.3. Floor sensor installation 50

A.4. General installation guide 51

DEVI - an abbreviation of Dansk El-Varme Industri – was established in

Copenhagen, Denmark, in 1942. As from January 1st 2003 DEVI has become

a part of the Danfoss Group - Denmark’s largest industrial Group. Danfoss

is one of the world’s leading companies within heating, cooling and airconditioning. The Danfoss Group has more than 23000 employees and serves

customers in more than 100 countries.

DEVI is Europe’s leading brand of electrical cable heating systems and electric

pipe heating systems with over 70 years of experience. The production of

heating cables takes place in France and Poland while the head office is

situated in Denmark.

The value of experience

We have installed literally millions of systems across the globe, in every

conceivable setting. This experience means that we can offer you practical

advice about precisely which components you need to get the best results at

the lowest cost.

Indoor Cable Floor Heating Systems

This design guide presents DEVI’s recommendations for design and

installation of cable floor heating systems for indoor application.

It provides guidance for heating cable positioning, electrical data and system

configurations.

Following DEVI’s recommendations will ensure energy efficient, reliable and

maintenance free solution for constant wattage heating cables with 20 year

warranty.

6. Cases 52

Page 4

1. DEVI electrical heating systems

This document includes all necessary

information about DEVI cable heating

systems which can be helpful in your

decision making during its design,

installation and operation. The

distinctive feature of DEVI’s profile is

production of cable heating systems.

DEVI A/S was founded in in Denmark

in 1942 and within over 75 years of its

existence it has made the way from a

private company to a large industrial

enterprise developing and providing

solutions for electrical heating

cables in more than 100 countries

around the world. DEVI takes a

leading position as a founder and

an innovator in the field of electrical

heating cable systems for indoor and

outdoor installation.

Since 2003 DEVI has being a part of

the Danfoss Group.

DEVI is the Europe’s largest supplier

of electrical floor heating. Our

business philosophy is based

on marketing electrical heating

solutions that clearly stand out as the

following:

• Increasing comfort in everyday life;

• Greater reliability;

• Better design;

• Improved operating costs.

DEVI develops, manufactures and

sells heating cable systems for the

following main applications:

• Total electrical floor heating;

• Comfort electrical floor heating;

• Ice and snow melting on ground –

roads, pavements / pedestrian

walkways, bridges etc.;

• Ice protection and snow melting

for roofs and gutters;

• Protection against freezing

and temperature maintenance

of pipelines, tanks and other

industrial applications;

• Heating of play-fields with

natural or artificial grass, soil in

greenhouses, etc.;

• Heating of agricultural premises;

• Frost protection of foundations

and floors in cold stores and ice

stadiums;

as well as many other heating

solutions.

Complete systems

DEVI is the only global company in

the industry that develops, produces and markets complete systems

containing both heating cables and

thermostats in the global market.

Consequently, there is a full harmony

between the single components that

make up our heating systems, which

means high performance, optimum

reliability and usability and as a result

low energy consumption.

Integrated solutions

For almost 75 years DEVI has been

producing a wide range of proven

tested heating cable solutions –

everything from thin heating mat

systems mainly intended for renovation purposes, to complete heating

systems for room heating in private

dwellings as well as offices and industrial buildings. DEVI also supplies

ice and snow melting solutions. Our

cables and thermostats keep traffic

areas, loading ramps and roof constructions safe in cold areas throughout the world. We provide anti-frost

systems for pipes and roof gutters

and we heat the soil in greenhouses,

or even under football fields.

Intelligent heating systems

The main DEVI product is a complete

heating system (heating cable or

mat, thermostat and accessories).

Energy efficiency and it’s intelligent

use is built in DEVI thermostats

since the 90’s. Saving up to 30% of

electrical bill, compared with an

advanced electronic thermostat

without a timer, DEVI intelligent

thermostats are world leading

example to follow in the area of

intelligent electrical floor heating.

High quality heating elements

manufactured in EU

DEVI heating element is a screened

twin or single conductor made

with different specific outputs and

insulation options. DEVI heating

elements are produced in over thirty

different types allowing application

of the product that suits best to your

specific requirements.

Thin heating mats designed for

installation under the tiled floor are

most in demand. DEVI mats consist

of a thin cable fixed on a composite

or glass fiber self-adhesive mesh,

which makes mats easy to install and

a logical choice for thin floors. When

laying heating mats the floor level is

virtually the same since installation

can be performed with a standard

thickness of the tile glue.

System installation and calculation

of desired output shall be performed

based on specific conditions of

premises (application). To ensure

proper installation and operation of

each DEVI system it is accompanied

by multilingual detailed instructions.

In addition, most of heating cables

and mats have 20 year warranty.

DEVIreg™ Smart, the latest solution,

that is worth special attention – it

embodies the essence of DEVI

commitment to improve user

comfort, interaction with intelligent

electronic devices, Nordic design

and energy efficiency. DEVIreg™

Smart thermostat with:

• user-friendly interface via APP

and Wi-Fi control,

• touchs creen,

• intelligent timer functions with

an intuitive user-friendly interface

which is designed specifically to

meet the needs of modern users,

• extended warranty period –

5 years.

Reliable choice.

DEVI is the world leader in the

production of electrical heating

cable systems and is a part of the

Danfoss group. Presented in the

global market for almost 75 years

and available in more than 100

countries on five continents. You can

safely recommend products to your

clients as far as DEVI trademark has

occupied a leading position on the

world market and has been a trusted

partner for decades.

4 Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 5

2. Application Briefing

2.1 General information

Optimal comfort

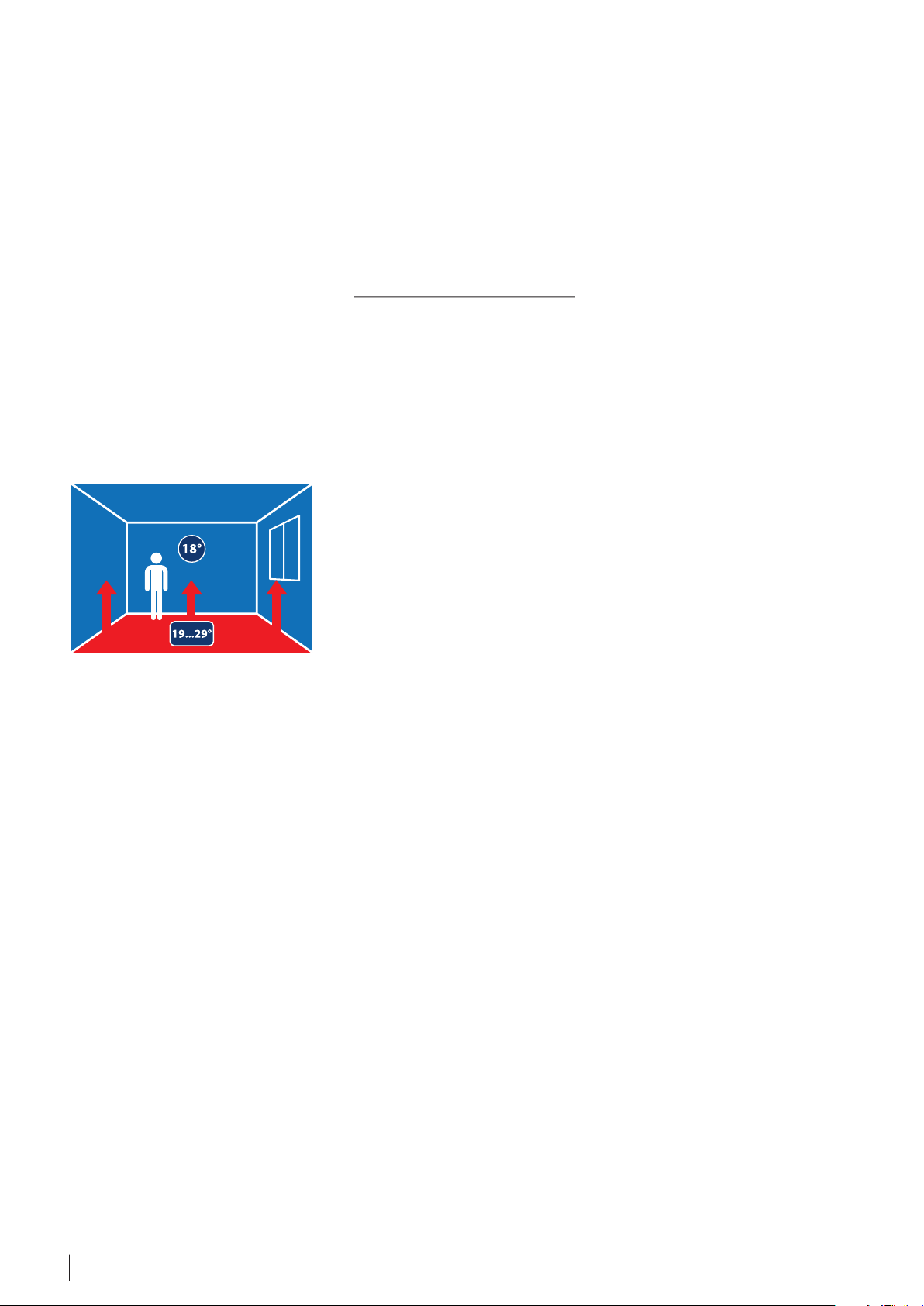

All heat moves upwards! This simple

fact explains why a floor heating system

provides more comfortable heat, than

the alternative radiator system. The

radiator system provides convective

air movement up to head height and

ceiling, only to travel downwards and

return as a cold draft around ones feet.

DEVI’s floor heating system, on the

other hand, provides pleasant heat

for ones feet, body and head.

As it produces only a very gentle

upward air movement the amount

of travelling dust particles is reduced

considerably making the system a

great asset to people suffering from

allergies or asthma. It also minimizes

presence of moisture at floor level.

Minimal energy consumption

Thanks to heat distribution from the

floor and precise temperature control

system with a DEVIreg™ thermostat,

the average room temperature can

be reduced by 1-2 °C compared with

traditional radiator heating, without

influencing the thermal comfort

or even improving it. This enables

reducing energy losses, from a

dwelling, by 10-20%, which is both

economically and environmentally

beneficial.

Flexible system

DEVI’s floor heating system ensures

comfortable room temperatures, be it

at home, at the office, in a workshop,

sports hall or virtually anywhere

where comfortable heat is required.

Equally important is the fact that

DEVI’s floor heating system can be

installed in all floor types whether

they are new concrete or wooden

floors or renovated floors.

Invisible heat source

DEVI’s floor heating system is invisible.

As the system is hidden under the

floor it gives exciting new possibilities

for furnishing and interior design and

the problem of space-consuming and

unattractive radiators (or heaters) no

longer has to be considered.

Ease of Installation

DEVI electrical underfloor heating

provided as a system, be it a

heating mat, cable with installation

accessories or a thermostat with easy

setup feature, quick and effortless

installation.

High durability, no maintenance

DEVI’s floor heating system has a long

life. Practically speaking DEVI’s heating

cables and mats last as long as the

house where they are installed and no

maintenance is required!

Quick and Precise Response Time

Electrical floor heating system has

a quick response time. Along with

DEVIreg™ intelligent thermostats

it also offers precise increase and

regulation of room temperature

comparing to water based

floor heating systems. System’s

responsiveness to temperature

changes and user adjustments is

also better.

20-year DEVI Warranty™ and

Full Service warranty

20-year DEVI Warranty™ is valid

for most of DEVI heating mats and

heating cables. DEVI support Full

service warranty for cables and mats

installed indoor for floor heating –

included costs for installation and

floor materials such as damage to

bricklaying and tiles. Full Service

20-year warranty implies that

when there is a warranty case DEVI

undertakes a responsibility to

correct the defect free of charge or

offer product replacement during

the warranty period. In addition,

DEVI covers all costs associated with

the replacement of any heating

system element and floor cover

restoration costs.

5Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 6

3. Product overview

3.1. Cables

Electrical floor heating system

consists of two main components:

• Heating element (cable, thin

heating mat, or heating element

for laminate floors, etc.);

• Thermostat with air or/and floor

temperature sensors.

Heating cables are usually installed

in thick/concrete floor constructions.

The main feature of a thin heating

mat is its low thickness. This gives

the possibility for it to be installed

in a thin layer of tile glue avoiding

considerable increase of floor level.

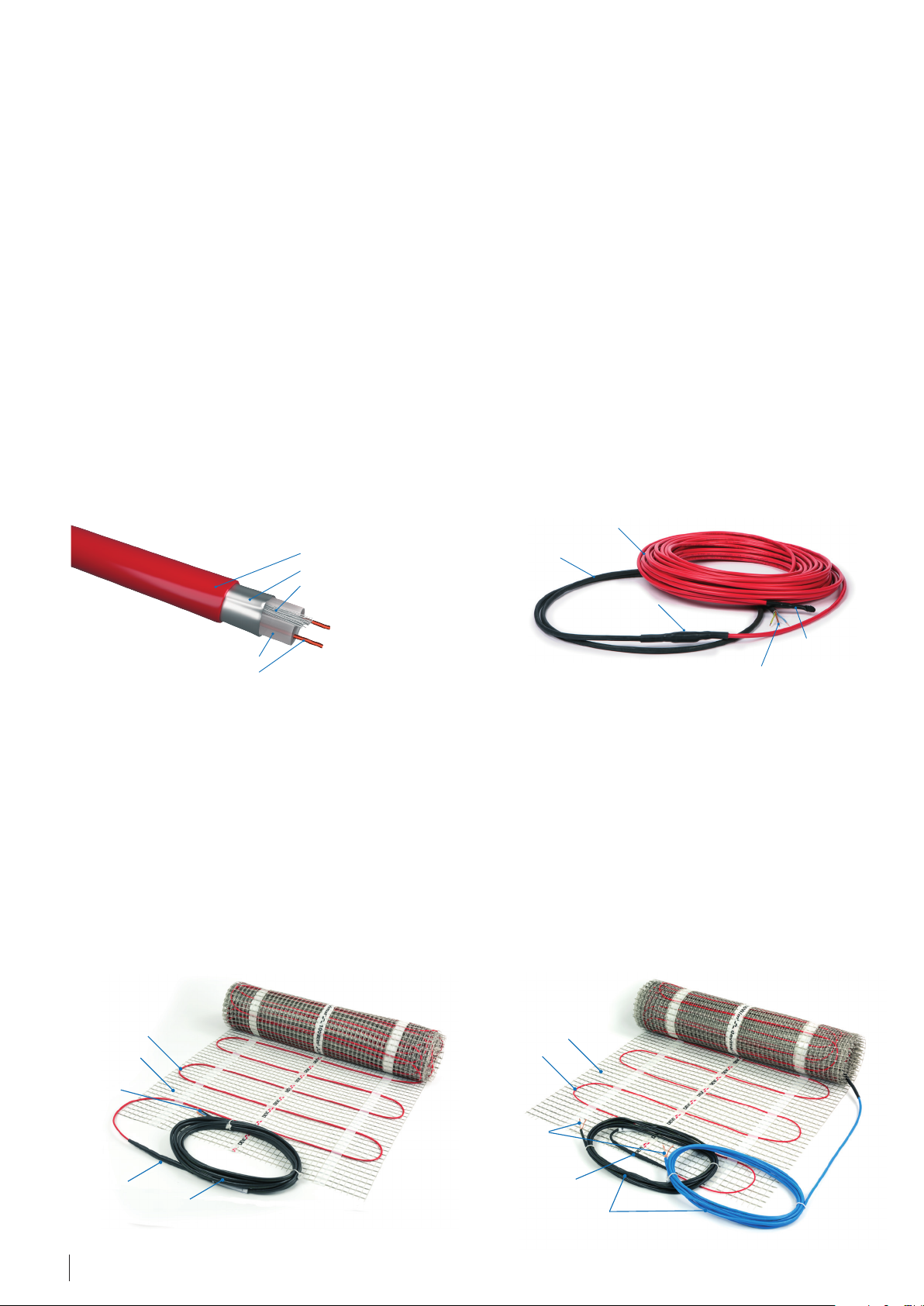

internal insulation ( XLPE)

heating element (resistance thread)

DEVIflex™ heating cable construction

DEVI heating cable (e.g. DEVIflex™)

is designed for installation in thick

concrete floor constructions. Usual

thickness of top/finish floor layer is

at least 3 cm. Heating cables used in

floor constructions are serial resistive

cables, preferably twin conductor,

but also a limited range of single

conductor cable is available. Cables

are manufactured as ready-to-install

heating elements with specific length

(i.e. 7, 10, 15, up to approx. 410 m),

with a power supply cable (cold tail)

and hermitically closed connections

(muffs or end terminations).

outer PVC coating

protective screen foil (Aluminum)

protective conductor

supply cable

Output of heating cables for

installation in floor constructions is

limited to 20 W/m and DEVI cables are

available with 6, 10. 18 and 20 [W/m]

for 230 and 400 V. Most DEVI cables

are manufactured and approved in

accordance with the latest version

of IEC 60800:2009, with mechanical

strength class M2 (for rough concrete

constructions). The main type of DEVI

heating cables for installation in the

floor construction is DEVIflex™.

Internal and external design of

modern DEVIflex™ cable is shown in

the figures below.

heating cable

connecting muff

end of the heating cable

connection to power supply

DEVIflex™ 6T/10T/18T heating cable

3.2 Mats

The thin heating mat is designed

for installation in a thin tile glue

layer adhesive, self-leveling mixture

or alike. The standard minimum

thickness of the floor layer is 5-8 mm

while the thickness of DEVI mats

is 3-4,5 mm. It allows minimizing

the floor level increase. DEVI thin

heating mats consist of a thin cable

fixed on self-adhesive glass-fiber

heating cable

adhesive mesh

connection to

power supply

connecting muff

supply cable

DEVImat™ 100T/150T Heating mat

mesh usually of 50 cm width. Thin

heating cables are serial twin or

single conductor resistive cables.

Thin heating mats are manufactured

as ready-made heating sections with

a specific area (i.e. 0,5, 1, 1,5 … 12 m²)

including a power supply cable

(cold tail) and hermetically sealed

connections.

adhesive mesh

heating cable

connection to

power supply

connecting muff

supply cable

DEVIheat™ 150S Heating mat

Thin heating mats are available with

various outputs, for example: 70 W/

m², 100 W/m², 150 W/m² and 200 W/

m². DEVI thin heating mats comply

with IEC 60335-1 & IEC 60335-2-96.

The most commonly used DEVI

twin conductor heating mats for

installation in the floor construction

are DEVImat™ and DEVIcomfort™.

6 Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 7

Center-to-center distance between

mat’s cable lines is usually 7,5 cm. It

allows even distribution of heat on

the floor surface avoiding cold zones

between the cable lines.

The modern thin twin conductor

DEVImat™ and single conductor

DEVIheat™ are shown below.

3.3 Thermostats

DEVI heating cables and thin heating

mats mentioned above are the most

used floor heating elements. DEVI

also produces other floor heating

elements, i.e. DEVIdry™ and DEVIcell™

heat distribution panels for heating

constructions with wooden surface

(laminate, multi-layer boards,

parquet, etc.) or/and on wooden

subfloors. DEVIdry™ has 55 and 100

W/m² outputs.

For further information please refer

to the DEVI Product Catalogue.

DEVI offers specialized thermostats

for electrical floor heating systems.

All thermostats are electronic devices

allowing precise control of the

floor surface or air temperatures. In

general three types of thermostats

are available:

• for air/room temperature

control and limitation of floor

temperatures – with room sensor

and floor sensor;

• for floor temperature control –

with floor sensor only;

• for air/room temperature control –

with room sensor only.

DEVI offers thermostats that are:

• Intelligent, PWM (Pulse Width

Modulation regulated)

• Simple (hysteresis regulated).

Intelligent thermostats provide stateof-the-art wireless control system for

control of heating and electrical units

in private houses. Some thermostats

are fitted with Wi-Fi allowing remote

control of heating systems via mobile

application.

Simple thermostats are electronic

control units with or without

display allowing setting the heating

system type, adjustment of control

parameters and timer mode.

NEW!!

Adjust your

floor heating

from your

smartphone

DEVIreg™ Smart

DEVIreg™ Smart is the DEVI’s latest

solution and a further development

of, the very well known DEVIreg™

Touch with Wi-Fi control via mobile

application, unique Nordic design

and advanced user experience,

with application that enables up

to 10 different users to control

electrical heating systems from

anywhere in the world using a

smartphone or a tablet.

DEVIreg™ Smart is an intuitive

programmable intelligent timer

thermostat used for controlling

electrical floor heating elements.

The thermostat is designed for flushmount installation into a standard

wall installation box, or on wall with

a special on-wall box. Due to the

special 2-part construction it fits a

wide range of frames and sensors.

DEVIreg™ Smart builds further on

energy saving functions introduced

earlier in DEVIreg™ Touch, like:

• fast and intuitive setup using the

built-in wizard;

• energy-saving program –

including optimum start/end

control ensuring the desired

temperature at the correct time

and thereby reducing heating

costs;

• open window function;

• very precise regulation of user set

room temperature by means of a

specially developed PWM (Pulse

Width Modulaton) regulation,

including optimal change from

comfort to economy mode.

DEVI Link

system

covers the control

of both radiator

heating and

floor heating –

individually or

combined

DEVIlink™ CC

DEVIlink™ CC (Central Controller)

is the central brain in the DEVIlink™

system which includes several

wireless DEVIlink™ devices installed

inside the building.

Several functions, i.e. room control,

intelligent timer, modes for the whole

house – “Away”, “Comfort”’, “Frost

Protection”, are integrated into the unit

to reduce energy consumption when

using electrical floor heating system.

The idea of the DEVIlink™ System is

to provide wireless connection of

your heating system and to control it

from one central point. The DEVIlink™

CC communicates wirelessly with

all other DEVIlink™ units of the

installation. A single DEVIlink™ CC

can control up to 30 rooms and

allows connection up to 50 units and

specially developed to satisfy the

needs of any family house: it can

be also used for apartments, and

multifamily buildings.

DEVIlink™ is fitted with Danfoss

Link™ App, and the latest version

provides the possibility of Wi- Fi

control by mobile application,

anywhere in the world.

7Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 8

DEVIreg™ Touch

DEVIreg™ 130

DEVIreg™ 330

DEVIreg™ Touch is a thermostat

fitted with a display and an intelligent timer. It is designed for flushmount installation into a standard

wall installation box. It operates with

two sensors – floor wire and built-in

room sensor. It allows control setting

for one of 3 heating systems: with

wire floor temperature sensor, with

built-in room sensor or with built-in

room sensor and wire floor sensor

for limitation of floor temperature.

The touch screen menu and intuitive

user friendly interface allow easy use

and quick service. The thermostat

has four original colors – polar white,

pure white, ivory and black. It can be

installed in complex frames of different manufacturers.

DEVIreg™ Touch is fast and intuitive to

setup using the built-in wizard. It has

an energy saving program – including

optimum start/end control ensuring

the desired temperature at the correct

time and thereby reducing heating

costs.

DEVIreg™ 13x series thermostats

are designed for mounting directly

on the wall. Following models are

available:

• DEVIreg™ 130 with wire

temperature sensor;

• DEVIreg™ 132 with built-in room

sensor and wire floor sensor for

limitation of floor temperature.

DEVIreg™ 233

DEVIreg™ 233 is an electronic

thermostat designed to be flushmounted in an installation box

from the LK FUGA series frame. The

thermostat is provided with a single

pole switch and a floor sensor (wire)

to measure and control the desired

floor temperature. Alternatively an

external room sensor can be used, for

room temperature regulation.

The thermostat has a button to adjust

the temperature setting in the range

of (0) 1 to 6.

DEVIreg™ 330 (5…45°C) – is an

electronic thermostat to be installed

in electric cabinets with DIN rail

attachment. The set includes wire

temperature sensor. To control room

temperature an external air sensor is

required.

DEVI offers over 20 different types

of thermostats. The product range

includes easy to operate (by APP)

intelligent Wi-Fi control thermostats

to specifically designed digital,

thermostats with moisture sensors

for ice and snow melting on ground

as well as ice protection for roofs and

gutters (refer to Ice & Snow melting

Application Sheet). DEVIlink™ and

DEVIreg™ Smart system is equipped

with wireless functions and Wi-Fi

control of heating systems and

indoor electrical equipment.

DEVI provides a unique solution –

that is “top quality intelligent heating

system”, giving consumers the

highest level of comfort and safety!

The intelligent component of these

systems is the DEVIreg™ electronic

thermostat which is available in

several options, i.e. for total heating

or comfort floor heating.

More information about DEVI

thermostats you can find further

in this document and in the DEVI

Product Catalogue.

DEVIreg™ 530

DEVIreg™ 53x series thermostats are

designed for flush-mount installation

into a standard wall installation box.

Three models are available:

• DEVIreg™ 530 with wire temperature sensor;

• DEVIreg™ 531 with built-in room

sensor;

• DEVIreg™ 532 with built-in room

sensor and wire floor sensor for

limitation of floor temperature.

8 Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 9

4. Heating systems in floor constructions

Electrical floor heating systems for

indoor heating can be divided into

3 main heating categories (types):

• Comfort floor heating;

• Total or Direct heating;

• Accumulating heating.

4.1. Comfort Floor Heating

4.1.1. About the system

Comfort Floor Heating or “Warm

Floor” system provides heated floor

surface, in any rooms, and especially

used for bathrooms and kitchens.

Comfort floor heating can be used

in any room fitted with another

heating system to provide required

air temperature, for example water

based radiators on the walls. Warm

Floor/ Comfort heating installed

in such premises only maintains

constant floor temperature at all

times, regardless of the heating

season. As an additional benefit

the Comfort heating increases air

temperature in the room, and due to

large heated floor surface will allow

compensation of inadequate heating

during extremely cold winter days

or in case of lack of heat regulation

in rooms which are not fitted with

a modern thermostat controlled

room heating systems. Comfort

floor heating system is controlled

by a thermostat with a floor sensor

(usually wire sensor). The heating

element is activated by a thermostat

based on the floor temperature set

by the user.

A comfortable floor temperature

has been evaluated many times, for

example, described in standard ISO/

TS 13732-2. The maximum long term

comfort floor surface temperature

is defined at the level of 29,5 °C.

Additionally: sedentary people

needed extra 1-2 °C. For floors in

wet rooms maximum temperature

can reach 31 °C. These maximum

temperature values can be used for

calculation and selection of installed

outputs (in [W/m²]) of comfort floor

heating systems. Different types of

floor surfaces need different comfort

floor temperatures, e.g. wooden

floor surface has an optimal comfort

temperature of approximately 26

°C, carpet – approximately 24 °C.

But it is impossible to predict type

of floor surfaces during life time of

floor construction, as well as that

comfort temperature is perceived

differently by different individuals. It

is advised to use maximum comfort

floor temperature level to satisfy all

possible options, but often a floor

temperature few degrees above

the current room temperature will

already satisfy the needs of most

users. It is important that most of

wooden floor surfaces have limitation

of max. temperature at the level of

27 °C (for more details concerning

maximum allowed temperatures

of the floor surface please refer to

a manufacturer of wooden floor

materials).

EXAMPLE:

The optimal required output (in

[W/m²]) for comfort floor heating

system, can be evaluated by a simple

calculation. Assuming that the room

temperature is 20 °C (supported by

another heating system during the

heating season) and the floor surface

needs to reach up to 29 °C. The floor

temperature must be increased as

follows: 29 - 20 = 9 °С. Information

about the installed output (in [W/

m²]) needed to heat up 1 m² of

floor surface to 1 °C can be found in

physic books and standards (e.g. DS/

EN 1264. Heat exchange coefficient,

usually named alfa – α [W/(m²·K)], can

vary, however for general evaluation

α =10 W/(m²·K) can be used.

This will be described in details on

the following pages.

Consequently to heat 1 m² of floor up

to 9 °С in relation to air temperature,

approximately an installation of

9 °С · 10 W/(m²·K) = 90 W/m² is

required.

As a “rule of thumb” a safety value of

30% should also be added offering

a minimum output for electrical

heating element used in comfort

floor heating system as calulated in

the following example:

90 W/m² · 1,3 ≈ 120 W/m²

Recommendation: output for

comfort floor heating systems should

be no less than 120 W/m², unless any

special restrictions are specified.

The following power outputs for

comfort floor heating systems

are recommended based on floor

constructions, insulation levels,

surface types, room air temperature

and individual user preferences:

• Wooden floor constructions – no

more than 100 W/m²;

• Dry rooms, thermal insulated

floors – 100 W/m² or more;

• Floors without thermal insulation –

130-160 W/m²;

• Wet rooms – 150-180 W/m²;

• Low voltage, insufficient insulation,

covered balcony slabs –

160-200 W/m²;

• maximum output in floor

construction – should not exceed

200 W/m².

Find more details and restrictions for

special floor constructions such as

wood, later in this document.

9Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 10

Comfort floor heating systems do

not require heat loss calculation. It

is advised to install power at least

100 W/m² in all dry premises, and

at least 150 W/m² in wet premises,

however note that norms for wooden

floors specify no more than 100 W/

m², and require a thermostat with a

floor sensor to limit maximum floor

temperature. Heating system must

be controlled by thermostat and it is

worth mentioning that installation

of increased power, e.g. 150 W/m²

instead of 100 W/m² does not affect

energy consumption of the system,

but can influence user comfort

feeling.

C-C distance

Heating cables are installed inside

floor construction with some

distance between them (or so called

installation step, centre-centre

or cable-to-cable distance: C-C

distance). To achieve a warm floor

with even distribution of heat and

to provide comfortable temperature

on the floor surface, the floor surface

temperature variation should not

exceed 1,5 °С (e.g. DIN 44576).

There will always be a difference in

temperature on the floor surface, in

areas between heating cables and

directly above them. The bigger C-C

distance – thicker layer of concrete

above cable is necessary to ensure

a uniform/comfort temperature

distribution along the floor surface.

This difference is always more

pronounced during periods, when

electrical heating cables are turned

on (providing heat to the floor

heating). The instant thermostat

disconnects the heating cables,

because desired floor temperature

is reached, the temperature on the

top of the floor surface is equalized

greatly, giving an increasingly

comfortable floor surface.

A rule of thumb indicates:

• The thickness of concrete & floor

structure above the heating cables

need to be ~½ the C-C distance.

Here is the additional explanation:

For Warm Floor system installed

into a thick concrete slab the

C-C distance of 5-10 cm is

recommended. The thickness of the

concrete slab top layer is usually

not less than 3-5 cm, regardless

whether heating cables are to be

installed there or not. For thin floor

constructions, such as tile glue,

laminate etc., the C-C distance

should not exceed 10 cm and is

recommended to be even less: 7,5

cm. To install heating cables under

the tile glue the best solution is

DEVI thin heating mats with

C-C = 7,5 cm that guarantees floor

surface without cold zones.

Recommendation: it is always

advised to insulate the floor structure

below the heating cables.

More details about cable installation

step (C-C distance) and appropriate

outputs are described below in this

document.

Thermostat with floor sensor:

The thermostat uses a wire sensor to

measure the temperature inside the

floor construction. The sensor needs

to be placed directly between, and if

possible, slightly above the lines of a

heating cable or a mat. Temperature

measured by the floor sensor is

not the real surface temperature

and depends on placement of the

floor sensor. It is difficult to give

any recommendations about the

thermostat settings for a specific floor

construction.

The thermostat with a floor sensor

has a scale without degree marking.

4.1.2. System Design

Following stages will help you to find

a right solution for your comfort floor

heating system (more about DEVI

products find in the DEVI Product

Catalogue):

Choice of a heating element type

(mat or cable).

Define the thickness of floor

construction over the cable, and a

type of the installation. For example

for renovation, where small floor

structure needs to be enlarged, a

heating mat is a preferable solution

due to the element’s height.

If you plan to increase the floor

construction by less than 30 mm,

it’s preferred to use a heating mat,

suitable for floor increase of 3-5 mm.

If you plan to increase the floor

construction by more than 30 mm,

a heating cable is usually applied.

It should be noted that there are

no restrictions for use of heating

mats in concrete or thick floor

constructions. The question of

thermal insulation, installation

thickness in floor construction should

also be addressed, as it’s important to

minimize heat losses downwards.

Choice of specific output.

Specific output (p in [W/m²]), for

Comfort Floor Heating usually does

not require calculation and is selected

from recommendations for specific

floor construction and environment.

For standard floors without insulation

the output of no less than 100 W/m²

is usually chosen and for wet rooms –

no less than 150 W/m². In the lack of

reliable information about the floor

construction, flooring type, supply

voltage, etc., it is better to choose

an output as close as possible to the

maximum recommended (see page

above).

To fix heating cables DEVIfast™ fitting

bands are usually applied, it offers

a cable attachments with a step

distance (C-C) of 2,5 cm.

This leads to the situation that the

value of the specific output for a

heating cable cannot be chosen

arbitrarily, and it should be taken

into consideration that the cable can

be installed at 2,5 cm intervals only,

and respectively output will match

attachment distance.

For example if:

• cable is DEVIflex™ 18T,

• supply voltage is 230 V,

• the C-C distance of 12,5 cm

gives output of 145 W/m².

And for installation step with the

C-C of 10 cm – 180 W/m² (see the

DEVI Product Catalogue for product

selection). Thereby, for heated area

the value of the specific output - p

INST

[W/m²[, which is actually installed,

should be chosen for fixed C-C,

following the table or calculated

value.

It should be noted that in some

countries the supply voltage is lower

than 230 V that leads to decrease

of the cable specific output and

respectively, different [W/m²] with

10 Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 11

the same step (C-C). For example,

if the given output is 230 V the

coefficient of 0,915 should be applied

with 220 V supply.

Estimation of heated floor area.

Installation area of heating cable/mat

has to be calculated A

[m²]. To do

INST

this, from the total area of the room

(in [m²]), the area under stationary

objects (bath, toilet, shower, cabinet,

cupboards, etc.) and a strip of free

floor along walls (usually 10-15 cm

wide) is deducted, as well as special

customer’s preferences should be

taken into account.

The heating cable or mat is set

into the floor for many years, so it’s

advised to exclude from heated area

items/furniture that can be moved

over the operation life of the premises:

cupboards, cabinets, bed etc.

Along the interior walls, where

any furniture most probably will

be located up to 30-40 cm can be

allowed. For heating systems installed

in the floor construction, furniture

on legs, that provide air circulation

underneath is recommended.

Choice of a specific heating

element (length of heating cable or

area of heating mat).

Heating cable is normally chosen

based on required heating output

for room (the calculated total output

P

[W]). This output is calculated as

CALC

the chosen specific output

P

[W/m²] multiplied by the installa-

INST

tion area A

P

[W] = P

CALC

[m2]:

INST

[W/m²] · A

INST

[m²]. The

INST

heating element is selected from the

product list of factory-produced elements, with specific output P

INST

[W].

Always the product nearest to, but

larger than, calculated total output

P

[W], is to be chosen. For indoor

CALC

heating DEVI recommends to use

screened twin conductor DEVIflex™ 18T,

DEVIflex™ 10T, DEVIflex™ 6T heating

cables or if nothing else is suitable, a

screened single conductor

DEVIbasic™ 20S heating cable.

The number at the end of the cable’s

name refers to: its specific output for

1 m in [W/m] at 230 V, and letter “T”

means a twin conductor cable (Twin),

letter “S” - single conductor cable

(Single).

The most frequently used cable type

is DEVIflex™ 18T – twin conductor,

18 W/m at 230 V (16,5 W/m at 220 V).

A linear output of DEVIbasic™ of

20 W/m, is not the best choice for

even temperature distribution along

the floor construction, if installed in

the same floor, compared to

DEVIflex™ 6,10 or 18 W/m.

The heating mat is selected from a

range of factory-produced elements

(covering area from 0,5 to 12 m²),

with an area covering usually the

nearest less value to available

installation space A

installation area (A

[m²]. If the

INST

[m²]) exceeds

INST

12 m², a multiplication of chosen

heating mats needs to be applied.

For example, DEVI screened heating

mats designed for floor installation

have the cable/mat thickness for:

• twin conductor of ~3,0 mm:

DEVImat™ 70T, DEVImat™ 100T,

DEVImat™ 150T, DEVImat™ 200T;

• twin conductor of ~4,0 mm:

DEVIcomfort™ 100T, DEVIcomfort™

150T;

• single conductor of ~3,0 mm:

DEVIheat™ 100S or

DEVIheat™ 150S.

The number at the end of a mat’s

name refers to its specific output for

1 m² in [W/m²] at 230 V, and letter “T”

means twin conductor mat (Twin),

letter “S” a single conductor mat

(Single). A single conductor heating

mat requires more planning before

installation, to ensure that the power

supply cord attached to both ends

of the heating mat starts and ends at

the same place.

For Comfort Floor Heating

DEVImat™ 150T and DEVIcomfort™ 150T

heating mats are used most often –

twin conductor, 150 W/m² at 230 V

(135 W/m² for 220 V ).

Calculation of the fitting band

length (DEVIfast™).

If heating cable is applied, it is

recommended to use fitting band to

fix it to the floor base. For example,

metal galvanized DEVIfast™ fitting

band. It is attached to the floor

(nailed or fixed with screws or glued)

in parallel lines, usually every 50 cm.

This equals to two (2) meters of band

for each square meter [m²] of cable

installation.

Simple calculation of the fitting band

length L

(m): cable installation

FIX

space is multiplied by two, e.g.

L

= S

FIX

· 2 (m).

INST

Thermostat selection.

Thermostat for Comfort Floor Heating

system should be fitted with a floor

temperature sensor.

Choice recommendations:

heating area is larger than 5 m² –

programmable thermostat with

timer, for example, DEVIreg™ Smart;

smaller than 5 m² – simple one

without a timer, for example,

DEVIreg™ 530 or DEVIreg™ 130, can

be chosen. Simple thermostats are

only recommended due to their

lower cost, and as there are no

restrictions for use of thermostat with

timer for small areas.

The maximum output (in Amperes),

that thermostat is able to switch on

usually varies between 3450-3600 W

(15-16 A). This needs to be taken into

consideration for larger rooms. If

more than maximum 3450-3600 W is

needed the following two solutions

are possible:

1. Heating area is divided into

independent zones with separate

cables and individual thermostats.

Each zone not exceeding the

connected output indicated

above, and with the same output

(in [W/m²]) installed;

2. Contactor (additional relay) with

increased maximum current is

used (e.g. 20 A or more), usually

mounted on a DIN rail in the

electrical switchboard.

Recommendation: it is advised to

choose thermostat load of 70-80% of

maximum installed output.

Choice of additional equipment.

Mounting box for thermostat,

conduit pipe for floor temperature

sensor, screws, nails or anchors for

attaching fitting band to the floor, etc.

It is assumed that the voltage supply

is stable and properly connected,

11Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 12

according to electrical laws of the

country of installation e.g. fuse and

RCD (Residual Current Device) are

of power supply cable are properly

chosen. Otherwise these elements

have to be selected too.

installed in switchboard, section and

length and cross section area

4.1.3 Design Example. Calculation and selection of equipment

Floor construction.

Follow installation instructions

provided by manufacturers of

floor elements, and local building

regulations.

Comfort floor heating for

bathroom.

Input data: bathroom, 2nd floor (over

heated room), no floor insulation,

size 3 x 4 m, total area of 12 m², with

installed 0,9 х 1,7 m bathtub, stable

power supply voltage of 230 V, floor

surface made of tiles.

Restrictions for the floor height: can

be increased maximum by 2 cm.

Heating mat or cable?

Since the floor height is an issue

the concrete thickness is less than

3 cm. Choose a mat, DEVImat™

or DEVIcomfort™ twin conductor

screened mat (find a detailed

description of products in the

DEVI Product Catalogue).

Installed output.

Wet room, stable voltage, 2-nd floor,

tiles, heated room below: an output

of 150-180 W/m² (chapter 4.1.1) is

recommended.

Calculation of heated floor space

(area of cable installation).

Out of the total space A (in [m²])

bathtub area (0,9 х 1,7 m) and strips

of floor of 10 cm along the walls are

subtracted:

A

= 12 m² – (0,9 m · 1,7 m) – ((3 m + 4 m) +

INST

+ (3 m – 0,9 m) + (4 m – 1,7 m)) · 0,1 m =

= 12 m² – 1,53 m² – 1,14 m² ≈

≈ 9,33 m².

Select the desired mat size.

Available floor area is 9,33 m².

DEVImat™ 150T covering 9 m² of

floor, and with total output of 1235 W

at 230 V, is chosen.

If the mat covering 10 m² of floor is

chosen, there will be a surplus of

0,67 m² of mat, and since it’s not

allowed to cut or shorten a heating

cables and mats, the mat covering

9 m² of floor is a preferred choice.

Fitting band.

It is not needed, since DEVImat™ has

a self-adhesive glue on the underside.

We advise to clean the floor and

remove all debris and dust.

Thermostat selection.

DEVImat™ 150T with 1235 W output,

less than 3450- 3680 W maximum

allowed, can be connected to a

DEVI thermostat. For the heating

area exceeding 5 m² – thermostat

with a timer is recommended. For

example, choose the most modern

programmable WiFi thermostat with

intelligent timer – DEVIreg™ Smart.

Type System Temperature sensor Range IP class Load, max.

DEVIreg™

Programmable:

Air: embedded,

Floor 5…45 °С.

IP21 3680 W

Smart

Comfort Floor Heating or Heating

with floor temperature limiting

As an option, simple thermostat

with floor sensor can be chosen:

e.g. DEVIreg™ 530. When thermostat

is installed in a wet room, the

requirements of electrical safety

norms and corresponding IP

class should be strictly followed!

It is recommended to install the

thermostat outside the bathroom.

Additional equipment.

Electrical materials necessary for

installation will typically include

the following: wall mounting box

for thermostat, 4-5 m conduit pipe

for a floor temperature sensor and

additional power supply if necessary.

It is assumed that there is a proper

power supply, according to the rules

Floor: included wire

sensor

Air 5…35 °С

and regulations for safety elements

of electrical installation, e.g. fuse and

RCD are installed.

Summary:

For comfortably warm floor in 12

m² bathroom (with free area of 9,33

m²), the following DEVI floor system

elements are recommended:

Equipment Characteristics Quantity

Twin conductor screened DEVImat™ 150T

9 m² 1235 W (at 230 V), (150 W/m²) 1 pcs.

heating mat

DEVIreg™ Smart thermostat Programmable, WiFi, APP enabled, intelligent timer,

1 pcs.

air and floor sensors, IP21

Conduit pipe Ø 16 4 m

Mounting box 1 pcs.

12 Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 13

4

2,3 1,7

0,1

0,9

3

Temperature sensor in corrugated pipe

0,5

0,075

C-C distanceConnection muff

Thermostat

Figure 1 – Example of heating mat installation in bathroom. All distances are in [m].

4.2. Total (Direct) floor heating

4.2.1. About the system

Total or Direct electrical floor heating

is the only heating system installed

in a room (or area) for maintaining a

user specified room temperature. It

is ensured by adjusting floor surface

temperature, due to the changeable

heat transfer from the surface of

the floor. Such a system is regulated

by a thermostat with air & floor or

only room temperature sensor. Air

room sensor is an integrated part

of DEVIreg™ room thermostats. A

floor heating system has a large

heated surface of the floor, and it is

a convection and radiation heating

system. Advantage of a floor heating

system is to provide heat in the

lower part of a room near legs and

relatively less heat around room

ceiling, where it’s not so highly

needed. It is proven by many studies,

that such temperature division is the

most comfortable for any person,

independent of gender, age and

activity level. Floor heating system

provides a feeling of the same or

improved thermal comfort at lower

overall room temperature setting.

As a result, it can be lowered by app.

1...2 °C, compared with an earlier

used radiator heating system, with

heating element installed visibly

under the window. This provides a

user with improved thermal comfort

and energy savings of approximately

10-20%.

Output of a heating system is chosen

based on the level of calculated

heat loss (in Watts). Energy, which is

provided via a floor heating system,

must cover heat loss and support

a specified air (room) temperature.

End muff

Usually a safety factor of 20-30% is

added to the heat loss calculated

output value, depending on room’s

specific thermal condition. As the

heating system is controlled by a

thermostat, installing larger power

output does not affect the overall

consumption of electrical energy for

heating.

Total electrical floor heating, “Heating

via floor” should not be confused

with “Comfort Floor Heating/Warm

Floor”. The need for warmth is

variable, because of the changing

outside temperatures during the

heating period, and accordingly

floor temperatures varies too. As

an example, in October, when the

outside temperature is +5 °C, it

would be enough to heat the floor

up to 21...22 °C to maintain indoor

temperature of 20 °C. But in February,

13Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 14

when the outside temperature is

lower e.g. -15 °C, floor will be heated

more e.g. 25...26 °C, to maintain the

same room temperature.

When utilizing floor heating system

for total heating you should always

choose as technically correct

solution, but observe the limitation

of the maximum floor temperature.

For regulation of a total heating

system a thermostat measuring

air (room) temperature and fitted

with floor temperature sensor is the

preferred choice. Allowing setting

maximum floor temperature level

and constantly monitoring prevents

overheating of floor. Such limitations

are strictly necessary for floors with

wooden surface.

Special DEVI thermostats are used

where setting of the maximum

floor temperature is necessary or

advisable:

• in programmable models: by

setting of special option.

• in simple models: by manual

potentiometer under the

thermostats cover.

Factory default setting for maximum

floor temperature limit is 35 °C.

Even if a specific floor installation

doesn’t particularly require a floor

sensor to be installed, it’s strongly

advised to do so. Install a plastic pipe

conduit where, at later date, floor

sensor could be fitted. The heating

element (cable or mat), is installed in

the floor construction where it forms

parallel lines. When using a heating

cable: output density of heating

system (in [W/m²]) is determined

by C-C distance (cable-to-cable or

center-to-center distance) of heating

cable. Increasing the distance

between cables leads to decreasing

of output and vice versa. When a

desired output density is calculated

and chosen, than C-C distance,

that will determine the number of

cable lines per 1 m² of floor or the

cable length per 1 m² is calculated.

Multiplying the chosen cable length

on a total area of heating cable

installation will give the calculated

length of heating cable.

C-C distance (cm) =

Available floor area (m²) · 100 (cm/m)

=

Length of chosen cable (m)

Detailed information about cable

installation procedure is found later

in this document.

For modern houses or dwellings

calculated heat loss is small and,

consequently, the output of floor

heating system is also limited. As a

result, to prevent a heating cable

from being installed with a large C-C

distance, it’s advisable to use one

with less linear output. For example,

for calculated heat loss of 50 W/m²,

when using the most common

DEVI cable: DEVIflex™ 18T, the C-C

distance will be as big as 36 cm. That

will inevitably lead to a floor surface

pitted with cold zones situated

between lines of the installed heating

cable. As aim for a floor heating

system is to achieve and maintain

a constant and comfortable floor

temperature, for heating systems

with required low specific output,

we recommend heating cables with

lower linear output (in [W/m²]): for

example DEVIflex™ 10T or DEVIflex™ 6T.

This allows reduction of C-C

distance and leads to a more even

temperature division on the floor.

Safety coefficient.

For heating systems installed in

floor structure, it’s necessary to add

a safety coefficient of 1,2-1,3, when

designing a power output that needs

to be installed in the floor. This factor

is an experience value used by the

industry, and is based on following

facts:

• heating cables length, resistance

and wattage tolerance,

• power supply voltage has some

accuracy,

• heat loss downwards, floor

buildup, and surface material type.

Floor surface temperature.

It should be taken into account that

the big heat loss leads to necessity

of big output from a heating

system and, accordingly, to high

and perhaps not a comfortable

temperature on the surface of the

floor. The maximum temperatures

of the floor surface for different

types of applications are specified in

the relevant standards. For a rough

estimation of the possible floor

temperature for a given output the

value of heat exchange coefficient of

α =10 W/(m²·K) (more description is

found in paragraph about Comfort

floor heating) should be used. For

example, if the output of the heating

system is 150 W/m² and heat loss

down is ~ 20%, than the heat flow up

is 150 – (150 · 20%) = 120 W/m².

If actual heat loss is close to that

value, it will imply a requirement

of an increase of a floor surface

temperature with as much as 12 °C

(120 W/m² /10 W/(m²·K) in relation

to air temperature. E.g. if the air/

room temperature is 18 °C, the floor

temperature can reach 18 + 12 = 30 °C

in the coldest time of the year to

satisfy the rooms actual heat loss.

4.2.2. Calculation and selection of

elements/products

For more detailed information refer

to the DEVI Product Catalogue and

previous chapters of this document.

Estimation of a heating system’s

calculated output.

Define heat loss of the premises

Q [W]: from documentation or by

calculation (e.g. EN 12831).

Floor heating system calculated

output is determined with taking into

account a safety factor of 1,3:

P = Q · 1,3 [W].

Choice of a specific heating

element (mat or cable).

Define the thickness of floor

construction over the cable. If

planned concrete height is 3 cm

or more, heating cable is usually

installed, if floor construction is thin

(tile adhesive, etc.), heating mat

(with thickness of ~ 3-4,5 mm) is a

preferred choice. It should be noted

that there are no restrictions for use

of heating mat in concrete or thick

floor construction.

14 Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 15

It’s strongly advised to install

insulation in the floor construction

if possible. Its thickness should be

selected according to local norms.

When heating system works for a

fairly long period during the year

(e.g. in the Nordic countries for

6-8 months per year), thickness of

thermal insulation in the floor has a

direct influence on level of heat loss

and therefore additional electricity

costs. For the durability of the floor

construction concrete installed

over/onto insulation, has to have

a thickness of at least 3 cm and be

in accordance with local building

norms.

Estimation of heated floor area.

To estimate installation area of

heating cable or mat A

(in [m²]):

INST

deduct the area, where cable is not

installed, from the total area of the

installation (room). It’s recommended

that strip along the walls without

cable/mat has width of ~ 10-15 cm

and along the interior walls, where

furniture will be most probably

installed, is within 30-40 cm.

For heating systems in the floor

construction, furniture on legs

(min. 5 cm of air gap to the floor) is

advised, allowing airflow underneath,

so the cable/mat under the furniture

will not overheat.

Estimation of the calculated output

per [m²].

Specific calculated area output, p

CALC

[W/m²] is calculated by dividing the

calculated heat loss Q [W] by the

installation area A

p

= Q / A

CALC

INST

[m²]:

INST

[W/m²].

It should be noted that the calculated

output is typically slightly less than

real chosen output of heating cable,

which is installed in the floor. This

is due to the fact that cable can be

attached on DEVIfast™ fitting band

with a fixed distance of 2,5 cm (or

multiplication thereof) only.

Choice of length of heating cable

or area of heating mat.

Total cable/mat output should not

be less than the calculated heat loss,

including the safety factor of 1,3.

Heating cable.

Cable is usually fixed with help of

DEVIfast™ metal fitting band, with

cable attachment points every 2,5 cm

and allows to implement different

fixed output on 1 [m²]. This fact

should be taken into consideration

during calculation of a specific

solution. For example, if the cable is

DEVIflex™ 18T and supply voltage

is 230 V for C-C distance of 12,5 cm,

output is 145 [W/m²], and for

C-C = 10 cm – 180 [W/m²]

(See also Appendix A.1).

It should be noted that in some

countries supply voltage is lower

than 230 V, which leads to a decrease

in cable output and, respectively,

different [W/m²] with the same

installation distance. For example

at 220 V electrical supply, the output

form a heating element, rated at

230 V is only 91,5% (coefficient

0,915 should be applied to heating

element output from DEVI Product

Catalogue).

For heating cable with defined

installation C-C distance, a specific

output p

[W/m²] is selected,

INST

with help of a product table or

calculated using the formula. Usually

a product with nearest larger value

to calculated output p

is chosen.

CALC

This chosen/calculated output will

be the actual output for 1 m² of the

heating system. In other words, it is

area specific output p

[W/m²] of

INST

selected heating cable installation

C-C distance.

Heating cable total output p

calculated as the specific output p

CALC

[W] is

INST

[W/m²] multiplied by the installation

area A

p

CALC

[m²]:

INST

[W] = p

[W/m²] · A

INST

INST

[m²]

Cable is selected from a list of factory

produced products, with output

p

[W], usually the nearest larger

INST

to calculated output p

[W]. The

CALC

nearest lower output can only be

recommended, if it differs from the

estimated no more than ~5%.

Output of the selected cable is

the actual output of the heating

system.

For total room heating DEVI

recommends to choose screened

twin conductor DEVIflex™ 18T,

DEVIflex™ 10T, DEVIflex™ 6T heating

cables or, only if necessary, a single

conductor DEVIbasic™ 20S heating

cable.

The number at the end of the

cable’s name refers to its specific

output for 1 m – W/m at 230 V,

letter T – twin conductor cable

(Twin), letter S – single conductor

cable (Single).

In floor construction the most

frequently used cable is

DEVIflex™ 18T – twin conductor,

18 W/m at 230 V.

Heating mat.

When installing thin heating mat, it

is chosen with a specific output

p

[W/m²] the nearest larger to

INST

calculated output p

. However

CALC

installation also needs to look at

the available floor area A

and choose a mat, that covers an

area close to available. Otherwise

installation will leave unheated

and cold floor areas, resulting in

users dissatisfaction with the total

heating system.

For example, DEVI screened heating

mats designed for installation in

floor construction:

• twin conductor of ~3,0 mm:

DEVImat™ 70T, DEVImat™ 100T,

DEVImat™ 150T, DEVImat™ 200T;

• twin conductor of ~4,0 mm:

DEVIcomfort™ 100T,

DEVIcomfort™ 150T;

• single conductor of ~3,0 mm:

DEVIheat™ 150S.

The number at the end of the mat’s

name refers to its specific output for

1 m2 in [W/m²] at 230 V, letter T –

twin conductor mat (Twin), letter S –

single conductor mat (Single).

INST

[m²],

15Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 16

For example, DEVIcomfort™ 100T

heating mat is a twin conductor,

100 W/m² at 230 V (91 W/m² at 220 V).

Output of the selected heating mat

will be the actual output of the

heating system.

Calculation of the length of the

fitting band.

If heating cable is chosen, it is

recommended to use fitting band

to fasten it to the floor base, for

example, galvanized DEVIfast™

fitting band. DEVIfast™ is usually

attached to the floor (screwed,

nailed or glued) in parallel lines

spaced every 50 cm, but not more

than 1 m. As a result, approximately

two meters of band for each square

meter of installation area are used.

Calculation of fitting band length

L

(m) - cable installation area is

FIX

multiplied by two:

L

= AS

FIX

· 2 [m].

INST

Alternatively, if installation allows,

heating cable can be fixed to metal

reinforcement mesh placed in the

floor construction with help of

DEVIclip™ twist.

Choose a thermostat.

Thermostat designed for electrical

floor heating system for total

heating is fitted with an internal

air temperature sensor and

usually with an additional floor

temperature sensor (included

with thermostat). The floor sensor

allows controlling and limiting the

maximum temperature of the floor

surface. This restriction is often

mandatory and standardized for

some producers of floor coverings,

e.g. for laminate or parquet boards.

Following is recommended, if:

• heating area is larger than 5 m²:

programmable thermostat with

timer, for example, DEVIreg™

Smart or DEVIreg™ Touch

• heating areas is smaller than 5 m²:

simple thermostat without timer,

for example, DEVIreg™ 532 or

DEVIreg™ 132, can be chosen.

Simpler thermostats are only

recommended in terms of their

lower cost. But for heating system

thermostats with timer are the

most energy-efficient choice, since

there is a possibility to save energy

during the absence of people in the

room, e.g. reduce temperature in

the room at night.

Thermostats have an internal

relay that has a limitation of the

maximum output (Amperes), that

thermostat can switch on: typically

3450-3680 W (15-16 A).

In case of need to install more than

maximum 3450-3600 W, following

two solutions are possible:

1. Heating area is divided into

independent zones with separate

cables and individual thermostats,

each zone not exceeding the

connected output indicated

above, and with the same output

(in [W/m²]) installed;

2. Contactor for proper current

isused (additional larger relay),

usually mounted on a DIN rail in

the switch panel.

Recommendation: it is better to

choose thermostat load at 70-80%

of maximum.

Choice of additional equipment.

Mounting box for thermostat,

conduit pipe for floor temperature

sensor, nails or anchors for

attaching fitting band to the floor,

etc.

It is assumed that the voltage

properly supplies the place of

the thermostat installation, e.g.

fuse and RCD are installed in

switchboard, section and length of

power cable are properly chosen,

etc. Otherwise these elements have

to be selected too.

Floor construction.

In multi-layer floor construction,

consisting of many elements, a wide

range of considerations need to be

made. Always follow the national

rules for construction and in case of

uncertainty get in contact with your

local DEVI product supplier.

Example. Direct Floor Heating – calculation and selection of equipment

Total heating system for new build

living room.

Total heating via electrical floor, using

the heating cable including limiting

of maximum floor temperature.

Data:

Room size 3 x 5 m, total area of 15 m²,

concrete floor, stable supply voltage

230 V, ground floor, concrete is

assumed more than 3 cm thick,

calculated heat loss is 1100 W.

Definition of cable system’s

calculated output.

The calculated heat loss Q is 1100 W

or per [m²]: 73,3 W/m². To select cable

heating systems take into account

the safety factor of 1,3, the calculated

output is: P = 1100 · 1,3 = 1430 [W].

16 Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Choice: heating mat or cable.

Concrete is assumed not less than

3 cm thick, floor construction is

“thick”. Twin conductor screened

DEVIflex™ 18T heating cable is

chosen for installation.

It is assumed that insulation of

necessary thickness will be laid under

the cable, so downward heat loss is

minimal and does not require taking

into account.

Estimation of heating cable or mat

installation area.

It is proposed that the cable is placed

at a distance of 10 cm (0,1 m) from

the 3 m length outer wall and the

same from opposite wall with the

door. There are no other permanent

(fixed) installations in the room,

limiting the availability of the floor

area. Under these assumptions for

3 x 5 m room the area for cable

installation is:

A

= 15 m² – (3 + 5 m) · 0,1 m –

INST

– (5 + 3 m) · 0,8 m =

= 15 m² – 0,6 m² – 3,2 m² =

= 11 m²

4. Estimation of the calculated

output per 1 m².

The calculated heat loss Q [W] should

be divided into cable installation area

A

[m²]:

INST

p

CALC

= Q / A

= 1430 W/11 m² =

INST

= 130,3 ≈ 131 W/m².

Page 17

Calculation of the length of the

heating cable

Choose twin conductor screened

DEVIflex™ 18T heating cable. Cable

installation on DEVIfast™ fitting band

requires the choice of C-C distance

with step of 2,5 cm (see Appendix A.1.).

Specific output p

[W/m²] is

INST

selected by the table or calculated

using the formula as the nearest

larger settlement to calculated

output p

For calculated above p

CALC

.

= 131 [W/m²]

CALC

for cable 18 [W/m] – DEVIflex™18T,

choose from the table the nearest

larger specific output (at 230 V) and

appropriate C-C distance

(see Appendix A.1):

C-C distance,

cm

18 W/m

DEVIflex™18T

… …

12,5 144 W/m²

15 120 W/m²

17,5 103 W/m²

… …

Choose specific installation output

p

= 144 W/m² and

INST

respectively C-C = 12,5 cm.

Note: For the heating system, mat

heating element can be installed in

concrete too. The nearest larger to

p

= 131 W/m² is mat output

CALC

150 W/m², so mats which names

end with 150T are suitable

(DEVIcomfort™ 150T etc.).

Heating cable calculated specific output:

P

= p

· A

CALC

INST

INST

= 144 W/m² · 11 m² = 1584 W.

Factory-produced cable DEVIflex™ 18T

with the nearest larger to1584 W

output is 1625 W cable 90 m

(see DEVI Product Catalogue) .

It should be noted that cable with

less power – 1485 W (82 m) could not

be selected as a variant, because its

power varies more than 5% from the

calculated of 1584 W.

Calculation of the length of the

fitting band.

Using of metal fitting band DEVIfast™

for cable fixing is supposed. Band is

attached to the floor in parallel lines

spaced every 50 cm. So band length

can be defined as the area of cable

installation multiplied by two:

L

= A

FIX

· 2 = 11 m² · 2 = 22 m ≈

INST

≈ 23 m.

You can choose, for example, 1

packaging of 25 m of DEVIfast™.

Thermostat selection.

Thermostat designed for heating

system has to be selected. e.g.

thermostat with air temperature

sensor and an additional floor

temperature sensor. The heating

system will operate during the

whole heating period: therefore,

it is important to save electricity.

To do this, choose thermostat with

timer, with possibility to set low

temperature at night and during

periods of absence of people in

the room.

For rooms with area smaller than

5 m², consider also the economic

implication of choosing a thermostat

without timer.

For this example the selected heating

cable’s output is1625 W. It is less than

the maximum allowable 3500 W

(15-16 A) for most DEVI thermostats.

For example, DEVIreg™ Smart

thermostat: it can be used for

comfort or total room heating, with

the ability to limit the maximum floor

temperature. With DEVI Smart APP, an

intelligent timer, and stylish design,

it should be installed in the wall

mounting box, maximum load is 3,7

kW (16 A), 230 V, IP21.

Choice of additional equipment.

Mounting box for thermostat,

conduit pipe for floor temperature

sensor, nails or anchors for attaching

fitting band to the floor, etc.

It is assumed that there is a stable

voltage supply to the place of

the thermostat installation, and

safety fuse and RCD are installed in

switchboard, section and length of

power cable are properly chosen, etc.

Otherwise these elements have to be

selected too.

Summarizing the above:

DEVI electrical floor heating system

for total heating (Direct Heating via

Floor) with limitation of maximum

floor temperature is implemented for

a floor area of 15 m² with calculated

heat loss of 1100 W, following

equipment is needed:

Equipment Characteristics Quantity

Twin conductor screened heating cable

DEVIflex™ 18T

90 m, 1625 W (at 230 V), C-C distance of 12,5 cm,

~144 [W/m²], avaliable floor area of 11 m²

1 pcs.

DEVIfast™ Metal fitting band Galvanized metal, distance of 2,5 cm 1 pcs. of 25 m pack

DEVIreg™ Smart thermostat, white

Programmable, Wi-Fi, accessible with APP,

intelligent timer, air and floor sensors, IP21

1 pcs.

Conduit pipe Ø 16 4 m

Mounting box 1 pcs.

17Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 18

5 m

heating

cable

DEVIfast™ fitting band outer wall

max. 1 m

50 cm

C-C

3 m

outer

wall

muff

Fig. 2 - Example of heating cable installed in a room. Direct Floor Heating

thermostat sealed pipe with the sensor cable end

4.3. Accumulating heating via electrical floor heating system

4.3.1. About the system

DEVI’s accumulating heating system

is designed to be used in houses,

offices, and factories where there is an

opportunity to use electricity during

low tariff periods.

The heating cables are embedded

in a thick layer of concrete (7-15 cm)

typically >10 cm, that accumulates the

heat produced during the low tariff

period. The bigger amount of concrete is

installed, enveloping the heating cables,

the bigger is the thermal capacity of the

floor (more energy can be stored).

Installed output.

As already described in the previous

chapter, the heat loss in a room needs

to be known in order to calculate the

installed output for accumulating

heating.

A low tariff period of e.g. eight hours

during night means that the cables/

mats have eight hours to generate the

required amount of heat to be released

over approximately the next 16 hours

before the next low tariff period sets in.

So output for this accumulating system

has to be 3 times higher than output of

direct heating system. To ensure that

the system responds quickly, a safety

factor of approx. 1,3 has to be included

in the output calculation.

It should be noted that air (room)

temperature regulation is different,

with almost no possibility of adjustment during day. That’s because floor

is overheated in the morning, due to

heat accumulation in the night, and

under-heated at the end of a day.

Difference of the air (room) temperature, according to standards, usually

should not be more than 4 °C. To avoid

uncomfortable room temperatures at

winter time, it is advised to install an

additional direct heating system. It has

to be designed in such way, that the accumulating heating system should be

supplemented by direct cable rim zone

heating, or other heating source.

Accumulating heating system has

to be controlled by special timer

thermostat, to regulate the floor

storage heating during low tariff

periods and save energy. Thermostat

is usually connected to an outdoor

sensor, in order to constantly measure

an outdoor temperature or weather

conditions, and calculate amount of

energy which has to be stored in floor.

Alternatively a thermostat with a timer

can also be used as a regulation unit.

More information about accumulating

heating can be found in specialized

standards, e.g. DIN 44576.

18 Division · Cable Floor Heating Systems · VGLUH102 · ©DEVI

Page 19

4.3.2. Calculation and selection of equipment for Accumulating heating system

Installed output

As already described in the previous

paragraph, the heat loss in a room needs

to be known in order to calculate the

installed output for accumulating heating.

To ensure that the system responds

quickly a safety factor of approx. 1,3 has

to be included in the calculation.

A low tariff period of e.g. eight hours

means that the cables/mats have

eight hours to generate the required

amount of heat to be released over

approximately the next 16 hours before

the next low tariff period sets in.

The following equation is used to

calculate the total required output [W]

for accumulating heating systems:

Calculated heat loss · T · C

P =

t

Where:

T – hours of use, 24 hours;

C – safety factor, 1,3;

t – time of low tariff, hours.

Normally, the installed output of an accumulating heating system is between:

125-200 W/m². If the calculation reveals