Page 1

Data sheet

Self-acting controllers integrated to heat exchanger (PN16)

IHPT, Termix TPV – Flow-compensated temp. controller with ∆p controller built in (NO)

Description

IHPT

Self-acting controllers are designed to be

integrated directly to heat exchanger. They are

developed to control instantaneous heating of

domestic hot water by means of heat exchanger.

The family of products offer full flexibility

of different requirements regarding control

performance and idle condition (no load

conditions).

Innovative design enables simple, fast and

reliable connection to heat exchanger and most

important production of ultra compact and user

friendly stations for heating of domestic hot

water.

The controller is connected to primary heating

system as well as cold water system. To avoid

risk of leaking from one media to the other the

controller is equipped with double sealing.

Between both sealings there is a bore to the

outside of the valve. In case of leakage from one

sealing the media can escape through the bore.

There are two different controller housings:

- original (IHPT)

- Gemina housing (Termix TPV)

Termix TPV controller has the same function as

IHPT controller, but different (Gemina) housing.

Controllers have:

- WRAS approval,

- ETA VA approval.

Main data:

• DN 15

• kVS 2,4; 3,0 m3/h

• PN 16

• Setting range: 45 ... 65 °C

• Temperature:

Circulation water 2 ... 120 °C

• Connections:

- Union nut

- External thread

The capacity of controllers fully covers the needs

of domestic hot water for flats, one family houses

or dwellings and can be mounted to district

heating network directly, to a block of heating

systems or central located boiler system in a

dwelling house.

© Danfoss | 2017.02

VD.LY.A2.02 | 1

Page 2

Data sheet Controller IHPT and Termix TPV

Ordering

Example 1:

Flow-compensated temperature

controller with ∆p controller built in

(NO); 90O version; not damped;

DN 15; kVS 2,4; PN 16; setting range

45 ... 65 °C; union nut connection

- 1× IHPT DN 15 controller

Code No: 003L3875

Option:

- 1× Housing of sensor stuffing

box

Code No: 013U 8102

IHx Controllers, 90° version - Damped

Picture Typ e DN

3)

IHPT

1)

(m3/h) (°C)

15

k

2,4

3,0 003L3877

VS

Setting range

45 … 65 Union nut

4)

Connection

2)

Code No.

003L3875

Ter mix T PV 15 3,0 45 … 65 Union nut 0 03L 3914

1)

For details see “Selection guideline” section

2)

to heat exchan ger

3)

Controller is de livered with thermostatic ac tuator with standard sensor and M14 sensor stuf fing box (housing of sensor s tuffing box is

not delivered , it is available as an accessory)

4)

see Setting ra nge section

IHx Controllers, miscellaneous versions - Damped

Picture Type

3)

Termix TPV (IHPT) 15 3,0 45 … 65 180 °

1)

For details see “Selection guideline” section

2)

to heat exchan ger

3)

Controller is de livered with thermostatic ac tuator with standard sensor and M14 sensor stuf fing box (housing of sensor s tuffing box is

not delivered , it is available as an accessory)

4)

see Setting ra nge section

kVSSetting range

DN

(m3/h) (°C)

Accessories

Type designations Code No.

Housing of sensor stuffing box

1)

Code includes h ousing and gasket of sensor stuf fing box;

R ½ × M14 × 1 mm, rubber EPDM Ø 12,6 × 4 × 6 mm

1)

013U 8102

1)

4)

Version Connection 2)Code No.

Gemina

housing

Union nut 003L 3915

Ser vice kits

Type designations

Service thermostat 40 … 60 003L3868

Thermostatic actuator with

standard sensor

1)

For details see “ Installation positions” sec tion; sensor is

Setting range Code No.

(°C) for IHPT

45 … 65 003L3833

delivered wit h M14 sensor stuff ing box

1)

2 | © Danfoss | 2017.02

VD.LY.A2.02

Page 3

Data sheet Controller IHPT and Termix TPV

0.16

2

0.8

2

+

⎟

⎠

⎞

⎜

⎝

⎛

=

Technical data

Nominal diameter DN 15

kVS value of thermostatic controller (k

kVS value of built in p controller (k

Controlled p on thermostatic cont. (∆pTC)

Min. flow rate on primary side (Q

Max. flow rate on primary side (Q

Min. flow rate on secundary side (Q

Max. rec. flow rate on secondary side (Q

Nominal pressure

Max. dif f. pressure on primary side

Max. rec. diff. pressure on secondary side 1,0

Medium

Medium pH Min. 7, max. 10

Medium temperature

Setting range 45 … 65

Idle temperature T

Max. adm. temperature at sensor 120

Capillary tube length

Materials

Housings CuZn21Si3P (CW724R)

Cone and diaphragm support MPPE (Noryl)

Main spindle Stainless steel, mat. No. 1.4404

Diaphragm, O-rings EPDM

Temperature sensor Copper, mat. No. 2.0090

1)

valid for primary side

2)

valid for secondary side

3)

on primary and secondary side

4)

at diff. pressure on s econdary side (Δp2 ) 1 bar

)

vs, TC

) 5,0

VS, DP

)

1,min

) 1000 120 0

1,max

) 120

2,min

) 140 0

2,max

m3/h

bar

l/h

PN

bar

ºC

m

2,4 3,0

0,16

70 100

4)

3)

16

6

Circulation water / glycolic water up to 30 %

Domestic hot water (chlorine (cl) content max. 200 ppm)

2 ... 120

set

3)

– 8 °C

0,6

1)

2)

Classification according to VDI 6003

Typ e Wash basin 1)Showers

IHPT, Termix (TPV ) III III

1)

Tapping rate changing in s teps of 6-12-6 l/mi n.

2)

Tapping rate changing in step s of 9-12-9 l/min.

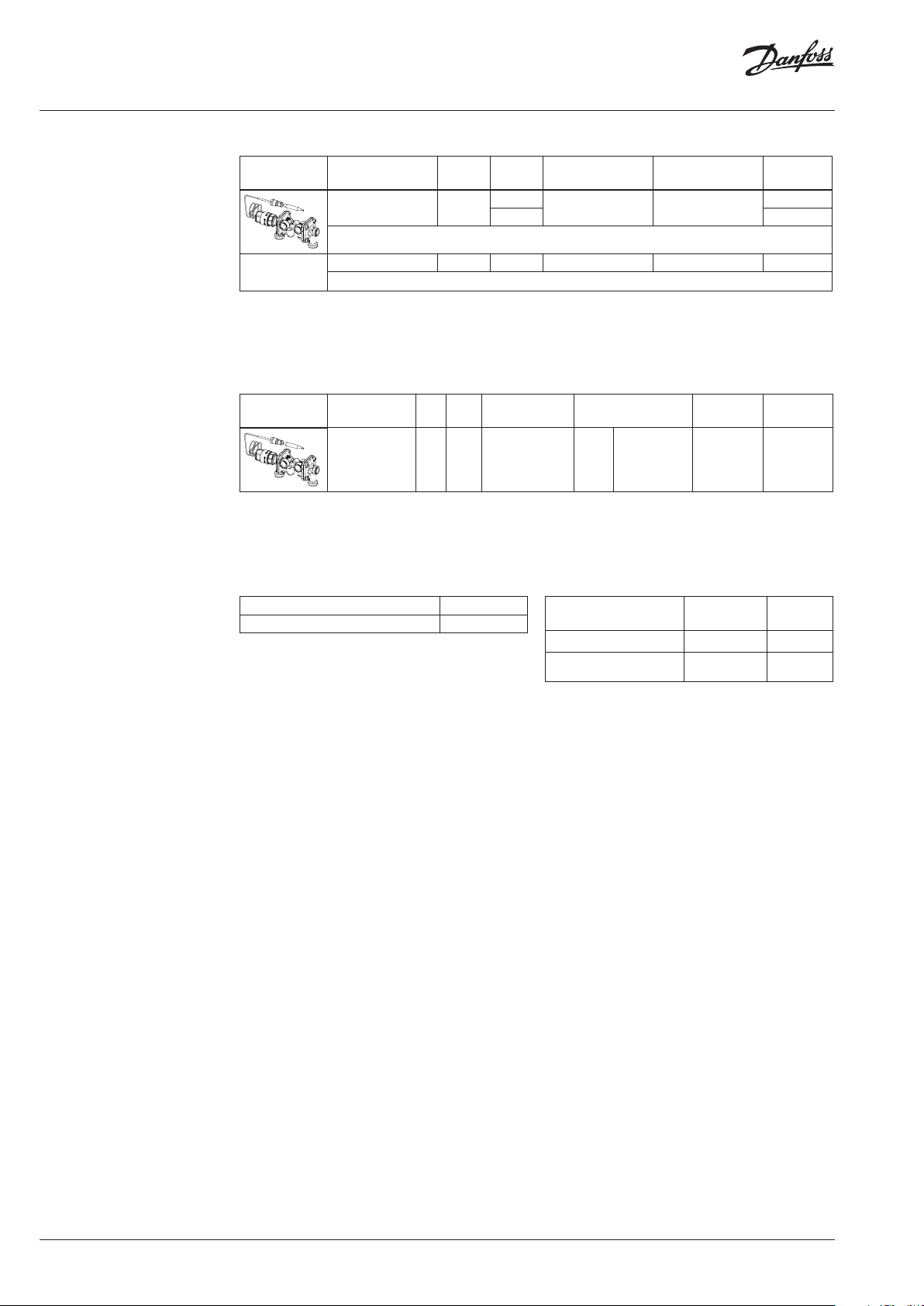

The min. required differential pressure across

primary side of the controller is calculated from

the formula:

2

Δp

⎛

Q

⎜

=

minPRIM,

⎜

⎝

⎞

maxPRIM,

⎟

Δp

+

TC

⎟

k

DPVS,

⎠

In graph pressure drop on secondary side in

relation to the secondary flow can be seen.

*

TC - thermostatic controller

Quick suggestion:

If the max. flow rate on primary side is below

1 m3/h (1000 l/h) always choose kVS = 2,4 m3/h

and if it is higher then choose kVS = 3,0 m3/h.

2)

Measured for constant supply temperature of

75 °C and system differential pressure of 0,5 bar.

Secondary side

VD.LY.A2.02

© Danfoss | 2017.02 | 3

Page 4

Data sheet Controller IHPT and Termix TPV

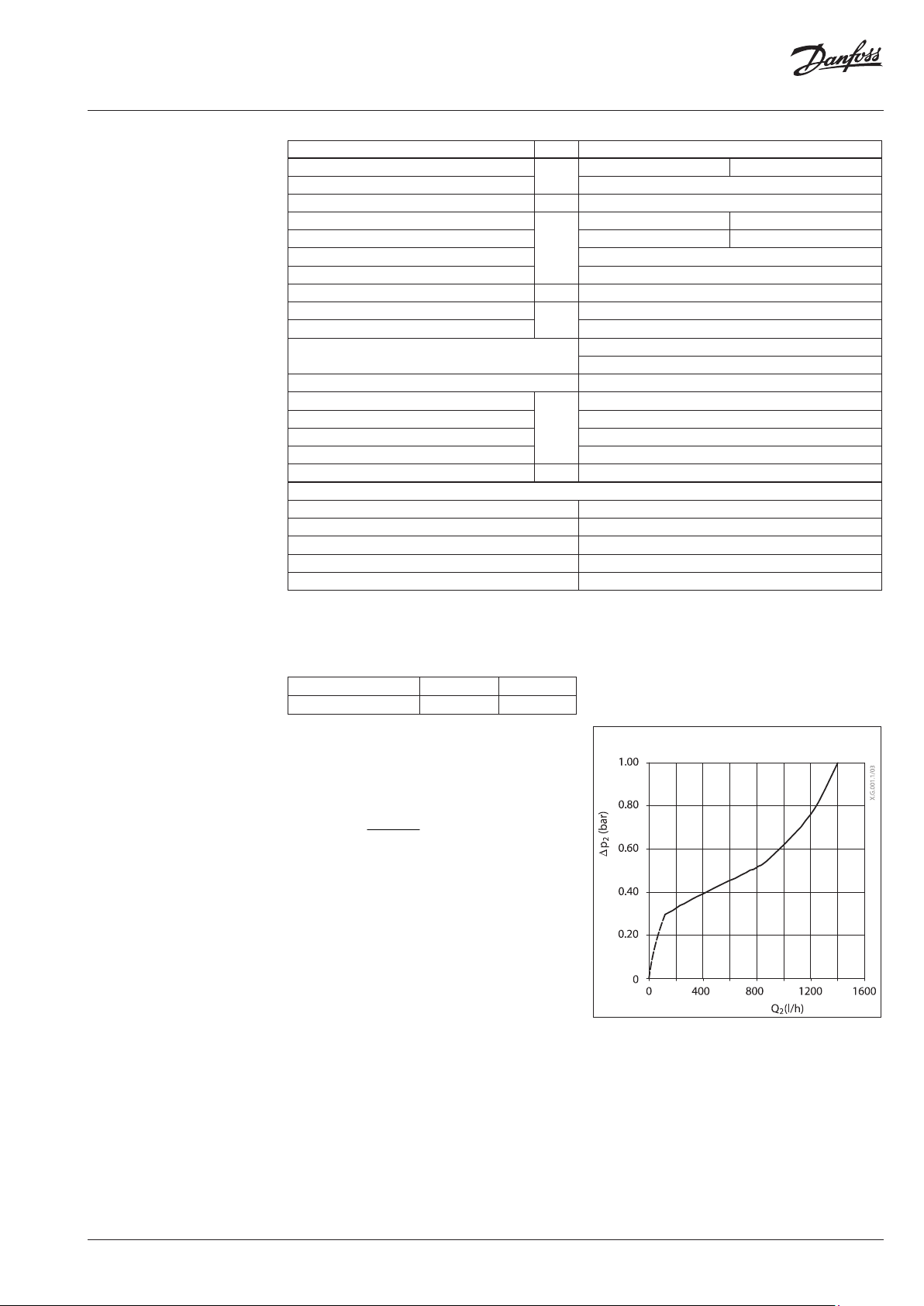

Setting range

Valid for thermostatic

controllers IHPT and Termix TPV

Selection guideline

Setting range 45 ... 65

Temperature setting depends on application parameters. Values given are approximate.

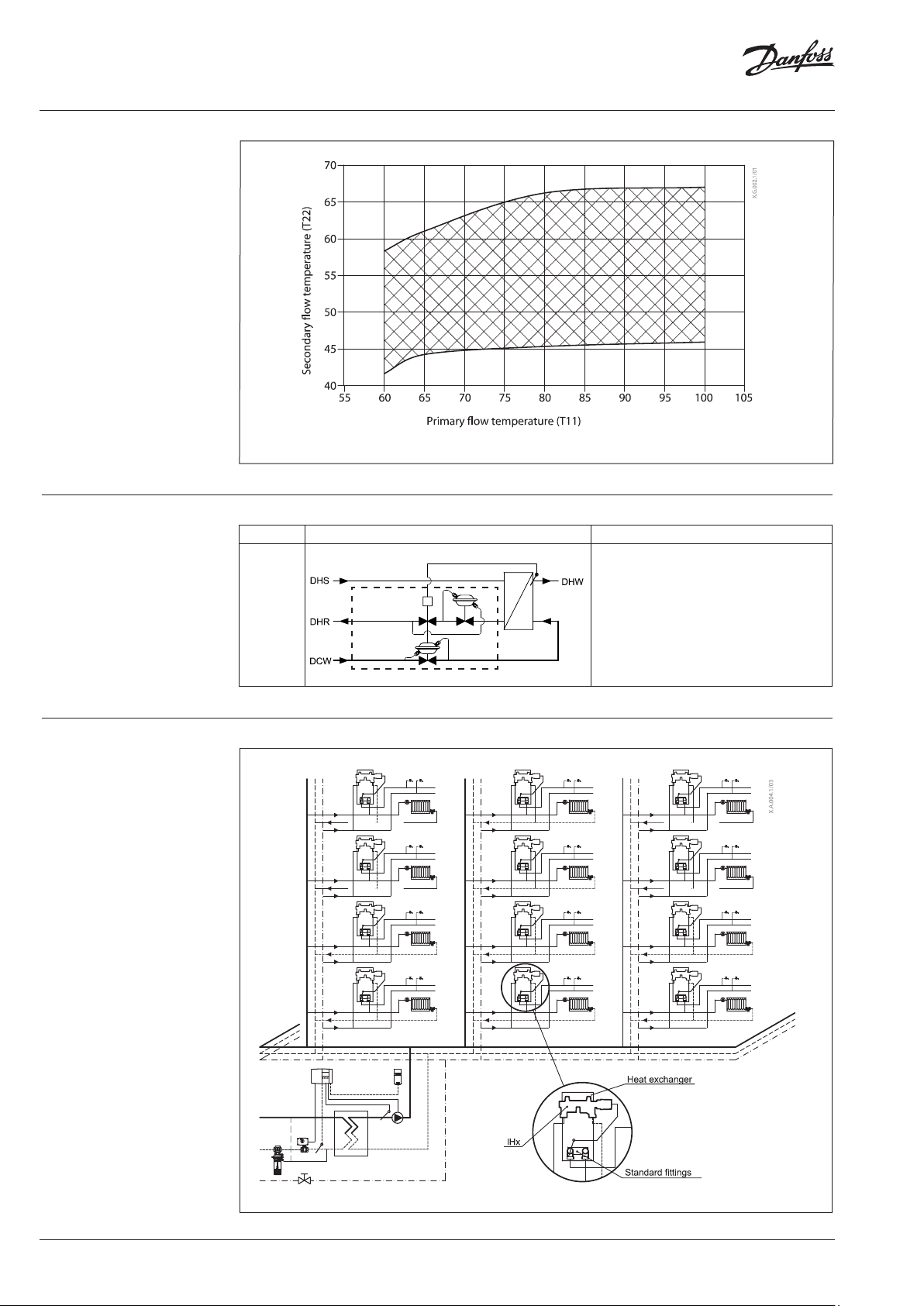

Typ e Application Description

Functions

Flow-compensated temp. controller with

differential pressure controller built in (N0)

IHPT,

Ter mix T PV

IHPT

TC

DP

QC

Typical system conditions

District heating systems with varying supply

temperature plus high and varying differential

pressure and where a high comfort idle

temperature is requested.

Idle control alternatives

Idle controller is built in.

Application principle

4 | © Danfoss | 2017.02

VD.LY.A2.02

Page 5

Data sheet Controller IHPT and Termix TPV

Sensor installation Temperature controller

Controller must be mounted on cold side of heat

exchanger (district heating outlet and domestic

cold water inlet side).

IHPT, Termix TPV controllers are delivered with

standard sensor.

Standard sensor

The sensor must always be placed warmer than

the controller.

Temperature sensor

Can be mounted on any direction.

For best performance it is recommended to

install the sensor facing up.

Strainers installation IIt is strongly recommended to install strainers

on both the cold water pipeline and the district

heating supply line.

Sizing

Example

Instantaneous domestic hot water production

requires primary flow of 800 l/h. Minimum

system differential pressure is 0,8 bar.

o

r

f

m

r

e

p

t

s

e

B

a

n

c

e

Select controller acc. to technical data, page 3,

with the smallest possible kvs value considering

available flow ranges:

Given data:

Q

= 0,8 m3/h (800 l/h)

PRIM, max

∆p

∆p

= 0,8 bar (80 kPa)

syst, min

= 0,1 bar (10 kPa)

exchanger

The total (available) pressure loss across the

primary side of the controller is:

∆p

= ∆p

PRIM,A

∆p

= 0,7 bar (70 kPa)

PRIM,A

syst,min

− ∆p

exchanger

= 0,8 − 0,1

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

∆p

∆p

TC

∆p

syst,min

TC

③

QC

②

k

= 2,4 m3/h

VS,TC

The other relevant data for this controller are:

k

= 5,0 m3/h

VS,DP

∆pTC = 0,16 bar (16 kPa)

The min. required differential pressure across

primary side of the selected controller is

calculated from the formula:

Q

Δp

∆p

∆p

minPRIM,

= 0,19 bar (19 kPa)

PRIM,min

> ∆p

PRIM,A

PRIM,MIN

2

maxPRIM,

k

DPVS,

Δp

TC

0,7 bar > 0,19 bar

PRIM, MIN

DP

exchanger

∆p

①

0.8

2

0.16

5

VD.LY.A2.02

© Danfoss | 2017.02 | 5

Page 6

Data sheet Controller IHPT and Termix TPV

Design

1. Secondary side cone (QC)

2. Moving seat

3. Main body

4. O-ring

5. Differential pressure cone

(DP)

6. Main spindle

7. Primary side cone (TC)

8. Stuffing box

9. Thermostat

10. Handle for temperature setting

11. Secondary side body

12. Circulation connection

plug (⁄”)

13. Temperature sensor

14. Differential pressure moving

seat

15. Washer of sensor stuffing

box

16. Gasket of sensor stuffing box

17. Sealing bolt of sensor

stuffing box

18. Primary side body

19. Housing of sensor stuffing

box

IHPT, Termix TPV

IHPT, Termix TPV

Function The controller has three main functions that

can be mounted in the controller based on

application demands:

QC Proportional flow controller

TC Thermostatic controller

DP Differential pressure controller

TC

QC

DP

To minimise the risk of calcium deposits on cold

water side and sensitivity to high temperatures

the controller is mounted on cold side of heat

exchanger (district heating outlet and domestic

cold water inlet side). In standard applications

at standard conditions with Danfoss heat

exchanger XB 06 primary return temperature is

below 30 °C.

6 | © Danfoss | 2017.02

VD.LY.A2.02

Page 7

Data sheet Controller IHPT and Termix TPV

Function (continuous)

Flow-compensated temperature controller with integrated differential pressure controller

(IHPT, Termix TPV)

Flow-compensated temperature controller IHPT with integrated differential pressure controller

When tapping starts, cold water flows into

secondary side of controller ① passes the

secondary side cone (QC) ②, leaves the

controller ③ and enters the heat exchanger.

When no load (no flow on secondary side) the

controller maintains constant temperature in

the heat exchanger few degrees below adjusted

temperature (Idle temperature).

The pressure drop generated on the orifice is

transferred to the diaphragm ④ which transfers

the force to the spring ⑫. This results in moving

of the main spindle ⑤ to the right which opens

the primary side cone ⑥.

The differential pressure controller ⑧ controls

the pressure over control valve and therefore

enables 100 % authority of the controller in all

conditions.

The opening results in primary flow entering

into controller ⑦, passing integrated differential

pressure controller (DP) ⑧, primary side cone

(TC) ⑥ and leaving controller ⑨.

The temperature sensor ⑩, mounted to

the secondary hot water side is sensing the

temperature. If the temperature is deviating from

setting temperature the thermostatic element ⑬

will move (open/close) primary side cone ⑥ until

desired temperature is reached.

Not to influence on tapping flow from

thermostatic adjustments the spring ⑫ is

mounted between main spindle ⑤ and

diaphragm which can be compressed when

needed.

Settings Temperature setting

Temperature setting is adjusted with handle for

temperature setting.

By rotating the handle for temperature setting ⑬

the temperature of tapping flow can be adjusted.

Domestic hot water circulation ⑪ are placed

directly on the controller and therefore minimize

the costs for mounting and optimize space for

the piping.

IHPT, Termix TPV controller

By turning it in (+) direction the setting is

increased, by turning it in (−) direction the

setting is decreased.

Scale on handle is approximate indication of

temperature setting where MIN represents

minimum and MAX maximum value of the

thermostat temperature setting range.

Temperature setting between MIN and MAX

values changes approximately linearly.

VD.LY.A2.02

© Danfoss | 2017.02 | 7

Page 8

Data sheet Controller IHPT and Termix TPV

Mounting specifics Connections to heat exchanger

Union nut connection

Second option is with union nuts to standard

threaded heat exchanger connections (fig.1)

which have distance between them 45 mm.

In order to cover the tolerances of heat

exchanger production special union nuts were

developed which can tolerate dimensions of

45 ± 1,5 mm (Factory assembled).

In this case standard fittings should be used

on hot side of heat exchanger.

Connections to pipes

For connecting controller to station ¾”

connections are used.

Fig. 1

8 | © Danfoss | 2017.02

VD.LY.A2.02

Page 9

Data sheet Controller IHPT and Termix TPV

Dimensions

IHPT

90°

200.3

VD.LY.A2.02

© Danfoss | 2017.02 | 9

Page 10

Data sheet Controller IHPT and Termix TPV

Dimensions (continuous)

IHPT

90/180

180

10 | © Danfoss | 2017.02

VD.LY.A2.02

Page 11

Data sheet Controller IHPT and Termix TPV

Dimensions (continuous)

Ter mix TPV

90°

180 °

VD.LY.A2.02

© Danfoss | 2017.02 | 11

Page 12

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Controller IHPT and Termix TPV

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

12 | © Danfoss | DHS-SRMT/SI | 2017.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

VD.LY.A2.02

Loading...

Loading...