Page 1

Data sheet

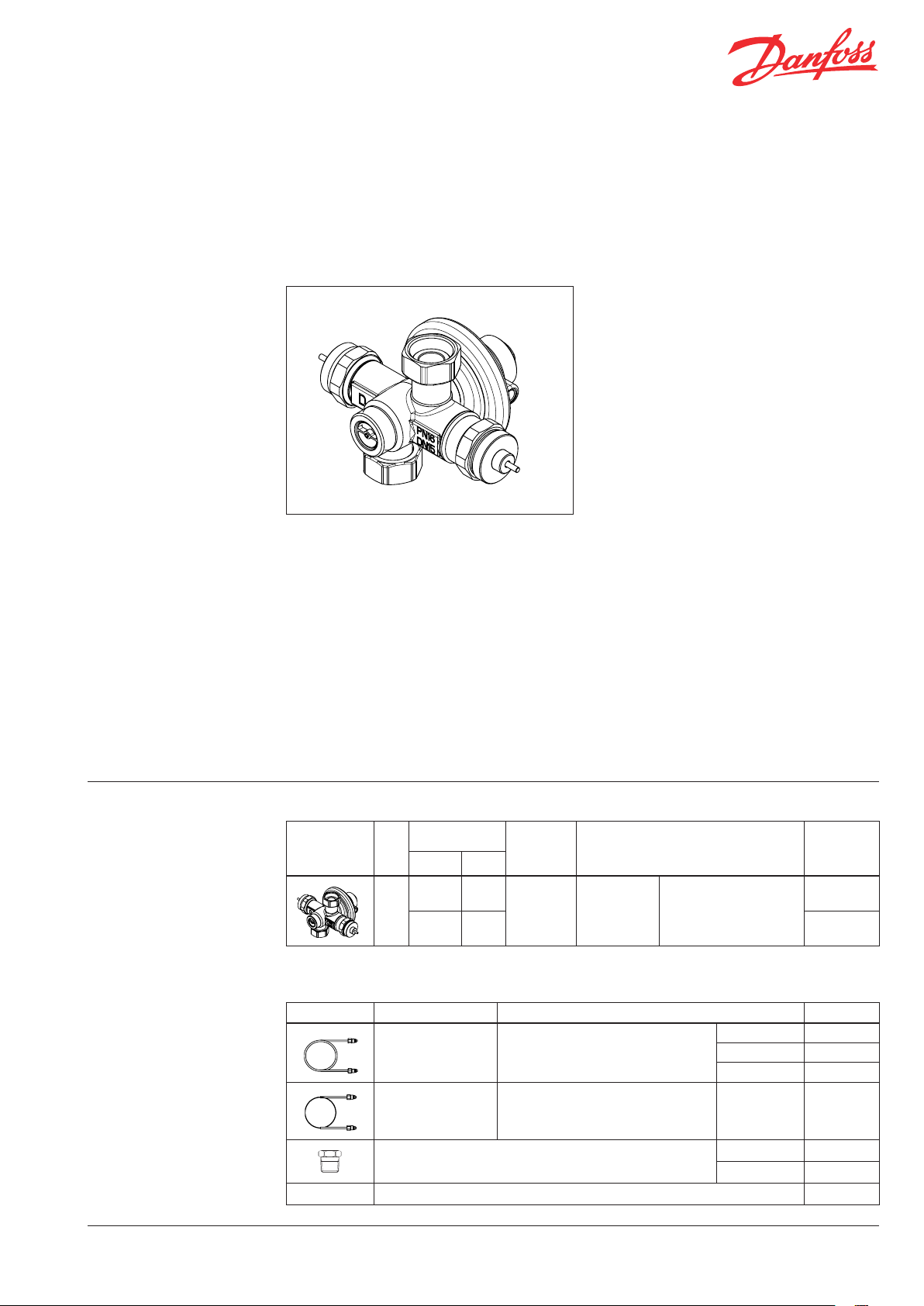

Integrated controller with two control valves and diff. pressure controller (PN 16)

IHPMM-F – flow mounting, fixed differential pressure setting

Description

IHPMM-F is an integrated controller which

consist of two control valves and one self-acting

differential pressure controller. It is developed

primarily for use in district heating systems. The

differential pressure controller closes on rising

differential pressure.

Two control valves are developed to control

heating circuit (HE) and domestic hot water

(DHW) production.

There are other possibilities to use controllers as

well:

- to use both control valves for heating

- to use both control valves for domestic hot

water production

In combination with Danfoss electrical actuators

AMV(E) can be controlled by ECL electronic

controllers.

Innovative compact design enables space

saving due to reduction of number components

and simple, fast and reliable mounting into

substation.

Control valves are used together with Danfoss

electrical actuators:

- AMV(E) 150

- AMV(E) 10 / AMV(E) 20 / AMV(E) 30

- AMV(E) 13 / AMV(E) 23 / AMV(E) 33 with spring

return function

- AMV 20SL / AMV 23SL / AMV 30SL with stroke

limitation

Main data:

• DN 15

• kVS values:

Heating 0.25 m3/h, DHW 1.6 m3/h /

Heating 0.63 m3/h, DHW 2.5 m3/h

• PN 16

• Fixed p setting range: 0.8 bar

• Temperature:

- Circulation water / glycolic water up to 30%:

2 … 150 °C

• Connections:

- Ext. thread (inlet) and int. thread (outlet)

Description

Example:

Integrated controller with two

control valves and differential

pressure controller, DN 15,

kVS HE 0.25, kVS DHW 1.6, PN 16,

fixed ∆p setting 0.8 bar, t

thread

- 1× IHPMM-F DN 15 controller

Code No: 003L354 0

Option:

- 1× Impulse tube set AH, 1.5 m

Code No: 003L8152

- 1× Nipple for imp. tube

Code No: 003L5042

External impulse tube (AH), nipple

for impulse tube and electrical

actuators AMV(E) must be ordered

separately.

DH-SMT/SI VD.LR.C 3.02 © Danfoss 06/2010 1

FOR INTERNAL USE ONLY

max

150 °C,

IHPMM-F Controller

k

Picture DN

1)

I-pack 24 pcs .

VS Δp setting

HE DHW

0.25 1.6

15

0.63 2.5 003L3541

range

(bar)

0.8

Cylindrical

thread acc. to

ISO 228/1

Connection Code No.

Inlet ext. thread G / A

outlet int. thread (nut)

G / A

Accessories

Picture Type designation Connection Code No.

Description:

Impulse tube set AH

Impulse tube set

AH for pressure

reduction

Nipple for impulse tube connection to pipe

10 EPDM o-rings for impulse tube 003L8175

- 1× copper tube Ø 3 × 1 mm

- 2× fitting for imp. tube connection

to actuator and pipe R /

Description:

- 1× stainless steel tube Ø 0.8 × 0.2 mm

- 2× fitting for imp. tube connection

to actuator and pipe R /

1.5 m 003L8152

2.5 m 003L5043

5 m 003L8153

0.8 m 003L3650

G / - R / 003L5042

G / - R / 003L8151

003L3540

1)

1)

Page 2

Data sheet

Integrated controller with two control valves and diff. press. controller IHPMM-F

(PN 16)

Technical data

Valve*

Nominal diameter DN 15

kVS value HE

DHW

kVS value DP m3/h 4.0

Stroke HE, DHW mm 5

Control ratio HE > 1:30

Control ratio DHW > 1:50

Control characteristic HE, DHW Split characteristics

Cavitation factor z ≥ 0.5

Leakage acc. to standard IEC 534 0.05

Nominal pressure PN 16

Max. differential pressure bar 10

Max. closing pressure HE, DHW bar 10

Medium Circulation water / glycolic water up to 30%

Medium pH Min. 7, max. 10

Medium temperature ºC 2 … 150

Connections

Materials

Valve body Dezincing free brass CuZn36Pb2As

Valve seat DP Stainless steel, mat. No. 1.4404 NC

Valve seat HE, DHW Dezincing free brass CuZn36Pb2As

Valve cone DP Dezincing free brass CuZn36Pb2As

Valve cone HE, DHW Dezincing free brass CuZn36Pb2As

Sealing DP EPDM

Sealing HE, DHW Metal

* HE - heating valve , DHW - domestic hot water valve, DP - d iff. p ressure controller

m3/h

0.25

1.6

Inlet ext. thread G / A

outlet int. thread (nut) G / A

0.63

2.5

Actuator

Type IHPMM-F

Actuator size cm

Nominal pressure PN 16

Diff. pressure setting range bar

Materials

Actuator housing

Diaphragm EPDM

Impulse tube

Upper casing of diaphragm Dezincing free brass CuZn36Pb2As

Lower casing of diaphragm Brass CuZn40Pb2

2

Copper tube Ø 3 × 1 mm

Stainless steel tube Ø 0.8 × 0.2 × 800 mm

20.5

0.8

(fixed setting)

FOR INTERNAL USE ONLY

2 VD.LR.C 3.02 © Danfoss 06/2010 DH-SMT/SI

Page 3

Data sheet

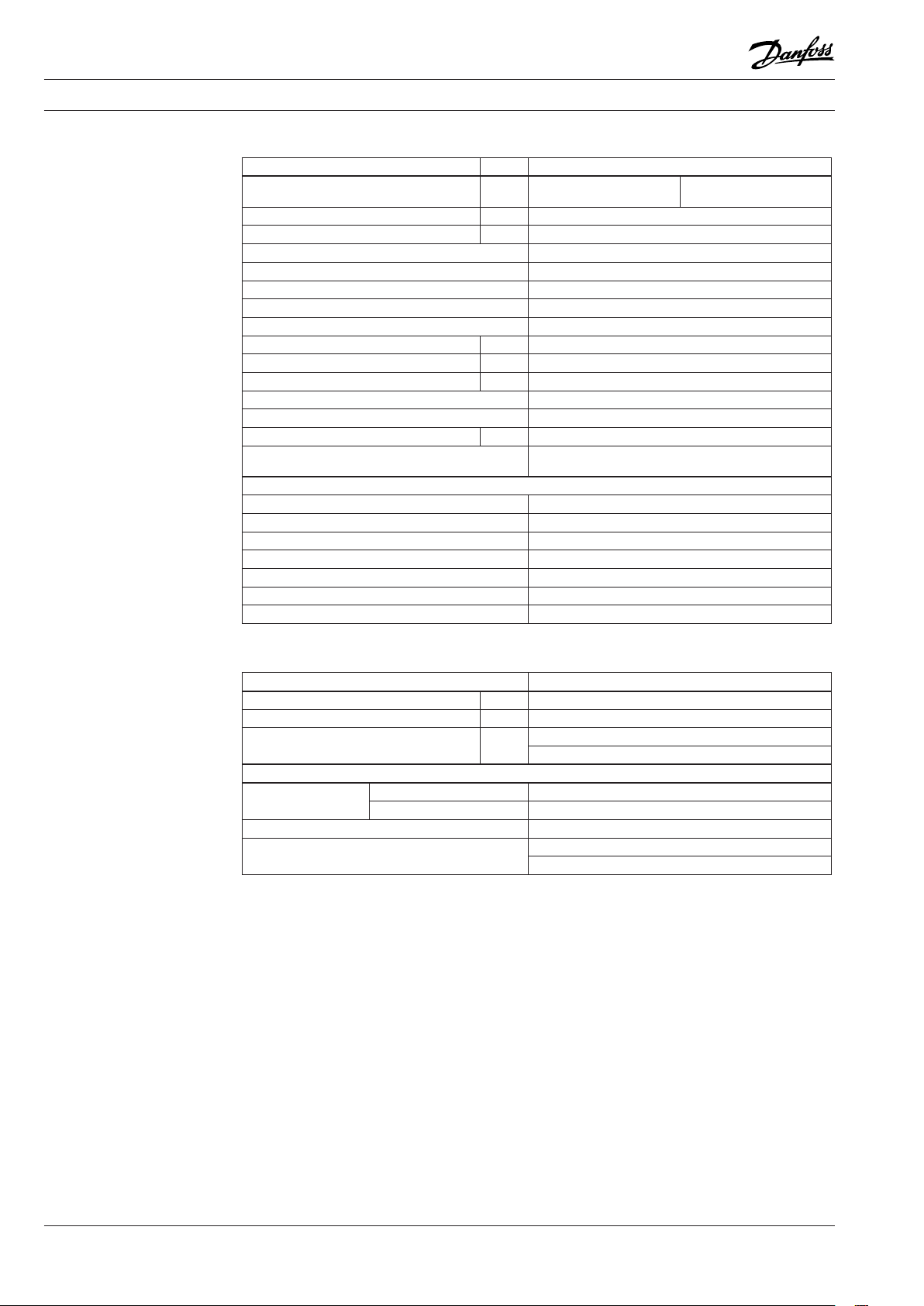

Application principles

Integrated controller with two control valves and diff. press. controller IHPMM-F

(PN 16)

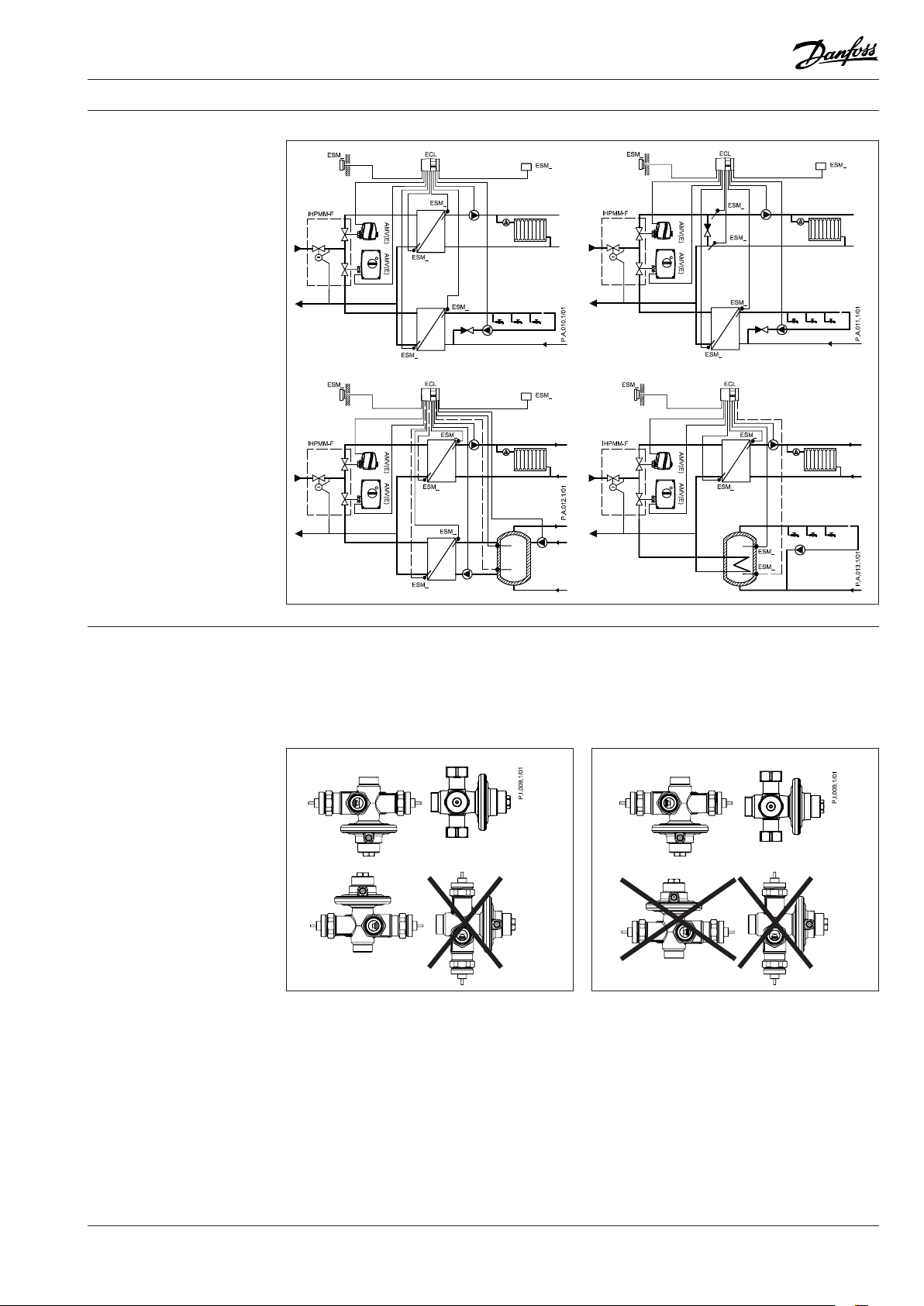

Installation positions

FOR INTERNAL USE ONLY

Up to medium temperature of 100 °C the

controllers can be installed in any position,

except with (connection neck for) electrical

actuator oriented downwards.

Electrical actuator

Note!

Installation positions for electrical actuator

AMV(E) have to be observed as well. Please see

relevant Data Sheet.

For higher temperatures the controllers can

be installed with differential pressure actuator

oriented downwards or horizontal, except with

(connection neck for) electrical actuator oriented

downwards.

DH-SMT/SI VD.LR.C 3.02 © Danfoss 06/2010 3

Page 4

Data sheet

Pressure temperature

diagram

Design

1. Valve body

2. Pressure relieved valve seat *

- DP controller

3. Valve cone * - DP controller

4. Valve steam - DP controller

5. Differential pressure actuator

6. Upper casing of diaphragm

7. Lower casing of diaphragm

8. Control diaphragm

9. Spring for DP control

10. Safety valve

11. Pressure connection (G /)

12. Control valve insert - Heating

13. Control valve cone - Heating

14. Control valve inser t -

Domestic hot water

15. Control valve cone - Domestic

hot water

16. Leakage protective cover

17. Connecting nut (G /)

* Differential p ressure controller has

fixed cone and mov ing seat

Integrated controller with two control valves and diff. press. controller IHPMM-F

CuZn36Pb2As (DZR) PN 16

working

area

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-3).

(PN 16)

Function

FOR INTERNAL USE ONLY

4 VD.LR.C 3.02 © Danfoss 06/2010 DH-SMT/SI

Temperature control

Medium temperatures on heating and domestic

hot water secondary sides are being controlled

by electronic controller (wheather compensator).

Electronic controller based on it’s algorithm

adequately, via electrical actuators, opens or

closes both valves.

Differential pressure control

Pressure changes from the flow and return

pipeline are being transferred through the

impulse tube and control drain in the actuator

stem to the actuator chambers and act on

control diaphragm. Control valve closes on

rising differential pressure and opens on falling

differential pressure to maintain constant

differential pressure.

Page 5

Data sheet

Dimensions

Integrated controller with two control valves and diff. press. controller IHPMM-F

Nipples

(PN 16)

FOR INTERNAL USE ONLY

DH-SMT/SI VD.LR.C 3.02 © Danfoss 06/2010 5

Page 6

Data sheet

Integrated controller with two control valves and diff. press. controller IHPMM-F

(PN 16)

FOR INTERNAL USE ONLY

6 VD.LR.C 3.02 © Danfoss 06/2010 DH-SMT/SI

Page 7

Data sheet

Integrated controller with two control valves and diff. press. controller IHPMM-F

(PN 16)

FOR INTERNAL USE ONLY

DH-SMT/SI VD.LR.C 3.02 © Danfoss 06/2010 7

Page 8

Data sheet

Integrated controller with two control valves and diff. press. controller IHPMM-F

(PN 16)

FOR INTERNAL USE ONLY

8

VD.LR.C3.02

Produce d by Danfoss A/S © 06/ 2010

Loading...

Loading...