Page 1

Data Sheet

Hot gas powered on/off valve

Type ICSX

For HFC/HCFC hot gas defrost application

ICSX hot gas powered on/o valve belongs to

the ICV (Industrial Control Valve) family but it is

dedicated designed for HFC/HCFC systems.

ICSX hot gas powered on/o valve is to be used

in wet and dry suction lines and in liquid lines

without phase change(i.e. where no expansion

takes place in the valve) providing ON/OFF

function in large refrigeration systems.

The valve comprises four components: valve

body, function module, top cover and external

pilot connection. However, only function

module is with dedicated design, valve body,

top cover(with one pilot pressure connection)

and external pilot connection are exactly the

same as standard pilot operated servo valve

ICS.

One NC(normally closed) and one NO(normally

open) solenoid valves with one power supply

signal are needed to control the ICSX hot gas

powered on/o valve. For safety purpose, it is

strongly recommended to install an additional

NC solenoid valve in parallel.

AI404219416371en-000102

Page 2

Hot gas powered on/o valve, type ICSX

Features

• Applicable to HCFC, HFC

• Modular Concept

• Fast and easy valve overhaul service

• Low pressure drop

• Designed to ensure less hot gas leakage

• Max. working pressure: 52 bar(754 psig)

• Temperature range: -60 °C to +120 °C (-76 °F to + 248 °F)

• Exact capacity and setting of the valve can be calculated for all refrigerants by means of Coolselector®2 (Select "ICS

external" from the "Product families")

• Low temperature steel body

• Low weight and compact design

• Covering sizes 32 to 80, others out of this range are upon request

• Replaceable teon valve seat

• Manual opening

• The top cover can be rotated into any possible position without aecting the operation of the valve

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 2

Page 3

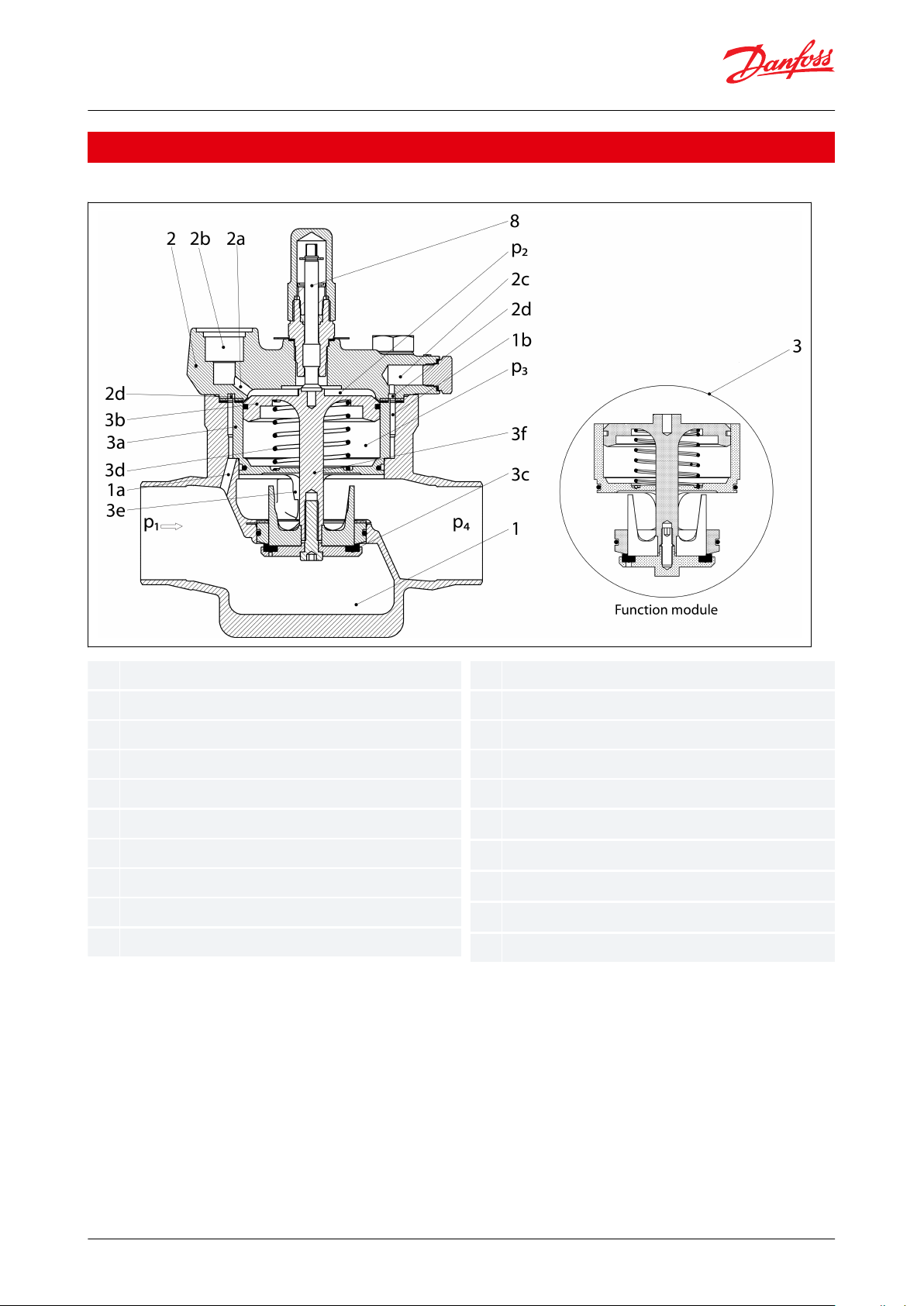

11a1b22a2b2c2d33a3b3c3d3e3f

p1p2p3p

4

8

Body

Pilot channel to inlet side

Circular gap between house and module

Top cover

Piston top inlet channel

External pilot connection hole

Pressure gauge connection

Circular groove

Function module

Cylinder

Piston

Valve plate

Spring

Cone

Piston rod

Inlet pressure

Pressure on piston

Pressure underneath piston

Outlet pressure

Manual operating spindle

Hot gas powered on/o valve, type ICSX

Functions

Figure 1: ICSX hot gas powered on/o valve

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 3

Page 4

NNC, energized/open

Activating coil

O, energized/closed

Pressure relief coil

ICSX open

NC, energized/opens prior to ICSX opening

Soft opening coil

NNC, deenergized/closed

Activating coil

NC, deenergized/closed

Soft opening coil

O

, deenergized/open

Pressure relief coil

ICSX closed

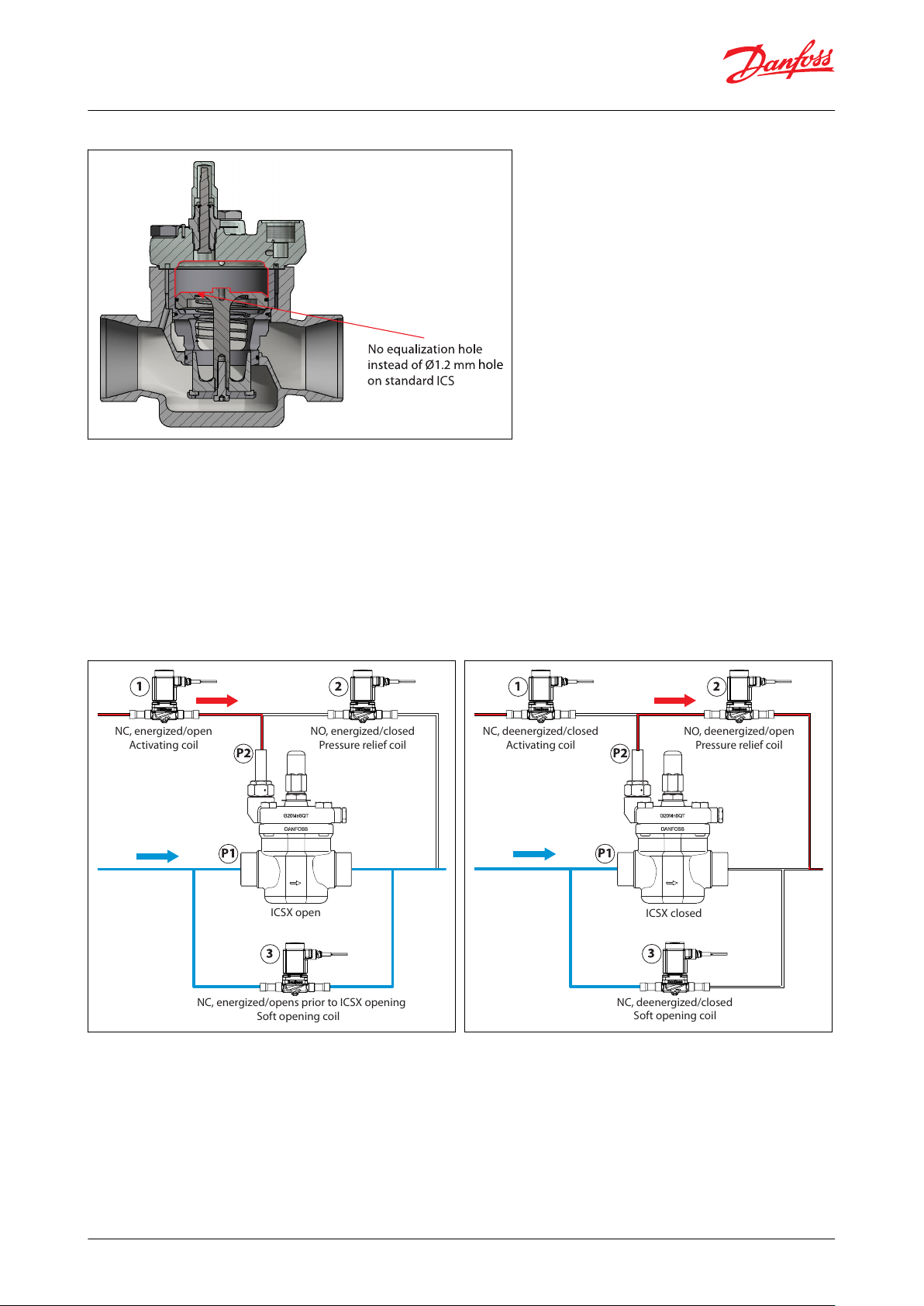

hole

ICS

Hot gas powered on/o valve, type ICSX

Figure 2: ICSX hot gas powered on/o valve

The function module of ICSX hot gas powered on/o valve is with a minor design change on current function

module of ICS pilot operated servo valve. The equalization hole in the piston is removed, see Figure 2. However, the

top cover and housing are remain the same as current ICS pilot operated serve valve.

NOTE:

There is a risk of trapped cold liquid in the volume above the piston (marked red on Figure 2) and the external pilot

connection and system pipes.

Figure 3: ICSX open

Solenoid NC external gas power energized, open

Solenoid NO drain energized, closed

Figure 4: ICSX closed

Solenoid NC external gas power deenergized, closed

Solenoid NO drain deenergized, open

ICSX is a pilot controlled valve used as a open/close valve in suction lines to open with external pressure. This means

that the valve can operate with no internal pressure dierential (Pd) at all and provide a low pressure loss over the

valve.

Low Pd is the key objective and makes the ICSX ideal for applications that are sensitive to dierential pressure loss.

Though Pd is kept low, it can still be quantied, and must be considered when choosing valve size. Check in the

Coolselector, select "ICS external" from the "Product Families".

To assure a proper opening of the valve, the hot gas inlet pressure must be higher than 0,5 bar above the inlet

pressure of the ICSX.

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 4

Page 5

Hot gas powered on/o valve, type ICSX

See Figure 3 and See Figure 4 above, two additional solenoid valves are needed to control the ICSX, pos.1(NC) and

pos.2(NO) with one power supply signal. The external pilot pressure line must be connected to a system pressure

(p2), and usage of NC and NO solenoid valves ensures that trapped liquid (condensed refrigerant) cannot build up

excessive hydraulic pressure due to pressure relief through the NO solenoid valve. Please consider the MOPD of the

solenoid valves.

ICSX hot gas powered on/o valve is kept open when power is applied to the coils of solenoid valves pos. 1 and pos.

2. It is closing and kept closed when the coils of solenoid valves pos. 1 and pos. 2 are de-energized.

It is strongly recommended to install an additional NC solenoid valve pos.3 in parallel for safety purpose so that soft

opening and also high pressure after defrosting is decreased softly. The open period for solenoid valve pos.3 to

drain the high pressure from evaporator has to be determined by commissioning. The opening of ICSX main valve

might not be done before high pressure of evaporator be drained.

The manual spindle can be used to open the valve. Be aware of, that it might not be 100% opening. Depending on

valve size.

NOTE:

The use of stop valves in the pilot lines need to be assessed by a risk assessment according trapped cold liquid. This

risk assessment must be carried out by the designer of the plant.

If other automatic controls are used for controlling the hot gas power or other systems to control the hot gas power,

a risk assessment according trapped liquid as mentioned above must be carried out by the designer of the plant.

Due to the design of the standard valve as a servo operating main valve controlled by dierential pressure, the

emptying of the volume over the piston (Marked red on Figure 2) might take longer than e.g. an ICLX valve. It might

take several minutes when the volume is lled with condensed refrigerant. This must be considered when designing

the defrost sequence, especially in the delay time for opening the hot gas line.

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 5

Page 6

Hot gas powered on/o valve, type ICSX

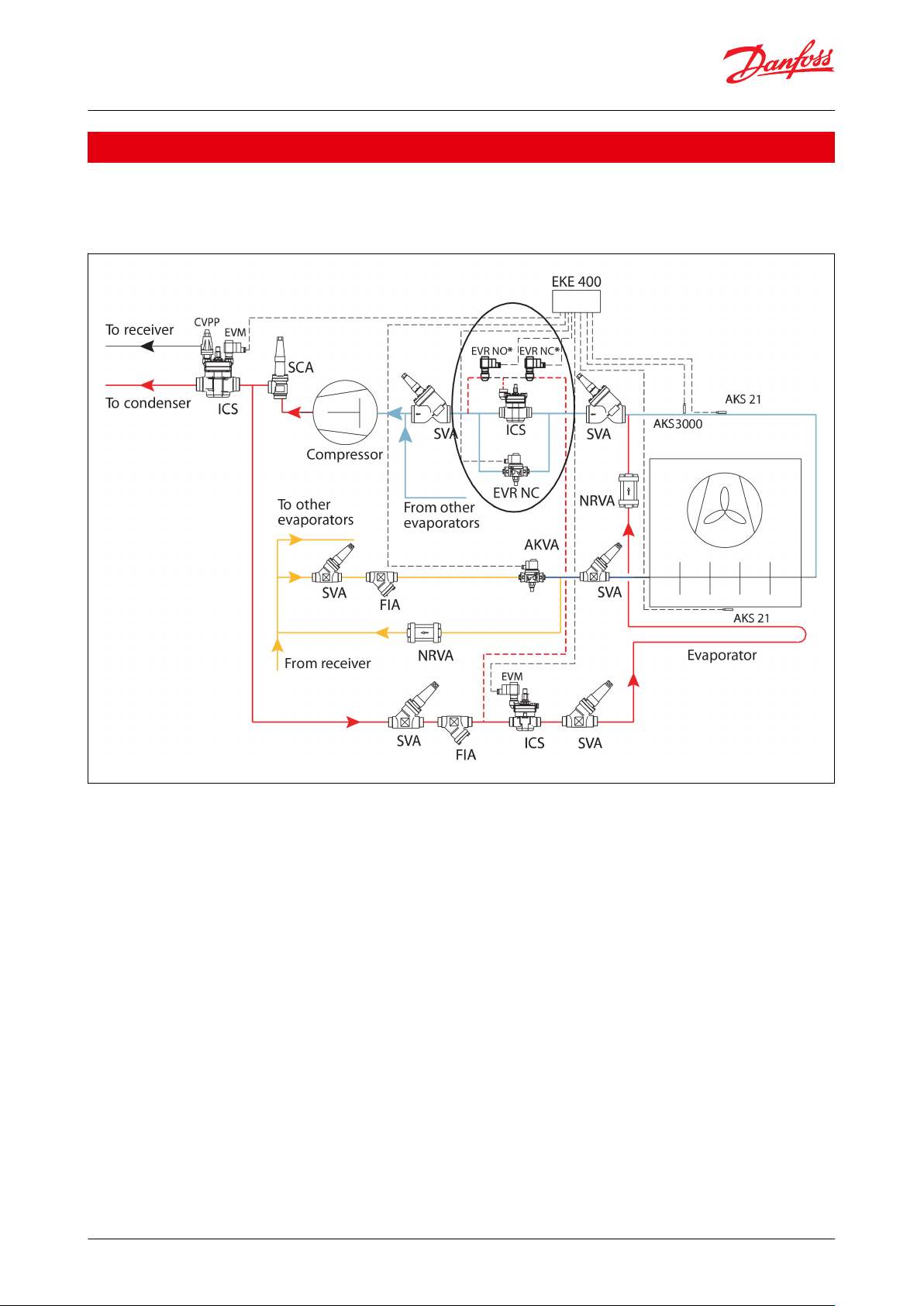

Application

Typical applications for large refrigeration systems with HFC/HCFC refrigerant, both pump and DX hot gas defrost

application.

Figure 5: ICSX Functional diagram

NOTE:

*Choose ICS+EVRST in EKE 400 and the NC and NO solenoid valves should be connected together.

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 6

Page 7

ICV 32

ICV 40

ICV 50

ICV 65

Hot gas powered on/o valve, type ICSX

Product specication

Design

ICSX hot gas powered on/o valve uses the same top cover with 1 pilot and housing as the standard ICS, but with

dedicated function modules.

ICSX hot gas powered on/o valve is no longer a standard pilot driven main valve, the one pilot hole has to be

connected to the system pipe by external pilot connection, see Ordering from the parts program.

Valve body and top cover material is in low temperature steel.

The external surface is zinc-chromated.

For the storage, transport and installation, the external surface of the valve housing must be protected against

corrosion with a suitable top coating after installation involving welding and consequent assembly.

Protection of the ID plate when painting the valve is recommended.

Refrigerant

Applicable to HCFC, HFC refrigerants.

Use with ammable hydrocarbons cannot be recommended; please contact Danfoss.

Pressure and temperature range

Temperature range

-60 °C /+120 °C (-76 °F /+248 °F)

Pressure range

The valve is designed for: Max. working pressure: 52 bar (754 psig)

Table 1: Valve body (ICSX 80 is with 65 body but with size 80 connections)

Figure 6: Top cover 1 pilot

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 7

Page 8

Type

Valve body size

K

v

(m3/h)

C

v

(US

gal/min

)

ICSX 32321720ICSX 40402731ICSX 50504451ICSX 65657081ICSX 808085

98

Hot gas powered on/o valve, type ICSX

NOTE:

A general overview of the modular concept of ICS and various types of housings/connections can be found in the

literature “Pilot-operated servo valve, type ICS”.

Select 1 pilot top cover only.

Figure 7: Function modules

Table 2: Kv and C

v

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 8

Page 9

Type

Screw

ICS 32

M14 × 35 A2-70 DIN 933

ICS 40

M14 × 40 A2-70 DIN 933

ICS 50

M16 × 40 A2-70 DIN 933

ICS 65/ICS 80

M16 × 50 A2-70 DIN 933

No.

Part

Material

EN

ASTM

JIS

1

Body

Low temperature steel

G20Mn5QT, EN 10213-3

LCC A352

SCPL1 G5151

2

Top cover

Low temperature steel

G20Mn5QT, EN 10213-3

P285QH+QT 10222-4

LCC A352

LF2, A350

SCPL1 G5151

3

Function module (assembled)

3a

o-ring

Cloroprene (Neoprene)

3b

o-ring

Cloroprene (Neoprene)

3c

Washer plate

SteelACylinder

SteelBPiston

Steel

C

Valve plate

PTFEDSpring

SteelECone

Steel4Gasket

Fiber, non-asbestos

5

Bolts

Stainless steel

A2-70, EN 1515-1

Grade B8 A320

A2-70, B 1054

6

External pilot connection

Steel7Gasket

Aluminium

Hot gas powered on/o valve, type ICSX

Material specication

Figure 8: ICSX 32,40,50,65,80

Table 3: Type and size of bolt (pos. 5)

Table 4: Material and parts list

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 9

Page 10

No.

Part

Material

EN

ASTM

JIS

8

Manual operating spindle

Steel9Plug

Steel10Gasket

Aluminium

ICS 1 pilot

Connection

H1H2H3H

4

L

L

1

Weight

ICS 1 Pilot

32 D (1¼ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00

4.5 kg

9.9 lb.

40 D (1½ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00

4.5 kg

9.9 lb.

32 A (1¼ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00

4.5 kg

9.9 lb.

40 A (1½ in.)

mm

in.401.57

160

6.30

100

3.93742.91

145

5.71512.00

4.5 kg

9.9 lb.

Hot gas powered on/o valve, type ICSX

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector®2. Rated and extended capacities are calculated with the Coolselector®2 calculation engine to ARI

standards with the ASEREP equations based on laboratory measurements of selected valves.

Download Coolselector®2 for free at coolselector.danfoss.com

Dimensions and weights

ICSX 32

Figure 9: ICSX 32, Dimensions and weights

Table 5: Connection types, dimensions and weights

Specied weights are approximate values only.

Be aware of the needed free space for external pilot connection. To be determined by designer with chosen NC/NO

solenoid valves.

D = Butt-weld DIN

A = Butt-weld ANSI

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 10

NOTE:

Page 11

ICS 1 pilot

Connection

H1H2H3H

4

L

L

1

Weight

ICS 1 Pilot

40 D (1½ in.)

mm

in.491.93

166

6.54

105

4.13783.07

160

6.30512.00

5.9 kg

13.0 lb.

50 D (2 in. )

mm

in.491.93

166

6.54

105

4.13783.07

180

7.09512.00

5.9 kg

13.0 lb.

40 A (1½ in.)

mm

in.491.93

166

6.54

105

4.13783.07

160

6.30512.00

5.9 kg

13.0 lb.

50 A (2 in.)

mm

in.491.93

166

6.54

105

4.13783.07

180

7.09512.00

5.9 kg

13.0 lb.

Hot gas powered on/o valve, type ICSX

ICSX 40

Figure 10: ICSX 40, Dimensions and weights

Table 6: Connection types, dimensions and weights

NOTE:

Specied weights are approximate values only.

Be aware of the needed free space for external pilot connection. To be determined by designer with chosen NC/NO

solenoid valves.

D = Butt-weld DIN

A = Butt-weld ANSI

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 11

Page 12

ICS 1 pilot

Connection

H1H2H3H

4

L

L

1

Weight

ICS 1 Pilot

50 D (2 in. )

mm

in.592.32

181

7.13

120

4.72933.66

200

7.87512.00

8.9 kg

19.6 lb.

65 D (2½ in.)

mm

in.592.32

181

7.13

120

4.72933.66

210

8.27512.00

8.9 kg

19.6 lb.

50 A (2 in.)

mm

in.592.32

181

7.13

120

4.72933.66

200

7.87512.00

8.9 kg

19.6 lb.

65 A (2½ in.)

mm

in.592.32

181

7.13

120

4.72933.66

210

8.27512.00

8.9 kg

19.6 lb.

Hot gas powered on/o valve, type ICSX

ICSX 50

Figure 11: ICSX 50, Dimensions and weights

Table 7: Connection types, dimensions and weights

NOTE:

Specied weights are approximate values only.

Be aware of the needed free space for external pilot connection. To be determined by designer with chosen NC/NO

solenoid valves.

D = Butt-weld DIN

A = Butt-weld ANSI

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 12

Page 13

ICS 1 pilot

Connection

H1H2H3H

4

L

L

1

Weight

ICS 1 Pilot

65 D (2½ in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

230

9.06512.00

13.4 kg

29.48 lb.

80 D (3 in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

245

9.65512.00

13.4 kg

29.48 lb.

65 A (2½ in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

230

9.06512.00

13.4 kg

29.48 lb.

80 A (3 in.)

mm

in.652.56

202

7.95

140

5.51

115

4.53

245

9.65512.00

13.4 kg

29.48 lb.

Hot gas powered on/o valve, type ICSX

ICSX 65 / ICSX 80

Figure 12: ICSX 65 / ICSX 80, Dimensions and weights

Table 8: Connection types, dimensions and weights

NOTE:

Specied weights are approximate values only.

Be aware of the needed free space for external pilot connection. To be determined by designer with chosen NC/NO

solenoid valves.

D = Butt-weld DIN

A = Butt-weld ANSI

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 13

Page 14

++ ++ ++ ==

Valve body 50 D (2 in.)

027H5120

Function module ICSX 50

027H5900

Top cover 1 pilot

027H5172

External pilot connection

027F1048

Valve body size

Connections

Code Number

ICV 32

32 D (1

1

⁄4 in.)

027H3120

ICV 32

40 D (1

1

⁄2 in.)

027H3125

ICV 32

32 A (1

1

⁄4 in.)

027H3121

ICV 32

40 A (1

1

⁄2 in.)

027H3126

ICV 40

40 D (1

1

⁄2 in.)

027H4120

ICV 40

50 D (2 in.)

027H4126

ICV 40

40 A (1

1

⁄2 in.)

027H4121

ICV 40

50 A (2 in.)

027H4127

ICV 50

50 D (2 in.)

027H5120

ICV 50

65 D (2

1

⁄2 in.)

027H5124

ICV 50

50 A (2 in.)

027H5121

ICV 50

65 A (2

1

⁄2 in.)

027H5125

ICV 65

65 D (2

1

⁄2 in.)

027H6120

ICV 65

65 A (2

1

⁄2 in.)

027H6121

ICV 65

80 D (3 in.)

027H6126

ICV 65

80 A (3 in.)

027H6127

Hot gas powered on/o valve, type ICSX

Ordering

Ordering from the parts program

Figure 13: Example (select valve body, function module, top cover from ICSX 50 and external pilot connection)

Figure 14: ICV 32,40,50,65 valve body with dierent connections

Table 9: Valve body with dierent connections

D = Butt-weld DIN

A = Butt-weld ANSI

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 14

Page 15

Description

Code Number

ICSX 32 function module

027H3900

(1)

ICSX 40 function module

027H4900

(1)

ICSX 50 function module

027H5900

(1)

ICSX 65 function module

027H6900

(1)

ICSX 80 function module

027H8900

(1)

Description

Code Number

ICS 32 top cover 1 pilot

027H3172

(2)

ICS 40 top cover 1 pilot

027H4172

(2)

ICS 50 top cover 1 pilot

027H5172

(2)

ICS 65 top cover 1 pilot

027H6172

(2)

ICS 80 top cover 1 pilot

027H8172

(2)

Hot gas powered on/o valve, type ICSX

Figure 15: ICSX 32,40,50,65,80 function module

Table 10: ICSX 32,40,50,65,80 function module

(1)

(1)

Including gasket and o-rings

Including gasket and o-rings

Figure 16: Top cover 1 pilot

Table 11: ICS 32,40,50,65,80 top cover 1 pilot

(2)

(2)

Including bolts

Including bolts

NOTE:

The capacity of the ICSX 80 module can only be achieved when using the valve body with 80 D or A (3 in.)

connections. If any other ICV 65 valve body is used the capacity of the complete valve will be reduced by

approximately 6%.

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 15

Page 16

ICS

Description

Code no.

32-80

External pilot connection (incl. damping orice, D: 1.0 mm)

027F1048

Accessories

H

H

1

OD

B

B1B

2

mm

in.903.54662.60180.71

AF 32

AF 32

M 24 × 1.5

Hot gas powered on/o valve, type ICSX

Figure 17: External pilot connection

Table 12: External pilot connection

Figure 18: Dimensions of external pilot connection

Table 13: Dimensions

Ordering solenoid valves from Danfoss product portfolio

Figure 19: Solenoid valves

Refer EVR Solenoid valve Data sheet.

For Spare parts, Please refer the Data sheet Spare parts and accessories.

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 16

Page 17

The ICV valve concept is designed to fulll global refrigeration requirements.

For specic approval information, please contact Danfoss.

The ICSX valves are approved in accordance with the European standard specied in the Pressure Equipment Directive and

are CE marked.

ICSX valves

Nominal bore

DN 32-65 (1¼ - 2½ in.)

DN 80 (3 in.)

Classied for

Fluid group I

Category

II

III

File name

Document type

Document topic

Approval authority

RU Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC

0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

-

TÜV

RU Д-DK.БЛ08.B.00189_18

EAC Declaration

EMC

EAC

RU Д-DK.РА01.B.72054_20

EAC Declaration

PED

EAC

RU C-DK.БЛ08.B.01093_20

Pressure - Safety Certicate

PED

EAC

033F0685.AK

EU Declaration

EMCD/PED

Danfoss

033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

0045 202 1204 Z 00355 19 D 001(00)

Pressure - Safety Certicate

-

TÜV

19.10325.266

Marine - Safety Certicate

-

RMRS

Hot gas powered on/o valve, type ICSX

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Valid approvals

Table 14: The ICV valve approvals

Table 15: ICSX valves

Table 16: Certicates and declarations

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 17

Page 18

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2022.02 AI404219416371en-000102 | 18

Loading...

Loading...