Danfoss ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR 25-65, ICLX-S9A 32-65 Installation guide

Page 1

Installation Guide

Danf

27H320_08-201

27H321_08-2015

Motor - and Servo operated valve

ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR sizes 25-65 (¾-2½) and ICLX-S9A sizes 32-65 (1¼-2½)

ICM

027R9968

027R9968

ICLX

ICS

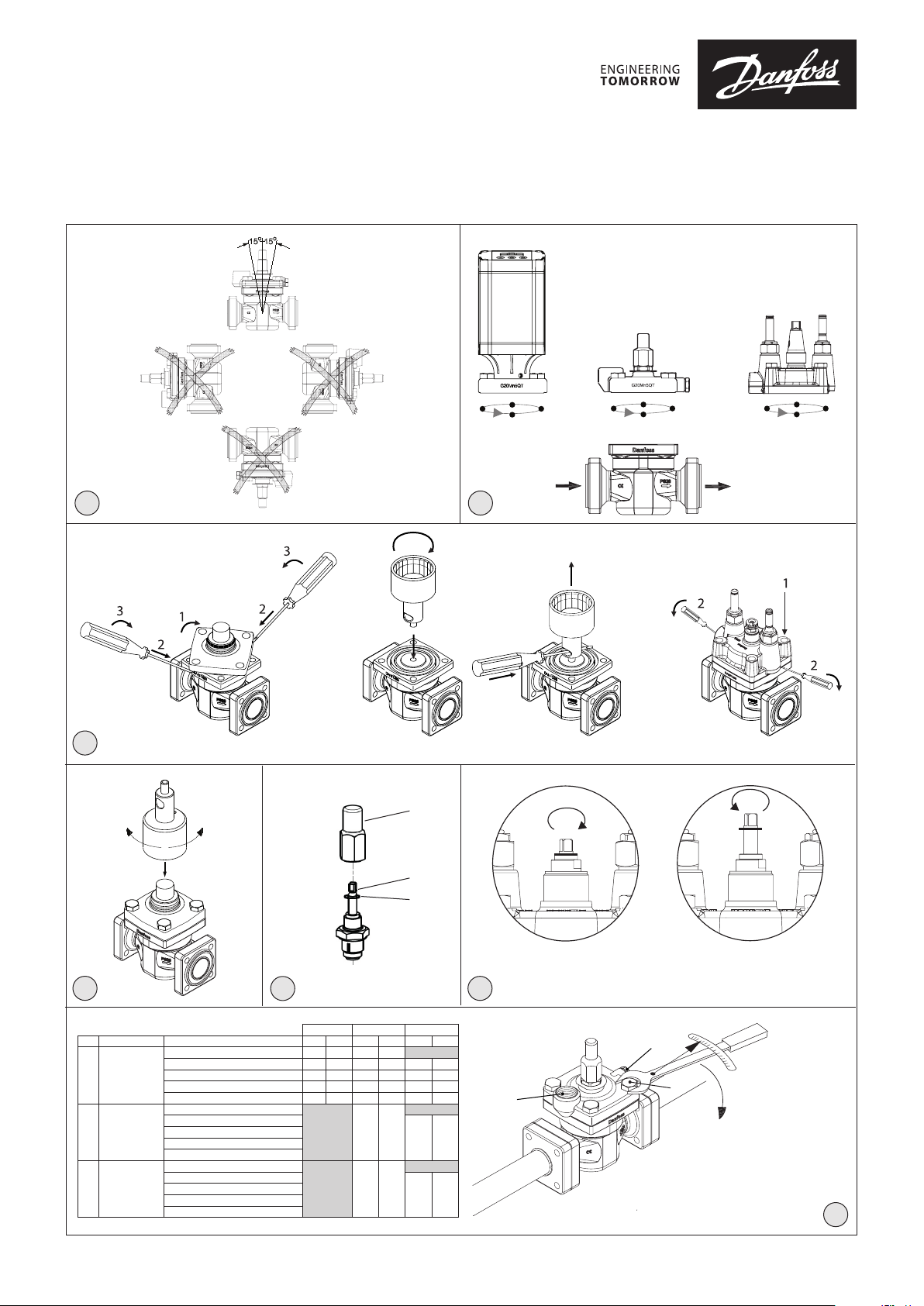

4 x 90° 4 x 90° 4 x 90°

5

1

2

oss

Danfoss

3

Open Close

4

A Bonnet

B External port

C Pilot

ICM ICS

A

B

C

5a

Valve body size Nm ft lb Nm ft lb Nm f t lb

25 100 74 100 74

32 120 88 120 88 120 88

40 120 88 120 88 120 88

50 140 103 140 103 140 103

65 150 110 150 110 150 110

25

32

40

50

65

25

32

40

50

65

ICM ICS ICLX

25 18

50 37

50 37

50 37

5b

ICS: Manual forced opened

ICLX: Normal operation mode

Danfoss

27H238_09-2014

C

ICLX

ICS: Normal operation mode

ICLX: Manual forced opened

B

A

6

© Danfoss | DCS (MWA) | 2015.11

DKRCI.PI.HL3.A1.02 | 520H10323 | 1

Page 2

ICMICS ICLX

7

© Danfoss | DCS (MWA) | 2015.11

DKRCI.PI.HL3.A1.02 | 520H10323 | 2

Page 3

ENGLISH

Installation

Refrigerants

Applicable to HCFC, HFC and R717 (Ammonia).

Flammable hydrocarbons are not recommended.

The valve is only recommended for use in

closed circuits. For further information please

contact Danfoss.

Temperature range

–60/+120°C (–76/+248°F).

Please note explicit limitations in function

modules installation guides

Pressure range

The valves are designed for a max. working

pressure of 28 bar g (406 psi g).

Important:

This pressure limitation is valid for all

covered valves in this guide despite the

function modules installation guides

statement.

Applications

All covered valves can be used in suction,

liquid, hotgas and liquid/vapor lines.

The valves regulates the ow of the medium,

modulating or on/o, depending on the actual

conguration.

Regulating range

Please refer to the regulating range of the

enclosed specic function module installation

guide

Design (g. 7)

For more details on ordered conguration

please refer to the enclosed specic function

module installation guide

The enclosed valves must not be mounted in

systems where the outlet side of the valve is

open to atmosphere. The outlet side of the

valve must always be connected to the system

or properly capped o, for example with a

welded-on end plate.

Silver label

Inside the valve box you’ll nd a small silver

label with pressure information. Please place

this label on the top cover.

Tightening (g. 6)

Tighten the top cover, pilot and/or external

connection with a torque wrench, to the values

indicated in the table g 6.

Colours and identication

The valves are Zinc-Chromated from factory.

If further corrosion protection is required, the

valves can be painted.

Precise identication of the valve is made via

the ID plate on the top cover.

Protection of the ID plate when painting the

valve is recommended.

Maintenance

Service

The involved valves are easy to dismantle.

Do not open the valve while the valve is still

under pressure.

Pressure relief can be done by carefully

opening the manual operating spindle (not ICM

versions). Small grooves along the thread will

release refrigerant into open air. This operation

must only be done after providing the correct

countermeasures under local legislation.

Dismantling of the individual function modules

must be done according to g. 3 and the more

detailed descriptions in the function module

installation guides.

Manual opening/closing of the mechanical

valves ICS/ICLX is shown in g 5b.

Returning to normal operating mode:

ICLX: Turn the spindle clockwise until the C-clip

gets in contact with the top nut.

ICS: Turn the spindle counterclockwise to the

top point and continue turning until a torque of

8 Nm (5.9 lb/ft) is reached.

Remount the cap and tighten it clockwise to 8

Nm (5.9 lb/ft) torque.

Use only original Danfoss parts, including

O-rings and gaskets for replacement. Materials

of new parts are certied for the relevant

refrigerant. In cases of doubt, please contact

Danfoss.

Drawings are only for illustration, not for

dimensioning or construction.

Danfoss accepts no responsibility for errors

and omissions. Danfoss Industrial Refrigeration

reserves the right to make changes to products

and specications without prior notice.

Installation

The valve must be installed with the spindle in

vertically upwards position (g. 1).

The valve must be installed with the arrow

in the direction of the ow and the top cover

upwards. The top cover can be rotated 4 X 90°

in relation to the valve body (g. 2).

Specic requirements for the individual

congurations must be followed. See enclosed

specic function module installation guide.

Mounting of valve anges

• Make sure that piping into which a valve/

ange is installed is properly supported and

aligned square and plumb to the joining

sections.

• Ensure that the nalized valve assembly is free

of any stresses from external loads.

• Make certain that the mating surfaces of

gasketed joints are free of rust and are in good

condition.

• Use only new gaskets manufactured by

Danfoss.

• Make sure that the bolts are adequately

tightened in an alternating pattern.

• Ensure that anges / valves are properly

pressure tested, leak tested, evacuated before

charging with refrigerant in accordance with

ANSI /IIAR 5, EN378-2 or ISO 5149-2.

Assembly

Remove any dirt from the body before the valve

is assembled. Check that all channels in the

valve are not blocked by particles or similar.

If possible, apply some refrigeration oil to ease

the insertion and to protect the o-rings.

Tightening (g. 6)

Tighten the top cover and externals with a

torque wrench, to the values indicated in the

table.

ICM: Manual opening/closing of the

motorized ICM valve is shown in g. 4

ICS/ICLX:

Always pay attention to the spindle during

operation of the manual opener (see g 5a)

1. Make sure that the C-clip (C) is positioned on

the spindle (B) and is intact. A new C-clip is

available in the inspection kit for the valve.

2. Pay attention to the C-clip reaching the top

nut of the packing gland when turning the

manual stem clockwise.

Never use excessive torque and stop

turning when the C-clip gets in contact

with the top nut.

© Danfoss | DCS (MWA) | 2015.11

DKRCI.PI.HL3.A1.02 | 520H10323 | 3

Page 4

© Danfoss | DCS (MWA) | 2015.11

DKRCI.PI.HL3.A1.02 | 520H10323 | 4

Loading...

Loading...