Page 1

Data sheet

Flanged ICV for Regulators, Solenoids, Motorized

valves and Gas-powered suction valves

Type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

With the introduction of the flanged ICV - the drop

in replacement valve for all common flanged control

valves on the market - Danfoss has invigorated

Industrial retrofitting.

The ICV valve family includes 3 different configurations.

The well-known pilot controlled ICS ((H)A4A) which

comes as a 1- or 3 pilot variant. Together with the

comprehensive program of pilots and numerous

pilot configurations, all common used pilot

regulations can be achieved.

The motor controlled ICM in 2 variants HMMR and

HMMV, which besides very accurate regulation also

handles and controls direct expansion.

The gas-powered 2 step solenoid valve ICLX (S9A)

designed for closing and opening of suction line

after defrost with minimum pressure drop at normal

operation.

Applications:

• Liquid line inlet for flooded evaporators

• Hot gas line for defrosting

Pilot operated servo valve

ICS

ICM

Motor operated valve

ICLX

2-step solenoid valve

• Crankcase pressure control

• Evaporator pressure control

• Liquid pressure control

• Constant temperature control

• Expansion control

• 2 step opening after defrost

Features • Modular Concept:

© Danfoss | DCS (ms) | 2020.09

• Designed for industrial refrigeration applications

for a maximum working pressure of 406 psig / 28

bar g.

• Applicable to HCFC, HFC and R717 (Ammonia).

• Low temperature steel body.

• Low weight and compact design.

• V-port regulating cone ensures optimum

regulating accuracy particularly at part load.

• Function module has a QPQ surface treated

insert and a steel piston ring ensuring precise

control accuracy.

– Valve overhaul is done by replacing the

function module.

– Interchangeability between ICS pilot-operated

servo valve, ICM motor operated valve and

ICLX 2-step solenoid valve

• Manual opening.

• PTFE seat provides excellent valve tightness.

• The top cover can be rotated into any possible

position without affecting the operation of the

valve.

AI193486423552en-US0301 | 1

Page 2

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Contents Page

Features .................................................................................................................................................................................................1

Introduction ......................................................................................................................................................................................... 3

Design ....................................................................................................................................................................................................4

Concept .................................................................................................................................................................................................5

ICS-(H)A4A and ICS-(H)S4A

ICS capacities .......................................................................................................................................................................................6

ICS function .......................................................................................................................................................................................... 7

ICS material specification ................................................................................................................................................................9

ICS configuration and ordering ................................................................................................................................................. 10

ICS pilots............................................................................................................................................................................................. 12

ICS accessories ................................................................................................................................................................................. 13

ICS dimensions ................................................................................................................................................................................ 15

ICM-HMMV and ICM-HMMR

ICM capacities .................................................................................................................................................................................. 16

ICM function ..................................................................................................................................................................................... 17

ICAD actuator details ..................................................................................................................................................................... 18

ICM material specification ........................................................................................................................................................... 22

ICM ordering ..................................................................................................................................................................................... 23

ICM and ICAD accessories ............................................................................................................................................................ 23

ICM and ICAD dimensions ........................................................................................................................................................... 24

ICLX-S9A

ICLX capacities ................................................................................................................................................................................. 25

ICLX function .................................................................................................................................................................................... 26

ICLX material specification .......................................................................................................................................................... 28

ICLX ordering .................................................................................................................................................................................... 29

ICLX accessories .............................................................................................................................................................................. 29

ICLX dimensions .............................................................................................................................................................................. 30

2 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 3

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Introduction The ICS servo variant is a pilot-operated valve for

regulation of pressure, temperature and/or with an

On/Off function for a refrigeration system. The valve

is suitable for low- and high-pressure refrigerants

and can be used in all locations in the system, when

not exposed to phase change (no expansion over

the valve).

The ICS is available with 1 or 3 pilot ports and

together with optional external pilot lines,

numerous variations in control functions can be

obtained.

The ICM motor variant is an electronic controlled

valve driven by the actuator type ICAD.

The ICM valve is designed to control pressure

or temperature in all locations of a refrigeration

system and additional the valve is designed to

control an expansion process (expansion over the

valve).

The opening and closing forces in the ICM are

minimized thus only 2 sizes of ICAD are required.

The ICLX servo variant is a solenoid pilot-operated

valve for opening of suction line against high

differential pressure e.g. after hot gas defrost.

The ICLX is factory default configured to open in

2 steps. First step opens to 10% of full capacity

while step two automatically, based on decreased

pressure differential, opens to 100%.

It is easy to modify the valve configuration from 2

steps to 1 step.

The ICLX solenoid function is achieved by 2 pilot

solenoid valves operating simultaneous and

controlled by only one signal.

All 3 valve variants are provided with a manual

opening option.

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 3

Page 4

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

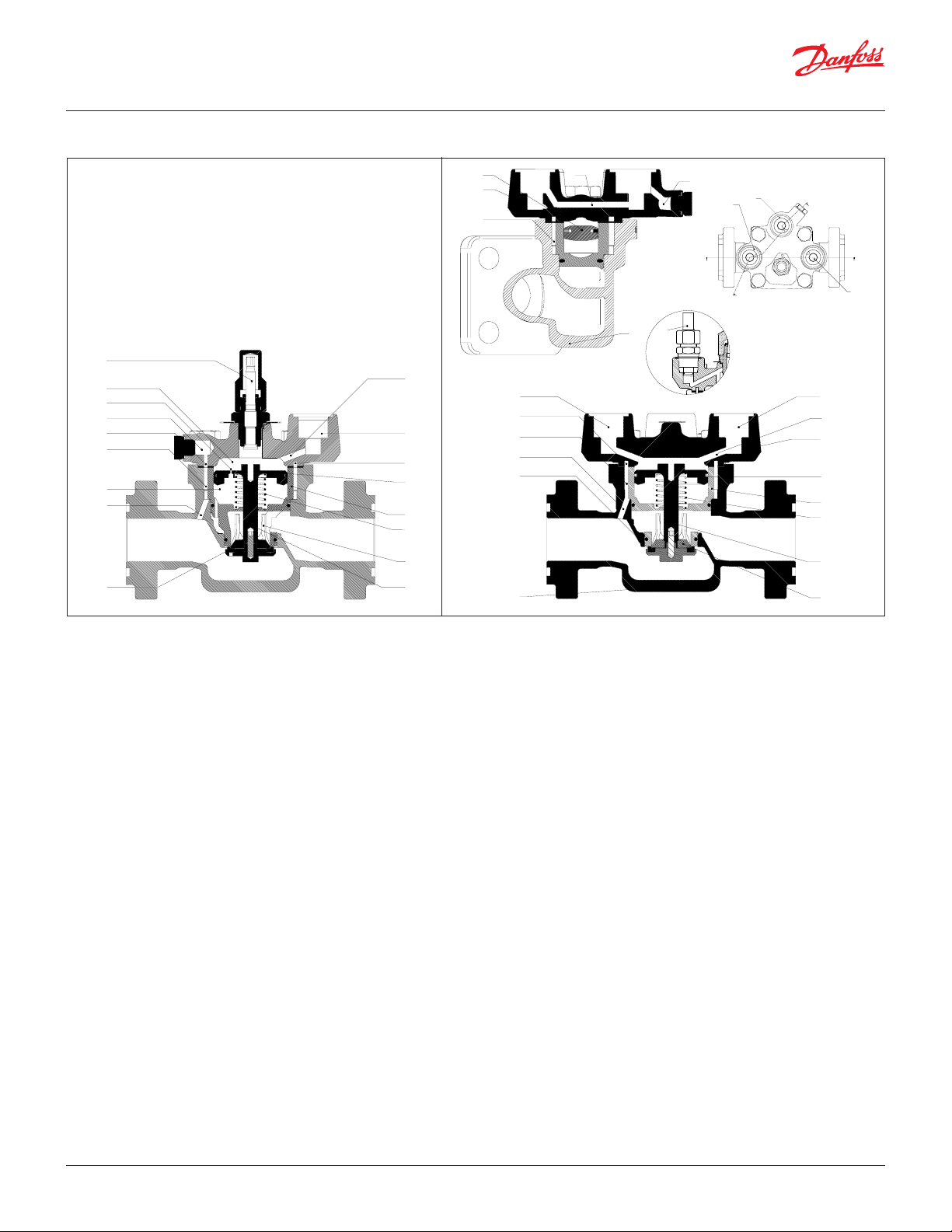

Design ICS valves are designed as pilot operated valves

requiring minimal pressure differential to open.

If the pressure difference is 0 psi (0 bar), the ICS

valve will be closed. If the pressure difference is

3 psi (0.2 bar) or more, the ICS valve will be fully

open. At pressure differences between 1 psi (0.07

bar) and 3 psi (0.2 bar), the opening degree will be

correspondingly proportional.

The ICS is available for use with either one or three

pilot valves.

Two of the three pilot pressure connections (S1

and S2) are connected in series whilst the third (P)

is connected in parallel to S1 and S2. This allows

different combinations of pilot valves to be used,

thus providing numerous variations in control

functions.

ICM valves are designed as hermetic encapsulated

valves driven by the fitted stepper motor ICAD via a

through-the-wall magnetic field. The valve opening

degree is completely independent of internal

system pressures and opening forces are balanced

and reduced to achieve MOPD’s up to max working

pressure i.e. 406 psi (28 bar).

The ICAD display allows, through an accurate

encoder feedback system, continuous observations

of valve opening degree.

ICLX valves are designed for 2 (or 1) step ON/OFF

solenoid valve function operated by one EVM NC

and one EVM NO solenoid pilots. The EVM NC and

NO coils are controlled by the same electric signal

thus limited wiring is needed.

The pressure and flow required for opening of the

main valve comes from an external source and

therefor the opening is independent of internal

pressures and the pressure drop through the valve

is reduced to a minimum.

The modification from 2 step to 1 step is done

mechanically by changing 2 bolts inside the valve.

MOPD of the valve is designed to 22 Psi (1.5 bar)

less than P(external source).

Approvals

CE

Valve body and top cover material

Low temperature steel

Nominal bore

Classified for Fluid group I

Category Article 3, paragraph 3 I II

Technical data • Refrigerants

Applicable to HCFC, HFC and R717(Ammonia).

• Temperature range

–76/+248°F (–60/+120°C).

• Surface protection

The external surface is zinc-chromated to provide

good corrosion protection.

• Pressure range

406 psig (28 bar)

DN≤ 25 (1 in.)

ICV valves

DN 32 (1¼ in.) DN 40 - 65 (1½ in. – 2½ in.)

4 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 5

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Concept

The concept is developed around a modular

principle. This gives the interchangeability of

function modules/top covers with the matching

valve body.

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 5

Page 6

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICS-(H)A4A and ICS-(H)S4A

ICS capacities

ICS with 1 pilot ICS with 3 pilots

In ICS, multiple inserts (function modules) are

available to give different capacities.

Type Valve body

ICS 5

ICS 10 4.1 3.5

ICS 15 7.0 6.0

ICS 20 9.3 8

ICS 25 13.3 11.5

ICS 32 32 20 17

ICS 40 40 31 27

ICS 50 50 51 44

ICS 65 65 81 70

ICS 5, 10, 15, 20 & 25 share same valve body size and flange

connection. Only insert is designed to create different flow values.

size

25

Cv

(USgal/min)

2.0 1.7

Kv

(m3/h)

6 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 7

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

BB

8

P

p2

3f

2c

2g

1b

p3

1a

3c

3a

2e

ICS function

2

1b

SII

SI

2c

SI

SII

A

ICS 1 Pilot

2d

2b

2g

2b

2g

3b

3a

p1

3d

p4

3e

3g

Fig. 1

ICS 3 Pilots

1b

1a

3c

1

The ICS main valve is a pilot operated valve. The

types of pilot valves used determine the function.

The ICS main valve with pilot valve(s) controls

refrigerant flow by modulation or on/off in

p

Inlet pressure p1 is led, via the drilled channels (1a,

1b, 2f, 2b (pilot), 2a, 2d) in the valve body (1) and

cover (2) through the individual pilot valves and

onto the top of the servo piston (3b).

61

1

A

2b

SII

2a

2

3b

3a

3d

3g

3e

Fig. 2

accordance with the pilot valve and main valve

status. The manual spindle can be used to manually

open the valve.

The opening degree of the main valve is

determined by the pressure difference (differential

pressure) between pressure p2, which acts on top

of the servo piston (3b), and pressure p3, which acts

on the underside of the servo piston.

If this pressure difference is 0, the main valve will be

fully closed.

If the pressure difference is 2.9 psi (0.2 bar) or

greater, the main valve will be fully open.

At pressure differences (p2 - p3) between 1 psi (0.07

bar) and 2.9 psi (0.2 bar), the degree of opening will

be correspondingly proportional.

The port of the throttle cone (3e) is V-shaped, which

provide good regulation characteristic to pilot

operated main valves even at low loads.

P3 pressure is equal to the valve outlet pressure (P4),

due to a clearance between the piston rod (3g) and

the function module. The opening degree of the

ICS valve is therefore controlled by the P2 pressure

acting on top of the servo piston, which is equal to

or greater than valve outlet pressure (P4).

The maximum pressure (p2) can act on the top of

the servo piston (3b). p2 normally corresponds to

The degree of opening of the individual pilot

valves determines the magnitude of pressure p2

and thus the degree of opening of the main valve.

The equalization hole (3f) in the servo piston (3b)

ensures that pressure p2 is balanced in accordance

with the degree of opening of the pilot valve.

Note:

When ICS valves with 3 pilot ports are used with

external pressure connector (fig. 2, pos. 61), the

valve port inlet pressure will be isolated.

The ICS can be fitted with just a single screwed-in

pilot valve or external pilot connection. The degree

of opening of the main valve will be in accordance

with the control status of the pilot valve or external

pilot flow control.

ICS main valve with one pilot connection is fully

closed when the pilot valve is fully closed and

fully open when the pilot valve is fully open.

Otherwise the degree of opening of the main valve

is proportional to the degree of opening of the pilot

valve.

The ICS 3 pilot version can be fitted with one, two,

or three pilot valves so that up to three regulating

functions are possible. If the external pilot

connection is used, more functions can be added.

the pressure, p1 - ICS main valve inlet pressure.

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 7

Page 8

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICS function (continued)

In the ICS three pilot version, the pilot ports are

related as follows:

• The pilot valves fitted in ports SI and SII are

connected in series.

• The ICS 3 pilot operated main valve will be

fully closed if just one of the series-connected

• pilot valves is closed. The main valve can only

open if both pilot valves are open at the same

time.

• The pilot valve fitted in port P is connected in

parallel to the pilot valves in ports SI and SII.

The ICS valve will be fully open if the pilot valve in P

is fully open, irrespective of the degree of opening

of pilot valves SI and SII.

The ICS valve will be fully closed if the pilot valve in

P is fully closed and at least one of the valves in SI

or SII is fully closed at the same time. The relation

between the pilot valves in ports SI, SII and P is

shown in Table 1 below.

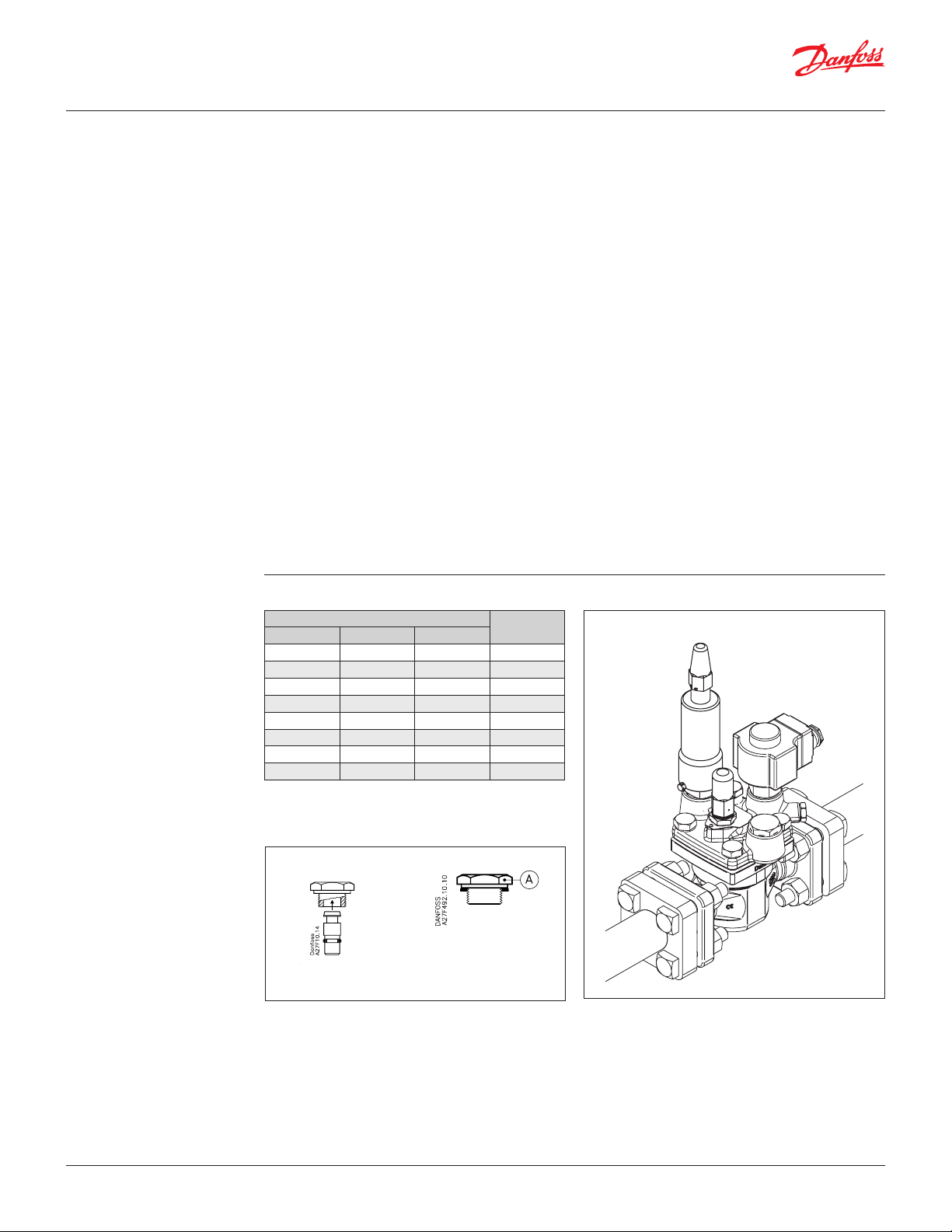

If the ICS is not fitted with three pilot valves, the

unused port(s) must be sealed with a pilot cap A

or a combination of pilot cap A and blanking plug

B. If the pilot cap and blanking plug are fitted as

an assembled unit, A + B, the channels from the

specific port will be closed. (See Figure 1)

Table 1

Pilot valve port

SI SII P

Open Open Closed Open

Open Open Open Open

Open Closed Closed Closed

Open Closed Open Open

Closed Open Closed Closed

Closed Open Open Open

Closed Closed Closed Closed

Closed Closed Open Open

ICS valve

If only cap A is fitted, the channels from the ports

in question will be open. If the degree of opening

of the ICS main valve is not to be a function of the

main valve inlet pressure, or if more than three

regulating functions are required, ports SI, SII or

P can be fitted with a nipple for the connection

of external pilot pressure. This applies to all ICS

versions.

The pressure to which the external pilot line is

connected will then determine the main valve

function. Pilot valves installed in external lines must

be mounted in a type CVH housing.

Depending on the function of the pilot valves, the

ICS regulating characteristic becomes:

• on/off

• proportional

• integral or

• cascade.

ICS main valves are therefore especially suitable for

all forms of temperature and pressure regulating

systems.

An overview of the types of pilot valves available

can be found in the accessories section.

Figure 2

Example (ICS with 3 pilot valves)

8 | AI193486423552en-US0301

Figure 1

Pilot cap A Pilot cap A+

Blanking plug B

© Danfoss | DCS (ms) | 2020.09

Page 9

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Danfoss

27H414_2015-11

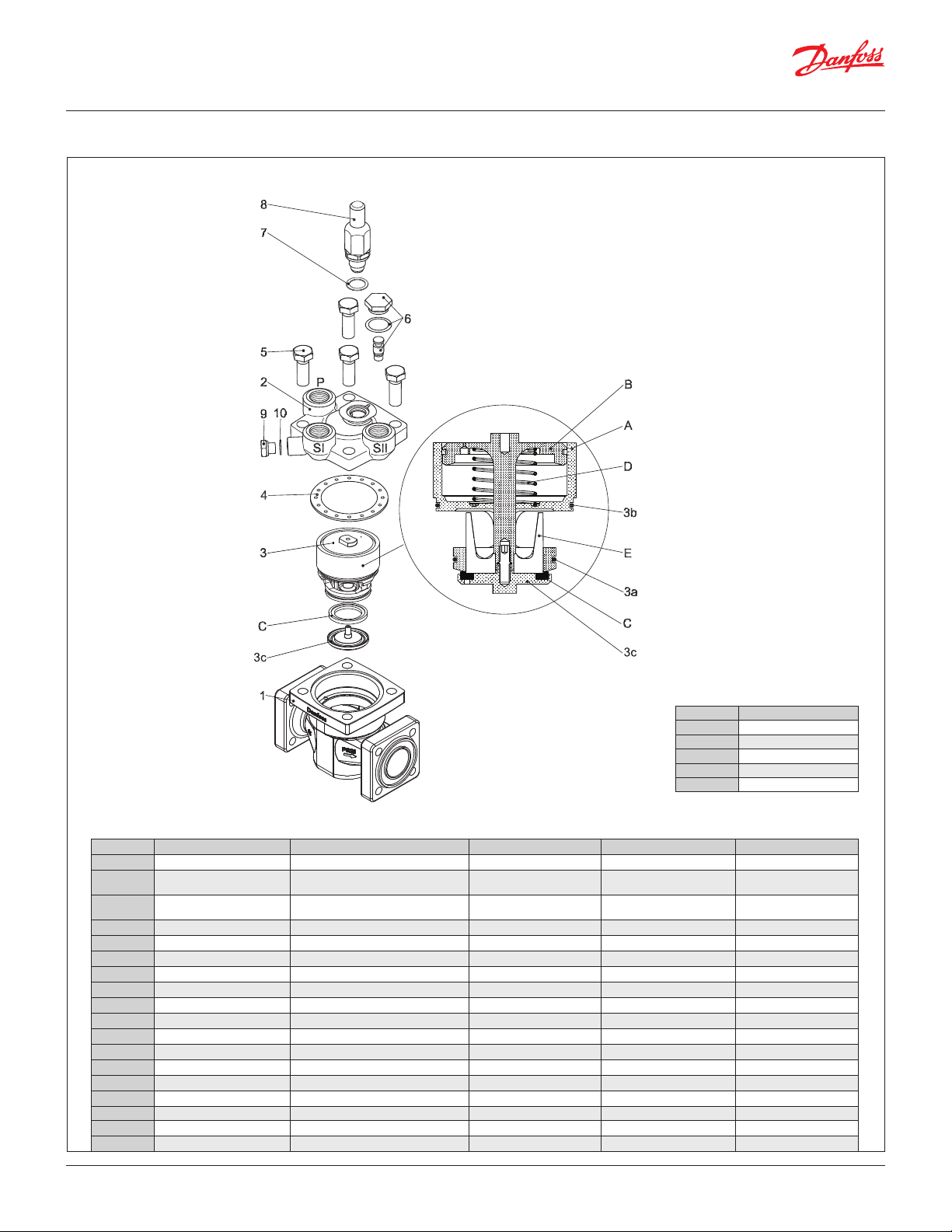

ICS material specification

Type and size of Bolt (pos. 5)

Valve body Screw

25 M12 × 30 A2-70 DIN 933

32 M14 × 35 A2-70 DIN 933

40 M14 × 40 A2-70 DIN 933

50 M16 × 40 A2-70 DIN 933

65 M16 × 50 A2-70 DIN 933

No. Part Material EN ASTM JIS

1 Body Low temperature steel G20Mn5QT, EN 10213-3 LCC A352 SCPL1 G5151

2 Top cover Low temperature steel G20Mn5QT, EN 10213-3

3 Function module

(assembled)

3a o-ring Cloroprene (Neoprene)

3b o-ring Cloroprene (Neoprene)

3c Washer plate Steel

A Cylinder Steel

B Piston Steel

C Valve plate PTFE

D Spring Steel

E Cone Steel

4 Gasket Fiber, non-asbestos

5 Bolts Stainless steel A2-70, EN 1515-1 Grade B8 A320 A2-70, B 1054

6 Plug Steel

7 Gasket Aluminium

8 Manual operating spindle Steel

9 Plug Steel

10 Gasket Aluminium

P285QH+QT 10222-4

LCC A352

LF2, A350

SCPL1 G5151

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 9

Page 10

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

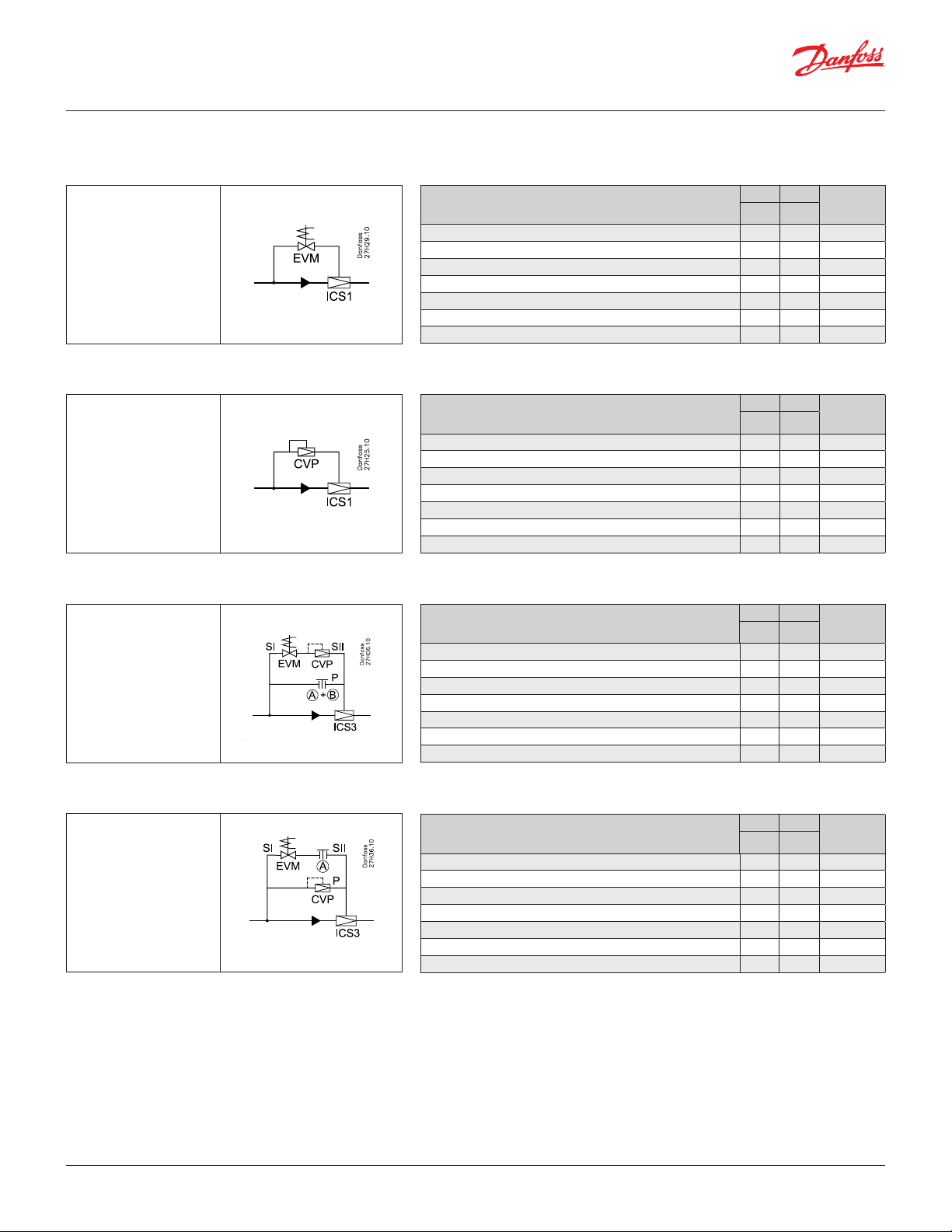

ICS configuration and ordering

Solenoid function

Solenoid Valve

ICS + EVM

Inlet pressure regulating - STD

Pressure Regulator

ICS + CVP

Inlet press. Regulator w/ electric shut-off - S

Pressure Regulator

ICS + EVM + CVP +

plug A+B

Inlet press. Regulator w/ electric wide-opening - B

Pressure Regulator

ICS + EVM + CVP + plug A

Type C

ICS 20 (H)S4A ¾ in.* 9.3 8 148X0866

ICS 25 (H)S4A 1 in.* 13.3 11.5 148X0853

ICS 32 S4A 1¼ in.* 20 17 148X0854

ICS 32 HS4A 1¼ in.* 20 17 148X0855

ICS 40 (H)S4A 1½ in.* 31 27 148X0856

ICS 50 (H)S4A 2 in.** 51 44 148X0857

ICS 65 (H)S4A 2½ in.** 81 70 148X0858

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

Type C

ICS 20 - STD - (H)A4A ¾ in. (19.5 in HG to 102 psig)* 9.3 8 148X0860

ICS 25 - STD - (H)A4A 1 in. (19.5 in HG to 102 psig)* 13.3 11.5 148X0847

ICS 32 - STD - A4A 1¼ in. (19.5 in HG to 102 psig)* 20 17 148X0848

ICS 32 - STD - HA4A 1¼ in. (19.5 in HG to 102 psig)* 20 17 148X0849

ICS 40 - STD - (H)A4A 1½ in. (19.5 in HG to 102 psig)* 31 27 148X0850

ICS 50 - STD - (H)A4A 2 in. (19.5 in HG to 102 psig)** 51 44 148X0851

ICS 65 - STD - (H)A4A 2½ in. (19.5 in HG to 102 psig)** 81 70 148X0852

Please check compliance before ordering

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

Type C

ICS 20 - S - (H)A4AS ¾ in. (19.5 in HG to 102 psig)* 9.3 8 148X0966

ICS 25 - S - (H)A4AS 1 in. (19.5 in HG to 102 psig)* 13.3 11.5 148X0967

ICS 32 - S - A4AS 1¼ in. (19.5 in HG to 102 psig)* 20 17 148X0968

ICS 32 - S - HA4AS 1¼ in. (19.5 in HG to 102 psig)* 20 17 148X0969

ICS 40 - S - (H)A4AS 1½ in. (19.5 in HG to 102 psig)* 31 27 148X0970

ICS 50 - S - (H)A4AS 2 in. (19.5 in HG to 102 psig)** 51 44 148X0971

ICS 65 - S - (H)A4AS 2½ in. (19.5 in HG to 102 psig)** 81 70 148X0972

Please check compliance before ordering

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

Type C

ICS 20 - B - (H)A4AB ¾ in. (19.5 in HG to 102 psig)* 9.3 8 148X0973

ICS 25 - B - (H)A4AB 1 in. (19.5 in HG to 102 psig)* 13.3 11.5 148X0974

ICS 32 - B - A4AB 1¼ in. (19.5 in HG to 102 psig)* 20 17 148X0975

ICS 32 - B - HA4B 1¼ in. (19.5 in HG to 102 psig)* 20 17 148X0976

ICS 40 - B - (H)A4AB 1½ in. (19.5 in HG to 102 psig)* 31 27 148X0977

ICS 50 - B - (H)A4AB 2 in. (19.5 in HG to 102 psig)** 51 44 148X0978

ICS 65 - B - (H)A4AB 2½ in. (19.5 in HG to 102 psig)** 81 70 148X0979

Please check compliance before ordering

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

v

[gpm] [m3/h]

v

[gpm] [m3/h]

v

[gpm] [m3/h]

v

[gpm] [m3/h]

K

Code

v

number

K

Code

v

number

K

Code

v

number

K

Code

v

number

10 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 11

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICS configuration and ordering

Dual Pressure regulator - D

Pressure Regulator

ICS + EVM + CVP + CVP

Electronically controlled regulator - J

Pressure Regulator

ICS + CVE

CVE

Type C

ICS 20 - D - (H)A4AD ¾ in. (19.5 in HG to 102 psig)* 9.3 8 148X0980

ICS 25 - D - (H)A4AD 1 in. (19.5 in HG to 102 psig)* 13.3 11.5 148X0981

ICS 32 - D - A4AD 1¼ in. (19.5 in HG to 102 psig)* 20 17 148X0982

ICS 32 - D - HA4AD 1¼ in. (19.5 in HG to 102 psig)* 20 17 148X0983

ICS 40 - D - (H)A4AD 1½ in. (19.5 in HG to 102 psig)* 31 27 148X0984

ICS 50 - D - (H)A4AD 2 in. (19.5 in HG to 102 psig)** 51 44 148X0985

ICS 65 - D - (H)A4AD 2½ in. (19.5 in HG to 102 psig)** 81 70 148X0986

Please check compliance before ordering

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

Type C

ICS 20 - J - HA4AJ ¾ in.* 9.3 8 –

ICS 25 - J - HA4AJ 1 in.* 13.3 11.5 –

ICS 32 - J - HA4AJ 1¼ in.* 20 17 –

ICS 40 - J - HA4AJ 1½ in.* 31 27 –

ICS 50 - J - HA4AJ 2 in.** 51 44 –

ICS 65 - J - HA4AJ 2½ in.** 81 70 –

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

v

[gpm] [m3/h]

v

[gpm] [m3/h]

K

Code

v

number

K

Code

v

number

Electronically controlled regulator - JD

CVE

Pressure Regulator

ICS + EVM + CVP + CVE

Inlet press. Regulator w/ electric wide-opening

and shut off - BS

Pressure Regulator

ICS + EVM + CVP + EVM

* Please contact Danfoss

Type C

[gpm] [m3/h]

K

v

Code

v

number

ICS 20 - JD - HA4A ¾ in.* 9.3 8 –

ICS 25 - JD - HA4A 1 in.* 13.3 11.5 –

ICS 32 - JD - HA4A 1¼ in.* 20 17 –

ICS 40 - JD - HA4A 1½ in.* 31 27 –

ICS 50 - JD - HA4A 2 in.** 51 44 –

ICS 65 - JD - HA4A 2½ in.** 81 70 –

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

Type C

[gpm] [m3/h]

K

v

Code

v

number

ICS 20 - BS - (H)A4A ¾ in.* 9.3 8 –

ICS 25 - BS - (H)A4A 1 in.* 13.3 11.5 –

ICS 32 - BS - A4A 1¼ in.* 20 17 –

ICS 32 - BS - HA4A 1¼ in.* 20 17 –

ICS 40 - BS - (H)A4A 1½ in.* 31 27 –

ICS 50 - BS - (H)A4A 2 in.** 51 44 –

ICS 65 - BS - (H)A4A 2½ in.** 81 70 –

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 11

Page 12

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Pilot valvesICS pilots

Type Description

CVP-L Pilot Valve, Inlet Pressure 19.5 in Hg to 102 -0.66 to 7 754 52 027B0920

CVP-M/H Pilot Valve, Inlet Pressure

Range MWP

psig Bar psig Bar

58 to 406 4 to 28 754 52 027B0921

363 to 754 25 to 52 754 52 027B0922

Code

number

CVE

EVM (NC)

EVM (NO)

Pilot Valve, Electronic

operated by ICAD stepper

motor

Pilot Valve, Solenoid

(Normally Closed)

Does Not Include Coil

Pilot Valve, Solenoid

(Normally Open)

Does Not Include Coil

19.5 in Hg to 116 -0.66 to 8 754 52 027B0980

- - 943 65 027B1120

- - 754 52 027B1130

12 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 13

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICS accessories

Pressure gauge adapter.

Description Code no.

¼ FPT adapter 027B2062

Dimensions

Decription Code no.

Pressure Gauge Connection Adapter

and SNV-ST ¼” MPT x ¼” FPT gauge

valve

in.

mm

027X0233

Blanking plug for pilot valves.

Description Code no.

Blanking plug 027F1046

L L

0.91

23

1.40

35.5

1

B B

G ¼ A AF 22 ¼ FPT

1

B

2

External pilot connection, 1/4’’ female - NPT

ICS Description Code no.

25-65

Dimensions

External pilot connection, ¼’’ female NPT (incl. damping orifice, D: 1.0 mm)

in.

mm

027B2065

Multi-function tool

Description Code no.

For all sizes of ICS and ICM 20 to 32 027H0180

For all sizes of ICS and ICM 40 to 65 027H0181

The multi-function tool can be used for:

• Removing the ICS function module

• Operating the ICS manual spindle

• Manually operating motorized valve type ICM

H H

3.54

90

2.60

66

1

OD B B

0.71

18

AF 32 AF 32 M 24 × 1.5

1

B

2

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 13

Page 14

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICS accessories

Flare

Pressure gauge connection, ¼ in. flare (self-closing)

Must not be used in R 717 plant.

Description Code no.

¼ in. flare 027B2041

Dimensions B B

¼ in. flare G ¼ A AF 19 ¼ in. flare

1

B

Cutting ring

Pressure gauge connection

Description Code no.

Cutting ring connection, ¼ in. (6 mm)

Cutting ring connection, 3/8 in. (10 mm)

Dimensions L L

¼ in. (6 mm)

3/8 in. (10 mm)

in.

mm

in.

mm

027B2063

027B2064

1.06

27

1.14

29

1.54

39

1.57

40

1

B B

G ¼ A AF 19 AF 14

G ¼ A AF 19 AF 14

1

B

2

2

Spare parts

ICV 25 (H)A4A Spare Kit 027H2306

ICV 32 HA4A Spare Kit 027H3132

ICV 32 A4A Spare Kit 027H3133

ICV 40 (H)A4A Spare Kit 027H4130

ICV 50 (H)A4A Spare Kit 027H5129

ICV 65 (H)A4A Spare kit 027H6130

All spare kits includes flange gaskets and flange bolts/nuts

14 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 15

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

27H423_12-2015

27H422_12-2015

ICS Dimensions and weights

ICS 1 pilot

Danfoss

Danfoss

ICS 1 pilot

Danfoss

27H422_12-2015

ICS 3 Pilots

Valve size H

25 (H)A4A

32 HA4A

32 A4A

40 (H)A4A

50 (H)A4A

65 (H)A4A

in. 1.67 5.43 3.39 2.36 6 .18 2 0. 59 2. 33 3.43 9. 5 lb. 10.8 l b

mm 42.5 138 86 60 157 51 15 59.2 87 4.3 kg 4.9 kg

in. 1.67 6.02 3.93 2.91 6 .18 2 0.59 2.36 3.43 12. 8 lb . 13. 9 lb.

mm 42.5 153 10 0 74 15 7 51 15 60 87 5.8 kg 6.3 kg

in. 1.90 6.02 3.93 2.91 7. 99 2 0.59 2. 01 3.43 15.6 lb. 16.7 lb.

mm 48.3 153 10 0 74 203 51 15 51 87 7. 1 kg 7. 6 kg

mm 60 159 105 78 2 51 51 15 60 87 10.9 kg 11. 3 k g

in. 2.36 6.26 4.13 3.07 9.88 2 0.59 2.36 3.43 24.0 lb. 24.9 lb.

in. 2.40 6.85 4.72 3.66 9.88 2 0.59 2.48 3.58 29.3 lb. 29.9 lb.

mm 61 174 120 93 251 51 15 63 91 13 .3 kg 13 .6 kg

in. 2.85 7.6 8 5 .51 4.53 9.9 0 2 0.59 2.85 3.58 43.8 lb. 44 lb.

mm 72.5 19 5 140 115 251. 5 51 15 72.5 91 19 .9 kg 20 kg

* Weight stated is for valve without pilots

© Danfoss | DCS (ms) | 2020.09

ICS 3 Pilots

1

H

2

H

3

H

4

L L

1

L

2

B

1

B

Weight

2

ICS 1 Pilot

Weight*

ICS 3 Pilots

AI193486423552en-US0301 | 15

Page 16

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICM-HMMV and ICM-HMMR

ICM capacities

ICM with ICAD actuator

ICM is for each size available in 2 variants for low

and high capacity

Type Valve body

ICM 25-HMMR

ICM 25-HMMV 13.9 12

ICM 32-HMMR

ICM 32-HMMV 20 17

ICM 40-HMMR

ICM 40-HMMV 30 26

ICM 50-HMMR

ICM 50-HMMV 46 40

ICM 65-HMMR

ICM 65-HMMV 81 70

size

25

32

40

50

65

Cv

(USgal/min)

7.0 6

10.4 9

17 15

27 23

41 35

(m3/h)

Kv

16 | AI193486423552en-US0301

A magnetic coupled actuator is easily installed.

Only two actuators are needed to cover the entire

ICM program

ICAD 600A ICAD 1200A

© Danfoss | DCS (ms) | 2020.09

Page 17

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

a

b

d

e

ICM function

c

g

f

P1

ICM, motor operated valves are designed for use

with the ICAD actuator with Display.

The driving force from the actuator is transferred

via a magnetic coupling (a) through the stainless

steel top housing (b) and thus eliminates the need

for a packing gland. The rotational movement of

the magnetic coupling (a) is transferred to a spindle

(c) which in turn provides the vertical movement

of the piston (d) and the valve seat (e), to open and

close the valve. The closing force of the actuator,

combined with the the valve seat (e) and PTFE

valve plate (f), provides an effective seal to prevent

leakage across the valve port, when the valve is in

the closed position. To prevent damage to the PTFE

valve seat (e) and plate (f) from system debris, it is

recommended that a filter is installed upstream of

the valve.

ICM 25-65:

Valve inlet pressure (P1) acting on the underside

of the PTFE valve seat (e) also passes through the

hollow piston assembly (d) on to the top of the

piston (d) and balances the pressure acting on the

piston (d). Any trapped liquid across the throttle

cone (g) is allowed to equalise down to the valve

outlet without affecting the valve performance.

ICAD

There are two sizes of ICAD actuator that covers

the range of valves from ICM 25 to ICM 65. The

actuators have a fully weather protected enclosure

with none of the moving parts exposed to the

environment.

The fast acting actuators and balanced valve design

results in the valve being able to move from the

fully closed to the fully open position in between

3 to 45 seconds depending on valve size and ICAD

setup.

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 17

Page 18

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICAD actuator details

The ICM motor operated valve and ICAD actuator

combinations are as follows:

Actuator ICAD 600A ICAD 1200A

ICM 40

Valve size

ICM 25 ICM 50

ICM 32 ICM 65

ICAD 600A / ICAD 1200A

ICAD actuators can be controlled using the

following signals:

• 0-20 mA

• 4-20 mA (default)

• 0-10 V

• 2-10 V

• One or two digital Input

ICAD actuators can operate an ICM valve as an On/

Off function supported by one digital input.

ICAD actuators can operate an ICM valve as Neutral

zone / 3 point control supported by two digital

inputs.

Actuator types ICAD 600A and 1200A are dedicated

for use with ICM motor operated valves. There are

only two sizes of ICAD actuators that cover the

range of valves from ICM 25 to ICM 65.

The ICM valve can be operated manually via the

ICAD actuator or the Multi-function tool for ICM

(see the ordering section).

Fail Safe supply options

In the event of a power failure, multiple fail safe

options are possible, provided that a ICAD-UPS or

similar is used.

During power failure, ICM can be selected to:

- Close ICM

- Open ICM

- Stay in the same position, as when power

failure occurs

- Go to a specific ICM valve opening degree

See the data sheet DKRCI.PD.HT0.B for further

information.

Please note:

A fail safe supply (battery or UPS) is required.

The ICAD is controlled via a modulating analogue

signal (e.g. 4-20 mA/2-10 V) or a digital ON/OFF

signal. ICAD incorporates an advanced MMI (Man

Machine Interface), including continuous display

of Opening Degree, which gives the user a very

advanced and flexible setup procedure that can

meet many different applications.

Features (actuator)

• Designed for industrial refrigeration installations.

• Advanced and high speed Digital Stepper Motor

Technology

• Seven segment LCD display and three

programming keys included

• Valve opening degree can be observed

continuously.

• Can easily be configured to different applications

on-site (change speed, ON/OFF, Fail Safe

operation, modulating valve, etc..)

• Open – Close time: 3-45 seconds depending on

valve size

• Modulating, ON/OFF operation or Neutral

zone / 3 point control

• Multiple speed selection during operation

• Logging of old alarms

• Password protection

• Control input signal :

4-20 mA, 0-20 mA, 0-10 V, 2-10 V.

One or two digital inputs.

• Position feed back : 0-20 mA, 4-20 mA (ICM)

• 3 Digital ON/OFF feedback

• Resolution: 20 micron/step

(0.02 mm stroke pr. step)

• Total steps: 250 – 3650 depending on size

• Auto Calibration, Neutral zone

• In the event of a power failure, multiple fail safe

options are possible. During power failure, ICM

can be selected to:

Close ICM,

Open ICM,

Stay in the same position, as when power failure

occurs

Go to a specific ICM valve opening degree

• Hermetic magnetic motor

• Enclosure: IP67 ~ NEMA 6

• Approvals: CE, UL, CRN

• Connectors for easy installation and servicing

• ICAD 600A/1200A ensures an acurate feedback

on the valve position.

18 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 19

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Technical data (actuator)

Electrical data

• Materials

Housing

Aluminium

Top part of ICAD

PBT thermo plastic

• Weight

ICAD 600A: 2.64 lb (1.2 kg)

ICAD 1200A: 4.19 lb (1.9 kg)

• Temperature range (ambient)

–22°F/122°F (–30°C/+50°C)

• Enclosure

IP 67 (~NEMA 6)

Electrical connection

Connection to ICAD is done via M12 connectors.

ICAD has two M12 male connectors build-in:

Power supply:

4 poled M12 male connector

Control signals:

8 poled M12 male connector

Supply voltage is galvanic isolated from Input/

Output.

Supply voltage: 24 V d.c., + 10% / -15%

Load: ICAD 600A: 1.2 A

ICAD 1200A: 2.0 A

Fail safe supply: Min. 19 V d.c, max. 26.4 V d.c.

Load: ICAD 600A: 1.2 A

ICAD 1200A: 2.0 A

Analogue Input - Current or Voltage

Current: 0/4-20 mA

Load: 200 W

Voltage: 0/2-10 V d.c

Load : 10 kW

Analogue Output: 0/4-20 mA

Load : ≤ 250 W

ICAD can be delivered with (60 in. (1.5 m.)) or

without cables with M12 female connectors:

Power Supply cable with 4 poled M12 female

connector: 3 x ~22 AWG (3 x 0.34 mm2)

Control cable with 8 poled M12 female

connector: 7 x ~24 AWG (7 x 0.25 mm2)

Cable set with M12 female connectors in other

lengths are available. See the section "Spare parts

and accessories".

Digital Input - Digital ON/OFF input by means of

volt-free contact (Signal/Telecom relays with goldplated contacts recommended) – Voltage input used

ON: Contact impedance < 50 W

OFF: Contact impedance > 100 k W

Digital Output - 3 pcs. NPN transistor output

External supply: 5-24 V d.c.

(Same supply as for ICAD can

be used, but please note that the

galvanically isolated system will

then be spoiled)

Output load: 50 W

Load: Max. 50 mA

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 19

Page 20

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

III

Technical data (cont.)

Electrical data

Cable connection

Two 1.5 m (60 in) cables premounted

Battery capacity:

For each open/closed cycle

Speed Parameter i04 ICM 25 ICM 32

ICAD 600A

ICAD 1200A

Max. (i04 = 100) 5 mAh 5 mAh

Min. (i04 = 1) 467 mAh 533 mAh

Speed Parameter i04 ICM 40 ICM 50 ICM 65

Max. (i04 = 100) 17 mAh 22 mAh 22 mAh

Min. (i04 = 1) 1667 mAh 2167 mAh 2167 mAh

Terminal box not supplied

by Danfoss

Control cable

Supply cable

Ref. Colour Description

A Black – Common Alarm

B Brown – ICM fully open

C Red – ICM fully closed

D Orange – GND ground

E Yellow + 0/4 - 20 mA Input ***

F Green + 0/2 - 10 V Input **

G Blue + 0/4 - 20 mA Output ***

I Black +

II White +

III Brown –

* Uninterruptable Power Supply

** Also used with D (GND, ground) for DI1 - Digital ON-OFF

operation.

*** If Neutral zone / 3 point control is selected (parameter i02 =

3) then E and G are used as DI2 - Digital ON/OFF input.

Note: Colour code changed when compared

to older colour wiring diagram.

Fail safe supply

Battery / UPS* 19 V d.c.

Supply voltage

24 V d.c.

Digital

Ouput

}

Analogue

In/Output

}

4 pin male connector 8 pin male connector

II

B

A

G

Approvals

CE according to 89/336 EEC (EMC)

Emission : EN61000-6-3

I

C

D

E

F

Immunity: EN61000-6-2

Function (actuator)

The design of ICAD is based on a digital stepper

motor technology combined with an advanced

MMI (Man Machine Interface), that gives excellent

The advanced menu system will allow several

parameters to be ajusted to obtain the required

function.

possibilities for having a high degree of flexibility

with the same type of ICAD actuator.

At the ICAD display the Opening Degree (0100 %) of the actual ICM valve installed can be

continuously observed.

20 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 21

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Function (actuator)

(continued)

Many different parameters can be configurated,

among these:

• Modulating, ON/OFF operation or Neutral

zone / 3 point control

• Analog input

0- 20 mA or 4-20 mA

0-10 V or 2-10 V

• Digital Input

ICAD can be configured to support one or two

digital inputs.

When using one digital input, 0-10 V can not be

used at the same time.

By using two digital inputs at Neutral zone /

3 point control, the analog input (0/2-10 V, 0/4-20

mA) and Analog Output (0/4-20 mA) can not be

used at the same time.

• Analog output

0- 20 mA or 4-20 mA

• Automatic or manual control

• Change of ICM valve speed

• Automatic calibration

• Multiple Fail Safe set-up options during power

cut

For service all Input and Output signals can be

recalled and observed from the ICAD display.

For further details on ICAD actuator please see the

data sheet DKRCI.PD.HT0.B

A password protection has been linked to the

parameter of entering the correct ICM valve to

avoid unintentional and non-authorised operation.

ICAD can manage and display different alarms.

If an alarm has been detected the display will

alternate between showing: Actual alarm present

and Opening Degree of ICM valve. If more than one

alarm is active at the same time the alarm with the

highest priority will take preference. The alarm with

the highest priority is shown on the display.

All alarms will automatically reset when

disappearing.

Previous alarms can be recalled for traceability and

service purposes.

Any active alarm will activate the common digital

alarm output.

All alarms will automatically reset when

disappearing.

ICAD provides two digital output signals to 3rd

party control equipment (e.g. PLC) indicating if the

ICM valve is completely open or completely closed.

The hermetic magnetic motor coupling makes it

easy to dismount the ICAD from ICM valve.

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 21

Page 22

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Material specification

Bolt sizes (pos. 5)

Type Screw

ICM 25 M12 × 30 A2-70 DIN 933

ICM 32 M14 × 35 A2-70 DIN 933

ICM 40 M14 × 35 A2-70 DIN 933

ICM 50 M16 × 40 A2-70 DIN 933

ICM 65 M16 × 40 A2-70 DIN 933

No. Part Material EN ASTM JIS

1 Housing Low temperature steel G20Mn5QT, EN 10213-3 LCC, A352 SCPL1, G5151

2 Top cover Low temperature steel G20Mn5QT, EN 10213-3 LCC, A352 SCPL1, G5151

2a O-ring Cloroprene (Neoprene)

2b O-ring Cloroprene (Neoprene)

2c O-ring Cloroprene (Neoprene)

3 Function module

4 Gasket Cloroprene (Neoprene)

4a Gasket Fiber, non-asbestos

5 Bolts Stainless steel A2-70, EN 1515-1 Grade B8 A320 A2-70, B 1054

11 Actuator

12 O-ring Cloroprene (Neoprene)

13 O-ring Cloroprene (Neoprene)

14 Seat High density polymer

22 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 23

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICM ordering

ICM accessories

Type C

[gpm]

ICM 25 HMMR 1 in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.* 7.0 6 148X0859

ICM 32 HMMR 1¼ in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.* 10.4 9 148X0861

ICM 40 HMMR 1½ in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.* 17 15 148X0862

ICM 50 HMMR 2 in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.** 27 23 148X0863

ICM 65 HMMR 2½ in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.** 41 35 148X0864

ICM 25 HMMV 1 in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.* 13.9 12 148X0865

ICM 32 HMMV 1¼ in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.* 20 17 148X0867

ICM 40 HMMV 1½ in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.* 30 26 148X0868

ICM 50 HMMV 2 in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.** 46 40 148X0869

ICM 65 HMMV 2½ in. incl. ICAD, control cable 9.84 ft and supply cable 9.84 ft.** 81 70 148X0892

* Includes flange gaskets and flange bolts.

** Includes flange gaskets, flange bolts and flange nuts.

K

v

[m3/h]

Code

v

number

ICAD-UPS

Description Code no.

ICAD-UPS 027H0182

Multi-funtion tool

Description Code no.

Multi-function tool for ICM 25-32 027H0180

Multi-function tool for ICM 40-65 027H0181

Cable for ICAD 600A / 1200A

Cable length (all female) Code no.

4.92 ft. (1.5 m) 027H0426

9.84 ft. (3 m) 027H0438

32.81 ft. (10 m) 027H0427

49.21 ft. (15 m) 027H0435

Connectors for ICAD 600A / 1200A

Connector type Code no.

Two Female Connectors with screw

terminals:

- connector for power

- connector for control signals

027H0430

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 23

Page 24

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

L

Protection cap for ICAD 600A / 1200AICM accessories

Description Code no.

Protection cap 027H0431

ICM dimensions and weights

H

1

H

2

H

L

L

Valve size L L

25 HMMR(V) 1 in.

32 HMMR(V ) 1¼ in.

40 HMMR( V) 1½ in.

50 HMMR(V) 2 in.

65 HMMR(V ) 2½ in.

in. 6.2 4.0 4.7 1.6 7.7 4.1 11.9 lb

mm 157 102 118.4 40 195 104.5 5.4 kg

in. 6.2 4.0 4.7 1.6 7.7 4.8 15.6 lb

mm 157 102 120.2 40 195 121.8 7.1 kg

in. 9.9 4.0 4.7 1.8 8.6 5.6 28.2 lb

mm 251 102 120 45 219 143.1 12.8 kg

in. 9.9 4.0 4.7 1.8 8.6 6.4 34.1 lb

mm 251 102 120 45 219 162.1 15.5 kg

in. 9.9 4.0 5.7 1.8 8.6 7.7 50.8 lb

mm 251.5 102 145 45 219 196.6 23.1 kg

1

L

2

1

L

2

L

H H

1

H

1

H

2

H

H

2

1

L

2

Weight ICM

incl. ICAD

24 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 25

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICLX-S9A

ICLX capacities

ICLX with coils

Type Valve body

size

ICLX 50 S9A 50 54.5 47

ICLX 65 S9A 65 95 82

Cv

(USgal/min)

(m3/h)

Kv

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 25

Page 26

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

P2

2

EV

ICLX function

M NO

P1

The ICLX valve is used as a shut-off valve in suction

lines to open after a hot gas defrost.

The valve is a pilot controlled valve operated by an

external pilot pressure source. This means that the

valve can operate with no internal pressure

differential (Pd) at all.

Low Pd is the key objective and makes the ICLX

valve ideal for applications that are sensitive to

differential pressure.

Though Pd is kept low, it can still be quantified, and

must be considered when choosing valve size.

The main valve is provided with two pilot solenoid

valves, as well as a nipple for connection to external

pilot pressure.

The external pilot pressure line must be connected

to a system pressure (p2) which is at least 1.5 bar

(20 psi) higher than the inlet pressure (p1) of the

valve. The difference between the external pilot

pressure and the inlet pressure of the valve defines

the maximum opening differential pressure (MOPD)

of the ICLX.

1

EVM NC

opens the first step corresponding to approximately

10% of the valve capacity. At the same time the

bleed spring will be compressed. This will start a

pressure equalization of the inlet pressure (p1) to

the outlet pressure. When the differential pressure

across the valve has fallen

to approximately 22 psig (1.5 bar) the spring will be

strong enough to open the second step and open

the valve to full capacity.

This way high-pressure pulsations, which would

occur when opening for full capacity in one step,

can be avoided.

ICLX must not be used in pipe systems where

the differential pressure across the main valve

in an open position can exceed 15 psig (1 bar),

otherwise the step two on the valve will close.

26 | AI193486423552en-US0301

The ICLX is kept open when power is applied to the

coils placed on the EVM pilot solenoid valves in pos.

1 and pos. 2.

The ICLX closes and is kept closed when the coils on

EVM pilot solenoid valves in pos. 1 and pos. 2 are

de-energised.

The pilot solenoid valve (pos.1) allows external pilot

pressure (p2) to the bottom of the servo piston and

© Danfoss | DCS (ms) | 2020.09

Page 27

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

Danfoss

M27H0231_1

ICLX function

(continued)

Two step opening principle

External pressure

Inlet pressure

Closed Bleed

Outlet pressure

Step 1

Important note for ICLX valves:

the ICLX valve is kept in its open position

by hot gas. The hot gas condenses in

the cold valve and creates liquid under

the servo piston. When the pilot valves change

status to close the ICLX, the pressure on the servo

piston equalizes with the suction pressure through

the pilot valve (pos. 2). This equalization takes time

because condensed liquid is present in the valve.

The exact time taken from when the pilot valves

change position to complete closing of the ICLX will

depend on temperature, pressure, refrigerant and

the size of the valve. Thus an exact closing time for

the valves cannot be given but, in general, lower

temperatures give longer closing times.

Open

Step 1 + 2

Time

It is very important to take the closing times into

consideration when a hot gas defrost is performed

on evaporators. Steps must be taken to ensure that

the hot gas supply valve is not opened before the

ICLX in the suction line is completely closed. If the

hot gas supply valve is opened before the ICLX in

the suction line is closed, considerable energy will

be lost and potentially dangerous situations might

arise because of “liquid hammer”. In ICLX valves, the

spring-loaded second stage might be induced to

hammer by gas and liquid being forced through the

valve at ∆p > 1.5 bar across the ICLX. The final result

could be severe damage to the valve.

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 27

Page 28

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

23

25

24

ICLX material specification

9

13

2

14

16

8

11

7

1

20

17

18

13

10

12

3

4

21

6

5

19

No. Part Material EN ASTM

1 Valve body Low temperature steel G20Mn5QT, EN 10213-3 LCC, A352

2 Top cover ICLX 50-65: Low temperature steel P285QH, EN 10222-4 LF2, A350

3 Main piston Steel

4 Bleed piston Steel

5 Seat plate main PTFE

6 Seat plate bleed PTFE

7 Gasket Fiber, non-asbestos

8 Spindle manual opener Stainless steel

9 Packing gland Steel

10 Insert Steel

11 Spring - main Stainless steel

12 Spring - bleed Stainless steel

13 O-ring Chloroprene (neoprene)

14 O-ring Chloroprene (neoprene)

16 O-ring Chloroprene (neoprene)

17 O-ring Chloroprene (neoprene)

18 O-ring Chloroprene (neoprene)

19 O-ring Chloroprene (neoprene)

20 Seal PTFE

21 Seal PTFE

22 Bolt Stainless steel A2-70 EN 1515-1 A2-70, B1054

23 EVM pilot NC

24 EVM pilot NO

25 External pressure inlet

28 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 29

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

ICLX ordering

ICLX accessories

Type C

[gpm] [m3/h]

ICLX 50 S9A 2 in. incl. connector* 54.5 47 148X0896

ICLX 65 S9A 2½ in. incl. connector* 95 82 148X0897

* Includes flange gaskets, flange bolts and flange nuts.

K

v

Code

v

number

External pilot connection, ¼’’ female - NPT

ICLX Description Code no.

50-65

50-65

50-65

50-65

External pilot connection

(incl. damping orifice, D: 1.0 mm)

External pilot connection (¼” FPT)

(incl. damping orifice, D: 1.0 mm)

Accessory bag with seal and o-ring for

pilot valve

Damping orifice for EVM. 10 pcs,

(D: 1.0 mm)

027F1048

027B2065

027F0666

027F0664

A damping orifice should be installed if the pressure difference between the low and the high pressure

side is more than 6 bars.

Dimensions

in.

mm

H H

3.54

90

1

2.60

66

OD B B

0.71

18

AF 32 AF 32 M 24 × 1.5

1

B

2

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 29

Page 30

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

H

L

H

LL

ICLX dimensions and weights

4

max

L

3

3

L3max

L

2

2

H

4

H

1

H

L L

L

4

max

L

3

L3max

1

L

2

2

H

4

H

3

1

Valve size L L

50 S9A 2 in.

65 S9A 2½ in.

in. 9.9 4.7 5.0 4.9 5.3 6.2 2.4 9.4 4.0 8.5 43.3 lb

mm 251 120 126 125 13 5 15 7 61 24 0 102 217 19.7 kg

in. 9.9 5.7 5.6 4.9 5.3 6.4 2.9 10.1 4.8 9.2 59.0 lb

mm 251. 5 145 141 125 135 163 72.5 257 12 3 234 26.8 kg

1

L

2

L3max

10W 20W

L

4

H

1

1

H

H

2

H

3

H

Weight

4

30 | AI193486423552en-US0301

© Danfoss | DCS (ms) | 2020.09

Page 31

Data sheet | Motor - and Servo operated valves, type ICS-(H)A4A, ICS-(H)S4A, ICM-HMMV, ICM-HMMR and ICLX-S9A

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 31

Page 32

© Danfoss | DCS (ms) | 2020.09

AI193486423552en-US0301 | 32

Loading...

Loading...