Page 1

Data Sheet

Pilot operated servo valve

Type ICSH 25-80

2 step opening of hot gas lines for defrosting

ICSH dual position solenoid valve belongs to

the ICV family and consists of an ICV housing,

an ICS insert together with an ICSH top cover

with 2 EVM normally closed solenoid pilots

installed in the top cover.

ICSH is used in hot gas lines for the opening of

hot gas defrost ow to the evaporator in 2

steps. Both steps are activated by a controller or

a PLC energizing the magnetic coils in a time

delay sequence.

Step 1 (approx. 20% of full ow) is to allow a

smooth pressure build-up in the evaporator,

while the subsequent step 2 opens the ow to

100% to get the full defrost capacity.

The ICSH is designed for large industrial

refrigeration systems with ammonia,

uorinated refrigerants or CO2.

The ICSH features 2 conguration options,

which is established at site.

First option is dependent conguration, which

secures that step 2 can never open unless step

1 has been mechanically activated.

Second option is independent conguration

that allows step 2 to open disregarding step 1.

By choosing the independent option attention

should be paid to the risk of liquid hammering

in case the step 1 for any reason is disregarded.

AI260929867804en-000501

Page 2

Pilot operated servo valve, type ICSH 25-80

Features

• Designed for Industrial Refrigeration applications for a maximum working pressure of 52 bar / 754 psig.

• Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO2).

• Direct welded connections.

• Connection types include butt weld, socket weld and solder connections.

• Low temperature steel body.

• Low weight and compact design.

• 2-wire connection for use with a timer relay or 4 wire connection for connecting to a controller or a PLC.

• The ICSH main valve top cover can be oriented in any direction without the function of pilot valves being aected.

• Stabilizes working conditions and eliminates pressure pulsations during opening of hot gas.

• Manual opening possible.

• PTFE seat provides excellent valve tightness.

• Service friendly design.

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 2

Page 3

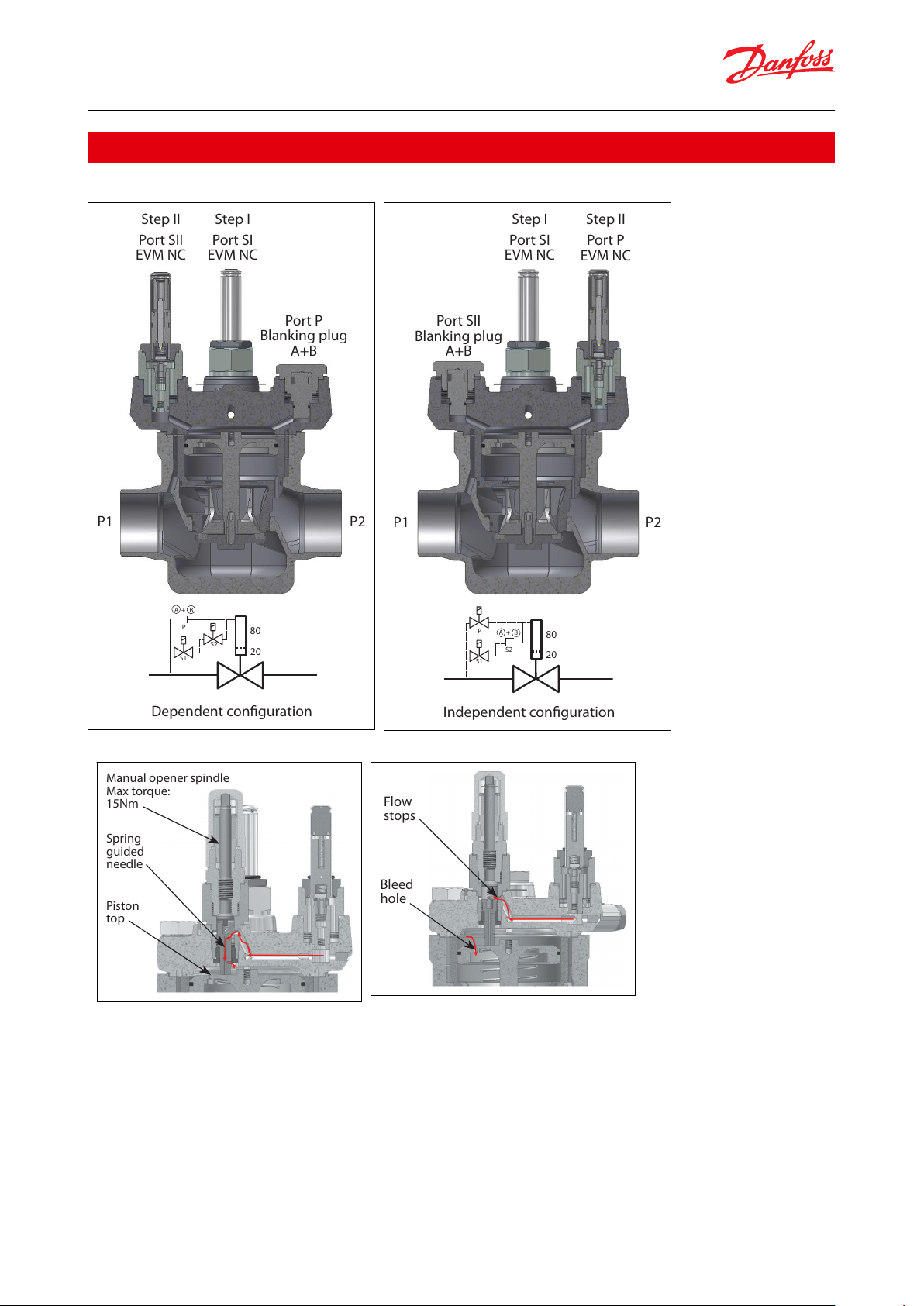

Dependent configuration

Step II

Port SII

EVM NC

Step I

Port SI

EVM NC

Port P

Blanking plug

A+B

P1 P2

A + B

P

S2

S1

80

20

Independent configuration

Step I

Port SI

EVM NC

Step II

Port P

EVM NC

P1 P2

Port SII

Blanking plug

A+B

A + B

P

S2

S1

80

20

Spring

guided

needle

Piston

top

Manual opener spindle

Max torque:

15Nm

Flow

stops

Bleed

hole

Pilot operated servo valve, type ICSH 25-80

Function

Figure 1: Dependent conguration

Figure 2: Independent conguration

Figure 3: Supply ow

The ICSH is designed for a 2 step opening of the hot gas ow for the evaporator defrost. Step 1 (20% capacity) is

intended for a smooth pressure build up in the evaporator - step 2 will open for full capacity.

The valve is pilot controlled by 2 standard EVM Normally Closed valves and the 2 EVM’s are controlled by an external

controller like PLC.

The external controller simply needs to activate the 2 EVM coils in a sequence with a certain time oset.

The time oset depends on the specic conditions around the ICSH and must be determined at site.

The opening of the ICSH is done by a pressure dierence between the inlet pressure P1 and the outlet pressure P2,

and for the main valve to open fully, a Δp of 0.2 bar (2.9 psi) is needed.

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 3

Figure 4: Supply ow

Page 4

Pilot operated servo valve, type ICSH 25-80

The ICSH main valve can be congured into 2 dierent congurations: Dependent or Independent.

The Dependent setup (Figure 1: Dependent conguration) means that fully open (step 2) can only be performed if

step 1 is performed successfully. If step 1 for some reason fails, the valve will not open at all.

The matching control program should, in this case, be to activate step 1 coil followed by activation of step 2 coil.

Dependent setup is done by installing the 2 EVM’s in Port SI (step 1) and Port SII (step 2), and blanking o the P port

with Blanking plug A+B.

The Independent setup (Figure 2: Independent conguration) involves the option to force step 2 to open

independent of the result of step 1.

The matching control program should also in this case be to activate step 1 coil followed by activation of step 2 coil.

When step 2 is activated the full ow will immediately be started.

ATTENTION:

A risk of liquid hammering in the system may appear.

Independent setup is done by installing the 2 EVM’s in Port SI (step 1) and Port P (step 2), and blanking o the SII

port with Blanking plug A+B.

The internal channel structure allows in both congurations a direct ow to the step 1 EVM. By activating step 1 the

ow will continue through the spring guided needle that is resting on the top of the piston (see Figure 3: Supply

ow).

The ow will build up a pressure on top of the piston, which will start moving down i.e. start open the main valve.

The spring guided needle follows the pistons movement downwards and after a predened distance the needle

reaches its stop position, where the needle closes the supply ow (see Figure 4: Supply ow).

The bleed hole in the piston top will allow a certain ow out of the pressurized chamber thus enable the piston to

move upwards, but any movement of the piston is now being controlled by the needle that compensates by

opening the supply ow.

The needle will balance the supply/bleed ows and keep the piston at this position. Step I ow - equivalent to

approx. 20% of capacity - has now been established.

After a predetermined period of time the step II coil is activated.

In dependent set-up further ow can only reach the step II EVM if step I EVM is open (working properly). In

independent set-up further ow can reach the step II EVM regardless the status of step I.

Once ow is passing through step II EVM it continues to the top of the piston and moves the piston to full open

position.

For both congurations the valve will close and stay closed when both coils are de-energised.

The closing is achieved by drainage through the bleed hole.

ICSH is including a manual opener like all the valves in the ICV family. The operation of the opener is done by

turning the spindle clockwise (opening the valve) or counterclockwise (closing the valve).

ATTENTION:

Attention should be paid to the maximum torque applied to the spindle when turning: Never exceed 15 Nm to the

spindle in any direction.

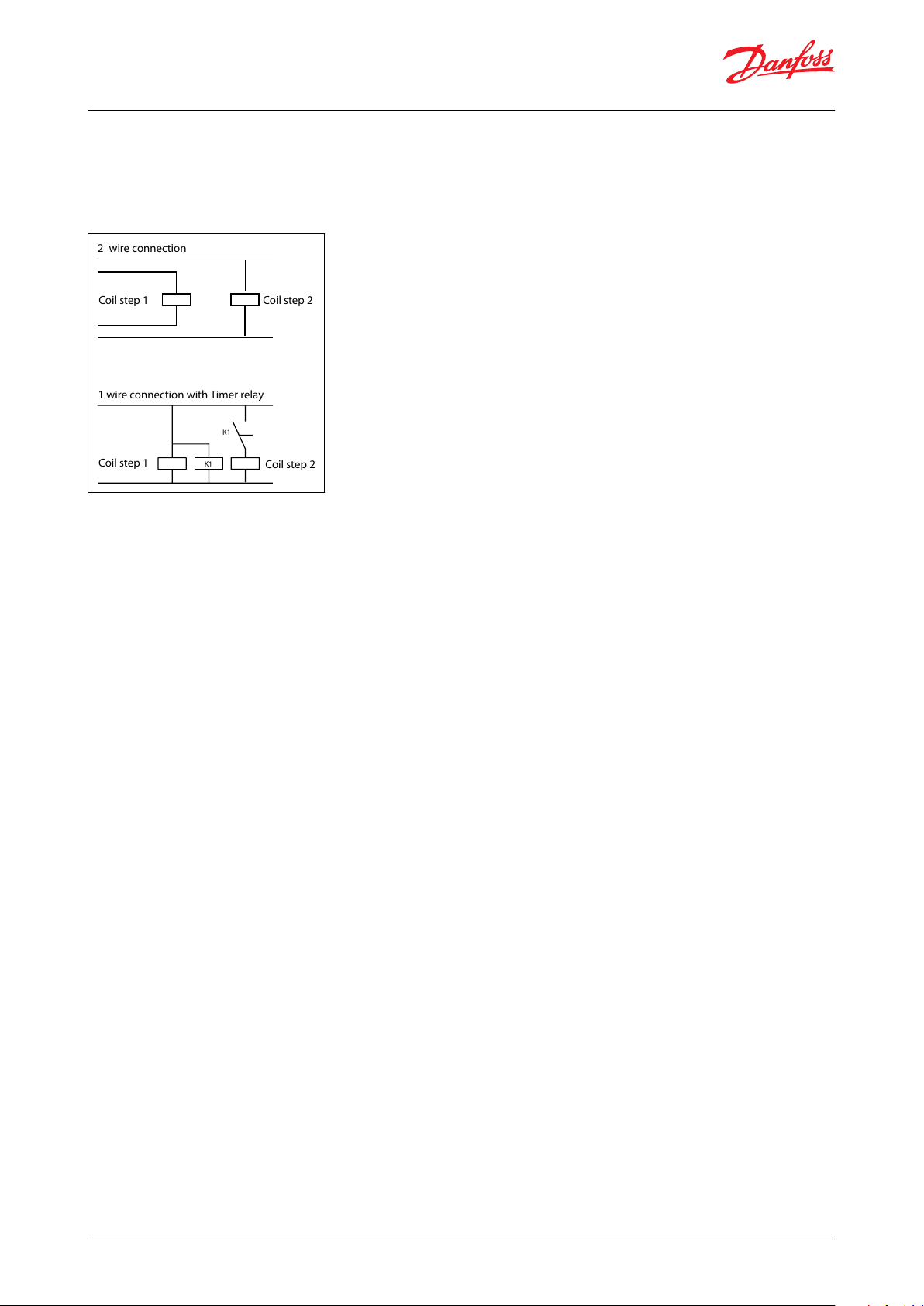

Controller and Wiring

The 2 steps need to be activated from a PLC in a time delay sequence. The time delay itself must be determined on

site since local conditions are decisive.

The wiring from the controller to the 2 coils can be done by either one or two cables.

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 4

Page 5

Coil step

2

K1

K1

2 wire connection

Coil step 2

Coil step 1

1 wire connection with Timer relay

Coil step 1

Pilot operated servo valve, type ICSH 25-80

By one cable layout only one signal is needed though an additional timer relay has to be connected according to

the gure to the right.

Two cable layout requires two subsequent output signals from the PLC.

Figure 5: Wire connection

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 5

Page 6

Pilot operated servo valve, type ICSH 25-80

Media

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO2).

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 6

Page 7

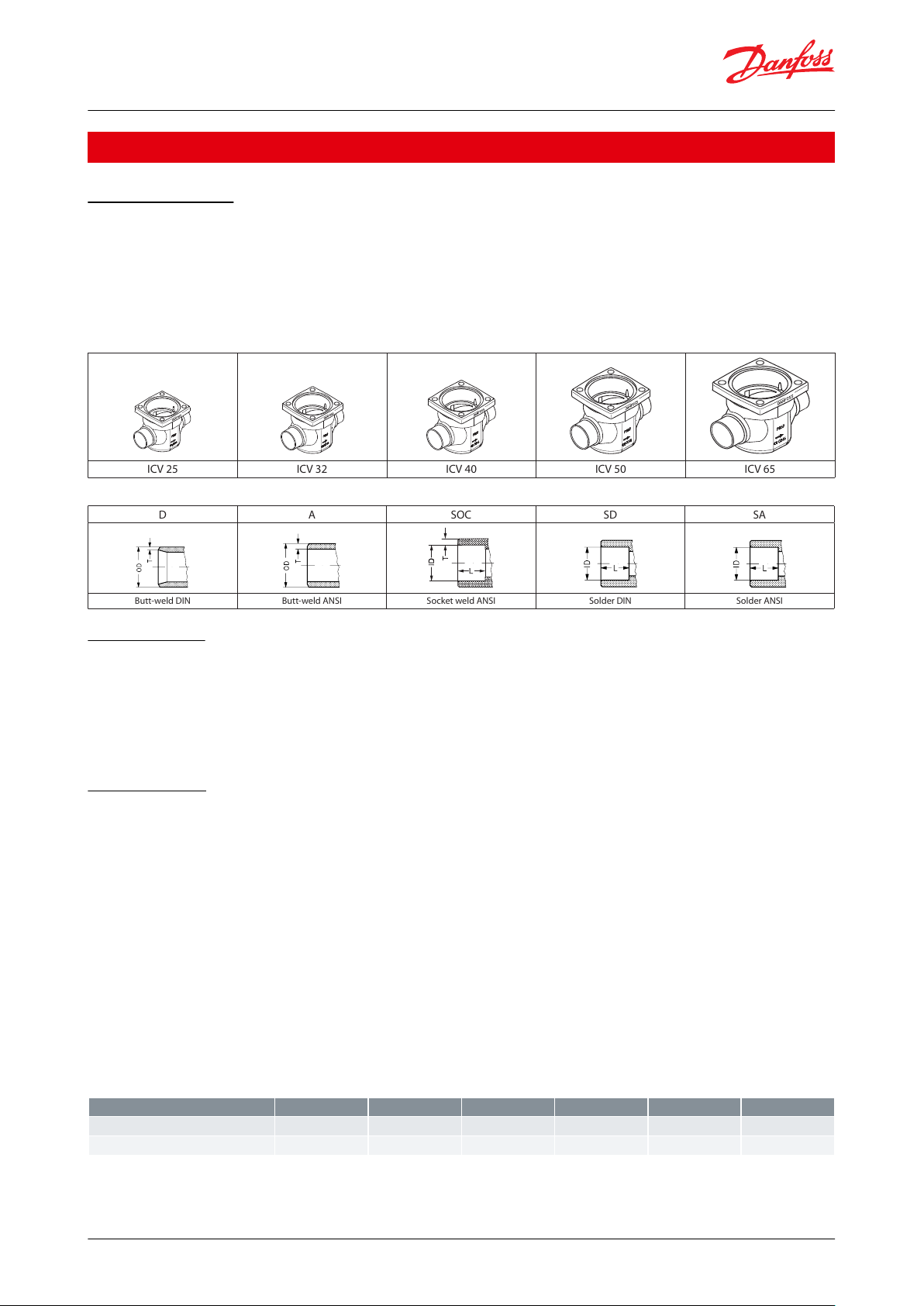

ICV 25 ICV 32 ICV 40 ICV 50 ICV 65

D A SOC SD SA

Butt-weld DIN Butt-weld ANSI Socket weld ANSI Solder DIN Solder ANSI

ICSH 25-25

ICSH 32

ICSH 40

ICSH 50

ICSH 65

ICSH 80

k

v

(m3/h) (full capacity)

11.517274470

85

C

v

(USgal/min) (full capacity)

13.320315181

98

Pilot operated servo valve, type ICSH 25-80

Product specication

The ICSH Concept

The ICSH concept is developed to highest exibility of direct welded connections. For valve sizes ICV 25 – ICV 65 a

wide range of connection sizes and types is available.

The direct welded (non-anged) connections secure low risk of leakage.

There are ve valve bodies available (ICSH 80 makes use of ICV 65 housing).

Figure 6: Valve bodies

Design (valve)

The ICSH valves are approved in accordance with the European standard specied in the Pressure Equipment

Directive and are CE marked.

For further details / restrictions - see Installation Instruction.

Valve body and top cover material Low temperature steel

Technical data

Temperature range

Media: -60 °C / +120 °C (-76 °F / +248 °F).

Pressure

The valve is designed for a max. working pressure of 52 bar / 754 psig

Step 1 20% capacity of step 2 (full capacity)

Surface protection

The ICSH external surface is zinc-chromated to provide good corrosion protection.

Min. opening pressure dierential

0.2 bar (2.9 psi) higher inlet pressure than otlet pressure for fully open.

Coil requirements: Both coils to be IP67.

Table 1: ICSH capacity values

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 7

Page 8

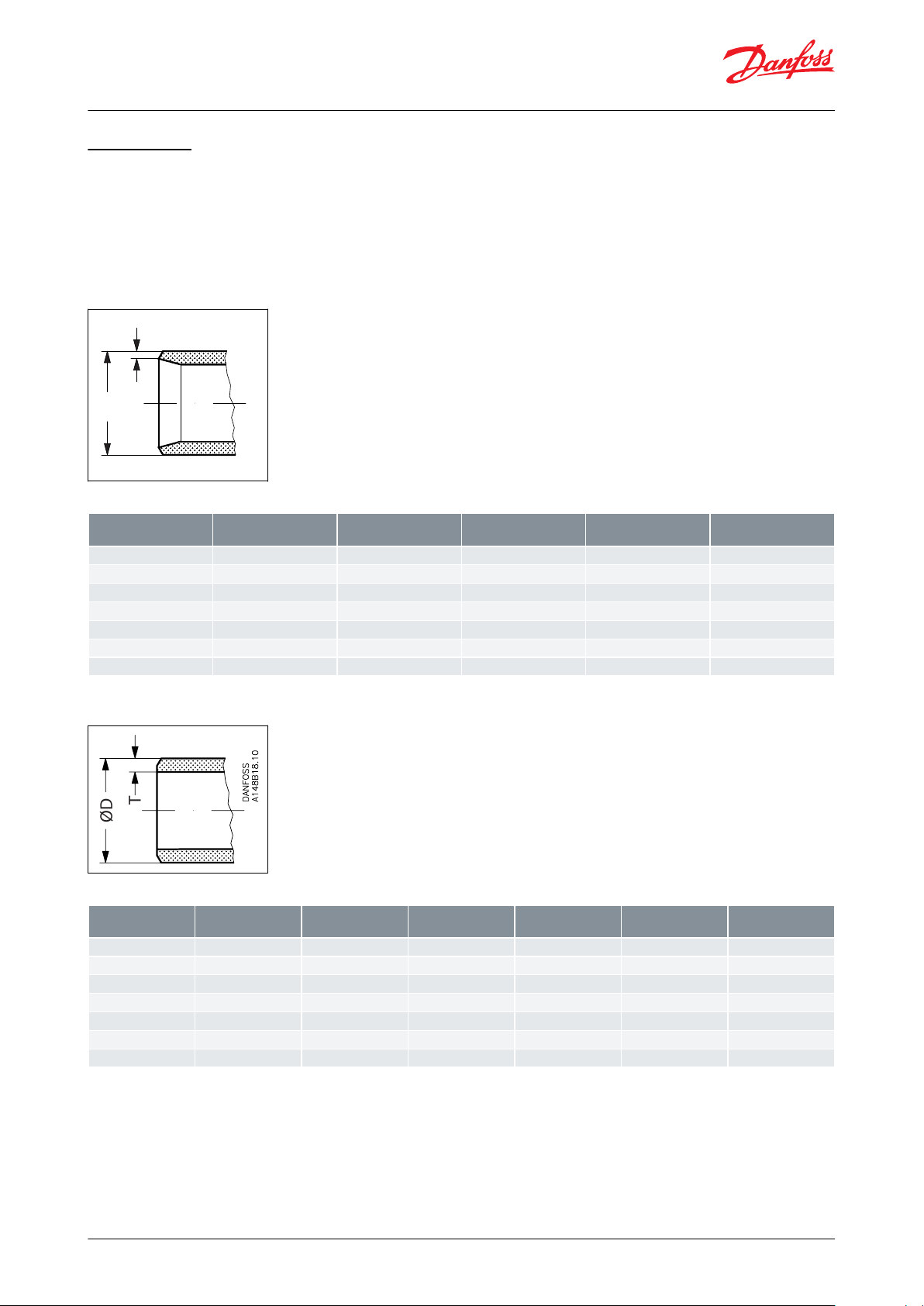

T

ØD

Danfoss

A148B15.10

SizemmSize

in.ØDmmTmmØDin.Tin.

20

(¾)

26.9

2.3

1.059

0.09125(1)

33.7

2.6

1.327

0.10332(1¼)

42.4

2.6

1.669

0.10240(1½)

48.3

2.6

1.902

0.10350(2)

60.3

2.9

2.37

0.1165(2½)

76.1

2.930.1180(3)

88.9

3.2

3.50

0.13

T

ØD

SizemmSize

in.ØDmmTmmØDin.Tin.

Schedule

(20)¾26.9

4.0

1.059

0.15880(25)133.7

4.6

1.327

0.18180(32)1¼42.4

4.9

1.669

0.19380(40)1½48.3

5.1

1.902

0.20180(50)260.3

3.9

2.37

0.1540(65)2½73.0

5.2

2.87

0.2040(80)388.9

5.5

3.50

0.22

40

Pilot operated servo valve, type ICSH 25-80

Connections

There is a wide range of connection types available with ICSH valves:

• D: Butt weld, EN 10220

• A: Butt weld, ANSI (B 36.10)

• SOC: Socket weld, ANSI (B 16.11)

• SD: Solder connection, EN 1254-1

• SA: Solder connection, ANSI (B 16.22)

Figure 7: D: Butt-weld

Table 2: Butt-weld (EN 10220)

Figure 8: A: Butt-weld

ANSI

Table 3: Butt-weld ANSI (B 36.10)

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 8

Page 9

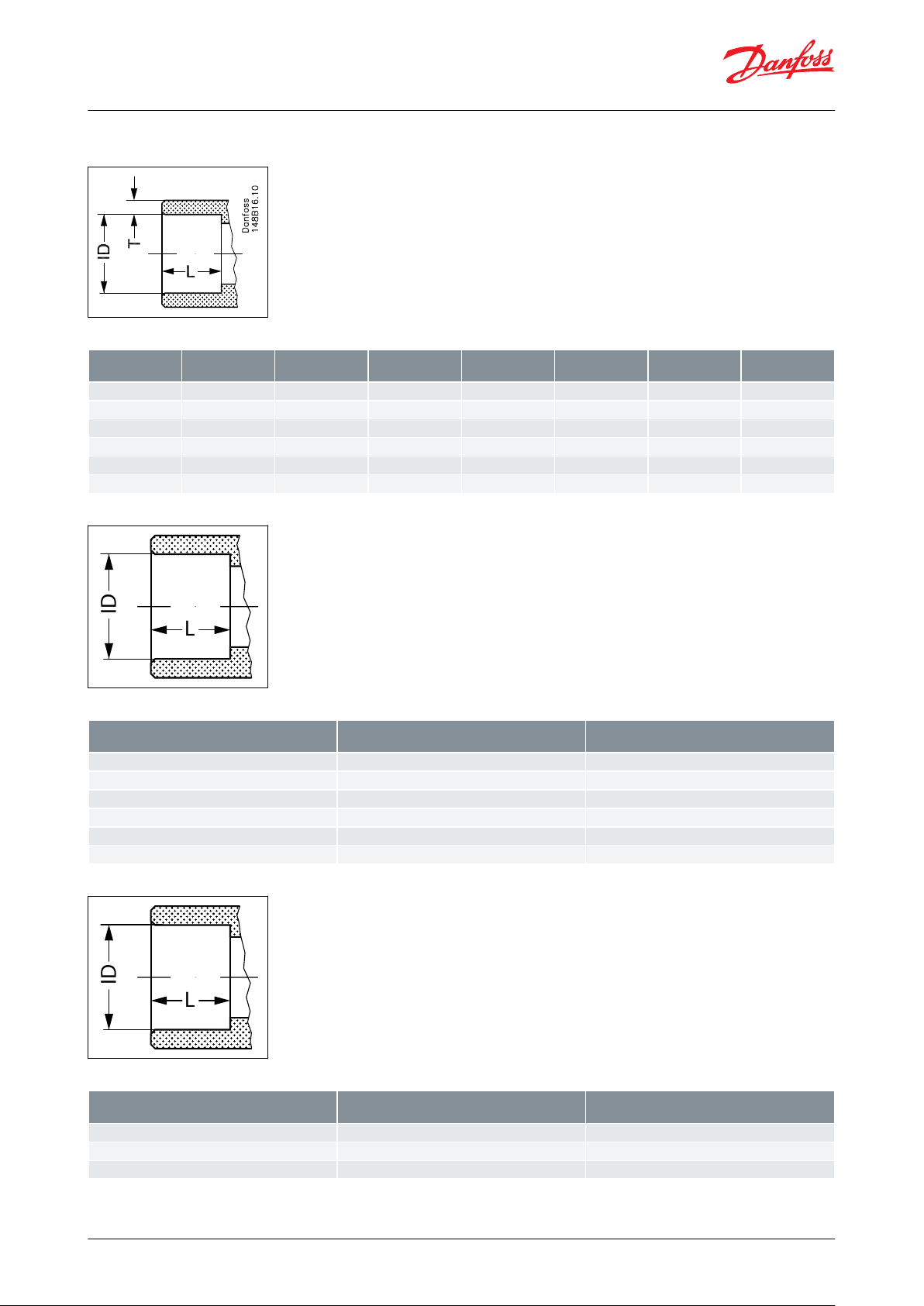

SizemmSize

in.IDmmTmmIDin.Tin.LmmLin.

(20)¾27.2

4.6

1.071

0.181130.51

(25)133.9

7.2

1.335

0.284130.51

(32)1¼42.7

6.1

1.743

0.240130.51

(40)1½48.8

6.6

1.921

0.260130.51

(50)261.2

6.2

2.41

0.24160.63

(65)2½74

8.8

2.91

0.344160.63

L

ID

SizemmIDmmL

mm

22

22.08

16.52828.082635

35.072542

42.072854

54.093376

76.1

33

L

ID

Size

in.IDin.Lin.

⅞

0.875

0.650

1⅛1.125

1.024

1⅜1.375

0.984

Pilot operated servo valve, type ICSH 25-80

Figure 9: SOC: Socket

welding ANSI

Table 4: Socket welding ANSI (B 16.11)

Figure 10: SD: Soldering

Table 5: SD: Soldering (EN 1254-1)

Figure 11: SA: Soldering

Table 6: SA: Soldering (ANSI B 16.22)

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 9

Page 10

Size

in.IDin.Lin.

1⅝

1.625

1.1022⅛2.125

1.3002½2.625

1.300

16

2

1

3

4

6

7

5

8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

24

DANFOSS

27H581

No

Part

Material

EN

ASTM

1

Body

Low temperature Steel

G20Mn5QT EN 10213-3

LCC A352

2

Top Cover

Low temperature Steel

P285QH EN-10222-4

LF2 A350

3

Gasket

Fibre non asbestos

4

Gasket

Aluminium

5

Gasket

Aluminium

6

EVM NC

7

Gasket

Nylon8Cap

Steel9Stopper

Nylon10Manual opener

Steel11Needle Housing

Stainless steel

12

Spring Bush

Stainless steel

13

Spring

Steel14Needle

Stainless steel

15

Nozzle

Cast iron

16

Plug

Steel17Piston

Steel

Pilot operated servo valve, type ICSH 25-80

Material specication

Figure 12: ICSH

Table 7: Material and parts list

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 10

Page 11

No

Part

Material

EN

ASTM

18

Cylinder

Steel19Spring

Steel20O-ring

Chloroprene (Neoprene)

21

O-ring

Chloroprene (Neoprene)

22

Cone

Steel23Valve Plate

PTFE24Bolt

Stainless steel

A2-70 EN1515-1

A2-70, B1054

L

H4

L3max

L4

H3

L3max

L2

H2

H1

L1

DANFOSS

27H582

ICSH 25-25

L

DINASOCmm135

135

147in5.31

5.31

5.79

ICSH 25-25L1L2

L3max(s1)

L3max(S-2)

L4H1H2H3H4

Weight

mm65146.5

138

123

100.5

39.5

168.561174

3.8 Kgin2.56

5.77

5.43

4.84

3.96

1.56

6.63

2.40

6.85

7.93lb

Pilot operated servo valve, type ICSH 25-80

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector®2. Rated and extended capacities are calculated with the Coolselector®2 calculation engine to ARI

standards with the ASEREP equations based on laboratory measurements of selected valves.

Download Coolselector®2 for free at coolselector.danfoss.com.

Dimensions

Figure 13: ICSH

Table 8: ICSH 25-25

Table 9: ICSH 25-25

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 11

Page 12

ICSH 32

L

DINASOCmm145

145

148in5.71

5.71

5.83

ICSH 32L1L2

L3max(s1)

L3max(S-2)

L4H1H2H3H4

Weight

mm75146.5

138

123

102

42.5

18272187.6

5.1 Kgin2.95

5.77

5.43

4.84

4.02

1.67

7.17

2.83

7.39

11.1 lb

ICSH 40

L

DINASOCmm160

160

180in6.30

6.30

7.09

ICSH 40L1L2

L3max(s1)

L3max(S-2)

L4H1H2H3H4

Weight

mm86146

138

123

102

51.5

186.578193

6.5 Kgin3.39

5.75

5.43

4.84

4.02

2.03

7.34

3.07

7.60

14 lb

ICSH 50

L

DINASOCmm200

200

216in7.87

7.87

8.50

ICSH 50L1L2

L3max(s1)

L3max(S-2)

L4H1H2H3H4

Weight

mm

100

146

138

123

1076120295209

9.4 Kgin3.94

5.75

5.43

4.84

4.21

2.40

7.95

3.74

8.23

20.3lb

ICSH 65

L

DINASOCmm230

230

230in9.06

9.06

9.06

ICSH 65L1L2

L3max(s1)

L3max(S-2)

L4H1H2H3H4

Weight

mm

130

145.6

138

123

106.769222.5

114.5

232

13.7 Kgin5.12

5.73

5.43

4.84

4.20

2.72

8.76

4.51

9.13

29.8lb

ICSH 80

L

DIN

Amm245

245in9.65

9.65

ICSH 80L1L2

L3max(s1)

L3max(S-2)

L4H1H2H3H4

Weight

mm

130

145.6

138

123

106.769222.5

112.5

232

13.7 Kgin5.12

5.73

5.43

4.84

4.20

2.72

8.76

4.43

9.13

29.8lb

Pilot operated servo valve, type ICSH 25-80

Table 10: ICSH 32

Table 11: ICSH 32

Table 12: ICSH 40

Table 13: ICSH 40

Table 14: ICSH 50

Table 15: ICSH 50

Table 16: ICSH 65

Table 17: ICSH 65

Table 18: ICSH 80

Table 19: ICSH 80

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 12

Page 13

+ + =

027H2120

Function module ICS 25-25

027H2200

Top cover ICSH

027H0159

Valve body 25 D (1 in.)

Valve size

Code Number

20 D (¾ in.)

027H2128

35 SD (1⅜ in. SA)

027H2134

22 SD (⅞ in.)

027H2123

20 SOC (¾ in.)

027H2132

25 D (1 in.)

027H2120

28 SA (1⅛ in.)

027H2126

20 A (¾ in.)

027H2131

25 SOC (1 in.)

027H2122

32 D (1¼ in.)

027H2129

22 SA (⅞ in.)

027H2125

25 A (1 in.)

027H2121

20 FPT (½ in.)

027H2133

40 D (1½ in.)

027H2135

28 SD (1⅛ in.)

027H2124

32 A (1¼ in.)

027H2130

25 FPT (1 in.)

027H2127

Pilot operated servo valve, type ICSH 25-80

Ordering

ICSH 25

Ordering from the parts programme

Figure 14: Example (select from below tables ICV 25 valve body w/dierent connections, ICS 25 function module and ICSH 25

top cover)

Figure 15: ICV 25 valve

body

Table 20: ICV 25 valve body w/dierent connections

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 13

Page 14

Description

Code Number

ICS 25-5

027H2201

(1)

ICS 25-10

027H2202

(1)

ICS 25-15

027H2203

(1)

ICS 25-20

027H2204

(1)

ICS 25-25

027H2200

(1)

Description

Code Number

Top cover ICSH

027H0159

(2)

Pilot operated servo valve, type ICSH 25-80

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

Figure 16: ICS 25

Table 21: ICS 25 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 17: ICSH 25 top

cover

Table 22: ICSH 25 top cover

(2)

(2)

Including bolts, one blanking plug (A+B) and 2 EVM NC

Including bolts, one blanking plug (A+B) and 2 EVM NC

Ordering complete factory assembled valve

(body, function module and top cover)

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 14

Page 15

+ + =

027H3120

Function module ICS 32

027H3200

Top cover ICSH

027H0164

Valve body 32 D (1¼ in.)

Available connections

20 D (¾ in.)

25 D (1 in.)

32 D (1¼ in.)

40 D (1½ in.)

35 SD (1⅜ in.

SA)

28 SA (1⅛ in.)

22 SA (⅞ in.)

28 SD (1⅛ in.)

ICSH 25-25

(3)

*

027H2309******

22 SD (⅞ in.)

20 A (¾ in.)

25 A (1 in.)

32 A (1¼ in. )

20 SOC (¾ in.)

25 SOC (1 in.)

20 FPT (½ in. )

25 FPT (1 in. )

ICSH 25-25

(3)

**027H2308**

027H2307**

Pilot operated servo valve, type ICSH 25-80

Figure 18: Vlave assembly

Table 23: ICSH 25-25 connections

(3)

(3)

Including one blanking plug (A+B) and 2 EVM NC

Including one blanking plug (A+B) and 2 EVM NC

ICSH 32

Ordering from the parts programme

Figure 19: Example (select from table ICV 32 valve body w/dierent connections, ICS 32 function module and ICSH 32 top

cover)

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 15

Page 16

Connection

Code Number

32 D (11/4 in.)

027H3120

35 SD (13/8 in. SA)

027H3123

40 D (11/2 in.)

027H3125

32 A (11/4 in.)

027H3121

42 SA (15/8 in.)

027H3127

32 SOC (11/4 in.)

027H3122

42 SD (15/8 in.)

027H3128

40 A (11/2 in.)

027H3126

Connection

Code Number

ICS 32

027H3200

(1)

Pilot operated servo valve, type ICSH 25-80

Figure 20: ICV 32 valve body

Table 24: ICV 32 valve body w/dierent connections

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

Figure 21: ICS 32 function module

Table 25: ICS 32 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 16

Page 17

Description

Code Number

Top cover ICSH

027H0164

(2)

Available connections

32 D (1¼ in.)

40 D (1½ in.)

42 SA (1⅝ in.)

42 SD (1⅝ in.)

35 SD (1

⅜ in.

SA)

32 A (1¼ in.)

32 SOC (1¼ in.)

40 A (1½ in.)

ICSH 32

(3)

027H3309****

027H3378

027H3377

*

Pilot operated servo valve, type ICSH 25-80

Figure 22: ICSH 32 top

cover

Table 26: ICSH 32 top cover

(2)

(2)

Including bolts, one blanking plug (A+B) and 2 EVM NC

Including bolts, one blanking plug (A+B) and 2 EVM NC

Ordering complete factory assembled valve

(body, function module and top cover)

Figure 23: Assemble valve

Table 27: ICSH 32 connections

(3)

(3)

Including one blanking plug (A+B) and 2 EVM NC

Including one blanking plug (A+B) and 2 EVM NC

* Select from parts programme

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 17

Page 18

+ + =

027H4126

Function module ICS 40

027H4200

Top cover ICSH

027H0169

Valve body 50 D (2 in.)

Connections

Code Number

40 D (1½ in.)

027H4120

50 D (2 in.)

027H4126

42 SA (1⅝ in.)

027H4124

42 SD (1⅝ in.)

027H4123

40 A (1½ in.)

027H4121

40 SOC (1½ in.)

027H4122

50 A (2 in.)

027H4127

Pilot operated servo valve, type ICSH 25-80

ICSH 40

Ordering from the parts programme

Figure 24: Example (select from table ICV 40 valve body w/dierent connections, table ICS 40 function module and ICSH 40

top cover)

Figure 25: ICV 40 valve body

Table 28: ICV 40 valve body w/dierent connections

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

Figure 26: ICS 40 function module

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 18

Page 19

Description

Code Number

ICS 40

027H4200

(1)

Description

Code Number

Top cover ICSH

027H0169

(2)

Available connections

40 D (1½ in.)

50 D (2 in.)

42 SA (1

⅝ in.)

42 SD (1

⅝ in.)

40 A (1½ in.)

40 SOC (1½ in.)

50 A (2 in.)

ICSH 40

(3)

027H4309***027H4308

027H4307

*

Pilot operated servo valve, type ICSH 25-80

Table 29: ICS 40 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 27: ICSH 40 top

cover

Table 30: ICSH 40 top cover

(2)

(2)

Including bolts, one blanking plug (A+B) and 2 EVM NC

Including bolts, one blanking plug (A+B) and 2 EVM NC

Figure 28: Valve assembly

Table 31: Ordering complete factory assembled valve (body, function module and top cover)

(3)

(3)

* Select from parts programme

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 19

Including one blanking plug (A+B) and 2 EVM NC

Including one blanking plug (A+B) and 2 EVM NC

Page 20

+ + =

027H5124

Function module ICS 40

027H5200

Top cover ICSH

027H0174

Valve body 65 D (2½ in.)

Connections

Code Number

50 D (2 in.)

027H5120

50 SOC (2 in.)

027H5122

65 D (2½ in.)

027H5124

65 A (2½ in.)

027H5125

54 SD (2⅛ in. SA)

027H5123

50 A (2 in.)

027H5121

Pilot operated servo valve, type ICSH 25-80

ICSH 50

Ordering from the parts programme

Figure 29: Example (select from below table ICV 50 valve body w/dierent connections, ICS 50 function module and ICSH 50

top cover)

Figure 30: ICV 50 valve body

Table 32: ICV 50 valve body w/dierent connections

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

Figure 31: ICS 50 function module

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 20

Page 21

Description

Code Number

ICS 50

027H5200

(1)

Description

Code Number

Top cover ICSH

027H0174

(2)

Available connections

50 D (2 in.)

65 D (2½ in.)

54 SD (2

⅛ in. SA)

65 A (2½ in.)

50 A (2 in.)

50 SOC (2 in.)

ICSH 50

(3)

027H5309***027H5308

027H5307

Pilot operated servo valve, type ICSH 25-80

Table 33: ICS 50 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 32: ICSH 50 top

cover

Table 34: ICSH 50 top cover

(2)

(2)

Including bolts, one blanking plug (A+B) and 2 EVM NC

Including bolts, one blanking plug (A+B) and 2 EVM NC

Figure 33: Valve assembly

Table 35: Ordering complete factory assembled valve (body, function module and top cover)

(3)

(3)

Including one blanking plug (A+B) and 2 EVM NC

Including one blanking plug (A+B) and 2 EVM NC

* Select from parts programme

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 21

Page 22

+ + =

027H6124

Function module Top cover ICSH

027H0179

027H0227

ICS 65 027H6200

ICS 80 027H8200

Valve body 76 SD (2 5/8 in.)

Connections

Code Number

65 D (21/2 in.)

027H6120

65 A (21/2 in.)

027H6121

65 J (21/2 in.)

027H6122

80 D (3 in.)

027H6126

80 A (3 in.)

027H6127

67 SA (2 5/8 in.)

027H6125

76 SD (3 in.)

027H6124

65 SOC (21/2 in.)

027H6123

Pilot operated servo valve, type ICSH 25-80

ICSH 65 and ICSH 80

Ordering from the parts programme

Figure 34: Example (select from table ICV 65 valve body w/dierent connections, table ICS 65-80 function module and table

ICSH 65-80 top cover)

Figure 35: ICV 65 valve body

Table 36: ICV 65 valve body w/dierent connections

D = Butt-weld DIN

A = Butt-weld ANSI

J = Butt-weld JIS

SOC = Socket weld ANSI

SD = Solder DIN

SA = Solder ANSI

FPT = Female Pipe Thread

Figure 36: ICS 65-80 function module

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 22

Page 23

Description

Code Number

ICS 65

027H6200

(1)

ICS 80

027H8200

(1)

Description

Code Number

Top cover ICSH (65)

027H0179

(2)

Top cover ICSH (80)

027H0227

(2)

Available connections

65 D (2½ in.)

65 A (2½ in.)

65 SOC (2½ in.)

80 D (3 in.)

80 A (3 in.)

67 SA (2

⅝ in.)

76 SD (3 in.)

65 J (2½ in.)

ICSH 65

(3)

027H6309

027H6311

027H6308****

*

ICSH 80

(3)

***

027H7302

027H7303**

*

Pilot operated servo valve, type ICSH 25-80

Table 37: ICS 65-80 function module

(1)

(1)

Including gasket and O-rings

Including gasket and O-rings

Figure 37: ICSH 65-80 top

cover

Table 38: ICSH 65-80 top cover

(2)

(2)

Including bolts, one blanking plug (A+B) and 2 EVM NC

Including bolts, one blanking plug (A+B) and 2 EVM NC

Figure 38: Valve assembly

Table 39: Ordering complete factory assembled valve (body, function module and top cover)

(3)

(3)

Including one blanking plug (A+B) and 2 EVM NC

Including one blanking plug (A+B) and 2 EVM NC

* Select from parts programme

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 23

Page 24

Description

Code no.

ICV 25 PM Valve housing

027H2119

(1)

ICV 32 PM Valve housing

027H3129

(1)

ICV 40 PM Valve housing

027H4128

(1)

ICV 50 PM Valve housing

027H5127

(2)

ICV 65 PM Valve housing

027H6128

(2)

PM

REMOVE

ICV PM

ICV PM

DROP IN

ICM

ICS/H

ICLX

CUSTOMIZE

Description

Code no.

ICV 25 (H)A4A Valve housing

027H2304

(3)

ICV 32 A4A Valve housing

027H3130

(3)

ICV 32 HA4A Valve housing

027H3131

(3)

Pilot operated servo valve, type ICSH 25-80

Accessories

ICV PM anged valve housings

ICV PM anged valve housings can replace the PM valves on already installed refrigeration systems.

Pressure range

The ICV PM valve housing is designed for a max. working pressure of 28 bar / 406 psig and therefore a suitable

replacement for PM valves in the service market. They also oer the same drop-in dimensions as the PM valves.

Table 40: ICV PM valve housing

(1)

(1)

Includes ICV PM valve housing, ange gaskets and ange bolts.

Includes ICV PM valve housing, ange gaskets and ange bolts.

(2)

(2)

Includes ICV PM valve housing, ange gaskets, ange bolts and ange nuts.

Includes ICV PM valve housing, ange gaskets, ange bolts and ange nuts.

Function modules and top covers must be ordered separately (see the section “Ordering”).

Figure 39: ICV PM anged valve housing

Figure 40: Function modules and top covers

ICV (H)A4A anged valve housings

ICV (H)A4A anged valve housings can replace the (H)A4A valves on already installed refrigeration systems.

Pressure range

The ICV (H)A4A valve housing is designed for a max. working pressure of 28 bar g / 406 psig and therefore a suitable

replacement for (H)A4A valves in the service market. They also oer the same drop-in dimensions as the (H)A4A

valves.

Table 41: ICV (H)A4A anged valve housings

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 24

Page 25

Description

Code no.

ICV 40 (H)A4A Valve housing

027H4129

(3)

ICV 50 (H)A4A Valve housing

027H5128

(3)

ICV 65 (H)A4A Valve housing

027H6129

(3)

(H)A4A

REMOVE

ICV (H)A4A

ICV (H)A4A

DROP IN

ICM

ICS/H

ICLX

CUSTOMIZE

Description

Code number

Blanking plug incl.

at gasket

027F1046

Pilot operated servo valve, type ICSH 25-80

(3)

(3)

Includes ICV (H)A4A valve housing, ange gaskets, ange bolts and ange nuts.

Includes ICV (H)A4A valve housing, ange gaskets, ange bolts and ange nuts.

Figure 41: ICV (H)A4A anged valve housing

Function modules and top covers must be ordered separately (see the section “Ordering”).

Figure 42: Function modules and top covers

Figure 43: Plug

Table 42: Blanking plug A + B for pilot valves

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 25

Page 26

The ICV valve concept has been designed to fulll global refrigeration requirements.

ICSH valves

Nominal bore

DN≤ 25 (1 in.)

DN 32 - 80 (1¼ - 3 in.)

Classied for

Fluid group I

Category

Article 4, paragraph 3

II

File name

Document type

Document topic

Approval authority

033F0685.AK

EU Declaration

EMCD/PED

Danfoss

033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

Д-DK.РА01.B.71727_20

EAC Declaration

PED

EAC

0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

-

TÜV

19.10325.266

Marine - Safety Certicate

-

RMRS

Pilot operated servo valve, type ICSH 25-80

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 43: Approvals

Table 44: ICSH valves

Table 45: Certicates and declarations

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 26

Page 27

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI260929867804en-000501 | 27

Loading...

Loading...