Page 1

Data sheet

Rotary valves HRE 3, HRE 4

Description

Ordering

Danfoss HRE rotary valves are primarily designed

for regulation of ow temperature in heating

systems where a certain leakage can be accepted

and where a dened control characteristic is not

required.

Typ e

HRE 3

HRE 4

DN k

(mm) (m3/h) HRE 3 HRE 4

20 6,3

25 10 Rp 1" 065Z0419 065Z0424

32 16 Rp 1 ⁄" 065Z0420 065Z0425

40 25 Rp 1 ⁄" 065Z0421 065Z0426

50 40 Rp 2" 065Z0422 065Z0427

VS

HRE rotary valves can be used in combination

with electric actuators AMB 162 and AMB 182.

Features:

• Cast iron body with internal thread

• Lowest leakage in class

• Unique position indicator (visible also when

actuator in mounted)

• Ergonomic handle

• For mixing and diverting applications

• Internal thread connection

Main data:

• DN 20–50

• kVS 6,3–40 m3/h

• PN 6

• T

=110 ° C

max

• 3-way or 4-way

• S characteristic

PN Connection

Rp ⁄" 065Z0418 065Z0423

6

Code No.

DEN-SMT/SI

Spare parts and accessories for HRE valves

Typ e DN Code No.

15-2 0 065Z0444

Transparent cover, scale and

pointer

HRE 3/4 15-2 0 065Z0449

HRE 3/4 25 065Z0450

HRE 3/4 32 065Z0451

Stung box

Replacement handle 065Z0442

Linkage kit for AMB (Gen. 2014) 082H0255

VD.LS.Z4.02 © Danfoss 11/2015

HRE 3 40 065Z0452

HRE 4 40 065Z0460

HRE 3 50 065Z0453

HRE 4 50 065Z0461

25 065Z0445

32 065Z0446

40 065Z0447

50 065Z0448

Spare parts for old generation AMB actuators

Picture Typ e Code No.

Connection plate HRE +

AMB (Gen. 2009)

065Z0439

1

Page 2

Data sheet Rotary valves HRE 3, HRE 4

Technical data

Pressure temperature

diagram

Nominal diameter DN 20 25 32 40 50

Control Characteristic S characteristic

Leakage

Nominal pressure PN 6

Max. closing pressure bar 1

Torque at PN Nm 5

Medium Circulation water / glycolic mixture up to 50 %

Medium pH Min. 7, max. 10

Medium temperature °C 2 … 110

Connections Internal thread. ISO 7/1

Materials

Valve body Grey cast iron EN-GJL-250(GG25)

Slide shoe CuZn36Pb2As (Brass DZR, CW 602N)

Stung box sealing EPDM

HRE 3 Diverting: max. 0,5 % of kVS / Mixing: max. 1,0 % of k

HRE 4 Max. 1,5 % k

VS

VS

PN 6

EN-GJL-250

(GG-25)

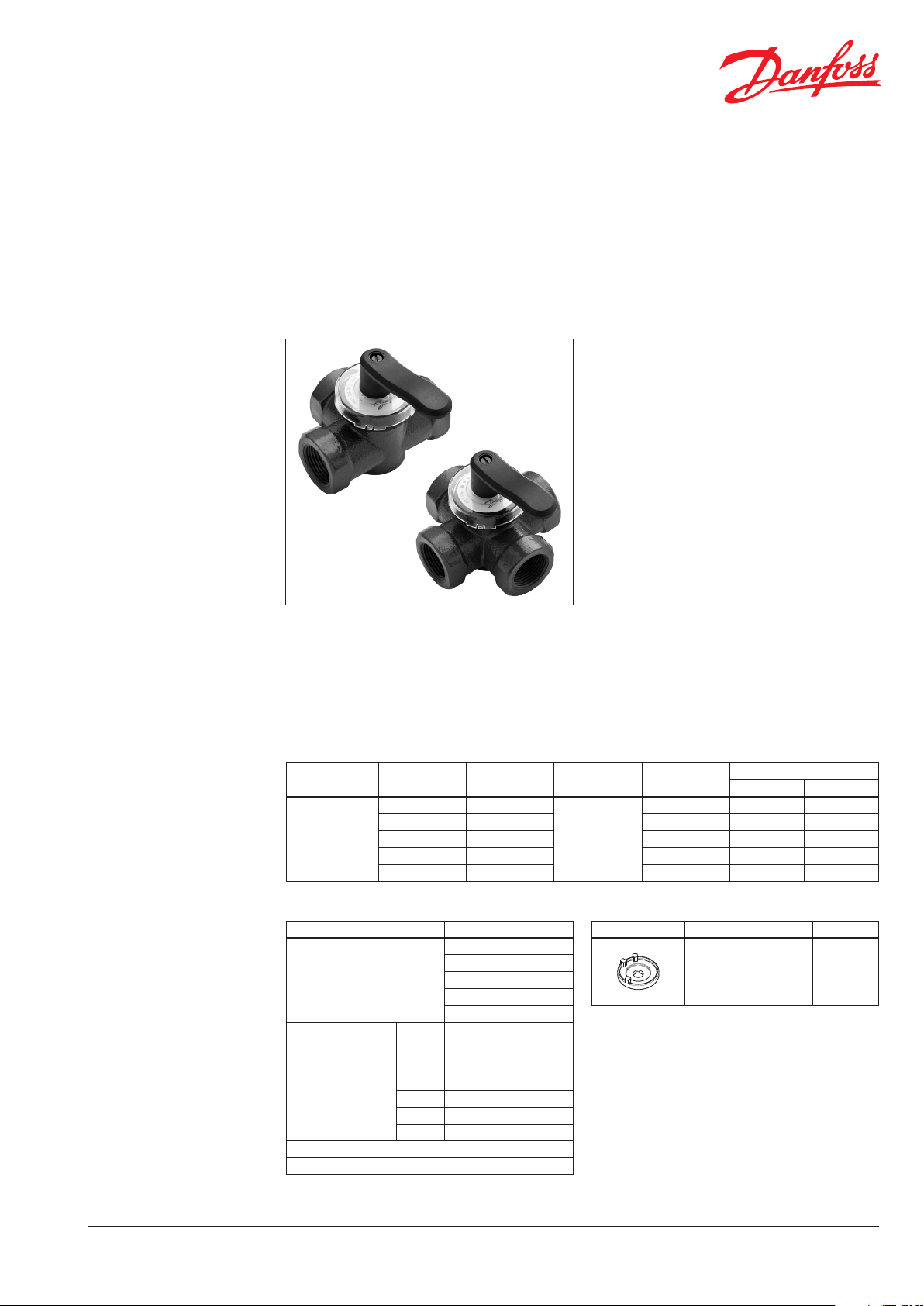

Valve characteristics

B

A

HRE 3 HRE 4

2

VD.LS.Z4.02 © Danfoss 11/2015

DEN-SMT/SI

Page 3

Data sheet Rotary valves HRE 3, HRE 4

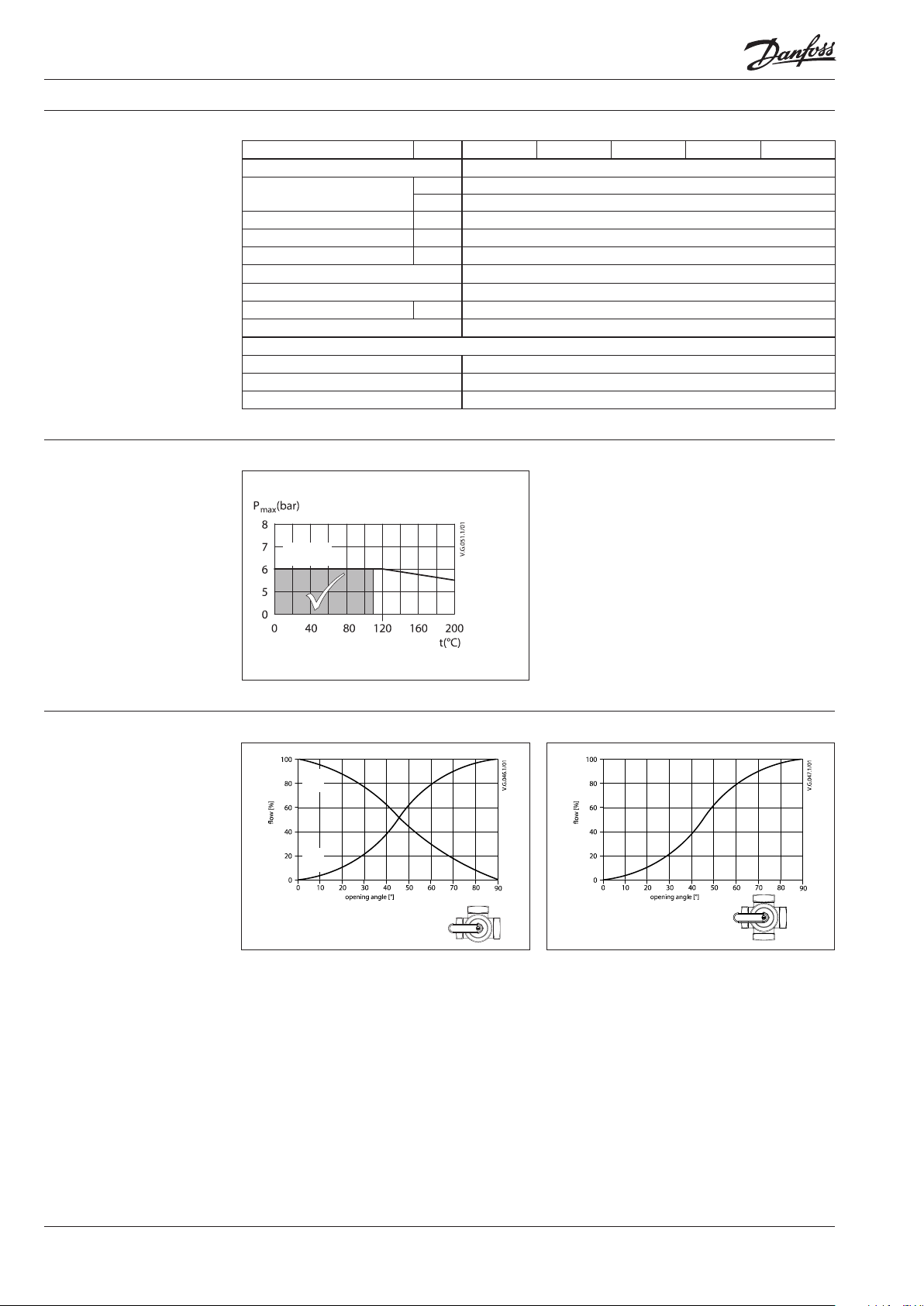

Installation

Mixing

Diverting

Flow

Return

From boiler

Back to boiler

Disposal

Valve mounting

Before valve mounting pipes have to be cleaned

and free from abrasion. Mechanical loads on

valve body caused by the pipes are not allowed.

It is recommended to install a strainer into

application to avoid damaging controlling

components.

Note:

Install a strainer upstream of the valve

(e.g. Danfoss FVR/FVF)

The valve must be dismantled and the elements

sorted into various material groups before

disposal.

Connection

HRE 3 can be used as a mixing valve, diverting

valve and in connection with heat exchangers

where a certain leakage can be accepted.

HRE 4 operates according to the double shunt

principle i.e. the water from the boiler is mixed

with a certain portion of the water in the return.

In this way the water which goes to the boiler

reaches a higher return temperature than by

using 3-way valves. This means that the risk of

corrosion in oil and solid fuel boilers is reduced.

AMB

FVR/FVF

DEN-SMT/SI

VD.LS.Z4.02 © Danfoss 11/2015

3

Page 4

Data sheet Rotary valves HRE 3, HRE 4

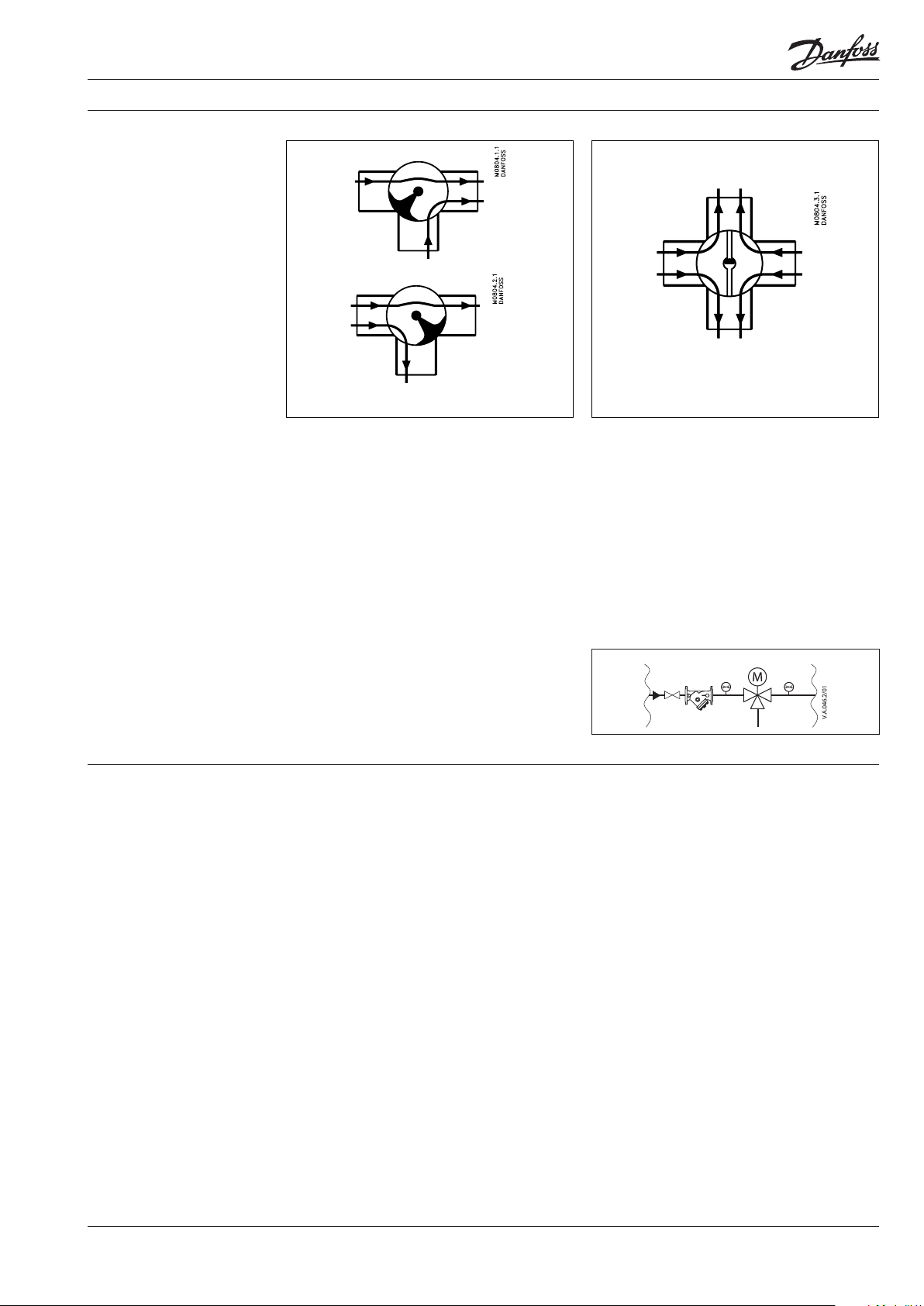

Application principles

HRE 3

The reverse function is obtained by turning the actuator's direction of rotation and the valve's sign.

HRE 4

The reverse function is obtained by turning the actuator's direction of rotation and the valve's sign.

Sizing

Flow Rate

(liquid w ith specic a gravi ty of 1)

l/sec m3/h

max

p

FLOW Pressure drop kPa (100 kPa = 1bar = ~ 10 m H2O)

4

VD.LS.Z4.02 © Danfoss 11/2015

DEN-SMT/SI

Page 5

Data sheet Rotary valves HRE 3, HRE 4

Design

1. Valve body

2. Slide shoe

3. Stung box

4. Transparent cover and

indicator

5. Handle

Dimensions

HRE 3 HRE 4

A

D

A

B

C

101

92

75

101

D

B

C

84

84

DEN-SMT/SI

HRE 3, HRE 4

A B C D

DN

20

52,5 105 130,5 88 Rp ⁄" 0,9 1,1

25

54 108 132 92 Rp 1" 1,2 1,4

32

57, 5 115 135, 5 102 Rp 1 ⁄" 1, 6 1,9

40

60 12 0 13 8 102 Rp 1 ⁄" 2,0 2,3

50

78 156 156 108 Rp 2" 3,9 4,2

VD.LS.Z4.02 © Danfoss 11/2015

mm HRE 3 HRE 4

Connection

Weight (kg)

Actuator

AMB 162

AMB 182

5

Page 6

Data sheet Rotary valves HRE 3, HRE 4

6

VD.LS.Z4.02 © Danfoss 11/2015

DEN-SMT/SI

Page 7

Data sheet Rotary valves HRE 3, HRE 4

DEN-SMT/SI

VD.LS.Z4.02 © Danfoss 11/2015

7

Page 8

Data sheet Rotary valves HRE 3, HRE 4

8

VD.LS.Z4.02

Produce d by Danfoss A/S © 11/2015

Loading...

Loading...