Page 1

Installation guide

How to use solenoid valves

Making it easy to be efficient

ia.danfoss.com

Page 2

How to use

solenoid valves

This booklet has been compiled to help in the installation of

compact and high performance solenoid valves and in

locating faults in systems with solenoid valves.

The compact range has small physical dimensions for control

of flow where space is limited.

The high performance range is a sturdy and universal valve

program for control of flow in industrial plants and within

heating and sanitary systems.

Note that this booklet describes only brass solenoid valves.

For other types, please contact Danfoss.

If you need help choosing a solenoid valve, visit the online

valve selector at valveselector.danfoss.com

Flexible and

user-friendly

© Danfoss | DCS (RJA) | 2015.11

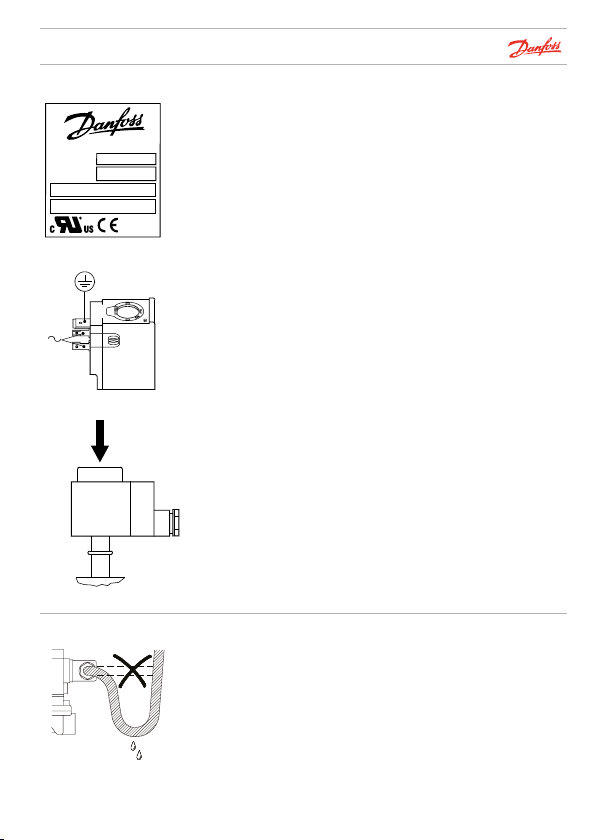

Danfoss solenoid valve bodies and electrical coils are normally

supplied separately and then combined together. They are

assembled quickly and simply without any tools.

This provides optimum product flexibility and availability. If a

coil needs replacement it can be done without stopping or

draining any system.

The solenoid valves are also available as assembled units if

required.

IC.PS.600.A8.02

Page 3

Contents

Identification .........................................................................................................3

Installation...............................................................................................................6

How to choose ..................................................................................................13

Valve overview ..................................................................................................18

Seal material .......................................................................................................22

Coils ..........................................................................................................................23

Opening and closing times .......................................................................25

Fault location ......................................................................................................27

Spare parts high performance range

......................................................

Spare parts compact range.......................................................................41

Tools .........................................................................................................................42

32

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 1

Page 4

Solenoid valves

Choosing the correct

solenoid valve

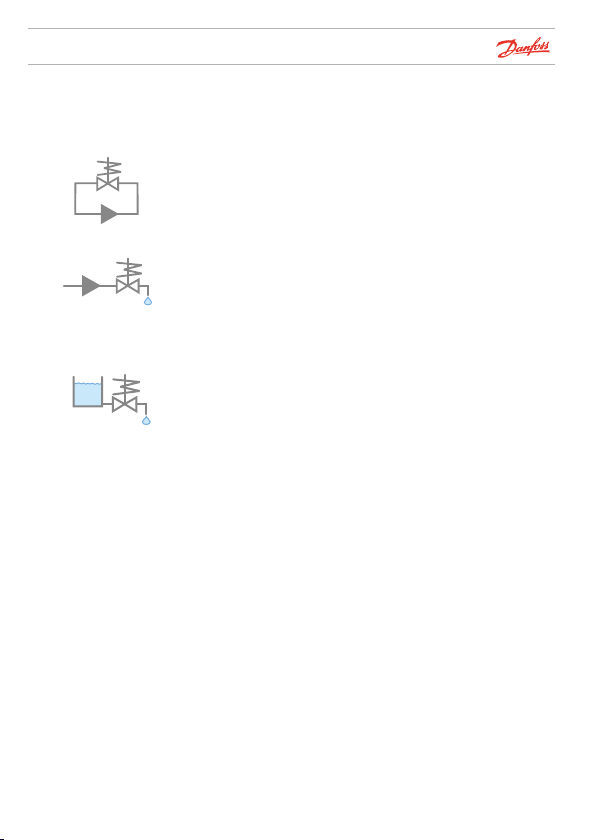

Symbolise valves used in a closed circuit system, typically

with low differential pressures.

Symbolise valves used in an open system.

Used typically for drinking water.

Differential pressure higher than 0.5 bar.

Symbolise valves used in a drain system.

Note ! For more details see How to choose on page 13

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 2

Page 5

Identification

Choosing the correct

solenoid valve

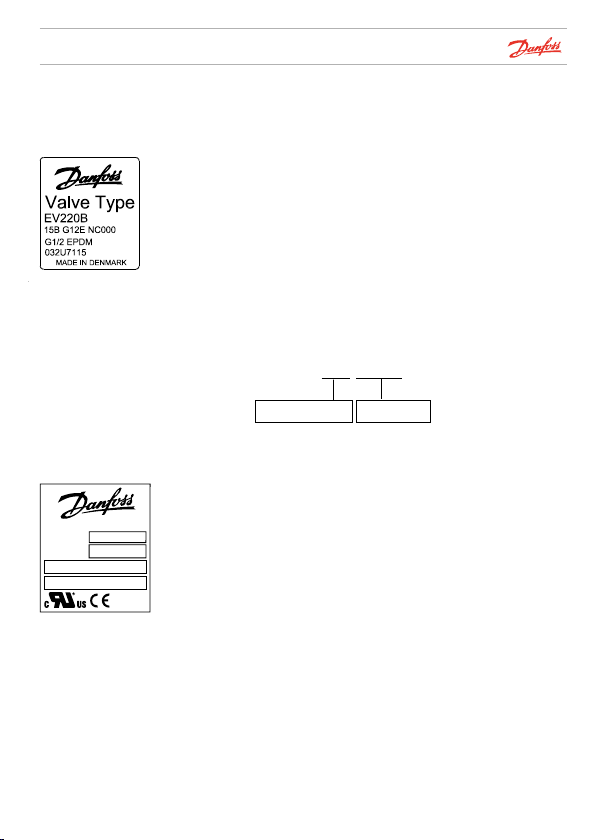

Illustration 1

MADE IN DENMARK

018F4517

Spare part no.

-40T40 °C

Tambient

24V 60Hz 8.5W 14VA

24V 50Hz 10.5W 16VA

Illustration 2

F4507

BQ024CS

Option 1: Identification using silver label (← 2011)

Illustration 1 shows the label with relevant information that is

attached to the coil.

The example here is from an EV220B solenoid valve:

15: 15 mm orifice

B: Brass body material

G 12: ISO 228/1, 1/2 inch connection

E: EPDM seal material

NC: Normally closed

If the the coil label cannot be read, the valve can be identified

from the letter/number combination stamped in the valve body.

Example:

506U4042

Week 50 2006 042U4042

The coil type (BQ024CS) is printed on the front of the coil as

well as voltage (V) and frequency (Hz) - see illustration 2.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 3

Page 6

Identification

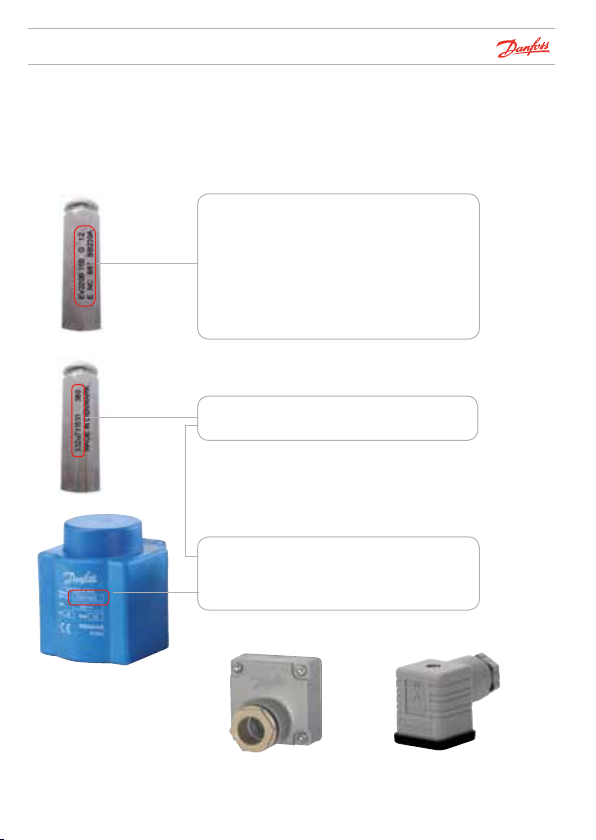

Option 2 (2011 →)

Printing on armature tube replaces silver labels and date /

code no. stamping for identification of the valve.

Type Designation

EV220B = Valve type

15 = 15 mm orifice

B = Brass body material

G 12 = ISO 228/1, ½ inch connection

E = EPDM seal material

NC = Normally closed

667 = Options

BB230A = Coil

Production Time

380 = Week 38 2010

032U711531 = Code Number

Note down following information

Valve code no: ______________

Sparepart no.: ______________

Plug

© Danfoss | DCS (RJA) | 2015.11

042N0156018Z0081

IC.PS.600.A8.02 | 4

Page 7

Identification

Valve identification

problem

If above mentioned method is not possible, state the

following when ordering Danfoss solenoid valves as

replacements:

• Application (closed circuit, open

system or drain application)?

• Function (Normally open or normally closed)?

• End connection?

• Medium (water, oil, air, etc.)?

• Kv value?

• Coil voltage?

• Alternating (AC) or direct current (DC)?

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 5

Page 8

32U1171.11

Installation

Flow direction

Water hammer

To be able to operate correctly, all solenoid valves must be

installed with the arrow cast on the body pointing in the

direction of flow.

Water hammer is a typical result of high liquid velocity

(high pressure and high flow velocity through small pipe

diameters).

There are several reasonable solutions to the problem:

1. Reduce the pressure by installing a pressure reduction

valve ahead of the solenoid valve. If possible, increase the

pipe diameter.

2. Damp the water hammer by installing a flexible hose or

flexible buffer ahead of the solenoid valve.

3. Use a solenoid valve of the type EV220B 15 – EV220B 50.

The equalizing orifice can be replaced by a version with

smaller diameter. This gives a longer closing time (see

Danfoss

“Spare parts” and “Opening and closing times”).

Equalizing orifice

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 6

Page 9

Danf

32U1521.11

Installation

Pipe

Test pressure

Tightening up

Danfoss

A32U1175.11

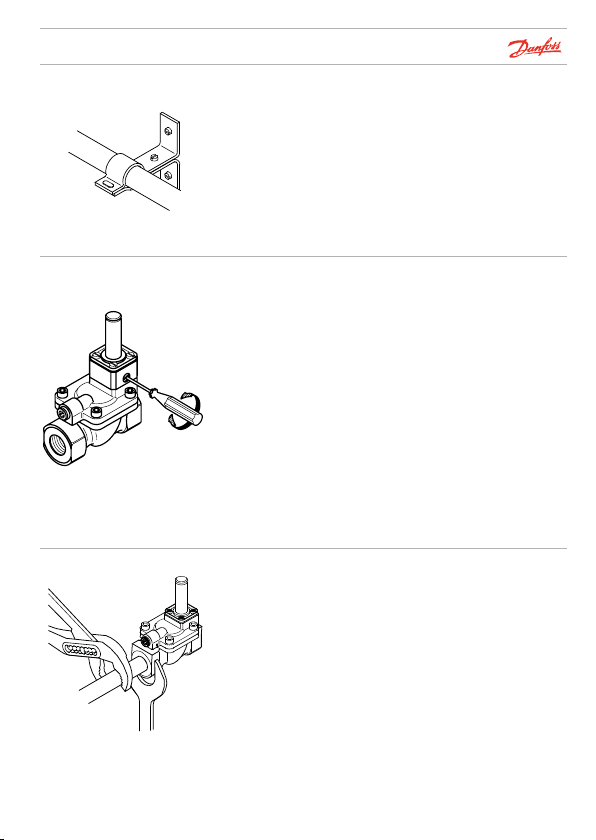

The pipes on both sides of the valve must be securely

fastened.

When applying test pressure: All valves in the system must

be open. There are three ways of doing this:

1. By applying voltage to the coil

2. By opening the valves manually(when the manual

override accessory is fitted)

3. By connecting the Danfoss permanent magnet

(see "Tools", page 42)

Note that the manual opening unit is not supplied as

standard, but as an accessory for EV220B 15 – EV220B 50

valves (see page 33).

Remember to screw the opening unit back (CLOCKWISE)

before starting up the system, otherwise the valve cannot

close.

Always use counter-force when tightening up pipe connections, i.e. use a spanner on both the valve body as well as on

the pipe connector (as shown).

oss

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 7

Page 10

Danfoss

Installation

Dirt in the system

32U1715.11

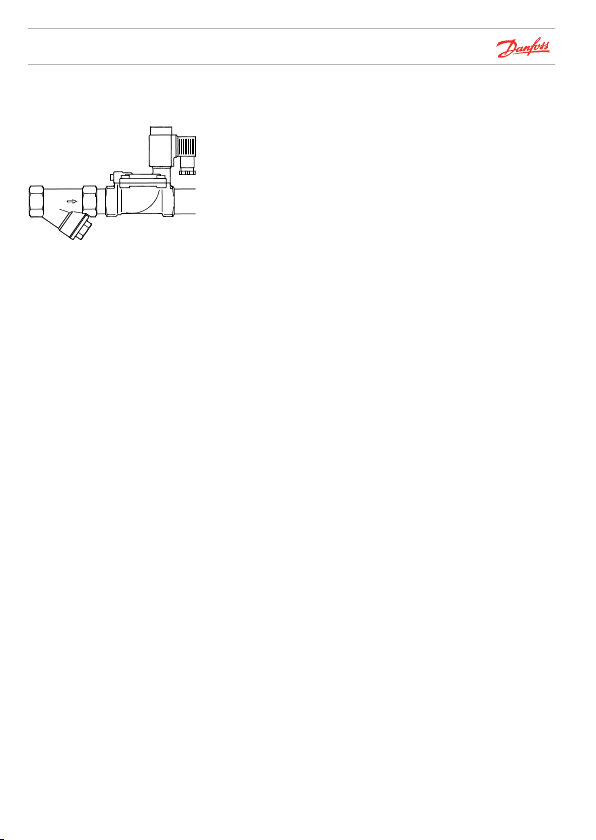

Always flush out piping before installing a solenoid valve. If

there is dirt in the medium, a filter should be installed ahead

of the valve.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 8

Page 11

Danf

32U1744.11

32U1743.11

Installation

Installing the coil

Servo-operated and

assisted lift

servo-operated valves

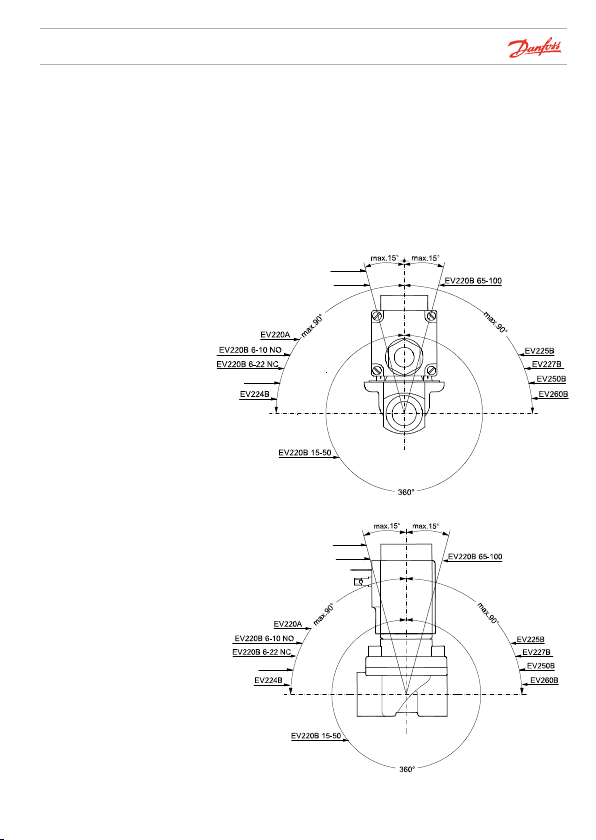

Danfoss recommends that the solenoid valve be installed

with coil upwards. This minimises the risk of dirt collecting in

the armature tube.

If “clean” media is used, i.e. media containing no dirt particles,

the solenoid valve will operate when installed in the

orientation as shown below.

EV245B

EV251B

EV222B

Danfoss

EV245B

EV251B

EV222B

© Danfoss | DCS (RJA) | 2015.11

oss

IC.PS.600.A8.02 | 9

Page 12

Installation

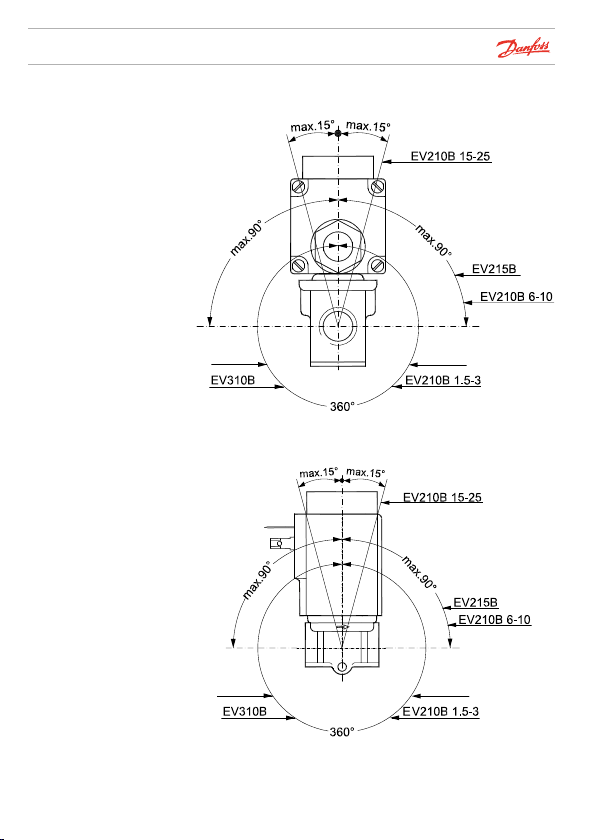

Direct-operated valves

Danfoss

32U1745.11

© Danfoss | DCS (RJA) | 2015.11

EV310A

EV310A

EV210A

EV210A

IC.PS.600.A8.02 | 10

Danfoss

32U1746.11

Page 13

Installation

Coil

MADE IN DENMARK

018F4517

Spare part no.

-40T40 °C

Tambient

24V 60Hz 8.5W 14VA

24V 50Hz 10.5W 16VA

F4507

BQ024CS

Cable connection

Check to ensure that the coil operating voltage is correct

(see text on coil, in “Volt”). Also ensure that the data is correct

(voltage and frequency) and matches the supply. If the two

sets of data do not correspond, the coil might burn out.

As far as possible, always choose single-frequency coils; they

give off less heat than double-frequency versions.

The coil has three pins. The middle pin is marked according to

the illustration (left) and must be used for earthing.

The two other pins are coil terminals and either can be used

for the phase or neutral supply. The terminals can be used

respectively for phase and neutral as required.

Please note for high performance range!

When mounting the clip-on coil, simply press it gently onto

the armature, until it clicks into place. An O-ring should be

fitted over the armature tube before fitting the coil.

Cable entries must always be screwed in correctly.

The cable must be installed as shown in the illustration to

avoid water running into the terminal box.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 11

Page 14

Installation

Cable

Coil replacement

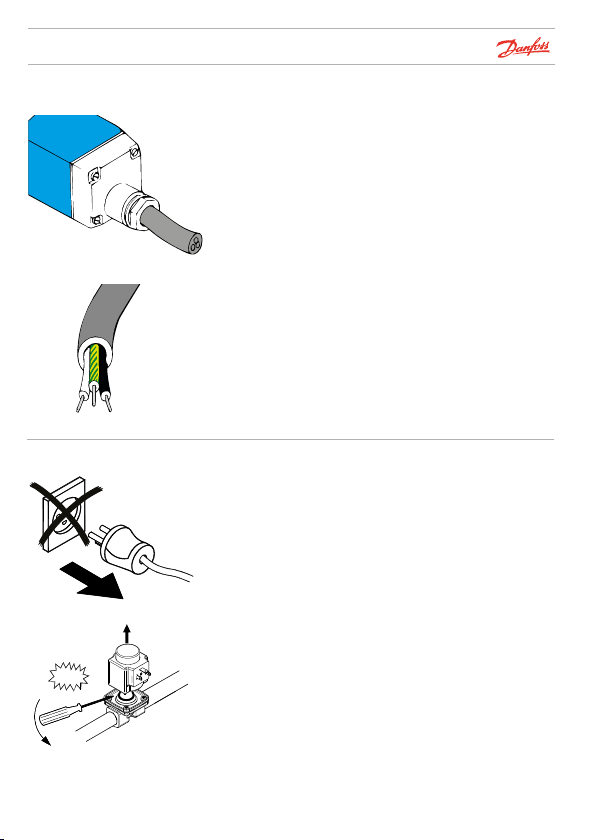

To avoid moisture penetrating in the terminal box, the whole

cable diameter must be secured in the entry. For this reason,

always use round cables as they are the only type that can be

effectively sealed.

Note the colours on the cable leads. Yellow/green is always

earth. The other leads should be for the phase and neutral

supply.

Please note for clip-on coils:

When replacing a coil, use a screwdriver to lever it from the

armature.

Caution: Before removing a coil, voltage must be

disconnec ted, otherwise the coil will burn out.

OFF

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 12

Page 15

How to choose

Product selection made easy for installers

With only a few clicks Danfoss Product Selector can help you find the right product for

stan dard applications.

The tool is developed to help wholesalers, retailers, installers and the end user to clarify

their needs within solenoid valves.

With Danfoss’ web based tool, you can access anywhere; from your laptop or smartphone,

as long as you have internet acces.

In the solenoid valve selector you only need to know 5 things:

1 Medium

2 System

3 Function

4 Connection size

5 Coil voltage

The Danfoss selector then presents a result for you which can be sent to your email, SMS or be

printed out.

Danfoss though recommends OEM-customers, which typically get customized products for

their applications, to contact their Danfoss distributor.

See how easy it is:

http://valveselector.danfoss.com/

"Scan me with your

smartphone"

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 13

Page 16

How to choose

If you do not have internet access try indentify all relevant parameters.

This includes:

1 Capacity / Kv - value

2 Pressure conditions

3 Media conditions

4 Other conditions

Capacity / Kv - value:

1 Specifies how many m3/ hour (capacity) water is passing through the valve at a

differential pressure at 1 bar.

2 Is a result of all the different constants coming from shape of orifices, units etc.

which are reduced to one new constant, the k

3 Is used to calculate capacity:

4 ρ = density (kg / m

5 ΔP = P

- P

1

3

)

2

Q = Kv

Pressure conditions

Open system (system with drain)

In an open system the pressure conditions are well-defined.

This enables clarification as to whether there is sufficient pressure differential to be able to

open a servo-operated valve. The following types of valves are well-suited for use in open

systems:

EV210B and EV310B direct-operated solenoid valves

EV220B, EV220A and EV225B servo-operated solenoid valves

Closed circuit (circulating system)

In a closed circuit system the pressure conditions are undefined. Therefore a solenoid valve

capable of opening without pressure differential is required.

EV250B assisted lift servo-operated valve

EV210B and EV310B direct-operated solenoid valves

- value.

v

3

∆P

[m

/ h]

√

ρ

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 14

Page 17

How to choose

Operating pressure

Valves in the standard range are designed for pressure of max 6–30 bar – the actual figure

depends on the type of valve.

The product range includes valves for special application, designed for pressures of up to 80 bar.

The large standard range combined with these valves enable the use of Danfoss solenoid valves

for all types of systems, wether with normal or more extreme inlet pressures.

Differential pressure/ MOPD

1 Difference between inlet pressure and outlet pressure (∆P = P1 - P2).

2 Max. permissible differential pressure against which the valve can open

3 Also specified as MOPD: Maximum Opening Pressure Differential

4 MOPD specifies the differential pressure value in worst case:

• 100 % duty rate

• Maximum medium and ambient temperature

• Nominel voltage, typically -10%

5 Specified pressure is often limited by endurance demands more than MOPD

Media conditions

The valves are designed to resist the temperatures normally found in industrial applications.

If the temperature is outside these limits, there is a risk of the valve not functioning correctly

because of, for example, rubber materials becoming hard. Exceeding the temperature rating

can also result in the shortening of valve life. If the valve is to be used in a special application,

with a temperature in excess of the rated limits, there are valves available in the product range

which have been designed for use in higher temperature systems.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 15

Page 18

How to choose

The characteristics of the medium

The valves have been designed for use with different media.

In general the following is valid:

Valves containing EPDM-rubber are suitable for water and steam*.

Valves containing FKM-/NBR-rubber are suitable for oil and air.

Incorrect use of valve types:

1 If a valve containing EPDM-rubber is used for a medium containing oil (compressed air

normally contains particles of oil from the compressor) the rubber will expand and the

valve will not be able to function optimally.

2 A valve containing FKM-/NBR-rubber can be used for water. However for servo-operated

valves, the water temperature must be kept below 60 °C for FKM, 90 °C for NBR. If this

temperature is exceeded it will have a negative effect on the life of the valve.

Other media

For slightly aggressive media (e.g. demineralised water) dezincificationresistant brass valves

must be used. Stainless steel valves are used for more aggressive media.

*For steam temperatures above 120 °C there is a type of valve especially designed for steam

Ambient temperature

The ambient temperature must be within certain limits for the coil to function optimally.

See data sheet for coils.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 16

Page 19

How to choose

Water hammer

All piping systems with relatively high flow rates are susceptible to water hammer when a

valve is opened or closed. A damped solenoid valve ( eg. EV220B 15–50) should be used if

there is a risk of water hammer. After installation the valve can be adjusted for water hammer

by changing a replaceable equalizing orifice. See "Spareparts" page 32.

Filter

In systems with contaminated media there is a risk of moving parts in a valve not working as

intended. Dirt is the most common cause of function failure in solenoid valves. To help avoid

this problem we suggest the fitting of a filter on the upstream side of the valve.

Coil voltage and power

It is necessary to know which voltage (Volt AC/DC nominel ± 10%) is available within an

application to select the correct coil. The maximum permissible differential pressure can also

be increased by fitting a more powerful coil. The coil power depends on the type of coil (BA,

BB, AM etc.).

Other environmental factors

In wet or very humid environments, coils with IP67 enclosure classification must be used.

Valve function

Most industrial systems operate with a de-energised closed valve (NC = normally closed).

Our valve range also offers de-energised open valves (NO = normally open) for applications

requiring this feature.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 17

Page 20

Valve overview - High performance (blue) range

Air and

neutral

gasses Water Oil Steam

EV210B

ü ü ü

EV310B

ü ü ü

EV220B

ü ü ü

EV250B

ü ü ü ü

EV225B BQ coil

Medium

© Danfoss | DCS (RJA) | 2015.11

ü

IC.PS.600.A8.02 | 18

Page 21

Valve overview - High performance (blue) range

Characteristics

Connection

[ISO 228/1] Function

G 3/8" - G 1" NC/NO

EV210B covers a wide range of direct-operated 2/2-way solenoid

valves for universal use. EV210B is a real robust valve program

with high performance and can be used in all kind of tough

working conditions.

Description

G 1/8" - G 3/8" NC/NO

G 1/4" - G 1" NC/NO

G 1/2" - G 2" NC/NO

G 3/8" - G 1" NC

G 1/4" - G 1" NC

© Danfoss | DCS (RJA) | 2015.11

EV310B is a direct-operated 3/2- way solenoid valve. The valve is

especially used in connection with air-operated valves to allow air

supply and air relief for the air actuator.

EV220B 6–22 is a direct servo-operated 2/2-way solenoid valve

program. This program is especially for OEM applications demanding a robust solution and moderate flow rates.

EV220B 15–50 is a universal indirect servo-operated 2/2-way

solenoid valve program. Valve body in brass, dezincification

resistant brass and stainless steel ensures that a broad variety of

applications can be covered.

EV250B with assisted lift is especially to use in closed circuits with

low differential pressure, but demanding moderate flow rates.

Valve body in DZR brass ensures a long life, even in connection

with aggressive steam media.

The EV225B design is based on a PTFE diaphragm and valve body

in dezincification resistant brass, ensuring high reliable function

and long life even in connection with contaminated steam.

IC.PS.600.A8.02 | 19

Page 22

Valve overview - Compact (black) range

EV220A

Medium Characteristics

Air and

neutral

gasses Water Oil Steam

ü ü ü ü

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 20

Page 23

Valve overview - Compact (black) range

Connection

[ISO 228/1] Function

G 1/4" - G 2" NC

G 1/4" - G 1" NO

Description

EV220A is a compact indirect servo-operated 2/2 way solenoid

valve program with brass valve body for robust industrial

application.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 21

Page 24

[bar]

Seal material

Media table

Seal material

[°C]

Medium EPDM

1)

Water / glycols - 30 – 140

Oil - 0 – 100 -10 – 90 -

Air - 0 – 100 -10 – 90 -

Steam up to 140 - up to 185

* Direct-operated valves

1)

FKM NBR PTFE

0 – 60

0 – 100*

-10 – 90 -

EPDM is suitable for water and steam within the

© Danfoss | DCS (RJA) | 2015.11

illustrated ranges

IC.PS.600.A8.02 | 22

Page 25

Coils

Coil consumption Supply voltage / frequency1)Code number

BB coils (IP65)

10 W without cable plug 220 – 230 V AC / 50 Hz 018F7351

10 W without cable plug 110 V AC / 50-60 Hz 018F7360

10 W without cable plug 24 V AC / 50 Hz 018F7358

18 W without cable plug 24 V AC 018F7397

Cable plug for BB coils 042N0156

BE coil (IP67)

10W with terminal box 220 – 230 V AC / 50 Hz 018F6701

10W with terminal box 115 V AC / 50 Hz 018F6711

10W with terminal box 48 V AC / 50 Hz 018F6709

10W with terminal box 24 V AC / 50 Hz 018F6707

18W with terminal box 24 V AC 018F6757

BG coils (IP67)

20 W with terminal box 24 V AC 018F6857

BQ coil

10W without cable plug 230 V AC / 50 Hz 018F4511

10W without cable plug 110 V AC / 50 Hz 018F4519

10W without cable plug 24 V AC / 50 Hz 018F4517

Cable plug for BQ coils 042N0156

For installations sensitive to noise

BN coil (hum-free, IP65)

20 W with 1 m cable 220 – 230 V AC / 50-60 Hz 018F7301

1)

For other voltages or coil types, see coil data sheet.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 23

Page 26

Coils

Coil consumption Supply voltage / frequency

1)

Code number

AM coils (IP00-IP65)

7.5 W without cabel plug 110 V AC / 50/60 Hz 042N0845

7.5 W without cabel plug 220–230 V AC / 50/60 Hz 042N0840

9.5 W without cabel plug 24 V DC 042N0843

Cable plug for AM coils 042N0156

1)

For other voltages or coil types, see coil data sheet.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 24

Page 27

Opening and closing times

Closing times and water

hammer

High performance (blue)

range

Compact (black) range

With the larger valves, very short closing times can cause

water hammer.

The EV220B servo-operated valves have damped closing and

fulfil EN60730-2-8 specifications.

The table gives the opening/closing times of the various

types, but it must be emphasised that tube dimensions /

lengths and differences in operating conditions - especially

pressure - can cause deviations from the values given.

Type Opening [ms] Closing [ms]

EV210B 1.5 10 20

EV210B 3 20 20

EV210B 6 20 20

EV250B 12 100 100

EV250B 18 150 100

EV250B 22 150 100

EV220B 10 50 300

EV220B 12 60 300

EV220B 15 40 350

EV220B 20 40 1000

EV220B 25 300 1000

EV220B 32 1000 2500

EV220B 40 1500 4000

EV220B 50 5000 10000

EV310B 2 10 – 20 10 – 20

Type Opening [ms] Closing [ms]

EV220A 6 40 250

EV220A 10 50 300

EV220A 12 60 300

EV220A 14 100 400

EV220A 18 200 500

EV220A 22 200 500

EV220A 32 2500 4000

EV220A 40 4000 6000

EV220A 50 5000 10000

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 25

Page 28

Opening and closing times

Changing opening and

closing times

Please note for high performance type.

EV220B 15 – EV220B 50 closing times can be changed by

replacing the equalizing orifice at the inlet side of the valve

(see "Water hammer" page 17, and "Spare parts" page 32). To

decrease water hammer, choose a smaller equalizing orifice.

The table shows the opening and closing times depending

on the equalizing orifice chosen (standard times marked in

bold). The times stated cover water as a medium, and are

for guidance only. Tube dimensions / lengths and operating

conditions, for example differential pressure, may influence

the values.

Orifice EV220B 15 EV220B 20 EV220B 25 EV220B 32 EV220B 40 EV220B 50

mm

Grooves

Open

Close

Open

Close

Open

Close

Open

Close

Open

Close

Open

0.5 1 0.04 0.35 0.04 1.0 0.11 3.0 1.6 6.0 1.3 8.0 3.4 40.0

0.8 2 0.04 0.3 0.04 0.5 0.3 1.0 1.0 2.5 1.5 4.0 3.6 11.0

1.2 3 0.04 0.12 0.04 0.25 0.30 0.5 1.2 1.0 1.5 2.0 5.0 10.0

1.4 4 0.04 0.1 0.06 0.18 0.30 0.4 1.0 0.8 2.0 1.5 5.2 6.5

Close

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 26

Page 29

Fault location

Symptom: Solenoid valve does not open

Probable cause Remedy

No voltage on coil Check whether valve is de-energised open or closed (NO

Incorrect voltage / frequency Check to make sure the coil's electrical require ments are

Coil burnt out See page 31.

Diff. pressure too high Check coil data. If necessary, replace coil with correct version.

Diff. pressure too low Check coil data and differential pressure. If necessary,

Damaged / bent armature tube Replace valve.

Dirt at diaphragm

Dirt in valve seat / dirt in armature /

armature tube

2)

2)

Corrosion Replace defective component(s)

Components missing after valve

dismantling

1)

See "Spare parts" page 32

2)

If there is repeated build up of dirt in the armature / armature tube, consider the installation af an isolating

diaphragm kit, if applicable (see "Spare parts" page 32)

or NC):

1. Use a magnetic detector

2. Lift coil slightly and note whether it offers resistance

against lifting

Note: Never remove a coil with voltage applied - it may

burn out.

Check relay contacts. Check lead connections. Check fuses.

the same as the installation supply. Measure the operating

voltage at the coil. Permissible voltage variation:

±10% for dual frequency; DC and NO applications

+10% / -15% for AC on single frequency voltages

If necessary, replace coil with correct version.

Reduce differential pressure, e.g. by limiting inlet pressure.

replace coil with correct version.

Clean diaphragm. If necessary, replace defective

component(s)1).

Clean valve; if necessary, replace defective component(s).

1)

.

1)

Fit missing component(s)

.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 27

Page 30

Fault location

Symptom: Solenoid valve partly opens

Probable cause Remedy

Differential pressure too low Check valve data, incl. differential pressure. Replace valve

Damaged or bent armature tube Replace valve.

Dirt at diaphragm Clean diaphragm.

Dirt in valve seat / dirt in armature /

armature tube

2)

Corrosion Replace defective component(s)

Components missing after valve

dismantling

1)

See "Spare parts" page 32

2)

If there is repeated build up of dirt in the armature / armature tube, consider the installation af an isolating

diaphragm kit, if applicable (see "Spare parts" page 32)

with correct version.

1)

If necessary, replace defective component(s)

.

Clean valve, if necessary, replace defective component(s).

1)

.

1)

Fit missing component(s)

.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 28

Page 31

Fault location

Symptom: Solenoid valve does not close/partly closes

Probable cause Remedy

Voltage remains on coil First lift coil slightly and note whether it offers

Dirt in or closed pilot orifice /

equalizing piece

Manual opening unit cannot be

screwed back after use.

Pulsation in pressure line.

Differential pressure too high in

open position.

Pressure on outlet side periodically

higher than pressure on inlet side.

Damaged / bent armature tube Replace valve.

Defective valve plate, diaphragm

or valve seat

Diaphragm upside down Check correct installation of valve

Dirt in valve seat/dirt in armature

tube

Corrosion, pilot / main orifice Replace defective components.

Valve installed wrong way round Check liquid flow direction and make sure the arrow is

Components missing after valve

dismantling

1)

See "Spare parts" page 32

resistance.

Note: Never remove a coil with voltage applied - it might

burn out.

Check wiring diagram and wiring.

Check relay contacts.

Check lead connections.

Clean orifice with needle or similar (max. dia. 0.5 mm).

Blow clean with compressed air.

If necessary, replace defective component(s).

Check position of opening unit and adjust as necessary.

Check valve data.

Check pressure and liquid flow.

Replace valve with one more suitable.

Check rest of installation.

Check pressure and liquid flow.

Replace defective component(s)

1)

.

1)

.

Clean valve; if necessary, replace defective components.

pointing in the same direction.

1)

Fit missing component(s)

.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 29

Page 32

Fault location

Symptom: Solenoid valve making noise

Probable cause Remedy

Hum Hum caused by AC frequency can be removed by changing

Water hammer when valve opens

Water hammer when valve closes

Differential pressure too high and /

or pulsation in pressure line

to coil with rectifier (see page 23).

See "Installation".

Check valve data and differential pressure.

Check pressure and liquid flow.

Replace with more suitable valve.

Check rest of installation.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 30

Page 33

Fault location

Symptom: Coil burnt - cold with voltage on

Probable cause Remedy

Incorrect voltage / frequency Check coil data.

Coil short-circuit

(could be moisture in coil)

Armature sluggish

1) Damaged / bent armature tube

2) Damaged armature

3) Dirt in armature tube

Temperature of medium too high Check valve and coil data in relation to installation

Ambient temperature too high If possible, move valve to colder surroundings.

If necessary, change to correct coil type.

Check wiring diagram and wiring.

Check maximum voltage variation:

Permissible voltage variation:

±10% for dual frequency; DC and NO applications

+10% / -15% for AC on single frequency voltages

Check rest of installation for possible short-circuiting.

Check lead connections at coil.

When fault has been found, replace coil. (See also "Coil" in

section "Installation"). Consider fitting a 'clip-on' style coil

with addional sealing O-ring (for high performance range only)

Replace defective component(s).

Remove dirt.

specification.

Change to suitable coil or valve.

Check valve and coil data in relation to installation

specification.

Increase ventilation around valve and coil.

.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 31

Page 34

Spare parts high performance range

Normally open

components (NO)

The set contains locking button and nut for coil, normally open

assembly kit (armature and armature tube) and an O-ring.

Code number

Type

FKM seal

material

1)

EPDM seal

material

EV210B 1.5 – EV210B 4.5 NO 032U2004 032U2005

EV220B 6 NO 032U0166 032U0165

EV220B 10 NO 032U0167 -

EV220B 15 – EV220B 50 NO 032U0295 032U0296

NO components are also available for Danfoss valves with other seal

materials.

1)

See page 22 for description of seal materials

1)

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 32

Page 35

32U1785.11

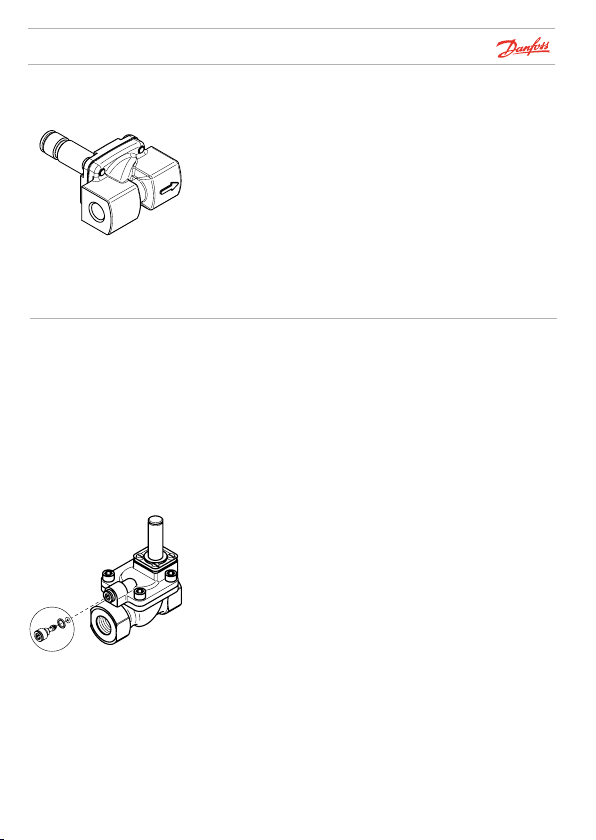

Spare parts high performance range

Manual override unit

tool operated

Danfoss

32U947.11

Manual override unit

hand operated

The manual opening unit for EV220B 15 – EV220B 50 can be

used to open and close the valve in the event of power failure

or when applying test pressure.

Material

Brass, size

DN 15–32, seal NBR

Brass, size

DN 40–50, seal NBR

Stainless steel, seal

NBR

Media

temperature [°C] Code number

-10 – 90 032U0150

-10 – 90 032U0260

-10 – 90 032U0149

Used for manual override in event of power failure.

Material

Stainless steel,

seal EPDM

Media

temperature [°C] Code number

-30 – 120 032U7390

Danfoss

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 33

Page 36

Spare parts high performance range

Spare parts set for

EV210B NC

Isolating diaphragm kit

for EV210B 1.5 –

EV210B 4.5 NC

and EV220B 15 –

EV220B 50 NC

The spare parts set contains:

Locking button

Nut for coil

Armature with valve plate and spring

O-rings

EPDM versions

Type Code number

EV210B 6, EV210B 8, EV210B 10 032U2006

FKM versions

Type Code number

EV210B 1.5 – EV210B 4.5 032U2003

EV210B 6, EV210B 8, EV210B 10 032U2011

1)

See page 22 for description of seal materials

Avoids build up of contaminates that can block movement of

the armature. Permits use of more agressive media that would

normally attack the armature. Gel filled; guarentees operation

after long periods on inactivity.

Seal material

1)

EPDM

1)

FKM

1)

See page 22 for description of seal materials

Media

temperature [°C]

-20 – 50

0 – 50

Code number

042U1009

042U1010

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 34

Page 37

Spare parts high performance range

Spare parts set for

EV220B 6 – EV220B 12

NC

The spare parts set contains:

Locking button

Nut for coil

Armature with valve plate and spring

Diaphragm

2 O-rings

EPDM versions

Valve type Code number

EV220B 6 NC 032U1062

EV220B 10 NC 032U1065

EV220B 12 NC 032U1068

Spare parts sets are also available for Danfoss EV220B valves with

other seal materials (see page 22 for description of seal materials)

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 35

Page 38

Spare parts high performance range

Spare parts set for

EV220B 15 – EV220B 50

Danfoss

32U11786.10

The spare parts set contains:

Locking button and nut for the coil

Armature with valve plate and spring

O-ring for the armature tube

Spring and diaphragm

2 O-rings for the pilot system

O-ring and gasket for the equalizing orifice

Equalizing orifice

Type Seal material Code number

EV220B 15 EPDM

EV220B 20 EPDM

EV220B 25 EPDM

EV220B 32 EPDM

EV220B 40 EPDM

EV220B 50 EPDM

Spare parts sets are also available for Danfoss EV220B valves with other

seal materials.

1)

See page 22 for description of seal materials

1)

032U1071

1)

1)

1)

1)

1)

032U1073

032U1075

032U1077

032U1079

032U1081

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 36

Page 39

Spare parts high performance range

Equalizing orifice

The kit comprises:

An equalizing orifice includes 2 O-rings. The valves closing

time can be changed by installing an equalizing orifice of a

size which deviates from the standard valve:

• A shorter closing time is obtained with a larger orifice

(the shorter closing time, the greater risk of water

hammering)

• A longer closing time is obtained with a smaller orifice.

See also “Opening and closing times”, page 25.

Equalizing

orifice size

[mm] Seal material Applicable in Code number

EV220B 15

0.5 EPDM

0.8 EPDM

1.2 FKM

1.2 EPDM

1.4 FKM

Equalizing orifice sets are also available for Danfoss EV220B valves

with other seal materials.

1)

See page 22 for description of seal materials

1)

EV220B 20

EV220B 25

1)

EV220B 32

EV220B 40

EV220B 25

1)

EV220B 32

1)

EV220B 50 032U0086

EV220B 40

1)

EV220B 50

032U0082

032U0084

032U0085

032U0087

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 37

Page 40

Spare parts high performance range

Spare parts set for

EV250B 12 –

EV250B 22 NC

EPDM seal material

Spare parts set for

EV250B 12 –

EV250B 22 NC

FKM seal material

The spare parts kit comprises:

1. O-ring for coil

2. 4 screws

3. Complete NC actuator unit with diaphragm, assist spring,

armature, closing spring, cover and armature tube

Valve type Code number

EV250B 10 – EV250B 12 BD 032U5315

EV250B 18 – EV250B 22 BD 032U5317

The spare parts kit comprises:

1. O-ring between armature tube and cover

2. Service element consisting of an armature with valve

plate and spring fitted on the diaphragm

Valve type Code number

EV250B 10 – EV250B 12 BD 032U5271

EV250B 18 – EV250B 22 BD 032U5273

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 38

Page 41

Spare parts high performance range

Spare parts set for

EV250B 12 –

EV250B 22 NO

Spare parts kit

for EV310B

The spare parts kit comprises:

1. O-ring for coil

2. 4 screws

3. Complete NO actuator unit with diaphragm, assist spring,

NO armature unit and cover

Valve type Seal material Code number

EV250B 10 – EV250B 12 BD

EV250B 18 – EV250B 12 BD

EV250B 10 – EV250B 22 BD

EV250B 10 – EV250B 22 BD

EPDM 032U5319

FKM 032U5320

EPDM 032U5321

FKM 032U5322

The spare parts kit comprises:

Armature with mounted spring

Type Seal material Code number

NC FKM 032U2033

NO FKM 032U2035

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 39

Page 42

Spare parts high performance range

Spare parts kit for

EV225B 6 – EV225B 25

Coil for BQ high

performance steam valve

Spare parts kit for EV225B comprises:

Armature with valve plate and spring

Closing spring

Diaphragm

O-ring

Type Code number

EV225B 6 – EV225B 10 032U3171

EV225B 15 032U3172

EV225B 20 – EV225B 25 032U3173

Coil consumption [W]ACSupply voltage [V]/

10 230 / 50 018F4511

10 24 / 50 018F4517

10 110 / 60 018F4519

frequency [Hz] Code number

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 40

Page 43

Spare parts high performance range

Spare parts kit for

EV220A 6 – EV220A 50

NC

Spare parts kit comprising:

Armature assembly

Diaphragm assembly

Armature spring

Diaphragm spring

2 O-rings

Type Seal material Code number

EV220A 6 – EV220A 10 B EPDM 042U1000

EV220A 6 – EV220A 10 B NBR 042U1001

EV220A 6 – EV220A 10 B FKM 042U1002

EV220A 12 – EV220A 14 B EPDM 042U1003

EV220A 12 – EV220A 14 B NBR 042U1004

EV220A 12 – EV220A 14 B FKM 042U1005

EV220A 18 – EV220A 22 B EPDM 042U1006

EV220A 18 – EV220A 22 B NBR 042U1007

EV220A 18 – EV220A 22 B FKM 042U1008

EV220A 32 B EPDM 042U1037

EV220A 32 B NBR 042U1038

EV220A 32 B FKM 042U1046

EV220A 40 B EPDM 042U1039

EV220A 40 B NBR 042U1040

EV220A 40 B FKM 042U1047

EV220A 50 B EPDM 042U1041

EV220A 50 B NBR 042U1042

EV220A 50 B FKM 042U1048

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 41

Page 44

Tools

Magnetic field indicator

Permanent magnet

This handy key ring tool reacts to magnetic fields from

solenoid valves. Place the indicator close to the coil, and the

red-white disc will prove the coil to be active by rotating.

With this tool it is possible to operate solenoid valves without

wiring up the electrical coil.

Please contact your local Danfoss office to obtain these popular tools.

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 42

Page 45

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 43

Page 46

Subheading Myriad Pro Semibold 7 pt.

How to use solenoid valves

Making it easy to be efficient

© Danfoss | DCS (RJA) | 2015.11

IC.PS.600.A8.02 | 44

Loading...

Loading...