Danfoss How to design balancing and control solutions for energy efficient hydronic applications in residential and commercial buildings Application guide

Page 1

Application guide

Hydronic applications

Commercial

Hydronic applications

How to design

balancing and control solutions for

energy ecient hydronic applications

in residential and commercial buildings

44

applications with

detailed descriptions

about the investment,

design, construction

and control

Residential

Mixing loop

AHU application

AHU heating

AHU application

AHU cooling

hbc.danfoss.com

1

Chillers applications Boilers applications Hot water

Page 2

Content structure in this guide

1. Hydronic applications

1.1 Commercial

1.1.1 Variable ow

1.1.2 Constant ow

1.2 Residential

1.2.1 Two-pipe system

1.2.2 One-pipe system

1.2.3 Heating – special application

Typical page shows you:

Chapter

Schematic drawing

2. Mixing loop

3. AHU applications

3.1 AHU applications heating

3.2 AHU applications cooling

4. Chillers applications

5. Boiler applications

6. Hot water applications

Recommendation Type of solution

7. Glossary and abbreviations

8. Control and valve theory

9. Energy eciency analyses

10. Product overview

Application

General system description

Danfoss products

Performance indicators

Application details

2

Page 3

Introduction Notes

Return of investment

poor exellent

poor exellent

Design

acceptable

acceptable

Designing HVAC systems is not that simple. Many factors need to be considered

before making the nal decision about the heat- and/or cooling load, which terminal units

to use, how to generate heating or cooling and a hundred other things.

This application guide is developed to help you make some of these decisions by showing

the consequences of certain choices. For example, it could be tempting to go for

the lowest initial cost (CAPEX) but often there would be compromises on other factors, like

the energy consumption or the Indoor Air Quality (IAQ). In some projects the CAPEX might

be the deciding factor but in another ones it is more about energy eciency or control

precision, therefore it diers from project to project. We collected the most important

information concerning a particular solution on a single page with clear indications what

consequences can be expected when certain choices are made.

The aim of this guide was not to cover each and every application because that would

be impossible. Every day, smart designers come up with new solutions that might be

relevant only to one specic problem or that is solving new problems. That is what engineers

do. The drive for greener, more energy-friendly solutions is creating new challenges every

day, so there are always some new applications. In this particular guide we will nd to cover

the applications that are the most common.

Danfoss also has many competent people available that can support you with specic

challenges or that can support you with calculations. Please contact your local Danfoss

oce for support in your native language.

We hope this guide will help you in your daily work.

Each application shown here is analyzed for four aspects:

Return on Investment, Design, Operation/Maintenance, Control

Return of investment

poor exellent

Design

poor exellent

acceptable

acceptable

All of them are marked as:

Technically and economically optimized solutions as recommended by Danfoss.

This solution will result in eciently operating systems.

Depending on the situation and the particularities of the system this will result in a good

installation. However, some trade-os are made.

Operation/Maintenance

poor exellent

Control

poor exellent

Recommended

Acceptable

acceptable

acceptable

This system is not recommended since it will result in expensive and inecient systems or

the Indoor Air Quality is not ensured.

Not Recommended

3

Page 4

Table of Contents

Content structure in this guide 2

Typical page shows you: 2

Introduction 3

1. Hydronic applications

1.1Hydronic applications – commercial buildings 6

1.1.1 Commercial - Variable ow

1.1.1.1 Variable ow: Pressure Independent Control (PICV) with ON/OFF actuator 8

1.1.1.2 Variable ow: Pressure Independent Control (PICV) with proportional control 9

1.1.1.3 Variable ow: Pressure Independent Control (PICV) with digital actuator 10

1.1.1.4 Variable ow: Flow limitation (with ow limiter) on terminal unit with ON/OFF or modular actuator 11

1.1.1.5 Variable ow: Dierential pressure control with ON/OFF or modulation 12

1.1.1.6 Variable ow: Shell and Core installation for Oces and Shopping malls* 13

1.1.1.7 Variable ow: Manual balancing 14

1.1.1.8 Variable ow: Manual balancing with reverse return 15

1.1.1.9 Variable ow: Four-pipe Changeover (CO6) for radiant heating/cooling panels,

chilled beams, etc. with PICV control valve 16

1.1.1.10 Variable ow: Two-pipe heating/cooling system with central changeover* 17

1.1.2 Commercial - Constant ow

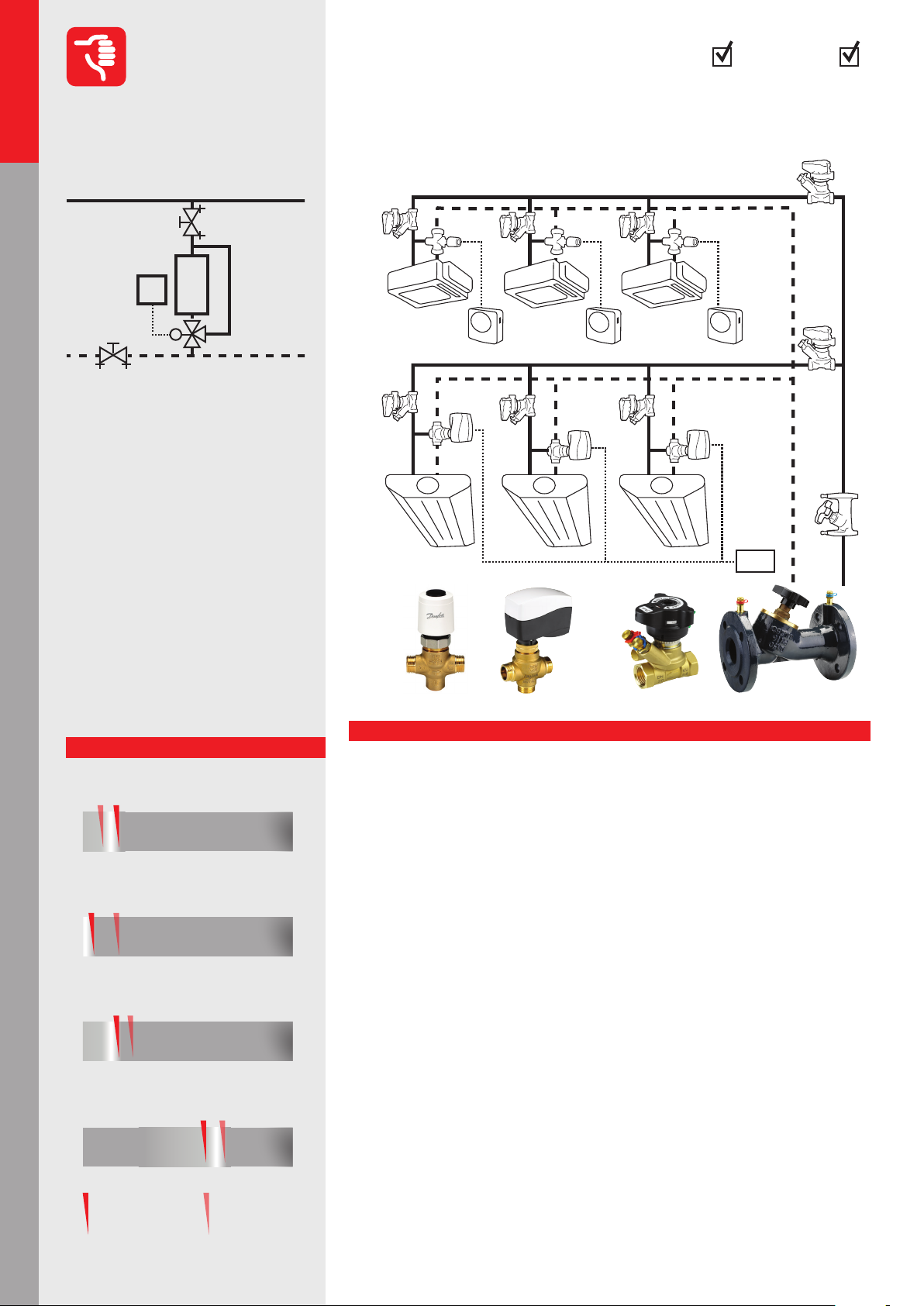

1.1.2.1 Constant ow: 3-way valve with manual balancing (in fan-coil, chilled beam etc. application) 18

1.1.2.2 Constant ow: 3-way valve with ow limiter on terminal units (fan-coil, chilled beam etc. application) 19

1.2 Hydronic applications - residential buildings

1.2.1 Residential - Two pipes system

1.2.1.1 Two-pipe radiator heating system – risers with, thermostatic radiator valves (with presetting) 20

1.2.1.2 Two pipe radiator heating system – risers with, thermostatic radiator valves (without presetting) 21

1.2.1.3 Pressure Independent Control for radiator heating system 22

1.2.1.4 Subordinated risers (staircase, bathroom, etc.) in two- or one-pipe radiator heating system without thermostatic valve 23

1.2.1.5 Δp control for manifold with individual zone/loop control 24

1.2.1.6 Δp control and ow limitation for manifold with central zone control 25

1.2.2 Residential - One pipe system

1.2.2.1 One-pipe radiator heating system renovation with automatic ow limitation

and possible self-acting return temperature limitation 26

1.2.2.2 One-pipe radiator heating system renovation with electronic ow limitation and return temperature control 27

1.2.2.3 One-pipe radiator heating system renovation with manual balancing 28

1.2.2.4 One-pipe horizontal heating systems with thermostatic radiator valves, ow limitation

and return temperature self-acting control 29

1.2.3 Residential - Heating - special application

1.2.3.1 Three-pipe, at station system; Δp controlled heating and local DHW* preparation 30

Page 5

2. Mixing loop

2.1 Mixing with PICV – manifold with pressure dierence 31

2.2 Injection (constant ow) control with 3-way valve 32

2.3 Mixing with 3-way valve – manifold without pressure dierence 33

3 AHU applications

3.1 AHU applications - heating

3.1.1 Pressure Independent Control (PICV) for cooling 34

3.1.2 3-way valve control for cooling 35

3.2 AHU applications - cooling

3.2.1 Pressure Independent Control (PICV) for heating 36

3.2.2 3-way valve control for heating 37

3.2.3 Keep proper ow temperature in front of AHU in partial load condition 38

4. Chillers applications

4.1 Variable primary ow 39

4.2 Constant primary variable secondary (Step Primary) 40

4.3 Constant primary and variable secondary (Primary Secondary) 41

4.4 Constant primary & secondary (Constant Flow System) 42

4.5 District cooling system 43

5. Boiler applications

5.1 Condensing boiler, variable primary ow 44

5.2 Traditional boilers, variable primary ow 45

5.3 System with manifolds de-couplers 46

6. Domestic hot water

6.1 Thermal balancing in DHW circulation (vertical arrangement) 47

6.2 Thermal balancing in DHW circulation (horizontal loop) 48

6.3 Thermal balancing in DHW circulation with self–acting disinfection 49

6.4 Thermal balancing in DHW circulation with electronic desinfection 50

6.5 DHW* circulation control with manual balancing 51

7. Glossary and abbreviations 54

8. Control and valve theory 56

9. Energy eciency analyses 65

10. Product overview 75

Page 6

Commercial

Hydronic applications

Residential

Hydronic applications

Mixing loop

Hydronic applications – commercial buildings

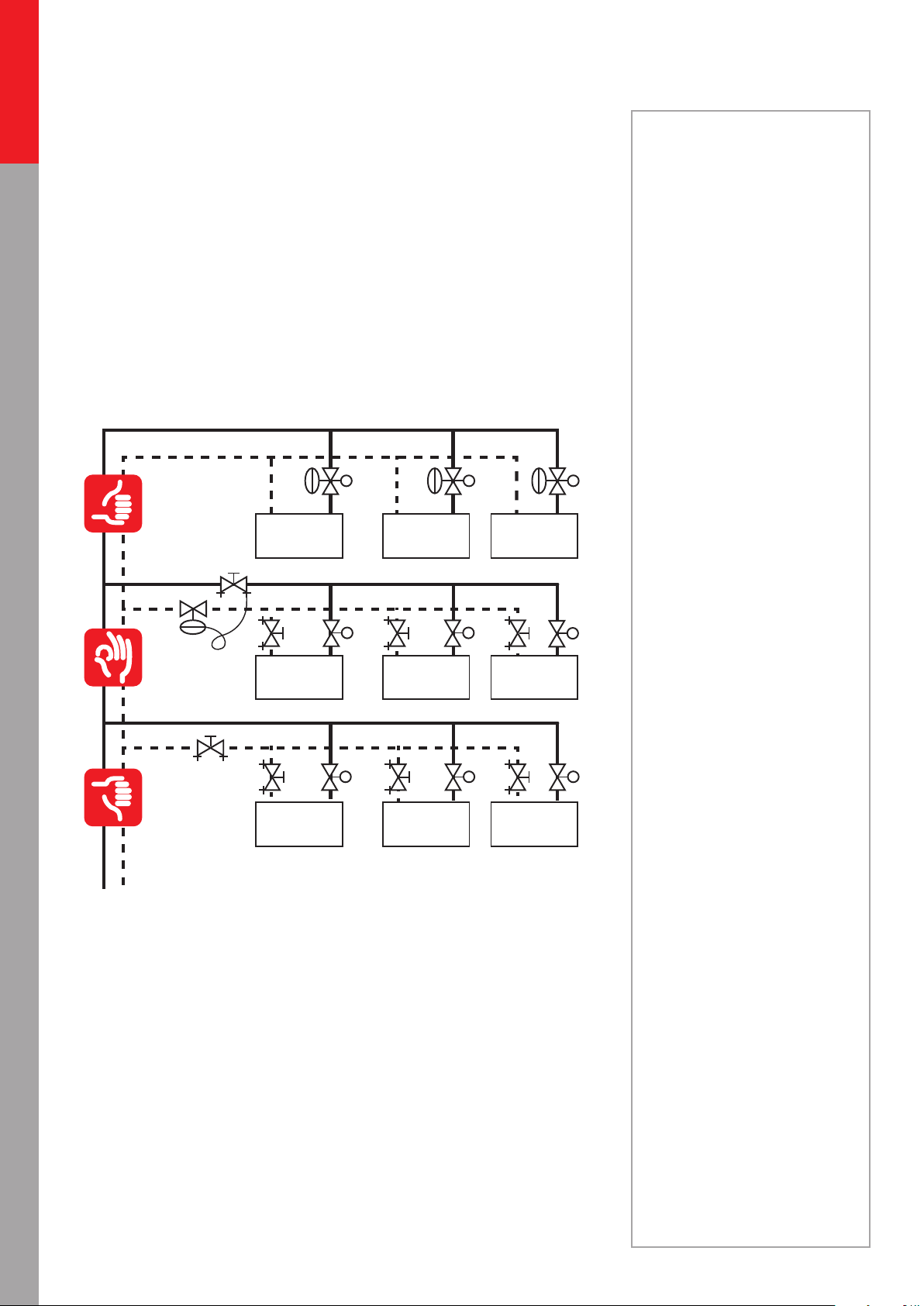

Variable flow* systems

1.1.1.1 - 1.1.1.6**

Hydronic applications can be controlled and balanced based on a lot of dierent type of

solutions. It is impossible to nd the best one for all.

We have to take into consideration each system and its specic to decide what kind of solution will be the most ecient and suitable.

All applications with control valves are variable ow* systems. Calculation is generally done

based on nominal parameters but during operation ow in each part of the system is changing (control valves are working). Flow changes result in pressure changes. That’s why in

such case we have to use balancing solution that allows to respond to changes in partial load.

Pressure

Independent

Control

Notes

AHU application

AHU application

Chillers applicationsBoilers applicationsHot water

AHU heating

Dierential

Pressure

Control

AHU cooling

Manual

Balancing

The evaluation of systems (Recommended/Acceptable/Not recommended) is principally

based on combination of 4 aspects mentioned on page 3 (Return on investment/Design/

Operation-Maintenance/Control) but the most important factors are the system performance and eciency.

On application above the manual balanced system is Not recommended because the static

elements are not able to follow the dynamic behaviour of variable ow* system and during

partial load condition huge overow occurs on control valves (due to smaller pressure drop

on pipe network).

The dierential pressure controlled system performs much better (Acceptable) because

the pressure stabilization is closer to control valves and although we still have manual balanced system inside the dp controlled loop, the overow phenomenon mitigated. The

eciency of such system depends on location of dierential pressure control valve. The

closer it is to control valve, the better it works.

The most ecient (Recommended) system we can have is using PICV (pressure independent control valves). In this case the pressure stabilization is right on the control valve,

therefore we have full authority* and we are able to eliminate all unnecessary ow from

the system.

*see page 54-55

6

** applications below

Page 7

Commercial

Hydronic applications

Hydronic applications – commercial buildings

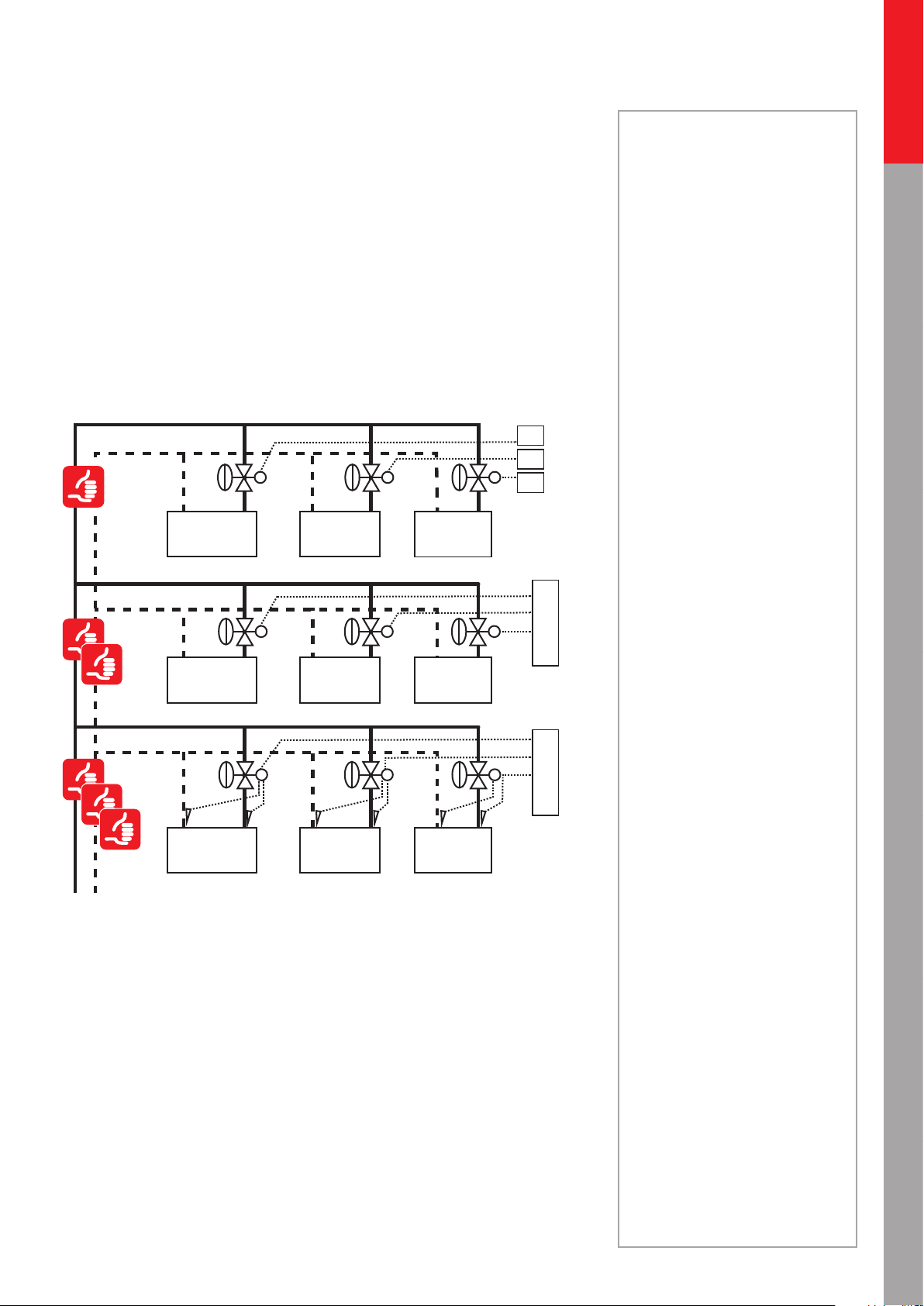

Variable flow* system: PICV – ON/OFF vs modulating vs smart control

1.1.1.1 - 1.1.1.3**

All these applications base on PICV (Pressure Independent Control Valve) technology. It

means the control valve (integrated into the valve body) is independent from pressure uctuation in the system during both full, and partial load conditions. This solution allows us to

use dierent types of actuators (control method)

• With ON/OFF control, the actuator has two positions, open and closed

• With modulation control the actuator is able to set any ow between nominal and zero

value

• With SMART actuator we can ensure (above modulation control) direct connectivity to

BMS (Building Management System) to use advanced functions such as energy allocation, energy management etc.

Controlers

Notes

Hydronic applications

Residential

Mixing loop

AHU application

AHU heating

PICV & ON/OFFPICV &

ControlerControler

modulating

T

PICV technology allows us to use proportional or end point (based on Δp sensor) pump

control

The above mentioned control types strongly aect on overall energy consumption of systems.

While ON/OFF control ensures either 100% or 0 ow during operation, the modulation

control enables to minimize the ow rate through on terminal unit according real demand.

For example, to the same 50% average energy demand we need around 1/3 of ow rate to

modulation control, compared to ON/OFF control. (You can nd more details in chapter 9)

The lower ow rate contributes to energy saving* on more levels:

• Less circulation cost (fewer ow needs less electricity)

• Improved chiller/boiler eciency (less ow ensures bigger ΔT in the system)

• Smaller room temperature oscillation* ensures better comfort and denes the room

temperature setpoint

T

PICV &

T

SMART actuator

T T

T

AHU application

AHU cooling

Chillers applications Boilers applications Hot water

The SMART control – over the above mentioned benets - enable to reduce the maintenance cost with remote access and predictive maintenance.

*see page 54-55

** applications below

7

Page 8

Commercial

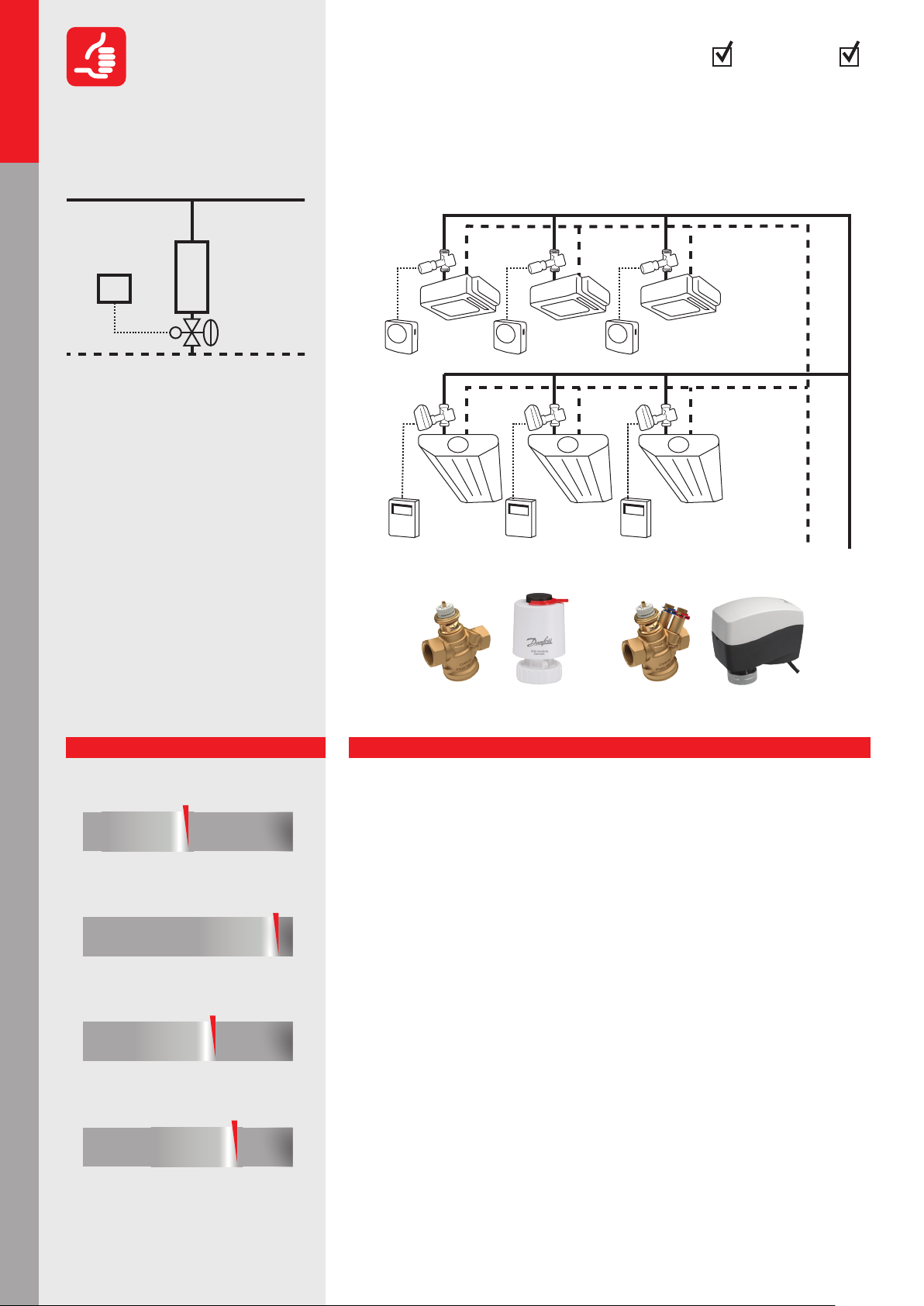

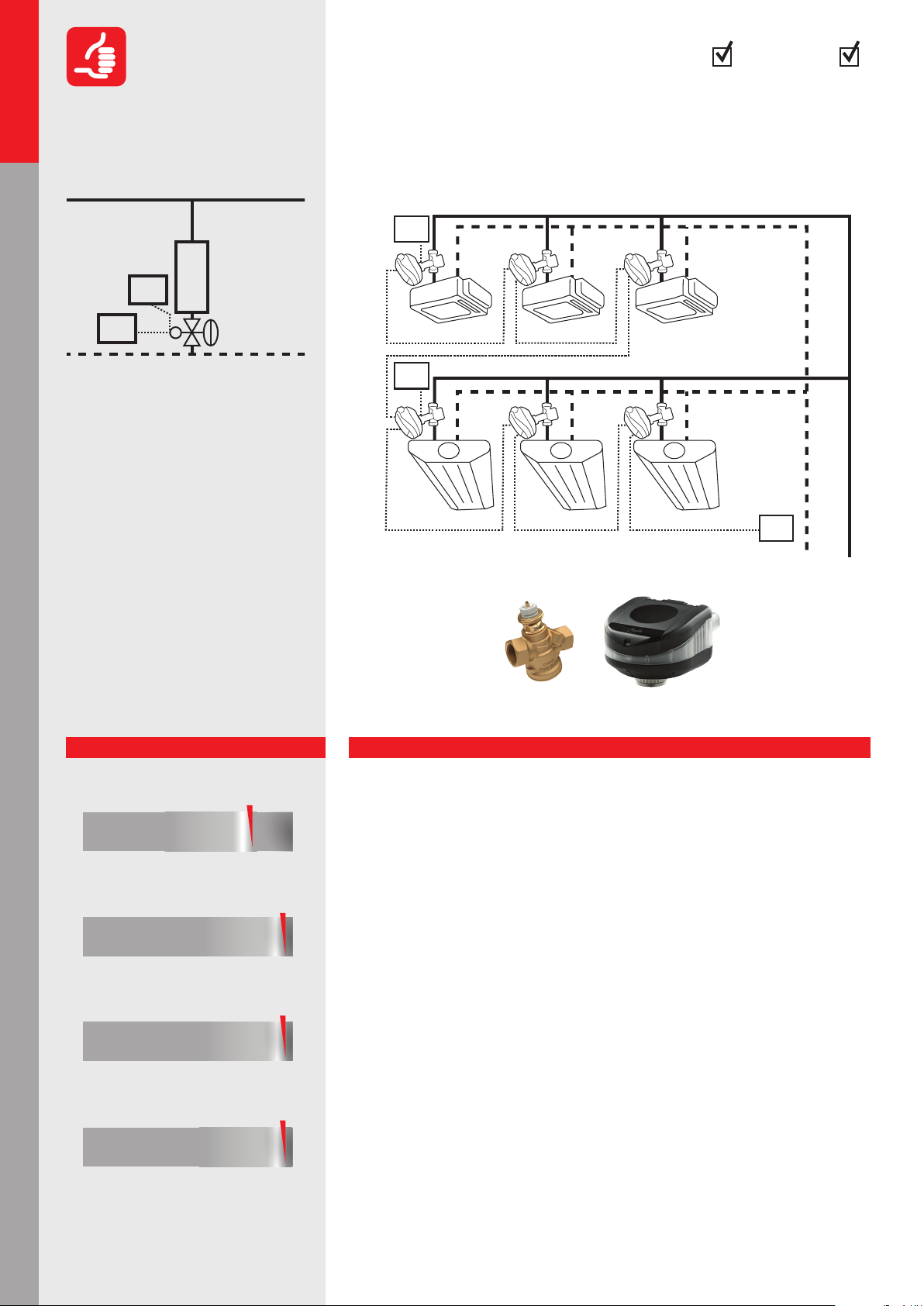

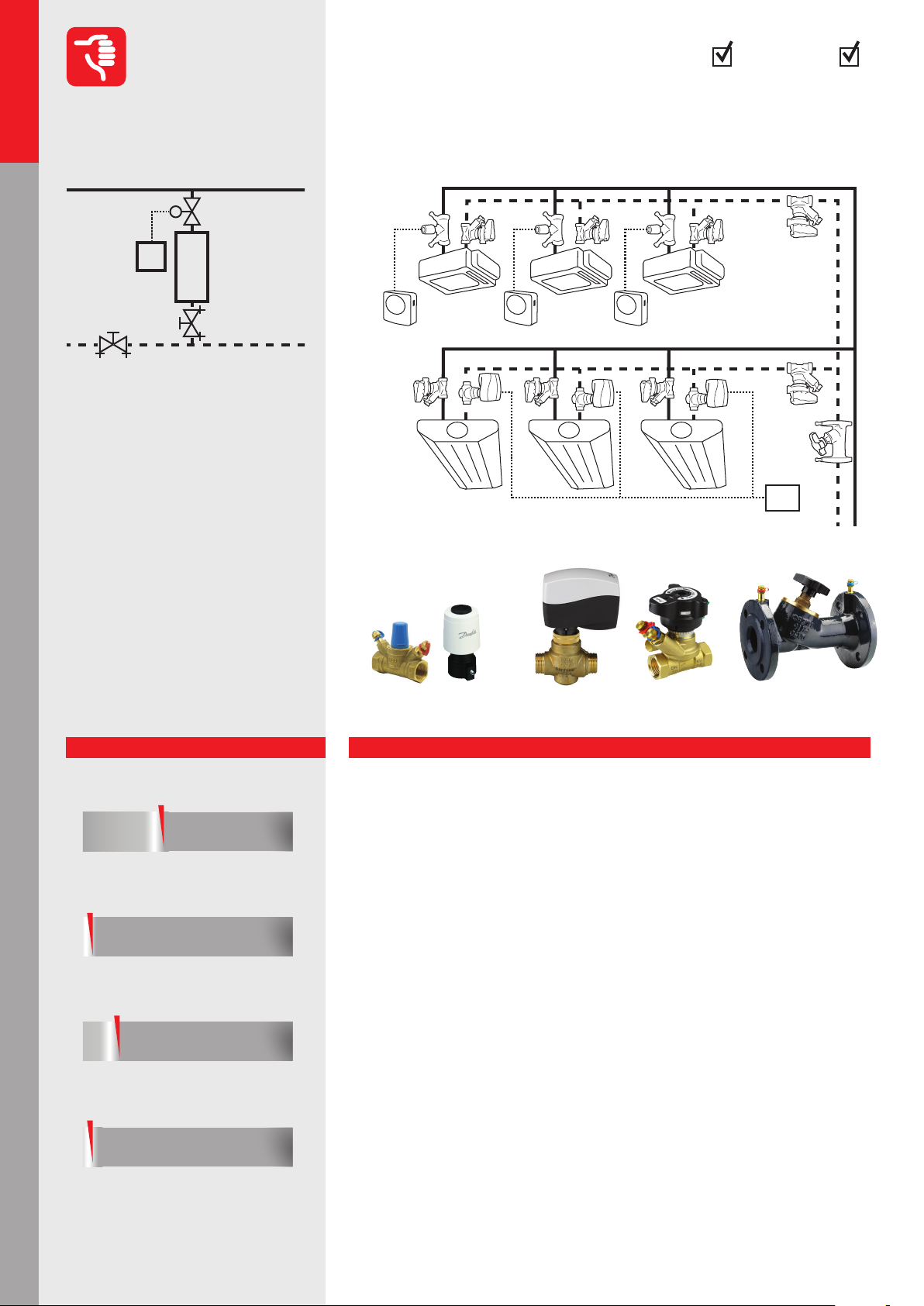

FAN COIL UNITS (FCU)

Hydronic applications

Recommended

1.1.1.1

CoolingHeating

Variable ow: Pressure Independent Control

(PICV) with ON/OFF actuator

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

2

1

1. Preasure Independent

Control Valve (PICV)

2. Room temperature Control (RC)

Balancing of the terminal unit by pressure

independent valves. This will ensure the

right ow at all system loads, regardless

of pressure uctuations. ON/OFF control

will cause uctuations in the room

temperature. The system will not be

operating optimally because the ΔT

is not optimized.

PICV-1

RC

CHILLED PANELS

PICV-2

RC

Danfoss products:

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

Performance

Return of investment

poor acceptable

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

PICV-1: AB-QM 4.0 + TWA-Q PICV-2: AB-QM 4.0 + AMI-140

Explanation

Return of investment

• Reduction of components by eliminating the need for balancing valves

• Lower installation cost due to simplied installation

• The chillers and boilers operate eciently but not optimally because the ∆T is not

optimized

• Handover of the building can easily be done in phases

Design

• Easy selection of valves based only on the ow requirement

• No Kv or authority* calculation is needed, the calculation is based on ow demand

• Perfect balance at all loads

• Proportional pump control is applicable and the pump(s) can be optimized* easily

• Min available ∆p demand on the valve can be taken for calculating the pump head

Operation/Maintenance

• Simplied construction because of a reduction of components

• Set and forget, so no complicated balancing procedures

• Fluctuating room temperature, so some occupant complaints can be expected

• Low operational and upkeep cost, so occupants may experience discomfort

• Good but reduced eciency in chillers, boilers and pumping

because of a sub-optimized ∆T in the system

Control

• Temperature uctuations *

• No overows*

• Pressure independent solution, so no pressure changes do not aect control circuits

• Low ∆T syndrome* is unlikely to happen

8

*see page 54-55

Page 9

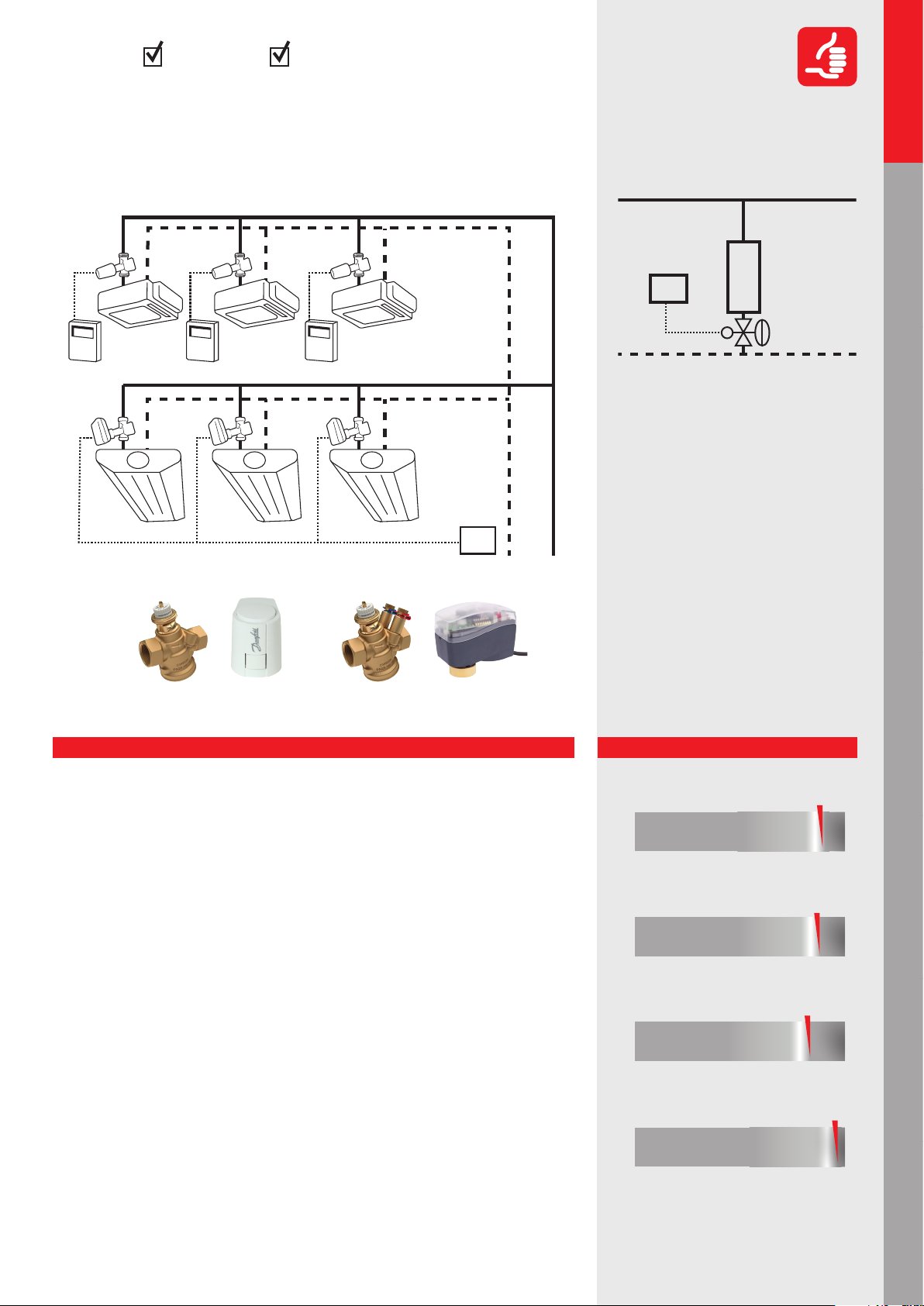

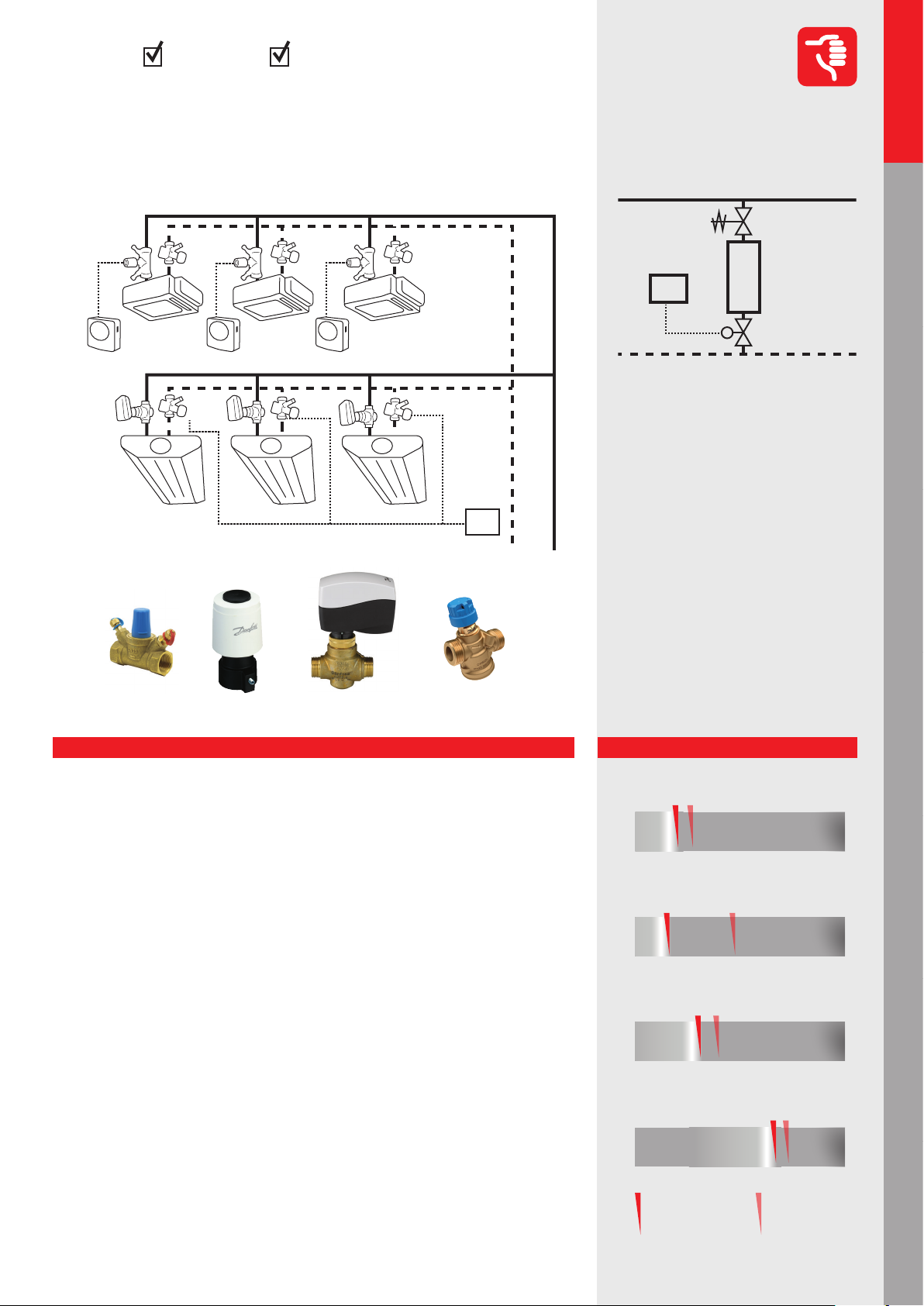

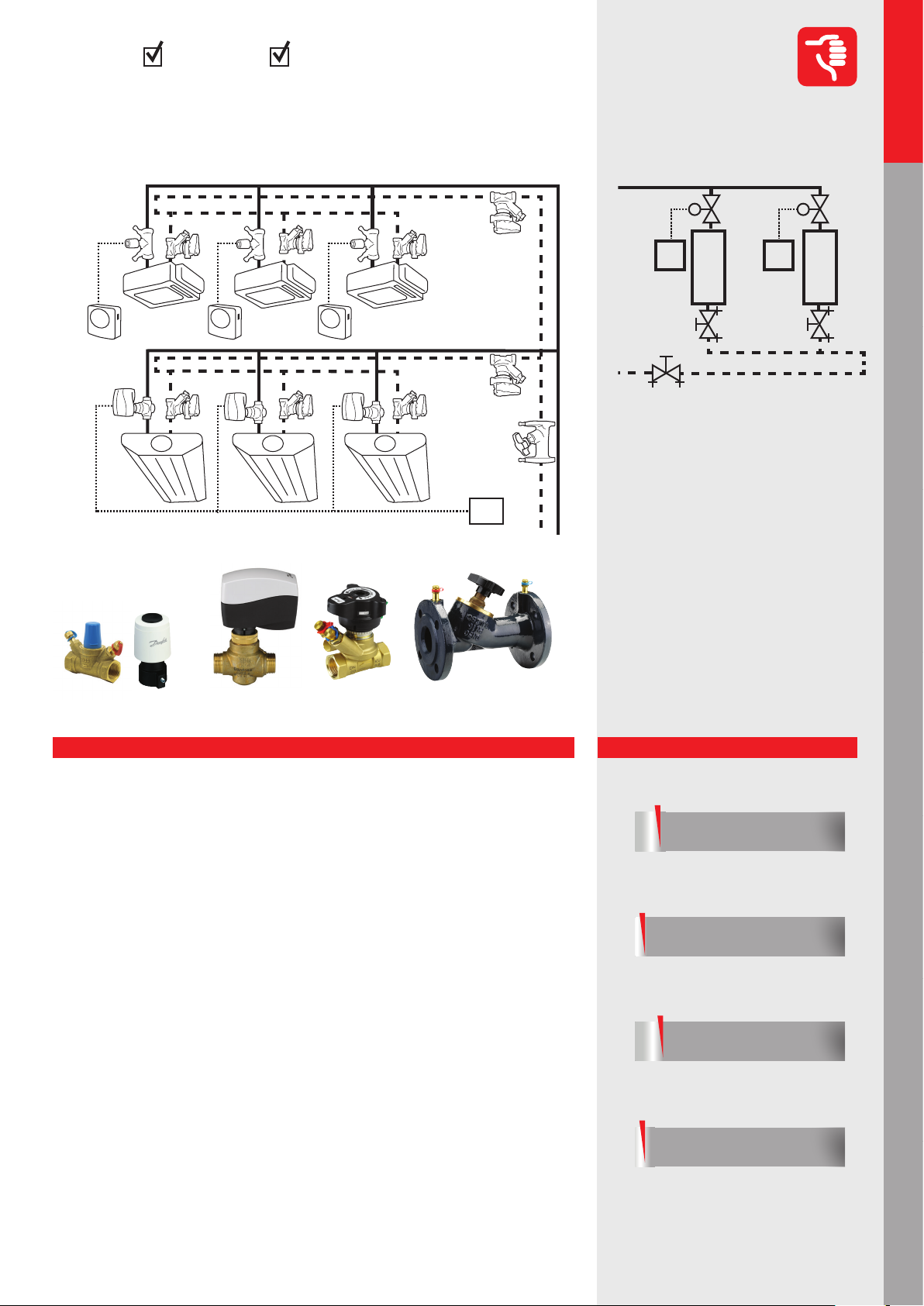

CoolingHeating

FAN COIL UNITS (FCU)

Variable ow: Pressure Independent Control

Hydronic applications

Commercial

Recommended

(PICV) with proportional control

PICV-1

0-10VRC

CHILLED PANELS

PICV-2

Danfoss products:

BMS

1.1.1.2

2

1

1. Pressure Independent

Control Valve (PICV)

2. Building Management System (BMS)

or Room temperature Control (RC)

Temperature control of the terminal unit

is ensured with pressure independent

valves. This will ensure the right ow at

all system loads, regardless of pressure

uctuations. The result will be stable*

and precise room temperature control to

ensure a high ΔT and prevent actuators

from hunting.

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

PICV-2: AB-QM 4.0 + AME 110 NLPICV-1: AB-QM 4.0 + ABNM A5

Explanation

Return of investment

• Reduction of components by eliminating the need for balancing valves

• Lower installation cost due to simplied installation

• Signicant energy savings* due to optimal working conditions for all components

• Handover of the building can easily be done in phases

Design

• Easy selection of valves based only on the ow requirement

• No Kv or authority* calculation is needed, ow presetting calculation based on ow

demand

• Proportional pump control is applicable. The pump(s) can be optimized easily *

• Suitable for BMS applications to monitor the system and reduce energy usage

Operation/Maintenance

• Simplied construction because of a reduction of components

• Set and forget, so no complicated balancing procedures

• Good control at all loads, so no complaints by occupants

• Low operational and upkeep cost

• High comfort (building classication*) because of precise ow control at all loads

• High eciency in chillers, boilers and pumping because of the optimized ∆T in the

system

Control

• Perfect control because of full authority *

• No overows* at partial system loads

• Proportional control minimizes the ow circulation and optimizes the pump head

• Pressure independent solution, so pressure interdependency of the control circuits

• No low ∆T syndrome *

Applicable for all terminal units, included

AHU (see page 34, 36)

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

AHU heating

Chillers applications Boilers applications Hot water

AHU applications

*see page 54-55

9

Page 10

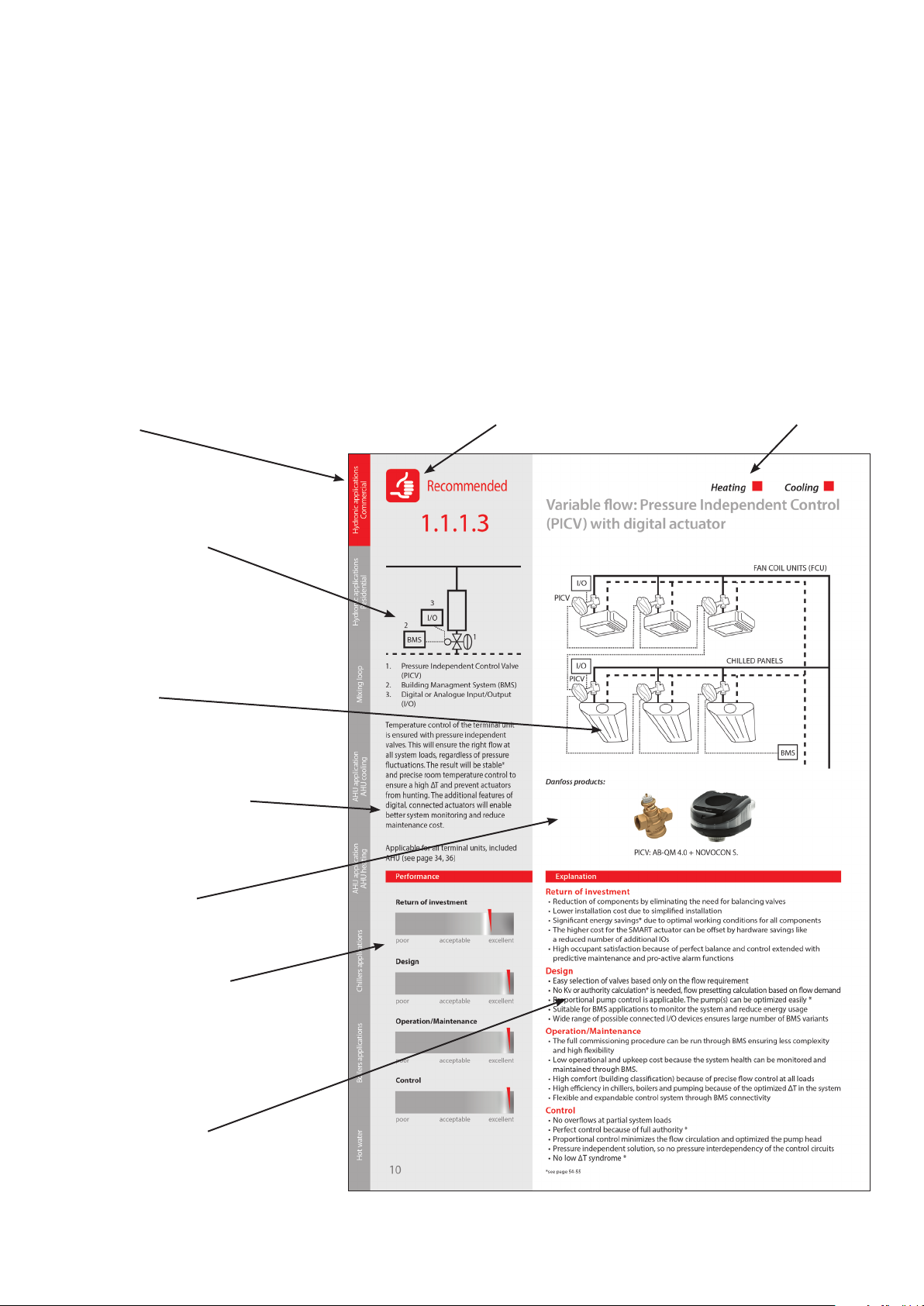

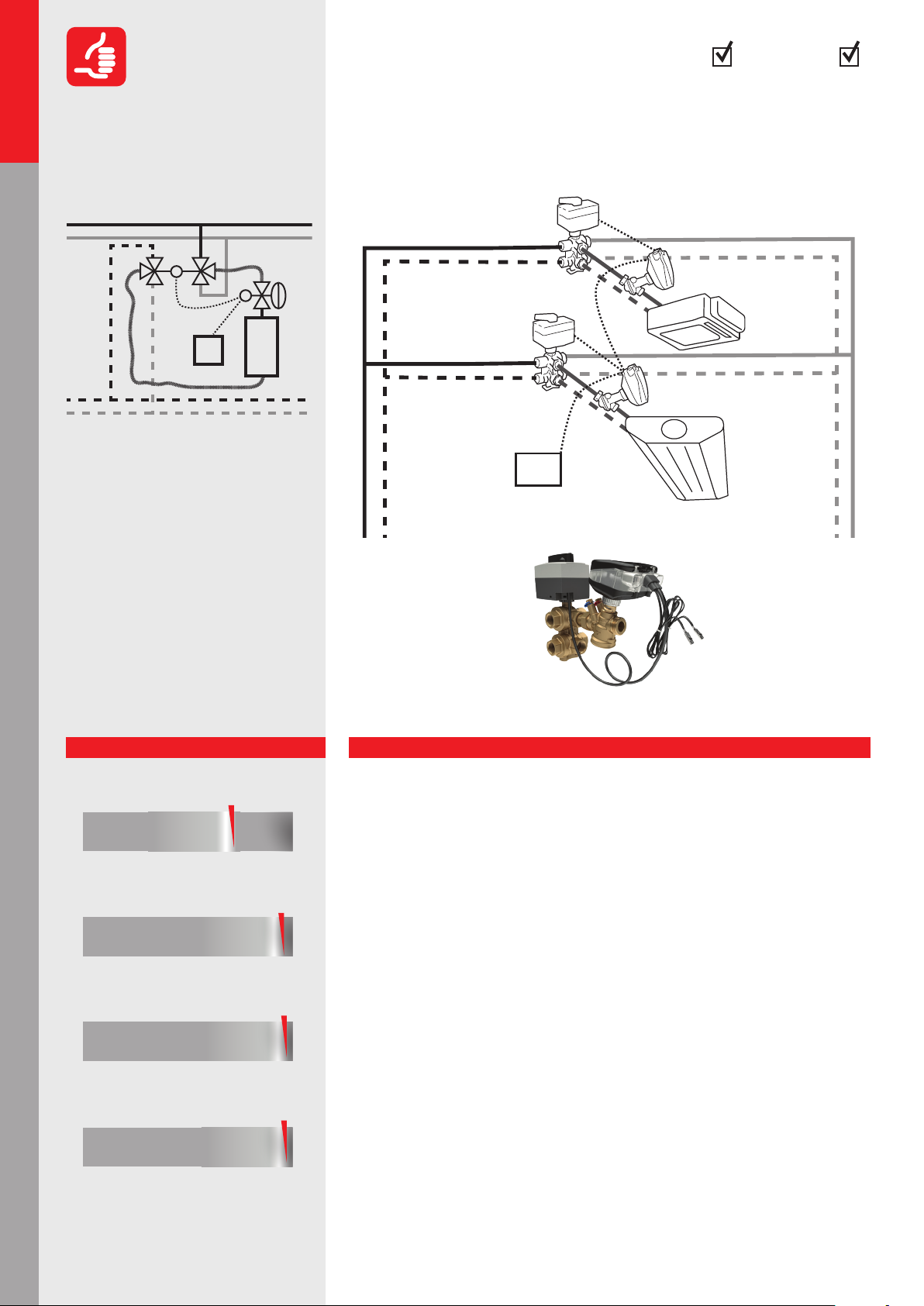

Commercial

Hydronic applications

Residential

Hydronic applications

Recommended

1.1.1.3

3

I/O

2

BMS

CoolingHeating

Variable ow: Pressure Independent Control

(PICV) with digital actuator

FAN COIL UNITS (FCU)

I/O

PICV

1

Mixing loop

AHU cooling

AHU applications

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

1. Pressure Independent Control Valve

(PICV)

2. Building Management System (BMS)

3. Digital or Analogue Input/Output

(I/O)

Temperature control of the terminal unit

is ensured with pressure independent

valves. This will ensure the right ow at

all system loads, regardless of pressure

uctuations. The result will be stable

and precise room temperature control to

ensure a high ΔT and prevent actuators

from hunting. The additional features of

digital, connected actuators will enable

better system monitoring and reduce

maintenance cost.

Applicable for all terminal units, included

AHU (see page 34, 36)

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

10

I/O

PICV

Danfoss products:

PICV: AB-QM 4.0 + NovoCon® S.

Explanation

CHILLED PANELS

BMS

Return of investment

• Reduction of components by eliminating the need for balancing valves

• Lower installation cost due to simplied installation

• Signicant energy savings* due to optimal working conditions for all components

• The higher cost for the SMART actuator can be oset by hardware savings like

a reduced number of additional IOs

• High occupant satisfaction because of perfect balance and control extended with

predictive maintenance and pro-active alarm functions

Design

• Easy selection of valves based only on the ow requirement

• No Kv or authority calculation* is needed, ow presetting calculation based on ow demand

• Proportional pump control is applicable. The pump(s) can be optimized easily *

• Suitable for BMS applications to monitor the system and reduce energy usage

• Wide range of possible connected I/O devices ensures large number of BMS variants

Operation/Maintenance

• The full commissioning procedure can be run through BMS ensuring less complexity

and high exibility

• Low operational and upkeep cost because the system health can be monitored and

maintained through BMS.

• High comfort (building classication) because of precise ow control at all loads

• High eciency in chillers, boilers and pumping because of the optimized ∆T in the system

• Flexible and expandable control system through BMS connectivity

Control

• No overows at partial system loads

• Perfect control because of full authority *

• Proportional control minimizes the ow circulation and optimizes the pump head

• Pressure independent solution, so pressure changes do not aect control circuits

• No low ∆T syndrome *

*see page 54-55

Page 11

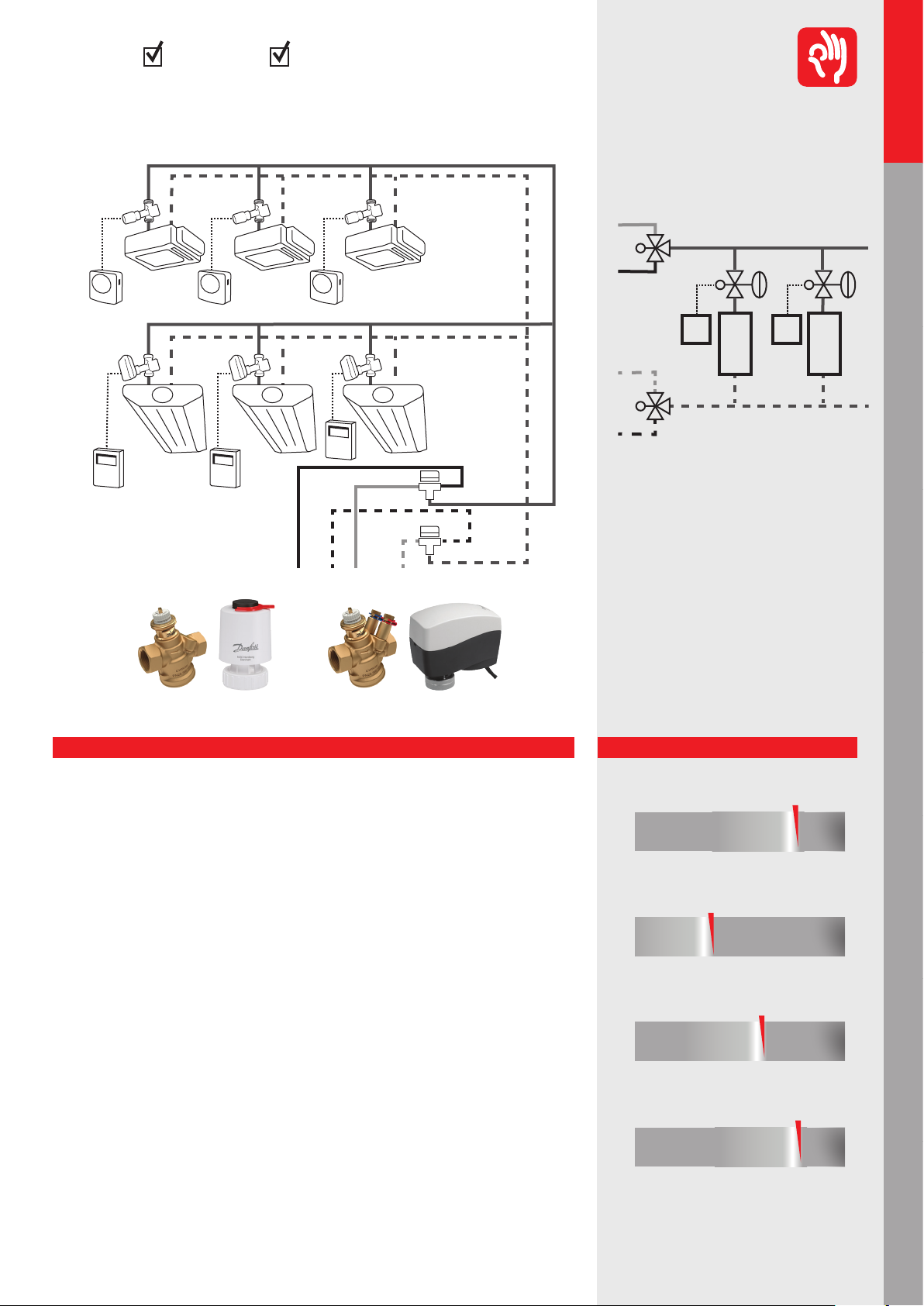

CoolingHeating

Variable ow: Flow limitation (with ow

Hydronic applications

Commercial

Not Recommended

limiter) on terminal unit with ON/OFF

or modular actuator

FAN COIL UNITS (FCU)

CV-1

ON/OFF

RC

CV-2

0-10V

Danfoss products:

FL

CHILLED PANELS

FL

BMS

CV-2: VZ2 + AME130 FL: AB-QMCV-1: RA-HC + TWA-A

1.1.1.4

2

3

1

1. 2-way Control Valve (CV)

2. Flow Limiter (FL)

3. Building Management System (BMS)

or Room temperature Control (RC)

Temperature control of the terminal unit

is done by conventional motorized control valves (CV) while the hydronic balance in the system is realized by automatic

ow limiter (FL). For ON/OFF control this

could be an acceptable solution, provided

that the pump head is not too high. For

modulating control this is not acceptable.

The FL will counteract the actions of the

CV and fully distort the control characteristic. Therefore, modulation with this

solutions is impossible.

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

AHU applications

AHU heating

Explanation

Return of investment

• Relatively high product cost because of 2 valves for all terminal units (one CV + FL)

• Higher installation costs although no manual partner valves* are needed

• Variable speed pump is recommended (proportional pump control is possible)

Design

• Traditional calculation is needed but only the kvs of the control valve. It is not necessary

to calculate the authority* since the FL will take away the authority of the CV

• For ON/OFF control it is an acceptable solution (simple design: big kvs of zone valve,

ow limiter selected based on ow demand)

• High pump head is needed because of the two valves (additional Δp on ow limiter)

Operation/Maintenance

• Closing force of actuator should be able to close the valve against the pump head at

minimum ow

• Most ow limiters have pre-determined ow, no adjustment is possible.

• For ushing cartridges need to be removed from the system and placed back

afterwards (emptying and lling the system twice)

• Cartridges have small openings and clog easily

• If modulation is attempted the lifetime of the CV is very short due to hunting at partial

system loads

• High energy consumption with modulation control due to higher pump head and

overow on terminal units in partial load

Control

• Temperature uctuations due to ON/OFF control, even with modulating actuators*

• No overows*

• No pressure interdependency of the control circuits

• Overow during partial load when modulating because the FL will keep the maximum

ow if possible

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

3-point or proportional control

acceptable

acceptable

acceptable

acceptable

Chillers applications Boilers applications Hot water

excellent

excellent

excellent

excellent

ON/OFF

control

*see page 54-55

11

Page 12

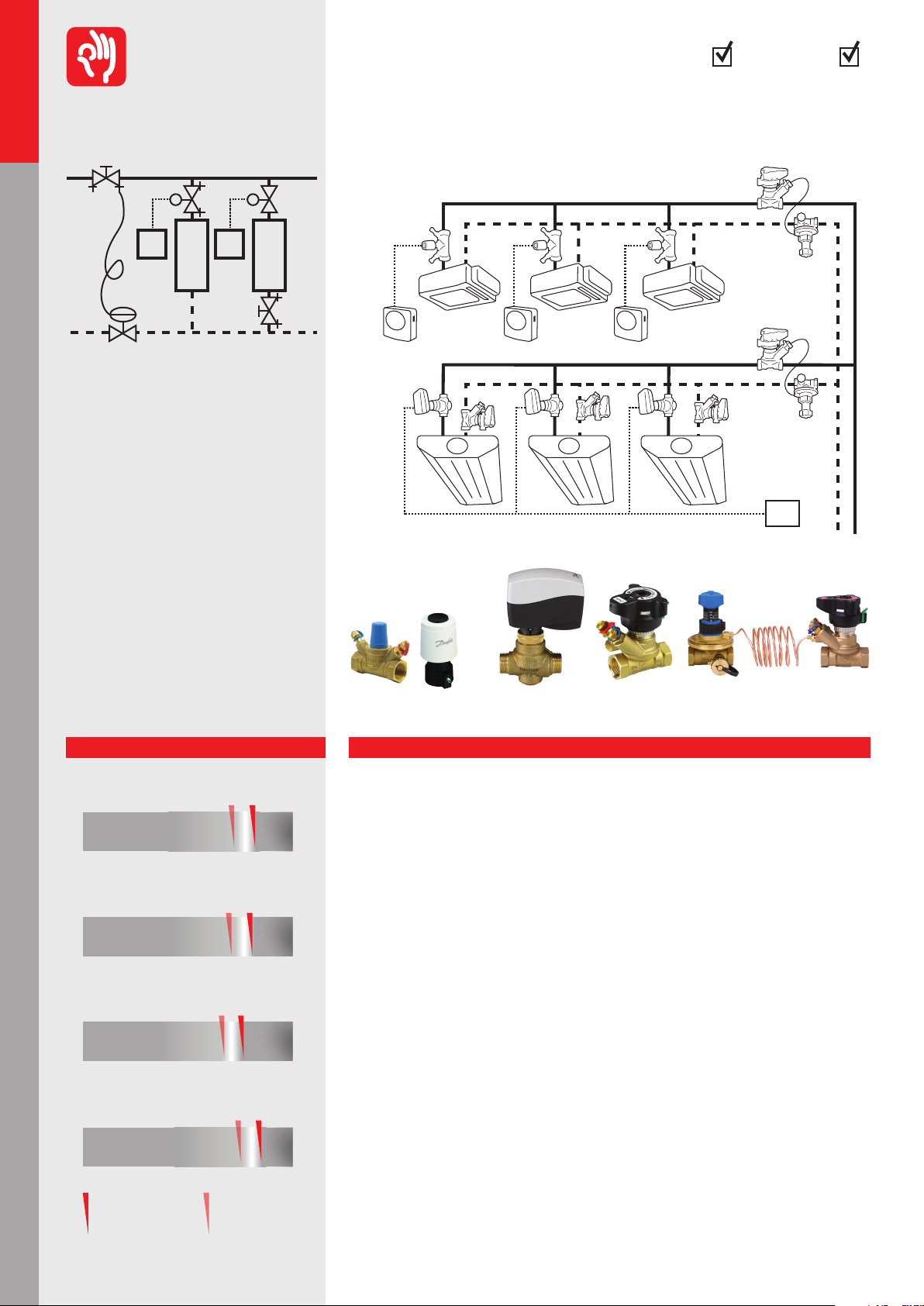

Commercial

Hydronic applications

Acceptable

1.1.1.5

CoolingHeating

Variable ow: Dierential pressure control

with ON/OFF or modulation

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

5

1. Zone Control Valve

(with presetting) (CV)

2. Zone Control Valve

(no presetting) (CV)

3. Manual Balancing Valve (MBV)

4. Δp Controller (DPCV)

5. Partner Valve*

6. Building Management System (BMS)

or Room temperature Control (RC)

1 2

6 6

4

3

Temperature control at the terminal unit is

done by conventional motorized control

valve (CV). Hydronic balance is achieved

by dierential pressure controllers (DPCV)

on the branches and manual balancing

valves (MBV) at the terminal unit. If the

CV has a pre-setting option the MBV is

redundant.

CV-1

ON/OFF

RC

CV-2

0-10V

Danfoss products:

FAN COIL UNITS (FCU)

DPCV

CHILLED PANELS

MBV

DPCV

BMS

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

It guarantees that, regardless of pressure

oscillations in the distribution network,

we have the right pressure and ow in the

pressure-controlled segment.

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

3-point or proportional control

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

ON/OFF

control

CV-2: VZ2 + AME130 DPCV: ASV-PV+ASV-BD MBV: MSV-BD CV-1: RA-HC +TWA-A

Explanation

Return of investment

• Requires Δp controllers and partner valves*.

• MBVs or pre-settable CV is needed for each terminal unit

• Cooling systems might require big and expensive (anged) Δp controllers

• Good energy eciency because there are only limited overows* in partial load

Design

• Simplied design because the branches are pressure independent

• Kv calculation needed for Δp controller and control valve. An authority* calculation is

also needed for modulating control

• Pre-setting calculation for terminal units is necessary for proper water distribution

within the branch

• The setting for the Δp controller needs to be calculated

• A variable speed pump is recommended

Operation/Maintenance

• More components to install included impulse tube connection between Δp - and partner valve*

• Simplied commissioning* procedure because of pressure independent branches

• Balancing on the terminal units is still required although simplied by Δp controlled branch

• Phased commissioning is possible (branch by branch)

Control

• Generally acceptable to good controllability

• Pressure uctuations that impact the controllability can occur with long branchesor

and/or big Δp on terminal units

• Depending on the size of the branch overows can still result in room temperature

uctuations.

• If we use ow limitation on partner valve* connected to Δp controller (not on terminal

units), higher overow and room temperature oscillation* are expected

12

*see page 54-55

Page 13

CoolingHeating

Variable ow: Shell and Core installation for

Hydronic applications

Commercial

Recommended

Oces and Shopping malls*

PICV-3

VACANT

Danfoss products:

PICV-1

?

PICV-3

PICV-2

PICV-3

RC

VACANT

FAN COIL UNITS (FCU)

CHILLED PANELS

PICV-1

?

BMS

1.1.1.6

1

?

1. Combined Automatic Balancing

Valve as Δp Controller (PICV 1)

2. Combined Automatic Balancing

Valve as Flow Controller (PICV 2)

This application is useful specically for

situations where the system is built in two

phases by dierent contractors. The rst

phase is usually the central infrastructure,

like boilers, chillers and transport piping,

while the second part includes the terminal units and room controls.

2

?

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

PICV-2 & PICV3: AB-PM + TWA-QPICV-1: AB-PM+AME435QM

Explanation

Return of investment

• Only one valve needed

• One actuator for zone or ow control

• Variable speed pump is recommended (proportional pump control is possible)

Design

• No kvs and authority* calculation needed.

• Presetting calculation needed only based on ow and Δp demand of loop

• For loop design (later stage of installation) the set parameters are available

Operation/Maintenance

• Reliable solution for shop or oor connection

• Flow setting can be done based on measurements on the test plugs of the valve

• Central distribution is always correctly balanced and independent of any mistakes

made in sizing on the occupant ‚s side

• Changes in secondary section of the system do not inuence other shops or oors

• Easy trouble shooting, energy allocation, management, etc. with NovoCon

Control

• Stable pressure dierence for shops or oors

• If only ow limitation is used small overows can happen within the loop during partial load

• Actuator on valve (if applied) ensures either zone control (Δp control application)

or ow control (ow control application)

This commonly occurs in shopping malls,

where the shops use their own contractor

to do the shop’s installation, or Shell &

Core oces where the renter of an oce

oor ts out his own space, including the

HVAC.

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

acceptable

acceptable

acceptable

excellent

excellent

excellent

AHU heating

Chillers applications Boilers applications Hot water

AHU applications

**Two dierent approaches can be chosen:

1. Flow and ΔP limitation. Here the valve limits both the ΔP and the ow.

2. Flow limitation only. This will require additional zone controls and balancing

for the terminal units

*see page 54-55

poor

Δp control

application

acceptable

excellent

Flow control

application

13

Page 14

Commercial

FAN COIL UNITS (FCU)

Hydronic applications

Not Recomended

1.1.1.7

CoolingHeating

Variable ow: Manual balancing

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

1

4

3

1. 2-way Control Valve (CV)

2. Manual Balancing Valve (MBV)

3. Partner Valve* (MBV)

4. Building Management System (BMS)

or Room temperature Control (RC)

2

The terminal units are controlled by

conventional motorized control valves

and the hydronic balance is achieved by

manual balancing valve. Due to the static

nature the MBV only ensures hydronic

balance in full system load. During partial

load under- and overows can be expected in the terminal units, causing excessive energy consumption as well as cold

and hot spots in the system.

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

CV-1

RC

MBV-1

Danfoss products:

Explanation

MBV-1

MBV-1

CHILLED PANELS

CV-2 MBV-1

MBV-2

BMS

CV-2: VZ2 + AME130 MBV-1: MSV-BD MBV-2: MSV-F2 CV-1: RA-HC +TWA-A

Return of investment

• Many components are needed: 2 valves per terminal unit and additional branch valves

for commissioning*

• Increased installation cost due to many valves

• Complex commissioning procedure is required increasing risk of a delayed.

• Variable speed pump is recommended with constant Δp function

Design

• Precise sizing is required (Kv-value, authority*)

• Authority* calculations are crucial for acceptable modulation

• Constant Δp pump control is recommended because of the proper location

for the pressure

• It is impossible to predict system behaviour in partial load

Operation/Maintenance

• Complicated commissioning procedure that can only be executed by qualied sta

• Commissioning process can only be started at the end of the project with full load on

the system and sucient access to all balancing valves

• High complaint costs because of balancing issues, noise and inaccurate control during

partial load

• Rebalancing needed regularly and in case of changes in the system

• High pumping costs* because of overows during partial load

Control

• Interdependence of circuits creates pressure uctuations, which inuence control

stability and accuracy

• The generated overow reduces the system eciency (high pumping cost*, low ΔT

syndrome* in cooling system, room temperature oscillation*)

• Failure to create sucient pressure drop on the valve will result in low authority* which

will make modulating control impossible

14

*see page 54-55

Page 15

CoolingHeating

FAN COIL UNITS (FCU)

Variable ow: Manual balancing

Hydronic applications

Commercial

Not Recommended

with reverse return

CV-1

RC

CV-2

Danfoss products:

Explanation

MBV-1

MBV-1

CV-2: VZ2 + AME130 MBV-2: MSV-F2 MBV-1: MSV-BD CV-1: RA-HC +TWA-A

MBV-1

CHILLED PANELS

MBV-1

MBV-2

BMS

1.1.1.8

1

4 4

2

3

1. 2-way Control Valve (CV)

2. Manual Balancing Valve (MBV)

3. Partner Valve* (MBV)

4. Building Management System (BMS)

or Room temperature Control (RC)

In a reverse return system (Tichelmann),

the piping is designed in such way that

the rst terminal unit on the supply is the

last one on the return. The theory is that

all terminal units have the same available

Δp and therefore are balanced. This system can only be used if the terminal units

are the same size and have constant*

ow. For other systems this application is

unsuitable.

Performance

1

2

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

AHU applications

AHU heating

Return of investment

• Due to extra pipe runs the investment is much higher

• More space needed in technical shaft for additional third pipe

• Bigger pump needed because of added resistance of additional piping

• High complaint costs because of the balancing issues, noise and inaccurate control

during partial loads

Design

• Complicated piping design

• Precise control valve sizing is required (Kv-values, authority*)

• Authority* calculations are crucial for acceptable modulation

• Constant Δp pump control is recommended, it is impossible to use a Δp sensor

• The system is only balanced during full load conditions

• It is impossible to predict system behaviour in partial load

Operation/Maintenance

• Complicated commissioning* procedure that can only be executed by qualied sta

• Commissioning process can only be started at the end of the project with full load on

the system and sucient access to all balancing valves

• Δp sensor does not solve over pumping issues

• Rebalancing needed in case of changes in the system

• Extra high pumping costs* because of third pipeline and overows during partial load

Control

• Interdependence of circuits creates pressure uctuations which inuence control stability and accuracy

• The generated overow reduces the system eciency (high pumping cost*, low ΔT

syndrome* in cooling system, room temperature oscillation*)

• Failure in creating sucient pressure drop on the valve will result in low authority

which* will make modulating control impossible

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

Chillers applications Boilers applications Hot water

excellent

excellent

excellent

excellent

*see page 54-55

15

Page 16

Commercial

Hydronic applications

Recommended

1.1.1.9

CoolingHeating

Variable ow: Four-pipe Changeover (CO6)

for radiant heating/cooling panels, chilled

beams, etc. with PICV control valve

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

1

2

3

1. 6-way Valve

2. Pressure Independent

Control Valve (PICV)

3. Building Management System (BMS)

This application is useful if you have one

heat exchanger that needs to do both

heating and cooling. This t well with

radiant panel solutions. The application

uses a 6-way valve for switching over

between heating and cooling and a PICV

is used to balance and control the ow.

Danfoss products:

6-way value

FAN COIL UNITS (FCU)

PICV

6-way value

PICV

BMS

6-way valve + PICV: NovoCon ChangeOver6 +AB-QM

CHILLED PANELS

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

Explanation

Return of investment

• Only two valves are needed instead of four. One for changeover* and one for heating/

cooling control

• Very energy ecient thanks to high ∆T and no overows*

• Low commissioning* cost because only the ow needs to be set either on PICV or on

BMS when using a digital actuator

• BMS costs are reduced because only one datapoint is needed

Design

• Easy selection of PICV, only the ow is required for sizing

• No Kv or authority* calculations needed

• The Δp on CO6 valve does need to be checked

• Perfect balance and control under all loads ensuring precise room temperature control

Operation/Maintenance

• Simplied construction because of reduction of components and pre-built sets

• One valve controls both cooling and heating

• Low complaint costs because of perfect balance and perfect control at all loads

• No cross ow between heating and cooling

• Low operational and upkeep cost. Flushing, purging, energy allocation and management can all be done through BMS.

Control

• Perfect control because of full authority*

• Individual settings for cooling and heating (ow), so perfect control in both situations

• Precise room temperature control

• Digital actuator ensures further saving with energy measurement and management

function

16

*see page 54-55

Page 17

CoolingHeating

Variable ow: Two-pipe heating/cooling

Hydronic applications

Commercial

Acceptable

system with central changeover*

FAN COIL UNITS (FCU)

PICV-1

RC

CHILLED PANELS

PICV-2

RC

HEATING

SUPPLY/RETURN

Danfoss products:

PICV-1: AB-QM 4.0 + TWA-Q PICV-2: AB-QM 4.0 + AMI-140

SUPPLY

RETURN

COOLING

1.1.1.10

1

1

1. Central Changeover Valve

2. Pressure Independent

Control Valve (PICV)

3. Room thermostat (RC)

In this application a central change

guarantees that the rooms can be cooled

and heated. It is strongly recommended

to use a PICV to control the temperature

because of the dierent ow requirements for the heating and cooling.

2

3 3

Hydronic applications

Residential

2

Mixing loop

AHU applications

AHU cooling

AHU applications

AHU heating

Explanation

Return of investment

• Heavily reduced construction cost due to elimination of a secend set of pipes

• Extra costs if automatic changeover* is required

• Proportional pump control is recommended

Design

• Simple PICV selection according to cooling ow, which is usually the highest

• The change-over valve needs to be selected according to the biggest ow rate (cooling)

and a big Kvs is recommend to reduce the pumping cost*

• Dierent ow rates for heating and cooling need to be ensured, either by limiting the

actuator stroke or by the ability to remotely set the maximum ow, (digital actuator)

• In most cases a dierent pump head is needed for heating and cooling

Operation/Maintenance

• Simple system setup with few valves, so low maintenance cost

• The seasonal changeover* needs to be managed

• No overow* (if ow can be set for dierent heating/cooling mode)

Control

• Simultaneous heating and cooling in dierent rooms is not possible

• Perfect hydronic balancing and control with PICV

• ON/OFF control results in overows when the ow limitation is not solved for lower

ow demand (heating)

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

Chillers applications Boilers applications Hot water

excellent

excellent

excellent

excellent

*see page 54-55

17

Page 18

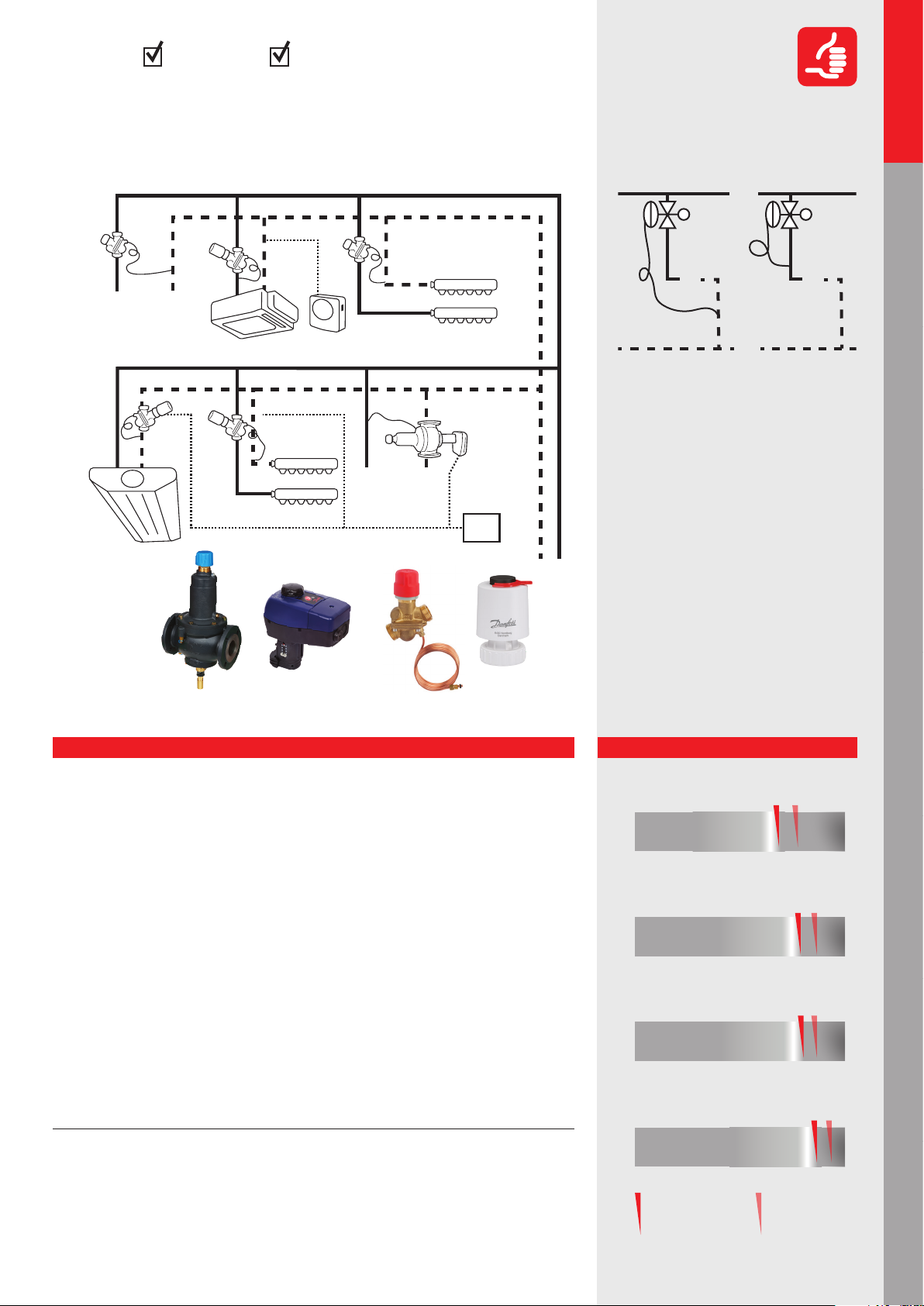

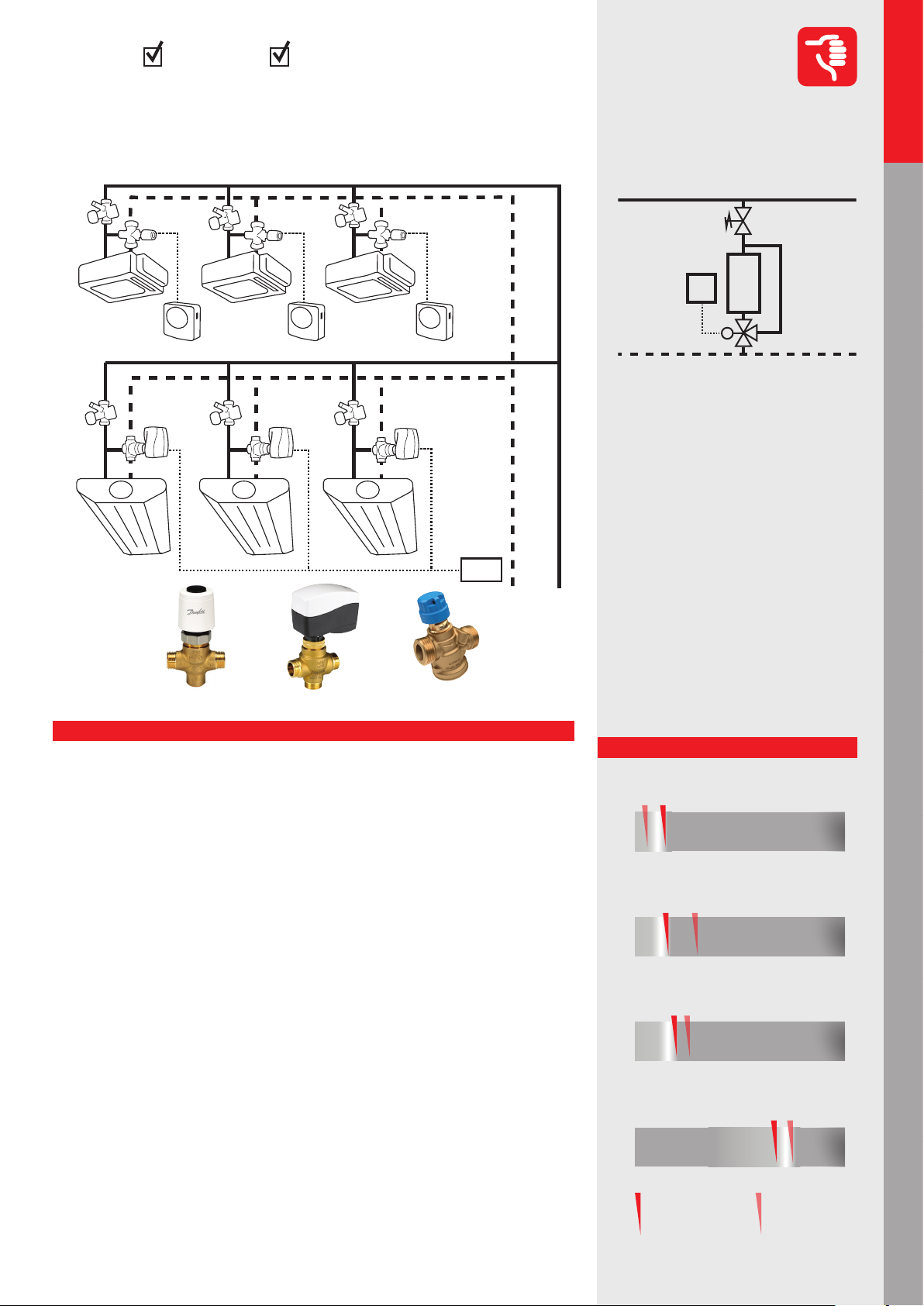

Commercial

Hydronic applications

Not Recommended

1.1.2.1

2

CoolingHeating

Constant ow: 3-way valve with manual balancing (in fan-coil, chilled beam etc. application)

FAN COIL UNITS (FCU)

MBV-1

CV-1

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

4

3

1. 3-way Control Valve (CV)

2. Manual Balancing Valve (MBV)

3. Partner Valve* (MBV)

4. Building Management System (BMS)

or Room temperature Control (RC)

1

In this application temperature control on

the terminal unit is done by using 3-way

valves. Manual balancing valves are used

to create hydronic balance in the system.

This application should be avoided due to

its high energy ineciency.

MBV-1

Danfoss products:

CV-2

RC

MBV-1

CHILLED PANELS

MBV-2

BMS

CV-2: VZ3 +AME130 MBV-2: MSV-F2CV-1: VZL3 + TWA-ZL

MBV-1: MSV-BD

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

Explanation

Return of investment

• Many components are needed: a 3-way valve and a balancing valve per terminal unit

and additional branch valves for commissioning*

• Extremely high operational cost, very energy inecient

• The ow is close to constant, no variable speed drive applied

• In partial loads very low ΔT in the system, so boilers and chillers run at very low eciency

Design

• Kv calculation is required, as well as an authority calculation* for the 3-way valve in case

of modulation

• A by-pass needs to be sized or a balancing valve should be tted. Otherwise big overows in partial loads can occur causing terminal unit starvation and energy ineciencies.

• For the Pump head calculation partial load needs to be considered if overows on the

by-pass are expected

Operation/Maintenance

• Commissioning of the system is required

• The hydronic balance at full- and partial load is acceptable

• Huge pump energy consumption due to constant operation

• High energy consumption (low ΔT)

Control

• The water distribution and the available pressure on the terminal units are more or less

constant under all loads

• The room temperature control is satisfactory

• An oversized control valve will result in low rangeability and oscillation* with modulation

18

ON/OFF

control

Modulation

control

*see page 54-55

Page 19

CoolingHeating

FAN COIL UNITS (FCU)

Constant ow: 3-way valve with ow limiter

Hydronic applications

Commercial

Not Recommended

on terminal units (fan-coil, chilled beam etc.

application)

FL

FL

Danfoss products:

CV-1

RC

CHILLED PANELS

CV-2

BMS

1.1.2.2

2

3

1

1. 3-way Control Valve (CV)

2. Flow Limiter (FL)

3. Building Management System (BMS)

or Room temperature Control (RC)

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

CV-2: VZ3 +AMV-130CV-1: VZL3 + TWA-ZL

Explanation

FL: AB-QM

Return of investment

• Many components are needed: a 3-way valve and an automatic ow limiter per terminal unit

• Fairly simple valve setup, no need for a balancing valve in by-pass or other valves for

commissioning*

• Extremely high operational cost, very energy inecient

• The ow close to constant, no variable speed drive applied

• In partial loads very low ΔT in the system, so boilers and chillers run at very low eciency

Design

• Kv calculation is required, as well as an authority* calculation for the 3-way valve in case

of modulation.

• Sizing and presetting of the ow limiters is based on the nominal ow of terminal unit

• For the Pump head calculation partial load needs to be considered if overows on the

by-pass are expected.

Operation/Maintenance

• Commissioning of the system is required

• The hydronic balance at full- and partial load is acceptable

• Huge pump energy consumption due to constant operation

• High energy consumption (low ΔT)

Control

• The water distribution and the available pressure on the terminal units are more or less

constant under all loads

• The room temperature control is satisfactory

• An oversized control valve will result in low rangeability and oscillation* with modulation

In this application temperature control on

the terminal unit is done by using 3-way

valves. Automatic ow limiters are used

to create hydronic balance in the system.

This application should be avoided due to

its high energy ineciency.

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

AHU heating

Chillers applications Boilers applications Hot water

AHU applications

*see page 54-55

ON/OFF

control

Modulation

control

19

Page 20

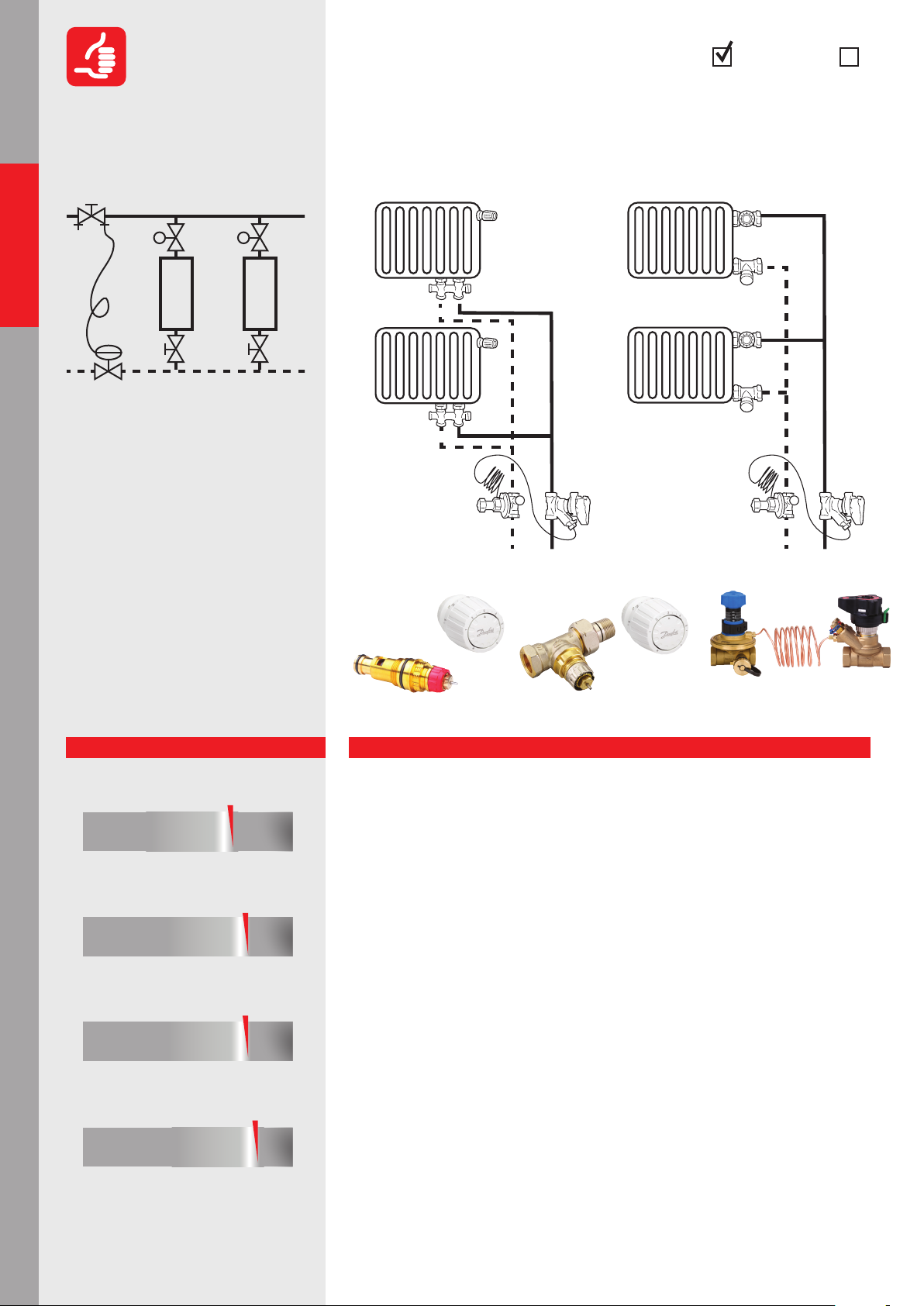

Commercial

Hydronic applications

Residential

Hydronic applications

Recommended

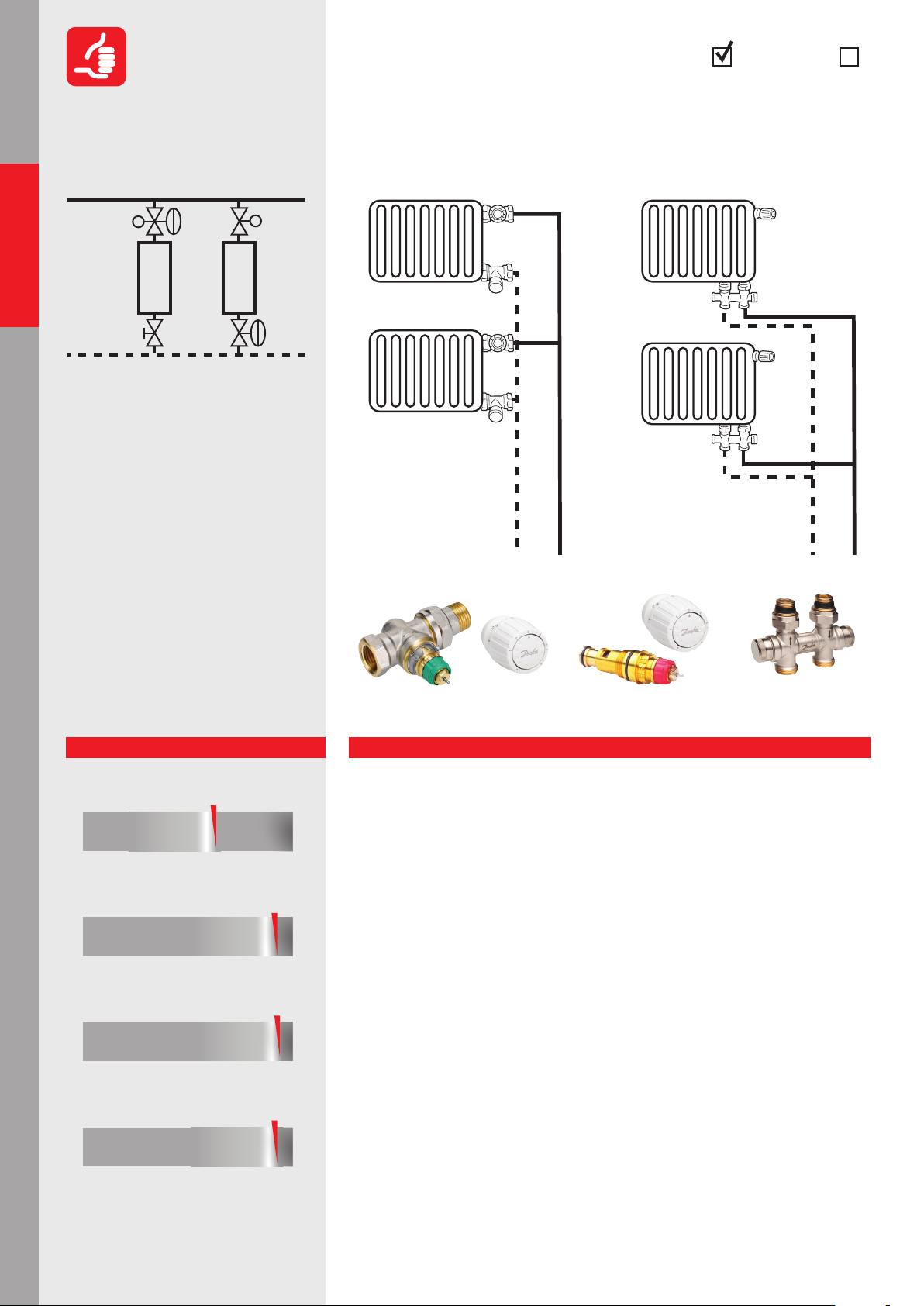

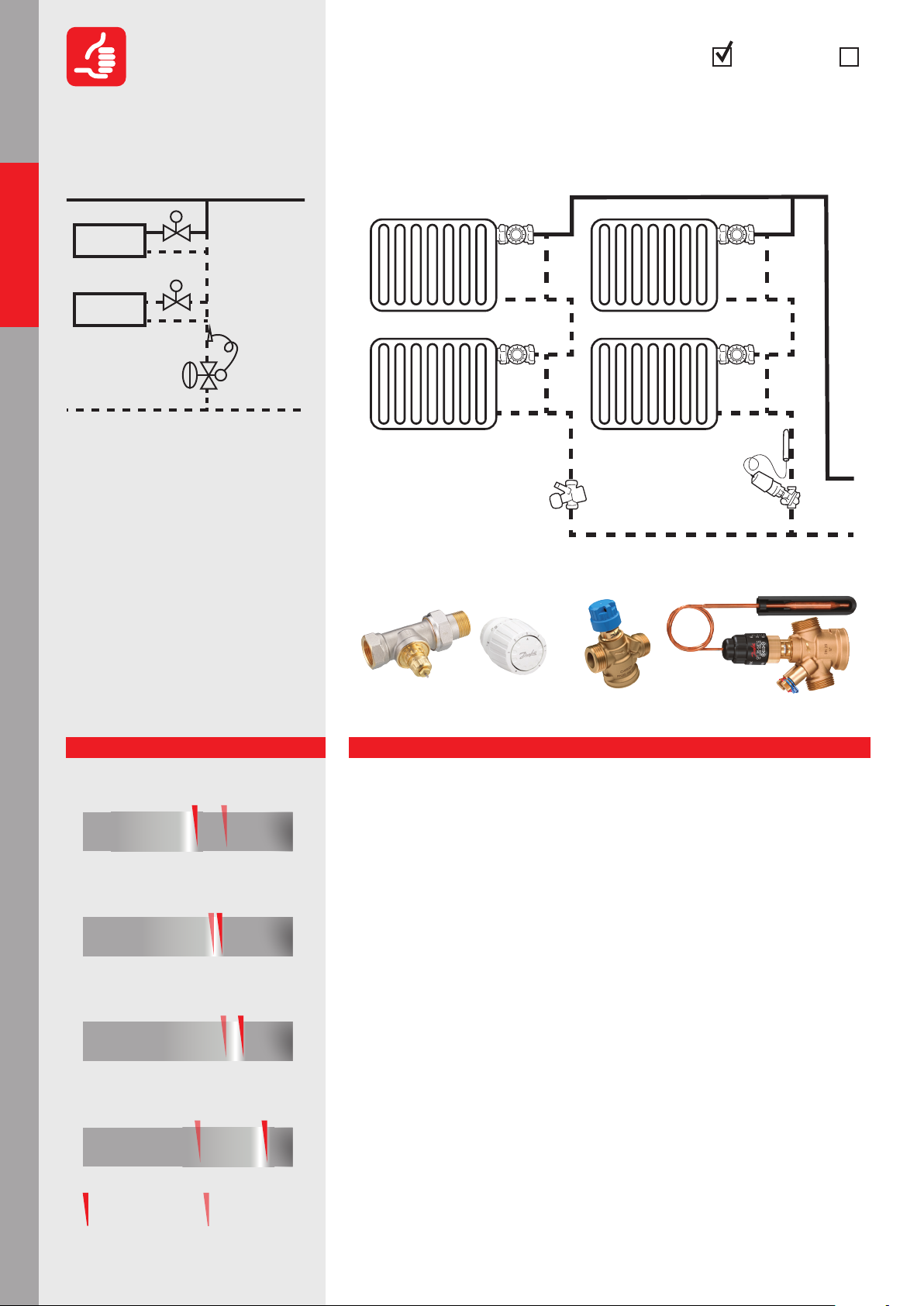

1.2.1.1

4

11

CoolingHeating

Two-pipe radiator heating system – risers

with, thermostatic radiator valves

(with presetting)

TRV-2

TRV-1

Mixing loop

AHU cooling

AHU applications

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

3

1. Termostatic Radiator Valve (TRV)

2. Return Locking Valve (RLV)

3. Δp controller (DPCV)

4. Partner valve*

In this application we ensure variable

ow* on risers with thermostatic radiator

valves. In case of presetting available

on TRV, ΔP controller used without ow

limitation on the riser.

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

2 2

acceptable

acceptable

acceptable

excellent

excellent

excellent

DPCV

Danfoss products:

TRV-1: RA build in + RA TRV-2: RA-N + RA

Explanation

DPCV

DPCV: ASV-PV+ASV-BD

Return of investment

• Δp controller is more expensive compared to manual balancing

• Commissioning is not needed only Δp setting on Δp controller and ow pre-setting on TRVs

• Variable speed pump is recommended

Design

• Simple calculation method, Δp controlled risers can be calculated as independent loops

(you can split the system by risers)

• The presetting calculation of radiators is needed,

• Kv calculation needed for Δp controller and control valve. Authority calculation also

needed for proper TRV operation

• The Δp demand of loop should be calculated and set according nominal ow and

system resistance

Operation/Maintenance

• Hydraulic regulation is in the bottom of risers and radiator presetting

• No hydronic interference among the risers

• Balancing at full and partial load – good – with TRV presetting

• Good eciency: increased ΔT on riser and variable speed pump ensures energy saving

Control

• The eciency of system good with individual presetting on radiators

• Low pumping costs – the ow rate of risers are limited.

• Maximum ΔT on risers

20

poor

acceptable

excellent

*see page 54-55

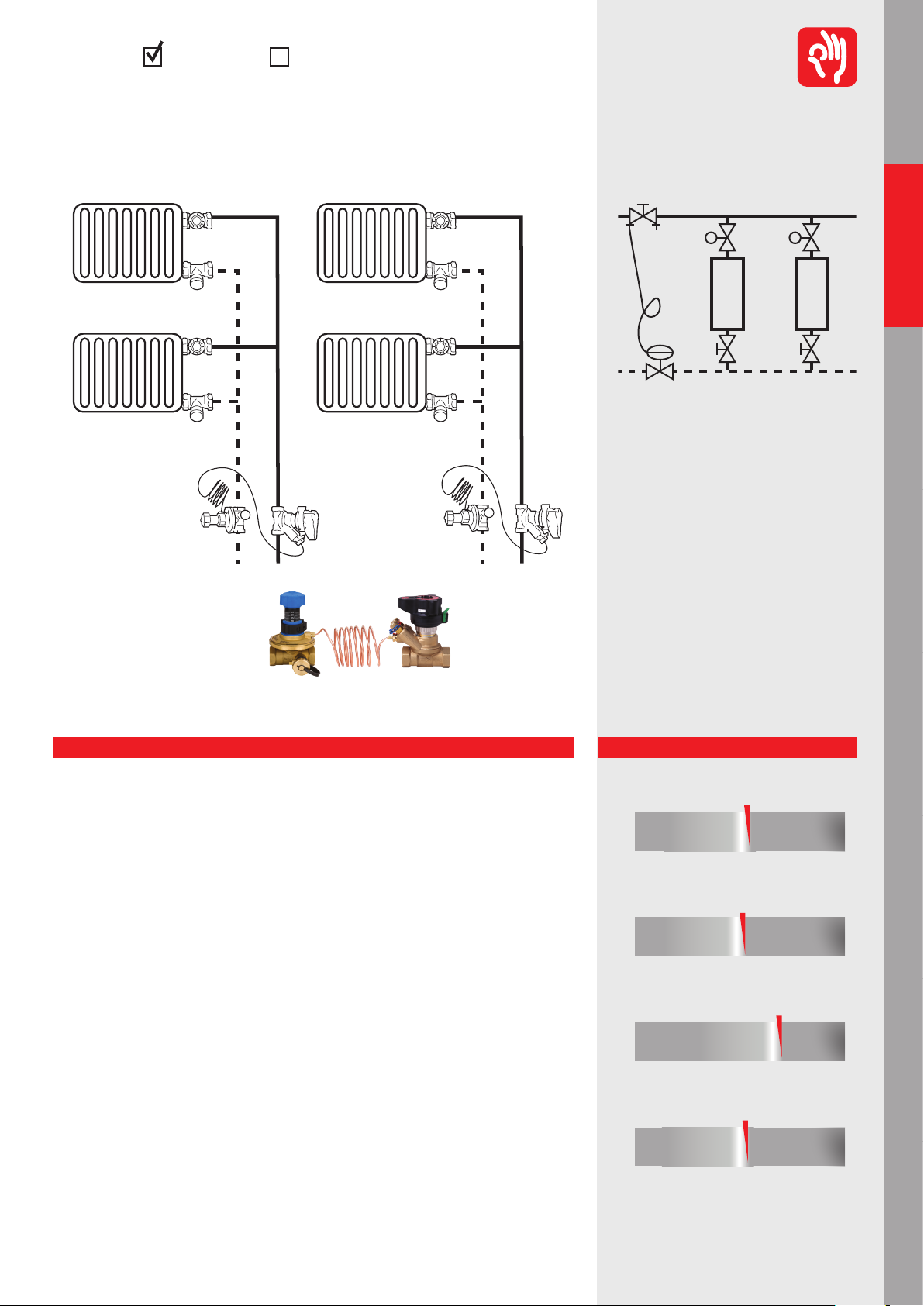

Page 21

CoolingHeating

TRV

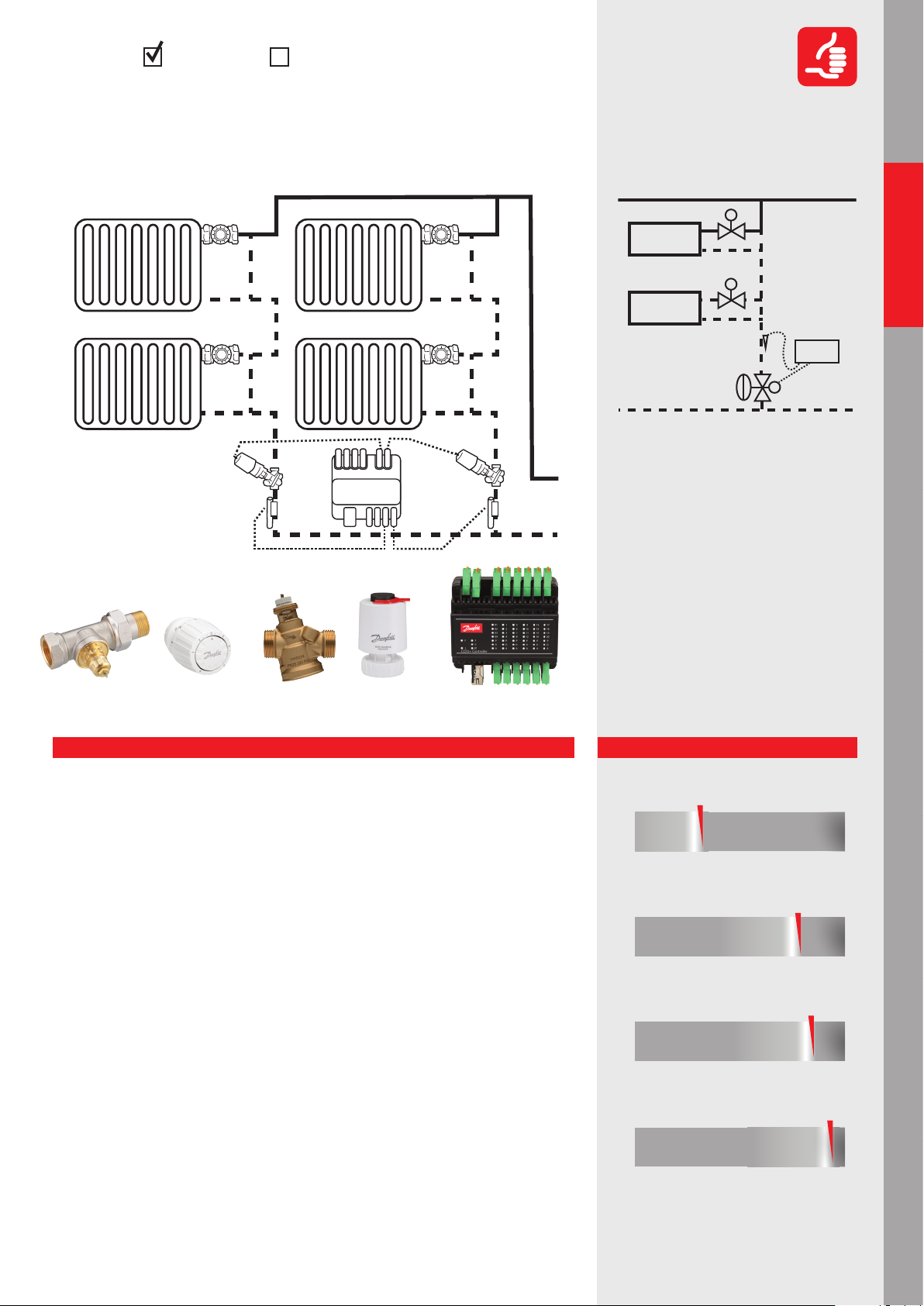

Two pipe radiator heating system – risers

Hydronic applications

Commercial

Acceptable

with, thermostatic radiator valves

(without presetting)

RLV-2

DPCV

1.2.1.2

Hydronic applications

Residential

4

11

3

2 2

Mixing loop

1. Termostatic Radiator Valve (TRV)

2. Return Locking Valve (RLV)

3. Δp controller (DPCV)

4. Partner valve*

AHU applications

AHU cooling

Danfoss products:

DPCV: ASV-PV+ASV-BD

Explanation

Return of investment

• Δp controller plus ow limitation is more expensive then manual balancing

• Commissioning* is needed for ow limitation on the bottom of riser plus dp setting on

Δp controller

• Variable speed pump is recommended

Design

• Simple calculation method, Δp controlled risers can be calculated as independent loops

(you can split the system by risers)

• The presetting calculation of partner valve* for ow limitation is required

• Kv calculation needed for Δp controller and control valve. Authority *checking is also

essential to know the control performance of TRV

• The Δp demand of loop should be calculated and set according nominal ow and

system resistance

Operation/Maintenance

• Hydronic regulation is at the bottom of risers only

• No hydronic interference among the risers

• Balancing at full and partial load is acceptable

• Acceptable eciency and variable speed pump ensures energy saving*

Control

• The ow limitation at the bottom of riser causes extra pressure drop within the Δp

controlled loop therefore higher overow appears during partial load (compared to

presetting on TRV )

• Higher pumping costs* – however the ow rate of risers is limited slight oveow occure

within the riser during partial load condition

• Acceptable ΔT on risers (lower comparing to presetting on TRV)

In this application we ensure variable*

ow on risers with thermostatic radiator

valves. No possibility of presetting on TRV,

ΔP controller used with ow limitation on

the riser with partner valve*.

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

AHU heating

Chillers applications Boilers applications Hot water

AHU applications

*see page 54-55

21

Page 22

Commercial

Hydronic applications

Recommended

1.2.1.3

CoolingHeating

Pressure Independent Control for radiator

heating system

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

1

3 4

1. Radiator Dynamic Valve (RDV)

2. Termostatic Radiator Valve (TRV)

3. Return Locking Valve (RLV)

4. Return Locking

Dynamic Valve (RLDV)

In this application Pressure Independent

Control Valves used in smaller radiator heating system combined with thermostatic

senor (self-acting proportional room

temperature control), give us a guarantee

that regardless of the pressure oscillation

inside the system, we will secure the right

ow, allowing the right amount of heat

to be delivered to the room. (Traditional

radiator or „H” piece connection available).

2

Danfoss products:

RDV

TRV-1: RA build in + RA

TRV

RLDV

RLDV: RLV-KDVRDV: RA-DV + RA

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

Explanation

Return of investment

• A minimal number of components is needed which means less installation costs

• Low complaint costs because of perfect balance and perfect control at all loads

• Highly energy eciency because of precise ow limitation at all loads

• High eciency of boilers and pumping because of high ∆T in the system

Design

• Easy selection of valves based only on ow requirement

• No Kv or authority* calculation is needed, presetting calculation is based on ow demand

• Perfect balance and control at all loads

• Proportional pump control is recommended, pump speed can be optimized easily

• This solution applicable up to max. 135 l/h ow rate on terminal unit and max 60 kPa

pressure dierence across the valve

• Min available Δp on the valve 10 kPa

Operation/Maintenance

• Simplied construction because of reduction of components

• Set and forget, no complicated balancing procedures are needed

• Changes of ow setting do not inuence the other users

• Flow verication is possible on the valve with special tool

Control

• Perfect control because of full authority*

• No overows*

• Fix 2K proportional Xp band

• Fully pressure independent so no interference from pressure uctuations and therefore

stable room temperatures*

22

*see page 54-55

Page 23

CoolingHeating

Subordinated risers (staircase, bathroom,

Hydronic applications

Commercial

Recommended

etc.) in two- or one-pipe radiator heating

system without thermostatic valve

TRV

RLV

PICV

+QT

Danfoss products:

TRV: RA-N+RA PICV+QT: AB-QT

1.2.1.4

1

2

3

1. Radiator Valve (without sensor) (RV)

2. Pressure Independent Control Valve

(PICV)

3. Temperature Sensor (QT)

In this application we have theoretical

constant ow* on subordinated risers and

no thermostatic sensor on radiator valve

(like staircase, bathroom etc.) For better

eciency we ensure variable ow* in case

of partial load condition when the return

temperature is increasing, with return

ow temperature limitation.

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

AHU applications

AHU heating

Explanation

Return of investment

• QT (temperature limiter sensor) is an extra cost (ow limiter is recommended in any case)

• Commissioning of the system is not required only setting of ow on PICV and temperature on QT

• VSD pump is recommended

Design

• Simple calculation is required for riser ow, based on heat demand and ΔT, the size of

radiator, convector has to be designed accordingly

• The ow is controlled by return temperature signal

• The presetting calculation of radiator is crucial due to no room temperature controller,

the heat emission will depend on ow rate and size of radiator. The presetting calculation is based on ow rate among radiators and pressure drop of pipeline

• Simplied hydraulic calculation (you can split the system by risers)

Operation/Maintenance

• No overheating on riser during partial load condition (strongly recommended for

renovation)

• Good balancing at full and partial load - additional energy saving*

• Higher eciency, limited return temperature and variable speed pump ensures energy saving*

Control

• Inner rooms (typically bathrooms) have constant heat demand, to keep constant heat

output, with increasing ow temperature, QT reduces the ow rate.

• Less overheating of risers – energy saving*

• ΔT increasement ensures lower heat loss and better heat production eciency

• LOW pumping costs* – the ow rate of subordinated risers are limited and reduced

even more with temperature limitation by QT

• Limited eciency of QT control when ow temperature drops. Electronic controller

(CCR3+) increases eciency at higher outdoor temperature.

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

Chillers applications Boilers applications Hot water

excellent

excellent

excellent

excellent

*see page 54-55

23

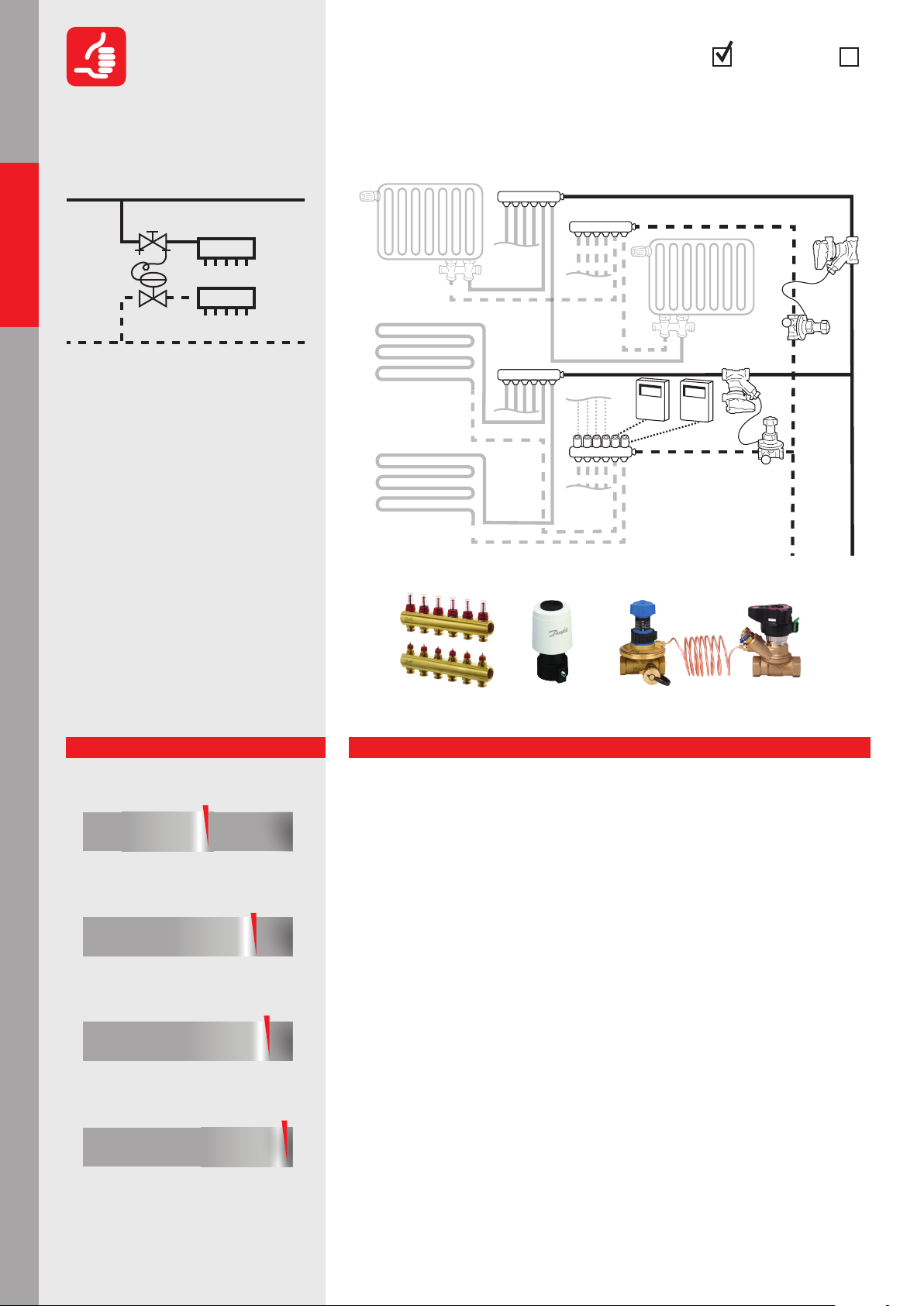

Page 24

Commercial

Hydronic applications

Residential

Hydronic applications

Mixing loop

Recommended

1.2.1.5

2

3

1

1. Δp controller (DPCV)

2. Partner valve*

3. Manifold with presettable valves

CoolingHeating

Δp control for manifold with individual

zone/loop control

RC

DPCV

AHU cooling

AHU applications

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

In this application we ensure variable

ow* in the distribution pipeline and

constant dierential pressure on each

manifold independently from temporal

load and pressure uctuation in the

system. Applicable for both radiator and

oor heating systems.

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

Danfoss products:

Manifold: FHF + TWA-A

Explanation

DPCV: ASV-PV + ASV-BD

Return of investment

• Beside manifold we need DPCV with partner valve*. Heat meter is often used for individual at connections

• Thermal actuator for zone control (oor heating) or thermostatic sensor (radiator)

• Commissioning is not needed, Δp setting and ow setting on manifold loops only

• With additional investment, the users’ comfort can be increased with individual, time

based wired or wireless room temperature control

• Variable speed pump is recommended

Design

• Simple DPCV sizing according kvs calculation and total ow demand of manifold

• Presetting calculation is needed for built in zone valves only

• The presetting of loops, limiting the ow to be ensured no under/overow on connections

Operation/Maintenance

• Reliable, pressure independent solution for individual at/manifold connection

• Partner valve* can have dierent functions like, impulse tube connection, shut o, etc.

• Flow setting can be done accurately via Δp setting on DPCV with heat meter

most often used

• NO noise risk thanks for Δp controlled manifolds

• High eciency, especially with individual programmable room control

Control

• Stable pressure dierence for manifolds

• Flow limitation is solved, no overow* or underow per connections

• Thermal actuators (oor heating) ensure manifold or individual time based room temperature zone control (ON/OFF) with suitable room controller

• Thermostatic sensor (radiator) ensures proportional room control with proper Xp band

24

*see page 54-55

Page 25

CoolingHeating

Δp control and ow limitation for manifold

Hydronic applications

Commercial

Recommended

with central zone control

Danfoss products:

Manifold: FHF

DPCV

RC

ABV: AB-PM +TWA-Q (optional)

1.2.1.6

1

2

1. Δp controller (DPCV)

2. Manifold with presettable valves

In this application we ensure variable

ow* in the distribution pipeline and

maximum pressure dierence on each

manifold independently from temporal

load and pressure uctuation in the

system. Furthermore, we limit the ow for

manifold and able to ensure zone control

with adding thermal actuator on DPCV.

Applicable for both radiator and oor

heating systems.

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

AHU applications

AHU heating

Explanation

Return of investment

• DPCV and impulse tube connection needed only. Heat meter often used for individual

at connection

• Thermal actuator for zone control as option (installed on DPCV)

• Individual zone control (oor heating) or thermostatic sensor (radiator) also possible

• Installation time can be reduced with usage of set solution

• Commissioning is not needed, ow setting on DPCV only and presetting of each loop

• Variable speed pump is recommended

Design

• Simple, no kvs and authority* calculation, valve selection based on ow rate and Δp

demand of loop

• Presetting calculation is needed for built-in zone valves (if there are)

• The presetting of ow limitation ensures no under/overow on manifold

• Pump head calculation is very simple, min available pressure dierence for DPCV

(included the loop Δp) is given

Operation/Maintenance

• Reliable, pressure independent solution for individual at connection

• Partner valve* – if applied - can have dierent functions like, impulse tube connection,

shut o, etc.

• No noise risk thanks to Δp controlled manifold

• High eciency, especially with individual programmable room control

Control

• Maximized pressure dierence for manifold

• Flow limitation is solved, no overow* or underow per connections

• ...but slight overow within the loop during partial load

• Thermal actuator ensures zone control (ON/OFF) with suitable room controller

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

Chillers applications Boilers applications Hot water

excellent

excellent

excellent

excellent

*see page 54-55

25

Page 26

Commercial

Hydronic applications

Recommended

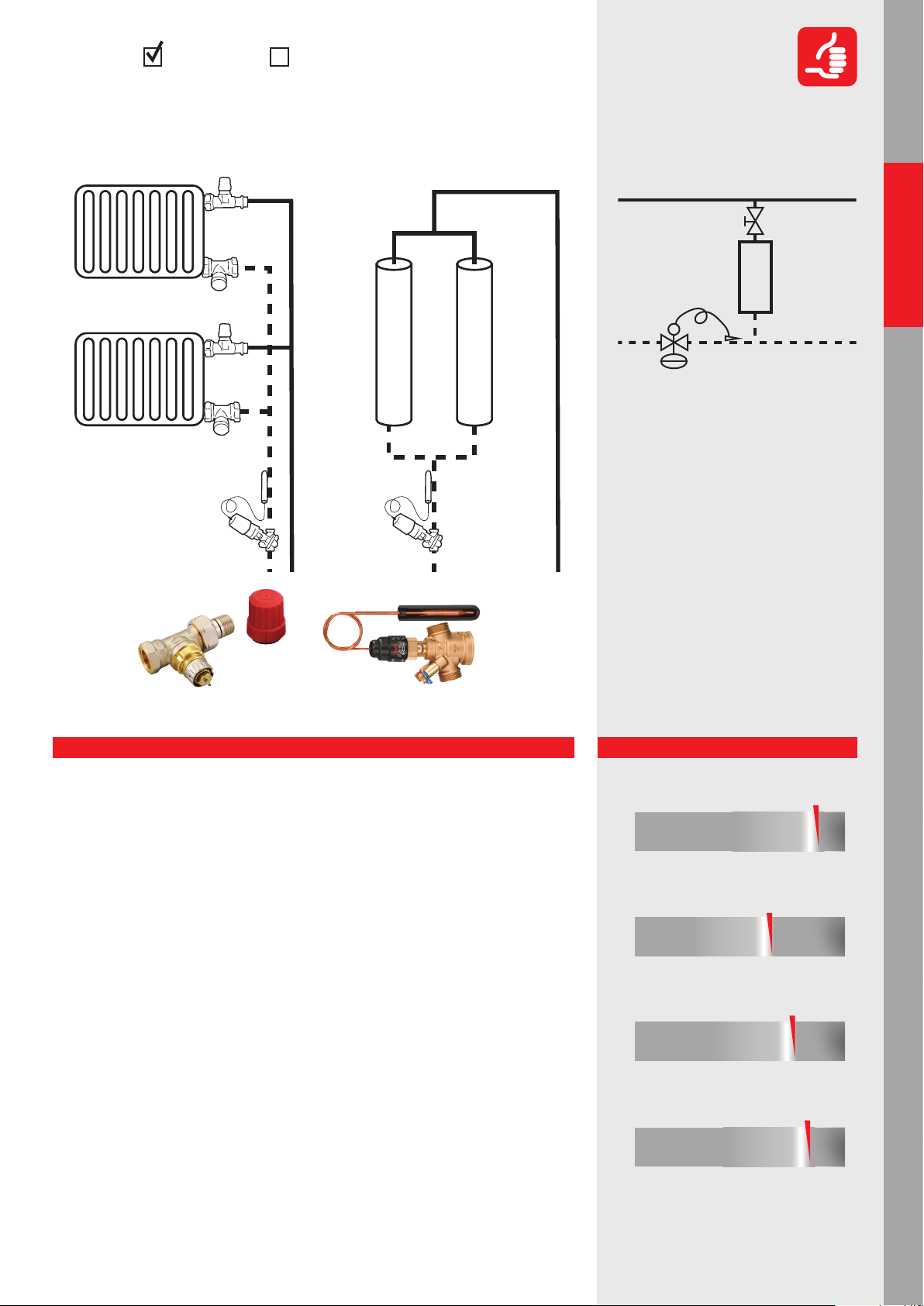

1.2.2.1

CoolingHeating

One-pipe radiator heating system renovation

with automatic ow limitation and possible

self-acting return temperature limitation

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

1

1

3

2

1. Radiator Valve (TRV )

2. Pressure Independent Control Valve

(PICV)

3. Optional - Temperature Sensor (QT)

This application is suitable for renovating

of vertical one-pipe radiator heating

system. We recommend high capacity

thermostatic radiator valve and ow

limiter installation on riser. For better

eciency we optionally recommend to

use return temperature control with QT

(Thermostatic Sensor)

Danfoss products:

TRV

PICV

PICV: AB-QM

PICV+QT

PICV+QT: AB-QTTRV: RA-G + RA

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

With QT Without QT

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

Explanation

Return of investment

• Investment cost are higher (thermostatic radiator valve + ow limiter + QT on risers)

compared to manual balancing

• Simple QT installation with low extra cost

• No commissioning* demand only ow setting

• Variable speed pump is recommended (without QT the pump control is not needed)

Design

• „α” (radiator share) calculation with iteration

• Big capacity TRV is needed to increase the „α”

• Radiator size depends on ow temperature changes

• Gravitation eect should be taken into account

• Simple hydronic calculation regarding riser controller, selection based on ow rate but

we need to ensure the minimum available pressure on it

• QT setting depends on system conditions

Operation/Maintenance

• System less sensitive for gravitation eect due to ow limitation

• „α” (radiator share) sensitive for installation punctuality

• Real constant ow* without QT, variable ow* with QT

• QT contributes to energy saving* on pumping

• QT ensures more accurate heat cost allocation

Control

• Accurate and simple water distribution among risers

• Improved room temperature control

• The radiator heat emission depends on varying ow temperature

• Heat gain from pipe in the rooms aects the room temperature

• QT eect is limited in case of higher outdoor temperature

26

*see page 54-55

Page 27

CoolingHeating

One-pipe radiator heating system renovation

Hydronic applications

Commercial

Recommended

with electronic ow limitation and return

temperature control

TRV

PICV

CCR3+

TS

1.2.2.2

1

1

4

2

1. Radiator Valve (TRV )

2. Pressure Independent Control Valve

(PICV)

3. Elecrtonic Controller (CCR3+)

4. Temperature sensor (TS)

3

CCR3+

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

Danfoss products:

TRV: RA-G + RA

Explanation

PICV: AB-QM+TWA-Q CCR3+

Return of investment

• High investment cost (thermostatic radiator valve + ow limiter with thermal actuator,

sensor on risers + CCR3+)

• Electronic wiring is needed, programing CCR3+

• No commissioning* demand only ow setting

• Variable speed pump is recommended

Design

• „α” (radiator share) calculation with iteration

• Big capacity TRV is needed to increase the „α”

• Radiator size depends on ow temperature changes

• Gravitation eect should be taken into account

• Simple hydronic calculation regarding riser controller, selection based on ow rate but

we need to ensure the minimum available pressure on it

• Dening of needed return characteristic

Operation/Maintenance

• The system less sensitive for gravitation eect due to ow limitation

• „α” (radiator share) sensitive for installation punctuality

• Programming CCR3+, data logging, remote maintenance and access

• Higher eciency due to improved ΔT, and reduced pipe heat loss

Control

• Accurate and simple water distribution among risers

• Improved room temperature control

• The radiator heat emission depends on varying ow temperature

• Heat gain from pipe in the rooms aects the room temperature

• CCR3+ Weather compensation on return temperature on all individual risers

This application is suitable for renovating

of vertical one-pipe radiator heating

system. We recommend high capacity

thermostatic radiator valve and ow limiter installation on riser. For best eciency

we recommend to use CCR3+ (Electronic

Controller)

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

AHU heating

Chillers applications Boilers applications Hot water

AHU applications

*see page 54-55

27

Page 28

Commercial

Hydronic applications

Not Recommended

1.2.2.3

CoolingHeating

One-pipe radiator heating system renovation with manual balancing

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

1

1

2

1. Radiator Valve (TRV )

2. Manual Balancing Valve (MBV)

This application is suitable for renovating

of vertical one-pipe radiator heating system. Many one-pipe system are renovated

based on thermostatic radiator valves and

manual balancing valves. It is not recommended due to its low eciency.

TRV

MBV

Danfoss products:

MBV: MSV-BDTRV: RA-G +RA

AHU heating

AHU applications

Chillers applicationsBoilers applicationsHot water

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

Explanation

Return of investment

• Medium investment cost (thermostatic radiator valve + manual balancing)

• Commissioning* is needed

• Complains can occur when not proper commissioning

• Traditional constant speed pump is acceptable

Design

• Dicult sizing of hydronic, presetting calculation of MBV is important

• „α” (radiator share) calculation with iteration

• Big capacity TRV is needed to increase the „α”

• Radiator size depends on ow temperature changes

• Gravitation eect should be taken into account

Operation/Maintenance

• System sensitive for gravitation eect (over/under pumping) during operation

• „α” (radiator share) sensitive for installation accuracy

• Not real constant ow*, the ow rate can vary 70-100% according to the radiator

valve operation

• High pumping energy consumption due to „constant” ow

• Inecient system, during partial load (when TRVs are closing) too high inlet temperature into radiators and overall return temperature

Control

• Inaccurate room temperature control

• The radiator heat emission depends on varying ow temperature

• Heat gain from pipe in the rooms aects the room temperature

• Inaccurate heat cost allocation

28

*see page 54-55

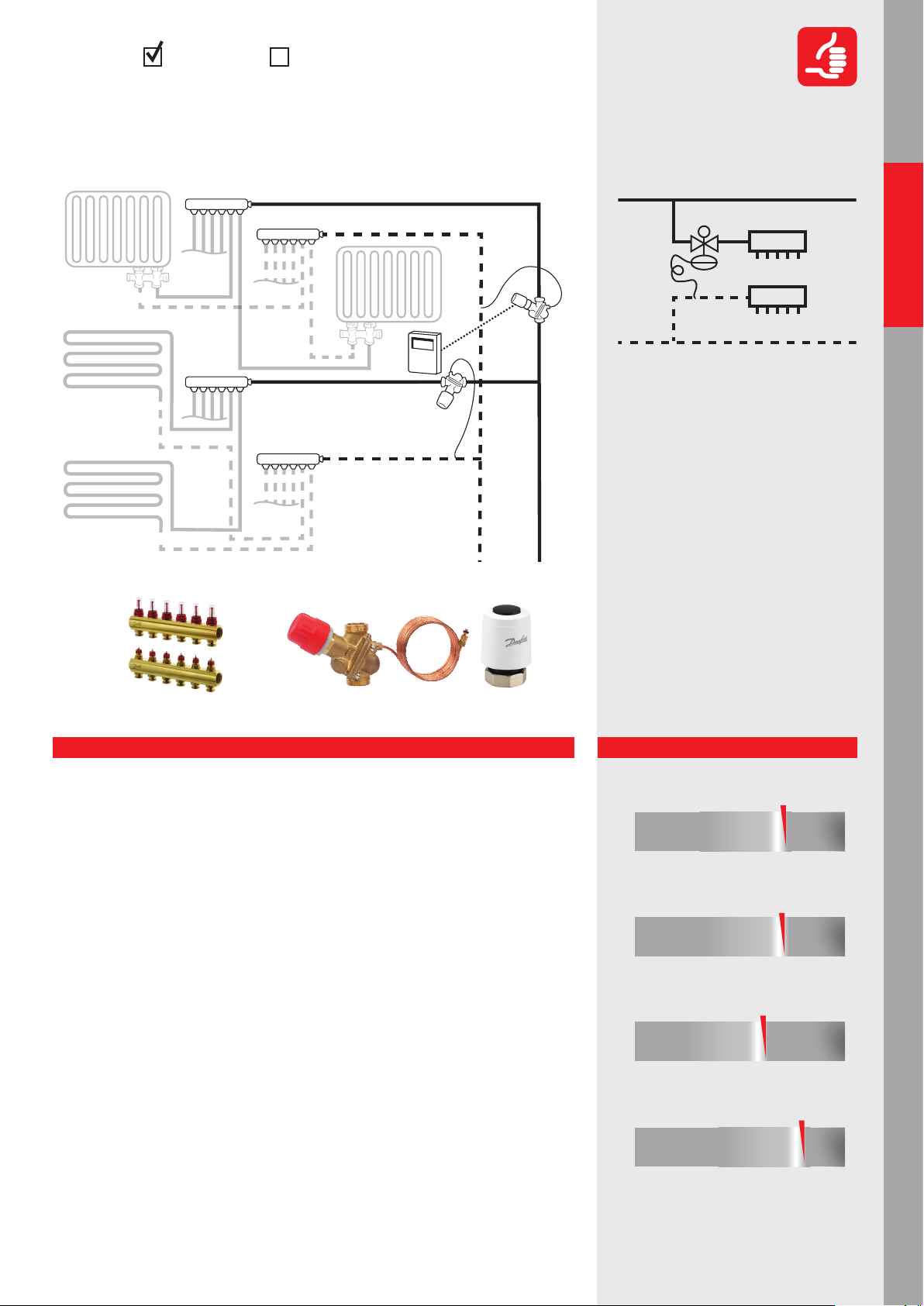

Page 29

CoolingHeating

One-pipe horizontal heating systems with

Hydronic applications

Commercial

Acceptable

thermostatic radiator valves, ow limitation

and return temperature self-acting control

TRV

PICV + QT

TRV

1.2.2.4

1

2

3

1. Radiator Valve (TRV )

2. Pressure Independent

Control Valve (PICV)

3. Temperature Sensor (QT)

Hydronic applications

Residential

Mixing loop

AHU applications

AHU cooling

Danfoss products:

TRV: RA-KE +RA

Explanation

PICV+QT: AB-QT

Return of investment

• Investment cost – good (thermostatic radiator valve + ow limiter + QT on risers)

• Less valves than in case of manual balancing, lower installation costs

• Simple QT installation and setting. (Re-set recommended based on operational experience)

• Commissioning* of the system not required (only ow and temperature setting)

• Variable speed pump is recommended

Design

• Traditional radiator connection. „a” (radiator share) eect on radiator selection

• Simplied hydraulic calculation, the loops are pressure independent

• No TRV presetting

• Return temperature setting on sensor of ow limiter according to system features

• Pump head calculation according to nominal ow and dp demand of ow limiter

• Heat metering applicable

Operation/Maintenance

• Minimal length of pipeline

• Higher pump head demand (vs. two pipe), due to minimum Δp on ow limiter, higher

pressure loss on pipeline, big Δp on radiator valve if no big Kvs selected

• The heat output of radiator depending on partial load condition due to varying inlet

temperature

• Optimization* of pump head is recommended (if variable pump control is available)

Control

• Thermostatic radiator valve has small Xp value

• Flow restriction in loop via QT when return temperature is increasing

• Loop ow demand is varying according to partial load condition

• Hydraulic regulation only at the end of loop, balancing at full and partial load – good

• Room temperature oscillation* occur s

In this application we ensure automatic

ow limitation for all heating circuits

and limit the return temperature with QT

(Thermostatic Sensor) to avoid small ∆T

in the loops during partial load. (More

ecient in case of lower outdoor temperature.)

Performance

Return of investment

poor

Design

poor

Operation/Maintenance

poor

Control

poor

acceptable

acceptable

acceptable

acceptable

excellent

excellent

excellent

excellent

AHU heating

Chillers applications Boilers applications Hot water

AHU applications

*see page 54-55

29

Page 30

1

Commercial

Hydronic applications

Recommended

1.2.3.1

Heating Cooling Water supply

Three-pipe, at station system; Δp controlled heating and local DHW* preparation

Residential

Hydronic applications

Mixing loop

AHU cooling

AHU applications

10

FLAT

STATION

5

4

2

1. Δp controller (DPCV)

2. Partner valve*

3. Heating return (primary)

4. Heating ow (primary)