Page 1

Data sheet

Data sheet

Hoses and fittings

Hoses and hose ttings

for APP pumps

www.ro-solutions.com

hpp.danfoss.com

Page 2

Data sheet | Hoses and hose ttings

Table of contents

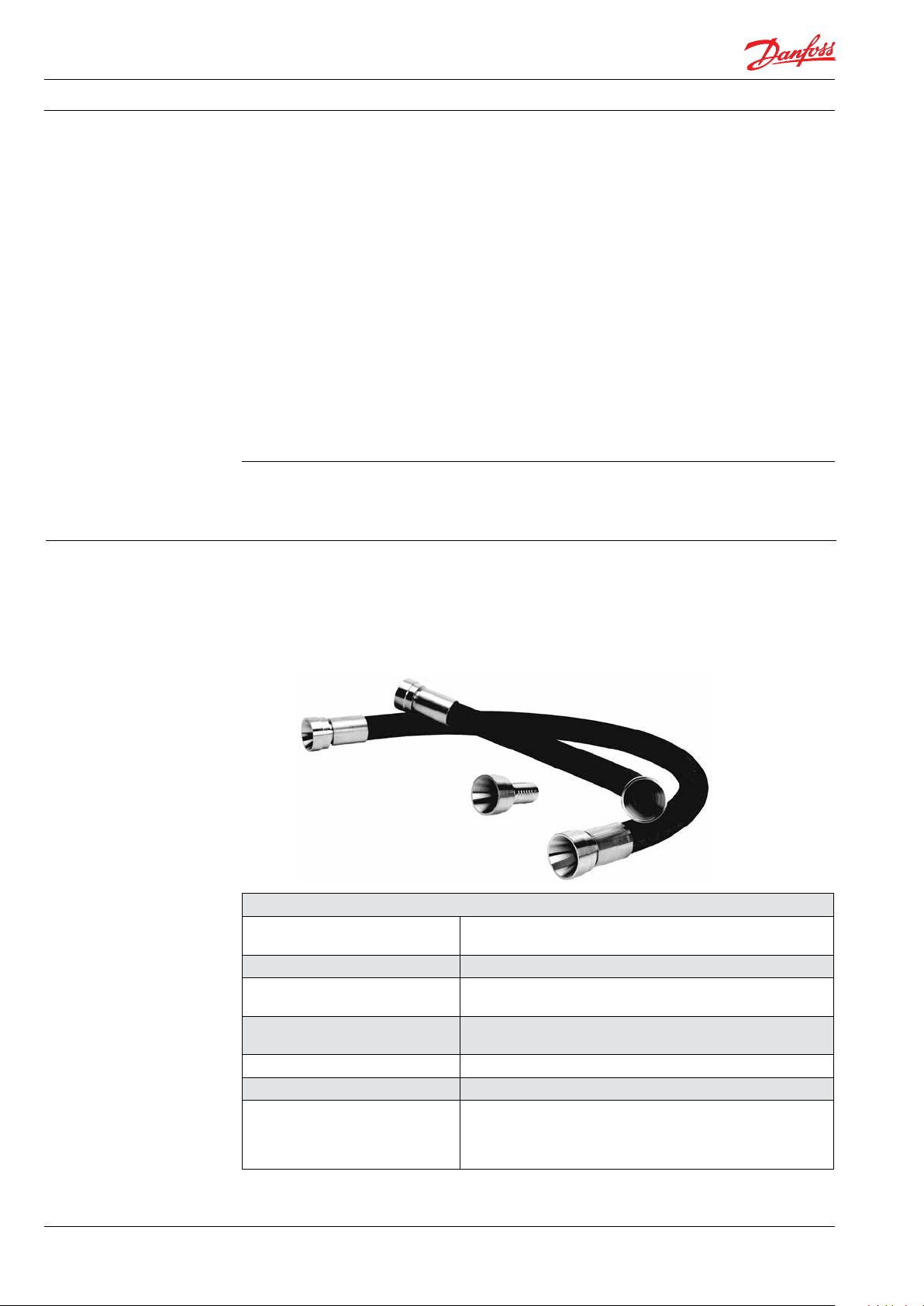

1. High-pressure hose

with Victaulic

(OGS cut groove)

Contents

Table of contents ...................................................................................2

1. High-pressure hose with Victaulic (OGS cut groove) .....................................2

2. 2” low-pressure hose kit with 2” Victaulic ................................................4

3. 3” low-pressure hose kit with 3” Victaulic ................................................6

4. Pump connections ......................................................................8

Victaulic® is a registered trademark of Victaulic Corporation Inc.

Introduction

The function of hoses with Victaulic® ends is to

connect the APP pumps with the rest of the

system in a exible and noise-reducing way.

Features

The hose assembly is produced with a nitrile

rubber high-pressure hose, highly exible, with

Victaulic ends made of Duplex/ Super Duplexstainless steel.

General conditions

Temperature

Fluid and ambient 2 - 50°C (35.6 - 112° F), storage -30 - 70° C

(-22 - 158°F)

Fluid Brackish, seawater and antifreeze solutions

UV resistant

Max. allowable working pressure

(MAWP)

Limited lifetime (annual inspection is recommended - max.

lifetime 5 years)

83 barg (1,200 psig)

Use only style 77DX coupling

1)

Test pressure 1.5 x MAWP according to ISO 1402, sec. 8.1

Test duration according to ISO 1402, sec. 8.1

Storage in a cool and dry location, protected from sunlight or

Storage

any articial light. The original packaging must be kept on as

long as possible, including caps protecting the ends of the

hoses.

1)

The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation Handbook

(htpp://static.victaulic.com)

2

AI319454706473en-000201 | 521B0909 | 10. 2019

Page 3

Data sheet | Hoses and hose ttings

Technical data

Code

number

Pipe connection1

[A]

Pipe connection material

180Z0228 1.5" Vic. OGS Super duplex

Hose size

Inner diam-

eter

25.4 mm (1.0") 0.66 m (26") 152 mm (6.08"), max. 90°

Hose length

ISO 1436

[B]

Bending radius

EN 1.4410

180Z0229 1.5" Vic. OGS Super duplex

25.4 mm (1.0") 1.16 m (45.7") 152 mm (6.08"), max. 180°

EN 1.4410

180Z0167 1.5" Vic. OGS Super duplex

38.0 mm (1.5") 1.16 m (45.7") 250 mm (9.84"), max. 180°

EN 1.4410

180Z014 0 2.0" Vic. OGS Super duplex

50 mm (2.0") 1.25 m (49") 630 mm (24.8"), max. 90°

EN 1.4410

180Z0263 2.5" Vic. OGS

)

Super duplex

50 mm (2.0") 1.78 m (70") 630 mm (24.8"), max. 180°

EN 1.4410

180Z0280 2.5" Vic. OGS Super duplex

50 mm (2.0") 1.00 m (39.4") 630 mm (24.8"), max. 90°

EN 1.4410

180Z0 619 2.5" Vic. OGS Super duplex

65 mm (2.5") 1.78 m (70") 200 mm (7.87"), max. 270°

EN 1.4410

180Z0618 2.5" Vic. OGS Super duplex

65 mm (2.5") 1.00 m(39.4") 200 mm (7.87"), max. 90°

EN 1.4410

180Z0612 3.0" Vic. OGS Super duplex

76 mm (3.0") 1.79 m (70.5") 250 mm (9.84"), max. 270°

EN 1.4410

18 0Z0611 3.0" Vic. OGS Super duplex

76 mm (3.0") 1.00 m (39.4") 250 mm (9.84"), max. 90°

EN 1.4410

180Z1000 3.0" Vic. OGS Super duplex

76 mm (3.0") 1,25 m (49") 250 mm (9.84"), max. 180°

EN 1.4410

180Z1001 3.0" Vic. OGS Super duplex

76 mm (3.0") 1,6 m (63") 250 mm (9.84"), max. 180°

EN 1.4410

1)

The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation Handbook (htpp://static.victaulic.com)

AI319454706473en-000201 | 521B0909 | 10.2019

3

Page 4

Data sheet | Hoses and hose ttings

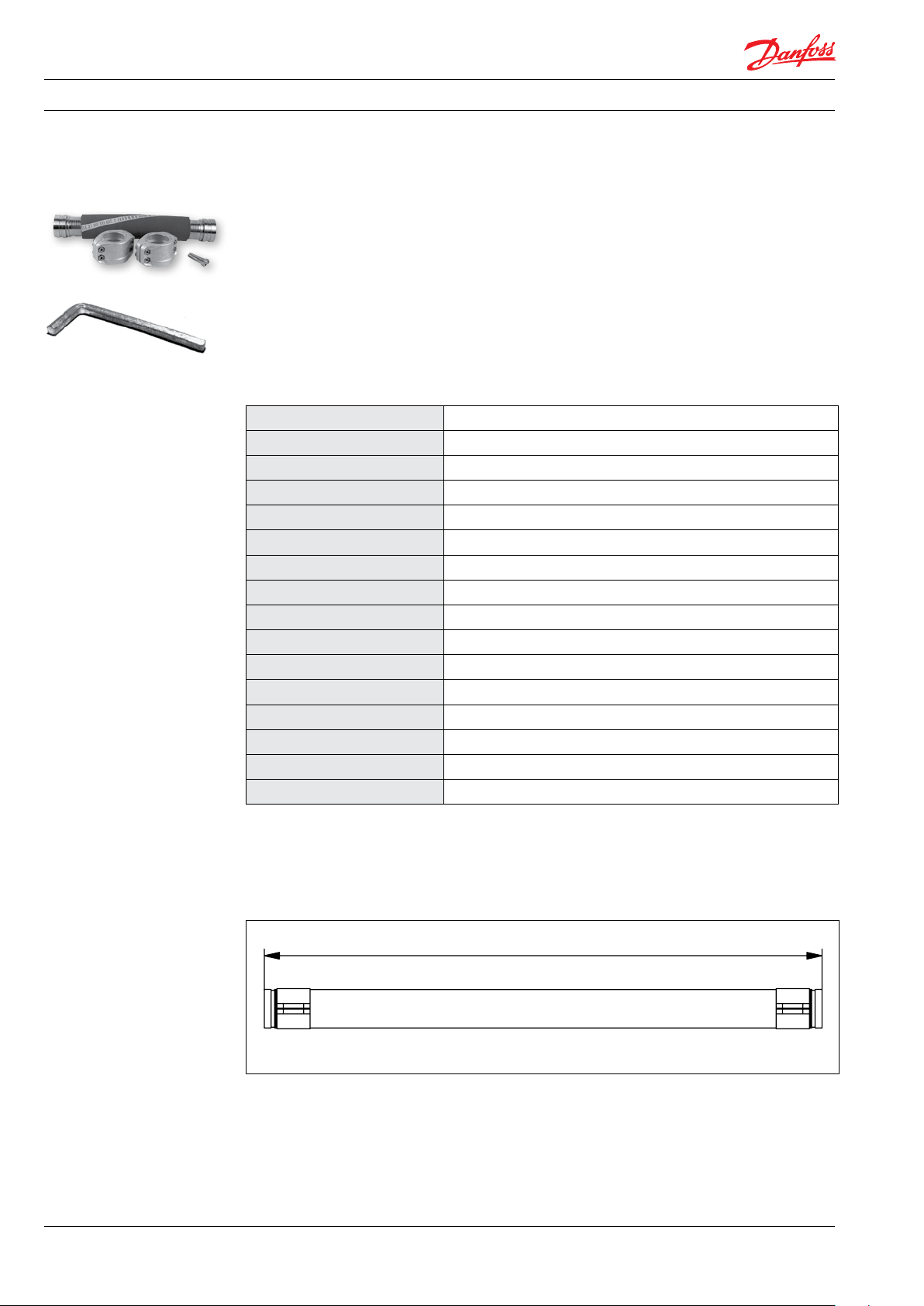

2. 2” low-pressure hose kit

with 2” Victaulic

Allen key (6mm)

Introduction

The function of hoses with Victaulic® ends is to

The allen key is used for assembling the hose

clamps.

connect the APP pumps with the rest of the

system in a exible and noise-reducing way.

The hose clamps secure the hose/hosetail

connection and prevent the hose from being

Features

torn o the hosetails.

The hose assembly is produced with a rubber

low-pressure hose, highly exible, and with two

2” Victaulic ends made of Super Duplex stainless

steel.

The hose can be reduced to t the length

required as long as the minimum bend radius is

observed. The longer the hose is the more

pulsation dampening eect it has.

Technical data

Code numbers

180Z0298 Low-pressure hose kit

Hose FDA Tilt.21 - item 177.2600 and BFR XXI Cat. 2

Inner diameter 50.8 mm (2”)

Min. bend radius 170 mm (6.7”)

Materials Chloridebutyl rubber (IIR)

UV resistant Limited lifetime

Max. working pressure 10 barg (145 psig)

Hosetails (connections)* 2” Victaulic OGS cut groove

Materials Super Duplex EN1.4410

Hose with Victaulic ends

Length (A) 2.135 m (84”)

Temperature 0 to + 50°C (32 to +122°F)

* Please see next page

A

Hose kit (assembled)

4

AI319454706473en-000201 | 521B0909 | 10. 2019

Page 5

Data sheet | Hoses and hose ttings

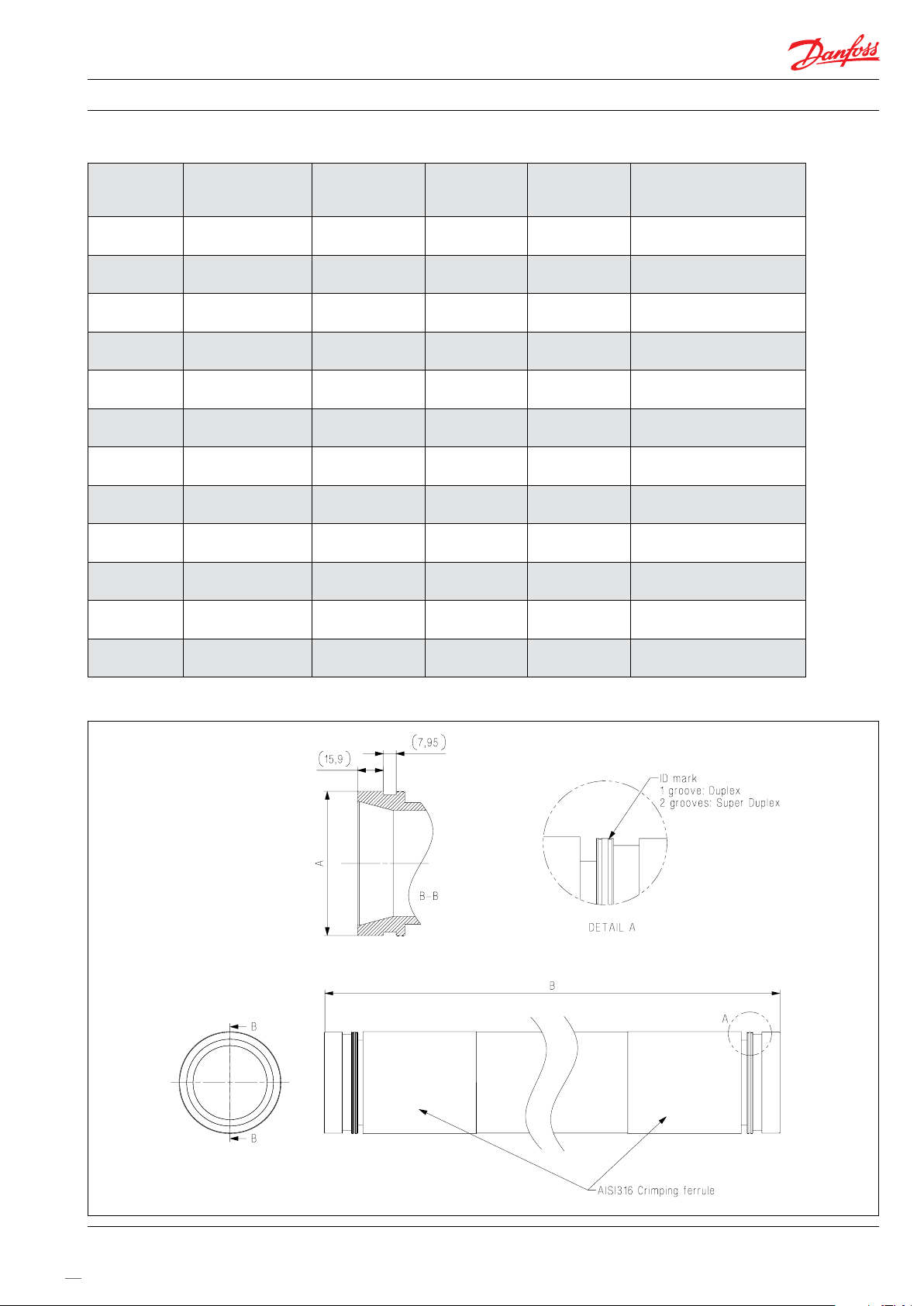

3” Victaulic

Ø 60.3 [ 2.375]

89[3.5]

7.95 [0.313] 15.9 [0.626]

44[1.73]

Ø 50 [1.968]

2x Hosetail

AI319454706473en-000201 | 521B0909 | 10.2019

5

Page 6

Data sheet | Hoses and hose ttings

3. 3” low-pressure hose kit

with 3” Victaulic

Allen key (6mm)

Introduction

The function of hoses with Victaulic® ends is to

connect the APP pumps with the rest of the

system in a exible and noise-reducing way.

The Allen key is used for assembling the hose

clamps. The hose clamps secure the hose/

hosetail connection and prevent the hose from

being torn o the hosetails.

Features

The hose assembly is produced with a rubber

low-pressure hose, highly exible, and with two

3” Victaulic ends made of Super Duplex stainless

steel.

The hose can be reduced to t the length

required as long as the minimum bend radius is

observed. The longer the hose is the more

pulsation dampening eect it has.

Technical data

Code numbers

180Z014 4 Low pressure hose kit

Hose FDA Tilt.21 - item 177.2600 and BGA XXI Cat. 2

Inner diameter 76.2 mm (3”)

Min. bend radius 300 mm (11.8")

Materials Chloridebutyl rubber (IIR)

UV resistant Limited lifetime

Max. working pressure 10 barg (145 psig)

Hosetails (connections) * 3” Victaulic OGS cut groove

Materials Super Duplex EN1.4410

Hose with Victaulic ends

Length (A) 2.135 m (84”)

Temperature 0 to + 50°C (32 to +122°F)

* Please see next page

A

Hose kit (assembled)

6

AI319454706473en-000201 | 521B0909 | 10. 2019

Page 7

Data sheet | Hoses and hose ttings

Ø 88.9 [ 3.5]

3” Victaulic

116 [4. 57 ]

70.9 [2.79]

Ø 76 [2.99]

7.95 [0.313] 15.9 [0.626]

2x Hosetail

AI319454706473en-000201 | 521B0909 | 10.2019

7

Page 8

Data sheet | Hoses and hose ttings

4. Pump connections

A

B

C

[B]

1)

Length

[C]

45 mm

(1.77” )

103 mm

(4.05”)

103 mm

(4.05”)

115 mm

(4.53”)

163 mm

(6.42”)

Material Max.

Pressure

Duplex 80 barg

(1160 psi g)

Super

Duplex

Super

Duplex

80 barg

(1160 psi g)

80 barg

(1160 psi g)

Duplex 80 barg

(1160 psi g)

Super

Duplex

80 barg

(1160 psi g)

To be used for

APP 5.1-10.2

APP 5.1-10.2

APP 11-13

APP 16-22

APP 21-26

APP 30-46

Code No. Thread

Victaulic

[A]

180B3202 M42 1.5” Vic. OGS

(48.3 mm)

180Z0166 M42 2.0” Vic. OGS

(60. 3 mm)

180Z0165 M52 2.0” Vic. OGS

(60. 3 mm)

180B3206 M60 2.5“ Vic. OGS

(73.1 mm)

180B3208 M60 3.0” Vic. OGS

(89.0 mm)

1)

The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation Handbook

(htpp://static.victaulic.com)

Code No. Outside

thread

(A)

180B3209 3/4” M42 38 mm

8

AI319454706473en-000201 | 521B0909 | 10. 2019

Inside

thread

(B)

Length

(C)

(1.50” )

Material Max.

Pressure

Duplex 80 barg

(1160 psi g)

To be used for

APP 1.5-3.5

Page 9

Data sheet | Hoses and hose ttings

Code No. Outside

thread

(A)

180Z0624 M60 M60 74 mm

Important:

If the rubber dampener is deselected an extension must be used together with a non return valve.

Inside

thread

(B)

Length

(C)

(2.913”)

Material Max.

Super

Duplex

Pressure

120 barg

(174 0 ps ig)

To be used for

APP 21-46

APP W HC

21-30

Code No. For hose

size

(A)

180B3205 1.5” M42 60 mm

180Z0059 2.0” M42 60 mm

AI319454706473en-000201 | 521B0909 | 10.2019

Thread size

(B)

Length

(C)

(2.83”)

(2.83”)

Material Max.

Pressure

Duplex 6 barg

(87 psig)

Duplex 10 barg

(145 psig)

To be used for

APP 5.1-10.2

APP 11-13

9

Page 10

Data sheet | Hoses and hose ttings

C

B

(B)

1)

Total length

(C)

89 mm

(3.50 inch)

116 mm

(4.57 inch)

Material Max.

Super Duplex 10 barg

Super Duplex 10 barg

Code No. For hose size

Victaulic size

(A)

180Z0297 2.0” 2.0” Vic. OGS

(60. 3 mm)

180Z0061 3.0” 3.0” Vic. OGS

(89.0 mm)

1)

The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation Handbook

(htpp://static.victaulic.com)

A

Pressure

(145 psig)

(145 psig)

10

AI319454706473en-000201 | 521B0909 | 10. 2019

Page 11

Data sheet | Hoses and hose ttings

Inlet 3" Vic. OGS

Outlet 3" Vic. OGS

[B]

1)

Length

[C]

61.0 mm

(2.40” )

65.0mm

(2.56”)

Material Max.

Pressure

Super

Duplex

Super

Duplex

10 barg

(145 psig)

80 barg

(1160 psi g)

To be used for

APP 53-86

(up to series 7)

APP 53-86

(up to series 7)

Code No. Diameter

Victaulic

[A]

180Z0654

Inlet

180Z0655

Outlet

1)

The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation Handbook

(htpp://static.victaulic.com)

87.8 m m

(3.46")

87.8 m m

(3.46")

3” Vic. OGS

(76.1 mm)

3” Vic. OGS

(76.1 mm)

AI319454706473en-000201 | 521B0909 | 10.2019

11

Page 12

Inlet 3" Vic. OGS

Outlet 3" Vic. OGS

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2019.10

[B]

1)

Length

[C]

61.0 mm

(2.40” )

65.0mm

(2.56”)

Material Max.

Pressure

Super

Duplex

Super

Duplex

10 barg

(145 psig)

80 barg

(1160 psi g)

To be used for

APP 53 - 92

(series 08 or higher)

APP 53 -92

(series 08 or higher)

Code No. Diameter

Victaulic

[A]

180Z1991

Inlet

180Z1992

Outlet

1)

The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation Handbook

(htpp://static.victaulic.com)

87.8 m m

(3.46")

87.8 m m

(3.46")

3” Vic. OGS

(76.1 mm)

3” Vic. OGS

(76.1 mm)

AI319454706473en-000201 | 521B0909 | 12

Loading...

Loading...