Page 1

Instruction

Instruction

Right and wrong

Right and wrong

Hose assembly routing tips

Hose assembly routing tips

danfoss.high-pressurepumps.com

hpp.danfoss.com

Page 2

Instruction | Right and wrong - Hose assembly routing tips

HOSES & HOSE COUPLINGS

GS-HYDRO PRODUCT CATALOGUE

Assembly and installation

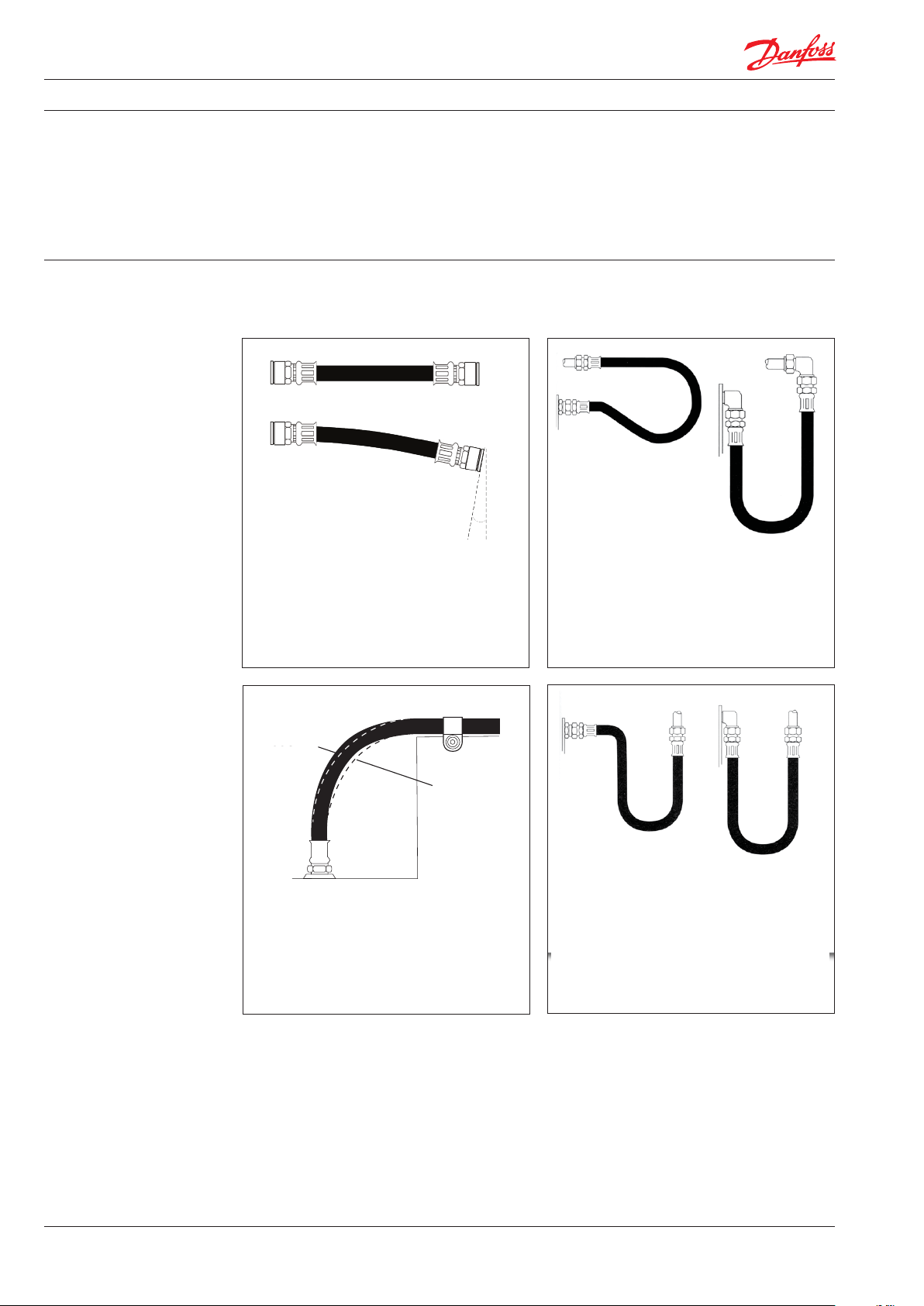

When hose installation is straight, allow enough slack in hose

line to provide for length changes which will occur when pres-

sure is applied.

Prevent twisting and distortion by bending hose in same plane as

the motion of the boss to which hose is connected.

User proper angle adaptors to avoid sharp twist or bend in hose. Adequate hose length is necessary to distribute movement on

flexing applications and to avoid abrasion.

When radius is below the required minimum, use an angle adap-

tor to avoid sharp bends.

Avoid twisting of hose lines bent in two planes by clamping hose

at change of plane.

Hose assembly routing tips

HOSES & HOSE COUPLINGS

GS-HYDRO PRODUCT CATALOGUE

Assembly and installation

When hose installation is straight, allow enough slack in hose

line to provide for length changes which will occur when pres-

sure is applied.

Prevent twisting and distortion by bending hose in same plane as

the motion of the boss to which hose is connected.

Avoid twisting of hose lines bent in two planes by clamping hose

at change of plane.

Hose assembly routing tips

HIGH

PRESSURE

NO

PRESSURE

Correct hose installation is essential for safe and

satisfactory performance. The size of the hoses

impacts the installation recommendations. This

manual has therefore been split in recommendation for hoses up to 2” and recommendation

larger than 2”.

1. Hoses up to 2” When installing hoses, avoid twisting the hose as

the hose will try to straighten under pressure.

MIN. 10°

Always provide some angle on straight

hose installations, this reduces forces

and ensures that hose is only bending i

one direction. The Hose must have some

slack to compensate for hose length

variations.

Hose routing tips:

Danfoss recommends installing hose whip

restraints whenever your pressurized hose

assemblies are in proximity to personnel or

crucial equipment.

Check with these examples when installing

your hoses.

This can cause hose failure via hose blowout

from the tting and/or hose burst at the point of

strain.

WRONG

RIGHT

When radius is below the required minimum, use an angle adap-

tor to avoid sharp bends.

At radius below required minimum, angle

adapters should be used to prevent sharp

hose bends.

NO

PRESSURE

To allow the hose to expand when

pressurized, clamps should not be used at

bends. If possible, do not clamp high and

low pressure lines together.

HIGH

PRESSURE

WRONG

RIGHT

Use proper angle adapters to avoid sharp twist

or bend of hose.

2

180R9434 | AN375455762639en-00 0201 | 07.2021

Page 3

Instruction | Right and wrong - Hose assembly routing tips

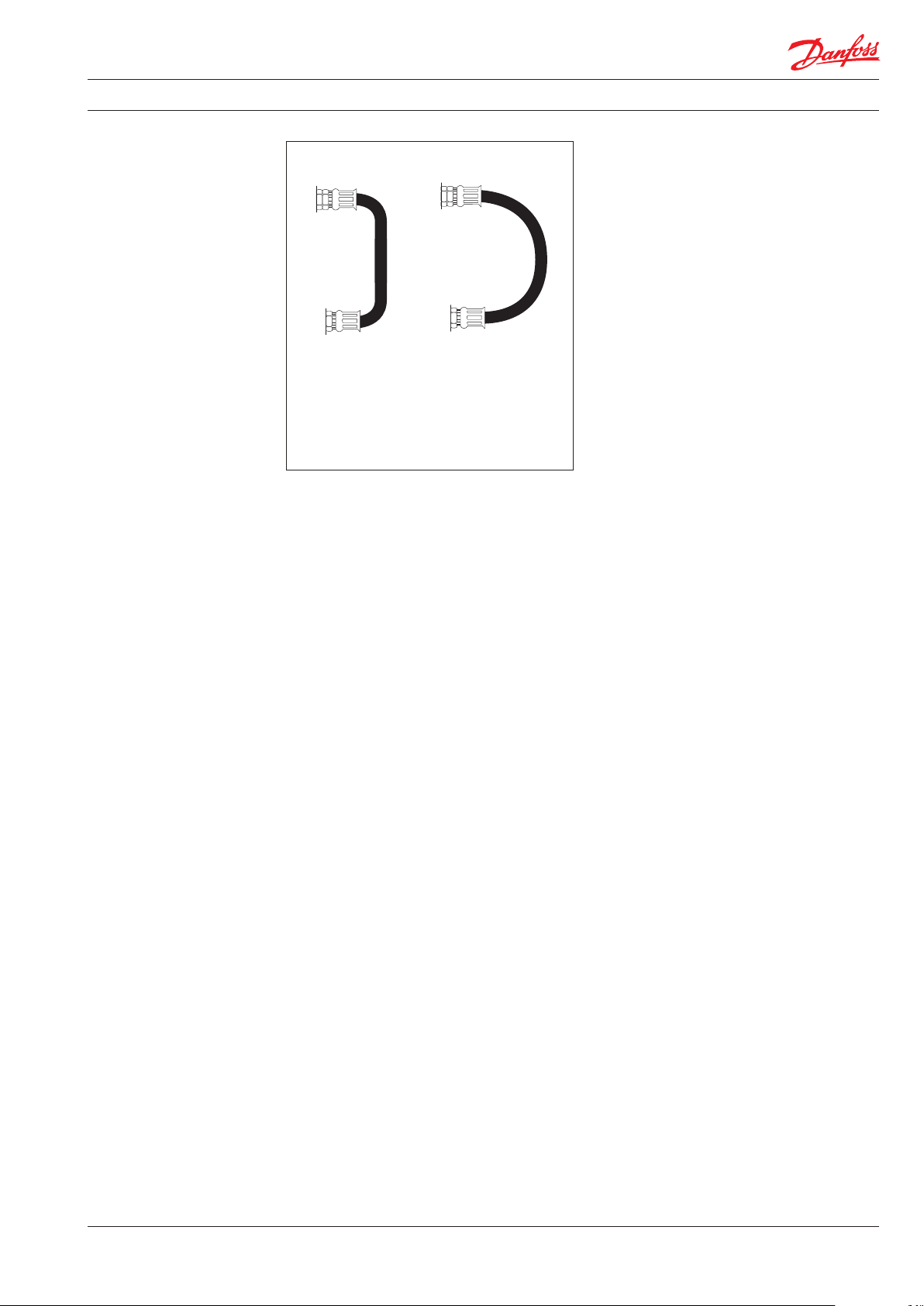

WRONG

WRONG RIGHT

To prevent hose collapse and ow restriction,

hose bend radii should be kept as large as

possible. Tight bends can also compromise

the hose reinforcement and cause premature

hose failure. Refer to hose specication table

on page 6 for minimum bend radii.

RIGHT

180R9434 | AN375455762639en-00 0201 | 07.2021

3

Page 4

Instruction | Right and wrong - Hose assembly routing tips

2. Hoses larger than 2”

Whenever possible, high pressure hoses should

always be connected directly to Danfoss provided adapters and check valves. Elbows and

distance pipes should be avoided to prevent

excessive side loads.

MIN. 10°

Always provide some slack on straight hose installations. This compensates for hose length

variations with dierences in internal uid

pressures. A small angle will reduce the forces

from the hose and allow the hose to bend

when pressurized.

Danfoss 3” HP hoses are nylon reinforced; when

using hoses that are not steel reinforced the

connected items must be grounded to avoid

electrical stray currents.

EXPANSION

EXPANSION

EXPANSION

Flexing a metal hose in two separate planes of

movement will torque the hose assembly.

Always install the metal hose assembly so

that exing occurs in one plan only and this

is the same plane in which bending occurs. If

multiple planes of motion are required use a

dog leg assembly.

The installation should allow a straight

distance S before bending the hose. Not

doing so may compromise the hose

reinforcement and cause hose failure.

Max. bending angle and distance S can be

found in table 1 on page 6.

WRONG

RIGHT

Hoses should not be twisted and should

only have one bend.

4

180R9434 | AN375455762639en-00 0201 | 07.2021

Page 5

Instruction | Right and wrong - Hose assembly routing tips

The use of pipe or ttings between pump

and iSave connectors and hoses should

be avoided. Such congurations can apply

excessive loads on the connectors and can

cause connector and/or connector bolt

failure. If this cannot be avoided, the piping

system must be protected by either hose

whip restraints mounted directly to the

frame or the hard piping must be xed relative to any pump/iSave movements.

MAX.

BENDING

ANGLE

If hose is bent, ensure max. bending angle

and distance S from each connector (see

table 1 on page 6).

WRONG

WRONG RIGHT

To prevent hose collapse and ow restriction,

hose bend radii should be kept as large as

possible. Tight bends can also compromise

the hose reinforcement and cause premature

hose failure. Refer to hose specication table

on page 6 for minimum bend radii.

NO

NO

PRESSURE

PRESSURE

RIGHT

HIGH

HIGH

PRESSURE

PRESSURE

WRONG

RIGHT

The hose must have a distance S before

bending starts.

To allow the hose to expand when

pressurized, clamps should not be used at

bends. If possible, do not clamp high and

low pressure lines together.

180R9434 | AN375455762639en-00 0201 | 07.2021

5

Page 6

Instruction | Right and wrong - Hose assembly routing tips

S

3. Hose specication

table

High pressure hoses

Code

number

180Z0228

Pipe connection1)

[A]

1.5" Vic. OGS Super duplex

Pipe

connection

material

EN 1.4410

Hose size

Inner

diameter

25.4 mm (1.0") 0.66 m (26") 152 mm (6.08"), max. 90° 79 mm (3.11”)

Hose length

ISO 1436

[B]

Bending radius S

180Z0229 1.5" Vic. OGS

180Z0167

180Z0140

180Z0263 2.5" Vic. OGS

180Z0280

180Z0619

180Z0618

180Z0 612

18 0Z0 611

180Z1000

180Z1001

Low pressure hoses

180Z0298 2.0” Vic. OGS

180Z0144 3.0” Vic. OGS

1.5" Vic. OGS Super duplex

2.0" Vic. OGS Super duplex

2.5" Vic. OGS Super duplex

2.5" Vic. OGS Super duplex

2.5" Vic. OGS Super duplex

3.0" Vic. OGS Super duplex

3.0" Vic. OGS Super duplex

3.0" Vic. OGS Super duplex

3.0" Vic. OGS Super duplex

Super duplex

EN 1.4410

EN 1.4410

EN 1.4410

)

Super duplex

EN 1.4410

EN 1.4410

EN 1.4410

EN 1.4410

EN 1.4410

EN 1.4410

EN 1.4410

EN 1.4410

Super duplex

EN 1.4410

Super duplex

EN 1.4410

25.4 mm (1.0")

38.0 mm (1.5") 1.16 m (45.7") 250 mm (9.84"), max. 180° 85 mm (3.35”)

50 mm (2.0") 1.25 m (49") 630 mm (24.8"), max. 90° 115 mm (4.53”)

50 mm (2.0") 1.78 m (70") 630 mm (24.8"), max. 180° 115 mm (4.53”)

50 mm (2.0") 1.00 m (39.4") 630 mm (24.8"), max. 90° 115 mm (4.53”)

65 mm (2.5") 1.78 m (70") 200 mm (7.87"), max. 270° 150 mm (5.90”)

65 mm (2.5")

76 mm (3.0") 1.79 m (70.5") 250 mm (9.84"), max. 270° 150 mm (5.90”)

76 mm (3.0") 1.00 m (39.4") 250 mm (9.84"), max. 90° 150 mm (5.90”)

76 mm (3.0") 1,25 m (49") 250 mm (9.84"), max. 180° 150 mm (5.90”)

76 mm (3.0") 1,6 m (63") 250 mm (9.84"), max. 180° 150 mm (5.90”)

1.16 m (45.7")

1.00 m

(9.4")

2.0 m

(79”)

2.0 m

(79”)

152 mm (6.08"), max. 180° 79 mm (3.11”)

200 mm (7.87"), max. 90° 150 mm (5.90”)

1)

The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation Handbook (htpp://static.victaulic.com)

O. D.

r

α

S

6

180R9434 | AN375455762639en-00 0201 | 07.2021

When using exible hoses, it is

recommened to use Hose Whip Restraint.

Page 7

Instruction | Right and wrong - Hose assembly routing tips

180R9434 | AN375455762639en-00 0201 | 07.2021

7

Page 8

Danfoss A/S

High Pressure Pumps • danfoss.com • +45 7488 2222 • E-mail: highpressurepumps@danfoss.com

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other technical data in

product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download, shall be considered informative, and

is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any responsibility for possible errors in catalogues, brochures,

videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to products ordered but not delivered provided that such alterations can be

made without changes to form, t or function of the product. All trademarks in this material are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are

tradem arks of Danfo ss A/S. All righ ts reserved .

© Danfoss | DCS (im) | 2021.07

180R9434 | AN375455762639en-000201 | 8

Loading...

Loading...