Technical Information

PLUS+1® HMI Peripherals

HMR CAN Rotary Input Device

www.danfoss.com

Technical Information

HMR CAN Rotary Input Device

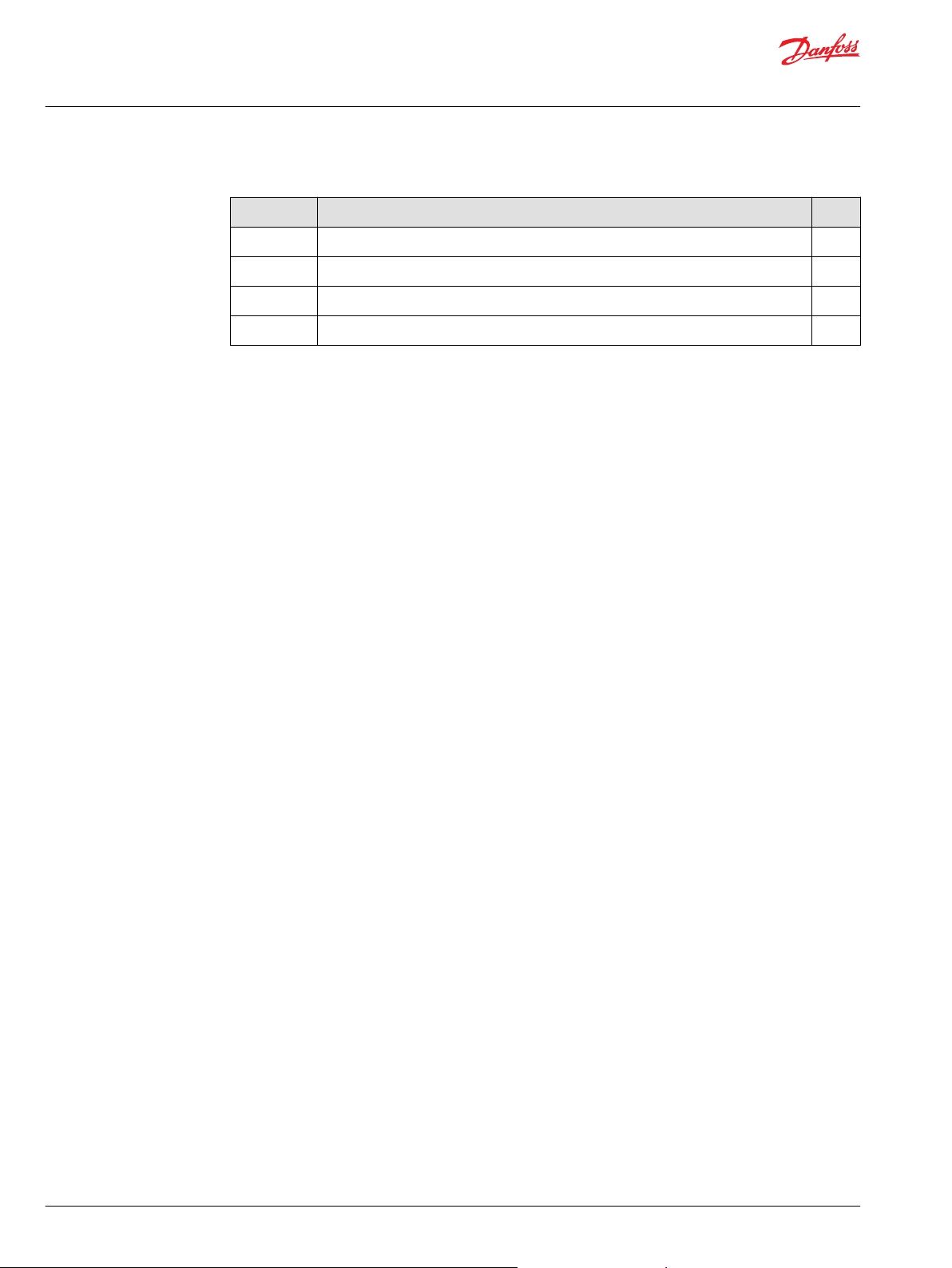

Revision history Table of revisions

Date Changed Rev

April 2019 Corrected pin connector name to DEUTSCH DT04-4 pin connector 0104

July 2018 Corrected reference literature titles 0103

June 2018 Corrected title 0102

June 2018 First edition 0101

2 | © Danfoss | April 2019 BC00000399en-000104

Technical Information

HMR CAN Rotary Input Device

Contents

HMR literature references

Technical Information (TI)............................................................................................................................................................. 4

Data Sheet (DS)................................................................................................................................................................................. 4

API Specifications (API)...................................................................................................................................................................4

PLUS+1® GUIDE User Manual....................................................................................................................................................... 4

Latest version of technical literature.........................................................................................................................................4

User liability and safety statements

OEM responsibility........................................................................................................................................................................... 5

Overview

HMR CAN Rotary Input Device.....................................................................................................................................................6

Features................................................................................................................................................................................................6

Ordering information

Model variants...................................................................................................................................................................................7

Model code.........................................................................................................................................................................................7

Model code key.................................................................................................................................................................................7

Related products...............................................................................................................................................................................8

Product ratings

Electronic components environmental testing.....................................................................................................................9

Specifications...................................................................................................................................................................................10

Ingress Protection (IP) rating .................................................................................................................................................... 10

Color and command options

Indicator and backlight color options.................................................................................................................................... 11

Indicator and backlight command options..........................................................................................................................12

CAN messaging protocol

J1939...................................................................................................................................................................................................13

HMR transmitted Message Structure......................................................................................................................................14

HMR configuration Message Structure..................................................................................................................................14

Command values......................................................................................................................................................................15

J1939 proprietary messages...................................................................................................................................................... 15

LED brightness...........................................................................................................................................................................15

Backlight LEDs............................................................................................................................................................................15

LEDs............................................................................................................................................................................................... 17

Blink rate and indicator configuration for buttons.......................................................................................................17

Blink rate and indicator configuration for rotary.......................................................................................................... 17

Rotary encoder configuration................................................................................................................................................... 18

Installation and start-up

Dimensions.......................................................................................................................................................................................19

Mounting.......................................................................................................................................................................................... 19

Connectors....................................................................................................................................................................................... 20

Pin assignments........................................................................................................................................................................ 20

Machine wiring guidelines......................................................................................................................................................... 20

Machine welding guidelines......................................................................................................................................................21

©

Danfoss | April 2019 BC00000399en-000104 | 3

Technical Information

HMR CAN Rotary Input Device

HMR literature references

Reference literature

Literature title Literature type Literature number

PLUS+1® HMI Peripherals — HMR CAN Rotary Input Device Technical Information BC00000397

PLUS+1® HMI Peripherals — HMR CAN Rotary Input Device Data Sheet AI00000327

PLUS+1® GUIDE Software User Manual AQ00000026

Technical Information (TI)

A TI is comprehensive information for engineering and service personnel to reference.

Data Sheet (DS)

A DS is summarized information and parameters that are unique to a specific model.

API Specifications (API)

An API is specifications for programming variable settings.

API specifications are the definitive source of information regarding pin characteristics.

PLUS+1® GUIDE User Manual

The Operation Manual (OM) details information regarding the PLUS+1® GUIDE tool used in building PLUS

+1® applications. This OM covers the following broad topics:

How to use the PLUS+1® GUIDE graphical application development tool to create machine

•

applications

How to configure module input and output parameters

•

How to download PLUS+1® GUIDE applications to target PLUS+1® hardware modules

•

How to upload and download tuning parameters

•

How to use the PLUS+1® Service Tool

•

Latest version of technical literature

Comprehensive technical literature is online at www.danfoss.com

4 | © Danfoss | April 2019 BC00000399en-000104

Technical Information

HMR CAN Rotary Input Device

User liability and safety statements

OEM responsibility

The OEM of a machine or vehicle in which Danfoss products are installed has the full responsibility for all

consequences that might occur. Danfoss has no responsibility for any consequences, direct or indirect,

caused by failures or malfunctions.

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained

•

equipment.

Danfoss does not assume any responsibility for Danfoss products being incorrectly applied or the

•

system being programmed in a manner that jeopardizes safety.

All safety critical systems shall include an emergency stop to switch off the main supply voltage for

•

the outputs of the electronic control system. All safety critical components shall be installed in such a

way that the main supply voltage can be switched off at any time. The emergency stop must be easily

accessible to the operator.

©

Danfoss | April 2019 BC00000399en-000104 | 5

Technical Information

HMR CAN Rotary Input Device

Overview

HMR CAN Rotary Input Device

The HMR CAN Rotary Input Device brings screen navigation closer to the operator, allowing “blind

operation” and minimizing the need to reach for buttons/dials/touch-screen on the display during

operation. The back-lit buttons can be used as hot keys to quickly navigate to a screen or used for

machine functions, while the indicator bars on each button provide optical feedback to the operator

The HMR has been optimized for ergonomic, five finger control. The seven large buttons are available

with standard icons, or customizable to meet application needs. Each button features RGB LEDs for

backlight and light bars that are controllable via CAN messaging, with adjustable light intensity. The

rotary knob encompasses an eighth push button and includes RGB LED lighting at the base.

The HMR features robust mechanical, electrical, and Ingress Protection specifications that meet the

demands of mobile machine operation. It is suitable for installation in open and enclosed cabs.

Features

•

6 | © Danfoss | April 2019 BC00000399en-000104

Technical Information

HMR CAN Rotary Input Device

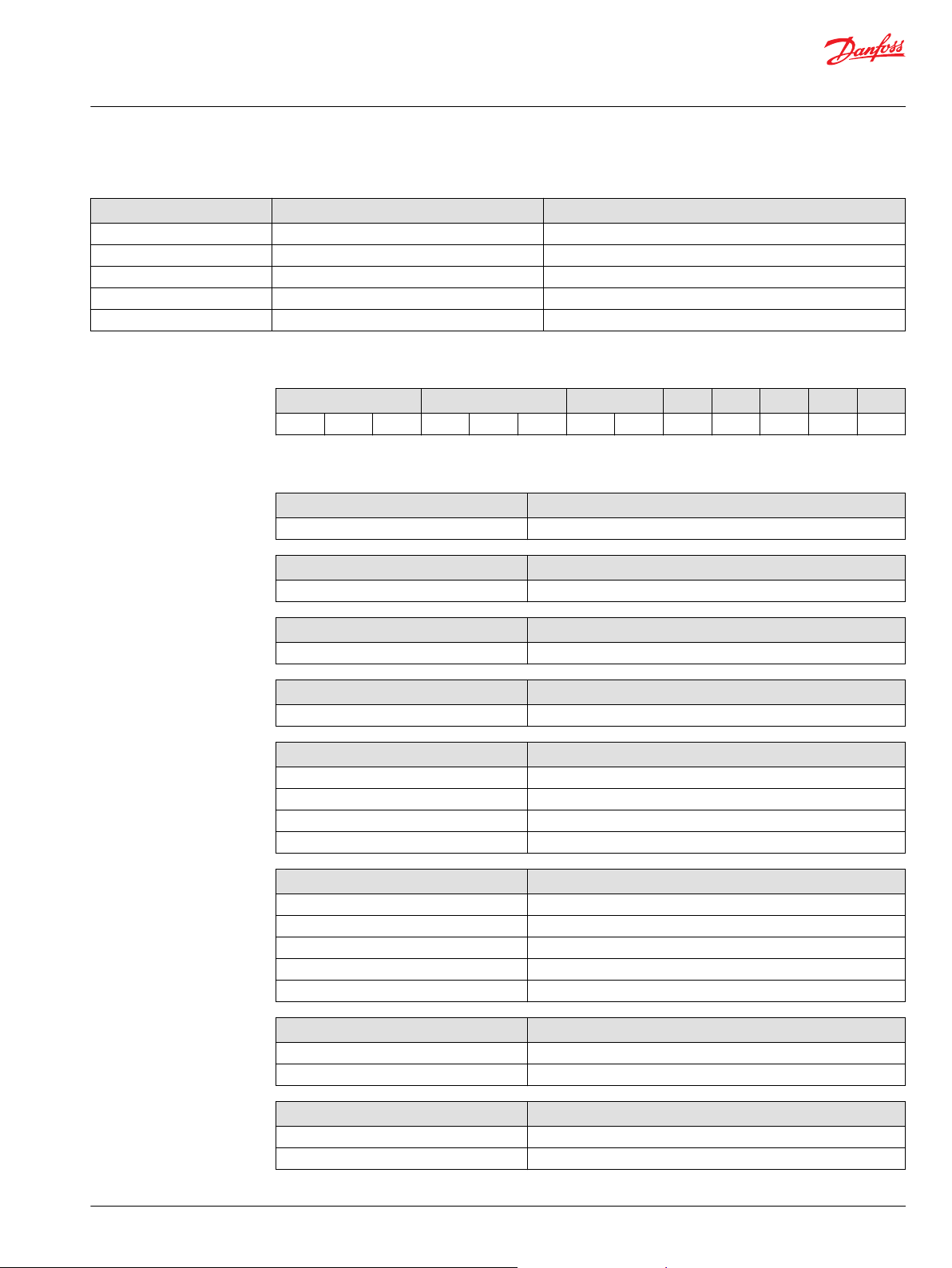

Ordering information

Model variants

Part number Order code Description

11217428 HMR-111-00-1-0-0-0-0 HMR, No Graphics, LED Indicators

11202900 HMR-111-00-1-0-1-0-0 HMR, Number Graphics, LED Indicators

11202899 HMR-111-00-1-0-2-0-0 HMR, Navigation Graphics, LED Indicators

11217427 HMR-111-00-1-1-1-0-0 HMR, Number Graphics, LED Indicators, Danfoss Logo

11217426 HMR-111-00-1-1-2-0-0 HMR, Navigation Graphics, LED Indicators, Danfoss Logo

Model code

A B C D E F G H

H M R

Model code key

A—Model name Description

HMR HMR CAN Rotary Input Device, PLUS+1® HMI Peripherals

B—LED lights Description

111 Indicator bar, back-light, and knob LEDs (RGB)

C—PCBA / Special features Description

00 HMR, version 0

D—Rotary knob configuration Description

1 Standard ring-style knob

E—Knob logo Description

0 No logo

1 Danfoss logo

2 Generic Your Logo Here logo

9 Custom logo

F—Button graphic configuration Description

0 No graphics (blank)

1 Number graphics

2 Navigation graphics

8 ISO graphics

9 Custom graphics

G—Special features (software) Description

0 No special software features

9 Custom configuration file

H—Hand-rest option Description

0 No hand-rest

9 Custom hand-rest

©

Danfoss | April 2019 BC00000399en-000104 | 7

Technical Information

HMR CAN Rotary Input Device

Ordering information

Related products

4 pin mating connector Part number

DEUTSCH 4 PIN Connector Kit 11028348

8 | © Danfoss | April 2019 BC00000399en-000104

Technical Information

HMR CAN Rotary Input Device

Product ratings

Electronic components environmental testing

Climate environment

Description Applicable standard Comment

Storage temperature IEC 60068-2-1, test Ab, IEC 60068-2-2 test Bb

Operating temperature IEC 60068-2-1, test Ab, IEC 60068-2-2 test Bd

Thermal cycle IEC 60068-2-2, test Na, IEC 60068-2-38 (partial)

Humidity IEC 60068-2-78, IEC 60068-2-30 test Db Damp heat steady state and cyclic.

Degree of protection IEC 60529

Chemical environment

Description Applicable standard Comment

Salt mist IEC 60068-2-58 test Kb

Chemical resistance ISO 16750-5

Mechanical environment

Description Applicable standard Comment

Vibration IEC 60068-2-6 test Fc, IEC6008-2-64 test Fh

Bump IEC 60068-2-29 test Eb

Shock IEC 60068-2-27 test Ea

Free fall IEC 60068-2-32 test Ed

Electrical/electromagnetic

Description Applicable standard Comment

EMC emission ISO 13766, SAE J1113-13 Electromagnetic compatibility for earth

moving machinery.

EMC immunity ISO 13766 Electromagnetic compatibility for earth

moving machinery.

Electrostatic discharge EN 60-1 000-4-2

Auto electrical transients ISO 7637-2, ISO 7637-3

Short circuit protection Danfoss test Inputs and outputs survive continuous

short circuit. Normal function resumes

when short is removed.

Reversed polarity

protection

Danfoss test Survives reverse polarity at supply

voltage for at least five minutes.

©

Danfoss | April 2019 BC00000399en-000104 | 9

Technical Information

HMR CAN Rotary Input Device

Product ratings

Specifications

Characteristics

Processor

RAM

EEPROM

Supply voltage

Connector

IP rating (with mating connector

attached)

Operating temperature

Storage temperature

Weight

Vibration/Shock

EMI/RFI rating

Humidity

Transients

Button Cycle Life

Rotary Dial Cycle Life

ARM Cortex M3, 32 bit, 120 MHz

64 kB

32 kB

9 to 36 V

DC

DEUTSCH DT-4

IP66 and IP67

-40°C to +85°C [-40°F to 185°F]

-40°C to +85°C [-40°F to 185°F]

0.159 kg [0.351 lb]

IEC 60068-2-64 (7.67g) /2-27 (50g)

100 V/M

IEC 60068-2-78, 60068-2-30

ISO 7637/1, 2, 3

1 Million Cycles

1 Million Cycles

Ingress Protection (IP) rating

HMR CAN Rotary Input Device carries a full Ingress Protection rating of IP 67.

10 | © Danfoss | April 2019 BC00000399en-000104

Technical Information

HMR CAN Rotary Input Device

Color and command options

The HMR offers various color and command option for application specific customization.

Each of the buttons has 2 Indicator LEDs located on the edge of the unit. Each one of these has an

•

Enable signal - they share the RGB signals.

Each of the buttons has 2 backlight LEDs paired together sharing the RGB signals.

•

The rotary encoder has a group of 6 backlights that can be configured.

•

Indicator and backlight color options

Indicator default colors

Index Default color R G B

0 Green 0 0xFFFF 0

1 Yellow 0xFFFF 0xFFFF 0

2 Red 0xFFFF 0 0

3 White 0xFFFF 0xFFFF 0xFFFF

4 Cyan 0 0xFFFF 0xFFFF

5 Blue 0 0 0xFFFF

6 Magenta 0xFFFF 0 0xFFFF

7 Black 0 0 0

8 Dark Blue 0x1919 0x1919 0x7070

9 Purple 0x5454 0x1919 0x6D6D

10 Amber 0xFFFF 0xBFBF 0

11 Maroon 0xFFFF 0xCCCC 0x3333

12 Teal 0x3838 0x8E8E 0x8E8E

13 Light Blue 0x8787 0xCECE 0xFAFA

14 Dark Green 0 0x6464 0

15 Light Green 0x3C3C 0xB3B3 0x7171

Backlight default colors

Index Default color R G B

0 White 0xFFFF 0xFFFF 0xFFFF

1 Green 0 0xFFFF 0

2 Red 0xFFFF 0 0

3 Blue 0 0 0xFFFF

4 Cyan 0 0xFFFF 0xFFFF

5 Yellow 0xFFFF 0xFFFF 0

6 Magenta 0xFFFF 0 0xFFFF

7 Black 0 0 0

8 Dark Blue 0x1919 0x1919 0x7070

9 Purple 0x5454 0x1919 0x6D6D

10 Amber 0xFFFF 0xBFBF 0

11 Maroon 0xFFFF 0xCCCC 0x3333

12 Teal 0x3838 0x8E8E 0x8E8E

13 Light Blue 0x8787 0xCECE 0xFAFA

14 Dark Green 0 0x6464 0

15 Light Green 0x3C3C 0xB3B3 0x7171

©

Danfoss | April 2019 BC00000399en-000104 | 11

Technical Information

HMR CAN Rotary Input Device

Color and command options

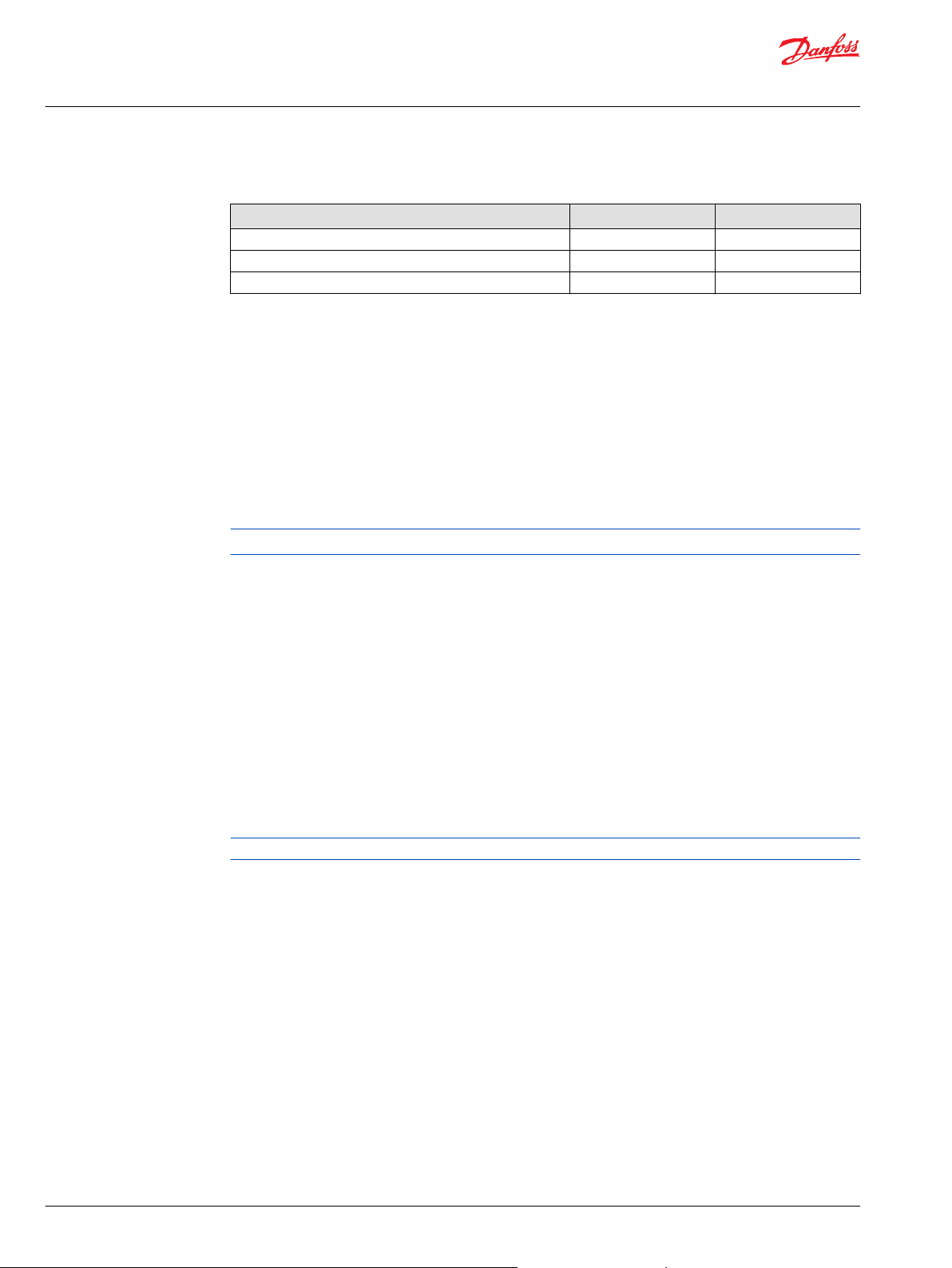

Indicator and backlight command options

Mode Allowed speeds Allowed phases

Off N/A N/A

On N/A N/A

Flashing Low Medium High Normal Inverted

Breathing Low Medium High Normal Inverted

12 | © Danfoss | April 2019 BC00000399en-000104

Technical Information

HMR CAN Rotary Input Device

CAN messaging protocol

J1939

The system supports various types of J1939 messaging, using J1939 compliant baud rates in the

following ranges.

Description Unit Minimum Maximum Typical Comment

Available Baud rates kbps 50 The default baud rate is 250

The system performs an address claim per J1939-73 and provide programmable name for various fields in

address claim.

Programmable name for various fields

Name field Default Customer configurable Comment

ECU Instance 1 Yes

Function Instance 0 Yes

Function 135 Yes Keypad

Vehicle System 0 Yes Non-specific

Vehicle System Instance 1 Yes

Industry Group 0 Yes Global

100

125

250

500

1000

kbit.

©

Danfoss | April 2019 BC00000399en-000104 | 13

Technical Information

HMR CAN Rotary Input Device

CAN messaging protocol

HMR transmitted Message Structure

The system default shall utilize a standard AUXIO1 message from J1939-71 to send the button and

encoder status.

DiffCount Differential count provides the count of rotary ticks since the last message. Turning

AbsCount Absolute count, since power up, tracks between start value and max value. If rollover is

Bit

0 - 1

Bit

2 - 3

Bit

4 - 5

Bit

6 - 7

clockwise provides positive incrementation, counter-clockwise negative.

enabled, AbsCount keeps track of counts until a max value is reached then rolls over to start

value if turning clockwise. As well as, rolls over from start value to max value if turning

counter-clockwise. Turning clockwise provides positive measurements, counter-clockwise

negative.

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Button4*Bit

Button3*Bit

Button2*Bit

Button1*Bit

0 - 1

2 - 3

4 - 5

6 - 7

Encoder

Button*

Button

7*

Button

6*

Button

5*

Reserved Reserved DiffCount

LSB

DiffCount

MSB

AbsCount

LSB

AbsCount

MSB

* States for buttons:

0 - Off

1 - On

2 - Error

3 - Not applicable

HMR configuration Message Structure

The system shall receive the AUXIO2 message from J1939-71 that contains the LED control data for all 7

buttons and rotary encoder, message only allows for 3 colors choices and 1 blink rate of medium. This is

the generic configuration.

Allowed colors

Allowed states

Value of 3

Bit 6-7

Bit 4-5

Bit 2-3

Bit 0-1

Byte 0

(Button 1)

Backlight

Color Index

Indicator

Color Index

LED 1

State

LED 2

State

Index 0 Index 1 Index 2

0 - Off 1 - On 2 - Blink medium

Indicates no change

Byte 1

(Button 2)

Backlight

Color Index

Indicator

Color Index

LED 1

State

LED 2

State

Byte 2

(Button 3)

Backlight

Color Index

Indicator

Color Index

LED 1

State

LED 2

State

Byte 3

(Button 4)

Backlight

Color Index

Indicator

Color Index

LED 1

State

LED 2

State

Byte 4

(Button 5)

Backlight

Color Index

Indicator

Color Index

LED 1

State

LED 2

State

Byte 5

Button 6

Backlight

Color Index

Indicator

Color Index

LED 1

State

LED 2

State

Color Index

Color Index

Byte 6

(Button 7)

Backlight

Indicator

LED 1

State

LED 2

State

Byte 7

(Encoder

Button)

Backlight 1

Color Index

Backlight 1

State

14 | © Danfoss | April 2019 BC00000399en-000104

Technical Information

HMR CAN Rotary Input Device

CAN messaging protocol

Command values

The HMK requires the reception of the J1939-21 PDU1 format for the proprietary messages.

The HMK will expect an ID of:

0X18EFDASA DA is the Destination Address (address of HMR).

Use the following command values.

SA is Source Address of sender of the data.

J1939 proprietary messages

Command

Value

0x0FCD CMD_BRIGHTNESS Changes the parameters for LED brightness, global

0x0FCC CMD_BACKLIGHT_COLOR Changes the RGB settings of one of the indexes of

0x0FCE CMD_AUX_OUTPUTS Commands the auxiliary outputs to turn on / off

0x0FCB CMD_BUTTON_LEDS Commands a single button indicator, backlight colors

0x0FCC CMD_MAIN_COLOR Changes the RGBW settings of one of the indexes of

0x0FCF CMD_CONFIG Changes various configuration settings of the unit

Name Description

setting

backlight colors

and blink rates

indicator colors

The message should be structured in the following format for the corresponding proprietary messages.

LED brightness

The system supports a LED brightness message that sets the global brightness of each of the RGB colors

with a value from:

•

0-254 (254 being full brightness)

•

255 Not Available / No Change

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Don't

No

255

save

through

Power

cycle

255

Save

through

power

cycle

CMD_BRIGHTNESS

LSB

CMD_BRIGHTNESS

MSB

Red Green Blue White

Min: 0 Min: 0 Min: 0 Min: 0 Min: 0

Max: 254 Max: 254 Max: 254 Max: 254 Max: 1

No

Change:

255

No

Change:

255

No

Change:

255

Change:

Backlight LEDs

The system supports a proprietary message to set the RGB Color configuration for one of the color

settings for the backlight LED and overwrites any of the corresponding indexes of the RGB settings from

the previous LED color table.

©

Danfoss | April 2019 BC00000399en-000104 | 15

Technical Information

HMR CAN Rotary Input Device

CAN messaging protocol

CMD_BACKLIGHT

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

_COLOR

LSB

CMD_BACKLIGHT

_COLOR

MSB

Color Index: 0-15 Red Green Blue White

Reserved: 16-127

No change: 255

0 = read

Bit 7

1 = write

RGB

0-255

RGB

0-255

RGB

0-255

RGB

0-255

Reset to

default

RGB

0-255

16 | © Danfoss | April 2019 BC00000399en-000104

Technical Information

HMR CAN Rotary Input Device

CAN messaging protocol

LEDs

The system supports a proprietary message to set the RGB Color configuration for one of the color

settings for the Indicator LED and overwrites any of the corresponding indexes of the RGB settings from

the previous Backlight color table.

CMD_BUTTON

Blink rate and indicator configuration for buttons

The system supports an individual message that allows for setting all the blink rates and selection of

colors for backlight and indicator for each button.

Type Speed Inverted

0 - Off 0 - Slow 0 - No

1 - On 1 - Medium 1 - Yes

2 - Blink 2 - Fast 2 Reserved

3 - Breathe 3-6 Reserved 3 - No Change

4-6 Reserved 7 - No Change

7 - No Change

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Color Index: 0-16 Red Green Blue

Reserved: 17-254

No change: 255

0 = read

Bit 7

1 = write

RGB

0-255

RGB

0-255

RGB

0-255

_LEDS

LSB

CMD_LED1_2

_COLOR

MSB

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

CMD_BUTTON

_LEDS

LSB

CMD_BUTTON

_LEDS

MSB

Button #:

1-7

Reserved:

0; 8-254

No

Change:

255

Backlight

Color:

0-15

Reserved:

16-254

No

Change:

255

Backlight

State:

Bit 0-2:

Type

Bit 3-5:

Speed

Bit 6-7:

Invert

Indicator

Color:

0-15

Reserved:

16-256

No

Change:

255

LED1

State:

Bit 0-2:

Type

Bit 3-5:

Speed

Bit 6-7:

Invert

LED2

State:

Bit 0-2:

Type

Bit 3-5:

Speed

Bit 6-7:

Invert

Blink rate and indicator configuration for rotary

The system supports an individual message that allows for setting all the blink rates and selection of

colors for backlight for the encoder dial.

Type Speed Inverted

0 - Off 0 - Slow, 0 - No,

1 - On, 1 - Medium, 1 - Yes,

2 - Blink, 2 - Fast, 2 - Reserved,

3 - Breathe, 3-6 - Reserved, 3 - No Change

4-6 - Reserved, 7 - No Change

7 - No Change

©

Danfoss | April 2019 BC00000399en-000104 | 17

Technical Information

HMR CAN Rotary Input Device

CAN messaging protocol

CMD_ENCODER

Rotary encoder configuration

The encoder count value configuration must be done using PLUS+1® Service Tool, it allows for more

customization to the rotary encoder.

Configuration Value Comments

Start Value 0 - Max Value The delta value defines how many counts can be done with the rotary.

Maximum Range Start Value - 65535

Rollover Enable/Disable

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

_LEDS

LSB

CMD_ENCODER

_LEDS

MSB

When max value is achieved the rotary is either:

(Enabled)

Encoder:

8

Reserved:

0-7; 9-254

No

Change:

255

Backlight

Color:

0-15

Reserved:

16-254

No

Change:

255

Count begins at max or start value depending which

Backlight

State:

Bit 0-2:

Type

Bit 3-5:

Speed

Bit 6-7:

Invert

Unused Unused

255 255

Clear

Counts:

Clear - 1

No

Change:

2-255

way rotary is being turned.

(Disabled)

Reaches max or start value and does not go further.

18 | © Danfoss | April 2019 BC00000399en-000104

213

4

88.96

[03.50]

96.44

[03.80]

Ø 45.00 [01.77]

Thread M6

46.00

[01.81]

62.00

[02.44]

56.77

[02.24]

51.20

[02.02]

38.27

[0151]

17.45

[00.69]

Max torque 4.5 N•m (40 in•lb)

Three bolts

R4 MAX

3X Ø 06.60 [00.260]

16.75 [00.66] MIN

18.50 [00.73]

90.00 [03.54] MIN

46.00 [01.81]

27.25 [01.07] MIN

17.50 [00.69] MIN

62.00 [02.44]

22.00 [00.87]

11.50 [00.45]

23.00 [00.91]

97.00 [3.818] MIN

17.50 [00.69] MIN

31.00 [01.22]

Technical Information

HMR CAN Rotary Input Device

Installation and start-up

Dimensions

HMR CAN Rotary Input Device

mm [in]

Mounting

©

Danfoss | April 2019 BC00000399en-000104 | 19

2 3

4

1

W

C

Technical Information

HMR CAN Rotary Input Device

Installation and start-up

Connectors

Pin assignments

DEUTSCH DT04-4 pin connector

Pin Controller function

1 Power ground 2 Power supply +

3 CAN Hi

4 CAN Lo

Machine wiring guidelines

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

Improperly protected power input lines against over current conditions may cause damage to the

hardware. Properly protect all power input lines against over-current conditions. To protect against

unintended movement, secure the machine.

Caution

Unused pins on mating connectors may cause intermittent product performance or premature failure.

Plug all pins on mating connectors.

•

Protect wires from mechanical abuse, run wires in flexible metal or plastic conduits.

•

Use 85˚ C (185˚ F) wire with abrasion resistant insulation and 105˚ C (221˚ F) wire should be

considered near hot surfaces.

•

Use a wire size that is appropriate for the module connector.

•

Separate high current wires such as solenoids, lights, alternators or fuel pumps from sensor and other

noise-sensitive input wires.

•

Run wires along the inside of, or close to, metal machine surfaces where possible, this simulates a

shield which will minimize the effects of EMI/RFI radiation.

•

Do not run wires near sharp metal corners, consider running wires through a grommet when

rounding a corner.

•

Do not run wires near hot machine members.

•

Provide strain relief for all wires.

•

Avoid running wires near moving or vibrating components.

•

Avoid long, unsupported wire spans.

•

Ground electronic modules to a dedicated conductor of sufficient size that is connected to the

battery (-).

•

Power the sensors and valve drive circuits by their dedicated wired power sources and ground

returns.

•

Twist sensor lines about one turn every 10 cm (4 in).

•

Use wire harness anchors that will allow wires to float with respect to the machine rather than rigid

anchors.

20 | © Danfoss | April 2019 BC00000399en-000104

W

Technical Information

HMR CAN Rotary Input Device

Installation and start-up

Machine welding guidelines

High voltage from power and signal cables may cause fire or electrical shock, and cause an explosion if

flammable gasses or chemicals are present.

Disconnect all power and signal cables connected to the electronic component before performing any

electrical welding on a machine.

The following is recommended when welding on a machine equipped with electronic components:

•

Turn the engine off.

•

Remove electronic components from the machine before any arc welding.

•

Disconnect the negative battery cable from the battery.

•

Do not use electrical components to ground the welder.

•

Clamp the ground cable for the welder to the component that will be welded as close as possible to

the weld.

Warning

©

Danfoss | April 2019 BC00000399en-000104 | 21

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | April 2019 BC00000399en-000104

Loading...

Loading...