Technical Article - hydronic balancing

New ways of balancing

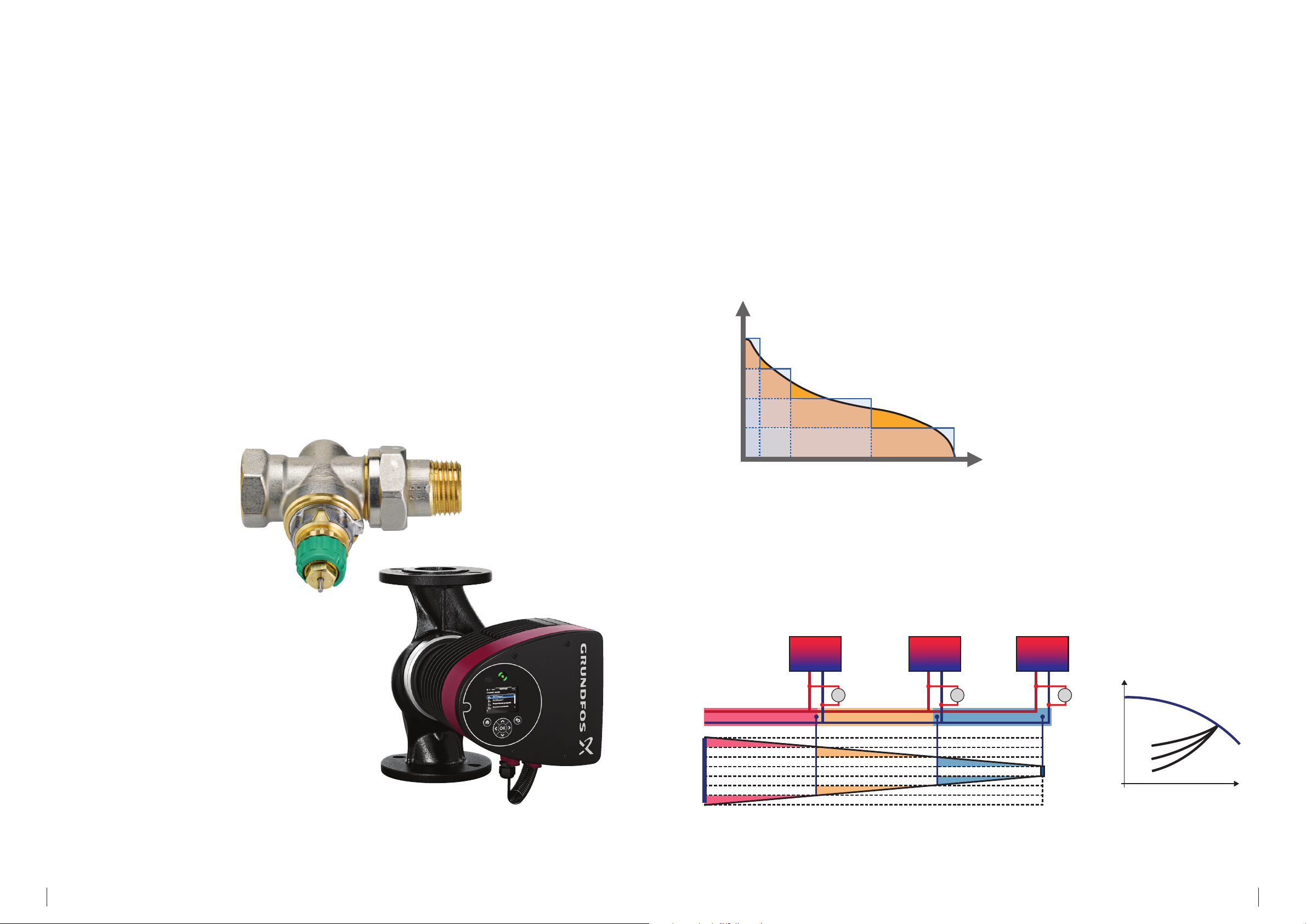

two-pipe systems

How to achieve superior hydronic balance in heating

systems by utilising the Danfoss Dynamic Valve™

type RA-DV and the Grundfos MAGNA3 speed

controlled pump

dynamic.danfoss.com

Introduction

The challenge: balancing two-pipe systems

Low energy consumption in buildings is not something which

comes easy. Ensuring that the components in a heating system

work together is a pre-requisite when we want low heating bills.

A means of ensuring low energy consumption is to balance the

heating system correctly, and this article will explain how the

new Danfoss Dynamic Valve™ type RA-DV and the new Grundfos

MAGNA3 speed controlled pump work together superbly to

achieve this.

We will first look at how we

compensate for the variations in

partial, and how the requirement to

balance the heating system means we

need to control flow; and to obtain

this, we need to control the differential

pressure across valves as well.

We will show how this can be done

by utilising the Danfoss Dynamic

Valve™ type RA-DV in combination

with the Grundfos MAGNA3 variable

speed controlled pump, looking at

an installation in Fredericia, Denmark,

where 60 apartments in a 10 storey

building has heating supplied from

a system consisting of two Grundfos

MAGNA3 pumps serving two mixing

loops, each supplying 10 raisers, each

of which has manual balancing valves

of Danfoss type MSV mounted. This

installation showed that utilising the

speed controlled Grundfos MAGNA3

pump and Danfoss Dynamic Valve™

type RA-DV in combination ensures

problem free operation of a heating

system.

The difference today is that designated

flow can now easily be set on each

radiator and pump set point by

means of the new Danfoss dP tool™

(for measuring differential pressure)

in combination with Grundfos GO

(offering mobile access to Grundfos

online tools). Not only does this

ensure pump optimisation and lowest

energy use, it also reduces time for

commissioning substantially.

The uneven distribution of heat

between units – single radiators or

apartments – in a heating system

is what we refer to as a balancing

problem. A heating system is balanced

when an even distribution of hot water

is ensured thereby ensuring maximum

comfort at minimum running cost.

LOAD

100%

75%

50%

25%

428 1050 2450 3080

6% 15% 35% 44%

In order to compensate for the

variations in load, we equip our

systems with thermostatic valves on

each radiator. The thermostat will

reduce the flow through the individual

radiator and ensure the required room

temperature is maintained.

Or to put it in another way, a heating

system is in balance when the flow

in the whole system corresponds to

the flow rates that were specified for

the design of the system. This is a key

challenge for many two-pipe systems.

Let us first look at the general

challenge in operating two-pipe

heating systems. The load profile below

shows how load is changing during a

heating season in Europe. In only 420

hours out of 7000 heating hours do we

need 100% capacity from our heating

system.

HOURS

As pressure loss increases by the

square of flow, the differential pressure

across the first radiator valves is

substantially higher than it is at the last

consumer, as shown in the illustration

below.

Heating systems need to be

commissioned properly to ensure

high comfort and lowest possible

cost of operation. In earlier days

commissioning was a complicated

matter where lots of different valves

and measuring tools needed to be

utilised for proper commissioning.

RAD RAD RAD

1 32

∆p

a.

∆p

b.

∆p

H

c.

a.

b.

c.

Q

32

As different radiators need different flows in order to heat up the room in question, it is possible to pre-set the maximum

flow on each radiator valve. The pre-setting can be seen in the graph below for a typical radiator valve. The pre-setting can be

adjusted from 1-7 and finally in “N position” which indicates a fully-open valve.

Static vs dynamic commissioning

of heating 2-pipe systems

When a heating system is equipped with a constant speed pump, the delivered differential pressure will vary greatly, as shown

in the illustration below. When flow is reduced the delta P across the individual valve will increase. In the above example the

needed flow at max load is 37 l/h. But when the differential pressure increases (+0.2 bar), the flow will increase, as shown to 62

l/h = 67 %.

A major challenge is that heating

systems are often constructed

and designed to meet the heating

requirements in the worst case

scenario, such as when outdoor

temperatures are extremely low. But as

this occurs only a few times every year

(if at all) the system will be oversized

in the remaining period. This typically

results in overspending on energy.

The following example of static

commissioning of a heating system

with dynamic requirements is from

an installation in Fredericia, Denmark,

where 60 apartments in a 10 storey

building has heating supplied from

a system consisting of two Grundfos

MAGNA3 variable speed controlled

pumps serving two mixing loops,

each supplying 10 raisers, with a total

273 RA-N DN 10 radiator valves and

and static balancing valves of Danfoss

type MSV mounted. The building is

from 1972 and was renovated in 1985,

including new windows and façade.

2

Delta P increase from

0,1 bar to 0,3 bar

1

FLOW

100% load 420 hours

As flow decreases, the differential pressure increases in a fixed speed pump.

The conclusion is that, in order to meet the designated flow, we need to control the differential pressure across valves as well.

We will now see how this was done.

100%

The two mixing loops each supply

10 raisers at the 10 storey apartment

building in Fredericia, Denmark.

54

We will now look at how the system

COOPERATION PUMP AND VALVES

20% 40% 50% 70% 100%

0 2 4 6 8 10 12 14 16 18 20 22 Q [m³/h]

0

1

2

3

4

5

6

7

[m]

H

MAX

MIN

operates, with static balancing

valves and static radiator valves, with

pre-setting. Later, the same test is

performed, but this time with dynamic

valves. The test is done not only at full

load but more importantly at partial

load too.

At the same time, differential

pressure has been measured at the

furthest radiator to make sure that

there is enough pressure to reach

the designated flow for the radiator

furthest away, in this case it is 10 kPa

and the designated flow is 30 l/h,

so the pre-setting will be 2.5 for the

radiator valve.

In the test we have set the control

mode for the pump to be proportional

pressure mode first and secondly

constant pressure mode.

And then we have added the new

Danfoss Dynamic Valve™ type RA-DV in

combination with the new Grundfos

MAGNA3 speed controlled pump.

The MAGNA3 pump can be set in

proportional pressure mode, which will

enable the pump to reduce delivered

differential pressure, when flow is

decreasing. See the chart, below left.

PRESSURE

PUMP CURVES

DESIGN

100%

85%

75%

70%

+4,4

60%

+4,0

+3,0

+3,1

DUTY POINT

CONTROL CURVE

RADIATOR VALVE

SYSTEM CURVE

ADITIONAL DELTA P

FLOWLIMIT AREA

FLOW

The red line shows the proportional control

curve and the green line the minimum required

differential pressure in the system. As can be

seen from the blue circles, there will always be

surplus differential pressure available. Therefore

we need the pump and the dynamic radiator

valve to work well together.

So what that this tell us is that, with

static radiator valves at partial load of

50 %, the radiators will have (17.1- 7.8)

+

= 9.3 kPa increased pressure. What this

means in risk of overflow can be seen

in the figure below.

H

p

[m]

[kPa]

7

60

50

40

30

20

10

MAX

6

5

4

3

2

1

0

0

0 2 4 6 8 10 12 14 16 18 20 22 Q [m³/h]

MIN

Even though the MAGNA3 pump

reduces its delivered differential

pressure, there will at partial load still

be a delta P surplus across the radiator

valves*, shown in the table below.

H

[m]

7

MAX

6

5

4

3

2

1

0

0 2 4 6 8 10 12 14 16 18 20 22 Q [m³/h]

MIN

The key issue here is that although

a speed controlled pump helps, it

cannot keep differential pressure

stable; this is an issue solved by

pressure-independent dynamic valves.

Static radiator valve

Control mode,

pump

Proportional 10.2 kPa 18.0 kP a 7.8 k Pa 33 % increase

Constant 10.2 kPa 27. 3 k Pa 17.1 kP a 46 % increase

System load

100 %

System load

50 %

Increased ΔP

(by 50 % load)

Increased flow

Meassured values at the radiator furthest away

Dynamic radiator valve

Control mode,

pump

Proportional 9.8 kPa 10. 5 kPa 0.7 k Pa < 1 % increase

Constant 9.9 kPa 10. 6 kPa 0.7 kPa < 1 % increase

System load

100 %

System load

50 %

Increased ΔP

(by 50 % load)

Increased flow

Meassured values at the radiator furthest away

When differential pressure increases

from 7.8 kPa to 17.1 kPa, the flow will

increase from 80 to 132 l/h, whereas

the dynamic valve will keep the flow

constant.

The increased delta P at part load

would create overflow and increase

the heating bill, showing the need to

control the delta P correctly. Using the

Using the Danfoss dP tool™ to balance a radiator.

Danfoss Dynamic Valve™ type RA-DV

keeps the flow constant, even when

delta P is changing. A differential

pressure controller inside RA-DV keeps

the pressure drop over the control

valve on the constant level which

means that a constant flow through

the RA-DV valve is maintained. This is

shown in the graph below.

*Assuming that the heating system is a traditional widespread system. If this is not the case

and instead the system is equally divided in two parallel systems, the optimum control

mode will be constant pressure.

So the answer to the challenge

about additional delta P, is to utilise

a speed controlled pump like the

Grundfos MAGNA3 and use Danfoss

Dynamic Valve™ type RA-DV, which

in combination ensures problem free

operation of a heating system, and this

has been shown from the example

from Fredericia discussed above. The

installation has been running now for

one year, and we can see that the cost

for pump operation has been reduced

by approximately 57 % or equal to 980

kWh/year.

76

Danfoss A/S · Heating Segment · Ulvehavevej 61 · 7100 Vejle · Denmark

Te

Pump optimisation

If the pump runs optimally, the lowest

possible energy use is ensured.

Pump optimisation together with

proportional pressure control is

possible only with automatic balancing

valves. Commissioning is made easy

using the new Danfoss dP tool™

(for measuring differential pressure)

in combination with Grundfos GO

(offering mobile access to Grundfos

online tools), and ensures pump

optimisation and lowest energy use.

The Danfoss dP tool™ is an extremely

useful, simple and unique tool used

during commissioning that measures

Conclusion

Superior heating systems need thorough

commissioning, when lowest possible

energy bills is the goal. By using the

new and innovative Danfoss Dynamic

Valve™ type RA-DV in combination

with the new Grundfos MAGNA3

variable speed controlled pump,

this is now highly achievable. In the

specific case in Fredericia, Denmark,

the achieved savings adds up to not

less than 12 % of the heating bill. This

is only possible utilising both the new

Danfoss dynamic valve in combination

with the new Grundfos MAGNA3 pump.

the available differential pressure. It is

mounted on the critical valve where

the differential pressure is lowest. In

full load mode, the delta P needs to be

10 kPa. If the differentail pressure turns

out to be either lower or higher than

this, the set point, is adjusted on the

MAGNA3 pump. The setpoint is related

to the differential pressure delivered

by the pump. Note that this value will

always be higher than what messured

across tha critical valve, as differentaial

pressure decreases throughout the

system.

Grundfos GO is the mobile tool box

The difference today is that designated

flow can now easily be set on each

radiator and pump set point can be

set by using both the Danfoss dP tool™

and Grundfos GO. Not only does this

secure optimal function, it also reduces

time for commissioning substantially.

This shows that there are plenty

of reasons for you as a consulting

engineer to chase down the potential

energy savings that are out there in

many housing associations.

for professional users on the go. It is

the most comprehensive platform

for mobile pump control and pump

selection including sizing, replacement

and documentation and can be downloaded to any iOs or Android device.

Having completed these steps you

have ensured that the energy system

is correctly commissioned, not only

at design flow conditions, but also

and most importantly at partial load

conditions. Result will be lowest

possible energy consumption for the

entire heating system.

Heating systems need proper

commissioning to ensure high

comfort and the lowest possible

cost of operation. In earlier days

commissioning was a complicated

matter where lots of different valves

and measuring tools were needed for

proper commissioning.

l.: +45 7488 8500 · Email: heating@danfoss.com · www.heating.danfoss.com

VFGWK202

Rene Hansen, Anders Nielsen,

Danfoss Grundfos

June 2015

Grundfos GO, for

Android and iOS.

© Copyright Danfoss | ... | 2019.06

Loading...

Loading...