Page 1

Document category | Product name

Application manual | Ground application. Ice & Snow Melting

Ground application.

Ice & Snow Melting

Application manual

Page 2

Page 3

Let Danfoss do the work

Index

Danfoss Group is Denmark's largest industrial group. It is one of the world's

leading companies within heating, cooling and air-conditioning. The Danfoss

Group has more than 23000 employees and serves customers in more than 100

countries.

Danfoss is Europe’s leading brand of electrical cable heating systems and electric

pipe heating systems with over 70 years of experience. The production of

heating cables takes place in France and Poland while the head office is situated

in Denmark.

The value of experience

We have installed literally thousands of systems across the globe, in every

conceivable setting. This experience means that we can offer you practical

advice about precisely which components you need to get the best results at

the lowest cost.

Ground application. Ice & Snow Melting

This design guide presents Danfoss’s recommendations for design and

installation of ice and snow melting systems for ground application.

It provides guidance for heating cable positioning, electrical data and system

configurations.

Following Danfoss’s recommendations will ensure energy efficient, reliable and

maintenance free solution for constant wattage heating cables with 20 year

warranty.

1. Application Briefing 4

2. System Description 5

3. Products 6

4. System Design 10

5. Installation 15

6. Appendixes 19

7. Cases 24

Our quality management

system

and compliances

ISO 9001 TS 16949

ISO 14001

Along with full compliance with EU

directives and product approvals

Page 4

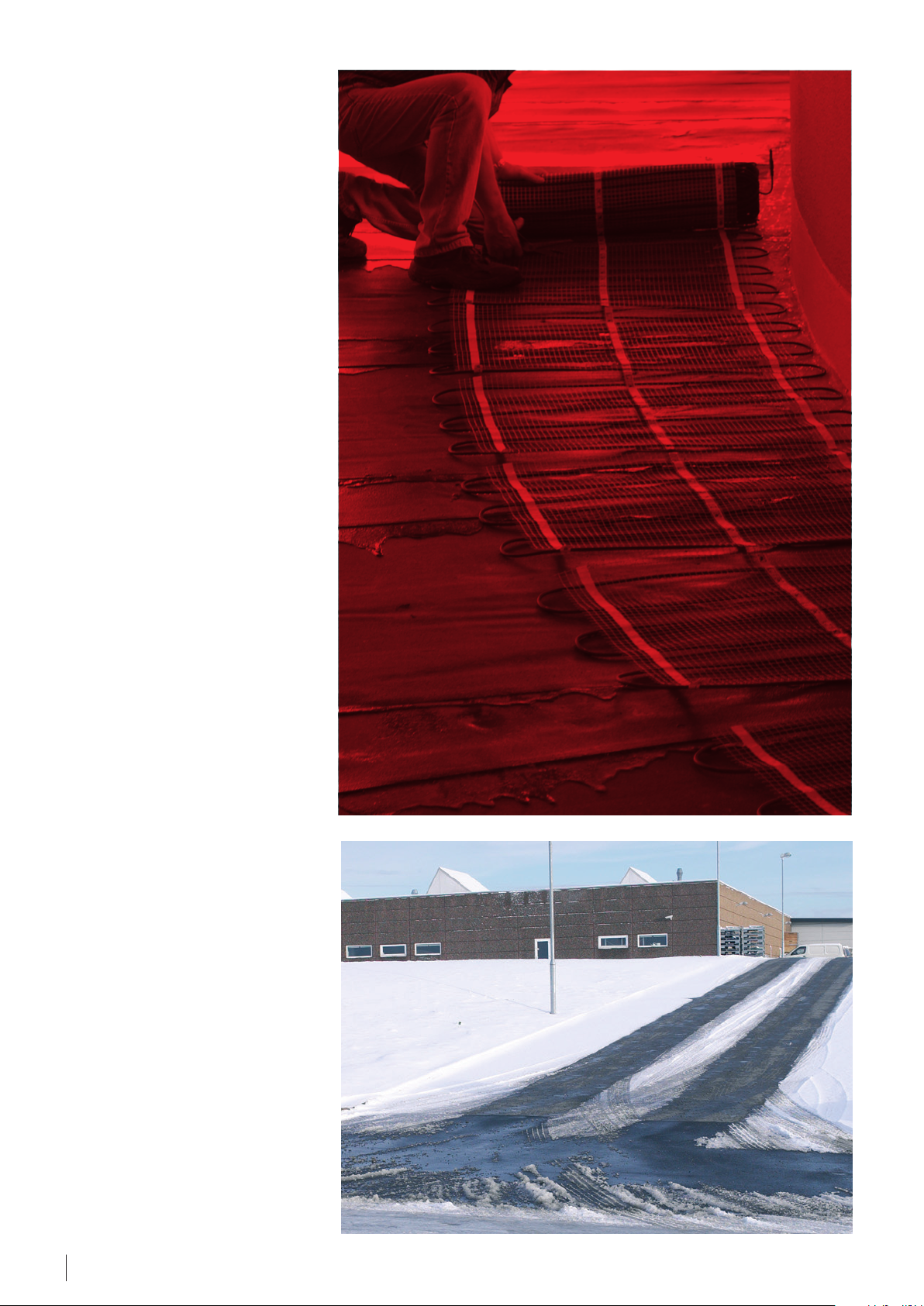

1. Application Briefing

Winter weather costs

In recent years there have been

plenty of new stories about human

and financial costs caused by harsh

winter weather. Property damage,

increased maintenance expenses,

lost productivity, rising insurance

premiums, personal injuries and even

worse. Installation of Danfoss Ice &

Snow Melting System ensures a steady

solution to address cold weather

related problems.

Danfoss’s ice and snow melting system

is designed to provide safety for

people, vehicles, and buildings safety

through safe walking and driving

during winter and safety in terms of

less damage to buildings.

Ground solutions –

with a first class product range

By using Danfoss heating cables

and mats controlled by electronic

thermostats with moisture sensors,

you can cost-effectively protect large

areas such as parking areas, ramps

or pedestrian accesses to buildings

giving you convenience and safety

while saving a lot of tiring and timeconsuming manual work.

Benefits

• Efficient snow removal - area is kept free from ice

and snow at all times

• No manual snow removal and salting becomes

unnecessary.

• Safe traffic and working areas for people

• Flexible system for most common surface covering

materials

• Cost saving for outdoor surface repair after winter

• Environment is protected against salting and

antifreeze related damages.

• Automatic ”Around the Clock” snow clearing service.

• Smart 2-zone control with low energy consumption

• Prioritizing – limited power output solution

• A maintenance free system with 20 year full

warranty on cables

One of the greatest advantages of

these systems is the most energy

efficient solution for the ground ice

and snow melting applications.

4

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

Page 5

2. System Description

Main purpose of the system is to melt

and remove snow and ice from ground

surfaces.

The most common Danfoss ice and

snow melting ground applications

are in residential car parking areas,

driveways, pavements, outdoor steps,

loading platforms, ramps, bridges and

drainage areas. It is even possible to

melt snow and ice on mastic asphalt

surfaces by using special heating

cables.

When heating cables are installed

to melt snow or slippery ice on the

ground, safety and cost saving go hand

in hand.

It can be done manually or in a smart

way – by means of electrical Ice &

Snow Melting system with thermostat

control and moisture and temperature

sensors that can control 2 zones

simultaneously. Inactive during cold

but dry weather 2 zone control saves

energy and reduces costs.

The automatic regulation of the snow

melting system keeps areas free from

snow and passable at all times – night

and day.

When installing ice and snow melting

systems on steep slopes it may be

necessary to provide some drainage for

melted water at the slope bottom. The

drain system should also be protected

against ice formations.

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

5

Page 6

3. Products

Electrical heating system consists of

two major components:

• Heating element – heating cable or

heating mat;

• Thermostat with a temperature

sensor or regulator/controller with

temperature and moisture sensor(s).

Heating cables and mats for Ground

applications are usually installed into

concrete construction or into special

glue under tiles.

Danfoss heating cables and mats for

Ground applications are designed for

installation in concrete constructions

or into special glue under tiles. Usual

thickness of top/finish concrete layer

for outdoor applications is at least 5

cm. But the thickness should comply

with a ground construction and local

norms and regulations.

Heating cables used in ground

constructions are serial resistive cables,

single or twin conductor. Most of

cables and mats are manufactured as

ready-to-install heating elements wth

a specific length (i.e. 7, 10, 15, up to

229 m), with connecting power supply

cable (cold lead or cold tail) and sealed

joints (muffs or end terminals).

Heating elements

For Ground Ice and Snow Melting

systems the following resistive

(constant wattage) heating elements

can be used.

Heating cables:

• Twin conductor ECflex 18T and

ECflex 20T (230 V);

• Single conductor ECbasic 20S

(230 V);

• Twin conductor ECsafe 20T (230 V);

• Twin conductor ECsnow 20T and

ECsnow 30T (230/400 V);

Note. The number at the end of the

cable’s and mat’s name refers to its

linear output – W/m or area output –

W/m², at 230 V or 400 V.

Letter “T” means twin conductor

cable/mat (Twin), letter ”S” – singleconductor cable/mat (Single).

Danfoss resistive heating cables ensure

safe, efficient and economical ground

application.

To ensure long life-time and quality

all cables are thoroughly inspected

including tests for ohmic resistance,

high voltage and material control.

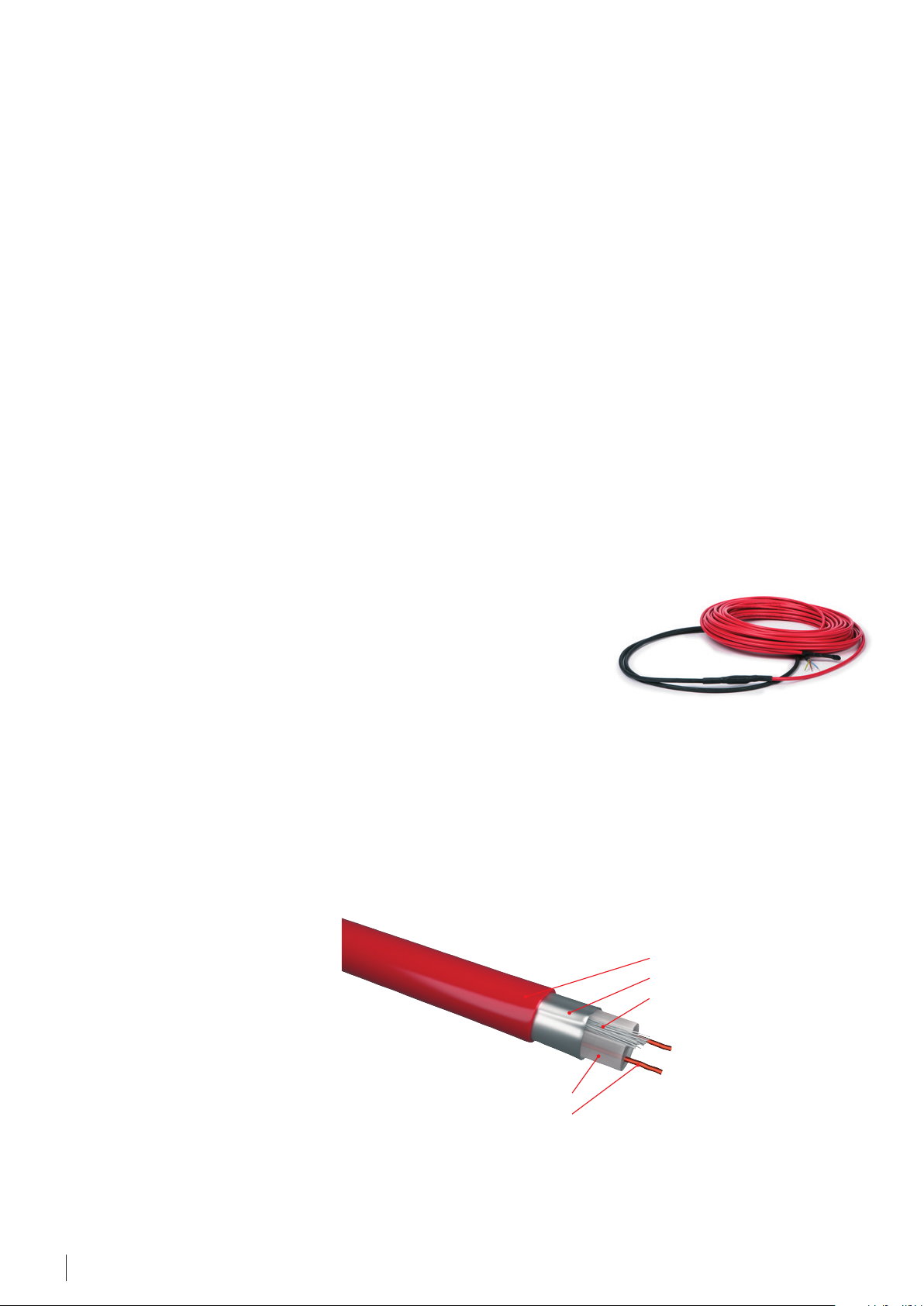

ECflex. It is a twin conductor fully

screened heating cable for installation

in concrete, pipe heating etc. The cable

complies with IEC 60800:2009 class M2,

and is designed for applications with

the high risk of mechanical damage.

It is supplied in readymade sets with

2,3 m cold lead, sealed joints and end

muffs.

Cable diameter is Ø 6,9 mm.

The cable is available for 230 V power

supply.

Cables of 18 and 20 W/m (230 V) linear

output are available.

Cable length:

ECflex 18T: 7,3-150 m ;

ECflex 20T: 7,1-148 m.

ECflex

Range of heating cables linear output

for ground application is usually

15-30 W/m. Danfoss ready-made

cables are available with 18, 20,

30 W/m output (for 230 and 400 V).

Most Danfoss cables are manufactured

and approved in accordance with the

latest revision of IEC 60800:2009, with

M2 mechanical strength class (for

rough concrete constructions).

The main type of Danfoss heating

cables is twin conductor heating

cables. Internal design of a modern

twin conductor ECflex cable are shown

in the figure below.

The most used heating elements for

Ground Ice and Snow Melting systems

are ECbasic, ECflex and ECsafe heating

cables.

Internal insulation ( XLPE)

Heating element (resistance thread)

ECflex heating cable construction

ECbasic. It’s a single conductor

screened heating cable complied with

IEC 60800:1992 class C and intended

for installation in concrete, for pipe

heating etc. It’s supplied in readymade

sets with 2 x 3 m cold leads and

2 sealed connection muffs.

Outer coating made of PVC

Protective screen foil (Aluminum)

Protective conductor

6

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

Page 7

Cable diameter is Ø 5,5 mm.

ECbasic 20S is available with

20 W/m output for 230 V power supply.

Cable length:

ECbasic 20S, 230 V: 9-228 m.

ECbasic 20S readymade

ECsafe. It is a twin conductor fully

screened heating cable for installation

on roofs, in gutters, down drain pipes

and on the ground.

The cable has UV stable tough outer

sheath which complies with IEC

60800:2009 class M2, and is designed

for applications with the high risk of

mechanical damage. It is supplied in

readymade sets with 2,5 m cold lead,

sealed joints and end muffs.

The cable is available with linear

output of 20 W/m and 30 W/m in two

options for 230 V and 400 V power

supply.

Cable length:

ECsnow 20T, 230 V: 12-205 m;

ECsnow 30T, 230 V: 8,5-215 m.

Fixing

In case of heating cables application,it

is recommended to use fittingbands

to fix the cable to the base, e.g. ECfast

metal galvanized fitting band (see

Appendix A.2 ). It should be attached

to the ground (e.g. nailed down) in

parallel lines usually at intervals of

50 cm or using 2 meters of fitting

band per each square meter of cable

installation. The same applies to plastic

bands.

ECfast

As an alternative to control small areas

near private houses etc. EFET 130 wall

mounted room thermostat can be used.

All thermostats above are supplied

with a wire temperature sensor –

NTC 15 kOhm @25 °C, 3 m.

To control ice and snow melting

systems especially with high output

the best solution is EFIT 850 regulator/

controller with integrated ground and

roof moisture and temperature sensors.

EFIT 850 is a two-zone controller with

possibility of connection up to 4

sensors to provide maximum control

of the outdoor heating system.

Comparing to installations with typical

ground temperature measuring this

regulator ensures reducing energy

consumption costs by up to 40%.

Cable diameter is Ø 7 mm.

The cable is available with linear

output of 20 W/m for 230 V power

supply.

Cable length:

ECsafe 20T, 230 V: 6-194 m.

ECsnow. It is a twin conductor fully

screened heating cable for installation

mainly on roofs, in gutters, down drain

pipes. It can be an option for installation

on the ground too. The cable has UV

stable tough outer sheath, FEP conductor insulation, it complies with IEC

60800:2009 class M2 and is designed

for applications with the high risk of

mechanical damage. It is supplied in

readymade sets with 2,5 m cold lead,

sealed joints and end muffs.

Cable diameter is Ø 7 mm.

Control

Ice and snow melting systems

are different and require different

thermostats/regulators.

EFET/EFIT thermostats and regulators

are fitted with a complete set of

control functions for heating systems

for ice and snow melting of any type

and allow attaching external sensors

for measuring ground temperature as

well as control of moisture conditions.

The product range of controls is

designed for ground outdoor systems

including the following:

• thermostats with a temperature

sensor – EFET 330 (5…45 °C),

EFET 610;

• regulator with an integrated

temperature and moisture sensor(s)

– EFIT 850.

EFET 330 (5…45 °C)

with wire sensor in set

EFIT 850

with ground sensor

EFET 610

ECsnow

To control simple or low output

systems a thermostat with a ground

temperature sensor is recommended.

EFET 330 (5…45 °C) thermostat

with the DIN rail attachment is

recommended as a standard solution.

Also can be used EFET 610, IP44 with

on wall/pipe mounting.

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

EFET 130

7

Page 8

Zone support saves energy

The EFIT 850 lets you divide your area

in to 2 zones, e.g. a North and South

side. In this way it is possible to save

energy, when the South side is free

of ice and snow faster because of the

heat from

the sun.

Prioritizing – for limited power

output

You can prioritize between the zones,

e.g. if you have limited power output.

This way one zone is made ice and

snow free before focus is put on the

other zone.

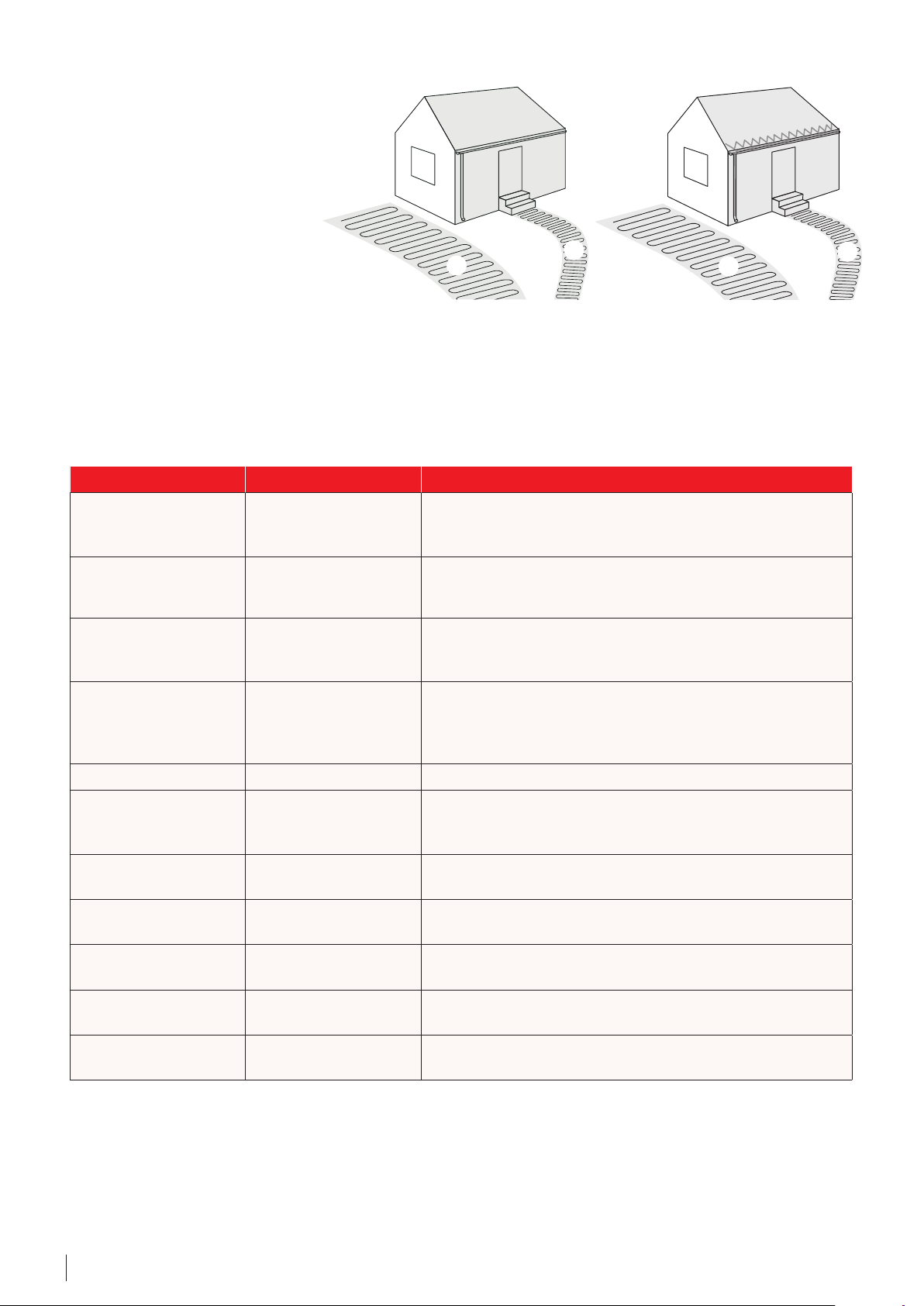

Products – general overview for Ground ice and snow melting systems

Product Options Description

Resistive heating cable

ECflex

Resistive heating cable

ECbasic 20S

ECflex 18T, 230 V;

ECflex 20T, 230 V

ECbasic20S,

230 V

A

B

Twin conductor, 100% screen, red.

18, 20 W/m (230 V).

DIN IEC 60800:2009 M2

Single conductor, wire screen, red.

20 W/m (230 V).

DIN IEC 60800:1992 C

A

B

B

Resistive heating cable

ECsafe 20T

Resistive heating cable

ECsnow

Fixing ECfast Metal 25 m pack; galvanized metal, fixings every 2,5 cm.

Regulator

EFIT

Moisture & temperature

sensor

Accessories

Thermostat

EFET

Thermostat

EFET

Thermostat

EFET

ECsafe 20T,

230 V

ECsnow 20T,

230 & 400 V program;

ECsnow 30T,

230 & 400 V program

EFIT 850

Ground sensor

for EFIT 850

PSU 24 V

for EFIT 850

EFET 330 (5…45 °C)

EFET 610

EFET 130

Twin conductor, 100% screen, UV stable, black.

20 W/m (230 V).

DIN IEC 60800:2009 M2

Twin conductor, 100% screen, FEP conductor insulation, UV stable,

black.

20 and 30 W/m (230/400 V).

DIN IEC 60800:2009 M2

Connection to Ground and Roof moisture and temp. sensor, max 4

sensors, 2 zones,

2x15 A, PSU 24 V, DIN rail

Ø93 x 98 mm, IP67, 15 m connection cable 4x1 mm²

Extra PSU for EFIT 850 with 3-4 sensors

5…45 °C, 16 A, IP20, with 3 m wire sensor,

DIN rail

-30…+50 °C, 10 A, IP44, with 3 m wire sensor,

on wall/pipe installation

5…45 °C, 16 A, IP30, with 3 m wire sensor,

room on wall installation

For additional information please refer to the Danfoss Catalogue.

8

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

Page 9

4. System Design

The following paragraphs contain

estimations according to ASHRAE,

Application Handbook and Historical

Weather Data.

Figures are for reference only and can

vary depending on the area size, wind

speed and ground construction.

4.1 Output

The heat required for snow melting

depends on the following main factors:

• Weather conditions (min.

temperature, max. snowfall rate, wind

speed, humidity, altitude);

• Project details (materials, foundation

type, dimensions, insulation);

• Electrical data (voltage, power, control

requirements);

• System performance expectations;

• Safety factor.

Evaluation of the specific output for

ice and snow melting systems can be

done based on the diagram and other

similar documents.

For more information about

performance of different ice and snow

melting systems, as well as control, see

Outdoor Application manuals.

No back loss & area width 6 m & 50% cloud cover

Surface temp. - 3 °C & 70% relative humidity

700

600

500

400

Heatloss [W/m²]

300

200

100

0

-3 -1 1 3 5 7 9 11 13 15 17 19 21 23 25

Temperature difference [K] between surface and ambience

Fig. 3. Wind and temperature dependent heat loss

When installing ice and snow melting

systems it may be necessary to

provide drainage for melted water at

the slope bottom, walkways, etc. The

drain system should also be protected

against ice formations.

0 m/s

2 m/s

4 m/s

6 m/s

8 m/s

10 m/s

15 m/s

20 m/s

25 m/s

30 m/s

For example, heat loss depending

on the wind speed and temperature

differences between the surface and the

ambient air is described in 2003 ASHRAE

Application Handbook (see fig. 3).

For example, for medium weather

conditions and 6 m/s wind speed, if

choosing ΔT = 10 K (from -3 K to +7 K)

the heat loss value is approx. 230 W/m²

(marked with the red dotted line in fig. 3).

In other words, surface heating up to

10 degrees requires 230 W/m² or

230 / 10 = 23 W/(m²·K).

All in all, for medium winter weather

conditions, heating of 1 m² outdoor

surface up to 1°С needs power of

approx. 23 Watts. Or the calculation

heat exchange coefficient for outdoor

surfaces is approx. 23 W/(m²·K)

(sometimes named α

– “alpha out”).

out

As an example IEC 62395-2 provides

another evaluation of typical snow

melting heat loads (see table 1).

Application criticality

Weathe r

severity

Mild 150 to 250 250 to 350 300 to 40 0

Severe 200 to 300 300 to 40 0 350 to 500

Very severe 250 to 350 400 to 550 450 to 750

Table 1. IEC62395-2. Typical snow melting heat loads

Minimum, for example,

residential walkways and

driveways

Values in table 1 less than 250 W/

m² should be used in limited circumstances, for example in countries with a

warm climate or based on the technical justification. Low output at the level

of 150-200 W/m² may be insufficient

for snow and ice melting.

Moderate, for example,

commercial walkways and

driveways

W/m²

Add 100 W/m² in the following cases:

• local winter design temperature is

lower than -15 °C;

• for every 1000 m altitude;

• if the heated area isafree standing

construction without insulation;

• if the local average wind speed is

Maximum, for example, tall

plazas, hospital emergency

entrances and helicopter

decks

>6 m/s;

For ice and snow melting systems it is

recommended the following simple

rule for output selection:

• if the more efficient system is required;

• if it snows at temperatures lower

than -10 °C.

• minimum– 250 W/m²,

• optimum – 350 W/m².

Note. It is recommended to design

output for ice and snow melting

Output for ice and snow melting systems

systems with maximum possible level.

should be designed in compliance with

applicable local norms and regulations.

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

9

Page 10

The recommended heat density values depend on the local climatic conditions and are shown in a table below.

Design temperature,

°C

-5 London 250 11

-15 Vienna, Beijing 350 15

-25 Oslo, Kyiv 400 17

-35 Moscow 500 21

Minimum melting temperature

The main task of ice and snow melting

systems is melting, i.e. to maintain

+3 °C on the surface. Any output

can be addressed to the lowest

temperature at which ice or snow

is still melting and a heating system

provides its main task. Table 2

shows some heat output (W/m²)

and temperature values at which the

system ensures ice & snow melting or,

in other words, provides constant

+3 °С on the surface.

City,

e.g.

Output,

W/m²

Recommended heat density,

W/m

Min air temperature

for +3 °C on surface

(α

= 23 W/(m²·K))

out

250 -8 °C

300 -10 °C

350 -12 °C

400 -14 °C

550 -21 °C

Table 2. Minimum melting air temperatures for

some outputs. ΔT surface-air is calculated as

output divided by the heat exchange coefficient

23 W/(m²·K).

2

°C

For example, if 250 W/m² is installed,

then the heating system enables

ice and snow melting at the air

temperature not lower than -8 °C

(ΔT = 250/23 ≈ 11 °C).

But if the ambient/air temperature is

-12 °C for instance, then the surface

temperature will be -1 °C, with

ΔT = -11 °C for output of 250 W/m².

It means that the system consumes

power to heat the surface, but doesn’t

melt ice or snow at all.

Maintenable air–surface ΔT,

4.2 Installation method for Ground applications

4.2.1 Heating cable/mat embedded in concrete

Heating cable/mat placed on concrete

or sand/grit basement.

• It is recommended to place the

cable min at 5 cm depth from the

surface if installed in concrete.

Concrete thickness has to be chosen

according to the local norms and

regulations.

• Make sure that the mat/cable

is fastened to the basement as

concrete might cause displacement

of the cable when poured.

• The concrete mixture must not

contain sharp stones which may

damage the cable.

4.2.2 Heating cable/mat with bricks/concrete tiles surface

Heating cable/mat placed into sand or

sand mixture.

• Special care must be taken to avoid

damage of the heating cable when

installed under bricks/tiles.

• The area must be completely

levelled and free of stones or other

sharp objects.

• The heating cable/mat must be

installed closely to the bricks/tiles,

typically in a sand layer (at least 2,5

cm under the brick/tile).

• Concrete needs 30 days to harden

before operation of the heating

cables.

Concrete

Heating cable/mat

Fixing: ECfast, mesh, etc.

Sensor tube

Concrete or sand/grit

Lower support of crushed stone, etc.

Ground

Bricks/Concrete tiles

Heating cable/mat

Fixing: ECfast, mesh, etc.

Sand or sand mixture

Sensor tube

Lower support of crushed stone, etc.

Ground

10

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

Page 11

4.2.3 Heating cable/mat with asphalt surface

Heating cable/mat placed into

protection layer. For information about

asphalt cable/mat installation please

refer to the “Asphalt application. Ice &

Snow Melting” Application manual.

• The cables must be covered with

sand or concrete (at least 2,5 cm)

prior to applying asphalt to protect

them from the asphalt heat.

• Allow asphalt to cool down to

130…140 ˚C.

• It is strictly prohibited to apply

asphalt directly onto the standard

cable/mat.

• Asphalt minimum thickness should

comply with local norms and

regulations.

4.2.4 Heating cable/mat with a thermal insulation layer

Heating cable/mat placed on a thermal

insulation into concrete protection layer.

• It is strictly prohibited to install

heating cable/mat directly on a

thermal insulating material.

• When a thermal insulation layer is

applied the concrete protection

layer should be provided.

• When laying a heating cable,

special care must be taken to avoid

its penetration of the thermal

insulating material.

Asphalt, one of several layers

Concrete, sand or similar material

Heating cable/mat

Fixing: ECfast, mesh, etc.

Sensor tube

Lower support of crushed stone, etc.

Ground

Surface (asphalt, bricks, concrete, etc.)

Heating cable/mat

Fixing: ECfast, etc; Mesh (optional)

Sensor tube

Concrete protection layer

Thermal insulation

Lower support of crushed stone, etc.

Ground

4.3 Insulation

The benefit of thermal insulation

is significant for free standing

constructions such as ramps or

bridges, steps, etc. Insulation of the

free sides of the construction must also

be considered.

For example, a 6 m wide bridge

is exposed to snow at -3 °C air

temperature and 4,5 m/s crossing

wind. Calculated approx. downward

heat losses are presented in the table

below.

Insulation

thickness

No insulation 36

20 mm 23

50 mm 15

100 mm 9

Downward

heat loss, %

Asphalt, one or more layers

Sand or concrete protection layer

Heating cable/mat

ECfast fitting or mesh for the cable

Insulation

Free standing construction

Ambient/air temperature

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

11

Page 12

4.4 C-C distance and corresponding output (W/m²)

The C-C distance is a centre-to-centre

distance between adjacent cables

(sometimes named “installation step”).

С-С

С-С

Note! Heating cable bending diameter

must be at least 6 times cable diameter.

4.5 Control

Ice and snow melting systems

are different and require different

thermostat types. The product range

of controls is designed for ground

outdoor systems including the

following:

• thermostats with a temperature

sensor – EFET 330 (5…45 °C),

EFET 610;

• regulator with integrated

temperature and moisture

sensors – EFIT 850.

To control simple or low output

systems – approx. up to 5 kW –

thermostat with a wire temperature

sensor is recommended.

To control systems with up to 10 kW

output a regulator/controller with

temperature and moisture sensors is

recommended. This solution should be

used for any smaller installations where

optimum power is a priority.

The C-C distance and corresponding

output W/m² can be calculated by

formulas – see Appendix.

Outputs for some cables with various

C-C distances for Ice and Snow

Melting Systems on the Ground are

presented in the table:

Heat density,

C-C distance,

cm

ECflex 18T

18 W/m

W/m² (230/400 V)

ECbasic 20S,

ECsafe 20T

20 W/m

5 360 400 600

7,5 240 270 400

10 - - 300

12,5 - - 240

can be used. Please pay attention to

Temperature adjustment.

the right place for the thermostat

installation, considering that this is an

IP20 room thermostat.

The temperature sensor is mounted

below the surface near the heating

cable, where it is “warmer” than on

To control ice and snow melting

systems EFIT 850 regulator/controller

with an integrated temperature and

moisture sensor is recommended at

the optimum power. We recommend

the surface. This enables system

adjustment to the desired temperature:

for each 1 cm below the surface it

should be adjusted to about +1,5 °C or

approx. 1,5 °C/cm.

this regulator for installations with

output exceeding 10 kW or for any

smaller installations where optimum

power is a priority.

For example, if the sensor is installed

under the pavement of 10 cm thickness,

temperature adjustment should be:

1,5 °C/cm · 10 cm = 15 °C. Taking into

account the required +3 °C at the

A

surface, the thermostat should be set to

15 °C + 3 °C = 18 °C. Therefore, the use

of EFET 330 with temperature range

-10… +10 °C is not recommended since

it is impossible to set temperature over

+10 °C.

B

B

Running costs

ECsnow 30T,

30 W/m

The wire temperature sensor is usually

installed in a conduit pipe nearby the

heating cable (“in the ground”).

EFET 330 (5…45 °C) thermostat

with the DIN rail attachment is

The ground sensor is equipped with

a 15 m cable for connection to a

regulator. The cable length can be

adjusted in accordance with the

Installation Instruction.

recommended as a standard solution.

It can be also used

EFET 610, IP44.

a wall/pipe mounted

Comparing to installations with typical

ground temperature measuring this

regulator allows reducing energy

As an option, to control small areas

consumption costs of up to 40%.

nearby private houses, etc., wall

mounted room thermostat EFET 130

12

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

The running costs are largely

influenced by how the system is

controlled. EFIT 850 is a more efficient

solution since a moisture sensor

enables its switching to a standby

mode during dry periods.

Thermostat Sensor type

EFIT 850

EFET 330

Reference Air temperature 2-5

Ground

temperature

and moisture

Ground

temperature

(e.g, +3 °C)

Running

cost index

1

1,2-1,4

Page 13

4.6 Design

0,5 m

Board

0,5 m

10 m

The system is usually designed taking

the available power supply into

account. If the available power supply

is limited, then:

• Reduce the area to be heated, e.g.

by heating tire tracks instead of the

whole driveway.

• Divide and prioritize the area in 2

zones by means of EFIT 850 or e.g.

2 EFET 330 (5…45 °C).

• Install minimum recommended W/

m², knowing that the snow melting

performance is reduced.

• Do not install less W/m² than

recommended in areas of drainage

e.g. in front of heated steps.

If the snow melting system is

undersized, e.g. due to power

limitations, the system will respond

slower and less efficiently. A higher

temperature level compensates this,

but causes higher running costs.

If the snow melting system is oversized,

the system will respond faster and

more efficiently. To lower the standby

temperature and running costs, EFIT 850

can be used.

Example 1.

Walkway with pavement blocks

An ice and snow melting system is

required to melt snow from a 2 x 10 m

walkway with pavement blocks on

sand. Power supply voltage is 400 V.

H

eating cable ECsnow 30T

400 V with C-C = 10 cm (300 W/m²) can

be chosen: either 5770 W (190 m, 19

m²) or 6470 W (215 m, 21,5 m²).

When thermostat EFET 330 (5…45 °C)

with a sensor cable placed in the

ground is chosen, EFIT 850 with two

ground sensors can be selected as an

option.

Example 2.

Driveway near garage of

a private house

Due to restriction of power supply it

should be recommended installation

of a heating cable in two tire tracks

instead of the whole driveway. Width

of tire track is 0,5 m.

1. Cable selection. For this system

it can be used for instance a

two-conductor ECflex 18T (see

chapter 3). To comply with the

recommended in 4.1 output of

350 W/m² it should be chosen

C-C = 5 cm that gives specific

output of 360 W/m² (see

Appendix A.1).

2. Calculation of the cable

installation area:

10 m · 0.5 m · 2 track = 10 m².

3. Calculation of

the total system power:

10 m² · 360 W/m² = 3600 W.

4. Selection of cable power/

length. Cable ECflex 18T with

3600 W output does not exist (see

Danfoss Catalogue), so you should

apply two cables with total capacity

of about 3600 W, i.e. cables with

the output: 3600 / 2 = 1800 W.

This output can be ensured by for

instance ECflex 18T – 90 m, 1625 W,

2 pcs. The total output of two cables

will be 3250 W that is a bit less than

the calculated value, and for C-C = 5

cm the heating area is approx. 9 m².

Alternatively you can select two

ECflex 18T – 105 m, 1880 W with

total output – 3760 W.

Note. If the driveway near the

garage has a tray for water drainage,

it is necessary to install at least two

lines of cable along the drainage

and its length should be taken into

account when choosing the cable.

5. Length of fixing tape. The cable

can be attached by e.g. ECfast.

Installation step is typically 50 cm

and the length is defined as the

heating area multiplied by 2 that is

10 m² · 2 = 20 m of ECfast.

6. Thermostat selection. Since the

system output is small – less than

recommended 10 kW (see 4.3),

you can choose “simple” EFET 330

(5...45 °C) with a wire temperature

sensor, which is installed in the

ground.

An appropriate connection scheme

should be chosen – with or without

contactor. The output of two 90 m

cables is 3250 W that enables their

connection to one EFET 330 of max

3680 W, therefore an additional

contactor is not required. The

output of two 105 m cables is 3760

W that disables their connection

to one EFET 330, therefore an

additional contactor is required.

7. Calculation of thermostat

temperature settings (see 4.3).

The installation depth of a wire

temperature sensor is 6 cm and

in order to maintain the surface

temperature of +3 °C the following

value should be set:

1,5 °C/cm · 6 cm + 3 °C = 12 °C.

Data: driveway dimensions – 10 m

length, 2 m width; surface thickness –

6 cm; power supply – 230 V; restriction

of power for electricity connection.

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

13

Page 14

5. Installation

9

4

6

5

8

7

2

3

1

5.1 General safety instructions

!

Never cut or shorten the heating

element.

• Cutting the heating element will

void the warranty.

• Cold leads can be shortened to suit

requirements.

Elements must always be installed

according to local building regulations

and wiring rules as well as the

guidelines in proper installation

instructions and this manual.

• Any other installation may hamper

element functionality or constitute

a safety risk, and will void the

warranty.

• Make sure that elements, cold

leads, connection boxes, and other

electrical components do not come

into contact with chemicals or

flammable materials during or after

installation.

Elements must always be connected

by an authorized electrician using a

fixed connection.

• De-energize all power circuits

before installation and service.

• The connection to the power source

must not be directly accessible to

the end user.

• Each heating cable screen must

be earthed in accordance with

local electricity regulations and

connected to a residual current

device (RCD).

• Recommended RCD trip rating is

30 mA, but may be up to 300 mA

where capacitive leakage may lead

to nuisance tripping.

• Heating elements must be

connected via a switch providing all

pole disconnection.

• The element must be equipped

with a correctly sized fuse or circuit

breaker, e.g. 10/13 A for a 1,5 mm²

cold lead and 16/20 A for a 2,5 mm²

cold lead.

The presence of a heating element

must

• be made evident by affixing caution

signs or markings at the power

connection fittings and/or

frequently along the circuit line

where clearly visible

• be stated in any electrical

documentation following the

installation.

Never exceed the maximum heat

density (W/m² or W/m) for the actual

application.

1. Fuse

2. RCD

3. All-pole switch

T

RCD

I≤30 mA

TS

14

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

4. Thermostat

5. Conduit pipe

6. Sensor

7. Connection muff

8. Cable screen

9. Heating cable

Page 15

5.1.1 When making installation:

Prepare the installation site properly by

removing sharp objects, dirt, etc.

Heating elements may not touch or

cross themselves or other heating

elements and must be evenly

distributed on areas.

Regularly measure Ohm resistance and

insulation resistance, minimum: before,

during and after installation.

The elements and especially the

connection must be protected from

stress and strain.

Do not install heating elements under

walls and fixed obstacles. Min. 6 cm

space is required.

Keep elements clear of insulation

material, other heating sources and

expansion joints.

The element should be temperature

controlled and not operate at ambient

temperature higher than

10 °C in outdoor applications.

5.1.2 Planning the installation

Draw a sketch of the installation

showing

• element layout

• cold leads and connections

• junction box/cable well (if

applicable)

• sensor

• connection box

• thermostat/regulator

Save the sketch

• Knowing the exact location

of these components makes

subsequent troubleshooting and

repair of faulty elements easier.

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

Please observe the following:

• Observe all safety guidelines.

• Observe correct cable C-C

distance and distance between

mats.

• Observe required installation

depth and possible mechanical

protection of cold leads according

to local regulations.

• When installing more than one

heating element, never wire

elements in series but route

all cold leads in parallel to the

connection box.

• For single conductor cables, both

cold leads must be connected to

the connection box.

15

Page 16

5.2 Installation

5.2.1 Preparing the installation area

Remove all traces of old installations, if

applicable.

• Ensure that the installation surface is

even, stable, smooth, dry and clean.

• If necessary, fill out gaps around

pipes, drains and walls.

• There must be no sharp edges, dirt

or foreign objects.

5.2.2 Installing heating elements

It is not recommended to install

heating elements at temperatures

below -5 °C.

At low temperatures, heating cables

can become rigid. Connect the cable/

mat to the mains for a short time

(few minutes). The cable or mat must

be rolled out during this process!

• The ohmic resistance must be

within -5 to +10 % of the value

labeled.

• The insulation resistance should

read >20 MΩ after one minute at

min. 500 V DC.

Observe all instructions and guidelines

in section about general safety and in

proper installation instructions.

Heating elements

• Position the heating element so that

it is at least half the C-C distance

from obstacles.

• Heating elements must always

be in good contact with the heat

distributor (e.g. concrete).

• When using heating mats secure

them to the ground, some mats are

mitted with a glue covered surface,

it attaches well to a cleaned and

primed surface.

6.2.3 Installation summary

Prepare installation surface with

fastening accessories and/or mesh

reinforcement.

Apply sensor conduit Ø 16-20 mm. Fix

conduit for sensor tube for EFIT 850

ground sensor, if any.

Place cold leads and connections in a

dry place. Seal all penetrations through

walls or similar structures. Apply

caution tape above cold leads.

After laying blocks or pouring

concrete/asphalt, install external

sensor(s), and extend sensor cable(s)

according to the sensor manual.

Measuring resistance

Measure, verify and record element

resistance during installation.

• After unpacking.

• After fastening the elements.

• After the installation is finalized.

If Ohm resistance and insulation

resistance are not as on label attached

to product and product transportation

box, the element must be replaced.

16

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

Heating mats

• Always roll out heating mats with

the heating cables facing up.

• When the heating mat reaches the

area boundary, cut the liner/net and

turn the mat before rolling it back.

Extending cold leads

• Avoid extending cold leads if

possible. Wire cold leads to e.g.

junction boxes or cable wells.

• Be aware of power loss in the

extending cold leads according to

local regulations and wiring rules.

The EFET/EFIT thermostat/regulator

must be commissioned as prescribed

in the installation manual and adjusted

where local conditions vary in relation

to factory settings.

Before every season, check for faults

in the switchboard, thermostat and

sensors.

Page 17

5.3 Precautions

Ensure to clean the area properly from

stone and sharp edges.

Protect the heating cables against

excessive use of rakes, shovels,

vibrators and rollers.

Ensure that all cables turn towards the

electrical cupboards where the cables

shall be connected.

Remember that the cable always shall

be fully embedded to avoid air gaps.

For second layer of asphalt should be

used drum/roller with the maximum

limited load of 500 kg.

It is not allowed to drive directly on

the cables with heavy trucks or asphalt

machinery. It will immediately lead to

cable damages.

5.3.1 Important

All electrical connections must be

done by authorized persons according

to local regulations.

When extending cold lead, observe:

• That there is max. 5% loss of

potential power in the whole length

of the cold cable.

• That the leak current of the whole

installation is less than 1/3 of the

RCD trigger level.

Thermostat controlling ground

temperature is mandatory.

Do not tip the wheel barrow by

supporting it directly on the cables.

Fasten the cables to the subconstruction in short distances to

ensure that the cable remains in right

position.

It is recommended to connect a buzzer

or other alarm giving device to the

cables if an incident anyway should

occur during installation despite all

caution and a cable is being damaged.

Then there will be the ability to quickly

detect this and get the problem solved

at the lowest possible cost and delay.

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

17

Page 18

6. Appendixes

A.1. C-C distance and corresponding output W/m²

The C-C distance is a centre-tocentre distance between the cables

(sometimes named installation step or

Cable-to-Cable distance).

When heating cables are installed, we

recommend the use of ECfast fitting

bands. These bands are designed

to ensure a C-C distance at regular

intervals of 2,5 cm, e.g. 5 cm, 7,5 cm, 10

cm, 12,5 cm, etc.

Two different formulas may be used to

calculate the C-C distance:

1) Using heating cable length

Heated floor space [m²] · 100 [cm/m]

C - C [cm] =

Cable length [m]

· 100 cm.

2) Using cable specific output and

output per m²:

C - C [cm] =

Output per m² heated floor space [W/m²]

Cable specific output [W/m] · 100 [cm/m]

C-C distances and corresponding outputs per m² for some linear outputs of heating cables.

Example 1

For a renovation we choose a ECflex 10T

cable (specific output is 10 W/m).

If the chosen output is 120 W/m²,

the calculated by formula no. 2 C-C

distance is:

10 W/m · 100 cm/m

C - C =

120 W/m²

= 8,33 cm.

Example 2

The ECflex 18T, 535 W, 29 m is to be

installed in a bathroom with heated

floor space of 3 m².

The calculated by formula no. 1 C-C

distance is:

3 m² · 100 cm/m

C - C =

29 m

· 100 cm = 10,35 cm.

If we use ECfast fitting bands with

regular intervals of 2,5 cm, we can

install the heating cable in this

bathroom with a C-C 10 cm.

Thermal output of heating surface for several Danfoss heating cables at 230* or 400* V,

C-C

distance,

cm

6 W/m 10 W/m 18 W/m 20 W/m 30 W/m

ECflex 6T

ECflex 10T,

ECbasic 10S

W/m²

ECflex 18T

ECflex 20T,

ECbasic 20S

ECsnow 30T

5 120 200 360 400 600

7,5 80 133 240 270 400

10 60 100 180 200 300

12,5 48 80 144 160 240

15 40 67 120 133 200

17,5 34 57 103 114 170

20 30 50 90 100 150

22,5 26 45 80 89 133

25 24 41 72 80 120

Usually used for Direct floor heating

* The outputs at 220 or 380 V has to be recalculated with the coefficient of 0,91.

Recommended

for Ice and snow

melting and Frost

protection systems

Recommended

for Comfort floor

or Direct heating

systems

Surface heating,

etc.

18

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

Page 19

A.2. Fitting

1 m

1 m

1

2

3

4

If we want to calculate the length of

fitting band (e.g. ECfast), first of all

we should determine the distance

between the fitting bands.

For concrete installation, where cable

is covered with 3 cm concrete or more,

and the C-C distance exceeds 10 cm,

the recommended distance between

fitting bands is 0,5 m.

For thin constructions where cable is

covered with 1-2 cm of self-leveling

compound and the C-C distance is

10 cm or less, the max. recommended

distance between fitting bands is

25 cm.

Below is a calculation formula for

C-C distance.

Length of fitting band [m] =

Heated floor space [m²]

=

Distance between fitting bands [m]

[m]

+ L

w

Lw is the length of the wall parallel to

fitting bands installation.

Example

The heated floor space is

1 m x 2 m = 2 m².

If we install ECfast fitting bands in

parallel to a 1 m wall (see fig. 1) and

the distance between the ECfast fitting

bands is 0,5 m, a fitting band with the

following length is required:

2 m²

0,5 m

+ 1 m = 5 m.

If we install ECfast fitting bands in

parallel to a 2 m wall (see fig. 2) and

the distance between the ECfast fitting

bands is 0,5 m, a fitting band of the

following length is needed:

2 m²

0,5 m

+ 2 m = 6 m.

As we can see from this example, the

fitting band length may vary although

the area and the distance between

fitting bands remain the same.

2 m

Fig. 1 - Fitting band installed in parallel

to a 1 m wall.

2 m

Fig. 2 - Fitting band installed in parallel

to a 2 m wall.

Fixing of the heating cable on the ECfast fitting band.

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

19

Page 20

A.3. Wire sensor installation

Regardless of the system type it is

always recommended install a ground

wire sensor or integrated ground

moisture and temperature sensor.

Before installation of the outdoor

heating mat or cable, determine

proper location for the connections

(indoor or outdoor) and make

a recession in the wall for the

mounting/connection box. Cut out

the wall groove from the connection

box location down to the ground

for connection cable (cold lead) of

the heating cable and a temperature

sensor conduit.

Wire sensor is usually mounted in a

corrugated plastic pipe with 10-20

mm diameter. The pipe is laid in the

wall grove starting from the mounting

box and along the underlay to the

heating area.

It must be installed within the heating

cable zone, at least 0,5-1 m inside (see

attached picture). The pipe should

enable easy replacement of a wire

sensor (remove-insert) through a hole

in the mounting box.

Where the pipe is bent between the

ground and the wall, the minimum

bending radius is 6 cm (marked R1

in the figure). It is necessary to make

a smooth bend of corrugated pipe

when going from the wall to the

ground.

The pipe end has to be sealed to

avoid concrete penetration inside it

(A mark in the figure). The pipe/sensor

must be positioned in the centre of an

open end of a cable loop and usually

at the same level or slightly above the

heating cables.

If thin heating mat is installed, conduit

pipe has to be laid in a groove so it

does not overhang above the surface.

Groove in the ground is also required

for the cold lead and muff for the

same reason.

Sensor cable can be extended to any

reasonable length, using a cable min.

0,75 mm².

After the wire temperature sensor

is installed it is recommended to

measure resistance.

For information about installation

of integrated ground moisture and

temperature sensor see proper

Installation Instruction.

Power supply cable

Heating cable,

cold lead

R1

To electrical board

Extension cable for sensor

Connection box

Wire sensor

50

Sensor has to be installed between two heating cables and, preferably a bit above their level.

20

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

-100 cm

Page 21

A.4. General installation guide

The installation of heating cables

and thermostats should comply with

general and local regulations. The

cables and the thermostats should

only be connected by an authorized

electrician and connected to an RCD.

It is important that the construction

is well insulated according to the

building standards so the downward

heat loss is kept to a minimum.

Rim zone insulation, along the walls,

which should be efficient in order to

prevent heat from being transported

to the foundation walls or adjoining

rooms, and allowing for thermal

expansion of the concrete.

The foundation must be clean and free

of sharp objects.

The cables must never get into contact

with the insulation material or become

enveloped by it in any way.

The cables must be evenly spread on

the available ground and led around

permanently fixed objects such as

bathtubs etc.

The cables must be gently attached so

they are not damaged.

The concrete around the cables must

not contain sharp stones and should

have a consistency enabling it to

surround the cable completely without

leaving air pockets.The concrete

should be applied very carefully in

order not to damage the heating

cables!

A damp proof membrane is needed

to prevent moisture from moving

upwards and into the construction.

The wire of the ground sensor must be

protected by a plastic pipe.

The wire sensor must be positioned in

the centre at an open end of a cable

loop. Where the pipe is bent between

the ground and the wall, the minimum

bending radius is 6 cm.

The pipe must be sealed at the end

to prevent concrete from entering.

Should the cable become damaged

while being laid out or later during the

building process, it is a great advantage

in the fault finding process to know

the exact positioning of the the

connection box between the heating

cable and the cold cable as well the

cable end, and the cable layout. It is

therefore important to make a sketch

showing the positioning of these

things in the room.

Heating cable and wire sensors

resistance needs to be measured

before, during and after installation

of concrete, before thermostat is

connected.

The heating cable and the connection

muff between the heating cable and

the cold cable must both be cast in

concrete. If the cable is pushed down

into the insulation material or covered

by it in any other way, the surface

temperature may become too high,

that might result in cable defects at

worst.

At low temperatures (below 5 °C) the

cable can become difficult to handle

due to the plastic sheath. This problem

can be overcome by connecting

the cables for a short period. For

this purpose THE CABLE MUST BE

ROLLED OUT! When the cable has

become flexible again, the electrical

flow should be disconnected. It is

not recommended to lay cables at

temperatures below -5 °C.

The ground heating must not be

turned on before the concrete has fully

set. It takes approximately 30 days for

concrete and usually

10-15 days for molding compound,

tile glue etc. (it is important to

comply carefully with manufacturer’s

recommendations).

Keep a min. 5 cm air gap beneath

permanent objects and ground surface

with installed heating.

To ensure an accurate and easy

installation of the cables, ECfast fitting

bands can be used.

The ECfast fitting bands are equipped

with attachment clips at intervals of 2,5

cm so the distance between the cable

loops will be

5, 7,5, 10, 12,5, 15, etc.

Concrete must be laid out in such a way

to avoid air pocket inside it.

In connection with wet rooms

(bathrooms etc.) a damp proof

membrane should always be used

in order to prevent moisture from

entering the construction.

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

21

Page 22

Notes

22

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

Page 23

Notes

Application manual · Ground application. Ice & Snow Melting · VGHWD102 · ©Danfoss

23

Page 24

7. Cases

ROZADOL BRATISLAVA

Bratislava, Slovakia

Purpose of the Danfoss system:

Ice and snow melting on driveway in

underground garage.

Project size:

400 m².

Products:

• ECflex 18T;

• EFIT 850.

CINEPLEXX CINEMA,

Hohenems, Austria.

Purpose of the Danfoss system:

Outdoor heating of the stairs to the

entrance.

Project size:

89 m² area heated with 86 pcs. mats.

Products:

• ECsnow 30T, 400 V;

• EFIT 850 + Ground sensor.

© Copyright Danfoss | Dec 23, 2016VGHWD102

Loading...

Loading...