Page 1

Installation Guide

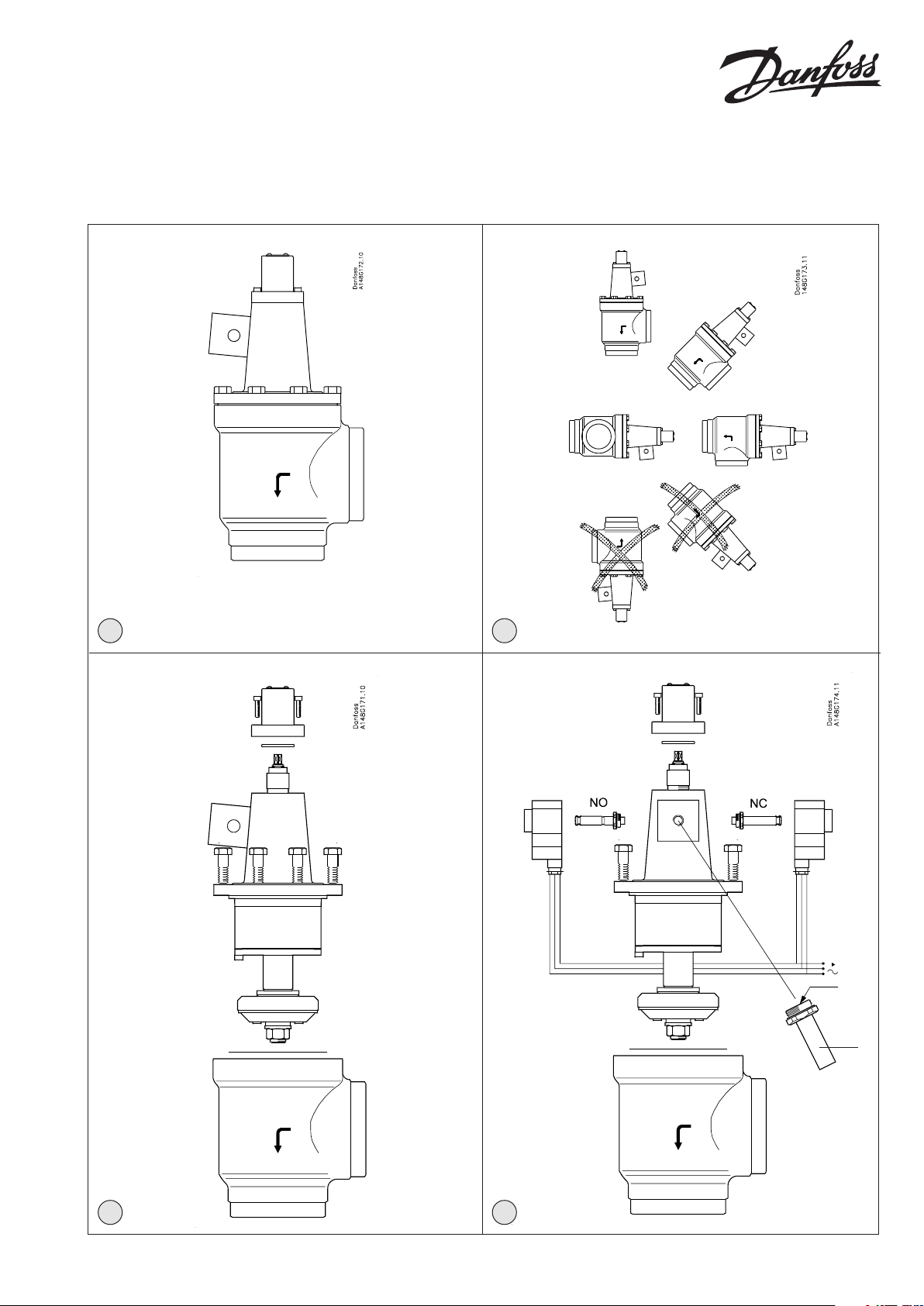

2-step solenoid valve

GPLX

Installation

148R9 513

1 2

148R9 513

G ¼”

A

3 4

© Danfoss A/S (MWA), 2015-03 DKRCI.PI.BO0.A4.02 / 520H4693 1

Page 2

Maintenance

Pos. 4 Nm LB-feet

DN 80 50 37

DN 100 100 74

DN 125-150 130 96

Pos. 20 Nm LB-feet

DN 80-100 100 74

DN 125-150 145 106

Pos. 24 Nm LB-feet

DN 80 44 32

DN 100 75 55

DN 125-150 183 135

5 6

7 8

2 DKRCI.PI.BO0.A4.02 / 520H4693 © Danfoss A/S (MWA), 2015-03

Page 3

ENGLISH

Installation

Application

The GPLX valves are specially designed for

evaporator return lines. The GPLX valve

enables the evaporator to be defrosted

when closed. It also ensures a proper and

safe equalization of the evaporator before

reaching its fully open position upon

defrost sequence completion.

Note:

Since GPLX valves remain closed while

de-energized, the valves must not be used

for applications where seat tightness is

essential over a long period of time (a small

leak-by rate when closed may occur).

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia)

and R744 (CO2).

Flammable hydrocarbons are not

recommended. The valves are only

recommended for use in closed circuits.

For further information please contact

Danfoss.

Temperature range

GPLX: –60º/+150ºC (–76º/+302ºF)

Pressure range

GPLX: The valves are designed for a max.

working pressure of 40 bar g (580 psi g).

Installation

GPLX valves in sizes DN 80 to DN 150 can

be installed as shown in g. 2, i.e. in 90º

from vertical position with pilot valve

and side branch downwards. If there is

welding slag and/or dirt in the system, it is

strongly recommended to install strainers

in connection with the GPLX valve.

The valve is designed to withstand a high

internal pressure. However, the piping

system should be designed to avoid liquid

traps and reduce the risk of hydraulic

pressure caused by thermal expansion. It

must be ensured that the valve is protected

from pressure transients like “liquid

hammer” in the system.

It is important always to install strainers

in the pipes leading to the pilot valves.

Recommended ow direction (Fig. 1)

Important:

The ow direction must be from the side

branch towards the cone.

Welding (Fig. 3)

Remove the actuator before welding to

prevent damage to the gasket (pos. 17)

between the valve body and bonnet, as

well as the teon gasket (pos. 18, 19) in

the valve seat. Only materials and welding

methods, compatible with the valve

housing material, must be welded to the

valve housing.

The valve should be cleaned internally to

remove welding

debris on completion of welding and

before the valve is reassembled.

Avoid welding debris and dirt in the

threads of the housing and the bonnet.

Removing the bonnet can be omitted

provided that:

The valve housing must be free from

stresses (external loads) after

installation.

OBS: Be sure not to damage the

teon gasket (pos. 18, 19) and the

spindle surface (pos. 3). If these parts

are damaged the valve will leak.

Removing the bonnet can be omitted

provided that:

The temperature in the area between the

valve body and bonnet during welding

does not exceed +150°C/+302°F. This

temperature depends on the welding

method as well as on any cooling of the

valve body during the welding itself.

(Cooling can be ensured by, for example,

wrapping a wet cloth around the valve

body.) Make sure that no dirt, welding

debris etc. get into the valve during the

welding procedure.

Be careful not to damage the gasket (pos.

17).

The valve housing must be free from

stresses (external loads) after installation.

GPLX valves must not be mounted in

systems where the outlet side of the valve

is open to atmosphere. The outlet side of

the valve must always be connected to the

system or properly capped o, for example

with a welded-on end plate.

Assembly (Fig. 5)

Remove welding slag and dirt from pipes

and valve body.

OBS: Only 1 hot gas supply is required

(Pos. A on g. 4); connect this supply to

the pilot valve armature.

Colours and identication

The GPLX valves are painted with a

yellow oxide primer in the factory and the

external actuator top is zinc-chromated.

Precise identication of the valve is made

via the ID plate (pos. 41) at the top of the

cap (pos. 12), as well as by the stamping on

the valve body. The external surface of the

valve housing must be prevented against

corrosion with a suitable protective coating

after installation and assembly.

Protection of the ID plate when repainting

the valve is recommended.

Maintenance

Replacement of sealing elements disassembling of GPLX

Evacuate the pipe system in which the

valve is installed. Switch o the pilot

current and the hot gas supply. Remove

the bolts (pos. 24). Remove the valve top

(actuator).

Replacement of teon rings in the seat

(Pos. 18 and pos. 19)

Remove the nut (pos. 20), the screw (pos.

22), the valve cone (pos. 8 and pos. 10), and

remove the bushing (pos. 9).

Replace the Teon rings (pos. 18) and (pos.

19) and assemble the parts in reverse order.

Replacement of sealing rings (pos. 27),

(pos. 29) and (pos. 30)

A. Remove the cap (pos. 12) and the lock

ring (pos. 38). Unscrew the spindle (pos.

13) clockwise till it is disengaged from

the thread.

B. Unscrew the bolts (pos. 23), Pull

the spindle (pos. 3) out of the

valve top. Unscrew the bolt (pos. 4)

counterclockwise. Remove the springs

(pos. 15 and 16) and the spindle (pos.

13) and bushing (pos. 14). Pull out the

piston (pos. 6) and guide (pos. 7)

C. NB: Handle the valve spindle very

carefully, as any damage (e.g. scratches

and marks) to the spindle may cause

valve leakage.

D. Remove the sealing rings (pos. 27, 29

and 30).

At renovation of the valve Danfoss

recommends replacement of all

sealing elements. The spare parts set

for the GPLX valves includes all sealing

elements.

E. Mount the O-ring (pos. 25, 28) and then

the sealing ring (pos. 29, 30) as shown in

g 7. Important:

Fold the sealing ring as shown. Be

certain that there are no sharp folds and

do not use tools to mount the sealing

ring.

F. Mount the O-ring (pos. 26) and then the

sealing ring (pos. 27) as shown in g 6.

In order not to damage the ring use 2

plastic strips to pull the ring to the right

place.

G. Reassemble the actuator in reverse

order: C-B-A. NB. Turn the piston (pos. 6)

as shown on g. 5.

Manual opening (Fig. 8)

In case of power loss the GPLX valve

will close (NC). The valve can be opened

by hand, if the cap (pos. 12) is removed

and the spindle (pos. 13) is turned anticlockwise. To close the valve, turn the

spindle (pos. 13) clockwise.

© Danfoss A/S (MWA), 2015-03 DKRCI.PI.BO0.A4.02 / 520H4693 3

Page 4

The spindle (pos. 13) must be screwed

to the lowest possible position (contact

between spring ring (pos. 38) and thread

bushing (pos. 11) during normal operation.

Tightening (Fig. 4)

Tighten the bonnet with a torque wrench,

to the values indicated in the table.

Use only original Danfoss parts, O-rings

and gaskets for replacement. Materials of

new parts are certied for the relevant

refrigerant. In cases of doubt, please

contact Danfoss.

Danfoss accepts no responsibility for

errors and omissions. Danfoss Industrial

Refrigeration reserves the right to make

changes to products and specications

without prior notice.

4 DKRCI.PI.BO0.A4.02 / 520H4693 © Danfoss A/S (MWA), 2015-03

Loading...

Loading...