Page 1

Data Sheet

Gas detection unit

Basic

Type GD Basic and Basic+

Next generation gas detection for industrial refrigeration

The Basic and Basic+ gas detection units are

used for monitoring and warning of hazardous

gas concentrations. They can be used for

detecting commonly used refrigerants.

Depending on the application, they are

available with an electrochemical or a

semiconductor sensor.

The Basic and Basic+ gas detection units are

intended to be connected to a central system

like Gas Detection Controller Unit, or a PLC, by

either Analog or RS485 open Modbus

communications. The central system converts

the alarm signal from the Basic unit to

activation of alarm devices.

The gas detection units come with a factory

default, 2-step alarm set-up ready for use. The

integrated software enables the user to

congure two individual alarm ranges. Alarm 1,

a pre-alarm indicating the gas level has passed

a predened treshold 1, and - if the gas level

passes predened treshold 2 - the nal alarm 2.

AI272545693488en-000701

Page 2

Gas detection unit, Basic

Features

• Digital, factory congured and pre-calibrated gas detectors for plug-and-play installation (no adjustment

required)

• Easy conguration via intuitive user-interface; helps simplify operator handling and minimize risk of operational,

settings and calibration errors

• Flexible connection - by either Analog or RS485 open Modbus communications

• Fieldbus wiring - connect and power up to 96 sensors, wire length max. 900 meter per segment; expansion

modules permits additional segments

• Automatic self-diagnostics to ensure correct communication and operation

• Sensor seal cap to prevent premature exposure during installation

• Digital user interface ensures higher sensor accuracy

• Reduced risk of false alarms due to temperature compensated sensors

• Password protected alarm settings allowing authorized access only

• LED status signals and alarms

• Buzzer & Light option for local audio and visual alarms (Basic+)

• On-board acknowledge button to reset alarms and to verify the that no gas leaks are present

• Service alerts on unit, controller or both, readable via service tool Display

• Quick and precise calibration procedures - either by Plug & Play replacement sensors or calibration with gas. No

potentiometers or multi-meters required

• For improved safety and to optimize the lifetime of the sensor, degenerated sensors with too low sensitivity

(<30%) are rejected during calibration process

• Conformity to EN 50271, EN 61010-1, ANSI/UL 61010 1, CAN/CSA-C22.2 No. 61010-1

• Enables regulatory compliance with EN 378:2016, ISO 5149:2014, IIAR 2-2017, and ASHRAE 15:2016

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 2

Page 3

Gas detection unit, Basic

Functions

Working principle/Operation

One sensor can be connected to the Basic/Basic+ sensor board via local bus. The Sensor board provides the power

supply of the sensor and prepares the measured data for digital communication.

The operation menu of the Basic/Basic+ software is accessed through the connected Gas Detection Controller or via

the dedicated GD Service tool (or PC tool). The Service tool (or PC tool) is plugged directly to the board of the unit.

The interfaces allow the unit conguration, setting of the unit alarm levels and calibration of the attached sensor.

The service tool (or PC tool) can be used on all units across the Basic, Premium and Heavy Duty platforms.

The alarm signals can be handled by the Gas Detection Controller (or a PLC) via the 4 – 20 mA (2 – 10V) analog

output or the RS485 open Modbus communication. For additional operational safety the changing of parameters is

password protected allowing authorized access only. The factory default password can easily be customized.

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 3

Page 4

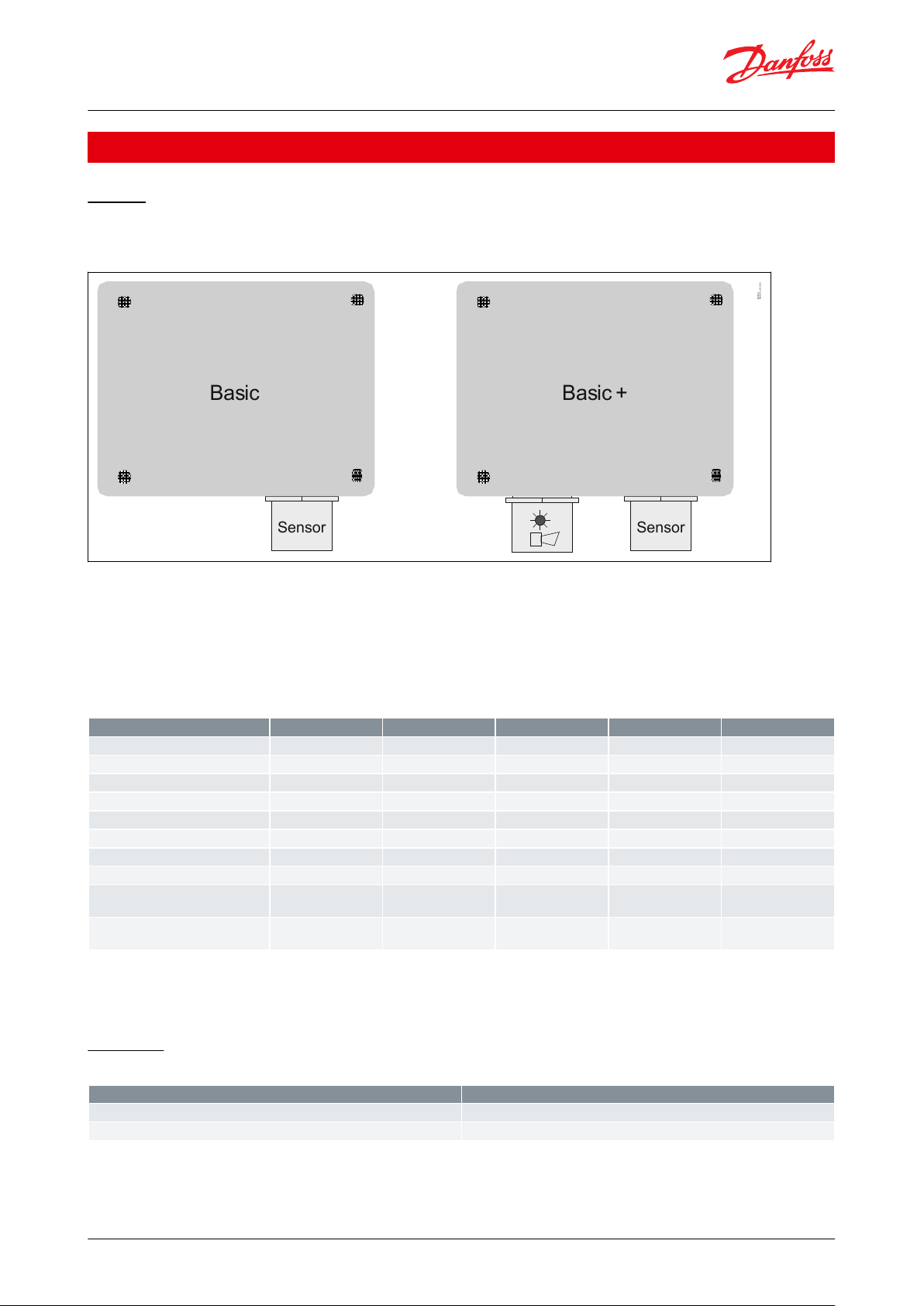

Basic Basic +

Danfoss

148H132_01-2018

Sensor Sensor

Sensor

Sensor Type

ppm range

Alarm 1

Alarm 2

Hysteresis

Ammonia EC 100

Electrochemical

0 – 100 ppm

25 ppm

35 ppm

2 ppm

Ammonia EC 300

Electrochemical

0 – 300 ppm

25 ppm

150 ppm

2 ppm

Ammonia EC 1000

Electrochemical

0 – 1000 ppm

500 ppm

900 ppm

25 ppm

Ammonia SC 1000

Semiconductor

0 – 1000 ppm

500 ppm

900 ppm

25 ppm

HF R1234yf SC 2000 (FR3)

Semiconductor

0 - 2000 ppm

500 ppm

900 ppm

25 ppm

HFC R134A SC 2000 (FR7)

Semiconductor

0 - 2000 ppm

500 ppm

900 ppm

25 ppm

HFC R404A, R507 SC2000

Semiconductor

0 – 2000 ppm

500 ppm

900 ppm

25 ppm

Ammonia SC 10000

Semiconductor

0 – 10000 ppm

5000 ppm

9000 ppm

250 ppm

Ammonia P LEL

Pellistor

0 – 100% LEL

(0 – 140000)

21% LEL

(30000 ppm)

21% LEL

(30000 ppm)

1%

CO2 IR 20000 (2% Vol.)

Infrared

(0 – 2% Vol)

(0 – 20000 ppm

0.5% Vol

(5000 ppm)

0.9% Vol

(9000 ppm)

0.025% vol

(250 ppm)

Details

Description

Power supply

19 – 29 V AC/DC, DC reverse-polarity protected (selected units 100 – 240V AC)

Power consumption (24 V DC)

Max. 250 mA (6 VA)

Gas detection unit, Basic

Product specication

Design

General information

Figure 1: GD Basic and Basic+

• Cable gland not mounted but enclosed

• 4 mounting ears included

• Sensor head mounted bottom right

• Alarm device (Buzzer & Light) mounted bottom left (only Basic +)

Gas types and thresholds

Table 1: Gas types and thresholds

NOTE:

Hysteresis = 5% of Alarm1 (rounded up to the next higher integer)

LEL/LFL = Lower explosive limit / Lower ammability limit

Electrical

Table 2: Electrical

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 4

Page 5

Details

Description

Power supply

5 V DC, 250 mA max., overload, short-circuit and reverse-polarity protected

Details

Description

Local bus

1-wire / 19200 baud

Fieldbus

RS 485 / 19200 baud

Tool bus

2-wire / 19200 baud

Details

Description

Temperature range

-40 °C to +50 °C (-40 °F to 122 °F)

Humidity range

15 – 90 % RH not-condensing

Storage temperature

+5 °C to +30 °C (41 °F to 86 °F)

Storage time

12 months

Details

Description

Housing

Type A

Material

Polycarbonate

Burning behaviour

UL 94 V2

Housing colour

Black

Dimensions (W x H x D in mm)

94 x 130 x 57

Weight (kg)

Approx. 0.3kg (0.8 lbs.)

Protection class

IP65

Installation

Wall mounting

Cable entry

2 x M12 / 3 x M20

Wire connection:

Power supply, eldbus

Screw-type terminals 0.25 to 2.5 mm

2

(25 AWG to 14 AWG)

Analog output

Screw-type terminals 0.25 to 1.3 mm

2

(25 AWG to 17 AWG)

Local bus for sensor

3-pin plug connector

Cable lengths local bus for remote sensor board

Max. 5 m (16.4 ft.)

Description

Proportional, overload and short-circuit proof, load ≤ 500 Ohm

4 – 20 mA = measuring range

3.0 < 4 mA = underrange

> 20 – 21.2 mA = overrange

2.0 mA = fault

(congurable)

Details

Description

Colour

3 color light: Green, yellow, red

Acoustic pressure

> 85 dB (A) (0.1 m distance)

Frequency

2300 Hz

Protection class

IP65

Gas detection unit, Basic

Outgoing line local bus

Table 3: Outgoing line local bus

Serial interface

Table 4: Serial interface

General

Table 5: General

Physical

Table 6: Physical

Analog output signal

Table 7: Analog output signal

Status LED / Buzzer & light (only Basic+)

Table 8: Status LED / Buzzer & light (only Basic+)

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 5

Page 6

1 2 4

Bus_B

Bus_A

0 V AC/DC

24 V AC/DC

Ackn. -/Test

button T1

X4

3

4

X8

X2

5

X9

Service Tool

Buzzer &

3-light alarm

X1

Analog Output

Status LED

Green/Yellow/Red

GND

JP5*

Open: 4-20mA

Closed: 2-10V AO_01

Jumper

J1

J2

J3

Sensor

Danfoss

148H119_11-2018

Analog Output

Sensor

Ackn.-/Test

button T1

Open: 4 – 20mA

Closed: 2 – 10V

Status LED

Green/Yellow/Red

Jumper

Bus_B

Bus_A

X9

Service Tool

Buzzer &

3-light alarm

Gas detection unit, Basic

Electrical connection

Figure 2: Electrical connection

Status LED:

• GREEN is power on

◦ ashing if maintenance needed

• YELLOW is an indicator of Error

◦ when the sensor head is disconnected or not the expected type

◦ AO is activated but nothing connected

◦ ashing when sensor is in special mode (e.g. when changing parameters)

• RED on alarm, similar to the buzzer & light alarm

Ackn. -/Test button:

• TEST:

◦ The button must be pressed for 20 sec

◦ Alarm1 and Alarm2 is simulated, stop on release

• ACKN:

◦ Pressed while Alarm2, the audible warning switches o and goes back on after 5 min. when the alarm situation

is still active

* JP5 open → AO 4 – 20 mA (Default)

* JP5 closed → AO 2 – 10 Volt

NOTE:

A resistor comes installed on the analog output connections – if analog output is used, remove the resistor.

Fieldbus loop

Each GD controller can handle up to 96 sensors and handle any mix of individual Gas detection units of the types

Basic, Premium and Heavy Duty.

The max. recommended loop wire length is 900 meter (2953 ft) per segment.

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 6

Page 7

= Terminating resistor 560 OhmR

R

R

= GDU (Basic, Premium and/or Heavy Duty)

R

R

RIGHT

WRONG

Controller

unit

Controller

unit

Wire length max. 900 meter (2953 ft) per segment.

More segments with additional expansion modules max. 7200 meter (23622 ft).

Additional power limitations must be calculated.

Danfoss

148H123

GDU Addr. 05 GDU Addr. 04

560 R

Controller Unit

0 V DC

24 V DC

BUS_B

BUS_A

0 V DC

24 V DC

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

U

min

= 16 V DC

GDU Addr. 01 GDU Addr. 02 GDU Addr. 03

Danfoss

148H139_01-2018

GDU Addr. 05 GDU Addr. 04

GDU Addr. 01 GDU Addr. 02 GDU Addr. 03

Controller

unit

Gas detection unit, Basic

With additional segments (and additional controller expansion modules) the max recommended loop wire length is

7200 meter (23622 ft).

The controller and the last GDU in each segment must be provided with a resistor of 560 Ohm. A Umin of 16 V DC

must be secured at any spot in the loop.

Figure 3: How to make proper connections between the controller and each GDU

Figure 4: How to make proper connections between the controller and each GDU

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 7

Page 8

Time

delay*

Buzzer &

3-light alarm

* Time delay set in config.

Gas

Alarm1

Alarm2

LED

If ackn. button

not pressed

LED

If ackn. button

pressed during

Alarm2

Ackn.

Buzzer

Buzzer

LED

If ackn. button

pressed after

Alarm

Buzzer

Ackn.

Ackn.

Alarm2

Alarm1

WAO

Housing

Sensor

Danfoss

148H158_03-2018

Alarm1

Alarm2

Housing

Sensor

Buzzer &

3-light alarm

Alarm1

Alarm2

Ackn.

Buzzer

LED

Ackn.

Buzzer

LED

Ackn.

Buzzer

LED

Alarm2

Alarm1

* Time delay set in config.

Alarm2

Alarm1

Time

delay*

If ackn. button

pressed after

Alarm

If ackn. button

pressed during

Alarm2

If ackn. button

not pressed

Blinking (2 sec.)

Fast blinking (1 sec.)

Very fast blinking (0.1 sec.)

Buzzer on

Static, Power LED

Gas detection unit, Basic

Alarm scheme

Figure 5: Alarm scheme

Buzzer & light

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 8

Page 9

Gas detection unit, Basic

Service and maintenance

The Basic/Basic+ gas detection units are calibrated either by replacing of sensor heads or by calibration with gas.

Plug & Play replacement sensors are pre-calibrated and factory certied for quick and easy calibration procedure.

The sensor is connected to the local bus via a plug connection enabling easy and simple exchange of sensor instead

of an on-site calibration. The internal X-change routine recognizes the exchanged sensor during the exchange

process and restarts the measurement mode automatically. An LED indicates the correct procedure of the exchange

operation. To ensure the proper functioning of the units and to prevent human errors, the sensor head can only be

replaced by the same type and ppm range (exact replacement) that match the conguration. If a dierent sensor

head is installed, the GD unit will show a communication error.

As an alternative, calibration with gas can be performed via the service tool (or PC tool), calibration gas with correct

concentration and the Danfoss calibration adapter. The Danfoss gas detection units have an integrated, digital

calibration interface and procedure, which makes the calibration process easy, accurate, and time-saving. No

potentiometers or multi-meters required for the calibration. The calibration procedure requires signicantly less

calibration gas per calibration compared to traditional routines.

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 9

Page 10

Type

Model

Refrigerant

Sensor

ppm range

Alarm ppm

Temp. Range

[°C]

Temp. Range

[°F]

Code number

GDA

Basic

Ammonia

Electrochemical

0 – 100

25/35

-40 to +50

-40 to +122

148H6000

Basic+

(1)

Ammonia

Electrochemical

0 – 100

25/35

-40 to +50

-40 to +122

148H6001

Basic

Ammonia

Electrochemical

0 – 300

25/150

-40 to +50

-40 to +122

148H6008

Basic+

(1)

Ammonia

Electrochemical

0 – 300

25/150

-40 to +50

-40 to +122

148H6009

Basic

Ammonia

Electrochemical

0 – 1000

500/900

-40 to +50

-40 to +122

148H6014

Basic+

(1)

Ammonia

Electrochemical

0 – 1000

500/900

-40 to +50

-40 to +122

148H6015

Basic

Ammonia

Semiconductor

0 – 1000

500/900

-40 to +50

-40 to +122

148H6023

Basic+

(1)

Ammonia

Semiconductor

0 – 1000

500/900

-40 to +50

-40 to +122

148H6024

Basic

Ammonia

Semiconductor

0 – 10000

5000/9000

-40 to +50

-40 to +122

148H6071

Basic Remote

Ammonia

Semiconductor

0 – 10000

5000/9000

-40 to +50

-40 to +122

148H6073

Basic

Ammonia

Pellistor

0 – 140000

30000

-40 to +50

-40 to +122

148H6070

GDHF

Basic + AC ( 100

– 240V AC)

R404a, R507a,

R32, R125,

R407c, R434a,

R488a,R410a,

R452b,R143b

Semiconductor

0 – 2000

500/900

-30 to +50

-22 to +122

148H6056

Basic + AC ( 100

– 240V AC)

R134a, R407a,

R416a, R417a,

R422a, R422d,

R427a, R437a,

R438a, R449a,

R407f, R450a

Semiconductor

0 – 2000

500/900

-30 to +50

-22 to +122

148H6057

Basic + AC ( 100

– 240V AC)

R1234yf, R452a,

R513a, R454c,

R455a, R454b,

R1234ze

Semiconductor

0 – 2000

500/900

-30 to +50

-22 to +122

148H6058

GDHF

Basic

R404a, R507a,

R32, R125,

R407c, R434a,

R488a, R410a

Semiconductor

0 – 2000

500/900

-40 to +50

-40 to 122

148H6045

Basic+

(1)

R404a, R507a,

R32, R125,

R407c, R434a,

R488a, R410a

Semiconductor

0 – 2000

500/900

-40 to +50

-40 to 122

148H6046

GDC

Basic

CO

2

Infrared

0 – 20000

5000/9000

-40 to +50

-40 to 122

148H6072

Description

Code number

Replacement sensor - Ammonia EC 100

148H6200

Replacement sensor - Ammonia EC 300

148H6201

Replacement sensor - Ammonia EC 1000

148H6202

Replacement sensor - Ammonia SC 1000

148H6203

Replacement sensor - HFC R404A, R507 SC 2000

148H6210

Replacement sensor - HFC R1234yf SC 2000

148H6239

Replacement sensor - HFC R134a SC 2000

148H6211

Controller unit

148H6231

Controller solution (controller + enclosure)

148H6221

Controller expansion module

148H6222

Service tool

148H6224

PC tool

148H6235

Calibration adapter

148H6232

Buzzer & light - acoustic buzzer and optic led

148H6225

Air duct set

148H6236

Seal cap

148H6227

Gas detection unit, Basic

Ordering

Table 9: Ordering

(1)

(1)

incl buzzer & Light

incl buzzer & Light

Spare parts and accessories

Table 10: Spare parts and accessories

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 10

Page 11

Description

Code number

Splash guard

148H6226

Gateway for controller

148H6228

Remote kit

148H6238

Gas detection unit, Basic

Accessories overview

Controller unit

Used for a centralized monitoring and warning. The input signals for the controller are collected via RS485 Modbus

or analog communication. The controller can handle up to 96 digital sensors via Fieldbus and four (4) analog input.

An additional 28 analog input is possible using seven (7) expansion modules (4 – 20 mA signal interface). The total

number of connected sensors should not exceed 128 sensors. The controller unit can be employed as pure analog

controller, as analog/digital, or as digital controller. Conguration is menu-driven via the keypad. For fast and easy

conguration, the PC Tool is recommended.

Controller solution

Controller unit placed in an enclosure ready to be connected to a power source. A separate UPS for the controller is

available.

Controller expansion module

The gas detection Controller Expansion module is used for expansion of the cable coverage in terms of number of

loops and the total wire length. Each Controller Unit can handle up to 7 Expansion modules allowing additional 7

segments with a total of 7200 meters (23622 ft.) wiring and a total of 32 relays for alarm device circuits.

Service tool

For interface with units with no display (Basic, Basic+, Premium, Premium+). Acts as a portable display and can be

connected to all Danfoss gas detection units. (Heavy Duty w. adapter).

PC tool

The PC tool is a menu-driven and standalone software used for easy addressing, parameter setting, calibration, and

data logging of the Basic, Premium and Heavy Duty gas detection units, and the controller unit.

Calibration adapter

The calibration adapter is required for connecting the calibration gas container, via the ow regulator, to the sensor

head on the gas detection units. (Two variants, One for Basic and Premium plastic head sensors; one for heavy duty

and Premium remote metal head sensors.).

Buzzer & light - acoustic buzzer and optic led

Can be installed in Basic or Premium units providing a local alarm.

Air duct set

The air duct set is specially designed to capture the airow in air ducts. It can be connected to the standard sensor

heads, except from Heavy Duty gas detection units.

Seal cap

Airtight seal cap to protect the sensor head against premature exposure during installation. The seal cap is mounted

on new sensors (complete units and replacement sensors) but is also available as an accessory.

Splash guard

To protect the sensor head against water exposure during wash-down cleaning and rinsing operations.

Gateway for controller

The gateway is an addition to the controller and used for communicating via Modbus TCP/IP.

Remote kit

Enabling installation of a sensor head in plastic housing 5m (16.4 ft.) from the unit. This means that the gas

detection unit can be placed outside the room where the sensor is placed to detect hazardous gases, allowing

reading of and interfacing with the unit without entering the dedicated space. Basic and Premium gas detection

units.

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 11

Page 12

Type

File name

Document type

Document topic

Approval authority

GDA

148R6115.AA

EU Declaration

EMCD/LVD

Danfoss

EMC directives 2014/30/EU

Conformity to EN 50271, EN 61010-1

ETL listed to UL 61010-1 and CSA C22.2 No.61010-1

Enables regulatory compliance with EN 378:2016, ISO 5149:2014, IIAR 2-2017, and ASHRAE 15:2016

Gas detection unit, Basic

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 11: Valid Approvals

Table 12: Compliance

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 12

Page 13

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.11 AI272545693488en-000701 | 13

Loading...

Loading...