Danfoss GDA SC 10000, GDA EC 300, GDA SC 1000, GDA EC 1000, GDC IR 10000 Installation Manual

...Page 1

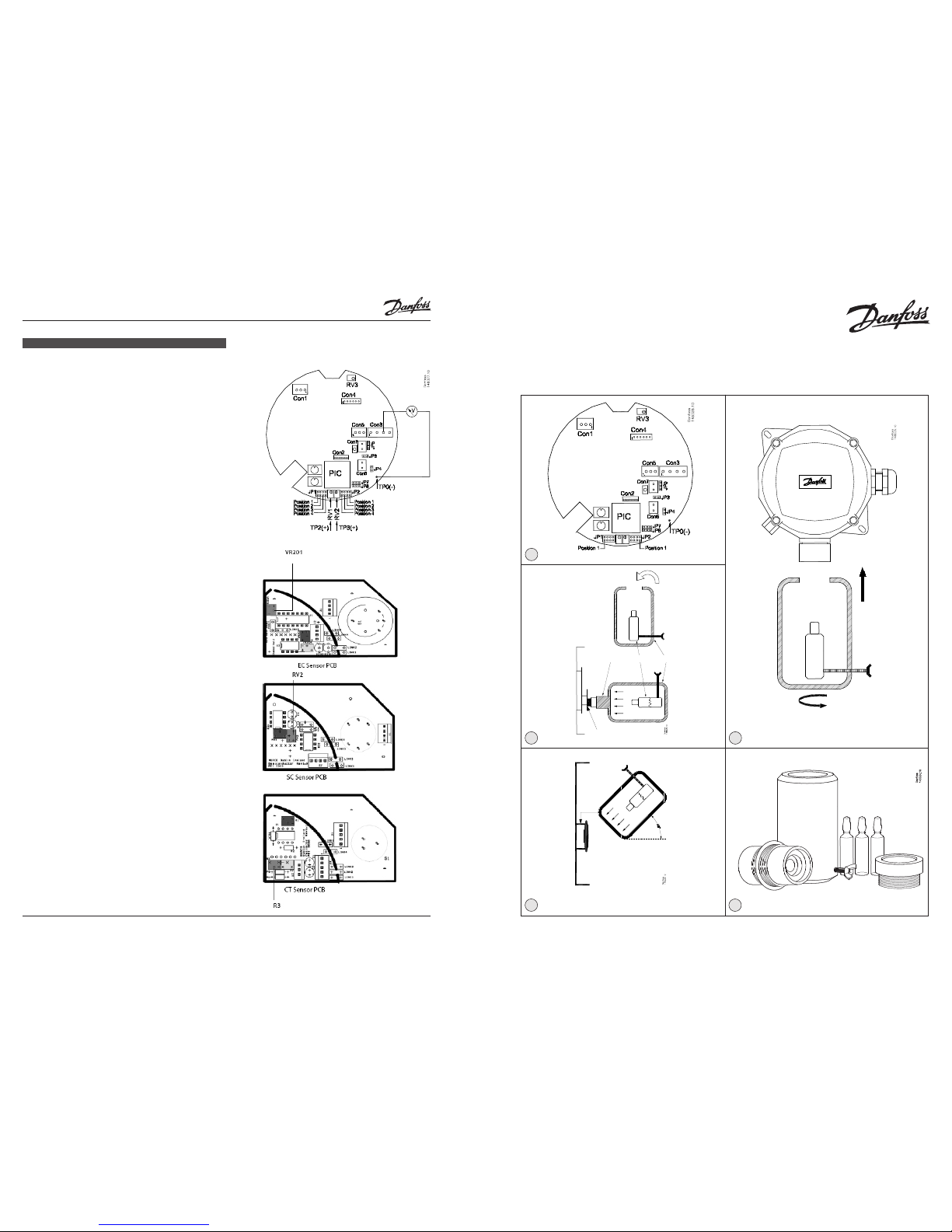

Installation Guide

Making Bump test on Danfoss gas detecting sensors,

types GDA and GDC

148 R95 44

148 R95 44

4 DKRCI.PI.S00.B2.02 / 520H2572 © Danfoss A/S (MWA), 2015-02 © Danfoss A/S (MWA), 2015-02 DKRCI.PI.S00.B2.02 / 520H2572 1

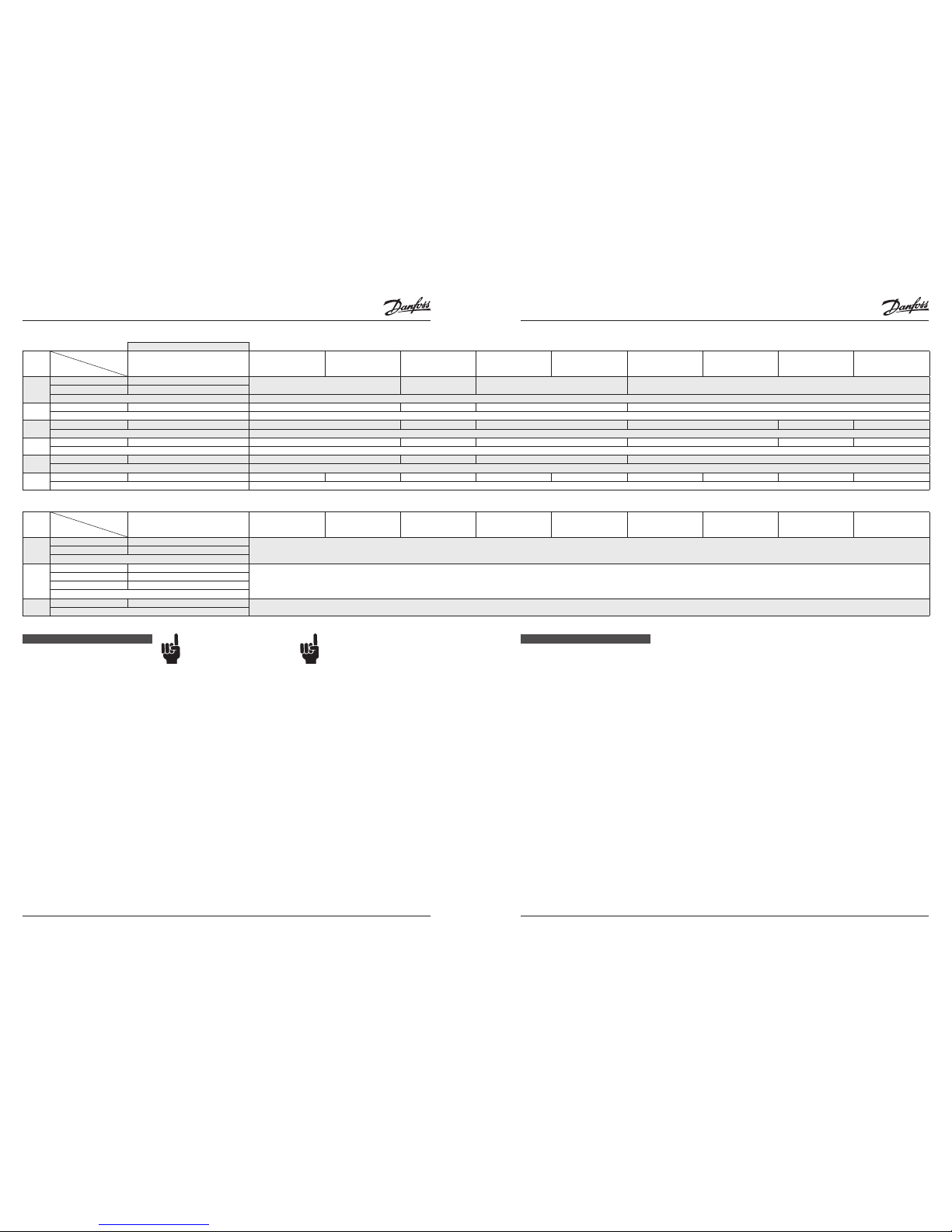

Beaker

EC/SC/CTAdaptor

Ampoules

M35

Adaptor

BUMP TEST equipment

EC/SC/CT-Adaptor Ampoule Breaker

Sensor PCB

Gas ows through

the back and

front of the

sensor head

Bump test on a wall mounted CO2 detector

1

2

3

4

5

ENGLISH

Appendix 1

Checking the zero. (0.0 V output)

EC sensor

To adjust the zero, Pot VR201 must be operated. It is located on the

Sensor PCB

Connect a voltmeter to TP0 on the mother PCB and Con3, pin 3 on

the mother PCB

Pot VR201 (on the Sensor PCB) is used to adjust the zero of the

range (span). Measure the Voltage output between TP0 (negative)

and Con3 pin 3 (positive) at the 0V signal and adjust the Pot to 0.0

V or slightly positive (0.01 V is acceptable).

SC sensor

To adjust the zero, Pot RV2 must be operated. It is located on the

Sensor PCB.

Connect a voltmeter to TP0 on the mother PCB and Con3, pin 3 on

the mother PCB (see g. A1)

Pot RV2 (on the Sensor PCB) is used to adjust the zero of the range

(span). Measure the Voltage output between TP0 (negative) and

Con3 pin 3 (positive) at the 0V signal and adjust the Pot to 0.0 V or

slightly positive (0.01 V is acceptable).

CT sensor

To adjust the zero, Pot R3 must be operated. It is located on the

Sensor PCB.

Connect a voltmeter to TP0 on the mother PCB and Con3, pin 3 on

the mother PCB (see g. A1).

Pot R3 (on the Sensor PCB) is used to adjust the zero of the range

(span). Measure the Voltage output between TP0 (negative) and

Con3 pin 3 (positive) at the 0V signal and adjust the Pot to 0.0

V or slightly positive (0.01 V is acceptable).

Page 2

© Danfoss A/S (MWA), 2015-02 DKRCI.PI.S00.B2.02 / 520H2572 32 DKRCI.PI.S00.B2.02 / 520H2572 © Danfoss A/S (MWA), 2015-02

Table 1 - Bump Test

Pass test criteria

Models

Sensor

Requirement for sensor response to pass Bump

Test. Measure Voltage Output on Con3,(mother

PCB)

pin 1 and 3

Standard Basic Standard Basic with

LCD display

IP 65 for High RH and

Fast response

IP 56 enclosure IP 56 enclosure

Low Temperature

EExd model EExd model

Low Temperature

IP 66 enclosure 5 m remote

IP 65 sensor

IP 66 enclosure 5 m remote

IP 65 EExd sensor

1

GDA EC 100 >= 5 .0 V

Beaker + EC/SC/CT-Adaptor Beaker Beaker + EC/SC/CT-Adaptor Beaker

GDA EC 300 >= 1.67 V

Bump test method 100 ppm Ammonia Ampoule

2

GDA EC 1000 >= 5 V Beaker + EC/SC/CT-Adaptor Beaker Beaker + EC/SC/CT-Adaptor Beaker

Bump test method 1000 ppm Ammonia Ampoule

3

GDA SC 1000 >= 5 .0 V Beaker + EC/SC/CT-Adaptor Beaker Beaker + EC/SC/CT-Adaptor Beaker + M35 Adaptor Beaker Beaker + M35 Adaptor

Bump test method 1000 ppm Ammonia Ampoule

4

GDA SC 10000 >= 0.5 V Beaker + EC/SC/CT-Adaptor Beaker Beaker + EC/SC/CT-Adaptor Beaker + M35 Adaptor Beaker Beaker + M35 Adaptor

Bump test method 1000 ppm Ammonia Ampoule

5

GDA CT 30000 >= 5 .0 V Beaker + EC/SC/CT-Adaptor Beaker + M35 Adaptor Beaker + EC/SC/CT-Adaptor Beaker + M35 Adaptor

Bump test method App. 5-8 % Ammonia water in a cloth

1

)

6

GDC IR 10000 >= 1.0 V Beaker Beaker not available Beaker Beaker Beaker Beaker not available not available

Bump test method 2000 ppm CO

2

Ampoule

1

) Drop a cloth to the bottom of the beaker, hold it at the bottom with the screw. Moisten the cloth (5-10 drops) with 5-8 % ammonia water.

Restricted bump test

Models

Sensor

Requirement for sensor response to pass Bump

Test. Measure Voltage Output on Con3,(mother

PCB)

pin 1 and 3

Standard Basic Standard Basic with

LCD display

IP 65 for High RH and

Fast response

IP 56 enclosure IP 56 enclosure

Low Temperature

EExd model EExd model

Low Temperature

IP 66 enclosure 5 m remote

IP 65 sensor

IP 66 enclosure 5 m remote

IP 65 EExd sensor

7

GDC IR 20000 >= 2 .0 V

Sensor is self calibrating. Breathe on sensor to see responseGDC IR 40000 >= 2 .0 V

Bump test method

8

GDHC SC 1000 >= 5 V

Long life sensor. Use a cigarette lighter to see response

GDHF SC 1000 >= 5 V

GDHF-R3 SC 1000 >= 5 V

Bump test method

9

GDH SC 5000 >= 5 .0 V

Long life sensor. Use a cigarette lighter to see response

Bump test method

ENGLISH

Introduction

The frequency of testing or calibration is

generally determined by local regulation or

standards.

There are two concepts that need to be

dierentiated: bump test and calibration

Bump Test: This consists of exposing

the sensor to a gas. The objective is to

establish if the sensor is reacting to the

gas and all the sensor outputs are working

correctly. A qualied bump test is a test

carried out using ampoules or cylinders of

known concentration.

Calibration: This consists of exposing the

sensor to a calibration gas setting the “zero”

or “Standby voltage”, the span or range,

and checking/adjusting all the outputs, so

that they are activated at a specied gas

concentration.

Danfoss recommends annual

checks by qualied bump test

and replacement of the sensor

PCB with a Danfoss pre-calibrated

certied sensor PCB every two

years. The mother PCB is at the

same time tested with the GD

tester.

The alternative to this is a full

on site calibration. Sensor

replacement should be more cost

eective, eliminates end of life

concerns, and constantly renews

the detection system.

Procedures for bump test and calibration

vary depending on the sensor technology

used and the gas in question.

The GD is available in four sensor versions:

Semiconductor (SC), Electrochemical (EC),

Catalytic (CT), and Infrared (IR) for CO

2

.

Before you carry out the test or

calibration:

1. Advise occupants, plant

operators, and supervisors.

2. Check if the relays (Con6 and

Con7) are connected

to external systems such as

sprinkler systems, plant

shut down, external sirens and

beacons, ventilation, etc. and

disconnect as appropriate.

3. Deactivate alarm delays with

JP1 and JP2. See g. 1.

For this the GD must be

powered o.

4. For Bump Test the GD should

be powered up overnight.

NOTE:

If unit has been installed and running

for about 24 hrs, and you need to power

it o to set the delay at 0 min, then the

warm-up is 2 min and you can begin the

testing or calibration.

ENGLISH

Bump test (every year)

Ideally bump tests are conducted on site in

a clean air atmosphere.

The bump test can be carried out on

following types of GD

(see table 1)

GDA (qualied bump test)

GDC (qualied bump test/ restricted

bump test)

GDHC (restricted bump test)

GDHF (restricted bump test)

GDHF-R3 (restricted bump test)

See table 1, to nd the GD type and the

corresponding Bump test method.

Checking the zero (0 Voltage output).

See Appendix 1. (not required for IR sensor)

1. Remove the cover of enclosure of the

GD

2. Make sure that both the ampoules and

the calibration beaker are clean and dry

(see g. 5).

3. Unscrew the beaker hold screw and

place the ampoule so that is sits in the

base of the beaker (see g. 2).

4. Tighten on the screw ampoule without

breaking it.

5. For the models:

Standard Basic

Standard Basic with LCD display

IP 56 enclosure

IP 56 enclosure Low Temperature

Screw in:

EC/SC/CT-Adaptor or M35-Adaptor into

the Beaker according to table 1.

Place the beaker with the EC/SC/CT Adaptor over the sensor.

It should be as tight tting as possible

to allow maximum exposure to the gas

(see g. 5).

For the GDC (CO2)models:

Standard Basic

Standard Basic with LCD display

IP 56 enclosure

IP 56 enclosure Low Temperature

Place the beaker over the sensor in a

45° degree (see g. 3). This allows gas to

ow through the back of the sensor

and through the calibration ports.

For the models:

IP 65 for High RH and Fast response

EExd model

EExd model Low Temperature

IP 66 enclosure 5 m remote IP 65 sensor

IP 66 enclosure 5 m remote IP 65 EExd

sensor

Screw/t the beaker (possibly with

M35 Adaptor) on the remote

sensorhead (see g. 4). It should be as

tight tting as possible to allow

maximum exposure to the gas.

6. Connect volt meter to monitor sensor

response.

(Con3 pin 1 and 3 - see g. 1).

7. Tighten on the ampoule until it

shatters allowing the content to diuse

in the beaker. It should be left in place

for approximately 5 min.

8. Voltage output will increase. This

conrms that the sensor is responding.

See Pass test criteria in table 1.

9. Carefully remove any ampoule remains

from the gas detector, and reassemble

the sensor enclosure.

Fill out the GD Bump Test Certicate.

Loading...

Loading...