Page 1

Installation Guide

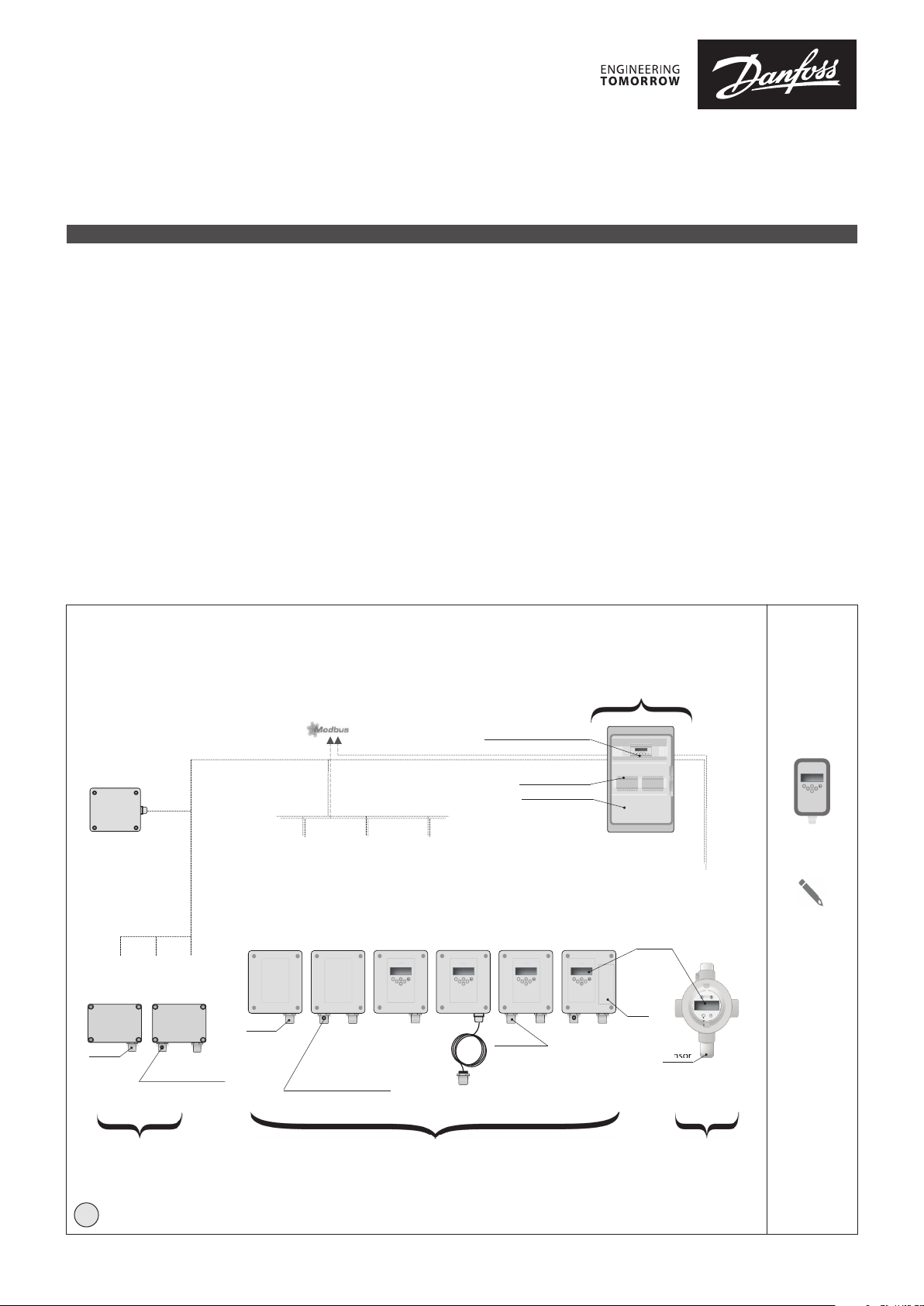

6 configurations

2 configurations

1 configuration

communication

Controller solution

monitoring unit

Gas Detection Unit (GDU)

GDA, GDC, GDHC, GDHF, GDH

Technician use only!

This unit must be installed by a suitably qualified technican who

148R9631

will install this unit in accordance with these instructions and the

standards set down in their particular industry/country.

Info for UK customers only:

Danfoss Ltd.

Oxford Road, UB9

4LH Denham, UK

ENGLISH

Please observe that a Danfoss GDU works as a safety device

securing a reaction to a detected high gas concentration. If a

leakage occur, the GDU will provide alarm functions, but it will

not solve or take care of the leakage root cause itself.

148R9631

Suitably qualified operators of the unit should be aware of the

regulations and standards set down by their industry/country for

the operation of this unit.

These notes are only intended as a guide and the manufacturer

bears no responsibility for the installation or operation of this unit.

Failure to install and operate the unit in accordance with these

instructions and with industry guidelines may cause serious injury

including death and the manufacturer will not be held responsible

in this regard.

It is the installer’s responsibility to adequately ensure that the

equipment is installed correctly and set up accordingly based on

the environment and the application in which the products are

being used.

Configurations and Wiring: All 3 types of Gas Detection Units (GDU)

Annual Test

To comply with the requirements of EN378 and the F GAS

regulation sensors must be tested annually. Danfoss GDU's are

provided with a test button that should be activated once a year

for testing of the alarm reactions.

Additional the sensors must be tested for functionality by either

Bump test or Calibration. Local regulations should always be

followed

After exposure to a substantial gas leak, sensor should be checked

and replaced if necessary.

Check local regulations on calibration or testing requirements.

Service tools

Gas Detection Controller

Option: Modbus

Option: UPS

Max. 96 sensors

Wire break

Premium

Basic +

Basic

Sensor

Sensor

Basic GDU

Buzzer and light

3-color-alarm

1

© Danfoss | Climate solutions | 2021.06

Premium+

Buzzer and light

3-color-alarm

Premium Flex

Premium GDU (Controller)

Premium Remote

5 meter

remote sensor

Premium Duplex

Sensor 2

Premium Uptime

Display

UPS

Service Tool

Handheld

Danfoss Pen

for Heavy

Heavy Duty

Sensor

Heavy Duty GDU

Duty display

AN272542819474en-000201 | 1

oss

Page 2

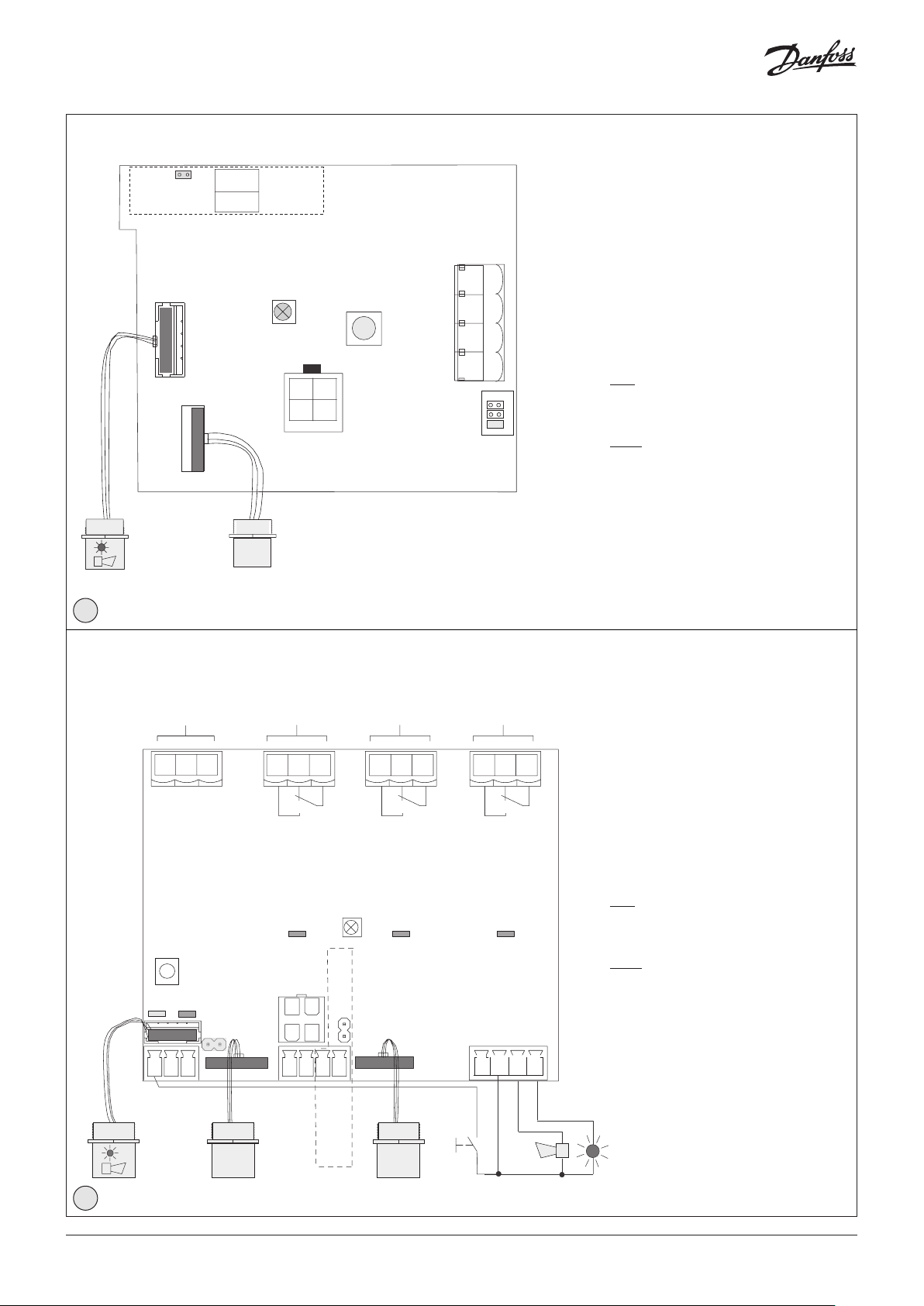

Relays 1 and 2 de-energized (default)

Relay 3 energized (default)

Danfoss Basic GDU

12 4

Bus_B

Bus_A

0 V AC/DC

24 V AC/DC

Ackn. -/Test

button T1

X4

3

4

X8

X2

5

X9

Service Tool

Buzzer &

3-light alarm

X1

Analog Output

Status LED

Green/Yellow/Red

GND

JP5*

Open: 4-20mA

Closed: 2-10V AO_01

Jumper

J1

J2

J3

Sensor

Danfoss

148H119_11-2018

Status LED:

GREEN is power on.

YELLOW is an indicator of Error.

- when the sensor head is disconnected or

not the expected type

- AO is activated but nothing connected

- flashing when sensor is in special mode

(e.g. when changing parameters)

RED on alarm, similar to the Buzzer & light

alarm.

Ackn. -/Test button:

TEST - The button must be pressed

for 20 sec.

- Alarm1 and Alarm2 is simulated, stop

on release

ACKN. - Pressed while Alarm2, the audible

warning switches off and goes back on after

5 min. when the alarm situation is still active.

* JP5 open → AO 4 – 20 mA (Default)

JP5 closed → AO 2 – 10 Volt

NOTE:

A resistor comes installed on the analog

output connections – if analog output

is used, remove the resistor.

2

Danfoss Premium GDU

Power 24 V DC

23

GND

24 V DC

Ackn./Test

button

Power Bus Comm.

2

3

1

X11

DI_1

DI_2

GND

Digital

Input

Buzzer &

3-light alarm

3

1

X1

NC

Local

Bus_1

Sensor

in operating mode at No alarm.

Configurable

Relay 1

Alarm 1

3

2

1

Status LED

Green/Yellow/Red

Relay status

LED Green

Service Tool

Bus_A

Field

Bus

321

Bus_B

Analog

Output

JP2*

AO_01

X12

in operating mode at No alarm.

Relay 2

Alarm 2

3

132

X2

Relays shown de-energized

open: 4-20mA

closed: 2-10 V

4

GND

2

Relay status

LED Green

X3

Local

Bus_2

Ackn.

Button

Sensor

Configurable

Relay 3

Error

Relay status

LED Green

Digital

Output

NC

567

4

X13

GND

1

Horn

X4

Flash light

Status LED:

GREEN is power on.

YELLOW is an indicator of Error.

- when the sensor head is disconnected or

not the expected type

- AO is activated but nothing connected

RED on alarm, similar to the Buzzer & light

alarm.

Ackn. -/Test button:

TEST - The button must be pressed

for 20 sec.

- Alarm1 and Alarm2 is simulated, stop

on release

ACKN. - Pressed while Alarm2, the audible

warning switches off and goes back on after

5 min. when the alarm situation is still active.

* JP2 open → AO 4 – 20 mA (Default)

JP2 closed → AO 2 – 10 Volt

NOTE:

A resistor comes installed on the analog

Danfoss

148H120_01-2018

output connections – if analog output

is used, remove the resistor.

© Danfoss | Climate solutions | 2021.06

AN272542819474en-000201 | 2

Page 3

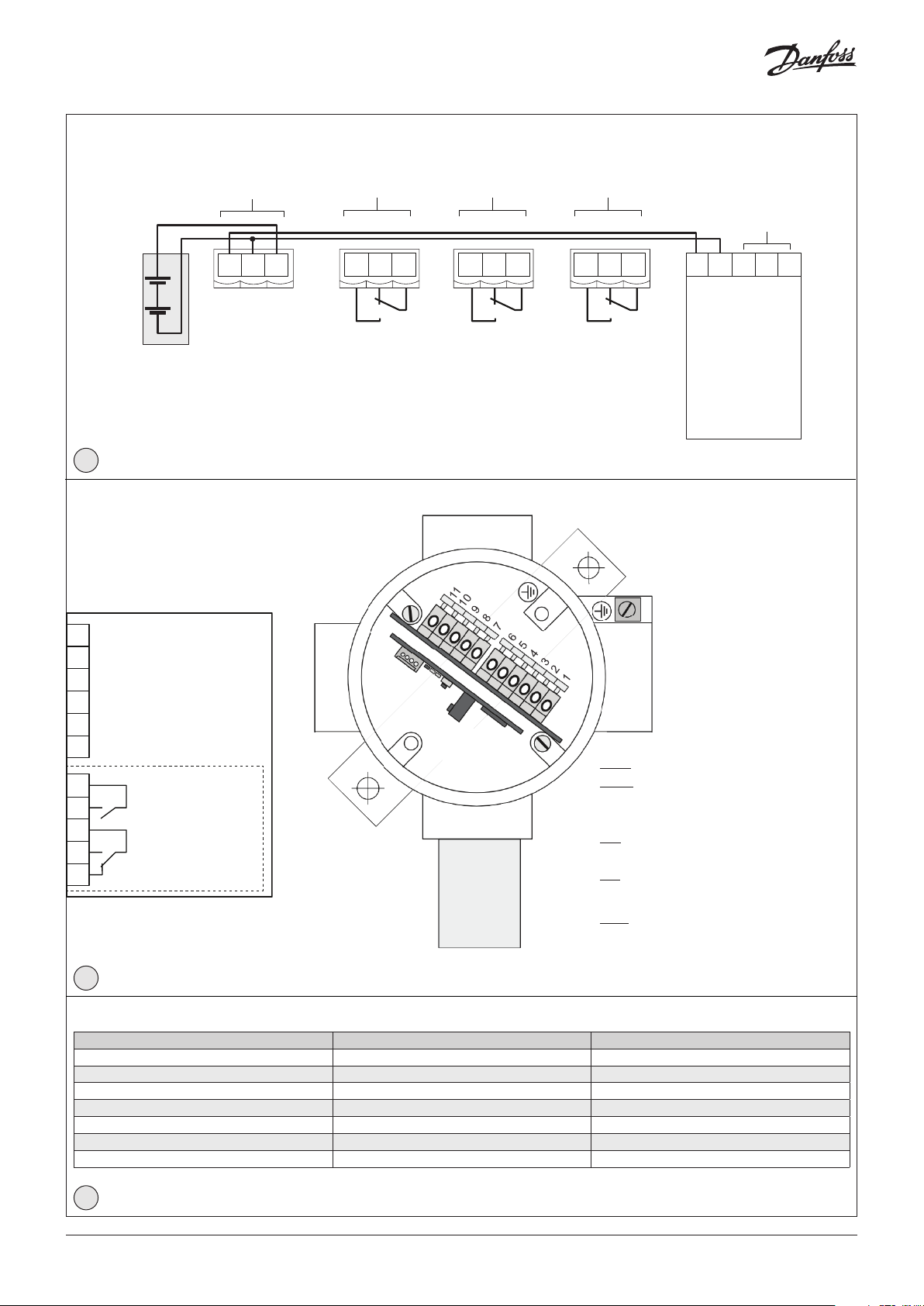

Sensor PX2

Danf

148H122_11-2018

NPT ¾ in.

Danfoss

148H121_01-2018

Danfoss Premium Uptime GDU

Power supply

Relay 1

Relay 2

Relay 3

12

0.8 Ah

12

0.8 Ah

Danf

148H147_02-2018

24 V DC

V

V

321321

24 V DC

GND

X1

ACCU

ACCU

4

Danfoss Heavy Duty GDU (ATEX, IECEx approved)

AR 01

AR 02

X2 X3 X4

NPT ¾”(ANSI B1.20.1)

Internal Thread

132 321

AR 03

90 - 240 V AC

V+ V- PE N

Power supply

90 - 240 V AC

L

24 V DC, 15 VA

oss

1

+24 V DC

2 +24 V DC

3

GND

4

BUS_A

56BUS_B

4 - 20 mA output

Service

Tool

LED

Status

Ackn. Button

Sensor

head

On board LED is similar to the display LED:

Green is power on

7

8

9

10

11

oss

Fault relais energized in

operating mode at No alarm

- Default

Alarm relais de-energized in

operating mode at No alarm

- Default (Configurable)

NPT ¾”(ANSI B1.20.1)

Internal Thread

Sensor

Yellow is an indicator of Error

- when the sensor head is disconnected or not

the expected type

- AO is activated but nothing connected

RED on alarm

On board Ackn. -/Test button:

Test: The button must be pressed

for 20 sec.

- Alarm is simulated, stop on release

Ackn.: Pressed while Alarm2, the audible

warning switches off and goes back on after

5 min. when the alarm situation is still active

(also possible over ESC button (use the

5

Location of Sensors

Gas type Relative density (Air = 1) Recommended sensor location

R717 Ammonia <1 Ceiling

R744 CO >1 Floor

R134a >1 Floor

R123 >1 Floor

R404A >1 Floor

R507 >1 Floor

R290 Propane >1 Floor

magnetic Pen).

6

© Danfoss | Climate solutions | 2021.06

AN272542819474en-000201 | 3

Page 4

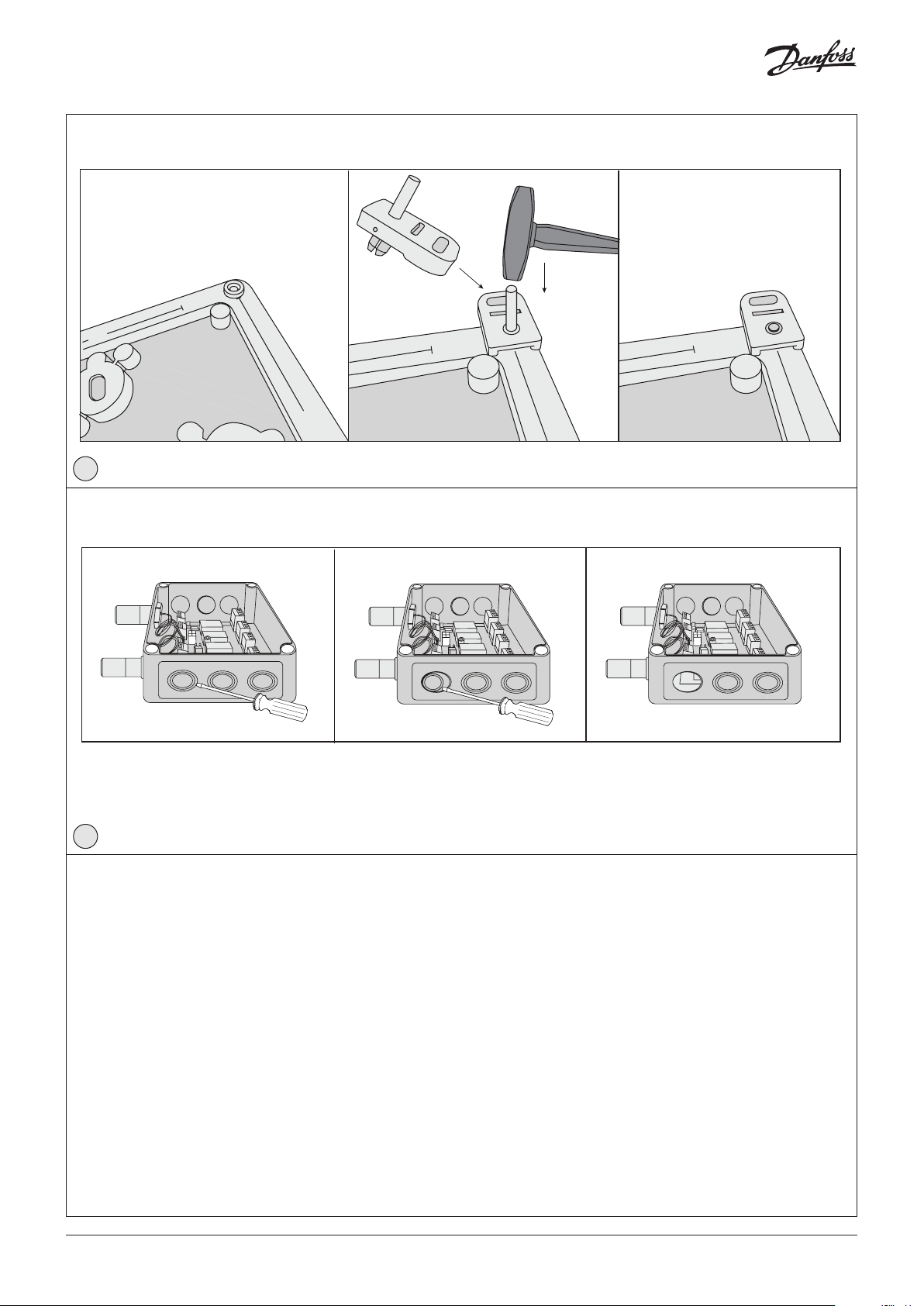

GDU Addr. 05 GDU Addr. 04

Danf

148H124_1

Gas Detection Controller: Fieldbus wiring - max 96 sensors in total i.e. up to 96 GDU (Basic, Premium and/or Heavy Duty)

WRONG

Wire length max. 900 meter (2953 ft) per segment.

More segments with additional expansion modules max. 7200 meter (23622 ft).

Additional power limitations must be calculated.

R

Controller

unit

= Terminating resistor 560 OhmR

= GDU (Basic, Premium and/or Heavy Duty)

R

Controller

unit

7

Check of loop completion. Example: 5 x Basic in return loop

R

R

RIGHT

Danfoss

148H123_03-2018

Controller Unit

0 V DC

24 V DC

BUS_B

BUS_A

0 V DC

24 V DC

Ohm

560 R

+

(DC)

4

3

2

1

GDU Addr. 01 GDU Addr. 02 GDU Addr. 03

4

3

2

1

V

4

3

2

1

+

V

(DC)

4

3

2

1

Heavy Duty GDU: U

Other GDU: U

4

3

2

1

= 16 V DC

min

= 20 V DC

min

oss

Check of loop resistance: See section: Controller unit multiple GDU commissioning 2. NOTE: Remember to disconnect the wire from the board during measuring.

Check of power polarity: See section: Controller unit multiple GDU commissioning 3.

Check of BUS polarity: See section: Controller unit multiple GDU commissioning 3.

Individual Addresses for the GDU's are given at commisioning, see Controller Unit multiple GDU's commisioning, according to a predetermined "BUS address plan"

8

© Danfoss | Climate solutions | 2021.06

AN272542819474en-000201 | 4

Page 5

Attachment of suspension ears (Basic and Premium)

Danfoss

Danfoss

70

115

9

Cable Gland opening

148H125_01-2018

148H126_01-2018

Hole punching for Cable gland:

1. Select the location for the safest cable entry.

2. Use a sharp screwdriver and a small hammer.

3. Place the screwdriver and hammer with precision

while moving the screwdriver within a small area

until the plastic is penetrated.

Continue precision punching with small movements

until the round piece can be pulled out by your

fingers.

Remove potential burrs and secure flat surfaces.

Install the Cable gland according to the enclosed guide.

10

Ambient conditions :

Please observe the ambient conditions specified for each specific GDU, as stated on the product. Do not install the units outside

the given temperature and humidity range.

© Danfoss | Climate solutions | 2021.06

AN272542819474en-000201 | 5

Page 6

ENGLISH

General GDU Mounting / Electrical wiring

• All GDU's are for wall mounting

• Supporting ears are installed like shown in fig. 9

• Cable entry is recommended on box side. See fig. 10

• Sensor position downwards

• Observe possible constructors instruction

• Leave the red protection cap (seal) on the sensor head until

commisioning

When choosing the mounting site please pay attention to the following:

• The mounting height depends on the relative density of the gas type to

be monitored, see fig 6.

• Choose mounting location of the sensor according to the local

regulations

• Consider ventilation conditions. Do not mount the sensor close to

airflow (air passages, ducts etc.)

• Mount the sensor at a location with minimum vibration and minimum

temperature variation (avoid direct sunlight)

• Avoid locations where water, oil etc. may influence proper operation and

where mechanical damage might be possible

• Provide adequate space around the sensor for maintenance and

calibration work.

Wiring

The technical requirements and regulations for wiring, electrical security,

as well as project specific and environmental conditions etc. must be

observed when mounting.

We recommend the following cable types¹

• Power supply for controller 230V at least

NYM-J 3 x 1.5 mm

• Alarm message 230 V (also possible together with power supply)

NYM-J X x 1.5 mm

• Signal message, bus connection to Controller Unit, warning devices 24 V

J-Y(St)Y 2x2 x 0.8

• Possibly connected external analog transmitters

J-Y(St)Y 2x2 x 0.8

• Cable for Heavy Duty: 7 - 12 mm diameter round cable

¹ The recommendation does not consider local conditions such as fire protection etc.

The alarm signals are available as potential-free change-over contacts. If

required the voltage supply is available at the power terminals.

The exact position of the terminals for the sensors and alarm relays is

shown in the connection diagrams (see figures 3 and 4).

Basic GDU

The Basic GDU is designed for the connection of 1 sensor via local bus.

The GDU provides the power supply of the sensor and makes the

measured data available for digital communication. Communication

with the Controller Unit takes place via the RS 485 fieldbus interface

with Controller Unit protocol. Other communication protocols for direct

connection to superordinate BMS are available as well as Analog Output

4-20 mA.

The sensor is connected to the local bus via a plug connection enabling

simple sensor exchange instead of an on-site calibration. The internal

X-Change routine recognizes the exchanging process and the exchanged

sensor and starts the measurement mode automatically.

The internal X-change routine examines the sensor for actual type of

gas and actual measuring range. If data does not match the existing

configuration, the build in status LED indicates an error. If everything is OK

the LED will light up green.

For convenient commissioning, the GDU is pre-configured and

parameterized with factory-set defaults.

As an alternative, the on-site calibration via the Controller Unit Service Tool

can be performed with the integrated, userfiendly calibration routine.

For Basic units with Buzzer & Light, alarms will be given according to

following table:

Digital outputs

Action Reaction

Gas signal < alarm threshold 1 OFF GREEN

Gas signal > alarm threshold 1 OFF RED Slow blinking

Gas signal > alarm threshold 2 ON RED Fast blinking

Gas signal ≥ alarm threshold 2,

but ackn. button pressed

Gas signal < (alarm threshold 2 - hysteresis)

but >= alarm threshold 1

Gas signal < (alarm threshold 1 - hysteresis)

but not acknowledged

No alarm, no fault OFF GREEN

No fault, but maintenance due OFF GREEN Slow blinking

Communication error OFF YELLOW

Alarm thresholds can have the same value, therefore the relays and/or Buzzer and LED

can be triggered simultaniously.

Horn

OFF after

delay ON

OFF RED Slow blinking

OFF RED Very fast blinking

Reaction

LED

RED Fast blinking

Premium GDU (Controller)

The Premium GDU is designed for the connection of max. two sensors

via local bus. The controller monitors the measured values and activates

the alarm relays if the set alarm thresholds for pre-alarm and main alert

are exceeded. In addition, the values are provided for direct connection

to the monitoring system (Controller Unit) via an RS-485 interface. Other

communication protocols for direct connection to superordinate BMS are

available as well as Analog Output 4-20 mA.

The SIL 2 compliant self-monitoring function in the Premium GDU and in

the connected sensor activates the error message in case of an internal

error as well as in case of an error in the local bus communication.

The sensor is connected to the local bus via a plug connection enabling

simple sensor exchange instead of an on-site calibration. The internal

X-Change routine recognizes the exchanging process and the exchanged

sensor and starts the measurement mode automatically.

The internal X-change routine examines the sensor for actual type of

gas and actual measuring range and if data does not match the existing

configuration, the build in status LED indicates an error. If everything is OK

the LED will light up green.

For convenient commissioning, the GDU is pre-configured and

parameterized with factory-set defaults.

As an alternative, the on-site calibration via the Controller Unit Service Tool

can be performed with the integrated, userfriendly calibration routine.

Digital outputs with three relays

Action Reaction Reaction Reaction Reaction Reaction Reaction

Gas signal < alarm threshold 1 OFF OFF OFF OFF ON GREEN

Gas signal > alarm threshold 1 ON OFF OFF OFF ON RED Slow

Gas signal > alarm threshold 2 ON ON ON ON ON RED Fast

Gas signal ≥ alarm threshold 2,

but ackn. button pressed

Gas signal < (alarm threshold

2 - hysteresis) but >= alarm

threshold 1

Gas signal < (alarm threshold

1 - hysteresis) but not

acknowledged

No alarm, no fault OFF OFF OFF OFF ON GREEN

No fault, but maintenance due OFF OFF OFF OFF ON GREEN Slow

Communication error OFF OFF OFF OFF OFF YELLOW

Note 1:

Status OFF = Relay is configured “Alarm ON = Relay“ or the Premium Multi-SensorController is free from tension.

Note 2:

Alarm thresholds can have the same value, therefore the relays and/or the horn and

flashlight can be triggered together.

Relay Mode

Definition of the relay operation mode. The terms energized / de-energized

come from the terms energized / de- energized to trip principle (opencircuit / closed circuit principle) used for safety circuits. The terms refer

to the activation of the relay coil, not to the relay contacts (as they are

executed as a changeover contact and available in both principles).

The LEDs attached to the modules show the two states in analogy (LED off

-> relay de-energized)

Relay 1

(Alarm1)

ON ON ON OFF after

ON OFF OFF OFF ON RED Slow

OFF OFF OFF OFF ON RED Very

Relay 2

(Alarm2)

Flashlight

X13-7

Horn X13-6 Relay 3

delay ON

(Fault)

LED

blinking

blinking

RED Fast

blinking

blinking

fast blinking

blinking

© Danfoss | Climate solutions | 2021.06

AN272542819474en-000201 | 6

Page 7

ENGLISH

Heavy Duty GDU

Approved according to ATEX and IECEx for zones 1 and 2.

Permitted ambient temperature range: -40 °C < Ta < +60 °C

Marking:

Ex Symbol and

II 2G Ex db IIC T4 Gb CE 0539

Certification:

BVS 18 ATEX E 052 X

IECEx BVS 18.0044X

The Heavy Duty GDU is designed for the connection of 1 sensor via local bus.

The GDU provides the power supply of the sensor and makes the

measured data available for digital communication. Communication

with the Controller Unit takes place via the RS 485 fieldbus interface

with Controller Unit protocol. Other communication protocols for direct

connection to superordinate BMS are available as well as Analog Output

4-20 mA.

The sensor is connected to the local bus via a plug connection enabling

simple sensor exchange instead of an on-site calibration. The internal

X-Change routine recognizes the exchanging process and the exchanged

sensor and starts the measurement mode automatically.

The internal X-change routine examines the sensor for actual type of

gas and actual measuring range. If data does not match the existing

configuration, the build in status LED indicates an error. If everything is OK

the LED will light up green.

For convenient commissioning, the GDU is pre-configured and

parameterized with factory-set defaults.

As an alternative, the on-site calibration via the Controller Unit Service Tool

can be performed with the integrated, userfriendly calibration routine.

Installation Work

Assembly work must only be carried out under gas-free

conditions. The housing must neither be drilled nor be

drilled through.

The orientation of the GDU should always be horizontal,

with the sensor head pointing downwards.

The mounting is done without opening the housing by

using the two holes (D = 8 mm) of the fastening strap with

suitable screws.

The Heavy duty GDU must only be opened under gas-free

and voltage-free conditions.

The enclosed cable gland has to be checked for

admissibility for the requested requirements before

installation in position “Entry 3”. If the Heavy duty

GDU is supplied without cable gland, a special cable

gland approved for Ex protection class EX d and for the

requirements of the application has to be mounted there.

When inserting the cables you have to strictly follow the

instructions enclosed to the cable glands.

No insulating sealing material must be poured into the NPT

¾ “threads of the cable gland and blanking plugs because

the potential equalization between housing and cable

gland / blind plugs is via the thread.

The cable gland must be tightened firmly with a suitable

tool to torque 15 Nm. Only when doing so you can ensure

the required tightness.

After completion of work, the GDU must be closed again.

The cover has to be completely screwed in and secured

with the locking screw against inadvertent loosening.

General Notes

• The terminals of the Heavy duty GDU are located behind the display.

• Only a professional should perform the wiring and the connection of

the electrical installation according to the wiring diagram in compliance

with the relevant regulations and only when de-energized!

• When connecting cables and conductors, please observe minimum

length of 3 m according to EN 60079-14.

• Connect the housing to the equipotential bonding via the external

ground terminal.

• All terminals are Ex e type with spring contact and push actuation. The

permissible conductor cross section is 0.2 to 2.5 mm² for single wires

and multi-wire cables.

• Use cables with a braided shield for compliance with the interference

immunity. The shield must be connected to the inside connection of the

housing with a maximum length of about 35 mm.

• For the recommended cable types, cross sections and lengths please

refer to the table below.

• To comply with the requirements of servicing or operating the device

without opening it (EN 60079-29- 1 4.2.5) it is possible to calibrate or

operate the device remotely via the central bus. For this it is necessary

to lead the central bus out to the safe area via a cable.

Further Notes and Restrictions

The maximum operating voltage and the terminal voltage of the relays

have to be limited to 30 V by adequate measures.

The maximum switching current of the two relay contacts should be

limited to 1 A by appropriate external measures.

Repairs to flameproof joints are not intended and lead to the immediate

loss of the type approval for the pressure-resistant casing.

Cross-section

(mm²)

With P, freon sensor heads

Operat ing voltage with

4-20 mA signal

Operat ing voltage with

central bus²

Operat ing voltage with

4-20 mA signal

Operat ing voltage with

central bus²

¹ The max. cable lengths and our recommendation don’t consider any local conditions, like fire

protection, national regulations etc.

² For the central bus we recommend using the cable JE-LiYCY 2x2x0.8 BD or 4 x2x0.8 BD.

0.5 250

1.0 500

0.5 300

1.0 70 0

With SC , EC sensor heads

0.5 400

1.0 800

0.5 600

1.0 900

Max. le ngth for 24 V DC¹

(m)

© Danfoss | Climate solutions | 2021.06

AN272542819474en-000201 | 7

Page 8

ENGLISH

Commissioning

For sensors that can be poisoned by e.g. silicones like all semiconductor

and catalytic bead sensors, it is imperative to remove the protective (seal)

cap supplied only after all silicones are dry, and then energize the device.

For fast and comfortable commissioning we recommend proceeding as

follows. For digital devices with self-monitoring all internal errors are

visible via the LED. All other error sources often have their origins in the

field, because it is here where most of the causes for problems in the field

bus communication appear.

Optical Check

• Right cable type used.

• Correct mounting height according to definition in Mounting.

• Led status

Comparing sensor gas type with GDU default settings

Each sensor ordered is specific and must match the GDU default settings.

The GDU software automatically reads the specification of the connected

sensor and compares with the GDU settings.

If other gas sensor types are connected, you have to adjust them with the

configuration tool, because otherwise the device will respond with an

error message.

This feature increases the user and operating security.

New sensors are always delivered factory-calibrated by Danfoss. This is

documented by the calibration label indicating date and calibration gas. A

repeated calibration is not necessary during commissioning if the device is

still in its original packaging (air-tight protection by the red protective cap)

and the calibration doesn’t date back more than 12 months.

Functional test (for initial operation and maintenance)

The functional test should be carried out during each service, but at least

once a year.

Functional test is done by pressing the test button for more than 20

sec and observing all connected outputs (Buzzer, LED, Relay connected

devices) working properly. After deactivation all outputs must

automatically return to its initial position

Zero-point test with fresh outdoor air

Zero-point test with fresh outdoor air. (If prescribed by local regulations)

A potential zero offset can be read out by use of the Service tool.

Trip test with reference gas (If prescribed by local regulations)

The sensor is gassed with reference gas (for this you need a gas bottle with

pressure regulator and a calibration adapter).

In doing so, the set alarm thresholds are exceeded, and all output

functions are activated. It is necessary to check if the connected output

functions are working correctly (e.g. the horn sounds, the fan switches on,

devices shut down). By pressing the push-button on the horn, the horn

acknowledgment must be checked. After removal of the reference gas, all

outputs must automatically return to its initial position.

Other than the simple functional testing, it is also possible to perform a

functional test by means of calibration. For further information, please

refer to the User Manual.

Controller Unit multiple GDU commisioning

For fast and comfortable commissioning we recommend proceeding as

follows. Especially the given specifications of the field bus cable have

to be checked carefully, because it is here where most of the causes for

problems in the field bus communication appear.

1. Optical Check

• Right cable type used (JY(St)Y 2x2x0.8LG or better).

• Cable topology and cable length.

• Correct mounting height of the sensors

• Correct connection at each GDU according to fig. 8

• Termination with 560 ohm at the beginning and at the end of each

segment.

• Pay special attention so that the polarities of BUS_A and BUS_B are not

reversed!

2. Check Short-circuit / Interruption / Cable Length of the Field Bus

(see fig. 8.1)

This procedure has to be executed for each single segment.

The field bus cable must be laid at the connector terminal block of the GDU

for this testing. The plug, however, is not yet plugged into the GDU.

Disconnect the field bus leads from the Controller Unit central control.

Connect ohmmeter to the loose leads and measure the total loop

resistance. See fig. 8.1 The total loop resistance is calculated as follows:

• R (total) = R (cable) + 560 Ohm (terminating resistance)

• R (cable) = 72 Ohm / km (loop resistance) (cable type JY(St)Y 2x2x0.8LG)

R (total) (ohm) Cause Troubleshooting

< 560 Short-circuit Look for sh ort-circuit i n the

infinite Open -circuit Loo k for interrupti on in the

> 560 < 640 Cable is o. k. --

field bus c able.

field bus c able.

The allowed cable length can be calculated in a sufficiently exact way

according to the following formula.

Total cable length (km) = (R (total) – 560 Ohm) / 72 Ohm

If the field bus cable is OK, reconnect it to the central unit.

3. Check Voltage and Bus Polarity of the Field Bus (see fig. 8.2 and 8.3)

• Bus connector to be plugged into each GDU.

• Switch operating voltage on at the Controller Unit central unit.

• The green LED at the GDU lights up weakly when operating voltage is

applied (voltage indicator).

• Check operating voltage and bus polarity at each GDU according to fig.

7.1 and 7.2. U

= 16 V DC (20 V DC for Heavy Duty)

min

• Bus polarity:

Measure tension BUS_A against 0 V DC and BUS_B against 0 V DC. U

BUS_A = ca. 0.5 V > U BUS_B

U BUS_B = ca. 2 – 4 V DC (depending on the number of GDU and on the

cable length)

4. Addressing of the GDU

After having checked the field bus successfully, you have to assign a basic

communication address to each GDU via the display on the unit, the

service tool or the PC tool. With this basic address, the data of the Sensor

Cartridge assigned to input 1 are sent via the field bus to the gas controller.

Any further sensor connected / registered on the GDU automatically gets

the next address.

Choose the menu Address and enter the predetermined Address according

to the Bus Address Plan.

If this connection is OK, you can read the current GDU address in the menu

“Address“ either at the display on the unit or by plugging in the service tool

or the PC tool.

0 = Address of new GDU

XX = Current GDU address (permissible address range 1 – 96)

The detailed description of the addressing can be taken from the user

manual of the Controller unit or the Controller unit service tool.

© Danfoss | Climate solutions | 2021.06

Further documentation:

AN272542819474en-000201 | 8

Loading...

Loading...