Page 1

Instructions

Upgrade of sensor in GD gas detecting sensors: IP 56 / IP 56 Low. temp.

with sensor type Infrared for CO

This sensor upgrade procedure replaces the internal sensor with an external sensor on Danfoss GD gas detecting sensors:

IP 56 enclosure and IP 56 enclosure Low Temperature.

148R9555

The procedure applies to the following Danfoss code numbers:

148H5072, 148H5082,148H5092: IP 56, without heater built-in

148H5075,148H5085: IP 56 Low Temperature, with heater built-in.

Step Description

1. Note that the sensor upgrade procedure is intended to be performed by a technically qualied person who is also familiar

with electronics, ESD eects, and related safety precautions.

2. When the actual Danfoss GD gas detecting sensor is located, gather the following components:

• Upgrade kit (GD Tester PCB, new sensor, sensor daughter PCB, nylon stando, and instructions)

• Crosshead screwdriver

• 4 mm Hex driver

3. IMPORTANT:

The device MUST BE powered o before replacing the sensor.

Remove power from the unit by shutting o power at the source.

4. ESD SENSITIVE COMPONENTS:

Follow proper electrostatic discharge (ESD) precautions. Touch a grounded metal object (e.g., conduit)

prior to working on the device in order to dissipate any built-up static and to reduce the risk of ESD

damage to components.

2

148R9555

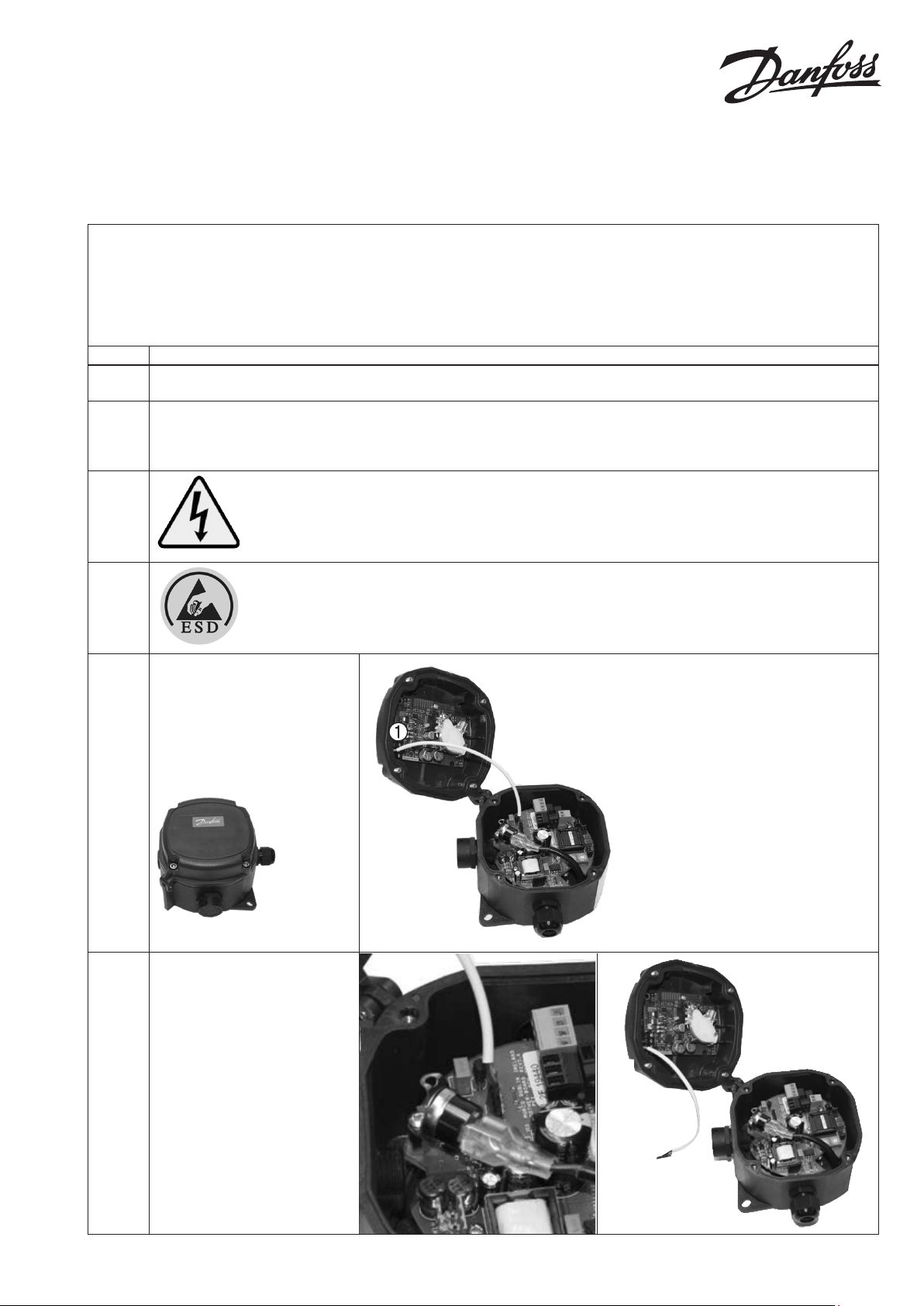

5. Locate and remove the 4

enclosure screws using the hex

driver.

Then carefully open the hinged

housing. The Infrared (IR) sensor

type is located in lid .

6. Carefully remove the sensor plug

from the daughter board

connector.

© Danfoss A/S (MWA), 2015-02 DKRCI.PI.S00.D2.02 / 520H6360 1

Page 2

Step Description

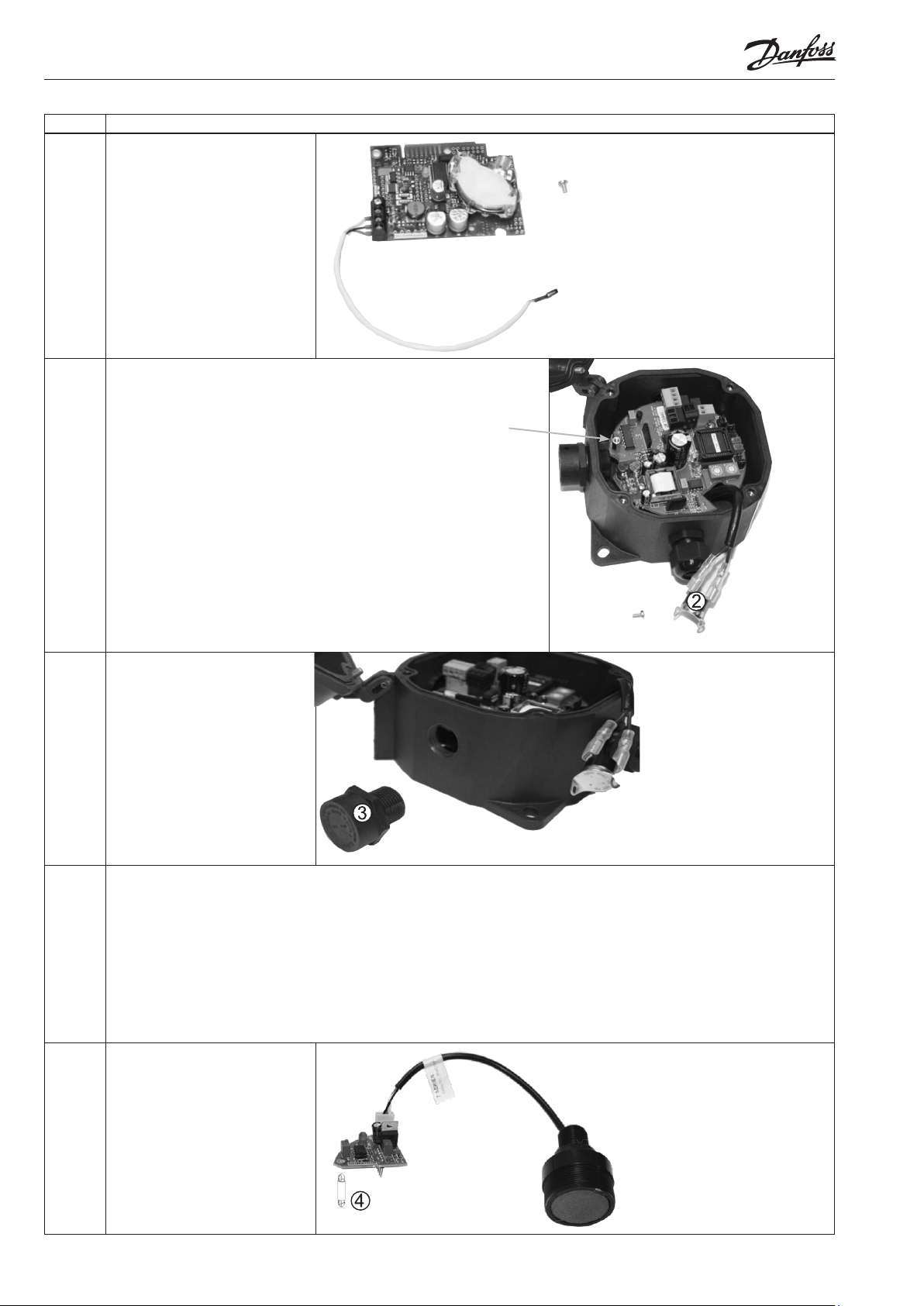

7. Unscrew and remove the sensor

board from the lid of the

enclosure using a standard

Crosshead screwdriver.

8. The IP 56 model are available in two versions:

Danfoss code no. 148H5075 and 148H5085 with heater built-in:

The thermocouple is attached to the main printed circuit board via a

screw on a metal stando or is lose inside the enclosure (see photo).

Unscrew the thermocouple if it is screwed on a metal stando and save

the screw for later. The metal stando and screw will be used to secure

the new sensor daughter board later in this procedure. If no stando was

present, proceed as below.

Danfoss code no. 148H5072, 148H5082 and 148H5092 without heater

built-in:

As no thermocouple is present, you will notice a hole on the mother board

(PCB).

Note the location of this hole as it will be used to secure a special nylon

stando (part of the upgrade kit) for the new sensor daughter board. This

nylon stando is only used when upgrading the versions without heater

built in.

9.

10. Check of mother board

11. Locate the new Sensor Upgrade

2 DKRCI.PI.S00.D2.02 / 520H6360 © Danfoss A/S (MWA), 2015-02

Unscrew the breather drain

from the enclosure.

With the GD tester it is possible to simulate GD Operation within the full ppm range, without any need for refrigerant

calibration gas locally.

Locate the GD Motherboard Tester, Danfoss code: 148H5239. Please Note: The GD Motherboard Tester is not included in

the Upgrade kit.

Locate the Instruction, GD tester for mother PCB, Literature number RI7HB252 for full instruction.

CAUTION

Before reconnecting power to GD, make sure that relevant people, managing the connecting equipment (BMS/PLC

systems) to GD has been advised, that the GD now will force Low and High alarms and generate maximum analog output

(Analog output 4-20 mA/0-5 V/0-10 V) during this test.

Kit. Note that a nylon stando is

included with the sensor daughter

board. This special nylon stando

is only used when upgrading the

versions without heater built-in.

Versions with heater built-in

already have a metal stando on

the main printed circuit board for

proper mounting of the daughter

board.

Page 3

Step Description

12. Temporarily disconnect the

provided daughter board from

the sensor.

13. Carefully mount the sensor daughter board to the main printed

14.

circuit board.

IMPORTANT: Alignment of the daughter board and the main

board header is critical.

CAUTION: Note that it is possible to be oset by one pin, and

still force the stando/screw to align, so be careful when

mounting the daughter board to the mother board (PCB).

Danfoss code no. 148H5072, 148H5082 and 148H5092

without heater built-in:

Install the nylon stando to the mother board(PCB) rst, then

carefully snap the daughter board into the mother board(PCB)

using the nylon stando as a guide. (NOTE: If the alignment is

not correct, but the stando has already been attached to the

daughter board, carefully squeeze the end of the stando that is

through the daughter board to release.)

Danfoss code no. 148H5075 and 148H5085 with heater

built-in:

Locate the existing metal stando and use the previously

saved screw to secure the daughter board to the existing metal

stando.

It is dicult to see the header where the daughter PCB plugs in. With a perpendicular view above the board, use the

stando hole and metal stando (or nylon stando) below to maintain proper alignment.

CAUTION:

If the daughter board is installed incorrectly, then on power-up the software sequence of the red and yellow LEDs may not

function as expected (or at all). The green LED, however, will likely appear to exhibit proper operation.

At Step 17 the check sequence of the LEDs are descriped at power-up

Thread the sensor cable

through the enclosure and screw

the sensor into the threaded

housing. Hand tighten the sensor

enough to just compress the

O-ring and create a seal

(approximately ¼ turn past hand

tight).

IMPORTANT:

Do not use a wrench or any other

tool. Do not over-tighten as this

will damage the O-ring.

© Danfoss A/S (MWA), 2015-02 DKRCI.PI.S00.D2.02 / 520H6360 3

Page 4

Step Description

15. Carefully connect the plug of the

sensor to the mating connector

on the main sensor board. Be

certain not to bend any pins.

Route the sensor wiring so that

it does not interfere with the

reset button and so it does not

get pinched when the cover is

replaced.

16.

17. Restore source power to the

18. Secure the lid using the 4 hex

Remove the thermocouple

from the spade connectors.

After removal, ensure the plastic

insulators cover the connectors to

prevent shorts. Then route the remaining thermocouple wiring so

that it does not interfere with or

short against other components

and so it does not get pinched

when the cover is replaced.

NOTE: The heaters are no longer

required and may be left in situ

without concern.

sensor.

Inspect the LEDs on the board

after power up to ensure that:

• The Red and Yellow blink twice

on powerup and then go out,

and

• The Green LED is on.

If this does not happen, then the

sensor was not installed properly.

nuts.

19. The device is calibrated at the factory and does not require calibration on installation. Please consult Danfoss technical

documentation for gas detecting sensors, type GDA, GDC, GDHC, GDHF, GDH (DKRCI.PD.S00.A).

IMPORTANT:

Before testing a detector on-site, it must be powered up and allowed to stabilize.

20. After restoring power and conrming normal operation, verify that the building management system (BMS) continues to

detect and communicate with the sensor (as required). If communication has been lost, re-scan the building sensors via the

BMS. No further interaction with the sensor itself should be necessary. If communication continues to be missing, remove

power from the sensor and conrm the wiring to the main PCB. Reference the sensor installation instructions provided

with the original equipment as needed.

21. The disposal of the removed electrical parts should be in accordance with the WEEE directive 2002/96/EC within the

European community and/or local regulations for countries outside this area.

4 DKRCI.PI.S00.D2.02 / 520H6360 © Danfoss A/S (MWA), 2015-02

Loading...

Loading...