Installation guide

Danfoss

9G221.10

Spareparts

Type GBC service kit (only for R744 applications)

Choose the correct Service Kit

1

according to the valve size.

00 9R9514

Valve size Code no.

GBC 6s –GBC 22s 009G8012

GBC 28s – GBC 35s 009G8014

GBC 42s –GBC 79s 009G8016

Locate the ball valve that needs to be fitted with the

2

service kit.

Pump down the section of system where the ball valve is

3

located to the lowest permissible pressure, governed by

the suction low pressure safety switch.

In case it is impossible to pump down the section of the

system, please contact Danfoss for further instructions.

00 9R9514

This kit is only suitable for old

design ball valves(009Gxxxx)!

If need more information, please

contact Danfoss.

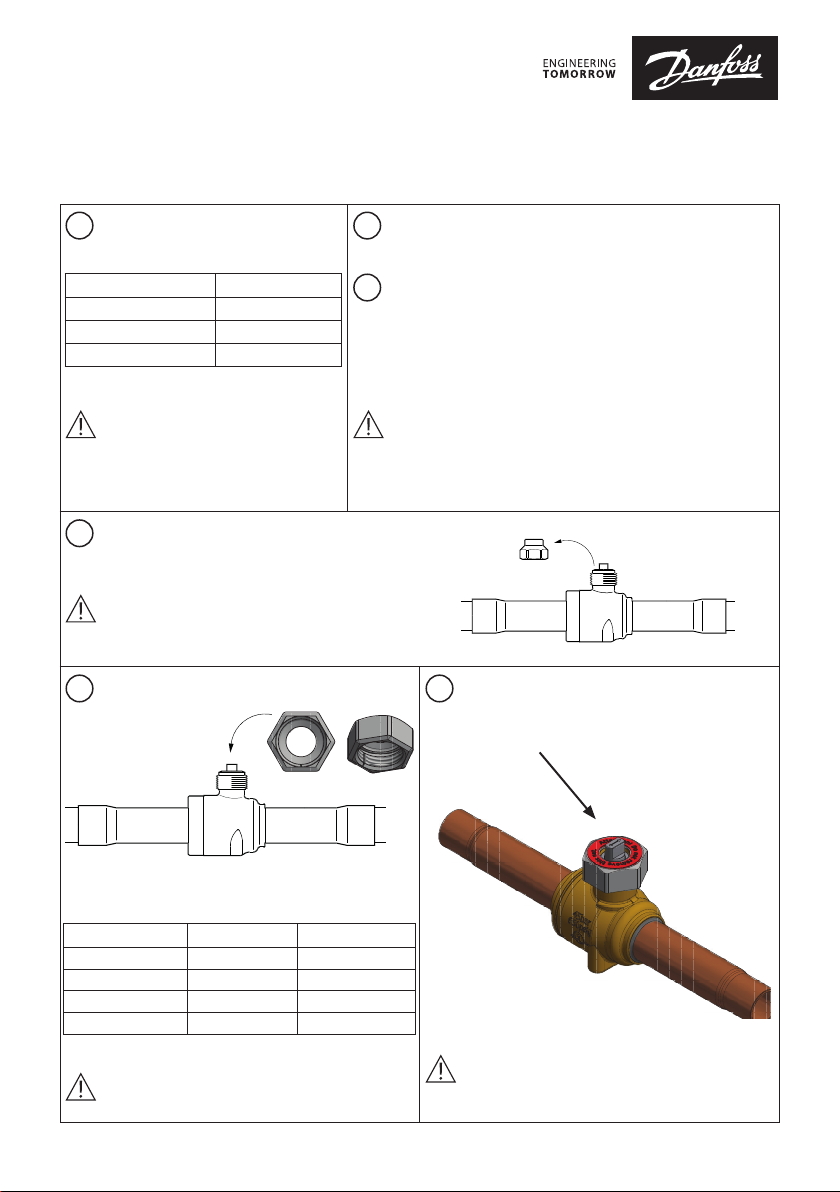

Remove the original cap from the valve.

4

If the thread or flanging area of GBC housing has

been damaged, do not use this service kit. GBC

valve needs to be replaced with a new valve.

Tighten the Service Kit with approx. torque.

Valve size

GBC 6s – GBC 16s 10 – 15 7.4 – 11.1

GBC 18s – GBC 22s 15 – 25 11.1 – 18.4

GBC 28s – GBC 35s 25 – 35 18.4 – 25.8

GBC 42s – GBC 79s 35 – 40 25.8 – 29.5

Min. – Max. [Nm] Min. – Max. [ft-lbs]

The Service Kit should be fitted by competent & trained

Service Technicians.

Before continuing with retrofit, please carefully review

enclosed extra caution recommendations on the back

page.

Danfoss

9G222.10

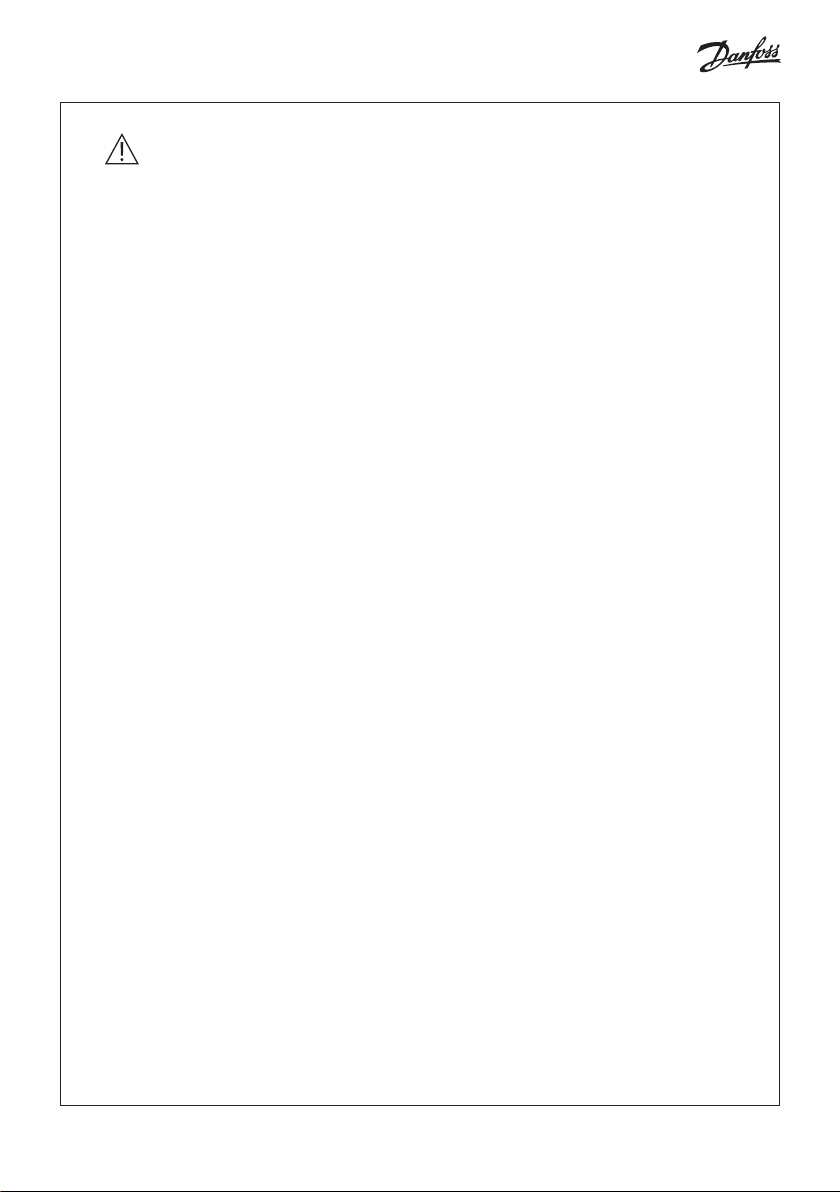

Final view

65

Valve is opened / closed using a

suitable wrench

Make sure to use torque wrench to tighten

the service kit.

© Danfoss | DCS (ms) | 2019.06

Do not remove the Service Kit under any

circumstances, once the installation is

complete.

AN213986438389en-000601 | 1

Below extra cautions should be followed

during the installation of service kit in CO2 systems

• Use appropriate safety equipment, such as: Safety glasses, anti-freeze gloves,

ear protectors and where necessary a helmet, before operating the GBC

during service.

• Be aware of your surroundings BEFORE removing the cap from the GBC ball

valve. ENSURE that you do not occupy the area in front of the spindle and

at arm’s length from the valve to avoid any potential danger of being hit by

the spindle and provide a means of stopping the spindle should it become

ejected from the body after the cap has been removed (in extreme cases).

• Take extra care when working on steps or in confined spaces.

• When working at height – Consider the use of a suitable safety harness.

Generally, all work should be carried out in a well-ventilated area. Ideally, the

technician should use a personal R744 detector to ensure that the area is safe to

work in.

All tools and equipment such as hoses should be rated for the pressure of the

system, R744.

The servicing technician should be familiar with the system and should

understand how sections of the system are safely isolated. This includes the effect

on the system when closing valves and the potential for trapping liquid R744

between closed valves.

Welding or brazing should not be attempted on the system until fully

de-pressurized.

© Danfoss | DCS (ms) | 2019.06

AN213986438389en-000601 | 2

Loading...

Loading...