Data Sheet

Shut-off ball valve

Type GBC, GBCH and GBCT

For CO2 application

Danfoss shut-o ball valves, type

GBC,GBCH,GBCT are manually operated shut-

o valves for CO2 refrigeration systems, in order

to open and to shut o inner ow path by

operating the valve spindle.

The valves are specically designed for intrinsic

standstill security, meaning that the valves can

withstand pressures normally arising when the

refrigeration system is shut o, i.e. during

serving or during unexpected power failure.

The valve structure and materials are designed

and tested specically for use with CO

refrigerant.

GBC and GBCH valves are designed to use in

subcritical CO2 refrigeration systems. GBCT

valves are approved for use in transcritical CO

systems.

Features:

• Bleed hole design to prevent liquid

entrapment when the valve is closed

• Sealing material especially for CO₂ to ensure

long term product reliability

• Customized brass material ensures consistent

performance under aggressive environment

• GBCH 28s~42s with stainless-steel butt

welding connections, suitable for systems

with stainless-steel piping

• GBCT with reinforced copper-iron tube

extensions to allow easy torch-brazing

installation

• UL/cUL Listed, complies with Pressure

Equipment Directive 2014/68/ EU

2

2

AI270047618978en-000601

MT

AK-PC 572

AK-SM 8XX

MBS 8250

MBS 8250

MBS 8250

MBS 8250

GBC 90 Bar

GBC 90 Bar

GBC 90 Bar

GBCT 140 Bar

GBC 90 Bar

GBC 90 Bar

AK- PC 572

®

AKVP

Gas cooler

Medium temp. load

Low temp. load

GBCT 140 Bar

GBCT 140 Bar

GBCT 140 Bar

NRV

NRV

NRV

NRV

LP

HP

009L6420

PS 20319SIG/140 BAR

TS -40 – 149 0C

ECO

0F

0C

<

<

<

<

SET

i

AKS 11

AKS 21A

AKS 11

AKS 11

AK-CC55

AKS 11

FC 103

AKS 11

AKS

2050

AKS

2050

AK-CC55

FC 103

AKVP

AKS 11

LT

CCMT

Light

MADE IN DENMARK

MADE IN DENMARK

CCMT

Light

DGS

ECO

0F

0C

<

<

<

<

SET

i

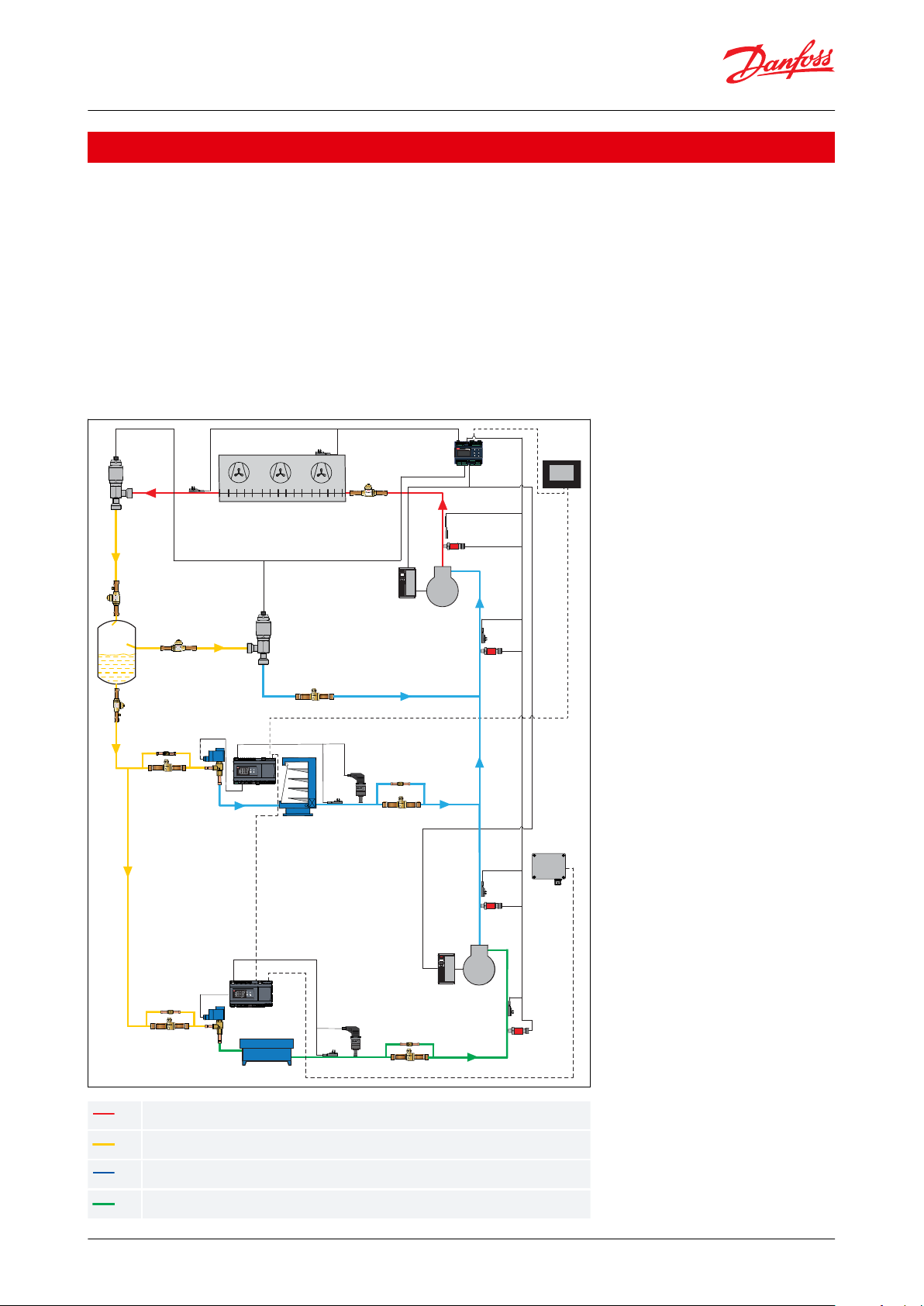

HP High Pressure (120-140 bar)

HP Receiver Pressure (60-90 bar)

LP Suction Pressure MT (35-55 bar)

LP Suction Pressure LT (25-30 bar)

Shut-o ball valve, type GBC, GBCH and GBCT

Applications

Typical applications for CO2 ball valves are:

• Display cases

• Supermarket stores

• Food Retail

• Industrial refrigeration

• Heat pump

Danfoss CO2 ball valves are designed for the following refrigerant cycles:

• GBC with PS = 45 bar, copper connections equipped, for subcritical systems

• GBCH with PS = 90/75 bar, copper/ stainless steel connections equipped, for subcritical systems

• GBCT with PS = 140 bar, reinforced copper connections (K65) equipped, for transcritical systems

Figure 1: Application

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 2

Refrigerants

R 744 (CO2)

Refrigerant oil

POE, PAG (PVE, PAO)

Shut-o ball valve, type GBC, GBCH and GBCT

Media

Table 1: Media

NOTE:

For the application use with R744 as part of a secondary loop or cascade:

1.

The design pressure of the refrigerant containing component is not less than the design pressure of the

associated components.

2.

The component is not provided with any pressure relief or pressure regulating relief valve and that a sucient

number of valves having capacity deemed adequate shall be eld installed on the refrigeration system.

3.

When the refrigeration system is de-energized, venting of R744 may occur through the pressure regulating relief

valves, and may need to be recharged, but the valve should not be defeated or bypassed.

4.

A sucient number of pressure relief and pressure regulating valves may need to be provided based upon

system capacity and located such that no stop valve is provided between the relief valve and the parts or section

of the system being protected.

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 3

Technical data

GBC

GBCH

GBCT

Max. working pressure

45 bar / 650 psig

6s - 28s: 90 bar / 1305 psig

35s - 42s: 75 bar / 1085 psig

140 bar / 2031 psig

Media temperature range

-40 °C – 100 °C / -40 °F – 212 °F

-40 °C – 100 °C / -40 °F – 212 °F

-40 °C – 149 °C / -40 °F – 300 °F

Flow direction

Single ow

Bi ow

Bi ow

Environmental transport/storage

temperature and humidity

-40 – 65 °C /-40 – 150 °F. Air humidity: RH≤95%.

Position

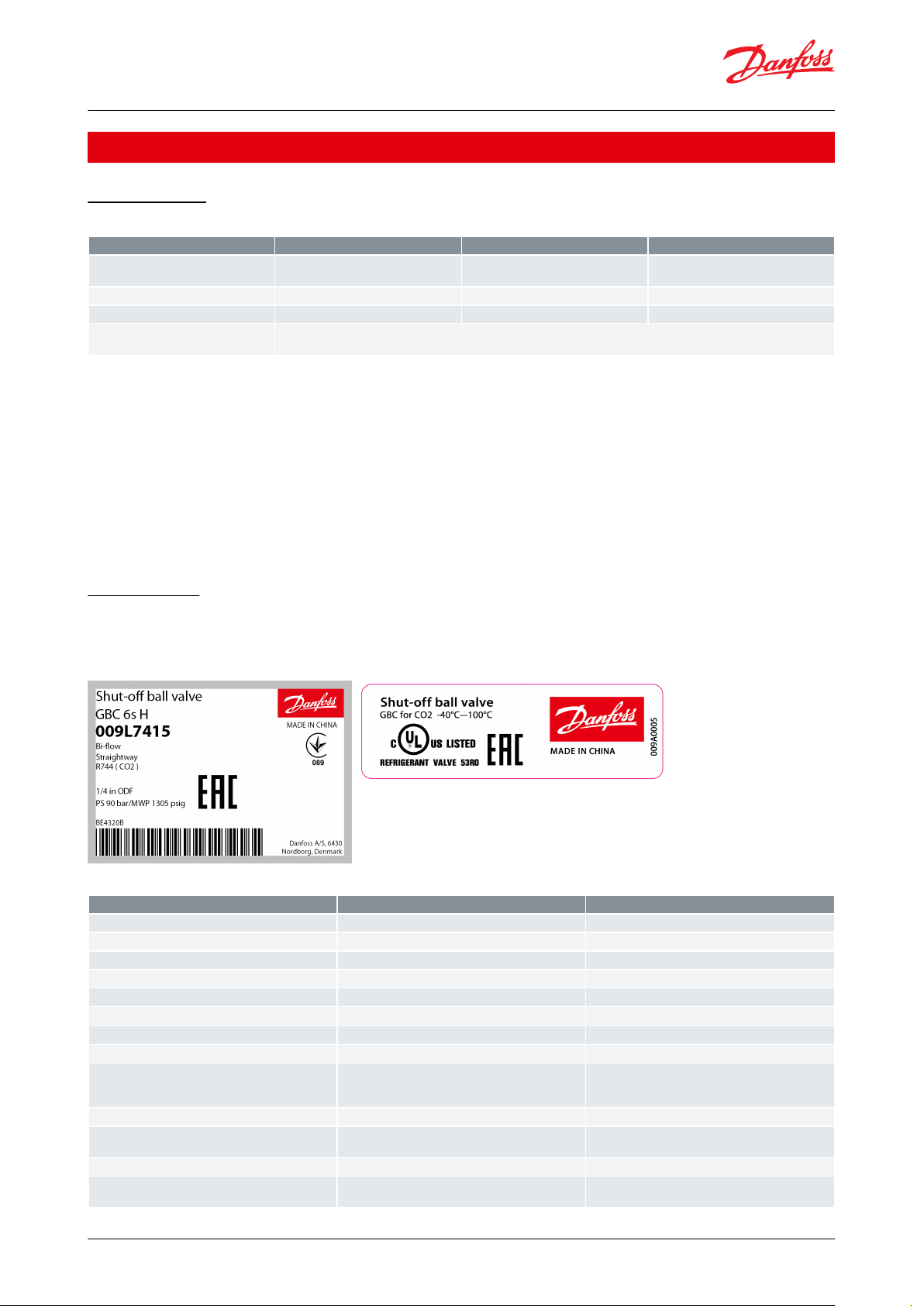

Inscription

Explanation

Box label; Product label

Shut-o

ball valve

Product name

Box label

GBC 6s H

Product type

Box label

009L7415

Code number for ordering

Box label

Bi-ow

Flow type

Box label

Straightway

Direction

Box label

R744(CO

2

)

Refrigerant

Box label

1/4 in ODF

Connection size and type

Box label

PS 90 bar/MWP 1305 psig

Max. working pressure in bar and psig

Box label

BE4320B

Code for production place and time

(BE = Wuqing, week 43, year 2020, weekday B = Tuesday)

Box label; Product label

MADE IN CHINA

Manufacturing site acc. to EN standards

Box label

EAN code

Barcode for individual code no.

identication accord-

ing to EAN standard

Product label

-40 °C – 100 °C

Media temperature range

Box label; Product label

Additional information: Relevant approval authority

logos

-

Shut-o ball valve, type GBC, GBCH and GBCT

Product specication

Technical data

Table 2: Technical data

CAUTION:

Danfoss recommends that GBCT valves are installed so that the HP side is oriented towards the highest

pressure side of the system when the valve is in the closed position.

GBCT CAUTION - RISK OF HIGH PRESSURE

Do not close with CO2 liquid temperature below ambient. This component shall be installed along with a pressure

relief valve set to discharge at no higher than the rated pressure of this component. This component is intended for

systems in which the critical pressure of the refrigerant will be exceeded. The relief valve shall comply with the

requirements of ASME Section VIII, be marked “UV” and sized based on the refrigeration system capacity.

An orange Hanging tag is added on all valves as per requirement of UL certicate.

Identication

Relevant product data is available on the product and box label. An example of a box label and product label are

shown, including an explanation of the content.

Figure 2: Box label Figure 3: Product label

Table 3: Product and label text

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 4

009L6420

PS 2031PSIG/140 BAR

TS -40C to 149C

HP LP

Inscription

Explanation

"HP"

Indicates where the bleed hole of ball is located and Danfoss recommends the HP

side is oriented towards the highest pressure side of system when valve is in

closed position.

"LP"

Indicates the side without bleed hole and shall be oriented towards to the low

pressure side of system when valve is in closed position.

Danfoss

9L75002

13

7

9 8

10

611

12

1

5

3

2

4

Position

Description

Material

1

Connection tube

Copper (Stainless steel for GBCH 28s~42s)

2

Valve body

Brass3Ball seat

PTFE4Valve tail

Brass5Ball

Stainless steel

6

Double O-ring seal in spindle

EPDM Rubber

7

Cap seal

PTFE8Seal cap

Brass9Spindle

Brass10Pin

Stainless steel

11

Guide ring

PTFE12Schrader valve

Stainless steel

13

Bleed hole

-

Shut-o ball valve, type GBC, GBCH and GBCT

Figure 4: Marking of GBCT

Table 4: Marking of GBCT

Design and materials

Direct ow gives maximum through-ow with minimum pressure drop across valve. The combination of laserwelded valve body (2) and valve tail (4), ball seat/seal (3), double O-ring seal in spindle (6), and cap seal (7) provides

the best tightness.

Figure 5: Design and materials

Table 5: Design and materials

Dimensions

We have chosen to show dimensions of the major versions.

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 5

H

H

1

L1

L2

L

L1

L5

L3

D

d

L

4

Mx2

Danfoss

09G80101

Type

Size

Con‐

nec‐

tion

Connection

tolerance

HH1LL1L2L3L4L5MDd

Weight

Code no.

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

without

access

port

with

access

port

GBC 6s

1/4 in.

6.35

+0.065/+0.155

50151397757322

31

M4 ×

0.7

14

1.5

0.2

009L7520

009L7553

6 mm

6.00

009L7570

009L7554

GBC 10s

3/8 in.

9.525015

1398757322

31

M4 ×

0.7

14

1.5

0.2-009L7555

3/8 in.

9.52

50151399757322

31

M4 ×

0.7

14

1.5

0.2

009L7521

-

10 mm

10.00

009L7571

009L7556

GBC 12s

1/2 in.

12.70

501516110868422

31

M4 ×

0.7

14

1.5

0.2

009L7522

009L7557

12 mm

12.00

009L7572

009L7558

GBC 16s

5/8 in.

16.005015

16112868422

31

M4 ×

0.7

14

1.5

0.2

009L7523

009L7534

16 mm

GBC 18s

3/4 in.

19.05

581918514999630

37

M4 ×

0.7

19

1.5

0.4

009L7524

009L7563

18 mm

18.00

009L7574

009L7564

GBC 22s

7/8 in.

22.22

+0.075/+0.185

581918517999630

37

M4 ×

0.7

19

1.5

0.4

009L7525

009L7536

22 mm

GBC 28s

1 1/8 in.

28.58

802520820112

1083844

M4 ×

0.7

26

1.5

0.9

009L7526

009L7565

28 mm

28.00

009L7576

009L7566

GBC 35s

1 3/8 in.

35.00

+0.09/+0.23

893025125136

1304844

M6 ×

1.0

32

1.5

1.4

009L7528

009L7567

35 mm

GBC 42s

1 5/8 in.

41.28

1103528129151

1455556

M6 ×

1.0

38

1.5

2.2

009L7529

009L7568

42 mm

42.00

009L7579

009L7569

Shut-o ball valve, type GBC, GBCH and GBCT

You will nd downloadable dimension drawings for individual code numbers on Danfoss store as part of the Visuals

tab for individual code numbers.

Weights also dier depending on the design of the individual code numbers. Weights are available as part of the

technical data for individual code numbers on Danfoss store.

GBC solder ODF/ODF, copper connections

Figure 6: GBC solder ODF/ODF

Table 6: GBC solder ODF/ODF, copper connections

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 6

L

H1

H

L1 L1

L3

L5

D

L4

Mx2

6s -16s

NON-AP

ONLY

Type

Size

Con‐

nec‐

tion

Connection

tolerance

HH1LL1L2L3L4L5MDd

Weight

Code no.

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

without

access

port

with ac‐

cess port

GBCH 6s

1/4 in.

6.35

+0.065/+0.155

50151395757322

31

M4 ×

0.7

14

1.5

0.2

009L7415

009L7581

6 mm

6.00

009L7395

009L7580

GBCH 10s

3/8 in.

9.52

50151397757322

31

M4 ×

0.7

14

1.5

0.2

009L7416

009L7582

10 mm

10.00

009L7396

009L7583

GBCH 12s

1/2 in.

12.70

50151618868422

31

M4 ×

0.7

14

1.5

0.2

009L7417

009L7585

12 mm

12.00

009L7397

009L7584

GBCH 16s

5/8 in.

16.005015

16110868422

31

M4 ×

0.7

14

1.5

0.2

009L7418

009L7586

16 mm

GBCH 18s

3/4 in.

19.05

581918512999630

37

M4 ×

0.7

19

1.5

0.4

009L7419

009L7588

18 mm

18.00

009L7399

009L7587

GBCH 22s

7/8 in.

22.22

+0.075/+0.185

581918515999630

37

M4 ×

0.7

19

1.5

0.4

009L7420

009L7589

22 mm

L1

L1

L2

L

D

H1

H

L3

L4

Mx2

Shut-o ball valve, type GBC, GBCH and GBCT

GBCH solder ODF/ODF, copper connections

Figure 7: GBC solder ODF/ODM

Table 7: GBCH solder ODF/ODF, copper connections

GBCH butt weld, stainless steel connections

Figure 8: GBC solder ODM/ODM, copper connections

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 7

Type

Size

Con‐

nec‐

tion

Connection

tolerance

HH1LL1L2L3L4MDdWeight

Code no.

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

without

access

port

GBCH 28s

28 mm

28

-0.1/+0.1

802520865115

116

38

M4 ×

0.7

25.5

1.5

0.9

009L7406

GBCH 35s

35 mm

358930

25179146

141

48

M6 ×

1.0

32

1.5

1.5

009L7410

GBCH 42s

42 mm

42

1103528188162

156

55

M6 ×

1.0

38

1.5

2.5

009L7411

L

H1

H

L1 L1

L3

L5

D

L4

Mx2

6s -16s

NON-AP

ONLY

Type

Size

Con‐

nec‐

tion

Connection

tolerance

HH1LL1L3L4L5MD

Weight

Code no.

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

without

access

port

with ac‐

cess port

GBCT 6s

1/4 in.

6.35

+0.051/+0.155

571412776922N/A

M4 ×

0.7

13

0.2

009L6415

-

5714127755

N/A44N/A130.3-009L6581

GBCT 10s

3/8 in.

9.52

571413297222N/A

M4 ×

0.7

13

0.2

009L6416

-

5714132958

N/A46N/A130.3-009L6582

GBCT 12s

1/2 in.

12.70

5714139107522N/A

M4 ×

0.7

13

0.2

009L6417

-

57141391061

N/A50N/A130.3-009L6585

GBCT 16s

5/8 in.

15.88

5714148138022N/A

M4 ×

0.7

13

0.2

009L6418

-

57141481366

N/A54N/A130.3-009L6586

GBCT 18s

3/4 in.

19.058732

1481778

N/A30N/A190.7

009L6419

009L6588

GBCT 22s

7/8 in.

22.228732

1852096

N/A40N/A190.7

009L6420

009L6589

GBCT 28s

1 1/8 in.

28.58

+0.075/+0.185

102371852495

N/A40N/A251.3

009L6406

009L6451

GBCT 35s

1 3/8 in.

34.93

1033520525102

N/A44N/A322.0

009L6410

009L6453

GBCT 42s

1 5/8 in.

41.28

+0.075/+0.203

1134024028120

N/A50N/A382.9

009L6411

009L6454

GBCT 54s

2 1/8 in.

53.98

1445227535138

N/A56N/A516.1

009L6412

009L6456

Shut-o ball valve, type GBC, GBCH and GBCT

Table 8: GBCH butt weld, stainless steel connections

GBCT solder ODF/ODF, copper connections

Figure 9: GBCT solder ODF/ODF, copper connections

Table 9: GBCT solder ODF/ODF, copper connections

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 8

Type

Inlet

Outlet

mm connections

Inch connections

GBC

Solder ODF

Solder ODF

6 mm x 6 mm

10 mm x 10 mm

12 mm x 12 mm

16 mm x 16 mm

18 mm x 18 mm

22 mm x 22 mm

28 mm x 28 mm

35 mm x 35 mm

42 mm x 42 mm

¼ in x ¼ in

⅜ in x ⅜ in

½ in x ½ in

⅝ in x ⅝ in

¾ in x ¾ in

⅞ in x ⅞ in

1

1

⁄8 in x 1 1⁄8 in

1

3

⁄8 in x 1 3⁄8 in

1

5

⁄8 in x 1 5⁄8 in

GBCH

Solder ODF

Solder ODF

6 mm x 6 mm

10 mm x 10 mm

12 mm x 12 mm

16 mm x 16 mm

18 mm x 18 mm

22 mm x 22 mm

¼ in x ¼ in

⅜ in x ⅜ in

½ in x ½ in

⅝ in x ⅝ in

¾ in x ¾ in

⅞ in x ⅞ in

Butt weld

Butt weld

28 mm x 28 mm

35 mm x 35 mm

42 mm x 42 mm

-

GBCT

Solder ODF

Solder ODF

-

¼ in x ¼ in

⅜ in x ⅜ in

½ in x ½ in

⅝ in x ⅝ in

¾ in x ¾ in

⅞ in x ⅞ in

1

1

⁄8 in x 1 1⁄8 in

1

3

⁄8 in x 1 3⁄8 in

1

5

⁄8 in x 1 5⁄8 in

2

1

⁄8 in x 2 1⁄8 in

Shut-o ball valve, type GBC, GBCH and GBCT

Connections

Standard GBC, GBCH, GBCT versions can be provided with straightway, connection types solder ODF or butt weld in

a wide variety of connection sizes. Solder ODF versions are with extended ends copper connections, butt weld

versions with stainless steel connections.

For details on availability, see Ordering

Connection table

Table 10: Connection table

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 9

Type

Solder ODF / ODF Connection

Kv

(1)

Cv

(1)

Max. working

pressure:

PS/MWP

Media tem‐

perature

range

Code no.

Multi pack

[in.]

[mm]

[m3/h]

[gal/min]

without

access port

with

access port

Qty/ pack

GBC 6s

1/4-1.74

2.01

45 bar /

650 psig

-40 °C – 100 °C

/

-40 °F – 212 °F

009L7520

009L755325-61.74

2.01

009L7570

009L7554

25

GBC 10s

3/8-7.52

8.69

009L7521

009L755525-107.52

8.69

009L7571

009L7556

25

GBC 12s

1/2-12.92

14.94

009L7522

009L755725-1212.92

14.94

009L7572

009L7558

25

GBC 16s

5/81615.66

18.10

009L7523

009L7534

25

GBC 18s

3/4-21.93

25.35

009L7524

009L756325-1821.93

25.35

009L7574

009L7564

25

GBC 22s

7/82233.34

38.54

009L7525

009L7536

25

GBC 28s

1 1/8-62.25

71.96

009L7526

009L75655-2862.25

71.96

009L7576

009L7566

5

GBC 35s

1 3/83592.76

107.23

009L7528

009L7567

5

GBC 42s

1 5/8-134.76

155.78

009L7529

009L75684-42134.76

155.78

009L7579

009L7569

4

Shut-o ball valve, type GBC, GBCH and GBCT

Ordering

GBC,GBCH,GBCT code numbers described in this data sheet are standard code numbers, i.e. made to stock.

Besides code numbers made to stock GBC,GBCH,GBCT is also made to order. Make to order options include:

• Mechanical connection type

• Mechanical connection size

• Access port size

Multipack contains several items, individually packed, so that customers can purchase 1 item and receive all relevant

documentation.

GBC solder ODF/ODF, copper connections

Figure 10: GBC without access

port, solder ODF/ODF

Figure 11: GBC with access port,

solder ODF/ODF

Table 11: GBC solder ODF/ODF, copper connections

(1)

(1)

Calculated based on uid dynamic equations

Calculated based on uid dynamic equations

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 10

Type

Solder ODF/ODF

connection

Kv

(1)

Cv

(1)

Max. working

pressure:

PS/MWP

Media tempera‐

ture range

Code no.

Multi pack

[in.]

[mm]

[m3/h]

[gal/min]

without

access

port

with access port

Qty/ pack

GBC 6s H

1/4-1.78

2.06

90 bar /

1305 psig

-40 °C – 100 °C

/

-40 °F – 212 °F

009L7415

009L7581

25-6

1.78

2.06

009L7395

009L7580

25

GBC 10s H

3/8-6.31

7.29

009L7416

009L7582

25-10

6.31

7.29

009L7396

009L7583

25

GBC 12s H

1/2-12.87

14.88

009L7417

009L7585

25-12

12.87

14.88

009L7397

009L7584

25

GBC 16s H

5/81611.77

13.61

009L7418

009L7586

25

GBC 18s H

3/4-31.07

35.92

009L7419

009L7588

25-18

31.07

35.92

009L7399

009L7587

25

GBC 22s H

7/82224.47

28.29

009L7420

009L7589

25

Type

Solder ODF/ODF

connection

Kv

(1)

Cv

(1)

Max. work‐

ing pres‐

sure:

PS/MWP

Media tempera‐

ture range

Code no.

Multi pack

[in.]

[mm]

[m

3

/h]

[gal/min]

without ac‐

cess port

with access

port

Qty/ pack

GBC 28s H-28

96.72

111.81

90 bar /

1305 psig

-40 °C – 100 °C

/

-40 °F – 212 °F

009L7406-5

GBC 35s H-35

106.95

123.63

75 bar /

1088 psig

009L7410-5

GBC 42s H-42

150.98

174.53

009L7411-4

Shut-o ball valve, type GBC, GBCH and GBCT

GBCH solder ODF/ODF, copper connections

Figure 12: GBCH without access

port,solder ODF

Figure 13: GBCH with access

port,solder ODF

Table 12: GBCH solder ODF/ODF, copper connections

(1)

(1)

Calculated based on uid dynamic equations

Calculated based on uid dynamic equations

GBCH butt weld, stainless steel connections

Figure 14: GBCH without access

port,butt weld

Table 13: GBCH butt weld, stainless steel connections

(1)

(1)

Calculated based on

Calculated based on

uid dynamic equations

uid dynamic equations

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 11

Type

Connec‐

tion

Kv

Cv

Max. working

pressure:

PS/MWP

Media tempera‐

ture range

Code no.

Multi pack

[in.]

[m3/h]

[gal/min]

without

access port

with access port

Qty/ pack

GBCT 6s

1/4

0.9

1.0

140 bar /

2031 psig

-40 °C – 149 °C /

-40 °F – 300 °F

009L6415

009L6581

30

GBCT 10s

3/8

3.7

4.3

009L6416

009L6582

30

GBCT 12s

1/2

5.4

6.2

009L6417

009L6585

30

GBCT 16s

5/8

10.4

12.1

009L6418

009L6586

30

GBCT 18s

3/4

16.4

19.0

009L6419

009L6588

18

GBCT 22s

7/8

23.7

27.5

009L6420

009L6589

18

GBCT 28s

1 1/8

42.3

48.9

009L6406

009L6451

4

GBCT 35s

1 3/8

67.1

77.6

009L6410

009L6453

4

GBCT 42s

1 5/8

83.1

96.1

009L6411

009L6454

4

GBCT 54s

2 1/8

171.3

198.0

009L6412

009L6456

2

Type

Valve connection size

Industrial pack [pcs]

Code no.

[inch]

[mm]

GBC/GBCH 6s - 22s

1/4 – 7⁄8

6 – 22

6

009L7210

GBC/GBCH 28s - 35s

1 1/8 – 1 3/8

28 – 35

3

009L7211

GBC/GBCH 42s

1 5⁄8423

009L7212

Shut-o ball valve, type GBC, GBCH and GBCT

GBCT solder ODF/ODF, copper connections

Figure 15: GBCT without access

port,solder ODF

Figure 16: GBCT with access

port,solder ODF

Table 14: GBCT solder ODF/ODF, copper connections

Spare parts

Figure 17: Seal cap kit

Table 15: Seal cap kit

Figure 18: Bracket kit

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 12

Type

Valve connection size

Industrial pack [pcs.]

Code no.

[inch]

[mm]

GBC/GBCH 6s -16s

1/4 – 5⁄8

6 – 16

12

009G7084

GBC/GBCH 18s - 22s

3/4– 7⁄8

18 – 22

12

009G7085

GBC/GBCH 28s

1 1⁄82810

009G7086

GBC/GBCH 35s

1 3⁄8355

009G7087

GBC/GBCH 42s

1 5⁄8424

009G7088

Shut-o ball valve, type GBC, GBCH and GBCT

NOTE:

The spare parts are only for GBC and GBCH. For GBCT spare parts, please consult Danfoss

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 13

Type

File name

Document type

Document topic

Approval authority

GBC, GBCH, GBCT

Д-DK.РА01.B.02567_19

EAC Declaration

Machinery & Equipment

EAC RU

GBC, GBCH, GBCT

Д-DK.БЛ08.B.02139_19

EAC Declaration

PED

EAC RU

GBC, GBCH

033F4001.AE

Manufacturers Declaration

PED

Danfoss

GBC, GBCH

033F4002.AE

EU Declaration

PED

Danfoss

GBCT

033F4003.AA

Manufacturers Declaration

PED

Danfoss

GBC, GBCH, GBCT

033F4006

Manufacturers Declaration

China RoHS

Danfoss

GBC, GBCH, GBCT

033F4010

Manufacturers Declaration

RoHS

Danfoss

GBCT

033F4013.AA

EU Declaration

PED

Danfoss

GBC, GBCH

UA.089. D. 00189-17

UA Declaration

PED

LLC CDC EURO TYSK

GBC, GBCH

UA.TR-089.0995-17

Pressure - Safety Certicate

PED

LLC CDC EURO TYSK

GBC, GBCH, GBCT

UL SA7200

Mechanical - Safety Certicate

UL

UL

Shut-o ball valve, type GBC, GBCH and GBCT

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 14

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI270047618978en-000601 | 15

Loading...

Loading...