Page 1

Operating guide

Gasketed Heat Exchangers

Introduction

This user guide is a guide for installation,

commissioning, operation and maintenance of

plate type heat exchangers supplied by Danfoss.

It is meant for those who are responsible for the

installation, the use and maintenance of the heat

exchangers. We recommend that you read this

user guide carefully before commencing any

work.

This user guide is applicable for all plate type

heat exchangers produced and supplied by

Danfoss if there is no local country specific

deviation from it (in a whole and/or in a part).

Danfoss can not be held responsible or liable

for damage as a result of incorrect installation,

use and/or maintenance of Danfoss plate type

heat exchanger or damage caused by as not

complying with the instructions in this user

guide.

Please note that our plate type heat

exchangers are specially designed and built

for the maximum design conditions (pressures,

temperatures, capacities and type of fluids)

provided by the customer and stated on the

nameplate.

Sudden pressure peaks within or beyond the

maximum operating pressure (or pressure

surges) which can occur during start-up or

stopping of the system can severely damage

the heat exchanger and should be prevented.

Danfoss can not be held responsible for any

damage as a result of any operation deviating

from the original design conditions.

Safety alert notices The following must always be observed when

installing or servicing plate heat exchangers:

• Comply with national/local safety regulations

• Ensure that the heat exchanger is

unpressurized and completely drained

• Ensure that the heat exchanger is cooled

down to a temperature below 40 °C (104 °F)

Warning symbols refer to safety alert notices.

Warning/safety notices should be observed

carefully to prevent:

Personal injury caused by:

• Wrong transport/lifting

• Burning/free zing as a result of touching

parts with ex treme temperatures.

• Burning/free zing/poisoning as a result of

uncontrolled release of p ressurized media

• Contact with chemicals

• Touching sharp edges of e.g. plates

Equipment damage caused by:

• Wrong transport/lifting

• Liquid hammering

• External fo rces

• Corrosion

• Chemical action

• Erosion

• Material fatigue

• Thermal and/or mechanical shock

• Freezing

• Blocking of the hea t exchanger due to particl es

© Danfoss | 2020.10 AQ356845617175en-010101 | 1

Page 2

Operating guide Gasketed Heat Exchangers

Cb

/L

Marking field

General Identification of the heat exchanger

All plate type heat exchangers supplied by Danfoss are provided with a name plate positioned on the

front (head) of the heat exchanger. Additional nameplates can be found elsewhere if specified by the

client and ordered as an option.

On this name plate main technical details of the heat exchanger are specified. Before installation

please make sure that the intended application is compliant with the name plate application data and

use limitations.

SW19A-IG25-40-TMTL38-LIQUID

Liquid/Steam-Liquid/Condenser/Evaporator

38 = % of plates that are „Thermal long“

TL = Thermal long, TK = Thermal short

TM = Thermal mix (pairs TL+TK) – in this case 62% of the plates

consists of TK/TL combination

40 = Number of plates

25 = 25 Bar nominal pressure (6/10/16/25 available)

S = Best frame, with carrier bar and roller. Connection on follower

side possible. Lock – bush on follower side (single sided disassembly

possible)

G = Medium frame, simple carrier bar without roller. Connection on

follower side possible. No lock bush on follower side.

Each heat exchanger comes with a

data list specifying key components

and relevant accessories as per

specific customer order, heat

exchanger dimensions, and an

assembly drawing.

For more detailed technical details

please contact our support team

T = No frame, connection on follower side not possible, only blue

color, no lock bush, no carrier bar

Industrial = painted version / F = food (glass blasted stainless steel)

Gasket type: IF blank = Sonderlock, A = Hang on type A, B = Hang

on type B (rare, mostly sold in US)

Approximate area per plate. (Not all plates are named according to

this rule)

S = Standard plate, SF = Freeflow plate, SW = Semi-welded, SEC =

evaporator, SWC = condenser, A = AHRI certified type

Name plate

(example, may vary)

, e.g. CE, NoBo, ASME U, DNV-GL etc.

Month and year of production

Tag number

Type designation

Serial number

Nominal assembly measure

Min./max design temperature

Dierential pressure

Inlet / outlet connections

Design pressure

Test pressure

Total internal volume

Fluid type

Tag no.

Unit No. 1

Plate heat exchanger type Month and year

S19A-DG16

Serial no. Marking

PHE085370

A-measure nominal (tolerance -1.5%)

141

Min. / Max. design temperature Differential pressure

0 11016

/°

Inlet > Outlet /

Design pressure/bar

Test pressure/bar

Volume

Fluid /

F1

F1

F2

A-measure

F4

F3

Manufactured by Danfoss A/S, 6430 Nordborg, Denmark - Tel. +45 74 88 22 22

09-2020

This product fulfils PED

requirements for SEP / Art.4,

Sec.3.

mm

Hot side

F1 > F4

16

20

15,0

Water

B1

B2

B4

Do not exceed above values at any time.

B3

Please read instruction manual before

installation, operation and maintenance.

MADE IN DENMARK

/

Cold side

F3 > F2

16

20

15,0

Water

MM-YYYY

ar

2 | AQ356845617175en-010101 © Danfoss | 2020.10

Page 3

Operating guide Gasketed Heat Exchangers

Name plate

(example, may vary)

(continuous)

SONDEX A/S

Plate heat

exchanger Type

Serial No

Nominal

capacity [k/w]

Assembly measure min. [mm]

Max working

pressure [Bar]

Max dierential pressure [Bar]

Volume Product

side [ltr]

Working temp.

min. [°C]

Product / Medium Product / Medium

IMPORTANT:

1) The plate heat exchanger must not be

assembled under the stated minimum assembling

measure. Please contact your SONDEX A/S

distributor if the heat exchanger is leaking when

tightened to the minimum measurement.

2) The starting up must be done without schocks

and against closed valves.

3) Max. working pressure may not be exceeded at

any time.

Build year

Heat surface

[m2]

Flow [l/h]

Max test

pressure [Bar]

Volume Medium

side [ltr]

Working temp.

max. [°C]

SONDEX A/S DK-6000 KOLDING DENMARK

Design: Gasketed heat

exchanger

(may vary)

1

2

3

4

6

5

7

9

10

8

AQ356845617175en-010101 | 3© Danfoss | 2020.10

Page 4

Operating guide Gasketed Heat Exchangers

Start plate

Left plate

Left plate

Right plate

End plate

Flow arrows shown are only indicative

Design: Gasketed heat

exchanger

(may vary)

(continuous)

1 Roller (for certain types)

Making it easier for service and maintenance to

slide the follower back and forth

2 Carrying bar

Connects and carries the head (frame plate),

plates (plate pack) and follower (pressure plate)

3 Column

Ensures plate pack support usually for mid ad

larger heat exchangers

4 Name Plate

Carries all the information about the heat

exchanger (design temperature, operating

pressure, testing pressure,…)

5 Follower

Back (pressure plate) of the gasketed heat

exchanger where we can connect it to the

pyping system

7 Plate

The plate pack package consists of plates with a

groove along the rim of the plate and around the

ports. The number of plates is, as well as size and

dimension dependant on the thermal output

required.

8 Anchoring brackets

Are used to prevent the heat exchanger’s

movement on the foundation/floor surface or

mouting frames

9 Guiding bar

Connects and keeps in place the plates (plate

pack package) at the lower part of heat

exchanger

10 Tie bolt

Are used to press the plate package together.

Size and number depends on the type of heat

exchanger.

6 Head

Front (frame plate) of gasketed heat exchanger

where we can connect it to the pyping system

Frame

The heat exchanger consists of a frame plate (head), a pressure plate (follower), a carrying bar, a

guiding bar and a column. To all these components we usually refer as a frame.

Single plates

Right (R)/ Left (L) plates

Plates are designed in such a way that they can be used both as right and left plates by alternately

turning them 180°.

On a right plate the flow runs from porthole 2 to 3 or reverse from porthole 3 to 2.On a left plate the

flow runs from porthole 1 to 4 or reverse from porthole 4 to 1.

The opening of the corner portholes is described in a “plate code index”. For instance 1234 means that

all corner portholes are open. Every plate can be identified by the gasket configuration, the plate code

index, and the plate geometry (e.g. thermal short or thermal long geometry).

F1

F4

Connections:

F1 > F4 (Flow 1)

F2 > F3 (Flow 2)

Special gasket

Used for start plate only.

All portholes are gasketed

F2

F3

Standard gasket.

Used on all plates except the first plate

Each plate are rotated 180° relative to the plate before/after

Used on all plates except the first plate

Each plate are rotated 180° relative to the plate before/after

Standard gasket.

Single plates x N

Standard gasket.

Used on all plates except the first plate

Each plate are rotated 180° relative to the plate before/after

Standard gasket.

Used on all plates except the first plate.

Note that the plate are without port holes

4 | AQ356845617175en-010101 © Danfoss | 2020.10

Page 5

Operating guide Gasketed Heat Exchangers

Design: Gasketed heat

exchanger

(may vary)

(continuous)

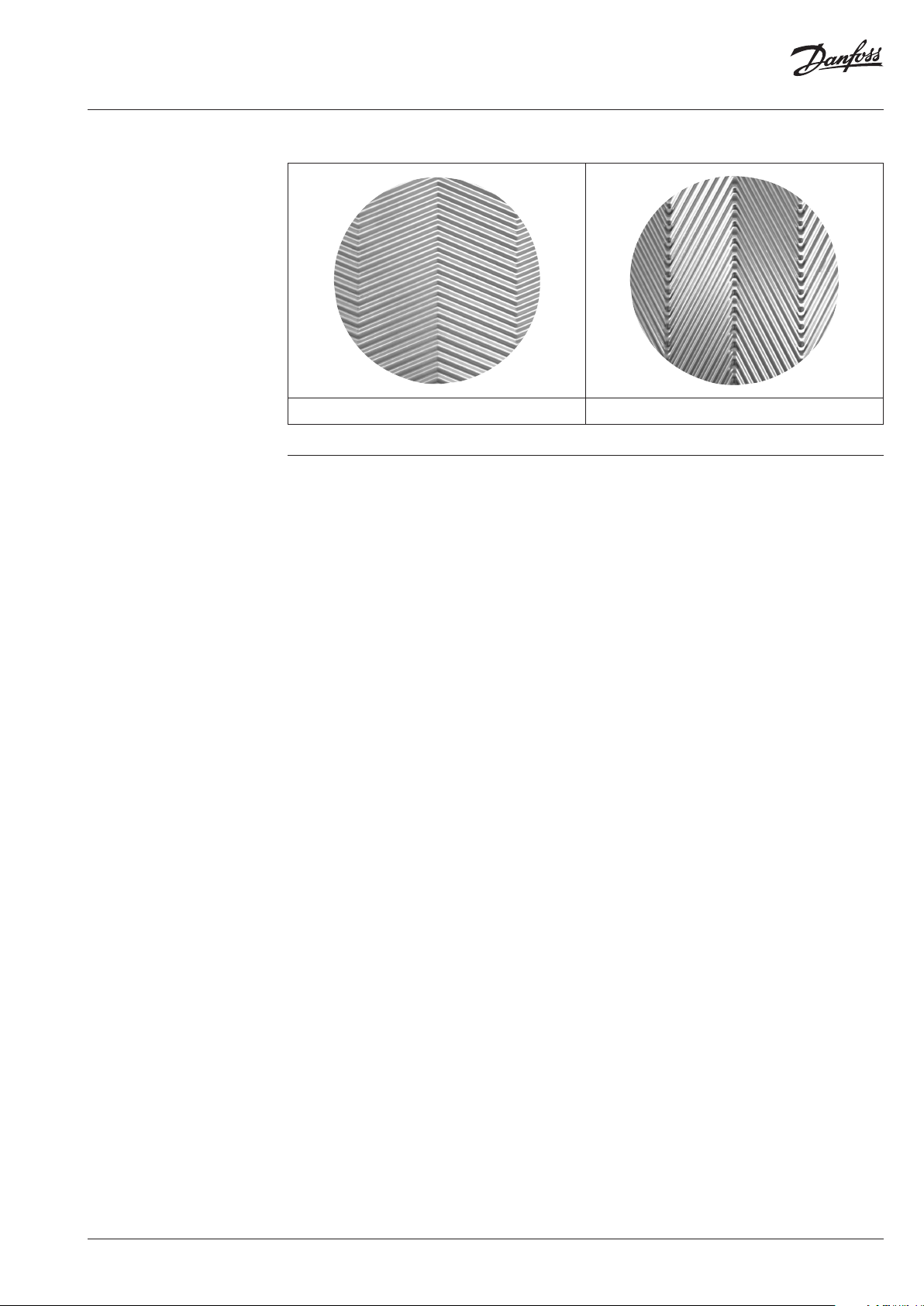

Fishbone design

TL plate TK plate

Gaskets

The channel gasket material is carefully selected to match the combination of temperature and

chemical resistance requirements.

The following gasket type are used in Danfoss gasketed plate type heat exchangers:

• D-Lock gaskets

• Sonderlock gaskets

• Hang-on gaskets

• Glued gaskets

If any recommendations are required please contact our representative in your country

AQ356845617175en-010101 | 5© Danfoss | 2020.10

Page 6

Operating guide Gasketed Heat Exchangers

Installation

Transport and lifting

WARNING:

To prevent perso nal injur y always use

approp riate hoist ing equipme nt. If you

are to lif t the heat exc hanger itse lf, straps sh ould

be used. T he straps sho uld be placed a s shown on

the pict ure below.

Usually the heat exchanger will be supplied

horizontally on a pallet.

The back side of the head will then be secured to

the pallet. This allows the unit to be transported

by means of a forklift truck.

• Raising of the unit (see Figure 1):

• Remove all tightening elements from the

pallet

• Place straps around opposite bolts on each

side of the column (1)

• Lift the unit vertically from the pallet (2)

• Remove the pallet securely(3)

• Slowly lower the heat exchanger to the floor

(4)

• Remove the straps atthe unit bottomside (5)

• Lift one-sided in an appropriate lifting angle

(6) and follow the raising of the unit carefully.

Avoid any bumps or shocks.

• When lifting all the personal safety

measurements should be considered and

keep safety distance

• If heat exchanger is supplied with feet

mounted on the header make sure they are

not damaged

• Once the heat exchanger is in upright position

place the straps in the dedicated lifting eyes

(where applicable)

(7) and lift the unit to its final position (8)

• Remove the straps and mount the heat

exchanger securely to the floor or mounting

frame

4

2

11

3

6

8

5

Figure 1

Never lift t he heat exch anger usin g any other meth od than desc ribed above. Neve r use the

connections, studs or any

interme diate plate s ( fitted) for l ifting (fig . 1).

7

6 | AQ356845617175en-010101 © Danfoss | 2020.10

Page 7

Operating guide Gasketed Heat Exchangers

Installation

(continuous)

Foundation

Install the heat exchanger on a flat foundation or mounting frames providing sufficient support for

the frame of heat exchanger.

Space

Ensure enough space around the plate heat exchanger for servicing the unit (renewal of plates,

tightening of the plate pack).

Min.

Figure 2

We recommend to leave Min. = 1.5 x W (where “W” is the width of header) on each side of the heat

exchanger for maintenance access. See Fig. 2.

Drip tray

Replaceable plate heat exchangers involve a risk of leakage.

It is recommended to take this into account while installing. Preferably install a drip tray underneath

the heat exchanger to prevent leakages onto the floor and/or harm to electrical equipment.

Safety cover

If the heat exchanger is being used with temperatures above 60 °C or with aggressive fluids, we advise

that you cover the heat exchanger with a screen plate to prevent the risk of human exposure to the

surface and fluids.

AQ356845617175en-010101 | 7© Danfoss | 2020.10

Page 8

Operating guide Gasketed Heat Exchangers

Piping system

Filtration

If the fluid in the plate heat exchanger contains particles larger than Ø 0.5 mm, ensure that adequate

pre-filtering is present.

Installing the pipe connections

Most plate heat exchangers are intended for counter-current flow directions, but some specific

applications require co-current flow. Refer to name-plate for information on each specific plate heat

exchanger.

Danfoss plate type heat exchangers are provided with various connection types depending on size,

application and conditions.

Gasketed heat exchangers might come with threaded pipe connections or studded flanges ready for

counter/blind flanges. Possible to have heat exchanger pressurized with nitrogen.

Before con necting any p iping to the pl ate heat exch anger make su re to clean and f lush the pip ing

system thoroughly or any foreign objects.

When con necting the p iping syste m to the plate hea t exchange r make sure tha t the piping sy stem

does not s ubject the pl ate heat exch anger to stre ss or strain .

Make sure t hat the pipi ng system, co nnected to the p late heat exc hanger, is secu red agains t pressure pe aks/

surges and temperature shocks!

When doi ng any welding i n the flange / valve/piping s ystem make ear thing to the pi ping oppos ite of the

plate hea t exchange r. Never use the heat e xchanger f or earthin g as plates and g askets migh t be severely

damaged.

For studded flange connection, insert the gaskets before bolting the blind flanges to the end plate. Tighten

the bolts evenly - do not over-tighten as this might damage bolts/threads.

Note:

• Identify actual flow inlets/outlets on the name plate before commencing piping work

• Heavy piping should be supported and not exceeding the maximu nozzle load. This will prevent

heavy forces on the plate heat exchanger

• To be able to open/close and dismantle the plate heat exchanger shut off valves should be

installed in all connections

• Remove flanges from the plate heat exchanger before connecting to the valve/piping system.

• Always install flexible connections on the follower to prevent vibrations on the plate heat

exchanger. The flexible connections also help prevent expansion of the pipes, which could be

caused by temperature influence.

• Also installed the draining connections to drain media from HEX

• Flexible connections must be fitted perpendicular to the header/follower

• Install vents on both sides of the plate heat exchanger

• The vents should be fitted on the highest point in the direction of the media flow

• The installation must be fitted with safety valves according to current pressure vessel regulations

Commissioning

Commissioning, control, maintenance and repair of the installation should be done by authorized,

trained and properly instructed staff. Before commissioning check if all connections are fitted

correctly.

Check the pressures and the temperatures of the media and make sure they are within the limits of

the values specified on the name plate.

The plate hea t exchange r must not be sub ject to therma l or mechani cal shock as t his could lea d to

premature gasket failure

Start-up process

For plate heat exchangers with liquid on both sides (liquid/liquid flow) the flow with an operating

temperature closest to the ambient temperature is to start first, i.e.

Flow 1

Lowest delta T to ambient temperature lowest

Flow 2

Highest delta T to ambient temperature highest

8 | AQ356845617175en-010101 © Danfoss | 2020.10

Page 9

Operating guide Gasketed Heat Exchangers

Commissioning

(continuous)

Start liquid flow 1 first, then liquid flow 2.

For both flows follow these steps:

• Vent the system fully

• Close shut off valve fitted between pump and plate heat exchanger

• Fully open valve fitted into return line from the plate heat exchanger

• Start the circulation pump usually placed at the inlet

• Gradually open the closed shut off valve between pump and plate heat exchanger

• Vent system again if necessary

Water hammer may cause considerable damage to the equipment and cause leakage. Equipment is

not designed to withstand water hammering.

Check during operation for proper and safe operation

• Check the system for potential pressure pulses caused by pumps or control valves. In case of

pressure pulses, stop operation and rectify

• Continuous pressure pulses could cause fatigue issues of flow plates

• Check that no leakages appear from the unit

• Check that all vents and drains are closed to prevent media coming from the unit

• Check that the operating conditions including media temperatures and pressures are within the

limitations stated on the name plate. These must not be exceeded

When in ope ration the con ditions sho uld not be chan ged. Media t emperatur es and press ures must be

within the limitations stated on the name plate and should not be exceeded

Shut-down Shut-down for a short period

If the plate heat exchanger has to be shut down for a short period the following procedure should be

followed:

• Gradually close the inlet shut off valve in the flow 1 circuit whilst maintaining the full flow in the

other side of HEX circuit (flow 2)

• For high temperature applications cool down the heat exchanger to below 40 °C ( 104 °F)

• Gradually close the inlet shut off valve in the liquid (flow 2) circuit

• Switch off the (flow 2) in circuit pump

Shut-down for a long period

If the unit is to be shut down for an extended period of time then the following procedure should be

followed:

• Follow steps above

• Allow unit to reach ambient temperature

• Ensure a minimum amount of medias in the heat exchanger.

• Drain flow 1 circuit and flow 2 circuit with precautious if handling dangerous media

• Lubricate threads on the tie bolts

• Loosen tie bolts according to the instruction in “opening the plate heat exchanger” section until

the length of the plate pack reaches:

Single plate: A-measure max. +10%

• The tie bolts should not be removed or loosened. It is recommended to attach a warning notice

to the plate heat exchanger to remind personnel that the tie bolts need adjustment before the

unit can be put back into service

• Cover the plate pack with black plastic to exclude any sunlight.

• Heat exchanger has to be protected from any dirt/particles entering the unit.

Note:

Special plate heat exchangers solutions:

• Multipass- / multisection plate heat exchanger has to be filled and pressured on all sides

simultaneously

• When start operating with the plate heat exchanger, all section have to operate simultaneously,

to avoid any damage at the plate heat exchanger

• The start up has to be done on all sides at the same time.

• The piping to this kind of plate heat exchanger has to be build in a zero-potential way

AQ356845617175en-010101 | 9© Danfoss | 2020.10

Page 10

Operating guide Gasketed Heat Exchangers

Maintenance CIP cleaning

Clean-in-Place, CIP cleaning, allows cleaning the plate heat exchanger without opening it and is done

by circulating cleaning agents in the heat exchanger.

The use of CIP cleaning is relevant for soluble fouling only. Prior to CIP cleaning ensure that all

materials in the entire circulation system are resistant to the cleaning agent/CIP liquid used.

We advise to ask f or a confirma tion from the s upplier of t he cleanin g agent that it w ill not damag e the

materials in heat exchanger.

Check maximum allowable working temperature on the name-plate mounted on the head of the

plate heat exchanger before performing CIP cleaning. Maximum working temperature should not be

exceeded at any time. Consult Danfoss if in doubt.

If the solution requires recirculation, select a flow that is as high as possible, and no less than the

service or operation flows.

Follow the instructions from the supplier of the cleaning agent. For re-circulated cleaning, we

recommend that fluid is circulated in the plate heat exchanger for no less than 30 minutes.

Rinsing

After using any type of cleaning agent, always rinse the plate heat exchanger thoroughly with fresh

water. After CIP cleaning, circulate fresh water for at least 10 minutes.

Cleaning agents guidance

Oil and grease can be removed with a water emulsifying oil solvent.

Organic and grease cover can be removed with sodium hydroxide (NaOH) maximum concentration

1.5% - max. temp. 85 °C (185 °F).

Mixture for 1.5% concentration = 5 l 30% NaOH per 100 l water.

Stone and limestone can be removed with:

- nitric acid (HNO₃) - max. concentration 1.5% - max. temp. 65 °C. Mixture for 1.5% concentration

= 2.4 l HNO₃ 62% per 100 l water. Nitric acid has a build up effect on the passivation film of

stainless steel.;

- specific Danfoss-branded solvents, such as “dan.Phoss”, available for purchase on certain markets.

CAUTION:

Nitric ac id and Sodiu m Hydroxide may c ause injur y to expose d skin, eyes, a nd mucous mem branes.

Use of protective eyewear and gloves is strongly recommended.

Opening the plate heat exchanger

When opening and disassembling the plate heat exchanger observe the following:

• Mark the plate package before opening. This can be done by a diagonal line (see fig. 3) or by

numbering each individual plate in sequence

• Measure and note the actual assembly measure (Reference name plate for validation).

• Use appropriate tools and lubricant

• Shut down the heat exchanger as described in section “Shut down”

• Make sure the heat exchanger cools down (<40 °C (104 °F))

• Both sides must be drained before the heat exchanger is opened

• Clean the tie bolts and grease the threads

• Loosen all the short tie bolts while leaving the long tie bolts in tension

• Loosen the long tie bolts evenly in the numbered order 1, 2, 3, 4 (fig. 3) i.e. the follower shall have

a parallel opening motion

CAUTION:

Ensure u nit is depre ssurized , vented and drai ned of hot and /or aggressive f luid before u nit is

opened t o prevent perso nal injur y.

10 | AQ356845617175en-010101 © Danfoss | 2020.10

Page 11

Operating guide Gasketed Heat Exchangers

ong tie bolt

Clean and grease

threads

Wr

Handle plates

with gloves only

Maintenance

(continuous)

ench

A-measure

3

1

2

4

Figure 3

Opening the plate heat exchanger (continued)

• Remove all tie bolts

• Pull the follower back towards the column

• Remove the plates one by one without damaging the gaskets

• While opening the PHE extra caution must be paid to prevent the plates sliding of the

carrying bar

CAUTION:

Plates have sharp edges! When handling plates always wear gloves.

Diagonal line

L

AQ356845617175en-010101 | 11© Danfoss | 2020.10

Page 12

Operating guide Gasketed Heat Exchangers

Maintenance

(continuous)

Mechanical/Manual Cleaning

• Plates can be mechanically cleaned by use of water and a soft brush. Alternatively a high pressure

cleaner might be used with caution and without abrasives

• If needed cleaning agents may be used

• Consult a cleaning specialist for choosing a suitable cleaning agent. Ensure that all agents used

are compatible with the plate and gasket material

• for proper selection see the paragraph Cleaning agents guidance

CAUTION:

Some cle aning agent s may cause inj ury to exp osed skin, eye s and mucous me mbranes . Use of

protective eye-wear and gloves is strongly recommended.

Mechanical Cleaning continued

• Always remove plates one by one and number them in right order

• Plates removed for manual cleaning must be re-fitted in the same order

• Single plates may be immersed into a solvent bath to dissolve hard fouling

Never use a meta l brush, ste el wool or sand/gl ass paper. This w ill damage t he passivati on film of the

plates . Never use Hydro chloric for St ainless ste el plates. N ever use Hydrof luoric for Ti tanium plat es

Before fitting chemical cleaned plates they need to be thoroughly rinsed with fresh water!

• Always remove plates one by one and number them in right order

• Plates removed for manual cleaning must be re-fitted in the same order

• Single plates may be immersed into a solvent bath to dissolve hard fouling

Plate replacement

If a plate has to b e renewed bec ause of seriou s damage, it i s recommend ed to replace t he plates nex t

to this pla te.

• Plates must be replaced if damaged or not cleanable

• When ordering new plates all data from the nameplate is required

• New plates are supplied with complete gaskets for immediate installation

Gasket replacement

No Glue gaskets / D-Lock, Sonderlock, Hang-On

These gaskets are mounted without the use of any glue. They are positioned by pushing the gasket

fully down into the gasket groove or fastened by special devices. Make sure groove and gasket are

clean.

CAUTION:

When using commercial solvents and adhesives, follow the manufacturers recommendations

carefully. Most of these solvents are hazardous.

12 | AQ356845617175en-010101 © Danfoss | 2020.10

Page 13

Operating guide Gasketed Heat Exchangers

Diagonal line

ong tie bolt

Clean and grease

threads

Wr

Le

Right plate

Right plate

End plate

Sideview

Maintenance

(continuous)

Closing the plate heat exchanger

When assembling and closing the heat exchanger observe the following:

• Check that all gaskets are correctly positioned in the grooves

• Check that plates are hanging correctly on the carrying bar

• Press the plate package together by pushing the follower

• Make sure the plates are in the correct position according to the marked diagonal or numbering

• Check the plate edge pattern for uniformity (see fig. 4, fig 5)

• Identify the A-measure noted prior to opening the heat exchanger (confirm with nameplate)

• Use appropriate tools and lubricant

• Ensure there is no flow to any part of the unit

• Clean the tie bolts and grease the threads

• Install the long tie bolts and tighten evenly

in the numbered order 1, 2, 3, 4 (fig. 5) until a resistance can be noticed. i.e. the follower shall have a

parallel closing motion

• Tighten the long tie bolts in sequence 1 to 4 alternately until the A-measure has been reached at

all long tie bolts

• Tighten the short tie bolts in an alternating order until the A-measure has been reached at all tie

bolts

• Prepare for operation. Follow instructions in section “Start-up process”

• If the heat exchanger does not seal immediately the tie bolts can gradually be tightened to

A-measure minimum (see name plate)

The A-measure shall never be less than A-measure minimum.

Correct stack

Gasket orientation opposing on

last effective plate and end plate.

End

Rotate end plate to suit type of last plate

Figure 4

ench

ft plate

Start plate

Start

n

3

2

If last normal

plate is

“right”...

Tip

Mark plates when servicing

to ensure same order during

reassembly

End plate

to be “left”

Sideview

Incorrect stack

A-measure

3

1

2

4

L

Figure 5

AQ356845617175en-010101 | 13© Danfoss | 2020.10

Page 14

Operating guide Gasketed Heat Exchangers

Regular Service of the plate

heat exchanger

Service sequence – once a year as a minimum

• Check temperatures and flows against commissioning data

• Check general condition and look for any signs of leakage

• Wipe clean all painted parts and check surfaces for signs of damage – “touch up” if necessary.

Check bolts and bars for rust and clean. Coat threaded parts with molybdenum grease or a

corrosion inhibitor (ensure that no grease, etc. falls onto the plate gaskets

• If rollers are fitted to the follower, lubricate the bearings with light machine oil

Years after

commissioning

2 -

3 PHE audit

5

6

7

8

10 Replace

12

13

15

* Ring gasket kit

** Full gasket kit

PHE audit: Visual inspecti on of operating conditions , leaks, corrosion and ge neral condition

Leak detecti on: Pressure test (at least once per year)

CIP: Clean in pla ce (See sectio n “clean in place”)

Manual clea ning: Plate pack disassembly/plate cle aning Replace gaskets: Plate pa ck disassembly/replace gaskets

At extrem e fluids/conditions audits sho uld be performed mo re frequent

Clean fluids/normal conditions Dirty fluids/severe conditions

CIP and

manual

cleaning

Leak

detection

CIP &

manual

cleaning

Leak

detection

CIP &

manual

cleaning

PHE audit

PHE audit

ring- and

main body

gaskets**

PHE audit

Leak

detection

Replace

ring- and

main body

gaskets**

Leak

detection

Leak

detection

Leak

detection

CIP

cleaning

Leak

detection

CIP

cleaning

CIP and

manual

cleaning

CIP

cleaning

-

CIP and

manual

cleaning

- PHE audit

- PHE audit

- PHE audit

PHE audit

PHE audit

Leak

detection

Replace

ring- and

main body

gaskets**

Leak

detection

Replace

ring- and

main body

gaskets**

Leak

detection

Replace

ring

gaskets*

CIP and

manual

cleaning

Replace

ring

gaskets*

CIP &

manual

cleaning

Replace

ring

gaskets*

14 | AQ356845617175en-010101 © Danfoss | 2020.10

Page 15

Operating guide Gasketed Heat Exchangers

Trouble-shooting

Service sequence – once a year as a minimum

Most common problems with a plate heat exchanger, can be solved by own trained personnel. Fig.6

lists a summary of possible problems together with relevant possible causes and solutions.

To maintain a continuous proper function of the plate heat exchanger, it is essential to keep the

operating pressure and temperature within the ranges stated on the nameplate.

Exceeding these values, even as short-lasting peaks, may damage the unit or could be the cause of

problems/issues.

To avoid costly repairs, it is recommended to have the installation and maintenance carried out by

properly trained personnel.

Figure 6

Problem Possible cause Possible solution

Check the rubber liners (if fit ted)

Connection sealing damaged

Leakage

Insufficient capacity

Too high pressure

drop

For nearly all l eakage problems it will be n ecessary to dismantle the uni t before any attempts to rec tify the fault can be made . Mark

the area(s) where the lea kage seems located with a felt tip m arker or similar before dis assembling the plate heat e xchanger. Follow the

instructio ns in section “Openin g the plate heat exchanger ”.

“Cold leakage ” is caused by a sudden change in tem perature. The sealing pr operties of certain e lastomers are temporaril y reduced when

the temperatu re changes suddenly. No actio n is required as the gaskets most of ten re-seal after th e temperature has stabilized .

Mixing of primary and secondary circuit

Plate package sealing damaged

The operating conditions deviate from the specification Adjust the operating conditions

Air in the system

The operating conditions deviate from the specification Adjust the operating conditions

The heat exchanger is fouled internally Clean the heat exchanger

The connections have been interchanged Redo the pipe work

Flow larger than the design flow Adjust the flow

Channels in plates blocked Flush / clean

Incorrect measurement Check the pressure indicator

Fluid deviating from the specification Check the chemical composition

Air in the system

Check the flange gasket (if fit ted)

Check the ring gasket at first plate

Fit the pipes tension-free

Check the plates for holes and/or cracks

Check the diagonal par t of the field gasket

and ring gasket

Check the assembly distance "A"

Check the condition of the gaskets

Check the proper position of the gaskets

Vent the piping system

Check the pipe work for possible air traps

Vent the piping system

Check the pipe work for possible air traps

Gasket failures are generally a result of

• Material aging/degradation

• Excessive exposure to ozone

• High or low operating temperature - outside specified material limits

• Exposure to pressure surges

• Attack by chemicals from medias and/or cleaning agents

• Physical damage from incorrect assembly work

• Misaligned plates (check the hanging system at the top of the plate for distortion)

Decrease in performance is generally a result of

• Plate surfaces require cleaning or de-scaling

• Pumps or associated controls failing

• Plate channels blocked

• Liquid flows not as specified

• Associated boiler under sized or dirty

• Cooling fluid temperature to the plate heat exchanger is higher than the design temperature

• Heating fluid temperature to the plate heat exchanger is lower than the design temperature

• Plate package has been assembled incorrectly

• Plate heat exchanger is running with co-current flow, instead of counter-current. (Check direction

of pump flows)

• Air trap has developed in the plate package or piping work

AQ356845617175en-010101 | 15© Danfoss | 2020.10

Page 16

Operating guide Gasketed Heat Exchangers

After sales service

Scrapping

Ordering parts

When ordering spare parts it is important to provide correct data for:

• Project and order number

• Plate heat exchanger type and manufacturing number (see name plate)

• Required parts

When ordering separate plates it is important that the correct plate code index and type of plate is

given.

When ordering separate gaskets it is important to indicate the correct gasket material.

When ordering tie bolts, the existing bolts should be measured in order to get spare bolts with the

same dimensions.

Modifications to the heat exchanger

Please note that a plate heat exchanger is specific designed and built for the operating parameters

(pressures, temperatures, capacity and type of fluids) initial provided by the customer.

If the plate heat exchanger needs to operate at a different capacity this can be achieved by adding or

removing plates.

Modification of the plate heat exchanger to match other parameters may also be considered. Consult

Danfoss for redesign and/or approval of any change to operating parameters.

After approval by Danfoss a new name plate will be issued.

You may only commission a plate heat exchanger under modified conditions after written approval

by Danfoss.

This product should be dismantled and its components sorted, if possible, in various groups before

recycling or disposal. Always follow the local disposal regulations. For any further information, please

contact your local Danfoss’s representative or your local Danfoss company.

© Danfoss | DHS-SMDBT/SI | 2020.1016 | AQ356845617175en-010101

Loading...

Loading...