Page 1

Application Guide

Gas detection in

refrigeration systems

GDIR.danfoss.com

Page 2

Page 3

Application Guide | Gas detection in refrigeration systems

Contents Page

Commonly used abbreviations......................................................................3

Introduction........................................................................................4

Sensor technology..................................................................................4

EC - Electrochemical sensor .....................................................................4

SC - Semiconductor sensor (solid state)..........................................................5

P- Pellistor sensor...............................................................................6

IR - Infrared.....................................................................................6

Which sensor is suitable to a given refrigerant? ..................................................6

Sensor response time ...............................................................................7

The need for gas detection..........................................................................8

Legislation and standards...........................................................................8

Requirements for gas detection according to EN 378:2016 and ISO 5149:2014 ....................9

F-Gas legislation.............................................................................. 10

Requirements for gas detection according to ASHRAE 15-2016 (USA)........................... 10

Requirements for gas detection according to ANSI/IIAR-2 (USA) ................................ 10

Installation guideline ............................................................................. 11

Location of gas detectors ......................................................................... 12

Number of gas detectors in a facility............................................................... 13

Calibration / test.................................................................................. 13

Calibration methods ..............................................................................14

Method I Calibration by means of replacing sensor heads...................................... 14

Method II Calibration of gas detectors by means of calibration gas .............................14

Bump test ....................................................................................15

Alarm / sensitivity range gas detectors ........................................................ 16

Danfoss recommendations for alarm levels.................................................... 16

Actions triggered by gas detection ...............................................................18

References .......................................................................................19

Annex I - Common refrigerant data................................................................ 20

Annex II - EN 378:2016 and ISO 5149:2014 ......................................................... 20

Annex III - ASHRAE 15-2016 ....................................................................... 21

Commonly used

abbreviations

© Danfoss | DCS (mwa) | 2018.08

• LFL = Lower Flammability Level

• OEL = Occupational Exposure Limits

• ATEL = Acute-Toxicity Exposure Limit

• ODL = Oxygen Deprivation Limit

• OSH = Occupational Safety Limit

• ODP = Ozone Depletion Potential

• GWP = Global Warming Potential

• TRK = Technische Richtkonzentrationen

• MAK = Maximale Arbeitsplatzkonzentrationen

• TLV = Threshold Limit Value

• STEL = Short Term Exposure Limit

• PEL = Permissible Exposure Limits

DKRCI.PA.S00.A2.02 | 520H12772 | 3

Page 4

Application Guide | Gas detection in refrigeration systems

e

Sensitivity

Introduction Gas detection and leak detection are two distinct

activities that covers the same topic, but the

methods are very different.

Gas detection covers the analysis of air samples

to determine whether they contain refrigerant

gas. Leak detection is a systematic inspection

of a refrigeration system to determine whether

it is leaking. The terms gas detection and leak

detection are not interchangeable, and must not

be mixed.

Leak detection equipment is normally handheld equipment carried by people, and used for

detection of leaks in refrigeration systems. There

are several types of leak detectors available,

ranging from simple techniques like soapy water

to sophisticated electrical instruments.

Gas detection equipment is usually used in

a fixed installation with a number of sensors

located in areas where refrigerant might be

expected to accumulate in the event of a plant

leak.

Sensor technology The choice of sensor technology for refrigerant

gas detection will depend on the specific target

refrigerant gas and ppm range required. Danfoss

offers a range of different sensor technologies

These locations depend upon the layout of

the machinery room and adjacent spaces, on

the configuration of the plant and also on the

refrigerant in question.

Before selecting the appropriate gas detection

equipment, a number of questions have to be

answered:

• Which gases have to be measured and in what

quantities?

– Which sensor principle is the most suitable?

– How many sensors are needed?

– Where and how should they be positioned

and calibrated?

• Which alarm limits are appropriate?

– How many are required?

– How is the alarm information processed?

This application guide will address these

questions.

to match most commonly used refrigerants,

appropriate ppm ranges, and safety requirements

for refrigeration systems.

EC - Electrochemical sensor Electrochemical sensors are mainly used for toxic

gases and are suitable for ammonia.

They consist of two electrodes immersed in an

electrolyte medium.

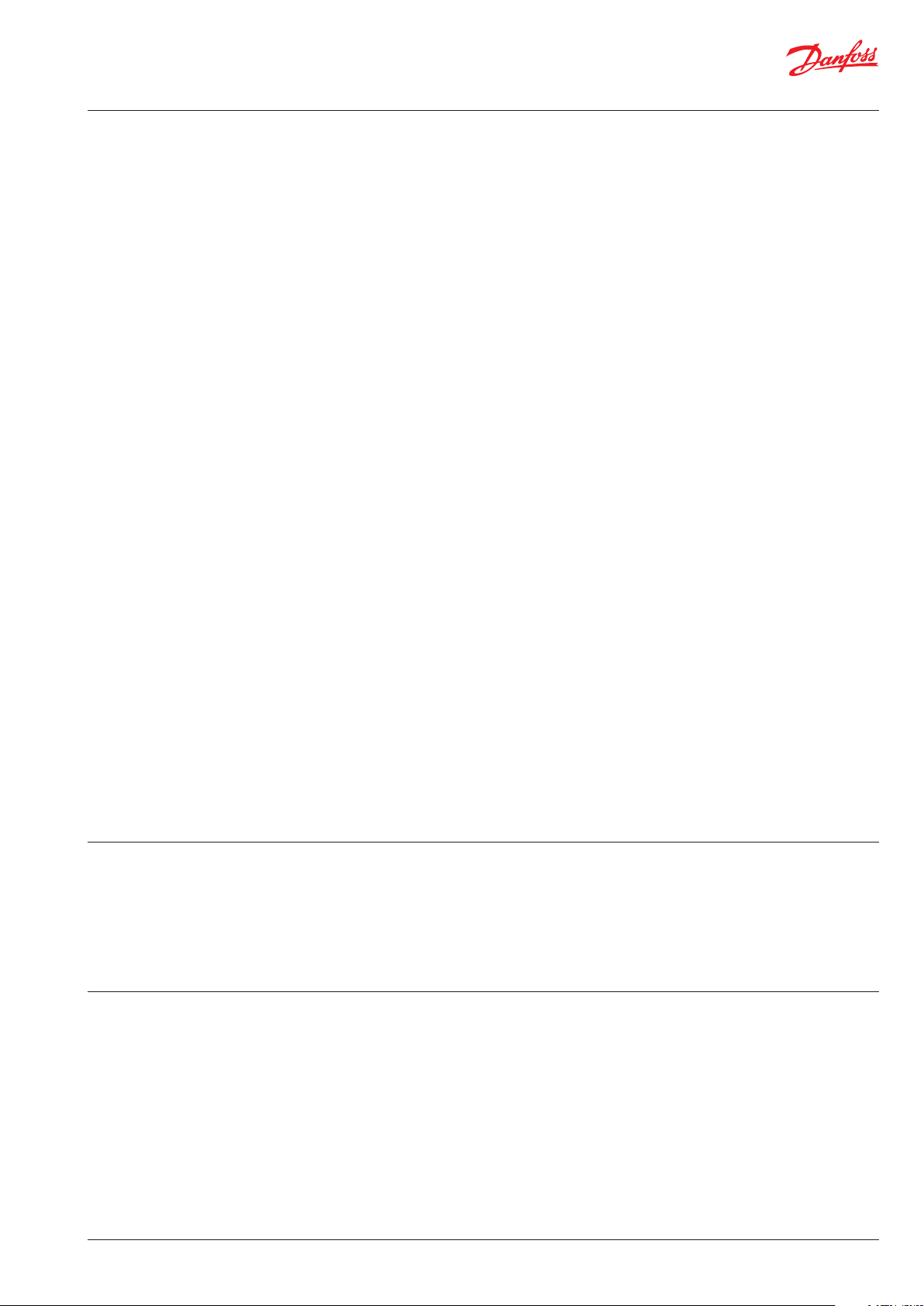

“High” gas concentration

“Low” gas concentration

Max. operating time

before calibration

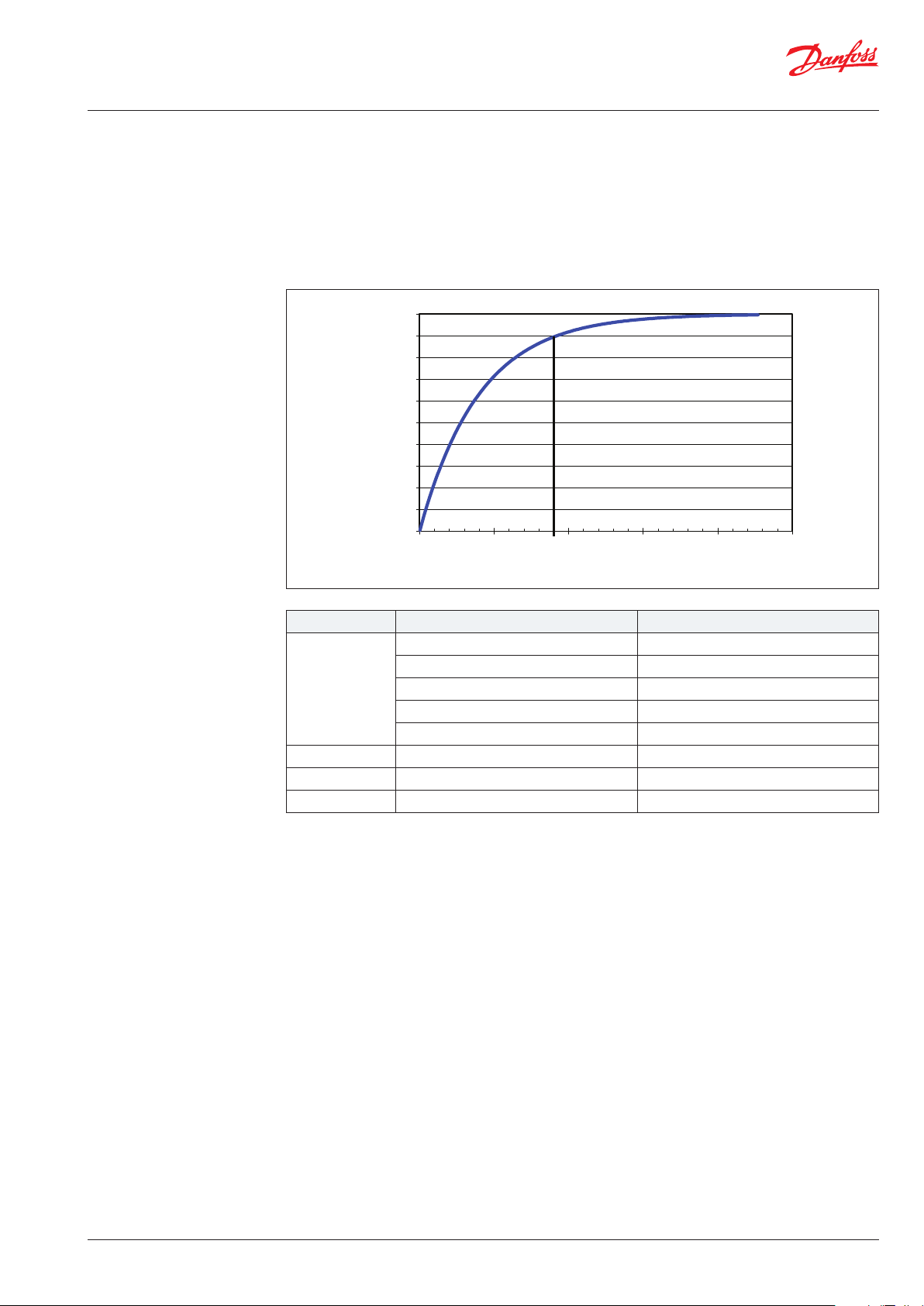

Fig. 1: Sensitivity of electrochemical sensors

They are very accurate (+/- 2%) and tend to be

used mainly for toxic gases, which cannot be

detected otherwise, or where high levels of

accuracy are needed (fig. 1).

An oxidation / reduction reaction generates an

electric current that is proportional to the gas

concentration.

max.

Tolerance rang

min.

Time

Exposure to large ammonia leaks or constant

background ammonia will shorten the sensor life

(fig. 2). EC sensors can be re-calibrated as long as

the sensitivity of the sensor is above 30%.

4 | DKRCI.PA.S00.A2.02 | 520H12772

Danfoss offers specific EC sensors for ammonia

in ranges up to 0-5.000 ppm with an expected

lifetime of 2 years, depending on exposure to

target gas.

They are very selective and rarely subject to

cross-interference. They may react to sudden

large humidity changes but settle quickly.

© Danfoss | DCS (mwa) | 2018.08

Page 5

Application Guide | Gas detection in refrigeration systems

e

Sensitivity

Gas specification

Sensitivity

EC - Electrochemical sensor

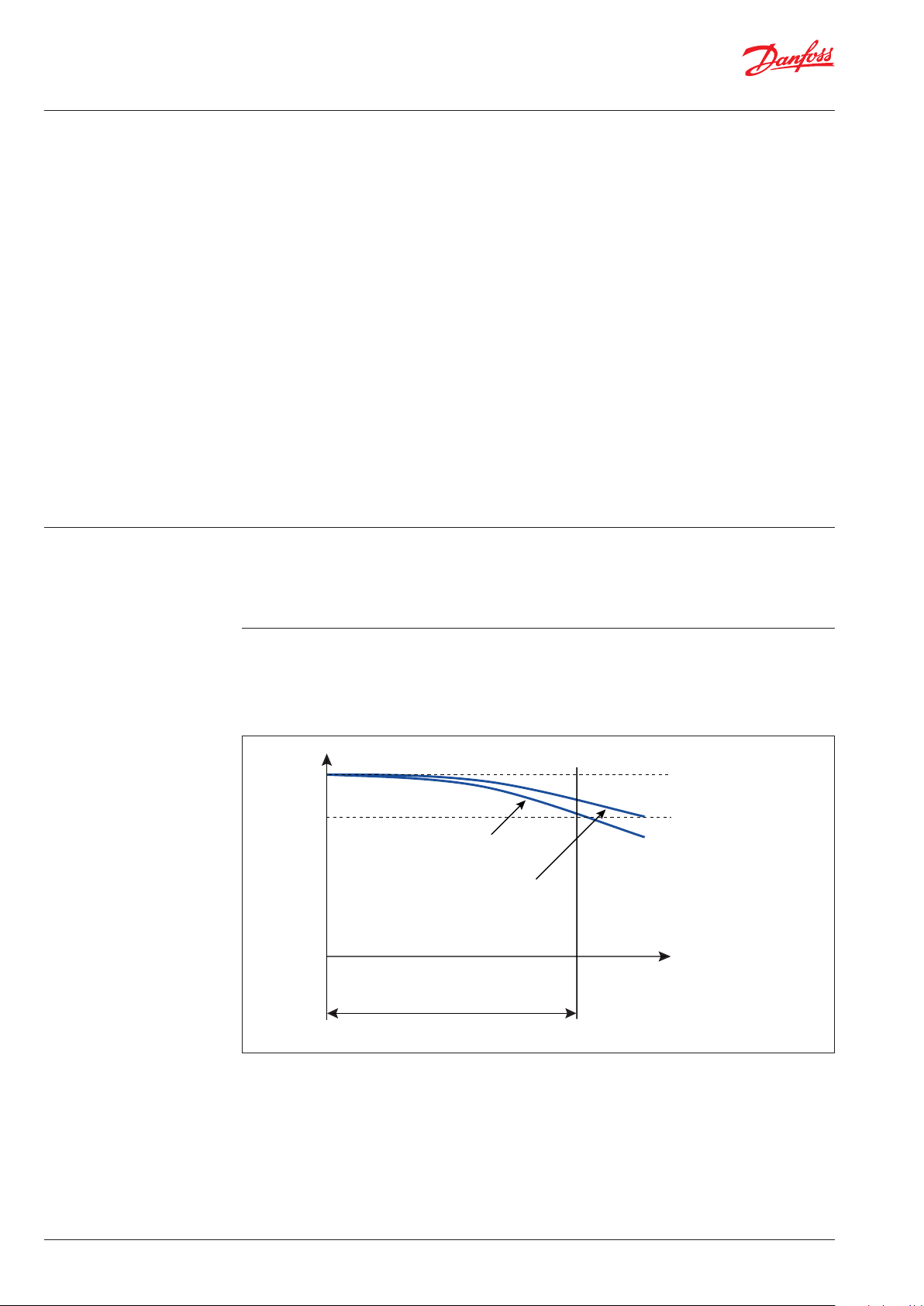

(continued)

“Substantial”

gas leak

Important!

Sensor must be calibrated or new

sensor must be installed.

max.

Tolerance rang

min.

SC - Semiconductor sensor

(solid state)

If the sensitivity of the sensor falls

below 30%; install new sensor

Max. operating time

before calibration

Fig. 2: Large ammonia exposure shortens the lifetime of electrochemical sensors.

The semi-conductor sensor functions by

measuring the resistance change (proportional to

the concentration), as gas is absorbed on to the

surface of a semi-conductor, which is normally

However, they are not selective, and are not

suitable for detecting a single gas in a mixture, or

for use where high concentrations of interfering

gases are likely to be present (fig. 3).

made from metal oxides.

Interference from short term sources (e.g.

These can be used for a wide range of gases

including combustible, toxic and refrigerant

gases.

It is claimed that they perform better than the

catalytic type in the detection of combustible

gases at low concentrations, up to 1.000 ppm.

exhaust gas from a truck), creating false alarms,

can be overcome by enabling a delay of the

alarm.

Semi-conductors for halocarbons can be used

to detect more than one gas or a mixture

simultaneously. This is particularly useful in

monitoring a plant room with several different

These are low-cost, long life, sensitive and can be

refrigerants.

used to detect a large range of gases including

all the HCFC, HFC refrigerants, ammonia and

hydrocarbons.

30% sensitivity

Time

“Broad” sensitivity

spectrum

– Semiconductor

– Pellistor

“Narrow” sensitivity

Gas 1

Fig. 3: Sensitivity spectrum of various sensor technologies

Gas 2

Gas 3

Gas 4

Gas 5

Target Gas

© Danfoss | DCS (mwa) | 2018.08

spectrum

– Electrochemical

– Infrared

DKRCI.PA.S00.A2.02 | 520H12772 | 5

Page 6

Application Guide | Gas detection in refrigeration systems

P- Pellistor sensor Pellistors (sometimes called a bead or catalytic)

are mainly used for combustible gases including

ammonia, and are the most popular sensors for

this application at high detection levels.

The sensor functions by burning the gas at

the surface of the bead and measuring the

resultant resistance change in the bead (which is

proportional to concentration).

These are relatively low-cost, well established

and understood, and they have a good life span

(expected life time 3 to 5 years). The response

time is usually below 10 seconds.

They can be subject to poisoning in certain

applications.

IR - Infrared Infrared technology utilises the fact that most

gases have a characteristic absorption band in

the infrared region of the spectrum, and this

can be used to detect them. Comparison with a

reference beam allows the concentration to be

determined.

Even though they are relatively expensive in

comparison to other sensor, they have long life

time of up to 15 years, high accuracy, and low

cross sensitivity

Poisoning is the reduction of the reaction of the

sensor to the target gas due to the presence

(contamination) of another substance on the

surface of the catalyst, that either reacts with it or

forms a layer on top of it reducing its capacity to

react to the target gas. Most common poisoning

substances are silicon compounds.

Pellistors are used mainly with combustible gases

and are therefore suited for ammonia and the

hydrocarbon refrigerants at high concentrations.

They do sense all combustible gases, but they

respond at different rates to each, and so they

can be calibrated for particular gases.

There are ammonia specific versions.

Due to its measuring principle infrared sensors

can be subject to issues in dusty environments,

where the presence of too many particles in the

air may disturb the reading.

They are recommended and commonly used for

Carbon dioxide detection. Although technology

exists for other gases also, it is not common to

find it in commercial solutions.

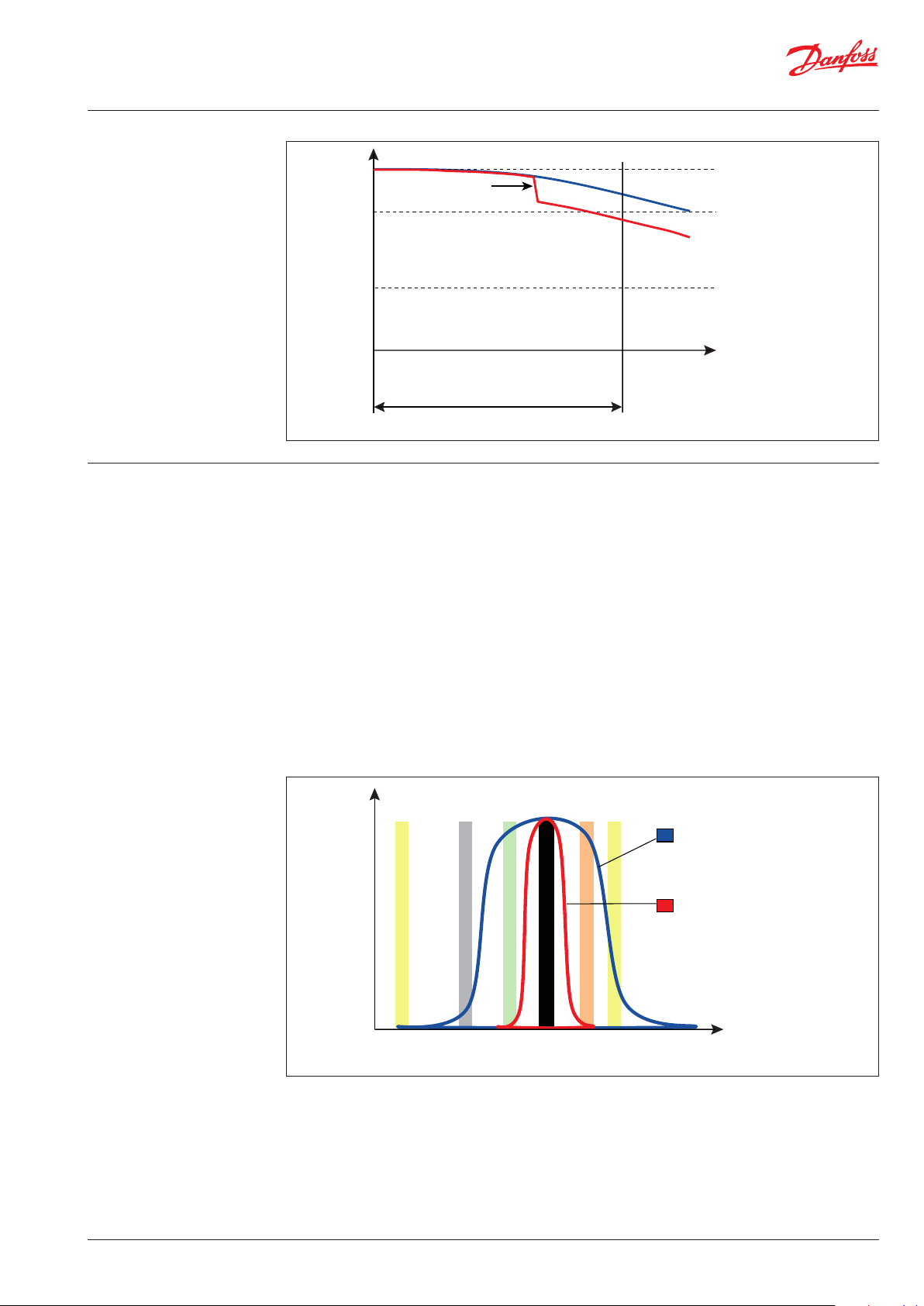

Which sensor is suitable to a

given refrigerant?

Based on the target refrigerant gas and the

actual ppm range the below table provides an

overview of the suitability of the various sensor

technologies offered by Danfoss.

Suitability of different sensor technologies:

Semi-conducter Electro-chemical

Ammonia “low” concentration

(< 100 ppm)

Ammonia “medium” concentration

(< 1000 ppm) 1)

Ammonia “high” concentration

(<10000 ppm)

Ammonia “very high” concentration

(> 10000 ppm)

Carbon Dioxide

CO₂

HC

Hydrocarbons

HCFC - HFC

Halocarbons

Best solution

1

) Measuring range 0-1000 ppm. Can be adjusted in the whole range.

2

) Up to 5000 ppm. For specific applications.

–

(4) 4

4 (4)

– –

– – –

– –

4

Suitable - but less attractive Not suitable

Pellistor

(Catalytic)

4

2

– – –

– –

– –

(4)

4

4

Infrared

–

–

4

–

6 | DKRCI.PA.S00.A2.02 | 520H12772

© Danfoss | DCS (mwa) | 2018.08

Page 7

Application Guide | Gas detection in refrigeration systems

1

Time, s

Fraction of Concentration Change

250

Sensor response time

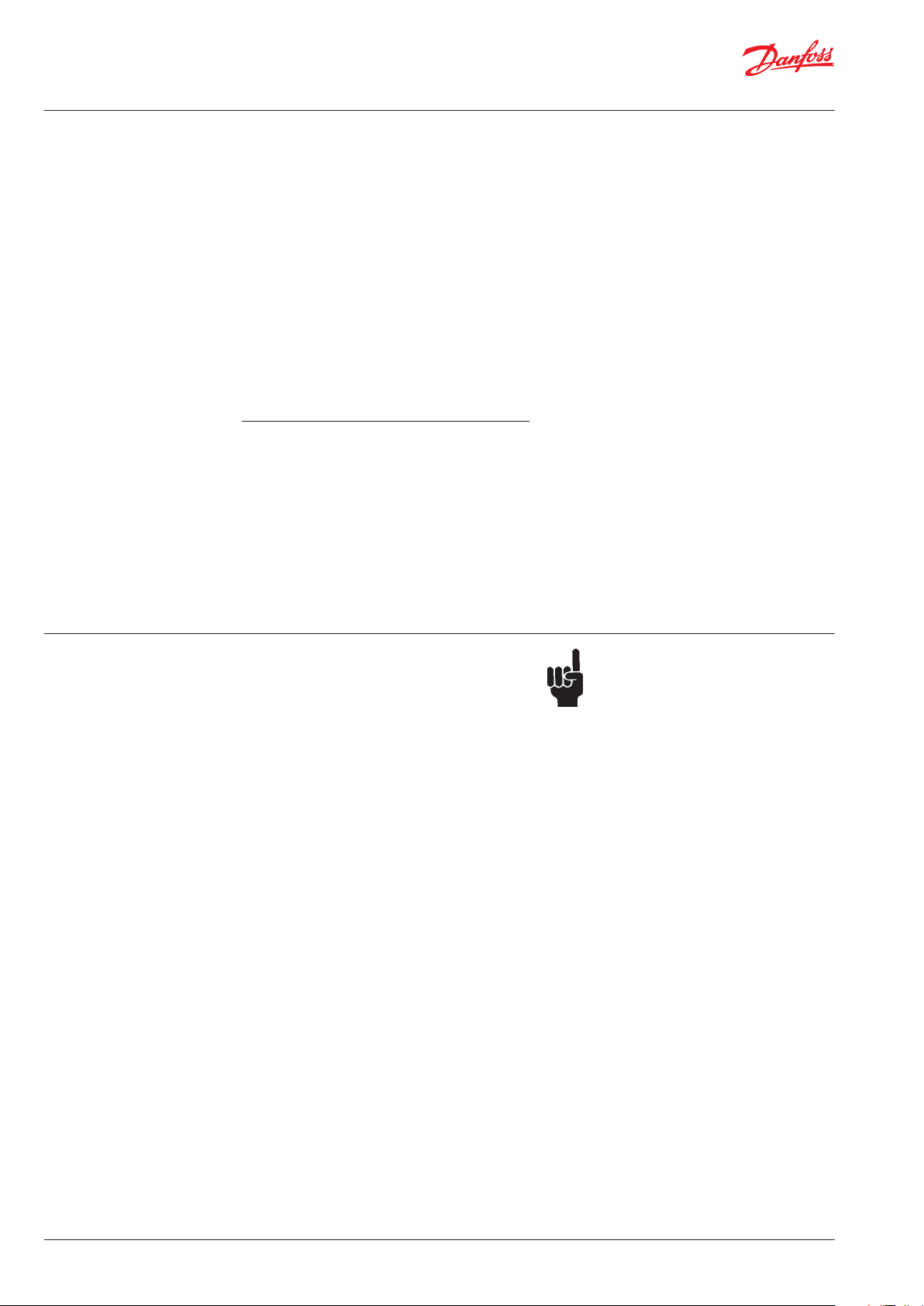

The response time is the elapsed time for a sensor

to read a given percentage of the actual value for

a step change in the target gas concentrations.

Response time for most sensors is given as t90,

meaning the time that it takes the sensor to read

90% of the actual concentration. Fig. 4 shows an

example of a sensor with a reponse time t90 of 90

seconds.

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

050 100 150 200

Fig. 4: Sensor with a response time t90 of 90 seconds

As shown in the graphic, the sensor reaction

above 90% becomes slower and takes longer to

read the 100%.

GAS Sensor technology Response time t90, seconds

Electrochemical 0-100/ 0-300 ppm <40s

Electrochemical 0-1000ppm <40s

Ammonia

Electrochemical 0-5000ppm <40s

Semiconductor >120s

Pellistor <20s

Infrared Infrared <90s

Halocarbons Semiconductor >120s

Hydrocarbons Pellistor <15s

© Danfoss | DCS (mwa) | 2018.08

DKRCI.PA.S00.A2.02 | 520H12772 | 7

Page 8

Application Guide | Gas detection in refrigeration systems

The need for gas detection

There are several reasons why gas detection

is required. Two obvious reasons are to protect

people, production and equipment from the

impact of potential gas leakages and to comply

with regulations. Other good reasons include:

• Reduced service cost (cost of replacement gas

and the service call).

• Reduced energy consumption cost due to lack

of refrigerant.

• Risk for damaging stock products due to a

substantial leak.

• Possibility to reduce insurance costs.

• Taxes or quota on non-environmentally

friendly refrigerants

The various refrigeration applications require gas

detection for different reasons.

Ammonia is classified as a toxic substance with

a very unique smell, as such it is “self alarming”.

However, gas detectors are required to guarantee

early warnings, and to monitor areas where

people are not always present, such as machinery

rooms. It is important to be aware that ammonia

is the only common refrigerant lighter than air.

In many cases, this will lead to ammonia rising

above the breathing zone making it impossible

for people to early detect ammonia leakages. The

use of gas detectors in the right zones ensures

early warnings in case of ammonia leakages.

Hydrocarbons are classified as flammable. Thus,

it’s critical to verify that the concentration around

the refrigeration system does not exceed the

flammability limit.

Fluorinated refrigerants all have a certain

negative impact on the environment, for which

reason it’s very important to avoid any leaks.

CO2 (Carbon Dioxide) is directly involved in

the respiration process and should be treated

accordingly. Approximately 0.04% CO2 is

present in the air. With higher concentration,

some adverse reactions are reported starting

with increase in breath rate (~100% at 3%

CO2 concentration) and leading to loss of

consciousness and death at CO2 concentrations

above 10%.

Legislation and standards The requirements for gas detection are different

across countries worldwide. An overview of the

most common rules and regulation can be found

on the following pages.

Europe:

The present safety standard for refrigeration

systems in Europe is EN 378:2016.

The specified alarm levels in EN 378:2016 are set

at levels to allow evacuation of an area. The levels

do not reflect the effects of long term exposure

to leaked refrigerants. In other words, in EN 378

a gas detector is to warn when a sudden large

release occurs, while machine room ventilation

and system quality measures are to ensure that

small leaks are too small to cause adverse health

effects.

Note!

Requirements for gas detection

equipment in Europe are covered by

national legislation in the different

countries, and consequently may differ

from the requirements specified in EN

378.

8 | DKRCI.PA.S00.A2.02 | 520H12772

© Danfoss | DCS (mwa) | 2018.08

Page 9

Application Guide | Gas detection in refrigeration systems

Requirements for gas detection

according to EN 378:2016 and

ISO 5149:2014

Start

Y

Y

Gas detector

used to start fan or

close valves

Y

Gas detector

required

Y

Y

Below ground

2

in machinery room

or open air

Gas detector

required

N

N

Ammonia

Y

Charge >

50 kg

Y

Gas detection

required

high/low level

using alternative risk

Y

Charge limits

for ventilated

enclosure

N

Charge limits

management

N

Charge >

100% practical

limit

N

Using EN 378

and charge >m

and A3 or B3

N

Fig. 5: Requirements for gas detection according to EN 378:2016 part 3 and ISO 5149:2014 part 3

With a few exceptions gas detection is required

by EN 378:2016 and ISO 5149:2014 for all

installations where the concentration in a room

may exceed the practical limit for that space.

The practical limits for various refrigerants are

given in Annex II, which are extracted from EN

378-2016 part 1. In these tables the practical

limit of ammonia is based upon its toxicity. The

practical limits of the hydrocarbons are based

In the case of flammable and toxic refrigerants

this means virtually all commercial and industrial

systems In the case of A1 refrigerants it is possible

to have small systems, which do not require gas

upon their flammability and are set at 20% of

their lower flammable limit. The practical limits

for all the A1 refrigerants are set at their Acute

Toxicity Exposure Limit (ATEL).

detection. However, in most of the larger plants

it is likely that the practical limit will be exceeded

in the event of a major leak, and therefore gas

detection is required.

If the total refrigerant charge in a room, divided

by the net room volume, is greater than the

“practical limit” (see Annex II), it is reasonable to

conclude that fixed gas detection system should

Guidance can be found in EN 378:2016 part

be installed.

3 or ISO 5149:2014 part 3. The requirements

of the two standards are very similar, and are

summarised in fig. 5.

Both EN378:2016 and ISO 5149:2014 require that

an indicating device is provided to show whether

the relief valve has discharged on systems with

If it can be shown by calculation that the

concentration of refrigerant in a room can never

300 kg refrigerants or more. A possibility is to

place a gas detector in the discharge line.

reach the practical limit; then there is no need for

fixed gas detection, except according to EN 378 if

the system is below ground with a charge above

m2 (approx. 1 kg of propane). ISO 5149 does not

have this exception. m2 is a constant equal to

26m3 x LFL. For propane it is 26 m3 x 0,038 kg/m3

= 0,988 kg, or, if your LFL is measured in gram, it is

26 m3 x 38g/m3 =988 g. As such m2 does not have

any units, since the units depend solely on which

unit you chose for LFL.

Most hydrocarbons have similar value of LFL, and

m2 is therefore typically around 1kg.

N

N

No requirements

© Danfoss | DCS (mwa) | 2018.08

However, if the concentration can reach the

practical limit, even for A1 refrigerants, then fixed

detection must be installed - again with a few

minor exceptions.

DKRCI.PA.S00.A2.02 | 520H12772 | 9

Page 10

Application Guide | Gas detection in refrigeration systems

(Clause 7.2)

(Clause 8.11.2.1)

(Clause 7.2)

(Clause 7.2.2)

F-Gas legislation The F-Gas Regulation (EC) No 517/2014

One objective of the F-Gas Regulation is to

contain, prevent and thereby reduce emissions

of fluorinated greenhouse gases covered by the

Kyoto Protocol. The F-gas directive is mandatory

in all EU member countries and in the three

European Economic Area (EEA) EFTA countries

including Iceland, Liechtenstein, and Norway.

The regulation covers, among other topics, the

import, export and use of the traditional HFCs

and PFCs in all their applications. The regulation

entered into force on January 1st, 2015.

Leakage checking requirements, to prevent

leakage and to repair any detected leakage,

depends on the CO2 equivalents of the refrigerant

in each circuit with refrigerant. The CO2

equivalents is the charge in kg x the GWP of the

refrigerant.

Requirements for gas detection

according to ASHRAE 15-2016

(USA)

Requirements for gas detection according

to ASHRAE 15-2016 state requirements for

rooms with refrigerating equipment including

machinery rooms. The “Low Level” alarm values

are less or equal to TLV-TWA levels.

A periodical leakage check by certified personnel

is required with the following frequency,

depending on the quantity used:

• 5 tCO

or more: At least once every 12 months

2eq

– except for hermetically sealed systems

containing less than 10 tCO

• 50 tCO

or more: At least once every 6 months

2eq

2eq

(12 months with an appropriate leakage

detection system)

• 500 tCO

or more: At least once every 6

2eq

months. An appropriate leakage detection

system is mandatory. The leakage detection

system must be checked at least once every 12

months.

In practice, the Occupational Exposure Limit

(OEL) values from ASHRAE 34 are used since they

are based on TLV-TWA (see also “Occupational

Exposure Limits”, page 18)

Start

Requirements for gas detection

according to ANSI/IIAR-2 (USA)

Y

Y

N

No requirements

Gas detection

required

No requirements

Gas detection

required

Charge < 3 kg

N

Machinery

room

N

Charge >

RCL

N

Y

Additional

requirements

Fig. 6: Gas detection requirements according to ASHRAE 15-2016.

* Note 1: The charge limit stated in ASHRAE 15-2016 can also be found in Annex II (RCL) - for selected refrigerants.

Note 2: ASHRAE 15 does not include Ammonia. Refer to ANSI/IIAR-2.

ANSI/IIAR -2 requires machinery rooms to be

provided with ammonia gas detectors. It requires

3 different alarm levels (25, 150 and 40000 ppm)

with different response requirements according

to each of the levels.

10 | DKRCI.PA.S00.A2.02 | 520H12772

Start

Gas detector required

Alarm at 25, 150,

and 40000 ppm (max)

Y N

Machine room

Fig. 7: Gas detection requirements according to the ANSI/IIAR-2

Gas detector required

Alarm at 25 ppm

© Danfoss | DCS (mwa) | 2018.08

Page 11

Application Guide | Gas detection in refrigeration systems

Relative density

0

1

2

3

4

Installation guideline When it comes to installation of gas detection

there are two approaches:

• Perimeter detection

• Point detection

With perimeter detection, you place sensors all

around the perimeter of the space in question, to

make sure you monitor the whole space.

With point detection, you locate a sensor at a

particular position, where you are concerned

about a leak (e.g. at the compressor).

For gases heavier than air, sensors should be

located close to the ground/lowest point.

For gases lighter than air, sensors should be

mounted high up on the walls, ceiling or near

exhaust, but convenient for maintenance.

If the density is equal to air, the sensors should be

mounted at face level.

In some countries it may be mandatory to

have an UPS (Uninterruptible Power Supply)

connected to the gas detectors to ensure safe

operation during a power failure.

(refrigerant/air)

Fig. 8: Relative density refrigerant/air

© Danfoss | DCS (mwa) | 2018.08

DKRCI.PA.S00.A2.02 | 520H12772 | 11

Page 12

Application Guide | Gas detection in refrigeration systems

Location of gas detectors Gas detectors must be powered as specified in

the installation guide and located within the

specified cable length from the central control

unit/monitor.

In general:

• Do not mount to a structure that is subject to

vibration and shock, such as piping and piping

supports.

• Do not locate near excessive heat or in wet or

damp locations.

The two methods of locating sensors:

• Point detection: Sensors are located as near as

possible to the most likely sources of leakage.

• Perimeter detection: Sensors surround the

hazardous area completely.

• Do not mount where it will be exposed to

direct solar heating.

• Do not install in areas where condensation may

form.

The most appropriate method is selected

depending on the size and nature of the site.

• Detectors shall be located high/low according

to the density of the actual refrigerant.

• If mechanical ventilation exists in a machinery

room, air will move towards the fan. In

problematic locations a smoke tube can

indicate air movements in a space and assist in

the location of sensors.

• In a cold store, sensors should, if possible, be

placed on the wall in the return airflow.

• Consideration should also be given to the

possibility of pockets of gas collecting in the

event of a leak.

The arrangement of the equipment in the room

can also have an impact on the most effective

place to monitor.

Locations requiring most protection in a

machinery or plant room would be around gas

boilers, compressors, pressurized storage tanks,

gas cylinders, storage rooms, or pipelines.

Most vulnerable are valves, gauges, flanges,

T-joints, filling or draining connections etc.

Sensors should be positioned a little way back

from any high-pressure parts to allow gas clouds

to form. Otherwise any leakage of gas is likely

to pass by in a high-speed jet and will not be

detected by the sensor.

Important!

Do not place immediately in front of a

coil due to temperature and humidity

fluctuations. These may occur especially

during defrost or loading of a cold store.

Make sure that pits, stairwells and

trenches are monitored since they

may fill with stagnant pockets of gas.

Monitoring where leaked refrigerant

can stagnate is generally required by

standards.

As general guideline:

• If there is one compressor/chiller in the room;

sample at the perimeter of the unit. For two

chillers; sample between them, with three or

more chillers; sample between and on each

side. Ensure that the area being sampled

is sufficiently monitored. Do not skimp on

sensors.

• Place the sensor in the location(s) most likely to

develop a gas leak, including mechanical joints,

seals, and where there are regular changes

in the system’s temperature and pressure or

excessive vibration, such as compressors and

evaporator control valves.

Accessibility and space to allow calibration and

service must be considered.

12 | DKRCI.PA.S00.A2.02 | 520H12772

© Danfoss | DCS (mwa) | 2018.08

Page 13

Application Guide | Gas detection in refrigeration systems

Number of gas detectors

in a facility

The requirements for the number of gas detectors

in a facility are not specifically stated in standards.

As general guideline:

• A gas detector can normally cover an area of

about 50-100 m2 depending on the actual

condition of the space to be covered. In

spaces with several obstructions and lack

of ventilation the coverage is approx. 50 m2,

provided it is mounted near ceiling level or

near floor level depending on the refrigerant

density.

In non-obstructed spaces with good

mechanical ventilation, the coverage can be

increased up to approx. 100 m2.

• Machinery rooms:

It is recommended that gasdetectors are

placed above or at both sides of compressors

or other non-static parts of the system

or down wind of such equipment, in the

direction of continuously operating ventilation

extractors.

Where there are deep beams and lighter than

air refrigerants, it is recommended that the

detectors are mounted between pairs of beams

and on the underside of the beams.

Calibration / test Calibration/test of gas detectors is extremely

important to ensure and document the proper

accuracy, responsiveness and operation of the

unit.

If there is a continuous airflow in the

room a sensor/sensing point should

be located downstream from the last

potential leak source.

From a technically and safety point of view, the

sensors offered by Danfoss should be calibrated/

tested according to the stated intervals in the

table below.

Gas detectors are subject to changes in the

measurement properties, dependent on the

operation time and/or exposure time. Therefore,

regular calibration is needed. The frequency

depends on various factors, however the

IMPORTANT!

If national legislation requires

calibration/test with intervals shorter

(stricter) than stated in the table below,

these requirements must be followed.

following four are of particular importance:

• Requirements of national legislation

• Recommended calibration interval

Note: EN 378:2016 and ISO 5149 require gas

detectors to be checked on an annual basis.

• Lifetime of the sensors

• The lifetime and calibration needs of

electrochemical sensors are highly affected

by exposure to the target gas, reducing the

lifetime and the calibration interval. For that

reason the concentrations of the target gas in

the area should also be considered.

Estimated life time

[year]

SC Semi-conductor >5 1 1

EC Electrochemical >2* 1 1

P Pellistor 3-5 6 months 1

IR Infrared 15 5 1

* If the sensor is exposed to high or constant ammonia concentrations, the life time will be reduced.

An EC sensor remain functional above 30% of sensitivity.

** If calibration is performed, test is not required. However, when calibration interval is longer than the test interval, then a “bump”

test must be performed.

Min. recomended

calibration interval

[year]

Recomended test

interval**

[year]

© Danfoss | DCS (mwa) | 2018.08

DKRCI.PA.S00.A2.02 | 520H12772 | 13

Page 14

Application Guide | Gas detection in refrigeration systems

Certificate:

On-board test functionExchange of sensor head

Calibration methods

Method I

Calibration by means of

replacing sensor heads

Two different methods are available for fulfilling

the calibration requirements.

• Replacing the sensor (sensor cartridge) with a

new factory pre-calibrated sensor.

• Performing a calibration to the sensor using

calibration gas (gas mixture with known target

gas concentration).

This method requires that the supplier offers

factory pre-calibrated sensor heads with

calibration certificate and traceability codes.

Additionally, an electrical simulation is required

to verify the output signals and alarm settings .

This method can be compared with the method

used for safety valves. The manufacturer

produces, tests, and certifies the product, which

can then be mounted in the system.

Danfoss offers the above-mentioned solution.

The sensor head, which is the essential measuring

element of the gas detector, is produced, tested,

calibrated, and certified by Danfoss.

After the gas detection unit has been tested

with the on-board test button function, which

In addition to these calibration methods, a

“bump” test can be used, but only to test the

responsiveness and operation of the sensor. It is

important to highlight, that a bump test is not a

calibration.

simulates alarm signals and relay activation, to

ensure all electrical components are functional,

the new calibrated sensor head can be installed.

Danfoss recommends that the calibration is done

by means of pre-calibrated replacement sensors:

• As sensors have a limited lifetime, this method

basically ensures that the customer has a gas

detector as good as new after replacing the

sensor head.

• The method is typically more efficient and cost

effective compared to calibration carried out

on site.

Method II

Calibration of gas detectors by

means of calibration gas

Gas/calibration levels etc.

Traceability

Certificate

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

Fig. 9: Test and calibration of Danfoss gas detection unit (GDU) by the use of the on-board test function and

replacement of the sensor head.

+

The calibration of gas detectors by means of

calibration gas has traditionally been made

by using multimeters and adjustment of

potentiometers, which makes the process

Test function button

2

1

3

4

321

Sensor

In order to execute the calibration function, the

gas detector unit needs to be equipped with a

display or connection to either the service tool or

the PC tool.

Gas detection unit

567

4

Sensor

tested and calibrated

relatively complicated, time consuming, and

expensive. However, the Danfoss gas detection

units have an integrated, digital calibration

function that makes the calibration process

Some calibration gas cylinders are treated as

dangerous substances, and therefore subject to

specific shipping requirements.

easier, cheaper, and faster. Even though the

calibration is a simple procedure, it still requires

test equipment and basic competence in

calibration.

Calibration equipment for Gas Detection Units

(GDU) consists of:

• Valve/Flow regulator.

• Gas cylinder with the correct calibration gas for

each refrigerant and concentration (ppm).

• Calibration adapter.

• If the gas detector unit does not have a display,

the service tool or the PC tool is required.

14 | DKRCI.PA.S00.A2.02 | 520H12772

© Danfoss | DCS (mwa) | 2018.08

Page 15

Application Guide | Gas detection in refrigeration systems

Method II

Calibration of gas detectors by

means of calibration gas

(Continued)

Valve/Flow

regulator

+

Generic

calibration

gas

Calibration equipment

Fig. 10

Bump test A bump test cannot supersede any tests

involving calibration. It is only a function test

(signal or no signal).

Bump test of gas sensors (this test is a function test - it is not a calibration)

Method Refrigerant

Ampoules Ammonia

Ampoules (or lighter gas) HCFC, HCF

Lighter gas HC - Hydro Carbon

Ampoules (or breath on sensor) CO

Calibration

adapter

GDU without displayService tool

Integrated digital calibration function

2

GDU with display

SC EC P IR

Semi-

conductor

4 4

4 4

=

Electro-

chemical

4

Gas detection unit

tested and calibrated

Pellistor Infrared

4

© Danfoss | DCS (mwa) | 2018.08

DKRCI.PA.S00.A2.02 | 520H12772 | 15

Page 16

Application Guide | Gas detection in refrigeration systems

Alarm / sensitivity range

of gas detectors

Danfoss recommendations

for alarm levels

All commonly used gas detectors have a

proportional output signal (4-20 mA, 0-10 V, or

0-5 V), and some pre-set alarm settings.

When selecting the actual measuring range and

sensor type, several factors should be considered:

In general, alarm levels should be as low as

practically possible, depending on the actual

refrigerant and the purpose of the alarm.

There are often requests for more alarm levels,

but experience shows that two alarm limits are

sufficient for gas detection.

The pre-alarm provokes a reaction, either

automatically and/or in the form of alarm

instructions; if not, the main alarm may

be triggered. This entails a whole series of

consequences, including switching off machines.

A main alarm should rarely (and preferably never)

be necessary!

DANFOSS recommendations for alarm levels:

EN 378:2016

Machinery rooms EC 500 P 30000

Alarms can be chosen to warn against gas

concentrations less than levels acceptable for

personal safety on short term or long term. Alarm

levels can also be chosen to specific levels due to

flammability/explosion risk.

The following recommendations are based on

the present experience with suitable limits,

taking into account the above mentioned

conditions, but also requirements in EN 378:2016,

ISO 5149:2014, IIAR 2-2017 and ASHRAE 15:2016.

The Danfoss gas detection units offer two pre-

set alarms and a proportional output signal,

both analog 4-20 mA and digital Modbus.

With this configuration, is it possible to fulfil all

requirements for alarm levels needed within the

specific operation range of the sensor.

National

requirements

LEVEL

I

Personal safety

(occupational)

(TWA-values)

Sensor type

[ppm] [ppm] [ppm]

Comply with: EN 378

LEVEL

II

(pre-alarm)

Sensor type

LEVEL

III

(main-alarm)

Sensor type

Ammonia R717

Carbon Dioxide R744 (CO2) IR 5000 IR 9000

Halocarbon

HFC

Hydrocarbon HCR290, R600, R600a,

1

) 50% of TWA-value

Note: All proposed levels are ≤ the max. values in EN 378:2016

DANFOSS recommendations for alarm levels:

ASHRAE 15:2016

Carbon Dioxide R744 (CO2) IR 5000 IR 9000

Halocarbon

HFC

Hydrocarbon HCR290, R600, R600a,

1

) 50% of TWA-value

Note: All proposed levels are ≤ the max. values in ASHRAE 15:2016

R134a, R404A,

R407C, R410A, R507

R1270

R134a, R404A,

R407C,R410A, R507

R1270

Machinery rooms EC 25 EC 150

Safety valves vent line

Concentration

≤ 20% of LFL

Concentration

≤ 25% of LFL

SC 5001) SC 900

CT 800 CT 2500

SC 5001) SC 900

CT 500 CT 2500

– SC 9000

Comply with: ASHRAE 15:2016

LEVEL

I

Personal safety

(occupational)

(TWA-values)

Sensor type

[ppm] [ppm]

Sensor type

LEVEL

(pre-alarm)

II

16 | DKRCI.PA.S00.A2.02 | 520H12772

© Danfoss | DCS (mwa) | 2018.08

Page 17

Application Guide | Gas detection in refrigeration systems

Danfoss recommendations

for alarm levels

(Continued)

DANFOSS recommendations for alarm levels:

ANSI/IIAR 2-2014

Ammonia R717

Machinery rooms EC 25 EC 150 P 30000

Safety valves vent line

Comply with: ANSI/IIAR 2-2014

LEVEL

I

Personal safety

(occupational)

(TWA-values)

Sensor type

[ppm] [ppm] [ppm]

– SC 9000

LEVEL

II

(main-alarm)

Sensor type

(deenergize

components)

Sensor type

LEVEL

III

main

© Danfoss | DCS (mwa) | 2018.08

DKRCI.PA.S00.A2.02 | 520H12772 | 17

Page 18

Application Guide | Gas detection in refrigeration systems

Actions triggered by gas

detection

Actions for

Ammonia – R717

Up to 50 kg refrigerant At max. 157 ppm:

More than 50 kg

refrigerant

More than 3000 kg

refrigerant

More than 4500 kg

refrigerant

The actions to be triggered when leaked

refrigerant is detected depends on the standard

applied. National regulations, especially the

“Occupational Exposure Limits”, varies from

country to country.

EN 378:2016 ISO 5149:2014 ASHRAE 34-2016 IIAR 2-2014

- Actuate an alarm

- Notify an authorised person

- Audible buzzer 15 dBA above background noise

level

- Flashing lamp

- Alarm to be inside the room

- For machinery rooms: Also outside the room,

which can be at a supervised location

- For machinery rooms: Start emergency ventilation

Same actions as above,

but starting at max. 500

ppm

At max. 30000 ppm also:

- Stop the system

- Stop the power supply

to everything which is

not Ex approved

Same as above, but also

- central alarm station

- specialized personnel

on site within 60 min of

alarm

Same actions as above,

but starting at max. 200

ppm

At max. 30000 ppm also:

- Stop the system

- Stop the power supply

to everything which is

not Ex approved

Same as above, but also:

- central alarm station

- specialized personnel

on site within 60 min of

alarm

At max. 1000 ppm:

- Audible and visual

alarm

- Inside the machinery

room and outside

each entrance

- Start mechanical

ventilation

- Shut down

combustion

processes drawing

air from the room

(except if the

combustion is driving

the compressor)

Machinery rooms at max.

25 ppm:

- Audible and visual alarm

- Inside the machinery

room and outside each

entrance

- Alarm to monitored

location

- Stop non-emergency

ventilation (unless it is

designed to work with

R717)

Machinery rooms at max.

150 ppm also:

- Start emergency

ventilation

Machinery rooms at max.

40000 ppm also:

- De-energize compressors,

refrigerant pumps, and

normally closed valves

Not in machinery rooms at

max. 25 ppm:

- Alarm to monitored

location

- Other actions depends

on system type and

location

Actions for refrigerants

other than ammonia

For all systems except

ventilated enclosures

and systems using

alternative risk

management

For ventilated

enclosures

For systems using

alternative risk

management

18 | DKRCI.PA.S00.A2.02 | 520H12772

At 50% ATEL/ODL/RCL or 25% LFL (see Annex II):

- For flammable refrigerants: Stop the system

- Actuate an alarm

- Notify an authorised person

- Audible buzzer 15 dBA above background noise level

- Flashing lamp

- Alarm to be inside the room

- For occupancy A: Also outside the room, which shall be at a

supervised location

- For occupancy B and C: Only inside is needed

- For machinery rooms: Also outside the room, which can be at a

supervised location

- For machinery rooms: Start emergency ventilation

If a detector is used for staring ventilation:

Start ventilation at 25% LFL (see Annex II)

If a detector is used for staring ventilation:

Start ventilation at 50% ATEL/ODL/RCL or 25% LFL (see Annex II)

EN 378:2016 ISO 5149:2014 ASHRAE 34-2016

At OEL (see Annex III):

- Audible and visual alarm

- Inside the machinery room and

outside each entrance

- Start mechanical ventilation

- Shut down combustion

processes drawing air from

the room (except if refrigerant is

R744)

Not applicable

Not applicable

© Danfoss | DCS (mwa) | 2018.08

Page 19

Application Guide | Gas detection in refrigeration systems

References • EN 378:2016 Refrigerating systems and

heat pumps – Safety and environmental

requirements

• ASHRAE 15:2016 Safety Standard for

Refrigeration Systems

• ASHRAE 34:2016 Designation and Safety

Classification of Refrigerants

• ANSI/IIAR 2-2014 American National Standard

for Safe Design of Closed-Circuit Ammonia

Refrigeration Systems

• ISO 5149:2014 Refrigerating systems and

heat pumps – Safety and environmental

requirements

• EU F-Gas Regulation (EC) No 517/2014

• Danfoss gas detector documentation

(www.danfoss.com/ir)

© Danfoss | DCS (mwa) | 2018.08

DKRCI.PA.S00.A2.02 | 520H12772 | 19

Page 20

Application Guide | Gas detection in refrigeration systems

Annex I

Common refrigerant data

Refrigerant

type

– R717 Ammonia NH

– R744 Carbon Dioxide CO

HCFC R22 Chlorodifluoromethane CHCIF

HFC R134a 1,1,1,2-tetraflouroroethane CH2FCF

HFC R404A R125/143a/134a (44/52/4) – A1 3.99 3.3 0 3260

HFC R407C R32/125/134a (23/25/52) – A1 3.53 2.9 0 1520

HFC R410A R32/125 (50/50) – A1 2.97 2.5 0 1900

HFC R507 R125/143a (50/50) – A1 4.04 3.4 0 3800

HC R290 Propane CH3CH2CH

HC R600 Butane CH3CH2CH2CH

HC R600a Iso-butane CH(CH3) A3 2.38 2.0 0 3

HC R1270 Propylene CH3CH=CH

HFC R32 Difluoromethane CH2F

HFO/HFC R1234ze(E) Trans-1,3,3,3-tetrafluoro-1-propene CF3CH=CHF A2L 4.66 3.9 0 7

Refrigerant Name Formula Safety

3

2

2

3

3

2

2

group

B2L 0.700 0.6 0 0

A1 1.80 1.5 0 1

A1 3.54 3.0 0.055 1810

A1 4.17 3.5 0 1430

A3 1.8 1.5 0 3

3

A3 2.38 2.0 0 4

A3 1.72 1.4 0 2

A2L 2.13 1.8 0 675

Vapour density

@ 25°C /

1 bar

[kg/m3] [–] [–] [–]

Relativ density ODP

Ozone Pepletion

Portential

GWP

Global Warming

Potential

(100 yr ITH/F

gas regulation)

100

Annex II

EN 378:2016 and ISO 5149:2014

Refrigerant

type

- R717 Ammonia B2L 0.00035 0.00022 0.116 157 33143

- R744 Carbon Dioxide A1 0.1 0.072 - 20000 - 20000

HCFC R22 Chlorodifluoromethane A1 0.3 0.21 - 29661 - 29600

HFC R134a 1,1,1,2-tetraflouroroethane A1 0.25 0.21 - 25180 - 25100

HFC R404A R125/143a/134a (44/52/4) A1 0.52 0.52 - 65163 - 65100

HFC R407C R32/125/134a (23/25/52) A1 0.31 0.29 - 41076 - 41000

HFC R410A R32/125 (50/50) A1 0.44 0.42 - 70707 - 70700

HFC R507A R125/143a (50/50) A1 0.53 0,53 - 65594 - 65500

HC R290 Propane A3 0.008 0.09 0.038 25000 4222 4200

HC R600 Butane A3 0.0089 0.0024 0.038 504 3193 500

HC R600a Iso-butane A3 0.011 0.059 0.043 12395 3613 3600

HC R1270 Propylene A3 0.008 0.0017 0.046 494 5349 490

HFC R32 Difluoromethane A2L 0.061 0.30 0.307 70423 28826 28800

HFO/HFC R1234ze(E) Trans-1,3,3,3-tetrafluoro-1-propene A2L 0.061 0.28 0.303 30043 13004 13000

Refrigerant Name Safety

group

Practical

Limit

[kg/m3] [kg/m3] [kg/m3] [ppm] [ppm] [ppm] [ppm]

Toxicity

ATEL /ODL

Flammability

LFL

50% of

ATEL/

ODL

25% of

LFL

Alarm settings

Pre-alarm

level MAX

refrigeration

concentration

EN 378: 500

ISO 5149: 200

Main-alarm

MAX

refrigeration

concentra-

tion

30000

20 | DKRCI.PA.S00.A2.02 | 520H12772

© Danfoss | DCS (mwa) | 2018.08

Page 21

Application Guide | Gas detection in refrigeration systems

Annex III

ASHRAE 15-2016

Refrigerant

type

- R717 Ammonia B2L 0.22 0.014 320 25

- R744 Carbon Dioxide A1 54 3.4 30000 5000

HCFC R22 Chlorodifluoromethane A1 210 13 59000 1000

HFC R134a 1,1,1,2-tetraflouroroethane A1 210 13 50000 1000

HFC R404A R125/143a/134a (44/52/4) A1 500 31 130000 1000

HFC R407C R32/125/134a (23/25/52) A1 290 19 81000 1000

HFC R410A R32/125 (50/50) A1 420 26 140000 1000

HFC R507 R125/143a (50/50) A1 520 32 130000 1000

HC R290 Propane A3 9.5 0.56 5300 1000

HC R600 Butane A3 2.4 0.15 1000 1000

HC R600a Iso-butane A3 9.6 0.59 4000 1000

HC R1270 Propylene A3 1.7 0.11 1000 500

HFC R32 Difluoromethane A2L 77 4.8 36000 1000

HFO/HFC R1234ze(E) Trans-1,3,3,3-tetrafluoro-1-propene A2L 75 4.7 16000 800

Refrigerant Name Safety

group

RCL RCL RCL OEL/TWA

[g/m3] [lb/Mcf] [ppm] [ppm]

(40 hours work week

without effect)

© Danfoss | DCS (mwa) | 2018.08

DKRCI.PA.S00.A2.02 | 520H12772 | 21

Page 22

Page 23

Page 24

Danfoss Industrial Refrigeration

Danf

his also applies to products

already on order pro

All trademarks in this material are property of the respec

A world of expertise at the click

of a button

Turn to Danfoss if you want to combine quality components with expert knowhow

and support. Try out these free tools, designed to make your work much easier.

DIRbuilder

DIRbuilder is designed to make selection processes for industrial refrigeration

projects easier and less time-consuming. Specify the valves you need from an

extensive pool of configuration options. The DIRbuilder library comprises all

Danfoss Industrial Refrigeration valves. Free of charge – no software needed.

Coolselector® 2 – New calculation software for Industrial Refrigeration

Coolselector® 2 is a calculation and support tool for contractors and system

designers, offering complete pressure drop calculations, analysis of pipe and valve

design and the ability to generate performance reports. It replaces the well-known

DIRcalc™ software and offers several new functionalities.

Danfoss IR app

The free IR App gives you a spare parts tool, which makes it easy for you to find the

spare part number for a given Danfoss industrial refrigeration valve.

Download 3D CAD symbols

From our online product catalogue on our website, you can download 3D CAD

symbols and illustrations to help you when designing refrigeration plants.

IR application tool

With this interactive PowerPoint slideshow, you can explore all the details of

a two-stage ammonia plant. You will find detailed cut-away drawings and

information on the valves in the installation along with links to videos, literature

and product animations.

Application handbook

The Application Handbook is designed to help you every step of the way when

working with industrial refrigeration systems. Among many other things, it

contains examples of how to select control methods for different refrigeration

systems, their design and which components to choose.

Visit www.danfoss.com/IR-tools and find all the tools you need.

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. T

© Danfoss | DCS (MWA) | 2018.03

24 | DKRCI.PA.S00.A2.02 | 520H12772

vided that such alterations can be made without subsequential changes being necessary in specications already agreed.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DKRCI.PA.S00.A1.02 | 520H12772

© Danfoss | DCS (mwa) | 2018.08

Loading...

Loading...