Fitters notes Filter driers & sight glasses

Contents Page

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Filter drier selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Location in refrigeration system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Soldering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Replace the lter drier when . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

DCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Using gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mounting gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Filter drier replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Special lters from Danfoss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Combidriers type DCC and DMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Burn-out lter, type 48-DA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Special application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

DCL/DML lter driers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Dimensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

EPD (Equilibrium Point Dryness) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Drying capacity (water capacity). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Liquid capacity (ARI 710*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Recommended system capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Filter driers from Danfoss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 51

Filter driers &

sight glasses

Notes

52 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Fitters notes Filter driers & sight glasses

Function

To ensure optimum function the refrigeration

system must be internally clean and dry.

Before starting the system, moisture must be

removed by evacuation at a max. pressure of 0.05

mbar abs.

During operation, dirt and moisture must be

collected and removed. This is performed by a

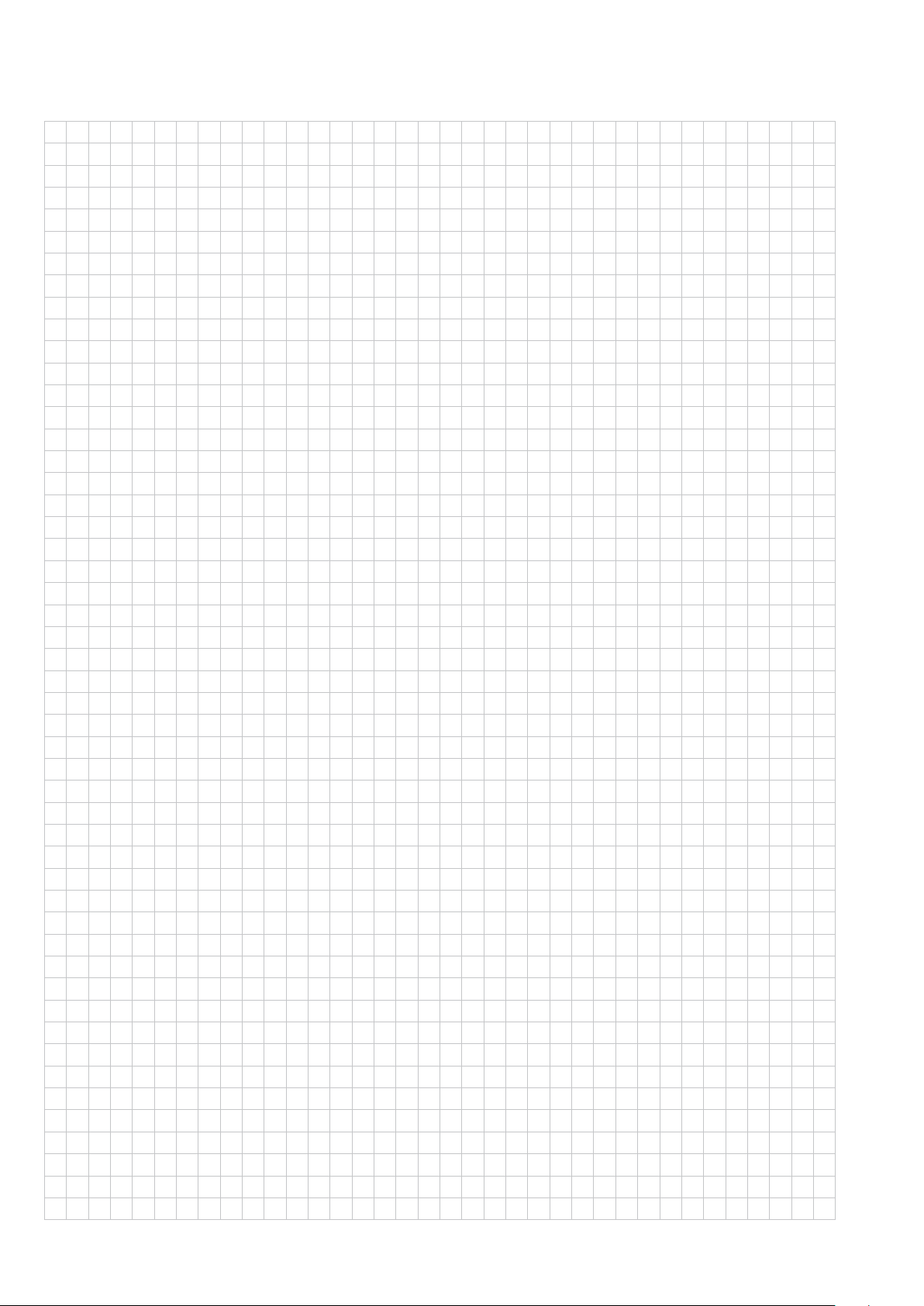

lter drier containing a solid core consisting of:

Molecular Sieves

Silica gel (low eectiveness - not used in

Danfoss driers)

Activated aluminium oxide and a polyester

mesh A inserted in the lter outlet.

DML: 100% Molecular Sieves

DCL: 80% Molecular Sieves

20% Activated aluminium

The solid core can be compared to a sponge’s

ability to soak up water and retain it.

Molecular Sieves retain water, whereas activated

aluminium oxide retains water and acids.

The solid core B together with the polyester mat

A also acts as a dirt lter.

The solid core retains large dirt particles and the

polyester mat small ones.

The lter drier is thus able to collect all dirt

particles larger than 25 micron.

Ah0_0001

Filter drier selection

The lter drier must be selected to suit the

connections and the capacity of the refrigeration

system.

If a lter drier with solder connections is required,

a Danfoss type DCL/DML lter drier can be

used to advantage. It has an extra-high drying

capacity which prolongs the interval between

replacements.

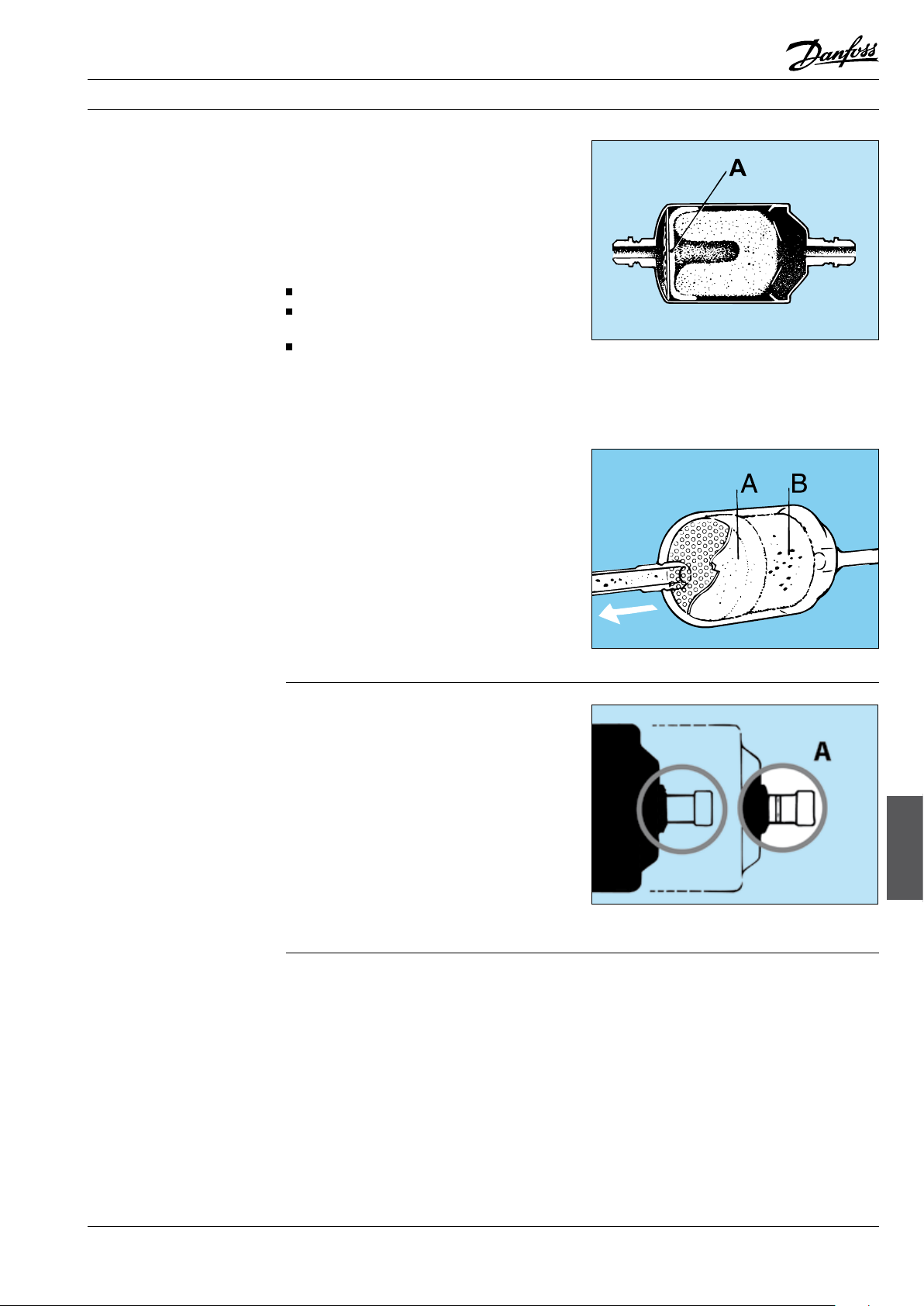

A collar on the connector A indicates that the

connection is a mm size. If the connector A is

plain, i.e. no collar, the connector is an inch size.

Type DCL can be used for CFC/HCFC refrigerants.

Type DML can be used for HFC refrigerants. See

page 60 for more details.

Ah0_0011

Ah0_0018

Filter driers &

sight glasses

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 53

Fitters notes Filter driers & sight glasses

Location in

refrigeration system

The lter drier is normally installed in the liquid

line where its primary function is to protect the

expansion valve.

The velocity of the refrigerant in the liquid

line is low and therefore contact between the

refrigerant and the solid core in the lter drier is

good. At the same time, the pressure drop across

the lter drier is low.

A lter drier can also be installed in the suction

line where its task is to protect the compressor

against dirt and dry the refrigerant.

Suction lters, so-called “burn-out” lters, are

used to remove acids after motor damage. To

ensure low pressure drop, a suction lter must

normally be larger than a liquid line lter.

A suction lter must be replaced before the

pressure drop exceeds the following values:

A/C systems: 0.50 bar

Refrigeration systems: 0.25 bar

Freezing systems: 0.15 bar

A sight glass with moisture indicator is normally

installed after the lter drier, where the sight

glass indication means:

Green: No dangerous moisture in the refrigerant.

Yellow: Moisture content too high in the

refrigerant ahead of the expansion valve.

Bubbles:

1) Pressure drop across the lter drier too high.

2) No subcooling.

3) Insucient refrigerant in whole system.

Ah0_0019

Ah0_0020

If the sight glass is installed ahead of the lter

drier the indication is:

Green: No dangerous moisture in the refrigerant.

Yellow: Moisture content in the whole

refrigeration system too high.

The changeover point from green to yellow in the

sight glass indicator is determined by the water

solubility of the refrigerant.

Note:

The changeover points in Danfoss sight glasses

are very small. This ensures that a switch to green

in the indicator only occurs when the refrigerant

is dry.

Bubbles:

1) No subcooling.

2) Insucient refrigerant in whole system.

Note!

Do not replenish refrigerant solely because of

bubbles in the sight glass.

First nd out the cause of the bubbles!

Ah0_0032

Ah0_0031

Ah0_0006

54 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Fitters notes Filter driers & sight glasses

Installation

The lter drier must be installed with ow in the

direction of the arrow on the lter drier label.

The lter drier can have any orientation, but the

following must be remembered:

Vertical mounting with downward ow means

rapid evacuation/emptying of the refrigeration

system.

With vertical mounting and upward ow,

evacuation/emptying takes longer because

refrigerant must be evaporated out of the lter

drier.

The lter core is rmly xed in the lter housing.

Danfoss lter driers are therefore able to resist

vibration up to 10 g*).

Find out whether the tubing will support the

lter drier and resist vibration. If not, the lter

drier must be installed using a clamping band or

similar secured to a rigid part of the system.

*) 10 g = Ten times the gravitational force of the earth.

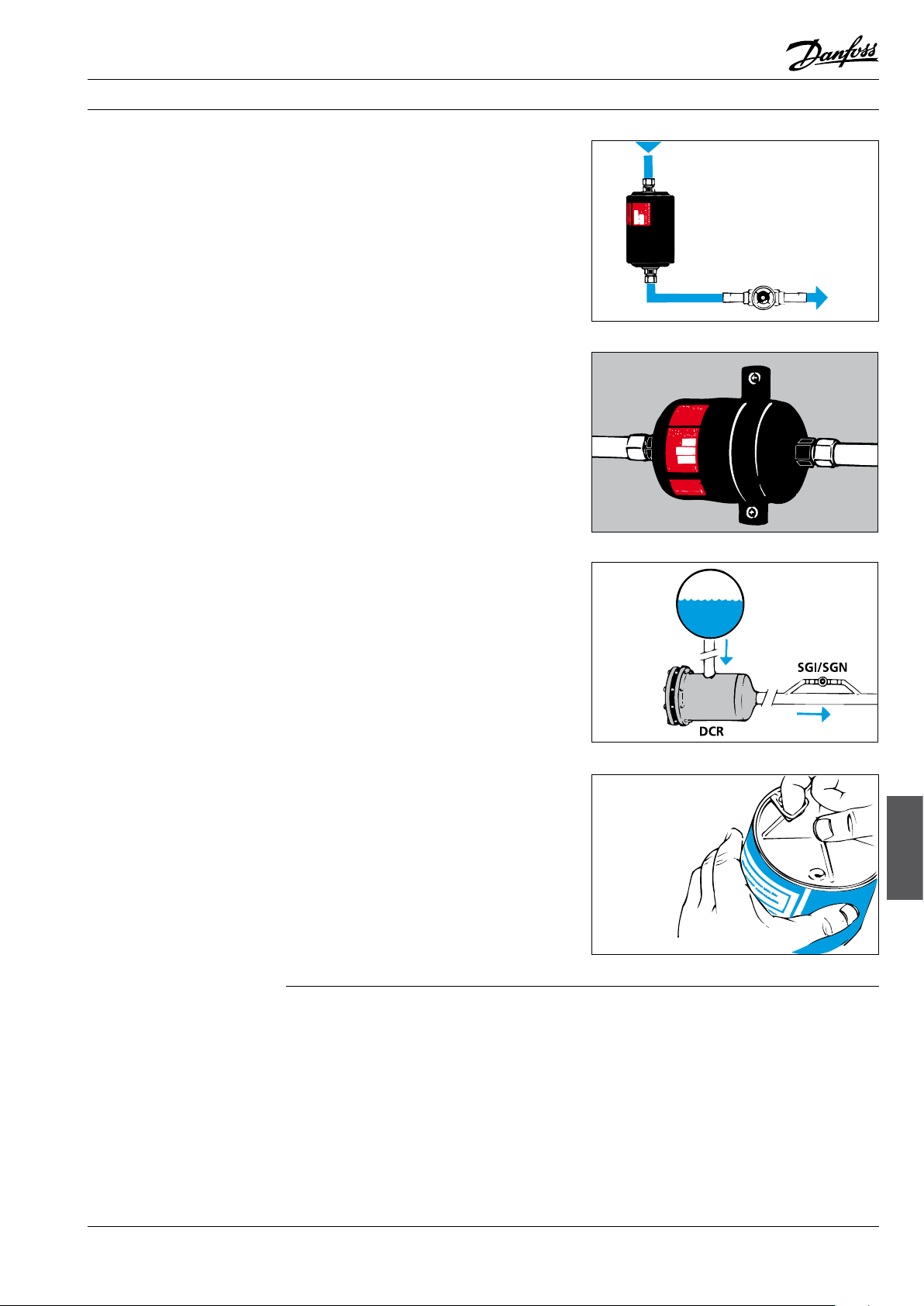

For DCR: Install with the inlet connector upwards

or horizontal.

This avoids collected dirt running out into the

tubing when the core is replaced.

When installing a new DCR, remember that

there must always be sucient space for core

replacement.

Ah0_0022

Ah0_0028

Do not unpack lter driers or cores until immediately before installation. This will safe-guard the

items in the best possible way.

There is neither vacuum nor overpressure in

lters or cans.

Plastic union nuts, capsolutes and the hermetically sealed can guarantee completely “fresh”

desiccants.

Ah0_0002

Ah0_0003

Filter driers &

sight glasses

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 55

Fitters notes Filter driers & sight glasses

Soldering

Operation

Protective gas, e.g. N2, should be used when

soldering the lter drier.

Ensure that the protective gas ows in the

direction of lter ow. This avoids heat from

soldering being damaging the polyester mesh.

Soldering alloys and ux give o

fumes that can be hazardous.

Read supplier instructions and

observe their safety stipulations.

Keep your head away from the

fumes during soldering.

Moisture enters the system:

1) When the refrigeration system is being built

up.

2) When the refrigeration system is opened for

servicing.

3) If leakage occurs on the suction side, if it is

under vacuum.

4) When the system is lled with oil or

refrigerant containing moisture.

5) If leakage occurs in a water-cooled condenser.

Moisture in the refrigeration system can cause:

a) Blockage of the expansion device because of

ice formation.

b) Corrosion of metal parts.

c) Chemical damage to the insulation in

hermetic and semihermetic compressors.

d) Oil breakdown (acid formation).

The lter drier removes moisture that remains

after evacuation or that subsequently enters the

refrigeration system.

Ah0_0004

Use strong ventilation and/or extraction at the

ame so that you do not inhale fumes and gases.

Use protective goggles.

Use wet cloth around lter driers with pure

copper connectors.

Ah0_0005

Warning!

Never use “antifreeze liquids” like

methyl alcohol together with a lter

drier. Such liquid can damage the

lter so that it is unable to absorb

water and acid.

Replace the lter drier when

1. The sight glass indicates that the moisture

content is too high (yellow).

2. Pressure drop across the lter is too high

(bubbles in sight glass during normal

operation).

3. A main component in the refrigerant system

has been replaced, e.g. the compressor.

4. Each time the refrigeration system is

otherwise opened, e.g. if the orice assembly

in an expansion valve is replaced.

Never re-use a used lter drier. It will give o

moisture if it is used in a refrigeration system with

low moisture content, or if it becomes heated.

Ah0_0008

56 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Fitters notes Filter driers & sight glasses

DCR

Using gaskets

Mounting gaskets

Note, there can be overpressure in the lter.

Therefore be careful when opening the lter.

Never re-use the ange gasket in the DCR lter.

Fit a new gasket and smear it with a little refri-

geration machine oil before tightening.

Only use undamaged gaskets.

Flange surfaces that are to form the seal must

be faultless, clean and dry before mounting.

Do not use adhesive ller, rust remover

or similar chemicals when mounting or

dismantling.

1. Moisten gasket surfaces with a drop of

refrigerant oil.

2. Put gasket in place.

3. Mount bolts and tighten slightly until all bolts

have made good contact.

4. Cross-tighten bolts.

Ah0_0009

Use sucient oil for lubricating bolts and

screws during mounting.

Do not use bolts which are dry, corroded or

defective in any other way (defective bolts can

give incorrect tightening which may result in

leaking ange joints).

Tighten bolts in at least 3-4 steps, e.g. as follows:

Step 1: to approx. 10% of required torque.

Step 2: to approx. 30% of required torque.

Step 3: to approx. 60% of required torque.

Step 4: to 100% of required torque.

Finally, check that the torque is correct in the

same order as used when tightening.

Disposal

Filter drier replacement

Always seal used lter driers. They contain small

amounts of refrigerant and oil residue.

Observe authority requirements when scrapping

used lter driers.

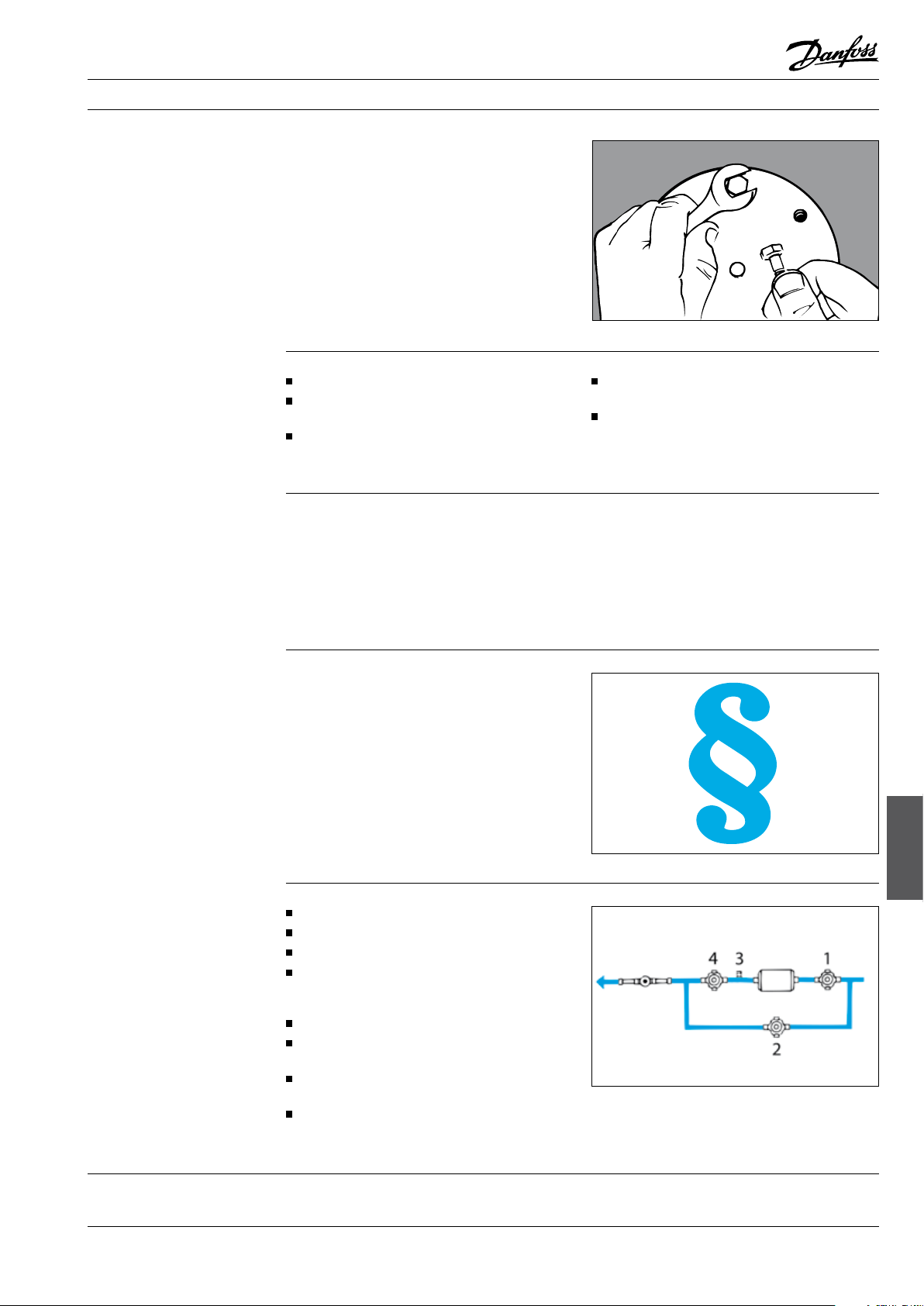

Close valve no. 1.

Suck the lter empty.

Close valve no. 4.

Close valve no. 2.

The system will now operate, bypassing the lter.

Replace lter or lter core.

Evacuate the lter drier via a schrader valve

(no. 3).

Restart the system by opening/closing the

valves in the reverse order.

Remove any levers/handwheels from the

valves.

Ah0_0023

Ah0_0014

Filter driers &

sight glasses

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 57

Fitters notes Filter driers & sight glasses

Special lters from Danfoss

Combidriers type DCC and DMC

Burn-out lter, type 48-DA

Combidriers type DCC and DMC are used in

smaller systems with expansion valve where the

condenser cannot contain the entire quantity of

refrigerant.

The receiver in the combidrier increases liquid

subcooling and creates the possibility of

automatic defrost on pumpdown. The receiver

takes up varying refrigerant volume (from varying

condensing temperature) and must be able to

contain the whole refrigerant quantity during

service and repair.

In the interests of safety, the volume of the

receiver must be at least 15% greater than the

refrigerant volume.

Burn-out lter, type 48-DA, is for use after a

hermetic or semihermetic compressor has

suered damage.

Compressor damage that gives rise to acid

formation will be revealed by oil odour and

perhaps discolouration. Damage can occur

because of:

moisture, dirt or air

defective starter

refrigerant failure because of too small a

refrigerant charge,

hot gas temperature higher than 175°C

Ah0_0012

Ah0_0013

After replacing the compressor and cleaning

the remainder of the system, two burn-out

lters are installed; one in the liquid line and

one in the suction line.

The acid content is then checked regularly

and the lters replaced as necessary.

When an oil check shows that the system no

longer contains acid, the burn-out lter in

the liquid line can be replaced by an ordinary

lter drier. The burn-out lter core in the

suction line can be removed.

Ah0_0010

Special application

DCL/DML lter driers

Type DCL/DML 032s, DCL/DML 032.5s and

DCL/DML 033s are manufactured specially for

capillary tube systems and are therefore used in

refrigeration systems where expansion is through

a capillary tube.

Ah0_0017

DCL/DML lter driers can also be used when

reparing refrigerators and freezers, etc. Both time

and money can be saved by installing a DCL/DML

lter drier in the suction line.

The advantage of doing so can best be illustrated

by comparing the normal repair procedure for a

defective compressor with a method that exploits

the good characteristics of the DCL/DML lter in

retaining moisture, acid and dirt.

NOTE: The „DCL/DML method“ can only be used

when the oil is not discoloured and when

the pencil lter is not clogged.

Ah0_0015

58 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Fitters notes Filter driers & sight glasses

Special application

DCL/DML lter driers (cont.)

Dimensioning

The advantages gained by installing a DCL/DML

lter in the suction line are:

1. Faster repair.

2. Increased drying and acid capacity.

3. Protection of the compressor against

impurities of every kind.

4. Better quality of repair.

5. Cleaner working environment.

The acid and moisture bound in the old oil will be

absorbed by the DCL/DML lter.

Therefore it is not necessary to remove remaining

oil from the refrigeration system.

A DCL/DML in the suction line retains impurities

from condenser, evaporator, tubing, etc. and

thereby prolongs the life of the new compressor.

DCL/DML lters having the same connections

as the compressor can be used. The Danfoss

range of hermetic compressors can also be

recommended.

When choosing lter driers from catalogues there

are several expressions each of which can form

the basis of selection.

Procedure with pencil lter Procedure with

Recover refrigerant and

evaluate for re-use

Remove compressor

+ pencil lter

Remove oil residue in system Nothing

Dry system with nitrogen Nothing

Connect new compressor and

t new pencil lter

Evaluate and change

refrigerant

DCL/DML lter

Recover refrigerant and

evaluate for re-use

Remove compressor

Connect new compressor

and t DCL/DML lter in

suction line

Evaluate and change

refrigerant

Example:

Compressor type Suction tube

TL Ø6.2 DCL/DML 032s

NL 6-7 Ø6.2 DCL/DML 032s

[mm]

Filter type

EPD (Equilibrium Point Dryness)

Drying capacity (water capacity)

Liquid capacity (ARI 710*)

Denes the least possible water content in a

refrigerant in its liquid phase, after it has been in

contact with a lter drier.

EPD for R22 = 60 ppmW *)

EPD for R410A = 50 ppmW *)

EPD for R134a = 50 ppmW *)

EPD for R404A / R507 / R407C = 50 ppmW *)

As stipulated by ARI 710, in ppmW

(mg

/kg

water

*) ARI: Air-conditioning and Refrigeration Institute, Virginia, USA

refrigerant

)

The quantity of water the lter drier is able to

absorb at 24°C and 52°C liquid temperature, as

stipulated by the ARI 710* standard.

The drying capacity is given in grams of water,

drops of water or kg refrigerant on drying out.

R22: 1050 ppmW to 60 ppmW

R410A: 1050 ppmW to 50 ppmW

R134a: 1050 ppmW to 50 ppmW

R404A / R507 / R407C: 1020 ppmW to 50 ppmW

1000 ppmW = 1 g water in 1 kg refrigerant 1 g water = 20 drops.

Gives the quantity of liquid able to ow through

a lter with a pressure drop of 0.07 bar at tc =

+30°C, te = -15°C.

The liquid capacity is stated in l/min or in kW.

Conversion from kW to litres/minute:

R22 / R410A 1kW = 0.32 l/min

R134a 1kW = 0.35 l/min

R404A / R507 / R407C 1kW = 0.52 l/min

*) ARI: Air-conditioning and Refrigeration Institute, Virginia, USA

Ah0_0025

Ah0_0016

Ah0_0024

Filter driers &

sight glasses

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 59

Fitters notes Filter driers & sight glasses

Recommended system capacity

Filter driers from Danfoss

Operating conditions:Stated in kW for dierent types of refrigeration

systems on the basis of a liquid capacity of

∆p = 0.14 bar and typical operating conditions.

Refrigeration

and freezing systems

A/C systems

A/C units

te = evaporating temperature

tc = condensing temperature

te = -15°C, tc = +30°C

te = -5°C, tc = +45°C

te = +5°C, tc = +45°C

Warning:

With the same system capacity in

kW for A/C units and for

refrigeration/freezing systems,

smaller lter driers can be installed

in A/C units because of higher evaporating

temperature (te) and the assumption that factory

produced units contain less moisture than

systems built up „on site“.

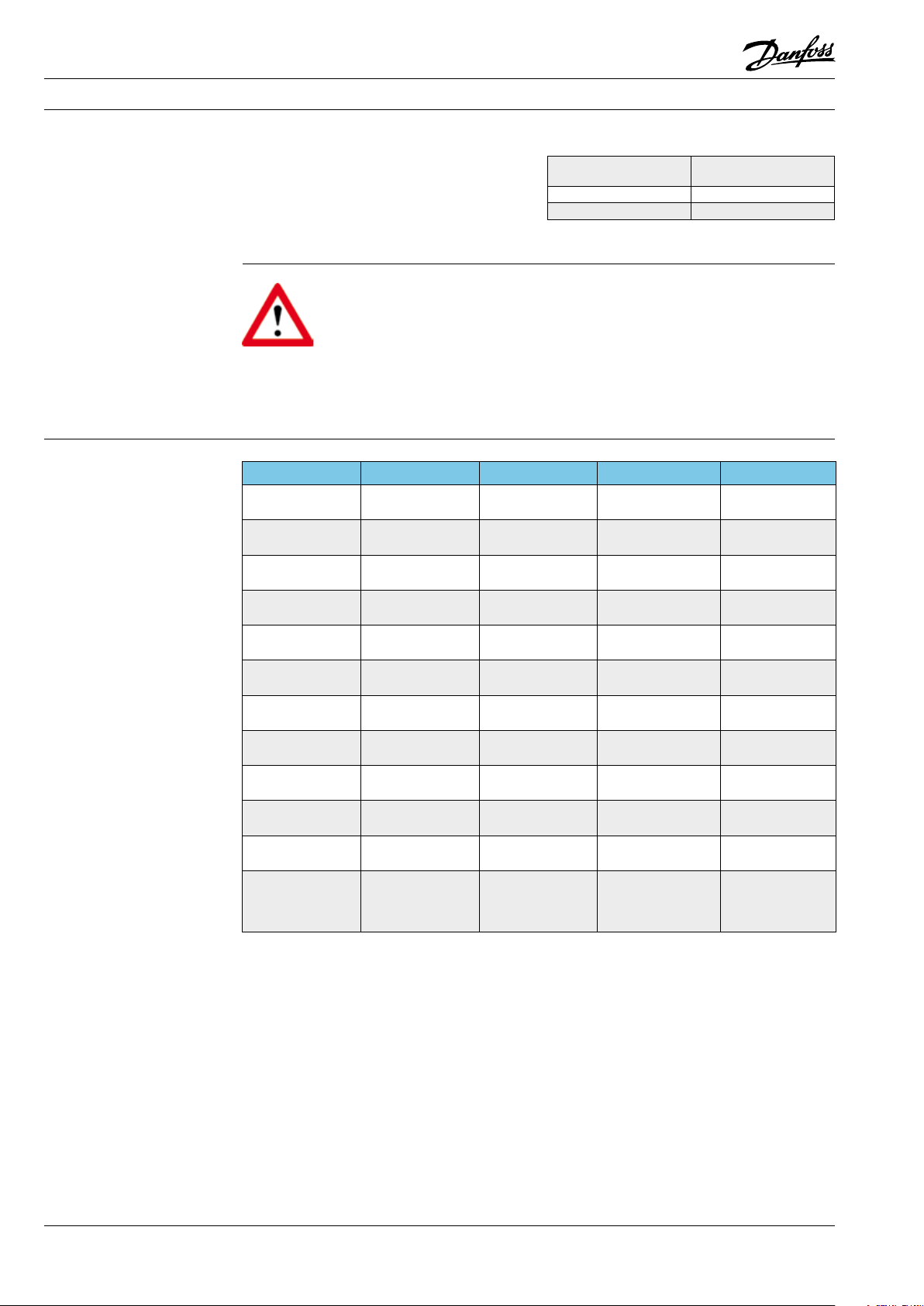

Product type Function Refrigerant Core Oil type

DML Standard lter drier HFC, compatible with

DCL Standard lter drier CFC/HCFC 80% molecular sieves

DMB Bi-ow lter drier HFC, compatible with

DCB Bi-ow lter drier CFC/HCFC 80% molecular sieves

DMC Combi lter drier HFC, compatible with

DCC Combi lter drier CFC/HCFC 80% molecular sieves

DAS Burn-out lter drier R22, R134a,

DCR Filter drier with ex-

48-DU/DM

for DCR

48-DN/DC

for DCR

48-DA

for DCR

48-F

for DCR

changeable core

Exchangeable core for

DCR: std. lter drier

Exchangeable core for

DCR: std. lter drier

Exchangeable core for

DCR: std. lter drier

Exchangeable

core for DCR with

exchangeable lter

insert

R22

R22

R22

R404A, R507

See core description

below

HFC, compatible with

R22

CFC/HCFC 80% molecular sieves

R22, R134a,

R404A, R507

All - All

100% molecular sieves Polyolester (POE)

20% activated alumina

100% molecular sieves Polyolester (POE)

20% activated alumina

100% molecular sieves Polyolester (POE)

20% activated alumina

30% molecular sieves

70% activated alumina

48-DU/DM, 48-DN DC,

48-DA, 48-F

100% molecular sieves Polyolester (POE)

20% activated alumina

Polyalkyl (PAG)

Mineral oil (MO)

Alkyl benzene (BE)

Polyalkyl (PAG)

Mineral oil (MO)

Alkyl benzene (BE)

Polyalkyl (PAG)

Mineral oil (MO)

Alkyl benzene (BE)

-

Polyalkyl (PAG)

Mineral oil (MO)

Alkyl benzene (BE)

60 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Loading...

Loading...