Data Sheet

Strainer housing

Type FIA 65

Reliable ltration up to 65 bar

FIA strainers are a range of angleway and

straightway strainers, which are carefully

designed to give favourable ow conditions.

The design makes the strainer easy to install,

and ensures quick strainer inspection and

cleaning.

FIA strainers are used ahead of automatic

controls, pumps, compressors etc., for initial

plant start-up and where permanent ltration

of the refrigerant is required. The strainer

reduces the risk of undesirable system

breakdowns and reduces wear and tear on

plant components.

FIA strainers are equipped with a screen mesh

of stainless steel, available in sizes 100, 150, 250

and 500μ (microns*), (US 150, 100, 72, 38

mesh*).

* Mesh is the number of threads per inch. μ

(microns) is the distance between two threads

(1μ = 1 /1000 mm).

AI367729235609en-000101

Strainer housing, type FIA 65

Features

• Modular Concept:

◦ Each valve housing is available with DIN and ANSI butt weld connection and in several dierent sizes.

◦ Possible to convert FIA strainers to any other product in the SVL family (Shut-o valve, regulating valve, check &

stop valve or check valve) just by replacing the complete top part.

• Quick and easy maintenance. Replacement of top part does not require welding.

• Filter net of stainless steel mounted direct without extra gaskets means easy servicing.

• Two types of strainer inserts are available:

◦ A plain insert made of stainless steel.

◦ A pleated insert (DN 15-200) with extra large surface, which ensures long intervals between cleaning and low

pressure drop.

• FIA 15-40 (½ – 1 ½ in.):

A special insert (50μ) can be used in combination with a standard version when cleaning a plant during

commissioning.

• FIA 50-200 (2 - 8 in.):

A large capacity lter bag (50μ) can be inserted for cleaning plant during commissioning.

• FIA 65-200 (2½ - 8 in.) can be equipped with a magnetic insert for detention of iron particles and other magnetic

particles.

• Each strainer clearly marked with type, size and performance range

• Housing and bonnet of low temperature steel in accordance with the requirements of the Pressure Equipment

Directive and those of other international classication authorities

• Classication: DNV, CRN, BV, EAC etc. To get an updated list of certication on the products please contact your

local Danfoss Sales Company.

• Equipped with 42CrMo5 bolts to withstand high pressure.

Media

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia), R744 (CO₂) and ammable refrigerants.

For further information refer to the product instruction for FIA.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 2

Description

Values

Temperature range

-60 °C /+150 °C (-76 °F /+302 °F)

Max working pressure

65 bar (943 psig)

OD

T

Size

ODTOD

T

kv-angle

kv-straight

Cv-angle

Cv-straight

mm

in.mmmm

in.

in.

m3/h

m3/h

USgal/min

USgal/min

6¼13.5

2.3

0.531

0.091

2.9

2.0

3.4

2.410⅜

17.2

2.3

0.677

0.091

4.5

3.2

5.2

3.615½

21.3

2.3

0.839

0.091

7.0

4.9

8.1

5.720¾

26.9

2.3

1.059

0.091

14.6

10.2

16.9

11.8251

33.7

2.6

1.327

0.103

24.8

17.4

28.8

20.2321¼

42.4

2.6

1.669

0.102

42.6

29.8

49.4

34.6401½

48.3

2.6

1.902

0.103

45.2

31.6

52.4

36.7502

60.3

2.9

2.37

0.1180659376652½

76.1

2.930.11

12097140

113803

88.9

3.2

3.50

0.13

182

152

211

176

1004114.3

3.6

4.50

0.14

313

278

363

323

1255139.7

4.0

5.50

0.16

514

470

596

545

1506168.3

4.5

6.63

0.18

785

597

911

693

2008219.1

6.3

8.63

0.25

1168

1024

1355

1188

OD

T

Size

ODTOD

T

k

v

-angle

k

v

-straight

C

v

-angle

C

v

-straight

mm

in.mmmm

in.

in.

m

3

/h

m

3

/h

USgal/min

USgal/min

6¼13.5

3.0

0.531

0.118

2.9

2.03

3.4

2.410⅜

17.2

3.2

0.677

0.126

4.5

3.15

5.2

3.615½

21.3

3.7

0.839

0.146

7.0

4.9

8.1

5.720¾

26.9

4.0

1.059

0.158

14.6

10.2

16.9

11.8251

33.7

4.6

1.327

0.181

24.8

17.4

28.8

20.2321¼

42.4

4.9

1.669

0.193

42.6

29.8

49.4

34.6401½

48.3

5.1

1.902

0.201

45.2

31.6

52.4

36.7

Strainer housing, type FIA 65

Product specication

Pressure and temperature data

Table 1: Temperature and pressure

Connections

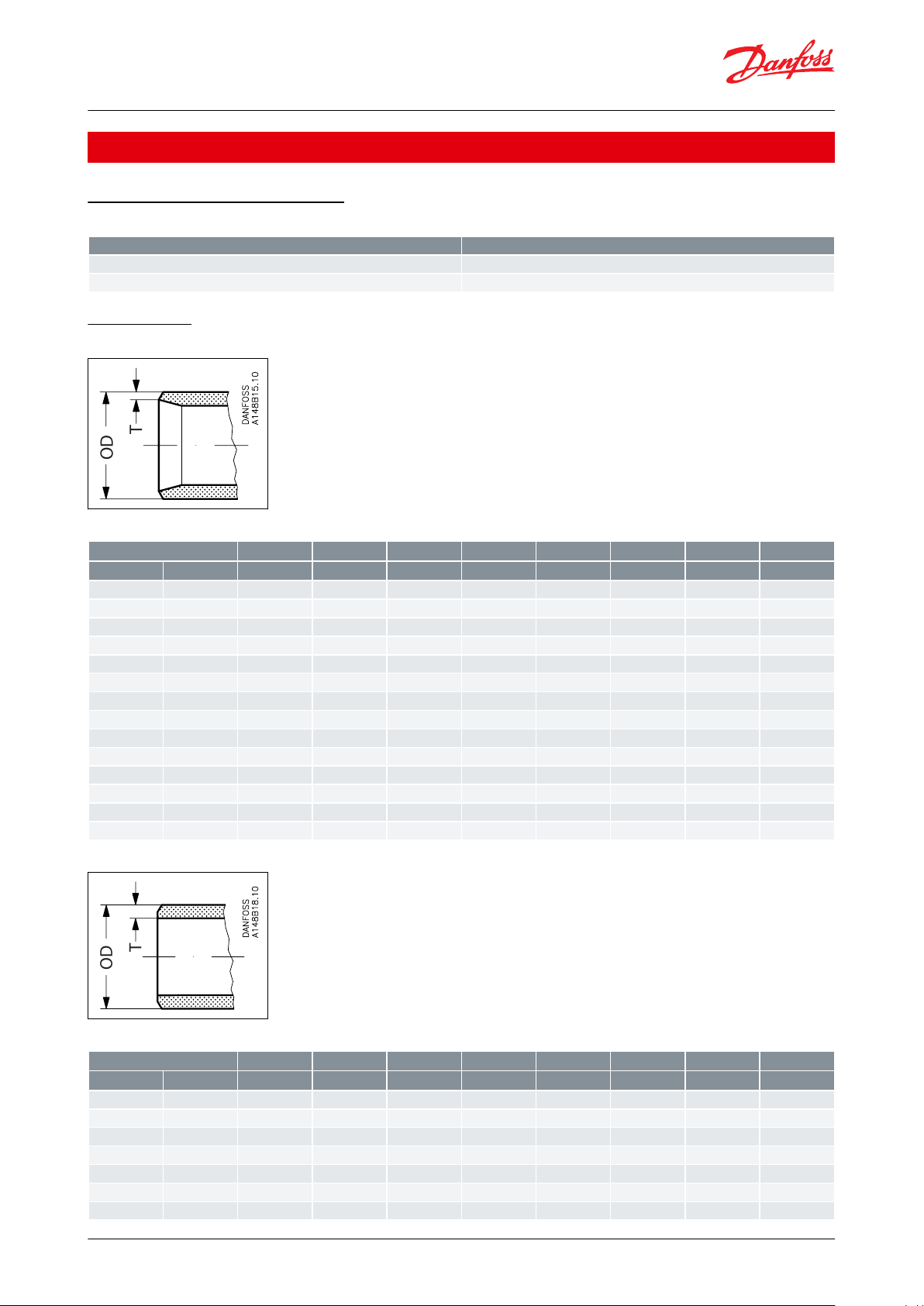

Figure 1: DIN

Table 2: Butt-weld DIN (EN 10220)

Figure 2: ANSI

Table 3: Butt-weld ANSI (B 36.10 Schedule 80)

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 3

Size

ODTOD

T

kv-angle

kv-straight

Cv-angle

Cv-straight

mm

in.mmmm

in.

in.

m3/h

m3/h

USgal/min

USgal/min

50260.3

3.9

2.37

0.1580659376652½

73.0

5.2

2.87

0.20

12097140

113803

88.9

5.5

3.50

0.22

182

152

211

176

1004114.3

6.0

4.50

0.24

313

278

363

323

1255141.3

6.6

5.56

0.26

514

470

596

545

1506168.3

7.1

6.63

0.28

785

597

911

693

2008219.1

8.2

8.63

0.32

1168

1024

1355

1188

Size

IDLOD

T

kv-angle

kv-straight

Cv-angle

Cv-straight

mm

in.mmmmmmmm

m3/h

m3/h

USgal/min

USgal/min

6¼6

7.7

12.7

3.35

2.9

2.0

3.4

2.410⅜108

15.88

2.94

4.5

3.2

5.2

3.615½168

21.3

2.65

7.0

4.9

8.1

5.720¾2211

26.9

2.45

14.6

10.2

16.9

11.82512811

33.7

2.85

24.8

17.4

28.8

20.2321¼3515

42.4

3.7

42.6

29.8

49.4

34.6401½4215

48.3

3.15

45.2

31.6

52.4

36.75025413.5

60.3

3.1580659376652½6413.5734.5

12097140

113803

76.11588.9

6.4

182

152

211

176

1004108

17.5

1185313

278

363

323

SizeIDLODT

k

v

-angle

k

v

-straight

C

v

-angle

C

v

-straight

in.mmmmmmmm

m

3

/h

m

3

/h

USgal/min

USgal/min

¼

6.35

7.7

12.7

3.18

2.9

2.0

3.4

2.4⅜9.53815.88

3.18

4.5

3.2

5.2

3.6⅝15.88821.3

2.71

7.0

4.9

8.1

5.7⅞22.231126.9

2.34

14.6

10.2

16.9

11.8

1⅛28.581133.7

2.56

24.8

17.4

28.8

20.2

1⅜34.931542.4

3.74

42.6

29.8

49.4

34.6

1⅝41.281548.3

3.51

45.2

31.6

52.4

36.7

2⅛54

13.5

60.3

3.1580659376

Strainer housing, type FIA 65

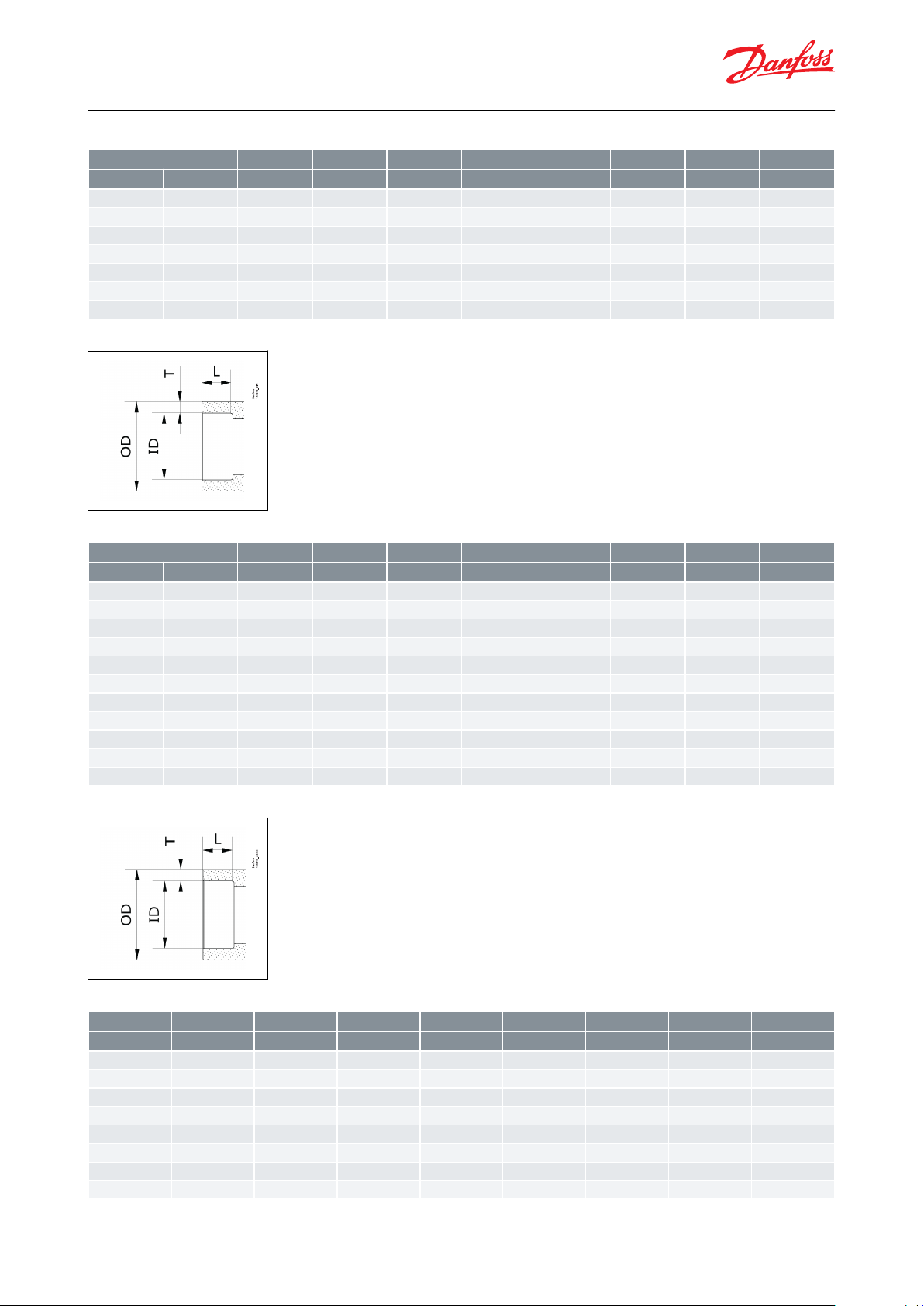

Table 4: Butt-weld ANSI (B 36.10 Schedule 40)

Figure 3: SD (DIN )

Table 5: Socket-Brazing DIN ( EN 1254-5)

Figure 4: SA (ASME)

Table 6: Socket-Brazing ASME (ASME B16.50)

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 4

SizeIDLODT

kv-angle

kv-straight

Cv-angle

Cv-straight

in.mmmmmmmm

m3/h

m3/h

USgal/min

USgal/min

2⅝

66.7

13.5

76.1

4.70

12097140

1133⅛79.381588.9

4.76

182

152

211

1764⅛104.78

17.5

114.3

4.76

313

278

363

323

Copper pipe diameter

Tolerance

≥3mm up to ≤18 mm

±0,04 mm

Over 18 mm up to ≤28 mm

±0,05 mm

Over 28 mm up to ≤54 mm

±0,06 mm

Over 54 mm up to ≤76,1 mm

±0,07 mm

Over 76,1 mm up to ≤88,9 mm

±0,07 mm

Over 88,9 mm up to ≤108 mm

±0,07 mm

Size

[DN]

Parts program

Service

kit

(1)

Complete valve

Housing

Top complete

O-ring kit

for

SVA (cap)

FIA

ANG

STR

SVA-

S

(cap)

SVA-

L

(cap)

SCA-XCHV-XREG-SAREG-

SB

FIA

R717

Heat

Pump

R1270

Pro‐

py‐

lene

ANG

STR

ANG

STR

DIN

AN‐

SI

SDSADIN

AN‐

SI

SDSADIN

AN‐

SI

DIN

AN‐

SI

DIN

AN‐

SI

DIN

AN‐

SI

6xxxxxxxxxxx10xxxxxxxxxxxxxxx15xxxxxxxxxxxxxxxxxxx20xxxxxxxxxxxxxxxxxxx25xxxxxxxxxxxxxxxxxxx32xxxxxxxxxxxxxxxxxxx40xxxxxxxxxxxxxxxxxxx50xxxxxxxxxxxxxxxxx65xxxxxxxxxxxxxxxxx80xxxxxxxxxxxxxxxx

100xxxxxxxxxxxxxxxx

125xxxxxxxxxxxx

150xxxxxxxx

200xxxxxxxx

Strainer housing, type FIA 65

The design ts with all copper pipes having following tolerance to the nominal diameter.

Table 7: Tolerance for nominal diameter

Table 8: Available SVL products for 65 bar (943 psi)

(1)

(1)

To be used for SCA-X, CHV-X (all sizes) and REG-SA/SB (sizes 10 to 40).

To be used for SCA-X, CHV-X (all sizes) and REG-SA/SB (sizes 10 to 40).

x = Available

Design

Strainer Insert

A lter grid and lter net of stainless steel ensure long element life. The lter net oers a very high degree of

cleanability.

Housing

The strainer housing is made of special, cold resistant steel.

Installation/Maintenance

The strainer is designed to resist high internal pressures. However, the piping system in general should be designed

to avoid liquid traps and reduce the risk of hydraulic pressure caused by thermal expansion.

Install the strainer with the cover in downward position.

Danfoss recommends replacement/cleaning of the strainer when the dierential pressure loss >0.5 bar (7.3 psi) in

the liquid line and >0.05 bar (0.7 psi) in the suction line. The max. permissible dierential pressure is 1 bar (15 psi).

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 5

P

S

6

5

/

9

4

3

p

s

i

g

S

T

R

A

I

N

E

R

F

I

A

D

N

8

0

/

3

”

@

–

6

0

°

C

\

–

7

6

°

F

→

1

5

0

°

C

\

3

0

2

°

F

Danfoss

M148G0020

First start up:

(Use strainer element with removable insert for FIA DN15-40 or separate lter bag

for FIA DN 50-200. 50μ insert should normally

be removed after the rst 24 hours of operation)

50μ

Ahead of pumps:

500μ [38 mesh]

After pumps:

150μ [100 mesh] / 250μ [72 mesh]

In front of AKVA valves:

100μ [150 mesh]

Generally

150μ [100 mesh] / 250μ [72 mesh]

Sensitive equipment, e.g.

suction regulators with low temperature

250μ [72 mesh]

Ahead of screw compressor

250μ [72 mesh]

Ahead of piston compressor

150μ [100 mesh]

Connection

size (DN)

μ

Mesh

Wire

Wire

Free space

Screen area

Plain elements

Pleated elements

FIAmmin.

%

cm2in2cm2in

2

15 - 20

(½” - ¾”)

100

0.068

0.0033525

3.9457.0

150

100

0.10

0.0043625

3.9457.0

250720.10

0.0045125

3.9457.0

500380.16

0.006

57.6253.9457.0

25 - 40

(1” - 1½”)

100

0.068

0.003357111160

25.0

150

100

0.10

0.004367111160

25.0

250720.10

0.004517111160

25.0

500380.16

0.006

57.67111

160

25.0

Strainer housing, type FIA 65

For further information refer to installation instruction for FIA.

Figure 5: Example of marking ring, FIA

Selection of strainer size

The mesh aperture size of the strainer must satisfy the requirements stated by the suppliers of the equipment to be

protected.

The following recommendations of aperture size apply in general to refrigeration installations:

Table 9: All lines

Table 10: Liquid Lines

Table 11: Protection of automatic regulation equipment

Table 12: Suction Lines

NOTE:

Mesh is the number of threads per inch. μ (microns) is the distance between two threads (1μ = 1 /1000 mm).

Table 13: Flow coecient (DIN/ANSI)

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 6

Connection

size (DN)

μ

Mesh

Wire

Wire

Free space

Screen area

Plain elements

Pleated elements

FIAmmin.

%

cm2in2cm2in

2

50 (2”)

100

0.068

0.003357111200

31.2

150

100

0.10

0.0043687

13.5

200

31.2

250720.10

0.0045187

13.5

200

31.2

500

0.16

0.006

57.68713.5

200

31.2

65 (2½”)

150

100

0.10

0.00436127

19.7

305

47.6

250720.10

0.00451127

19.7

305

47.6

500

0.16

0.006

57.6

127

19.7

305

47.6

80 (3”)

150

100

0.10

0.00436205

31.8

450

70.2

250720.10

0.00451205

31.8

450

70.2

500380.16

0.006

57.6

205

31.8

450

70.2

100 (4”)

150

100

0.10

0.00436370

57.4

790

123.2

250720.10

0.00451370

57.4

790

123.2

500380.16

0.006

57.6

370

57.4

790

123.2

125 (5”)

150

100

0.10

0.00436510

79.1

1105

172.4

250720.10

0.00451510

79.1

1105

172.4

500380.16

0.006

57.6

510

79.1

1105

172.4

150 (6”)

150

100

0.10

0.00436726

112.5

1600

249.6

250720.10

0.00451726

112.5

1600

249.6

500380.16

0.006

57.6

726

112.5

1600

249.6

200 (8”)

150

100

0.10

0.004361315

203.8

2900

453.1

250720.10

0.004511315

203.8

2900

453.1

500380.16

0.006

57.6

1315

203.8

2900

453.1

DN

FIA angle - plain lter net

FIA angle - pleated lter net

μ100

μ150

μ250

μ500

μ150

μ250

μ500

15

3.3

3.4

3.5

3.7

4.2206.9

7.1

7.3

7.7

8.82513.8

14.0

14.5

15.2

17.2

17.93223.0

23.8

24.7

25.5

29.2

30.54025.1

25.5

26.4

28.1

31.4

32.65045.1

45.9

47.6

50.2

56.7

58.8

62.06556.1

57.8

60.4

69.3

71.4

74.680104.6

108.0

113.1

129.2

133.4

139.7

100

162.4

167.5

176.0

200.6

206.9

217.4

125

275.4

283.9

298.4

340.2

350.7

368.6

150

362.1

373.2

391.9

447.3

462.9

200

572.9

590.8

620.5

704.9

730.0

DN

FIA straight - plain lter net

FIA straight - pleated lter net

μ100

μ150

μ250

μ500

μ150

μ250

μ500

15

2.5

2.6

2.7

2.8

3.3205.3

5.4

5.6

5.9

6.92510.5

10.7

11.1

11.6

13.8

14.53217.6

18.2

18.9

19.5

23.9

24.74019.2

19.5

20.2

21.5

25.5

26.45034.5

35.1

36.4

38.4

45.9

47.6

50.26542.9

44.2

46.2

56.1

57.8

60.48080.0

82.6

86.5

104.6

108.0

113.1

100

124.2

128.1

134.6

162.4

167.5

176.0

125

210.6

217.1

228.2

275.4

283.9

298.4

150

276.9

285.4

299.7

362.1

374.0

200

438.1

451.8

474.5

570.8

587.3

Strainer housing, type FIA 65

Table 14: kv values for FIA angle - plain lter net/pleated lter net

Table 15: kv values for FIA straight - plain lter net/pleated lter net

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 7

1

2

3

5

7

4

6

6

5

7

4

3

2

1

No.

Part

Material

DIN

ISO

ASTM

1

Housing

Steel

G20Mn5QT, 10213-3

P285QH+QT, 10222-4

LCC, A352

LF2, A350

2

Gasket

Fibre, Non-asbestos

3

Cover

Steel

P285QH EN10222-4

P275NL1 or 2 EN10028-3

LF2, A350

A, A662

4

Bolts

Stainless steel

A2-70

A2-70

Type 308

5

Marking label

Aluminium

6

Strainer insert

Stainless steel

7

Pressure relief screw NPT ¼”

Stainless steel

1

2

3

4

2

7

8

5

6

1

3

4

6

5

8

7

No.

Part

Material

DIN

ISO

ASTM

1

Housing

Steel

G20Mn5QT, 10213-3

P285QH+QT, 10222-4

LCC, A352

LF2, A350

2

Gasket

Fibre, Non-asbestos

3

Cover

Steel

P285QH EN10222-4

P275NL1 or 2 EN10028-3

LF2, A350

A, A662

4

Bolts

Stainless steel

A2-70

A2-70

Type 308

5

Marking label

Aluminium

6

Strainer insert

Stainless steel

7

Pressure relief screw G½”

Stainless steel

8

(1)

Packing washer

Aluminium

Strainer housing, type FIA 65

Material specication

Figure 6: FIA 15 - 40 (½ in. - 1 ½ in.)

Table 16: FIA 15 - 40 (½ in. - 1 ½ in.)

Figure 7: FIA 50 - 200 (2 in. - 8 in.)

Table 17: FIA 50 - 200 (2 in. - 8 in.)

(1)

(1)

pos 8 used in FIA 50-200

pos 8 used in FIA 50-200

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 8

A

Straightway

E

C

Cmin.

Fmin.

H

Angleway

H

A

C

A

Fmin.

Strainer size

ACH

F

min.

Weight

FIA 15-20

(½" - ¾")

mm451056068

1.1 kg

in.

1.77

4.13

2.36

2.68

2.4 lbs

FIA 25-40

(1" - 1½")

mm551327095

1.7 kg

in.

2.17

5.20

2.76

3.74

3.7 lbs

FIA 50

(2")

mm601327792

2.8 kg

in.

2.36

5.20

3.03

3.62

6.2 lbs

FIA 65

(2½")

mm7015290107

3.8 kg

in.

2.76

5.98

3.54

4.21

8.4 lbs

Strainer size

A

C

C

min.

H

E

F

min.

Weight

FIA 15-20

(½" - ¾")

mm

120991336020681.4 kg

in.

4.72

3.90

5.24

2.36

0.79

2.68

3.1 lbs

FIA 25-40

(1" - 1½")

mm

155

129

1777026952.4 kg

in.

6.10

5.08

6.97

2.76

1.02

3.74

5.3 lbs

FIA 50

(2")

mm

148

138

1847732923.5 kg

in.

5.83

5.43

7.24

3.03

1.26

3.62

7.7 lbs

FIA 65

(2½")

mm

176

165

2199040

107

5.3 kg

in.

6.93

6.50

8.62

3.54

1.57

4.21

11.7 lbs

Strainer housing, type FIA 65

Dimensions and weights

Figure 8: FIA 15 - 65 Angleway/Straightway dimensions

Table 18: Angleway

Table 19: Straightway

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 9

Danfoss

M148G0015_1

Danfoss

M148G0014_1

Fmin.

A

C

øH

øH

Cmin

C

E

A

Fmin.

Angleway Straightway

Strainer size

ACøH

F

min.

Weight

FIA 80

(3")

mm90189

129

133

7.3 kg

in.

3.54

7.44

5.08

5.24

16.1 lbs

FIA 100

(4")

mm

106

223

156

163

11.9 kg

in.

4.17

8.78

6.14

6.42

26.2 lbs

FIA 125

(5")

mm

128

268

192

190

21.2 kg

in.

5.04

10.6

7.56

7.48

46.7 lbs

FIA 150

(6")

mm

145

303

219

223

30.5 kg

in.

5.71

11.93

8.62

8.78

67.2 lbs

FIA 200

(8")

mm

180

372

276

280

68 kg

in.

7.09

14.65

10.87

11.02

150 lbs

Strainer size

A

C

C

min.

øH

E

F

min.

Weight

FIA 80

(3")

mm

216

204

271

12948133

8.6 kg

in.

8.50

8.03

10.67

5.08

1.89

5.24

19 lbs

FIA 100

(4")

mm

264

256

337

15660163

14.9 kg

in.

10.39

10.08

13.27

6.14

2.36

6.42

32.8 lbs

FIA 125

(5")

mm

322

313

408

19274190

26.9 kg

in.

12.68

12.32

16.06

7.56

2.91

7.48

59.3 lbs

FIA 150

(6")

mm

370

370

482

21991223

51 kg

in.

14.57

14.57

18.98

8.62

3.58

8.78

112 lbs

FIA 200

(8")

mm

464

465

605

276

117

280

95 kg

in.

18.27

18.31

23.82

10.87

4.61

11.02

209 lbs

Strainer housing, type FIA 65

Figure 9: FIA 80 - 200 Angleway/Straightway

Table 20: Angleway

Table 21: Straightway

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 10

FIA size

Strainer insert

100μ 150 mesh

Strainer insert

150μ 100 mesh

Strainer insert

250μ 72 mesh

Strainer insert

500μ 38 mesh

Pleated Strainer

insert 150μ 100

mesh

Pleated Strainer

insert 250μ 72

mesh

Pleated Strainer

insert 500μ 38

mesh

mm

in.

15

½

148H3122

148H3124

148H3126

148H3128

148H3303

148H3363

-

20¾25

1

148H3123

148H3125

148H3127

148H3129

148H3304

148H3269

-

321¼401½502148H3157

148H3130

148H3138

148H3144

148H3179

148H3184

148H3189

652½-

148H3131

148H3139

148H3145

148H3180

148H3185

148H3190

803-

148H3119

148H3120

148H3121

148H3181

148H3186

148H3191

1004-

148H3132

148H3140

148H3146

148H3182

148H3187

148H3192

1255-

148H3133

148H3141

148H3147

148H3183

148H3188

148H3193

1506-

148H3134

148H3142

148H3148

148H3226

148H3293

(1)

-

2008-

148H3135

148H3143

148H3149

148H3297

148H3294

(1)

-

Part

Accessory for

Code number

Magnet insert

FIA 65-100

148H3447

FIA 125-200

148H3448

Strainer element μ150 with removable element μ50

for the rst start up

FIA 15-20

148H3301

FIA 25-40

148H3302

Filter bag

FIA 50

148H3150

FIA 65

148H3151

FIA 80

148H3152

FIA 100

148H3153

FIA 125

148H3154

FIA 150

148H3155

FIA 200

148H3156

Purge valve complete

FIA 50 - 300

148B3745

Blind nut with gasket

148H3450

Strainer housing, type FIA 65

Ordering

Strainer element

Please note that you have to order FIA strainer without element, a strainer element and accessories.

Table 22: Strainer elements

(1)

(1)

60 mesh

60 mesh

Accessories

Table 23: Accessories

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 11

File name

Document type

Approval authority

RU Д-DK.БЛ08.B.00828_19

EAC Declaration

EAC

0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

TÜV

03709-F0 BV

Marine - Safety Certicate

BV

RU Д-DK.РА01.B.32851_20

EAC Declaration

EAC

RU C-DK.БЛ08.B.01095_20

Pressure - Safety Certicate

EAC

TAP000000S Rev. 1

Marine - Safety Certicate

DNV GL

EU 033F0685.AK

EU Declaration

Danfoss

MD 033F0691.AE

Manufacturers Declaration

Danfoss

MD 033F0686.AH

Manufacturers Declaration

Danfoss

0045 202 1204 Z 00355 19 D 001(00)

Pressure - Safety Certicate

TÜV

033F0453.AD

Manufacturers Declaration

Danfoss

19.10048.266

Marine - Safety Certicate

RMRS

CRN.0C16578.523467890YTN

Pressure - Safety Certicate

TSSA

07 202 STK1 Z 0540-2-D-01

Pressure - Safety Certicate

TUV

0045 202 1201 Z 00424 19 D 001(00)

Pressure - Safety Certicate

TÜV

Strainer housing, type FIA 65

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 24: Certicates and declarations

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 12

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.04 AI367729235609en-000101 | 13

Loading...

Loading...