Page 1

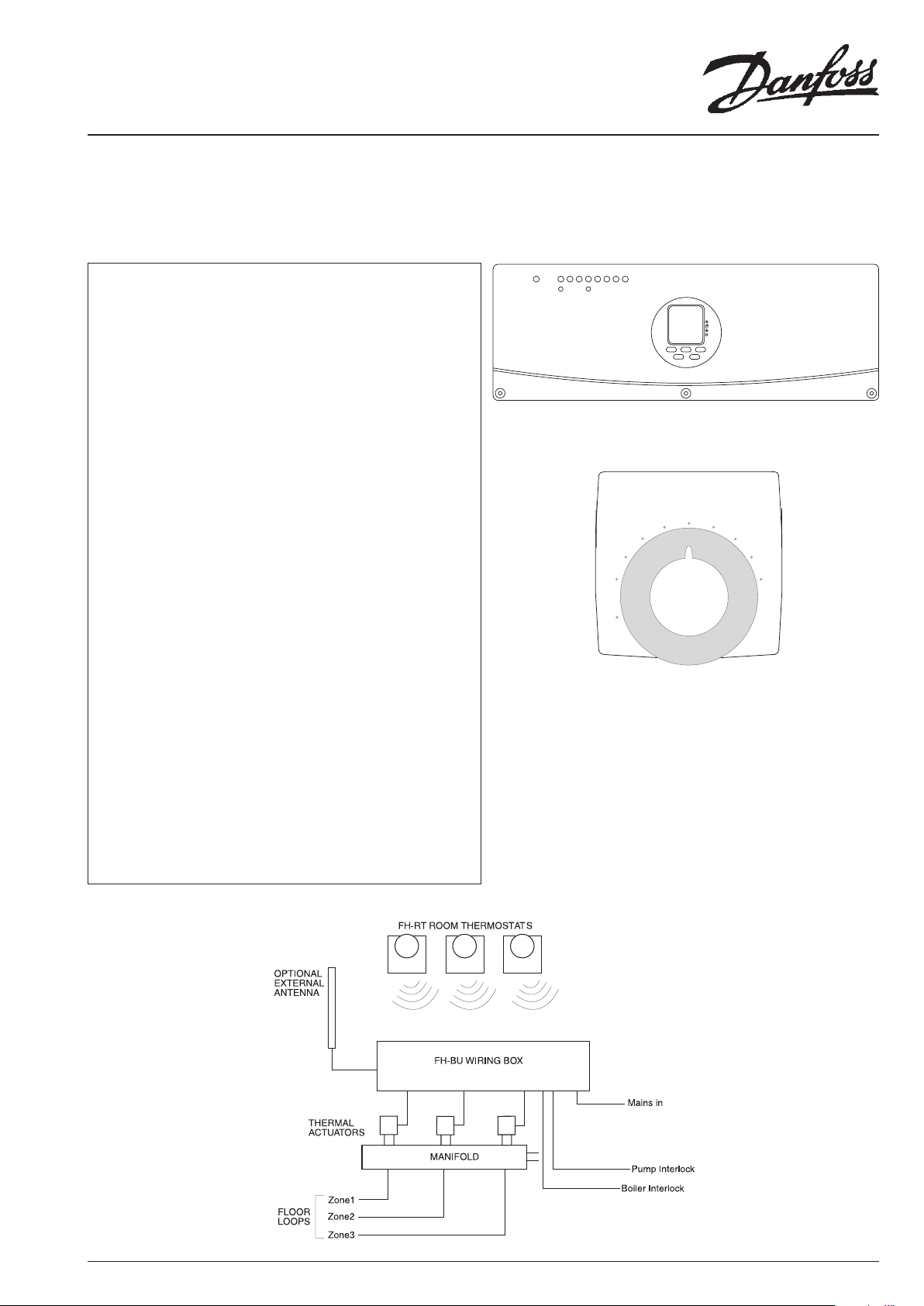

FH-RT Wireless Room Thermostat

Power

Mode OK

12345678

80 mm

30 mm

10

20

30

FH-BU Wireless Base Unit

Installation & Operating Instructions

Specification

Base unit (230 V)

Order Code: 088H011901

Primary voltage: 230 V a.c.

Secondary voltage: 230 V a.c.

Outputs 1-6: 230 V a.c., 1 A max., relay

controlled

Outputs 7-8: 8 A, 230 V a.c./50 Hz, relay

controlled, convertible to

volt-free outputs

Max. no. of thermostats: 8 (wireless)

Max. no. of thermal actuators: 20

Max. no. of thermal actuators

per output: 4

Output 8 run-on time: 10 min

Thermal actuator & pump exercise Once daily (approx. every 24

hours after connecting the

power supply for the first

time)

Settings after power failure: User settings are retained

Enclosure: IP20

Dimensions [mm] 310 x 110 x 55

Ambient temperature: 0-50°C

Humidity: Less than 85%

Thermostat

Order Code: 088H012100

Temperature scale: 6-30°C +/- 2K

Hysteresis: +/- 0.5°C

Scale accuracy: 2K around set point

Night set-back: 4K at 20°C

Frequency: 433.70 MHz

Battery life: Min. 5 years

Battery type: 3.6 V lithium battery, 2100

mAh, size AA

Transmission range: Up to 30 m (radius)

Transmission interval: 2-30 min

Ambient temperature: 0-50°C

Humidity: Less than 90%

System Schematic

1

Page 2

2

These installation and operating instructions describe system function and technical data.

10

20

30

Power

Mode OK

12345678

The system is a complete floor heating control system for individual rooms in dwellings, offices, institutions, business premises, etc.

The system is based on data transfer via radio, and is therefore quick and easy to install.

The system was developed to meet requirements for comfort, heat economy, flexibility and user-friendly operation.

Fig. 1. The system consists of a base unit, thermostat and, if necessary, an external aerial.

2.0 Operating principle

The system consists of two unit types: base unit and thermostat.

The base unit is connected to a 230 V supply and through eight outputs

controls the thermal actuators that regulate the flow of hot water to the

individual rooms. The system can also control circulation pump and boiler.

The base unit is centrally located in the dwelling adjacent to the distribution

manifold.

2.1 Base unit

The base unit is the system interface. It consists of a control panel, radio

receiver and alarm.

If faults occur in the wireless data transfer, the base unit raises an alarm in

order to make users aware of the fault. The alarm also informs the user when a

thermostat requires a new battery. The receiver in the base unit continuously

scans the radio signals it receives from installed thermostats.

The base unit is usually installed about 1.5 metres above the floor in order

to make the control panel easily accessible. Installation at this height also

enhances the radio signal range of the system.

2.2 Thermostat

Up to eight thermostats can be connected to the system. One thermostat

can be used to control several thermal actuators. Thermostats are positioned

at suitable locations in rooms where temperature control is required.

Thermostats have a knob for setting the desired temperature and a switch

for selecting one of three programs (day, timer control and night).

Each thermostat contains a small battery that supplies current to an electronic

temperature measuring circuit with associated radio transmitter. At suitable

intervals the measured temperature is sent as a radio signal to the radio

receiver in the base unit. If the temperature is changed the thermostat will

transmit the new temperature after the suitable interval. For transmission

test please see section on Transmission Testing, or Thermostat Test Mode.

Thermostats have no external cable connections.

Each thermostat has a unique identification (ID) number that is sent with

every transmission. The base unit uses these ID numbers to distinguish

the various thermostats. Thermostats must therefore be registered in the

base unit before the unit is able to receive data from the thermostats.

During registration, thermostats transfer their ID numbers to the base unit.

The use of ID numbers also prevents the base unit from reacting to signals

received from neighbouring systems or other systems based on radio

technology.

Thermostats are battery powered and thus fully mobile, making it easy to

re-configure the system if required.

The system is CE marked and approved for use in all EU and former EFTA

countries.

The actual temperature is measured by the thermostat. When the actual

temperature is lower than the set temperature, a command for heat is sent

to the base unit.

Temperature can be set between 6°C and 30°C. A function switch on the

thermostat allows day, timer control or night to be selected. The day setting

allows normal operation, the timer setting allows time-controlled night setback to be used, and the night setting permanently lowers the temperature

setting by 4°C.

Thermostats are supplied with pre-installed batteries. Before being taken

into use, thermostats are “dormant” and only begin measuring temperature

and transmitting data on being registered in the base unit for the first time.

The purpose of this dormant state is to minimise energy use during storage

and to avoid unnecessary radio transmission.

On being installed for the first time, thermostats automatically enter test

mode so that transmission can be tested immediately.

Battery life is guaranteed by the manufacturer to be at least 5 years.

A complete system is illustrated above in Fig. 1.

2.3 Aerial

Normally, the base unit uses a built-in aerial.

The location of the base unit is therefore important for the range, which can

be increased by equipping the base unit with an external aerial.

An external aerial must be used if the base unit is located in a metal

cabinet.

Page 3

3

3.0 Installation instructions

Ca. 1,5m

Power

123 45678

Mode OK

4.0 Operating instructions

The system should be installed by a competent person in the following

sequence.

3.1 Base unit

Install the base unit first. Mount the base unit above the distribution manifold

either direct on the wall or inside a wooden or metal distribution cabinet.

Ensure that the base unit is mounted horizontally, that there is easy access

to the control panel and thermal actuator connections, and that the base

unit cover can be easily removed. Fix the base unit to the wall using two

screws.

The base unit must be connected to a 230 volt supply via a double pole switch

socket outlet. If it is installed in a metal distribution cabinet, an aerial should

be installed outside the cabinet in order to improve radio communication.

3.2 Thermostat installation

Thermostats should be mounted on an internal wall at a height of 1.2-1.5

metres above the floor, using screws and fixings.

Thermostats must not be placed on an external wall or near heat sources

such as television and stereo sets, ovens or similar. Thermostats should not

normally be placed where they can be affected by direct sunshine. In rooms

that are very humid or damp, e.g. bathrooms, thermostats must be placed

as far from moisture sources as possible.

3.3 Pre-installation

4.1 Thermal actuator installation

1. Ensure that the power supply to the base unit is disconnected.

2. Lift base unit cover after loosening front screws.

3. Remove internal aerial.

4. Remove blue thermal actuator terminals from printed circuit

board.

5. Connect thermal actuator cables.

6. Reattach thermal actuator terminals in assigned order to printed circuit

board.

7. Position cables in strain-relief cable glands (see Fig 3).

8. Replace internal aerial.

9. Close base unit and tighten front screws

Thermostats must be registered in the base unit before being placed in

individual rooms.

When registering thermostats, it is important that the room in which they are

to be placed is written or marked on the rear of the thermostat. Thermostats

can then be registered in turn.

The channels to be used for individual rooms must therefore be decided

in advance.

Note: refer to section 4.3 for registration instructions

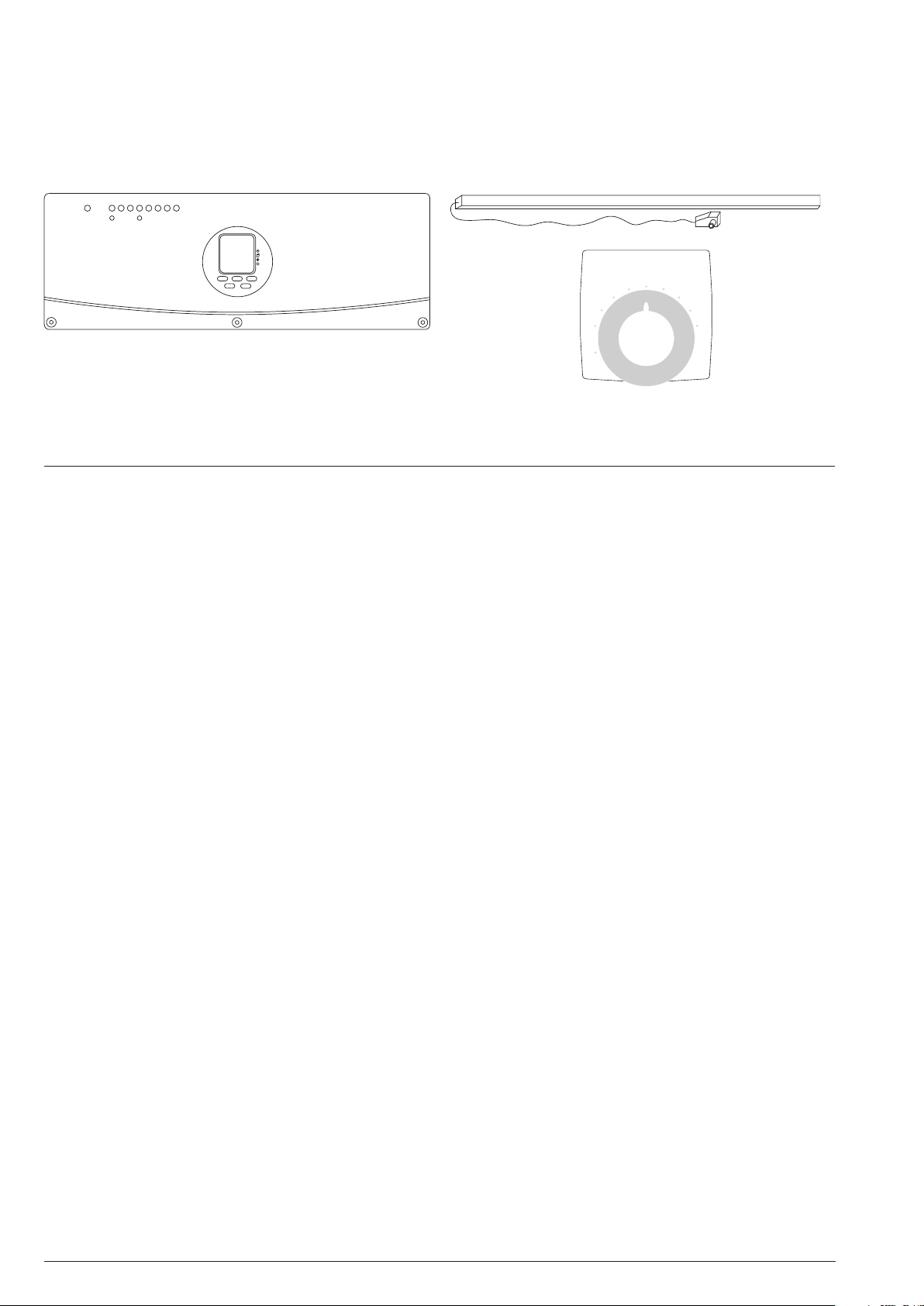

Fig. 2a. Thermostat location

Fig. 3. Push cable through cable gland.

4.2 Base unit installation

Once the base unit has been mounted on the wall, all thermal actuators

have been connected and any connections for pump and boiler control

have been made, the thermostats can be registered. First, power up the

base unit. The green ‘Power’ LED lights up.

Fig. 4. Control panel. LED indicators 1-8 and ‘Power’ LED.

Fig. 2b. Thermostat installation

Page 4

4

4.3 Thermostat registration

To get the FH-BU base into registration mode

Press and hold “MODE” and “OK” buttons on base unit for 3 seconds, (all LED’s

will flash) then release “MODE” and finally release “OK”. The system is now in

registration mode. Only the “POWER” LED should be on (unless thermostats

already have been assigned earlier- then the LED for these will be on)

Fig. 6. De-registering thermostats

Note: The system returns automatically to normal mode if no buttons are

pressed during a 5-minute period.

4.5 Setting room temperature

Fig. 5. Registration mode

Thermostat registration process

Using the point of a pencil press and release the thermostat transmission

button. The LED for the first available channel (1-8) will start to flash.

Select the channel to be assigned to the thermostat by pressing the “MODE”

button numerous times until the LED for the desired channel flashes. Then

press and hold “OK” for 3 seconds (the LED will flash and finally be on). The

thermostat is now registered. Repeat the thermostat registration process

for each thermostat. (Also if one thermostat should be assigned to several

channels).

After registering all thermostats, press and hold “MODE” for 3 seconds (all

LED’s will flash), to return the system to normal mode.

Note: The system returns automatically to normal mode if no buttons are

pressed during a 5-minute period.

4.4 De-registering thermostats

To get the FH-BU base unit into de-registration mode

Press and hold “MODE” and “OK” buttons for 3 seconds, (all LED’s will flash)

then release “OK”, and finally release “MODE”. The system is now in deregistration mode. (If only one thermostat is assigned the first assigned LED

will start to flash).

Press the thermostat transmission button. The LED for the first assigned

channel will start to flash, (the rest will be on). Select the channel to be deregistered by pressing the “MODE” button numerous times until the LED for

the desired channel flashes. Then press and hold “OK” for 3 seconds, (the LED

will flash and finally go out). The channel is now de-registered. Repeat the

thermostat de-registration process for each channel to be de-registered.

After de-registering thermostats, press and hold the “MODE” button for 3

seconds (all LED’s flash) to return the system to normal mode.

The temperature is set by turning the thermostat setting knob to the desired

temperature.

4.6 Setting min./max. temperature

Lift thermostat cover.

Set min./max. temperatures using the red and blue limiters respectively.

4.7 Setting thermostat operating mode

Switch position “sun” => normal => no night set-back.

Switch position “moon” => night set-back => 4°C at 20°C.

Switch position “clock” => timer-controlled set-back.

If timer-controlled set-back is required, it must be programmed via the time

clock/timer module (optional) fitted to the base unit.

5.0 Special functions

5.1 Master reset

This function deletes all registered data and reinstalls factory settings.

Switch off the power supply, press and hold “OK” and “MODE” simultaneously

and keep pressing them while switching the power back on.

LED indicators 1-8 then light up consecutively, and finally all eight indicators

flash. Release “OK” and “MODE”.

The system has now been reset to initial factory settings.

5.2 Transmission testing

Transmission testing is used to test and identify all registered thermostats.

Press and hold “OK” for 3 seconds (all LED indicators flash).

All channels with assigned thermostats light up on the indicator panel. When

a channel receives a signal from a thermostat, the corresponding indicator

flashes twice and the indicators go off. If a signal is subsequently received

from the same thermostat, the indicator for the corresponding channel

flashes twice.

The test is automatically terminated once all channels have received a signal

from their assigned thermostat.

Page 5

5

If no signal is received from one or more thermostats, the corresponding

LEDs on the indicator panel remain lit.

When the required number of thermostats have been checked, press and

hold “MODE” for 3 seconds to return the system to normal mode.

Note: The system returns automatically to normal mode if no buttons are

pressed during a 15-minute period.

5.3 Thermostat test mode

This mode is used to test thermostat transmission.

Using the point of a pencil or similar, press and hold the transmission button

on the front of the thermostat for 3 seconds.

This forces the thermostat to transmit a signal every 7 seconds for 5-6

minutes.

Then check whether a signal from the thermostat is received by the base

unit at 7 second intervals (the LED indicator for the assigned channel flashes

on receiving a signal).

The test can be terminated by again pressing the thermostat transmission

button.

Note: The system returns automatically to normal mode if no buttons are

pressed during a 5-minute period.

5.4 Thermal actuator output testing

Thermal actuator output testing is used to check the functioning of the base

unit output relays.

Press and hold the “MODE” button for 3 seconds (all LED indicators flash).

The first indicator then begins flashing.

Press “OK” to test the first channel. The LED indicator now flashes rapidly

(on/off at half-second intervals) and a small click can be heard after about 5

seconds indicating that the output has been activated. Press “OK” again to

de-activate the output.

Press “MODE” to select the next output to be tested, and repeat the process

described above.

The test can be terminated by pressing and holding the “MODE” button for

3 seconds.

Note: The system returns automatically to normal mode if no buttons are

pressed during a 10-minute period.

If after a further 8 hours the base unit has still not received a signal from the

thermostat, an acoustic alarm begins buzzing. The buzzer can be de-activated

by selecting the alarm “OFF” setting on the base unit (see Fig. 9). The alarm

is reset when a button on the control panel is pressed or when the base unit

receives a signal from the thermostat.

5.6 Thermal actuator & pump exercise

This function prevents the manifold valve and circulating pump from

sticking.

It is activated once yearly. First, all assigned outputs are activated for 5

minutes, and the pump output is then activated for 5 minutes (only if pump

output is installed).

The function can be turned off by switching the EXERCISE switch to the OFF

position. (See Fig. 10).

5.7 NO/NC thermal actuator settings

This function allows “Normally Closed’ (N/C) or “Normally Open” (N/O) thermal

actuators to be used.

Type is selected on the ACTUATOR switch (see Fig. 10).

5.8 “Cooling” mode

This mode allows thermostat signals to be inverted so that outputs are opened

when the temperature is above the desired temperature and closed when

below and is intended for use in cooling systems.

6.0 Boiler and pump interlock setting

As standard, outputs 7 and 8 are set to control thermal actuators.

However, output 7 can also be used to control a boiler via an ON/OFF signal,

and output 8 can be used to control a pump.

To enable a boiler or pump to be controlled, the system must be configured

as shown in Figs 8 and 9 respectively.

Note: If outputs 7 and 8 are not used for thermal actuators, the following

applies:

- LED indicators 7 and 8 light up when any other channel requires heat.

5.5 Alarm function

This function is initiated automatically in case of communication failure.

If the base unit does not receive a signal from a registered thermostat for 2

hours, the corresponding LED indicator starts flashing. Simultaneously, the

thermal actuator output begins a continuous cycle of 7 minutes’ activation

and 14 minutes’ de-activation.

Fig. 7. Switches

Fig. 9. Step 2. Bend left-hand jumper as illustrated.

Page 6

OUTPUT 7

MODE

SELECTION

OUTPUT 8

MODE

SELECTION

COOL

HEAT

TIMER

MMI MODULE

BUZZER

OFF -> ON

EXERCISE

OFF -> ON

ACTUATOR

NC -> NO

Min/ Max

indstilling

Tr ansmissionsknap

LED indikator

Indstilling af

natsænkning

DANSK VVS IMP ORT

8.0 Drawing of Base Unit & Thermostat

Connector for LEDs and buttons on lid

Aerial socket

Thermal actuators outputs 1-6

Fig. 10. Base Unit

Connector for timer module

Thermal actuator output 7

- alternatively:

boiler control

output

Special functions

Thermal actuator output 8

- alternatively:

pump control

output

Fuse holders

Power supply

connectors

LED indicator

Transmission button

Min/max setting

Thermostat mode switch

Fig. 11. Thermostat

9.0 Registration Record

Output Channel Room Circuit

1 1

2 2

3 1

4 2

5 1

6 2

7/boiler (optional) 1

8/pump (optional) 2

Part No: 90092v05 09/08

Danfoss Randall can accept no responsibilty for possible errors in catalogues, brochures and other printed material. Danfoss Randall reserves the right to alter its products without notice. This also

applies to products already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

Danfoss Randall Limited,

Ampthill Road,

Bedford, MK42 9ER

Telephone: (01234) 364621 Fax: (01234) 219705

Email: danfossrandall@danfoss.com

Website: www.danfoss-randall.co.uk

6

Loading...

Loading...