Data Sheet

FH-ME Floor Heating Manifold

Application

The FH-ME Manifold is used for controlling water

ow in under oor heating systems. Each tube of

the oor heating system is connected to the

manifold, thus making it possible to control water

ow or heat supply to each room in the building

individually.

The manifold consists of a supply and return

manifold. The supply manifold includes possibility for individual shut-o of each circuit and as a

ow adjustment. The return manifold is equipped

with integrated Danfoss RA connection.

The valves can be controlled electronically by

thermal actuators or act as self-acting units by

means of remote temperature adjusters.

The manifold is supplied in modules of 2 to 8

outlets. In addition extension pieces are available

for connecting the manifolds in series. Ball valves

are available as an option for positive shut-o

between manifold and system.

The end pieces FHF-EM and FHF-EA are supplied

with manual airvent or alternatively with

automatic airvent, purge and valve. The end

pieces are placed at the end of the manifold.

FH-ME supply

FH-ME return

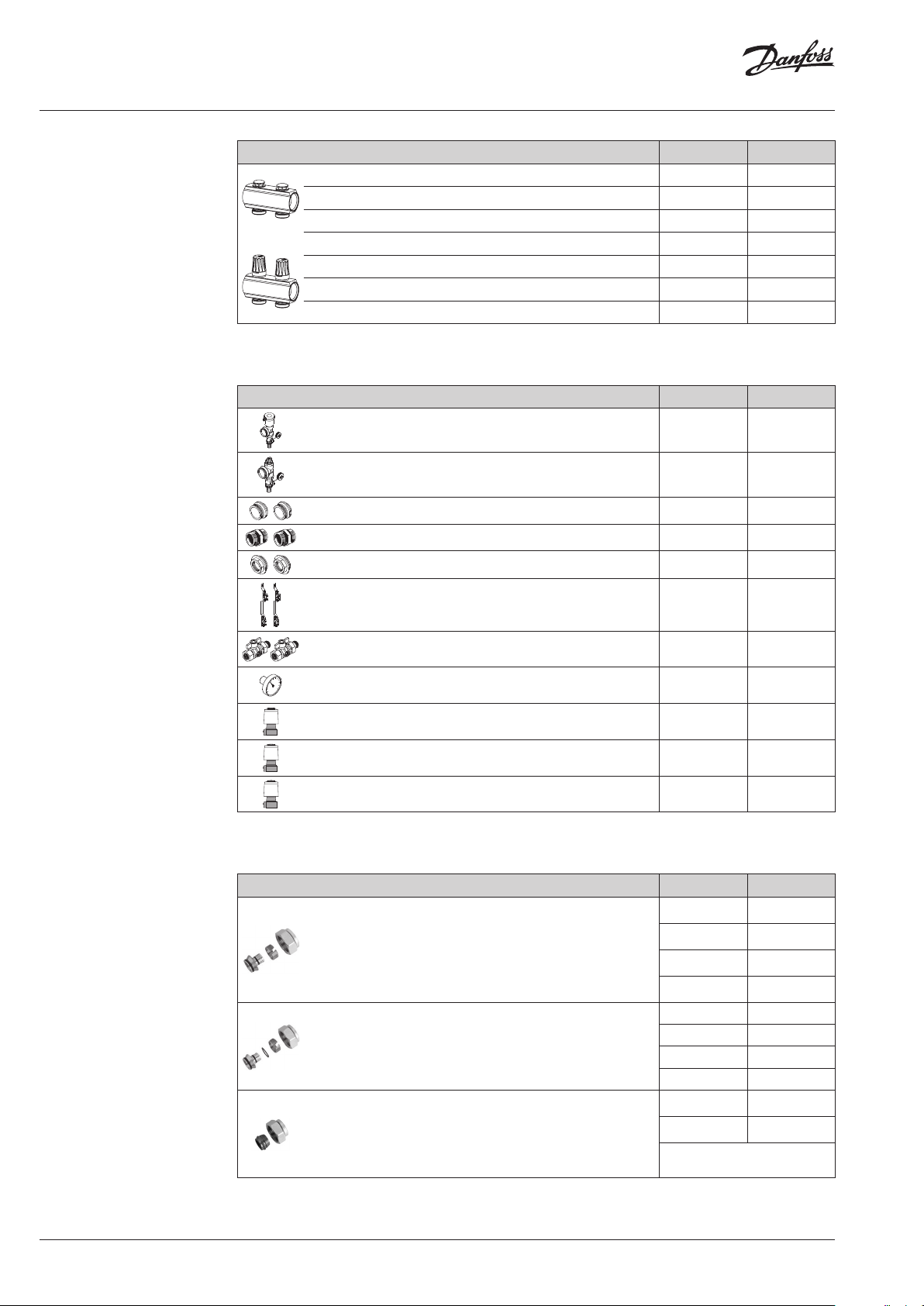

System Layout

VDUDT402

© Danfoss | FHH | 2015.10 | 1

Data Sheet

Ordering

Accessories

Description Typ e Code no.

Manifold set 2+2 FH-ME2 088U0612

Manifold set 3+3 FH-ME3 088U0613

Manifold set 4+4 FH-ME4 088U0614

Manifold set 5+5 FH-ME5 088U0615

Manifold set 6+6 FH-ME6 088U0616

Manifold set 7+7 FH-ME7 088U0617

Manifold set 8+8 FH-ME8 088U0618

Description Typ e Code no.

End section - automatic airvent and purge valve FHF-EA 088U0580

End section - manual airvent and purge valve FHF-EM 088U0581

End caps -set FHF-E 088U0582

Connection pieces - set FHF-C 088U0583

Reduction bushes/pieces -set 1" - 3/4" FHF-R 088U0584

Compression Fittings

Mounting brackets - set FHF-MB 088U0585

2 x ball valve 1” with tail piece - for connection to manifold

and for blocking of oor heating system

1 x thermometer 0-60°C Ø35mm - for ow/return temperature measurement

Thermal actuator, 24 V, NC, Danfoss RA connection to valve TWA-A 088H3110

Thermal actuator, 230 V, NC, Danfoss RA connection to

valve

Thermal actuator, 24 V, NC, with end switch, Danfoss RA

connection to valve

Description Type Code no.

Compression ttings for PEX tubing in accordance with ISO

15875.

• Max working pressure: 6 bar

• Test pressure: 10 bar

• Max. ow temperature: 95 °C

• G ¾” internal thread

Compression ttings for ALUPEX tubing.

• Max working pressure: 6 bar

• Test pressure: 10 bar

• Max. ow temperature: 95 °C

• G ¾” internal thread

Compression ttings for STEEL and COPPER tubing

• Max working pressure: 6 bar

• Test pressure: 10 bar

• Max. ow temperature: 95 °C

• G ¾” internal thread

FHF-BV 088U0586

FHF-T 088U0029

TWA-A 088H3112

TWA-A 088H3114

16x2 mm 013G4156

20x2 mm 013G4160

20x2.25 mm 013G4093

20x2.5 mm 013G4161

16x2 mm 013G4186

20x2 mm 013G4190

20x2.25 mm 013G4093

20x2.5 mm 013G4191

16 mm 013G4126

18 mm 013G4128

2 | © Danfoss | FHH | 2015.10

Note: Max ow temperature given by the tube manufacturer must not be exceeded.

VDUDT402

Data Sheet

4

Commissioning

Capacity

The pre-setting of the manifold valves determines the ow in the oor heating tubes and is

therefore an important factor for obtaining

optimal hydraulic balance in the system.

A correct hydraulic balance is important if

optimal comfort shall be achieved with a

minimum of energy consumption and is easily

carried out following the example shown below.

Example

Room 1: 1. Determine longest tube/largest room 25 m

2. Desired cooling (ΔT) 5° C (typical)

3. Determine heat requirement for the room 50 W/m

4. Conversion factor 1.16

5. Calculation of ow for the room

Q (l/h) =

50 W/m2 x 25 m

10° C x 1.16

2

= 108 l/h

Room 2: 6. Determine area for the next room 15 m2

7. Calculation of ow for the room (ΔT and heat

requirement is assumed identical for the rooms

in this case)

Q (l/h) =

50 W/m2 x 15 m

10° C x 1.16

2

= 65 l/h

The diagram shows the capacities of each

heating circuit for dierent settings of the ow

manifold.

The gures ¾ to 4 above the diagram indicate

how many turns of the key are required to obtain

¾ -

the correct water volume (count from closed

position onwards).

2

2

Operation Conditions

VDUDT402

Max. dierential pressure ................0.6 bar

Max. working pressure ...................10 bar

Max. test pressure ........................16 bar

Max. ow temperature ....................90° C

© Danfoss Danfoss | FHH | 2015.10 | 3

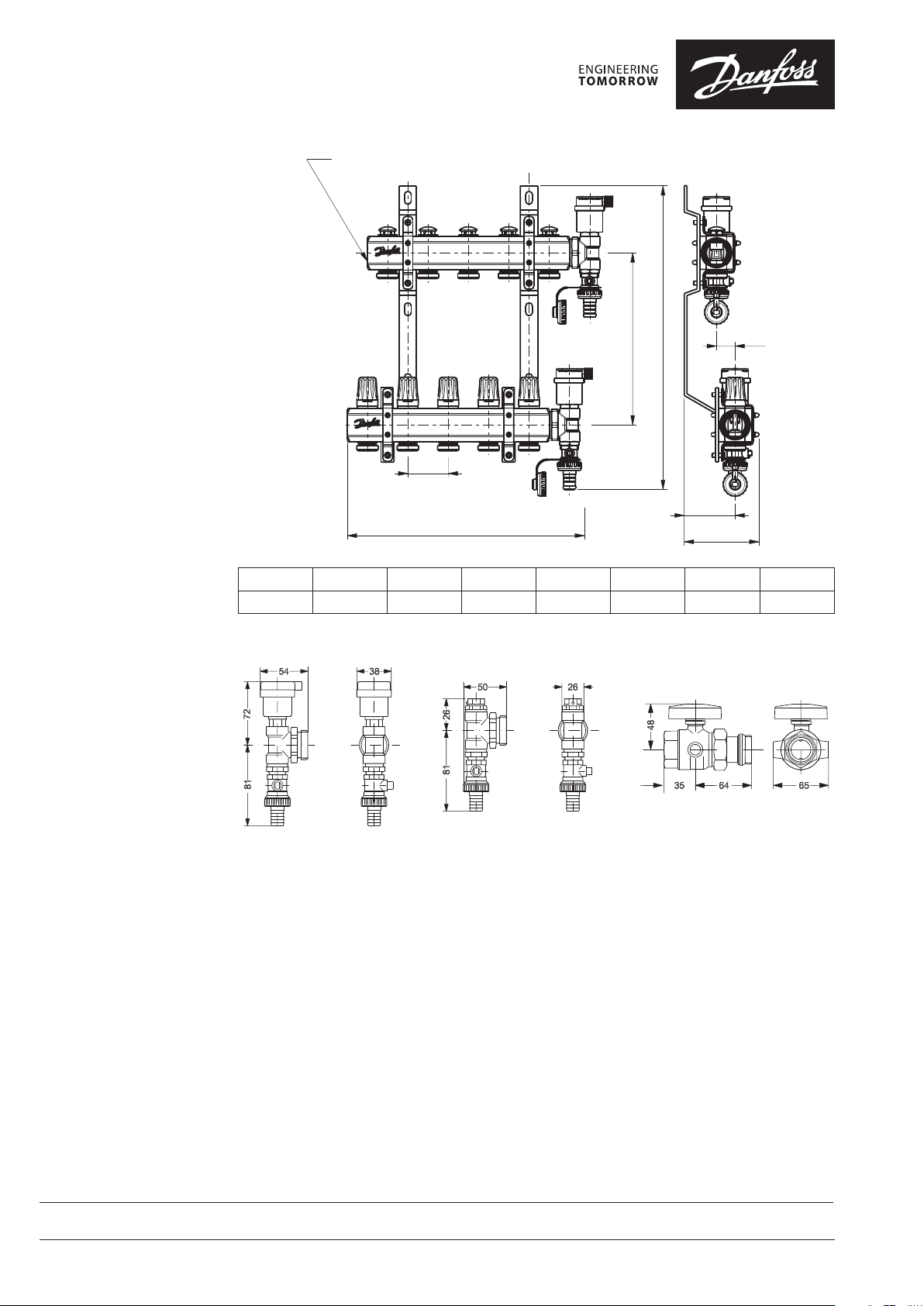

Dimensions

G1" ISO 228/1

23

95

50

376

213

63

L1

Typ e 2+2 3+3 4+4 5+5 6+6 7+7 8+8

L1 (mm) 143 193 243 293 343 393 443

Danfoss A/S

Floor Heating Hydronics • Ulvehavevej 61 • DK-7100 Vejle • Denmark • Phone: +45 7488 8500 • Fax: +45 7488 8501

heating@danfoss.com • www.oorheating.danfoss.com

Danfoss ca n accept no respons ibility for pos sible errors in ca talogues, bro chures and other pr inted material. Da nfoss reserves t he right to alter its p roducts with out notice. This als o applies to produ cts

already o n order provided t hat such alteratio ns can be made with out subsequenti al changes being n ecessary in spe cications alr eady agreed.

All trade marks in this mate rial are proper ty of the respec tive companies . Danfoss and the Dan foss logotyp e are trademark s of Danfoss A/S. Al l rights reserv ed.

4 | © Danfoss | Danfoss | FHH | 2015.10

VDUDT402

Loading...

Loading...