Installation Guide

FHM-CN5

Pre-assembled 3-Way Mixing Shunt

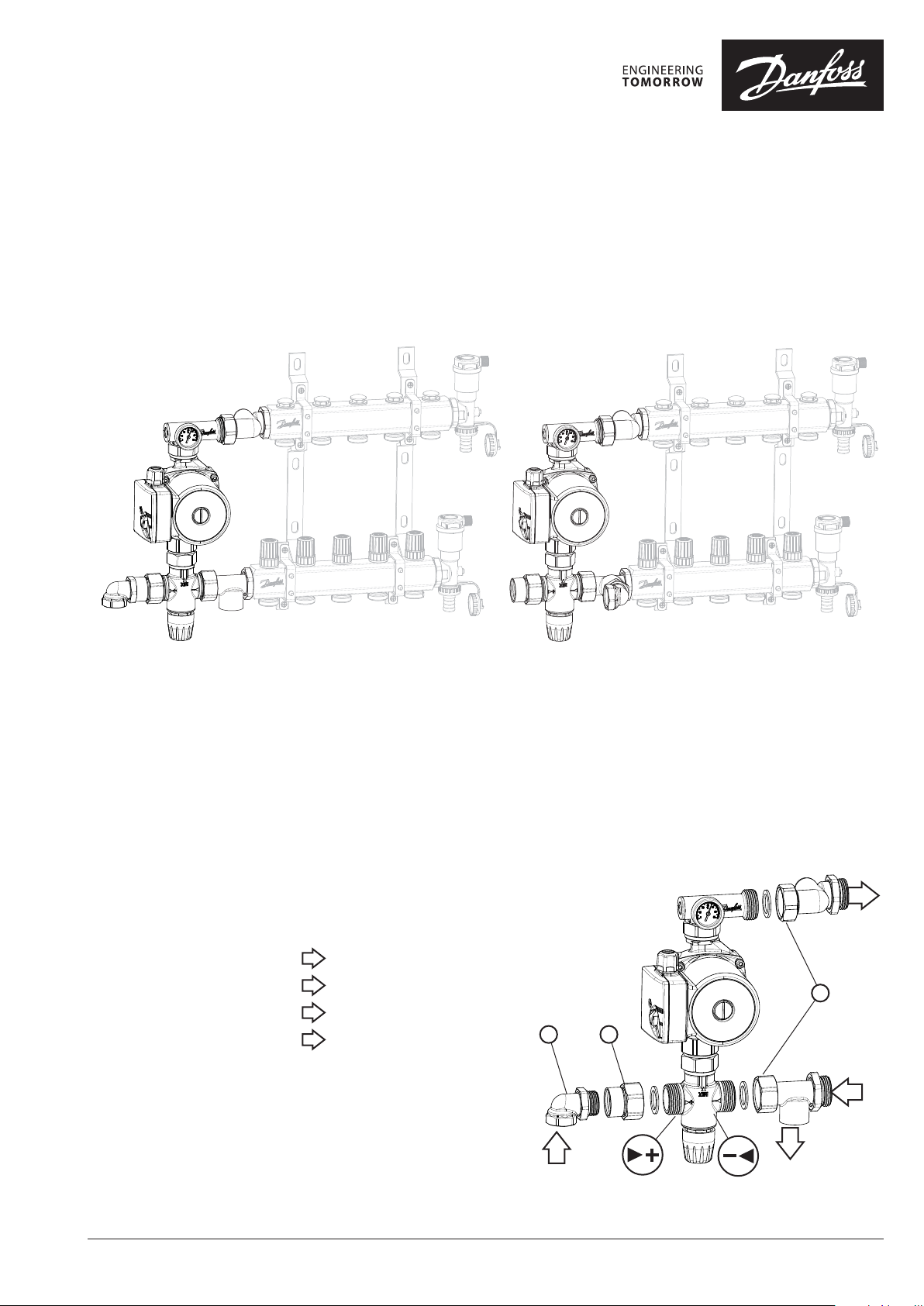

Installation overview

Installation procedure

Bottom in bottom out Side in side out

The FHM-CN5 must be connected to a system according to the illustrations.

1. Bend 1 is in package. Install bend 1 to the primary side pipe rstly. And then connect bend 1 and

connector 2 together with enclosed O-ring. Finally, connector 2 to 3-way mixing valve must be

tightened with a torque of 30 to 40 Nm with enclosed at gasket.

2. Pre-mounted union nut 3 for connection to the secondary side pipe or directly on a Danfoss manifold.

The nut 3 to mixing shunt must be tightened with a torque of 30 to 40 Nm with enclosed at gasket.

A

Supply of primary side

B

Supply of secondary side

C

Return of secondary side

D

Return of primary side

1

2

B

3

C

© Danfoss | FEC | 2020.05

A

AN33645914333101-000201 / 088U5014 | 1

D

Installation Guide FHM-CN5 Pre-assembled 3-Way Mixing Shunt

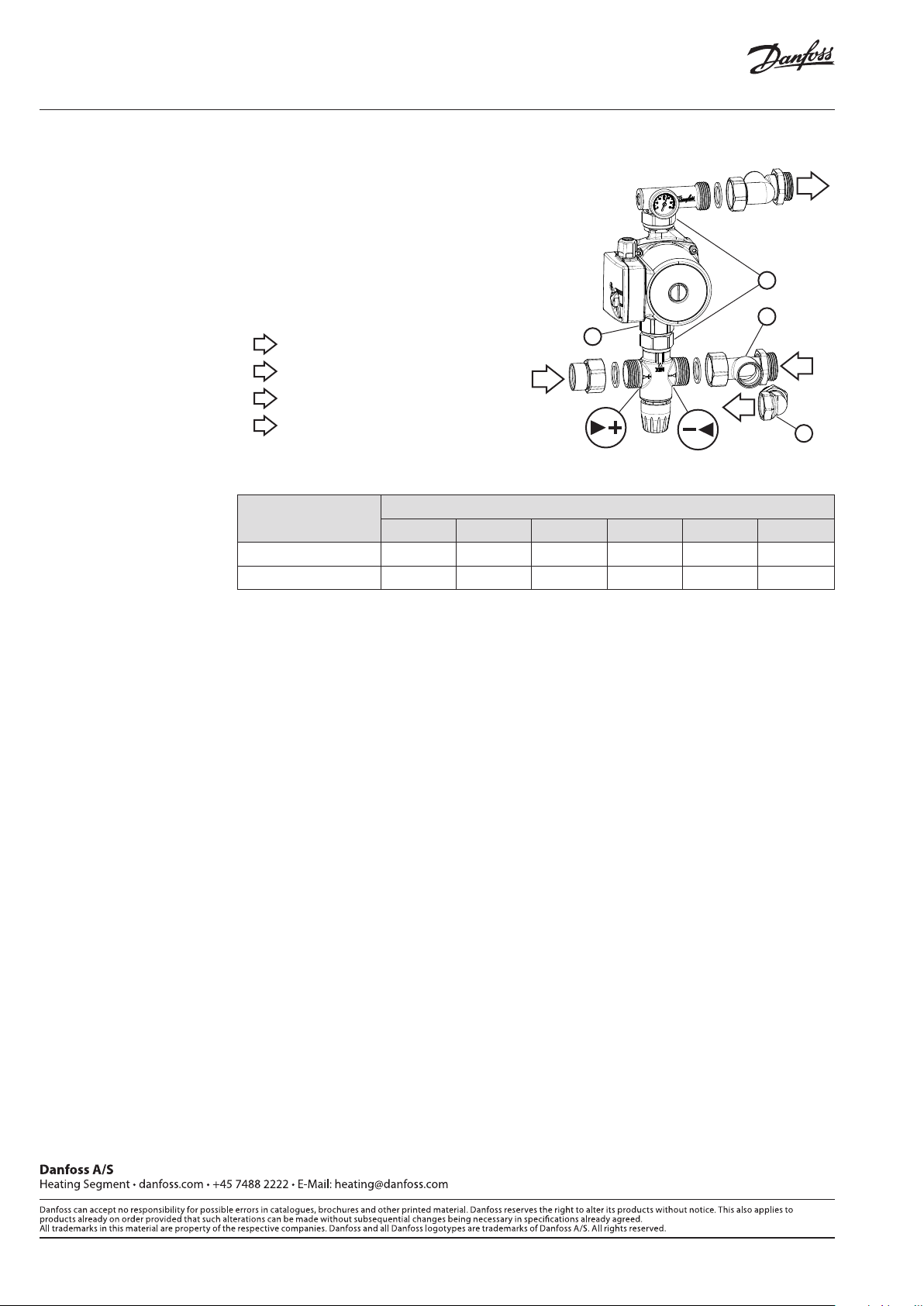

Tips

RoHS compliance

1. If the primary side pipe is coming from the side,

the bend 1 must be tightened with T-connection 4 with a torque of 30 to 40 Nm.

B

2. Connection 5 are tightened from the factory. If

leaks occur due to loosening during transportation, moving or similar, please tighten at a

torque of 30 to 40Nm.

5

4

A

Supply of primary side

B

Supply of secondary side

C

Return of secondary side

D

Return of primary side

Part Name

A

Hazardous Substances Table

Pb Hg Cd Cr(VI) PBB PBDE

5

C

D

1

Pump X O O O O O

Brass parts X O O O O O

O: Indicates that this hazardous substance contained in all of the homogeneous material for this

part is below the limit requirement in GB/T 26572.

X: Indicates that this hazardous substance contained in at least one of the homogeneous material

for this part is above the limit requirement in GB/T 26572.

2 | © Danfoss | FEC | 2020.05

AN33645914333101-000201 / 088U5014

安装指南

FHM-CN5

整体式三通混水中心

I安装概览

安装步骤

底进底出 侧进侧出

必须按图示要求将 FHM-CN5 连接至系统。

1. 活接弯头(1)在包装内。先将图中所示活接弯头(1)装到一次侧供水管上。再将活接弯头(1)与活接

(2)进行连接,密封材料为活接弯头自带的密封圈,并用30~40 Nm的力矩拧紧。然后再将活接(2)

与三通混水阀进行连接,密封材料为产品附带的密封平垫片,并用30~40 Nm的力矩拧紧螺母。

2. 将图中所示活接(3)先装到二次侧供回水管上或丹佛斯分集水器上。 再将活接(3)与混水中心连

接,密封材料为产品附带的密封平垫片,并用 30-40 Nm 的力矩拧紧螺母。

A

一次侧供水

B

C

D

二次侧供水

二次侧回水

一次侧回水

1

2

3

B

C

© Danfoss | FEC | 2020.05

A

AN33645914333101-000201 / 088U5014 | 3

D

Danf

小贴士

1. 如果一次侧供回水管是侧进侧出, 可将活接弯

头(1)与T型接头(4)连接,密封材料为活接弯

头自带的密封圈,并用30~40 Nm的力矩拧紧。

2. 连接螺母(5)在出厂时已拧紧。如果由于在运

输、搬运或类似过程中出现松动而导致泄漏的

话,请用30~40 Nm的力矩拧紧。

B

5

RoHS 指令

A

一次侧供水

B

二次侧供水

C

二次侧回水

D

一次侧回水

部件名称

水泵

铜制部分

O:

表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572规定的限量要求以下。

X:

表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572规定的限量要求。

铅 汞 镉 六价铬 多溴联苯 多溴二苯醚

X O O O O O

X O O O O O

A

5

D

有害物质含量表

4

C

1

丹佛斯自动控制管理(上海)有限公司

地址:上海市宜山路900号科技大楼C楼22层邮编:200233

电话:+86 21 61513000

传真:+86 21 61513100

电子邮件: heating@danfoss.com

http://heating.danfoss.cn

oss Danfoss

Danfoss ઼ᡰᴹ Danfoss Danfoss A/S( )

4 | © Danfoss | FEC | 2020.05

AN33645914333101-000201 / 088U5014

Loading...

Loading...