Data Sheet

FHF Floor Heating Manifold

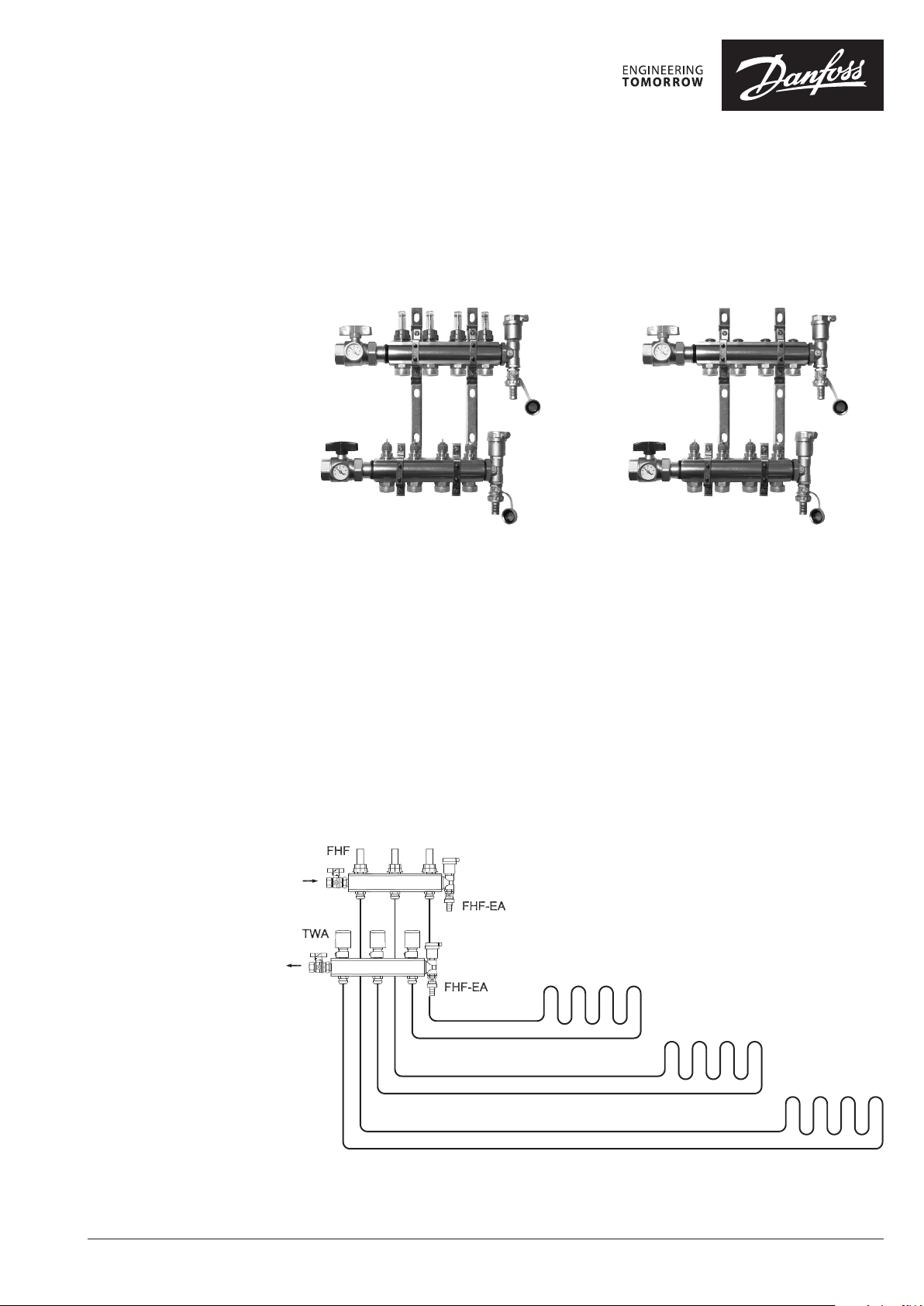

Application

System layout

Manifold with flowmeter

The Manifold FHF is used for controlling water flow

in under floor heating systems. Each tube of the

floor heating system is connected to the manifold,

thus making it possible to control water flow or heat

supply to each room in the building individually.

The manifold consists of a supply and return manifold. The supply manifold includes possibility for

individual shut-off of each circuit and as an option

also flowmeter. The return manifold is equipped

with integrated Danfoss pre-setting valves securing

optimal hydraulic balance in the system.

Manifold without flowmeter

The valves can be controlled electronically by

thermal actuators or act as self-acting units by

means of remote temperature adjusters.

The manifold is supplied in modules of up to 12

outlets. In addition extension pieces are available

for connecting the manifolds in series. Ball valves

are available as an option for positive shut-off

between manifold and system.

The end pieces FHF-EM and FHF-EA are supplied

with manual airvent or alternatively with automatic

airvent, purge valve. The end pieces are placed at

the end of the manifold.

© Danfoss | FEC | 2020.03

AI010286478228en-000601 / VDUDO | 1

Data Sheet FHF Floor Heating Manifold

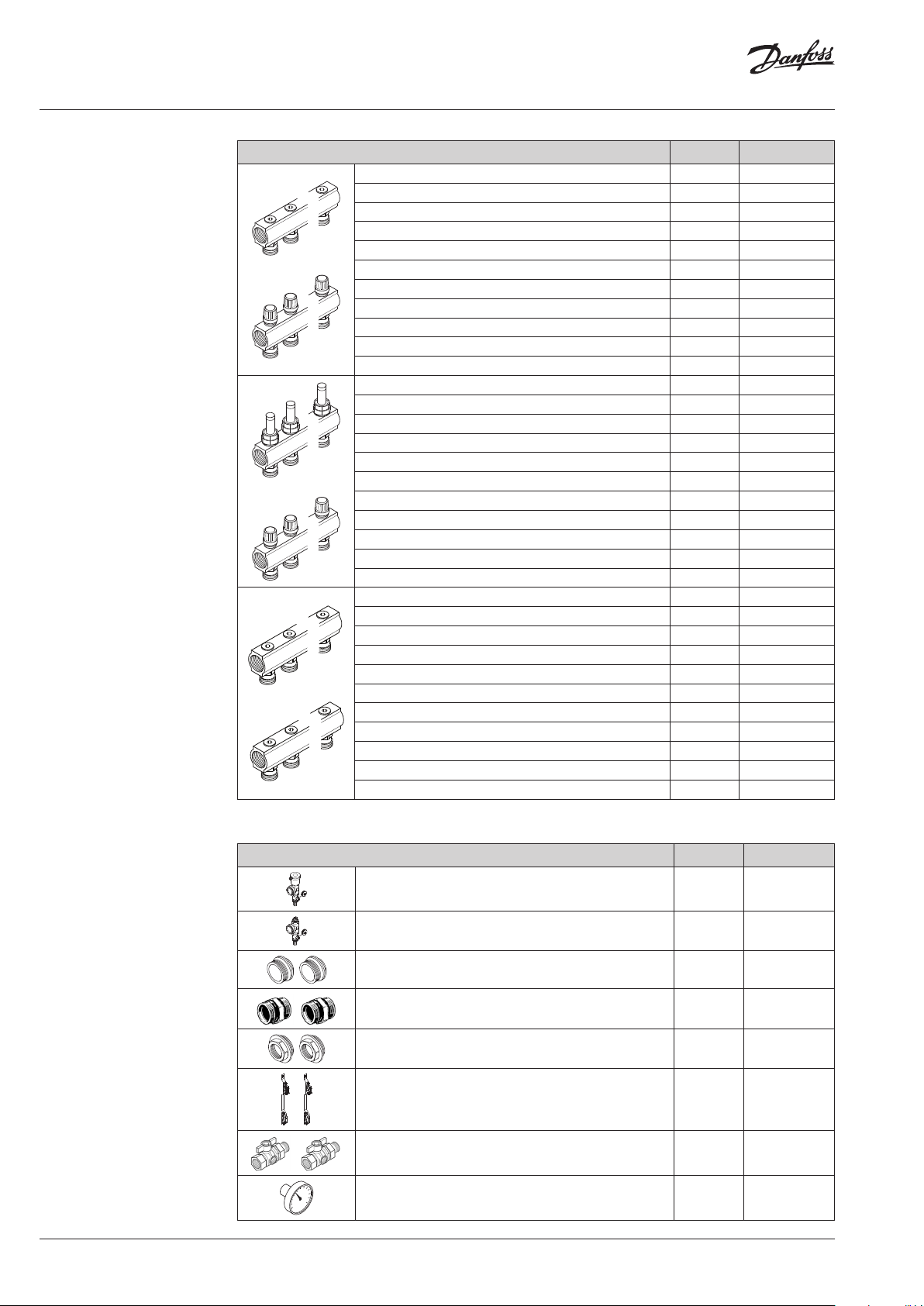

Ordering

Description Type Code no.

Manifold set 2+2 FHF-2 088U0502

Manifold set 3+3 FHF-3 088U0503

Manifold set 4+4 FHF-4 088U0504

Manifold set 5+5 FHF-5 088U0505

Manifold set 6+6 FHF-6 088U0506

Manifold set 7+7 FHF-7 088U0507

Manifold set 8+8 FHF-8 088U0508

Manifold set 9+9 FHF-9 088U0509

Manifold set 10+10 FHF-10 088U0510

Manifold set 11+11 FHF-11 088U0511

Manifold set 12+12 FHF-12 088U0512

Manifold set 2+2, with flowmeter FHF-2F 088U0522

Manifold set 3+3, with flowmeter FHF-3F 088U0523

Manifold set 4+4, with flowmeter FHF-4F 088U0524

Manifold set 5+5, with flowmeter FHF-5F 088U0525

Manifold set 6+6, with flowmeter FHF-6F 088U0526

Manifold set 7+7, with flowmeter FHF-7F 088U0527

Manifold set 8+8, with flowmeter FHF-8F 088U0528

Manifold set 9+9, with flowmeter FHF-9F 088U0529

Manifold set 10+10, with flowmeter FHF-10F 088U0530

Manifold set 11+11, with flowmeter FHF-11F 088U0531

Manifold set 12+12, with flowmeter FHF-12F 088U0532

Manifold set 2+2, basic FHF-2B 088U0542

Manifold set 3+3, basic FHF-3B 088U0543

Manifold set 4+4, basic FHF-4B 088U0544

Manifold set 5+5, basic FHF-5B 088U0545

Manifold set 6+6, basic FHF-6B 088U0546

Manifold set 7+7, basic FHF-7B 088U0547

Manifold set 8+8, basic FHF-8B 088U0548

Manifold set 9+9, basic FHF-9B 088U0549

Manifold set 10+10, basic FHF-10B 088U0550

Manifold set 11+11, basic FHF-11B 088U0551

Manifold set 12+12, basic FHF-12B 088U0552

Accessories

2 | © Danfoss | FEC | 2020.03

Description Type Code no.

End section – automatic airvent and purge valve FHF-EA 088U0785

End section – manual airvent and purge valve FHF-EM 088U0786

End caps – set FHF-E 088U0582

Connection pieces – set FHF-C 088U0583

Reduction bushes/pieces – set 1" - 3/4" FHF-R 088U0584

Mounting brackets – set FHF-MB 088U0585

2 x ball valve 1” with tail piece – for connection to

manifold and for blocking of floor heating system

1 x thermometer 0 °C to 60 °C, Ø 35 mm –

for flow/return temperature measurement

AI010286478228en-000601 / VDUDO

FHF-BV 088U0822

FHD-T 088U0029

Data Sheet FHF Floor Heating Manifold

Accessories

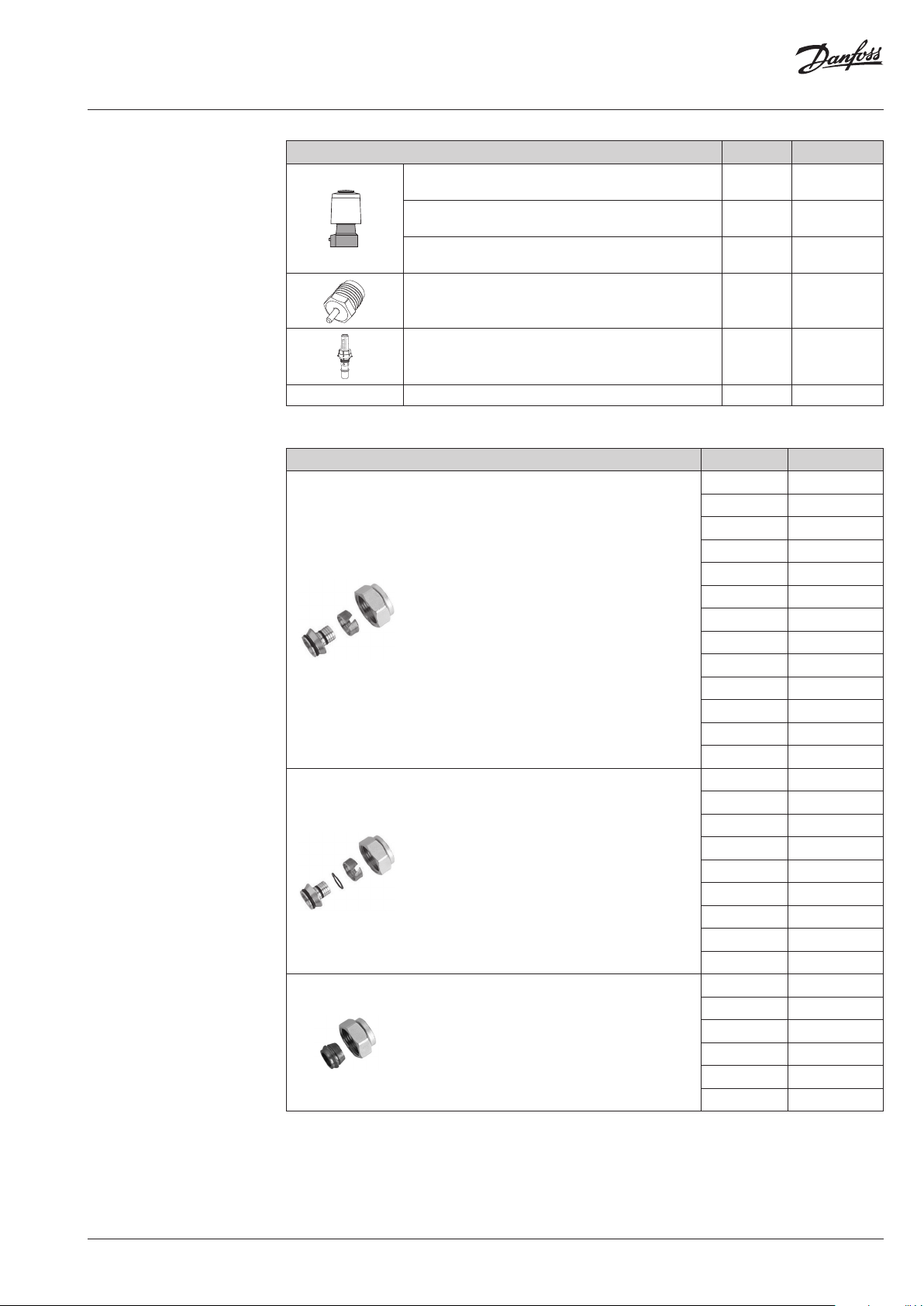

Compression fittings

Description Type Code no.

Thermal actuator, 24V, NC, Danfoss RA

connection to valve

Thermal actuator, 230V, NC, Danfoss RA

connection to valve

Thermal actuator, 24V, NC, with end switch,

Danfoss RA connection to valve

TWA-A 088H3110

TWA-A 088H3112

TWA-A 088H3114

Stuffing box for manifolds DZR 013G0554

Flowmeter – 088U0819

Manifold insulation – 088U0587

Description Size, mm Code no.

12 × 2 013G4152

13 × 2 013G4153

Compression fittings for PEX tubing in

accordance with ISO 15875.

Max working pressure: 6 bar

Test pressure: 10 bar

Max, flow temperature: 95 °C

G ¾” internal thread

Max, flow temperature given by the tube

manufacturer must not be exceeded.

1)

Compression fittings also suitable for PERT

tubing in accordance with ISO 15875.

14 × 2 013G4154

15 × 2,5 013G4155

16 × 1,5 013G4157

16 × 2 013G4156

16 × 2,2 013G4163

17 × 2 013G4162

18 × 2 013G4158

18 × 2,5 013G4159

20 × 2 013G4160

20 × 2,25 013G4093

20 × 2,5 013G4161

Compression fittings for ALUPEX tubing.

12 × 2 013G4182

14 × 2 013G4184

Max working pressure: 6 bar

Test pressure: 10 bar

Max flow temperature: 95 °C

G ¾” Internal thread

Max flow temperature given by the tube

manufacturer must not be exceeded.

2)

Compression fittings also suitable for PERT/

ALU/PERT tubing.

Compression fittings for STEEL and

COPPER tubing.

Max working pressure: 6 bar

Test pressure: 10 bar

Max flow temperature: 120 °C

G ¾” Internal thread

15 × 2,5 013G4185

16 × 2 013G4186

16 × 2,25 013G4187

18 × 2 013G4188

20 × 2 013G4190

20 × 2,25 013G4093

20 × 2,5 013G4191

10 013G4120

12 013G4122

14 013G4124

15 013G4125

16 013G4126

18 013G4128

1)

1)

2)

2)

© Danfoss | FEC | 2020.03

AI010286478228en-000601 / VDUDO | 3

Data Sheet FHF Floor Heating Manifold

Capacity/ commissioning

The pre-setting of the manifold valves determines

the flow in the floor heating tubes and is therefore an important factor for obtaining optimal hydraulic balance in the system. A correct hydraulic

balance is important if optimal comfort shall be

achieved with a minimum of energy consumption

and is easily carried out following the example

shown below.

Example

Room 1 1. Determine longest tube/largest room 25 m

2. Desired cooling (ΔT) 5 °C (typical)

3. Determine heat requirement for the room 50 W/m

4. Conversion factor 1,16

5. Calculation of flow for the room

Room 2 6. Determine area for the next room 15 m2

7. Calculation of flow for the room

(ΔT and heat requirement is assumed

identical for the rooms in this case)

Manifold with

flowmeter

Pre-setting:

Q (l/h)

Q (l/h)

2

2

50 W/m2 x 25 m

=

50 W/m2 x 15 m

=

5 °C x 1,16

5 °C x 1,16

2

216 l/h

2

129 l/h

Room 1 -> N

Room 2 -> 5

Manifold without

flowmeter

Pre-setting:

Room 1 -> N

Room 2 -> 6

4 | © Danfoss | FEC | 2020.03

AI010286478228en-000601 / VDUDO

Data Sheet FHF Floor Heating Manifold

5

4

3

2

1

0

l/min

Danfoss

88H191.10.10

1

2

3

4

5

6

Pre-setting the

manifold valves

Design

The diagrams shows the capacities for each heating circuit at different pre-settings of the manifold

valves. Please note that the capacities are slightly

different depending on whether a manifold with

flowmeter or a manifold without flowmeter has

Item

Description Material

1 Sightglass Heat resistant plastic

2 Flowmeter nut Brass, CuZn39Pb3

been chosen. Based on the above calculations and

capacity diagrams each manifold valve is pre-set

by rotating the red ring until the correct value on

the ring is in-line with the sight mark on the valve.

Supply manifold

with flowmeter

Item

Supply manifold

without flowmeter

Item

3 Flowmeter insert Brass, CuZn39Pb3

4 Supply manifold body Brass, CuZn40Pb2

5 O-ring EPDM

6 Union for compression fitting Brass, CuZn40Pb2

Description Material

1 Lock washer Brass, CuZn40Pb2

2 O-ring EPDM

3 Valve spindle Brass, CuZn40Pb2

4 O-ring EPDM

5 Valve tube Brass, CuZn40Pb2

6 Supply manifold body Brass, CuZn40Pb2

7 O-ring EPDM

Description Material

1 Gland seal -

2 Pre-setting ring PBT

3 Valve body Brass, CuZn40Pb2

© Danfoss | FEC | 2020.03

Return manifold

with control valve

4 Return manifold body Brass, CuZn40Pb2

5 Kv insert Brass, CuZn39Pb3

6 O-ring EPDM

7 Union for compression fitting Brass, CuZn40Pb2

AI010286478228en-000601 / VDUDO | 5

Data Sheet FHF Floor Heating Manifold

107

Operation conditions

Dimensions

Max. differential pressure: 0,6 bar.

Max. working pressure: Manifold without flowmeter 10 bar / Manifold with flowmeter 6 bar.

Max. test pressure: Manifold without flowmeter 16 bar / Manifold with flowmeter 10 bar.

Max. flow temperature: 90 °C.

213

386

23

50

78

Type 2+2 3+3 4+4 5+5 6+6 7+7 8+8 9+9 10+10 11+11 12+12

L1 (mm) 111 161 211 261 311 361 411 461 511 561 611

213

386

23

6 | © Danfoss | FEC | 2020.03

50

78

107

Type 2+2 3+3 4+4 5+5 6+6 7+7 8+8 9+9 10+10 11+11 12+12

L1 (mm) 111 161 211 261 311 361 411 461 511 561 611

AI010286478228en-000601 / VDUDO

Dimensions

FHF-EA

FHF-EM

FHF-BV

© Danfoss | FEC | 2020.03

AI010286478228en-000601 / VDUDO | 7

Loading...

Loading...