Page 1

1

2

3

4

5

Data Sheet

FED-W Sensors - Sequence Control of Cooling and

Heating Circuit

Products

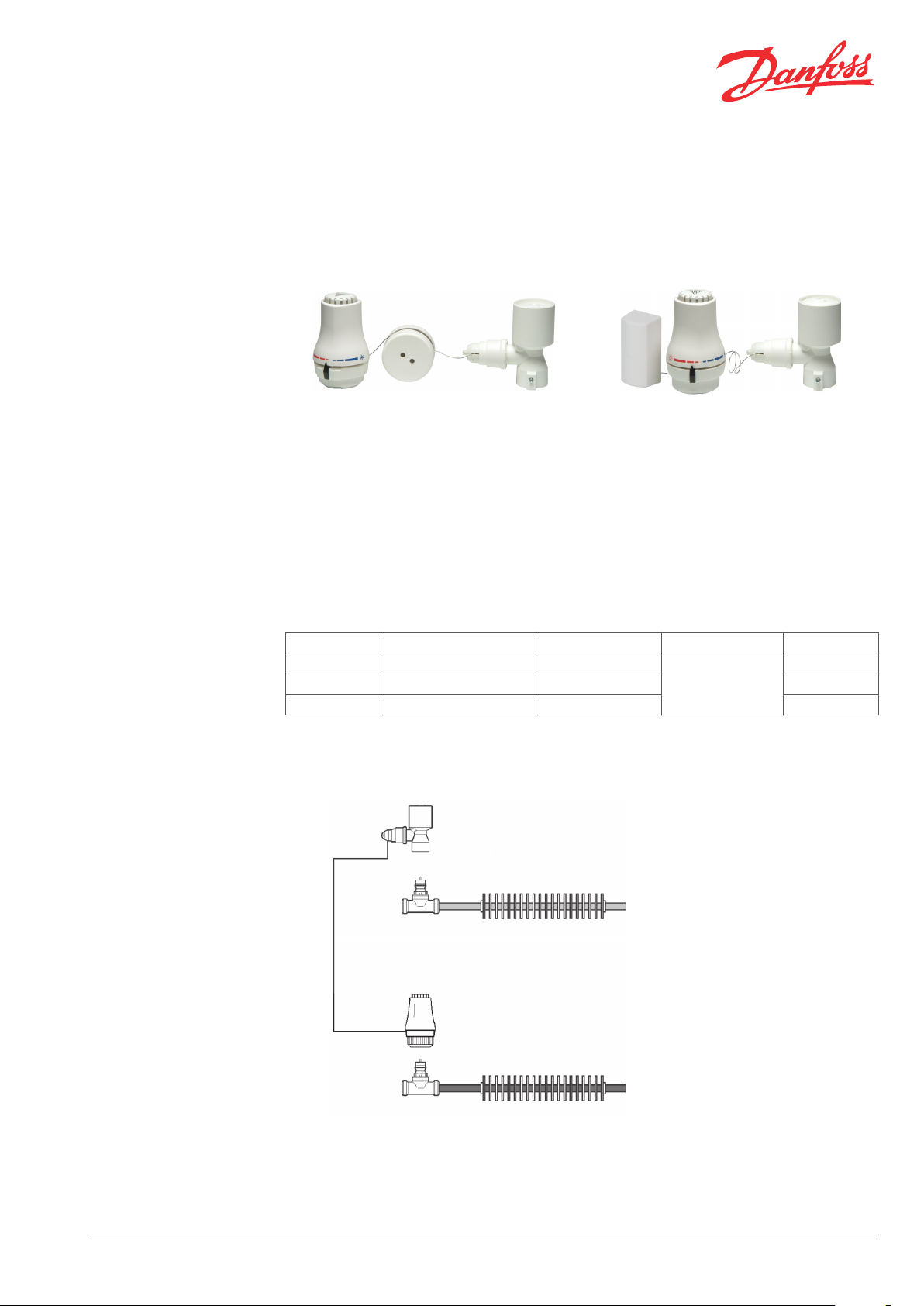

FED-W 10 with integrated sensor FED-WF with remote sensor

Ordering and Specifications

Application

The FED sensors are used in applications in which

a cooling and a heating circuit are to be

controlled by one controller.

Both FED-W and FED-WF sensors can be applied

to chilled ceilings, fancoils or induction units.

Type Sensor Capillary tube Setting range Code no.

FED-W 0.5 Integrated sensor 0.5 m

FED-W 10 Integrated sensor 10 m 013G5480

FED-WF Remote sensor 2 + 2 m 013G54xx

Sequence control of 4-pipe chilled ceiling or radiator

For control of cooling and heating circuits in

fancoil and induction units use the FED-WF with

remote sensor.

By placing the sensor in the air inlet a quicker

reaction time of the air temperature changes is

achieved.

013G5481

17-27 °C

1. RA-C

2. FED-W

3. RA-N

4. Cooling circuit

5. Heating circuit/radiator

Danfoss Heating Solutions VDUND202 © Danfoss 02/2011 1

Page 2

1

3

2

4

5

2

3

4

5

1

Data Sheet FED-W Sensors - Sequence Control of Cooling and Heating Circuit

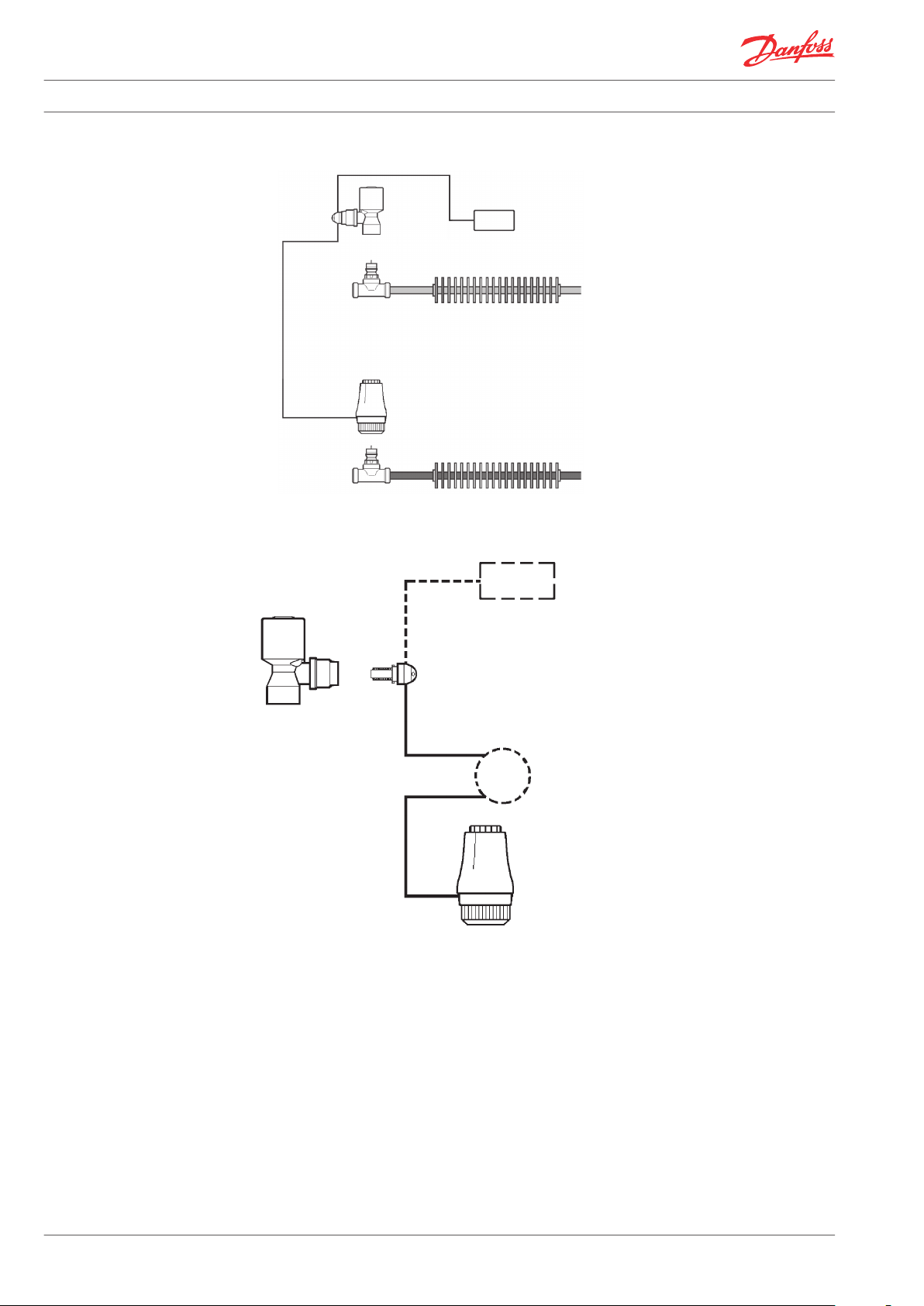

Sequence control of fancoils and induction units

1. RA-C

2. FED-WF

3. RA-N / RA-N

4. Cooling circuit

5. Heating circuit

FED Sensor Design

1. Cooling adapter

2. Actuator

3. Remote sensor (only FED-WF)

4. Capillary reel (only FED-W 10)

5. FED-W sensor

The FED sensors are applied with the RA-N and

the RA-C valves.

The FED sensors are equipped with a reverse

The valve in the heating circuit will open when

the temperature falls below the setpoint

temperature.

device for the control of cooling circuits. With the

reverse device the valve in the cooling circuit will

open when the temperature rises above the

setpoint temperature.

2 VDUND202 © Danfoss 02/2011 Danfoss Heating Solutions

Page 3

1

2

3

1

2

Data Sheet FED-W Sensors - Sequence Control of Cooling and Heating Circuit

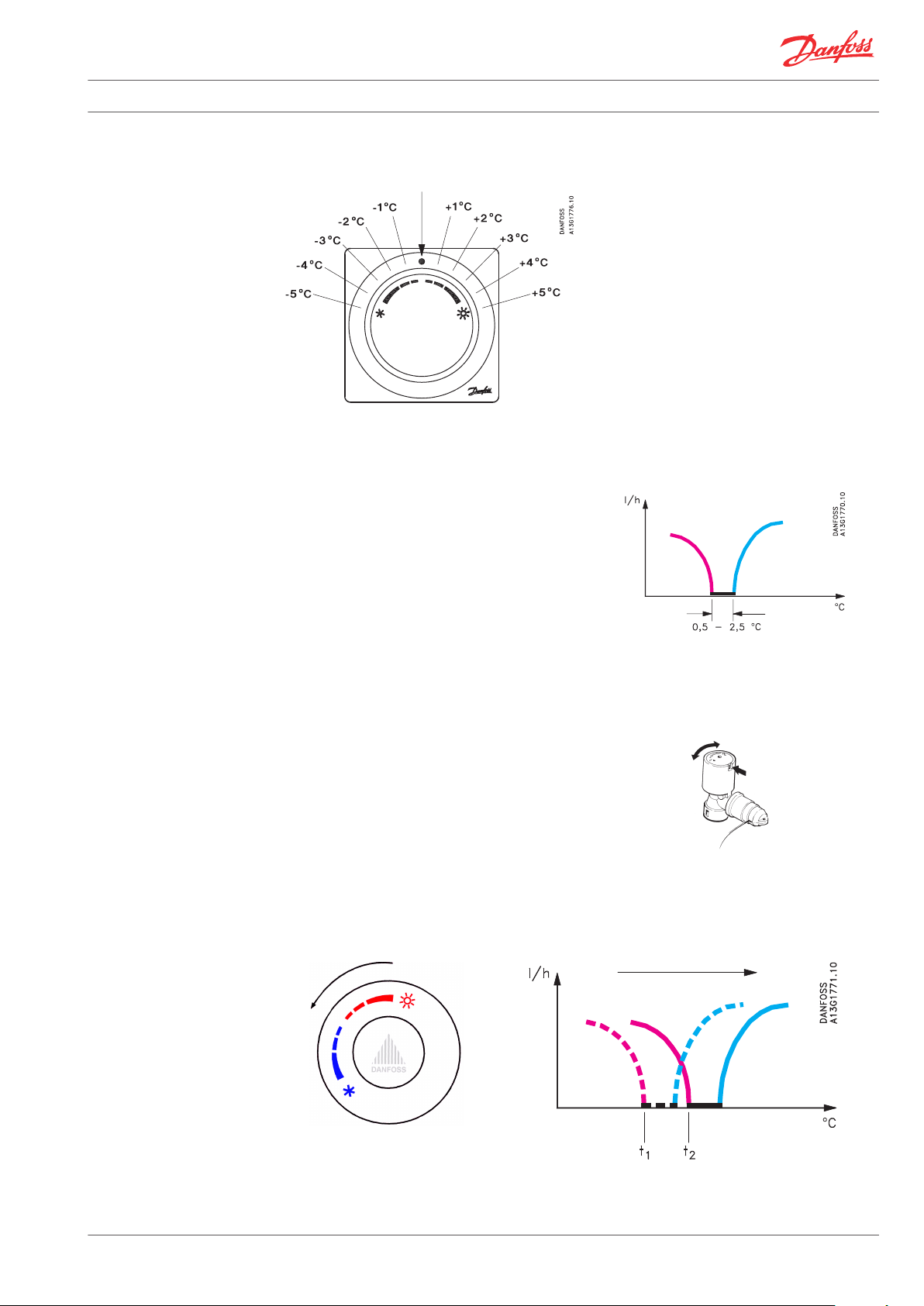

Temperature Setting

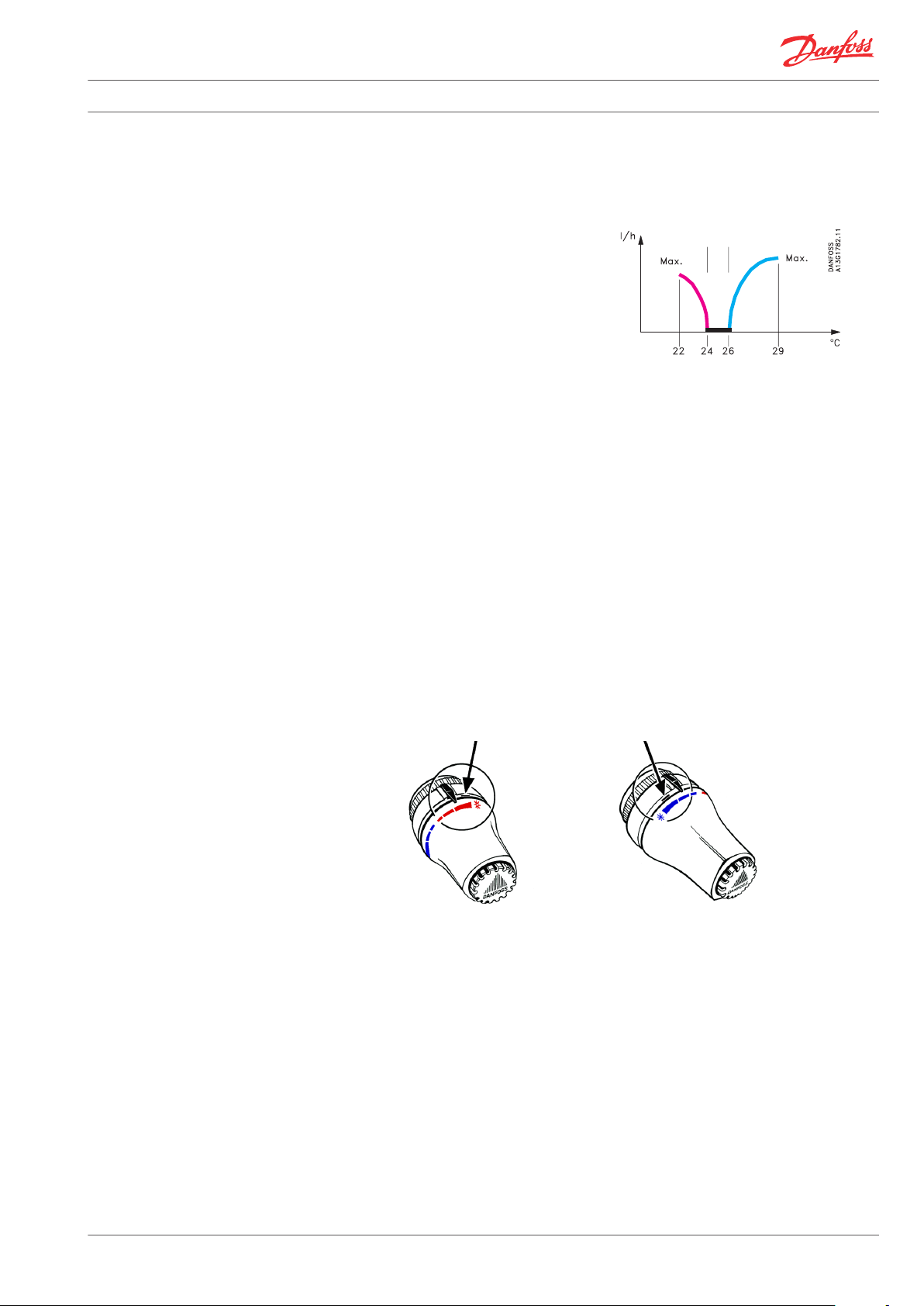

Sequence Control

Comfort temperature ~ 22 °C at Xp = 0 K The FED sensors have been developed for room

temperature control via water-based cooling and

heating systems.

The FED sensors are based on the self-acting

principle. The liquid-filled sensors control the

valves via capillaries and adapters.

The scale shows the approximate set-point offset

from the comfort temperature which is

approximately 22° C at Xp = 0 K.

The control is done by the sensor, in which a

Sequence control of cooling and heating circuit

neutral zone is built-in. In the neutral zone both

valves are closed and neither an activation of the

valve in the heating circuit nor of the valve in the

cooling circuit takes place. In that way it is

secured that cooling and heating do not take

place simultaneously.

The neutral zone is in the area from 0.5 - 2.5 °C

dependending on the system design. If the

differential pressure is high on both circuits (~0.6

bar), the neutral zone is at a minimum. On the

other hand if the differential pressure is low on

both circuits (~0.1 bar), the neutral zone is at a

maximum.

An adjustment of the neutral zone can be made

1. Water flow through heating circuit

2. Water flow through cooling circuit

3. Neutral zone

by turning the knob of the cooling adapter with a

pair of pointed pliers. Turning clockwise the

neutral zone is increased, turning counterclockwise the neutral zone is decreased. The

factory setting of the neutral zone is marked in

the knob recess.

Irrespective of the temperature setting of the

FED-sensor the necessary neutral zone will

always be kept. See also figures below.

1. Adjustment of the neutral zone

2. Factory setting mark

Setting of comfort temperature – hotter t1 –> t2 (e.g. 22 °C –> 24 °C)

Danfoss Heating Solutions VDUND202 © Danfoss 02/2011 3

Page 4

*

*

1 2

3

Data Sheet FED-W Sensors - Sequence Control of Cooling and Heating Circuit

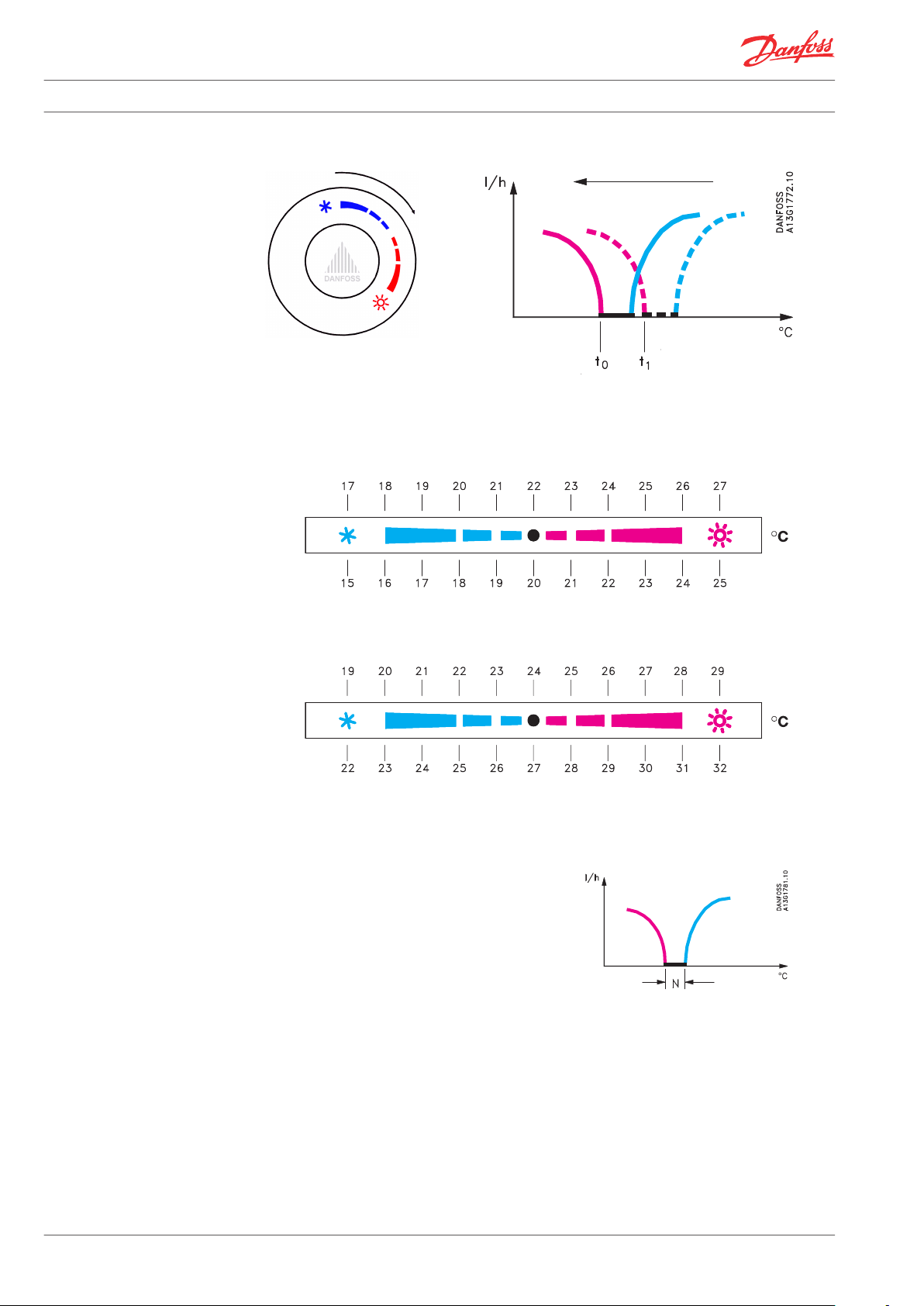

Setting of comfort temperature – colder t1 –> t0 (e.g. 22 °C –> 20 °C)

Temperature Control

Through Sequence Control

with FED Sensor

a) Control area of FEK sensor with RA-C valve

Xp = 0 K

Xp = 2 K

b) Control of cooling circuit - FED with RA-C valve

Xp = 0 K

Xp = 3 K

*Note! Example at neutral zone = 2 °C. Setpoint = 22 °C

The FED sensor controls in sequence via two

temperature scales: one for the heating circuit (a)

and one for the cooling circuit (b).

Sequenzing with FED thermostat

When the setting knob is turned a parallel control

of both temperature scales is taking place. The

neutral zone ensures that cooling and heating do

not take place simultaneously.

A setting in the red temperature area means that

the set point of both cooling and heating circuit

is raised.

A setting in the blue temperature area lowers the

set point of both cooling and heating circuits.

4 VDUND202 © Danfoss 02/2011 Danfoss Heating Solutions

1. Waterflow, heating

2. Waterflow, cooling

3. Setpoint on knob (N = neutral zone)

Page 5

1

2

3

Data Sheet FED-W Sensors - Sequence Control of Cooling and Heating Circuit

Example

The setting knob is turned to raise the room

temperature with 2 °C from 22 °C to

approximately 24 °C at Xp = 0 K on the heating

valve. Due to the neutral zone the set point of the

cooling valve at Xp = 0 K will be between 0.5-2.5 K

higher depending on the system design.

The valve in the heating circuit will open at a

sensor temperature below 24 °C. If an RA-N valve

is mounted in the heating circuit and

dimensioned at the presetting N, the RA-N valve

will provide full water quantity at a P-band of 2 K,

i.e. a sensor temperature of 22°C.

If the neutral zone e.g. is 2 K the valve in the

cooling circuit will start opening at a sensor

temperature above 26 °C (setpoint: 24 °C +

neutral zone: 2 K).

With a RA-C valve in the cooling circuit

(dimensioned at presetting N) the valve will

provide full water quantity with a P-band of 3 K,

i.e. at a sensor temperature of 29 °C (setpoint: 24

°C + neutral zone: 2 K + P-band: 3 K).

Sequence control when rising the setpoint

temperature with 2 °C

1. Waterflow, heating

2. Waterflow, cooling

3. Neutral zone

Limiting the Set

Temperature of FED Sensors

The set temperature of the remote temperature

adjuster depends on the sensor type and the

valves, which are used with the sensors.

Maximum limitation of temperature area Minimum limitation of temperature area

It is easy to limit or lock the set temperature by

means of the built-in locking/limiting device.

Danfoss Heating Solutions VDUND202 © Danfoss 02/2011 5

Page 6

11

6

5

1010

7

8

9

1

2

3

4

Data Sheet FED-W Sensors - Sequence Control of Cooling and Heating Circuit

Serial Coupling

Several possibilities of placing the FED remote temperature adjuster:

Design

Via the soft but strong ø 0.8 mm capillary and the patented serial coupling of capillary and adapters it

is possible to control two valves in sequence.

1. Heating sensor 7. Reverse device

2. Bellows 8. Adjustment bellow

3. Setting dial 9. Actuator

4. Reset spring 10. Capillary tube

5. Cooling adapter 11. Remote temperature sensor (only FED-WF)

6. Neutral zone adjustment knob

6 VDUND202 © Danfoss 02/2011 Danfoss Heating Solutions

Page 7

Data Sheet FED-W Sensors - Sequence Control of Cooling and Heating Circuit

Dimensions

FED-W

FED-WF

Danfoss Heating Solutions VDUND202 © Danfoss 02/2011 7

Page 8

Data Sheet FED-W Sensors - Sequence Control of Cooling and Heating Circuit

Danfoss A/S

Heating Solutions

Haarupvaenget 11

8600 Silkeborg

Denmark

Phone:+45 7488 8000

Fax: +45 7488 8100

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

8 VDUND202 © Danfoss 02/2011 Danfoss Heating Solutions

Loading...

Loading...