Page 1

ENGINEERING TOMORROW

Operating Guide

FC Series Add-On Instruction for VLT® EtherNet/IP MCA 121

VLT® HVAC Drive FC 102 • VLT® AQUA Drive FC 202

VLT® AutomationDrive FC 301/302 • VLT® Decentral Drive FCD 302

vlt-drives.danfoss.com

Page 2

Page 3

Contents Operating Guide

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Product Overview

1.3.1 Intended Use 2

1.3.2 Add-On Instruction Features 2

1.4 Disposal

1.5 Symbols, Abbreviations, and Conventions

1.6 Safety

2 General Conguration of the Frequency Converter

3 Importing the Add-On Instruction

4 Conguring the I/O of the PLC

5 Setting up the Add-On Instruction

2

2

2

2

3

3

3

4

6

8

10

MG92M102 Danfoss A/S © 02/2017 All rights reserved. 1

Page 4

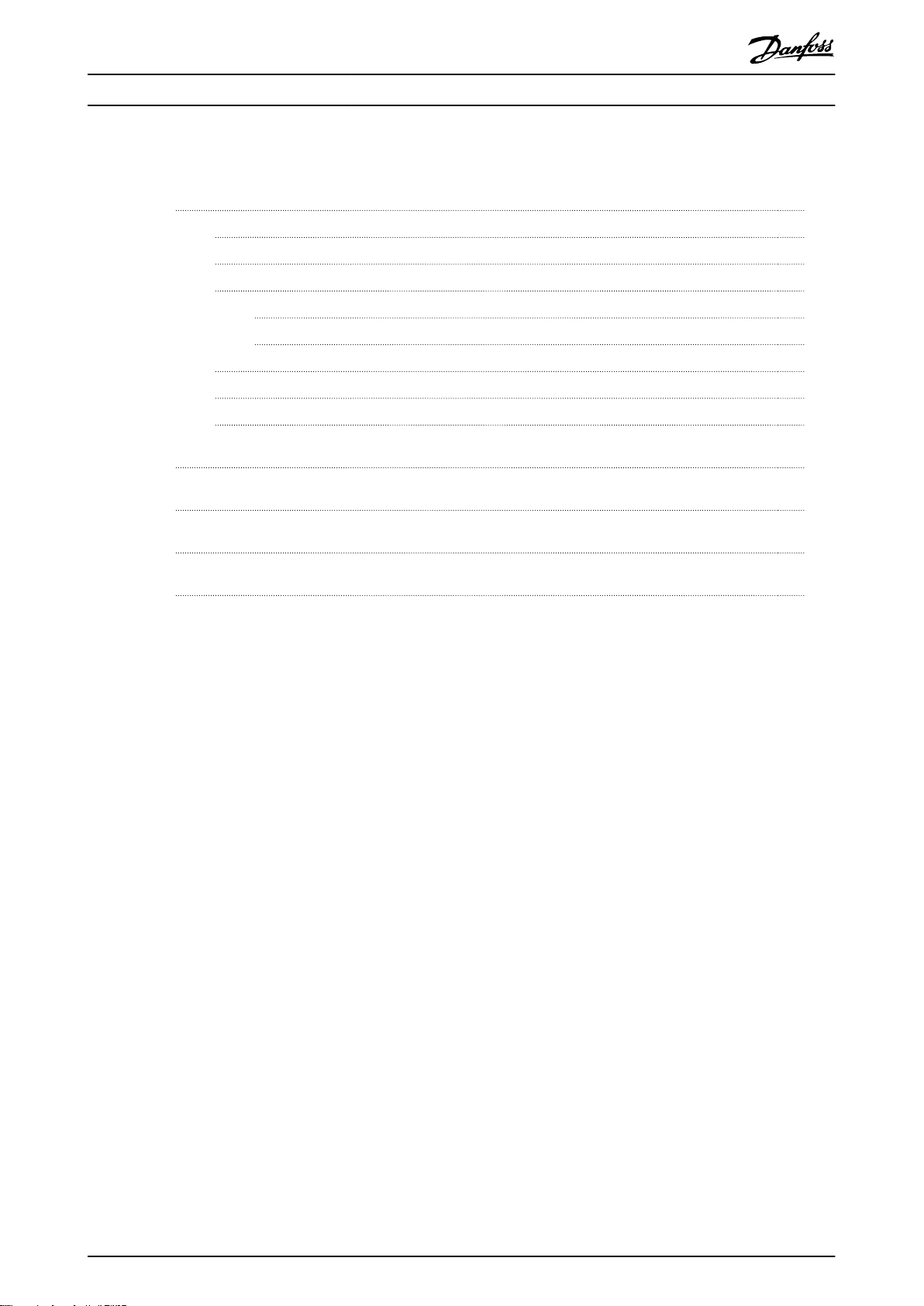

Danfoss_FC_Series

(Ready)

(Running)

(Warning)

(Alarm)

. . .

Danfoss_FC_Series

DriveIn

DriveOut

Run

Reverse

Reset

MRV

MAV

Current

?

?

?

?

??

?

??

??

??

??

?

?

130BF244.10

Introduction

FC Series Add-On Instruction for VLT® EtherNet/IP MCA 121

11

1 Introduction

1.1 Purpose of the Manual

This manual explains how to use the Add-On Instruction

(AOI) software to integrate a frequency converter and the

VLT® EtherNet/IP MCA 121 into the Logix5000 control

systems (ControlLogix, CompactLogix, and FlexLogix).

This operating guide is intended for use by

personnel. Users are assumed to be familiar with:

VLT® frequency converter.

•

EtherNet/IP technology.

•

PC or PLC that is used in the master system.

•

NOTICE

This version of the AOI supports version 20.0 or later of

the programming tool RSLogix 5000. Earlier versions of

RSLogix do not support the Danfoss EDS le and require

additional set-up of the module conguration.

VLT® is a registered Danfoss trademark.

EtherNet/IP™ is a trademark of ODVA, Inc.

Additional Resources

1.2

Resources available for the frequency converters and

optional equipment:

The relevant frequency converter operating guide

•

provides the necessary information for getting

the frequency converter up and running.

The relevant frequency converter design guide

•

provides detailed information about capabilities

and functionality to design motor control

systems.

The relevant frequency converter programming

•

guide provides greater detail on working with

parameters and many application examples.

qualied

Product Overview

1.3

1.3.1 Intended Use

This operating guide relates to the FC Series Add-On

Instructions for VLT® EtherNet/IP MCA 121.

The AOI for VLT® EtherNet/IP MCA 121 is intended for use

with:

VLT® HVAC Drive FC 102.

•

VLT® AQUA Drive FC 202.

•

VLT® AutomationDrive FC 301/FC 302.

•

VLT®Decentral Drive FCD 302.

•

1.3.2 Add-On Instruction Features

Easy handling of FC series frequency converters.

•

Start the motor with a single bit.

•

Speed reference as real value in percentage.

•

Actual speed of the motor in percentage.

•

Direct information when a warning or an alarm is

•

present.

Motor current as readout in Amps.

•

When the frequency converter prohibits the start

•

of the motor, it is shown.

Supplementary publications and manuals are available

from Danfoss. See drives.danfoss.com/knowledge-center/

technical-documentation/ for listings.

2 Danfoss A/S © 02/2017 All rights reserved. MG92M102

The VLT® EtherNet/IP MCA 121 Installation Guide

•

provides information about installing the

EtherNet/IP and about troubleshooting.

®

The VLT

•

provides information about conguring the

system, controlling the frequency converter,

parameter access, programming, troubleshooting,

and some typical application examples.

EtherNet/IP MCA 121 Programming Guide

Illustration 1.1 AOI Features

Page 5

Introduction Operating Guide

1.4 Disposal

Do not dispose of equipment containing

electrical components together with

domestic waste.

Collect it separately in accordance with

local and currently valid legislation.

1.5 Symbols, Abbreviations, and

Conventions

Abbreviation Denition

AOI Add-On Instruction

BOOTP Bootstrap protocol

DHCP Dynamic host conguration protocol

EDS Electronic data sheet

IP Internet protocol

LCP Local control panel

MAV Main actual value

MRV Main reference value

PC Personal computer

PLC Programmable logic controller

SINT Short integer

Safety

1.6

The following symbols are used in this guide:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

1.6.1 Qualied Personnel

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualied personnel are allowed to install or operate this

equipment.

1 1

Table 1.1 Symbols and Abbreviations

Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and description of

illustrations.

Italicized text indicates:

Cross-reference.

•

Link.

•

Parameter name.

•

Parameter group name.

•

Parameter option.

•

Qualied personnel are dened as trained sta, who are

authorized to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Also, the qualied personnel must be familiar

with the instructions and safety measures described in this

installation guide.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

DC supply, or load sharing, the motor can start at any

time. Unintended start during programming, service, or

repair work can result in death, serious injury, or

property damage. The motor can start with an external

switch, a eldbus command, an input reference signal

from the LCP or LOP, via remote operation using MCT 10

Set-up Software, or after a cleared fault condition.

To prevent unintended motor start:

Press [O/Reset] on the LCP before

•

programming parameters.

Disconnect the frequency converter from the

•

mains.

Completely wire and assemble the frequency

•

converter, motor, and any driven equipment

before connecting the frequency converter to

AC mains, DC supply, or load sharing.

MG92M102 Danfoss A/S © 02/2017 All rights reserved. 3

Page 6

General Conguration of th...

FC Series Add-On Instruction for VLT® EtherNet/IP MCA 121

2 General Conguration of the Frequency Converter

22

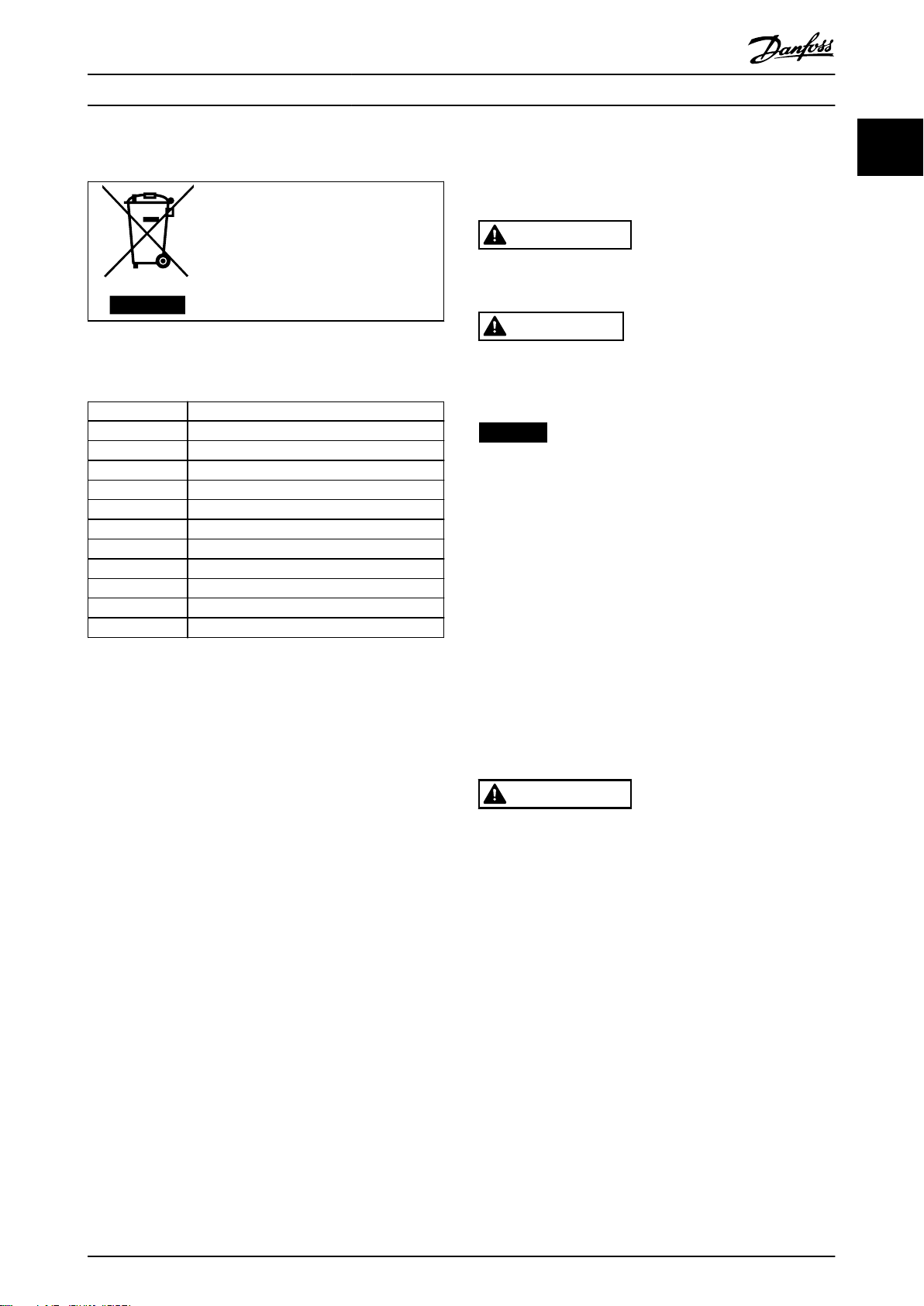

The parameters listed in Table 2.1 are required for enabling

the frequency converter to communicate with the VLT

®

EtherNet/IP MCA 121. When setting the parameters, use

the settings listed in Table 2.1.

Parameter Setting

Parameter 0-03 Regional Settings [0] International

Parameter 8-01 Control Site [0] Digital and ctrl. word or

[2] Control word only

Parameter 8-02 Control Word Source [3] Option A

Parameter 8-04 Control Word

Timeout Function

Parameter 8-10 Control Word Prole [0] FC prole

Parameter 12-00 IP Address

Assignment

Parameter 12-01 IP Address For example 192.168.1.10

Parameter 12-02 Subnet Mask For example

Parameter 12-21 Process Data Cong

Write [0]

Parameter 12-21 Process Data Cong

Write [1]

Parameter 12-22 Process Data Cong

Read [0]

Parameter 12-22 Process Data Cong

Read [1]

Parameter 12-22 Process Data Cong

Read [2]

Parameter 12-22 Process Data Cong

Read [3]

Parameter 12-22 Process Data Cong

Read [4]

Parameter 12-22 Process Data Cong

Read [5]

Parameter 12-22 Process Data Cong

Read [6]

Parameter 12-22 Process Data Cong

Read [7]

[0] O,

[1] Freeze output,

[2] Stop,

[3] Jogging,

[4] Max speed, or

[5] Stop and trip

[0] Manual

255.255.255.000

[1680] Fieldbus CTW 1

[1682] Fieldbus REF 1

[1603] Status word

[1605] Main actual value [%]

[1614] Motor current

[1614] Motor current

[1690] Alarm word

[1690] Alarm word

[1692] Warning word

[1692] Warning word

1. When the frequency converter is commissioned,

set parameter 0-03 Regional Settings before any

other changes are made to the frequency

converter via the Main Menu.

2. Press [Quick Menu] and select Q2 Quick set-up to

enter the motor data into the frequency

converter. The quick set-up can be done now or

at a later time. To ensure proper operation, it

must be done before running the motor.

3. Verify the settings of parameter 8-01 Control Site

and parameter 8-02 Control Word Source to ensure

that the PLC can control the frequency converter.

When parameter 8-01 Control Site is set to [0] Digital and

ctrl. word, a connection between terminal 12/13 and

terminal 27 is required to control the motor.

4. The default setting of the frequency converter

allows the frequency converter to continue

operation if the communication is lost to the PLC.

If this operation is not wanted, change

parameter 8-04 Control Word Timeout Function via

the Main Menu.

5. The Add-On Instruction requires that

parameter 8-10 Control Word

Prole is set to [0] FC

Prole. If parameter 8-10 Control Word Prole is set

to [5] ODVA, it leads to malfunction of the AOI.

Verify that parameter 8-10 Control Word Prole is

set correctly via the Main Menu. See VLT

®

EtherNet/IP MCA 121 Programming Guide for more

information.

6. Congure the IP settings of the frequency

converter by setting:

6a Parameter 12-00 IP Address Assignment.

6b Parameter 12-01 IP Address.

6c Parameter 12-02 Subnet Mask.

If the IP settings are set via a DIP switch, BOOTP,

or DHCP server, see the VLT® EtherNet/IP MCA 121

Programming Guide for more information.

Table 2.1 Settings for Required Parameters

4 Danfoss A/S © 02/2017 All rights reserved. MG92M102

Page 7

General Conguration of th... Operating Guide

7. For module connection instances 103/153,

congure the associated additional process data

(PCD) words by setting the following paramters

according to Table 2.1:

7a Parameter 12-21 Process Data Cong

Write [0].

7b Parameter 12-21 Process Data Cong

Write [1].

7c Parameter 12-22 Process Data Cong

Read [0].

7d Parameter 12-22 Process Data Cong

Read [1].

7e Parameter 12-22 Process Data Cong

Read [2].

7f Parameter 12-22 Process Data Cong

Read [3].

7g Parameter 12-22 Process Data Cong

Read [4].

7h Parameter 12-22 Process Data Cong

Read [5].

7i Parameter 12-22 Process Data Cong

Read [6].

7j Parameter 12-22 Process Data Cong

Read [7].

2 2

MG92M102 Danfoss A/S © 02/2017 All rights reserved. 5

Page 8

Importing the Add-On Instru...

FC Series Add-On Instruction for VLT® EtherNet/IP MCA 121

3 Importing the Add-On Instruction

1. Download the Add-On Instruction le

Danfoss_FC_Series.L5X from drives.danfoss.com/

33

downloads/software/. The le is included in the

zip-le VLT EtherNet IP Add-On Instructions and

User Tags.

2. Save the Add-On Instruction le

Danfoss_FC_Series.L5X on a PC.

3. Right-click Add-On Instruction in the navigation

tree.

4. Select Import Add-On Instruction.

Illustration 3.1 Import Add-On Instruction

5. Select the Add-On Instruction le

Danfoss_FC_Series.L5X.

The File selection window is shown in Illustration 3.1.

Illustration 3.2 Select Add-On Instruction File

6. Click Import… to import the AOI to the RXLogix

5000 tool.

7. Select the Error/warnings icon in the Import

conguration window to verify that there are no

warnings or errors. Illustration 3.3 shown an

example without errors.

6 Danfoss A/S © 02/2017 All rights reserved. MG92M102

Page 9

130BF247.10

130BF248.10

Importing the Add-On Instru... Operating Guide

3 3

Illustration 3.3 Check for Errors/Warnings

If warnings and/or errors exist, the AOI does not work

properly. If no errors/warnings are present, press OK to

import the AOI. No further settings are required in this

menu.

8. Verify that the AOI is available in the Add-On

Instruction menu and that it looks as in

Illustration 3.4. Also, verify that the name is the

same.

Illustration 3.4 Add-On Instruction Available in Menu

MG92M102 Danfoss A/S © 02/2017 All rights reserved. 7

Page 10

130BF249.10

Conguring the I/O of the ...

FC Series Add-On Instruction for VLT® EtherNet/IP MCA 121

4 Conguring the I/O of the PLC

Before continuing, install the EDS le for the frequency converter on the PLC. Download the le from drives.danfoss.com/

downloads/software/. See the VLT® EtherNet/IP MCA 121 Programming Guide for detailed information.

Add the frequency converters to the EtherNet/IP scanner module. When the module is added, the following module dialog

appears as in Illustration 4.1:

44

Illustration 4.1 New Module Window

1. Enter the IP address used in parameter 12-01 IP

Address, for example 192.168.1.10. All IP addresses

must be unique for each device connected to the

network.

2. Set the Name eld to, for example, FC302. This is

the tag used for the actual communication

between the PLC and the frequency converter. It

is also the input and output tag for the Add-On

Instruction.

3. Change the module connection instance from

100/150 to 103/153 by clicking Change... The

Module Denition dialog appears as shown in

Illustration 4.2.

8 Danfoss A/S © 02/2017 All rights reserved. MG92M102

Page 11

130BF250.10

Conguring the I/O of the ... Operating Guide

4 4

Illustration 4.2 Module Denition Window

4. Select the 103/153 IO connection and click OK to

accept the new setting. The Size eld is SINT to

match the EDS-AOP denition in RSLogix 5000.

5. Click Yes to accept the warning message that

follows.

6. Click OK to conrm the setting.

MG92M102 Danfoss A/S © 02/2017 All rights reserved. 9

Page 12

Danfoss_FC_Series

(Ready)

(Running)

(Warning)

(Alarm)

. . .

Danfoss_FC_Series

DriveIn

DriveOut

Run

Reverse

Reset

MRV

MAV

Current

?

?

?

?

??

?

??

??

??

??

?

?

130BF251.10

This is a basic Add-On Instruction le....

130BF252.10

130BF254.10

Setting up the Add-On Instr...

FC Series Add-On Instruction for VLT® EtherNet/IP MCA 121

5 Setting up the Add-On Instruction

The Danfoss Add-On Instruction can be copied to the PLC’s

rung.

Keep the new tag in the controller scope of the PLC to

have the status of the frequency converter available in the

entire project.

1. Open the Add-On Instruction folder.

2. Drag and drop the VLT AOI into a rung in the

programming window.

When the AOI has been placed, the GUI looks as in

55

Illustration 5.1.

4. Insert a name for the frequency converter to be

controlled (for example VLT_1) in the Name eld.

5. Click Create.

This generates a list of tags for this AOI. The tags

generated look as in Illustration 5.3.

Illustration 5.1 VLT Add-On Instruction

3. Select the eld Danfoss_FC_Series in AOI, rightclick, and select New Tag...

The New Tag window appears, see Illustration 5.2.

Illustration 5.2 New Tag Window

10 Danfoss A/S © 02/2017 All rights reserved. MG92M102

Illustration 5.3 Tag List

Name Type Description

EnableIn Boolean Activates the AOI if set to true (1).

Run Boolean Set to true (1): Starts the motor.

Reverse Boolean Set to false (0): Sets the motor direction to

clockwise (CW).

Set to true (1): Reverses the motor direction

to counterclockwise (CCW). If the motor has

to run in CCW, set parameter 4-10 Motor

Speed Direction to [2] Both directions.

Reset Boolean In transition from 0 to 1, a fault trip can be

reset.

MRV Real Main reference value: Speed setpoint in % of

nominal motor speed.

Table 5.1 Function of Input Tags

Page 13

130BF253.10

Setting up the Add-On Instr... Operating Guide

Name Type Description

Ready Boolean If true (1): The motor can be started.

If false (0): The frequency converter has a

local stop signal activated (for example LCP

stop, terminal 27=0), or an alarm that

prevents the frequency converter from being

ready.

Running Boolean If true (1): The motor is energized.

Warning Boolean If true (1): The frequency converter has an

active warning.

Alarm Boolean If true (1): The frequency converter has an

active alarm.

MAV Real Main actual value: Actual motor speed in % of

nominal motor speed.

Current Real Motor current in Amps.

Table 5.2 Functions of Output Tags

By double-clicking the eld DriveIn of the VLT AOI in the

PLC’s rung, the corresponding input tags (in the controller

scope of the PLC) appear as in Illustration 5.4. From the

drop-down list, select the input tag that corresponds to

the actual frequency converter (for example FC302:I1.Data).

5 5

Illustration 5.4 Selecting an Input Tag

New tags can be created by right-clicking in any eld and

selecting New Tag. The same procedure must be done with

the DriveOut eld to control the frequency converter (for

example FC302:O1.Data).

The frequency converter can now be controlled by just

calling the AOI, setting the RUN bit to true, and setting the

MRV to a value between 0.0 and 100.0%. If MRV is set to a

negative value, the motor runs in CCW (if

parameter 4-10 Motor Speed Direction is set to [2] Both

directions).

MG92M102 Danfoss A/S © 02/2017 All rights reserved. 11

Page 14

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed. All trademarks in this material are property

of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

130R0548 MG92M102 02/2017

*MG92M102*

Loading...

Loading...