Fact Sheet

VLT® DriveMotor FCP 106

Standalone frequency converter for

mounting on any standard induction

or permanent magnet motor from

0.55–7.5 kW.

With a wide range of standard integrated pump and fan features, the

VLT® DriveMotor FCP 106 can provide

efficient control of motors in the

0.55 – 7.5 kW range.

By mounting the drive directly on the

motor, owners are free to choose their

own manufacturer and design the

optimal system for their application.

Once attached to the motor the drive

automatically sets the optimal parameters to provide stable, energy efficient

operation.

NO

motor cable required.

The FCP 106 is the perfect solution for

both OEMs and end-users. By mounting

the drive directly on the motor, with an

adjustable adaptor plate, you eliminate

the need for cabinets and reduce cable

PC software tool:

VLT® Motion Control Tool

MCT 10

Ideal for commissioning and servicing

the drive with IM or PM motor attached.

costs significantly. Setup is easy with

VLT® Motion Control Tool MCT 10.

Product range

3 x 380 – 480 V...... ..................... 0.55 – 7.5 kW

(with 110% overload torque)

3 x 380 – 480 V...... ..................... 0.55 – 5.5 kW

(with 160% overload torque )

3 x 380 – 480 V...... ................................... 7.5 kW

(with 150% overload torque )

Available enclosure ratings

IP66 (UL type 4X outdoor) 0.55 – 7.5 kW

Mount the FCP 106 on your preferred motor.

Feature Benefit

Graphical display, 7 languages Effective commissioning

External connection for display as standard Fast connectivity

Motor data pre-programmed No programming needed

IP66/UL type 4X outdoor Reliable in wet and dirty environments

PCB protection class 3C3 Reliable in corrosive environments

Vibration fullfilling LVD requirments Suitable for all motor mounted challenges

110% overload (0.55 – 7.5 kW) Optimised for fans and pumps

160% overload (0.55 – 5.5 kW)

150% overload (7.5 kW) High starting torque

Asynchronous or permanent magnet motor Free choice of motor technology

Sleep mode Save energy and extend lifetime

Automatic Energy Optimizer function Saves an additional 5-15% energy

AHU dedicated functions Reduces cost and saves energy

Pump dedicated functions Protects the pump and extends the lifetime

Built-in PI controller No external PI controller required

Smart Logic Controller (SLC) Often makes PLC/DDC unnecessary

Control signal for mechanical brake Reduce effort in PLC

Embedded via RS485:

FC Protocol, Modbus RTU, BACnet

Optional:

PROFIBUS DP V1

Integrated DC link Meets EN 61000-6-12, small power cable

Integrated EMC filters

High starting torque by one step up

in power size

Flexible connectivity

Meets EN 61800-3, (C1 and C2), and

EN 55011 Class B and A1

www.danfoss.com/fcm106

VLT® Memory Module

MCM 101

Facilitates helpful implementation of

factory settings for OEM and machine

builders, fast installation of firmware

updates, and easy commissioning or

exchange of drives in service situations.

Ordering number: 134B0791

Memory Module Programmer

Simply use your PC to copy the drive

settings from one VLT® Memory Module

to another.

Ordering number: 134B0792

VLT® Control Panel LCP 102

(Graphical LCP only)

Ordering number: 130B1107

Remote Mounting Kit

(LCP 102)

3 m cable, panel mounting bracket,

gasket and fastners

Ordering number: 134B0564

Local Operation Pad LOP

Panel for start/stop and setting

the reference.

Ordering number: 175N0128

Potentiometer for cable gland

For setting the reference directly at the

drive.

Ordering number: 177N0011

Motor Adapter Plate FCP 106

Ordering numbers:

MH1: 134B0340

MH2: 134B0390

MH3: 134B0440

Crimp terminals for mounting

FCP on motor

Ordering numbers:

0.2–0.5 mm2, 25 pcs.: 134B0495

0.5 –1.0 mm2, 25 pcs.: 134B0496

1.0–2.5 mm2, 25 pcs.: 134B0497

2.5– 4.0 mm2, 25 pcs.: 134B0498

4.0– 6.0 mm2, 25 pcs.: 134B0499

Specifications

Mains supply (L1, L2, L3)

Supply voltage 380 – 480 V ±10%

Supply frequency 50/60 Hz

Displacement power factor (cos φ) > 0.98 near unity

Switching on input supply L1, L2, L3 1–2 times/min.

Output data (U, V, W)

Output voltage 0–100% of supply voltage

Switching on output Unlimited

Ramp times 0,05–3600 sec.

Output frequency 0–590 Hz

Digital inputs

Programmable digital inputs 4

Logic PNP or NPN

Voltage level 0– 24 VDC

Analogue input

Analogue inputs 2

Modes Voltage or current

Voltage level 0 V to +10 V (scaleable)

Current level 0/4 to 20 mA (scaleable)

Digital/analogue output

Programmable outputs 2

Analogue output current level 0/4– 20 mA

Relay outputs

Programmable relay outputs 2 (resistive load 250 VAC, 3 A 30 VDC, 2 A)

Additional features when mounting the electronic (FCP 106) on your motor

Note your production info into the drive Identification of your programming

Change motor data to fit your motor Optimize settings for your motor settings

Create new factory settings (SIVP Technology) Ensure correct motor data settings

Motor cable length up to 2 m Meets EN 61800-3 C2

Custom adapter plate Mount FCP on every motor make

Oversized FCP can be mounted on motor Higher overload for critical applications

Motor independent cooling FCP fits on any motor

Wall Mounting Plate FCP 106

Ordering numbers:

MH1: 134B0341

MH2: 134B0391

MH3: 134B0441

Motor Adapter Plate FCM 106

(for Lafert motors only)

Ordering numbers:

MH1 – frame 71: 134B0338

MH1 – frame 80/90: 134B0339

MH2 – frame 71, : 134B0388

MH2 – frame 80-100: 134B0389

MH2 – frame 112: 134B0393

MH3 – frame 112: 134B0438

MH3 – frame 132: 134B0439

MH3 – frame 90/100: 134B0443

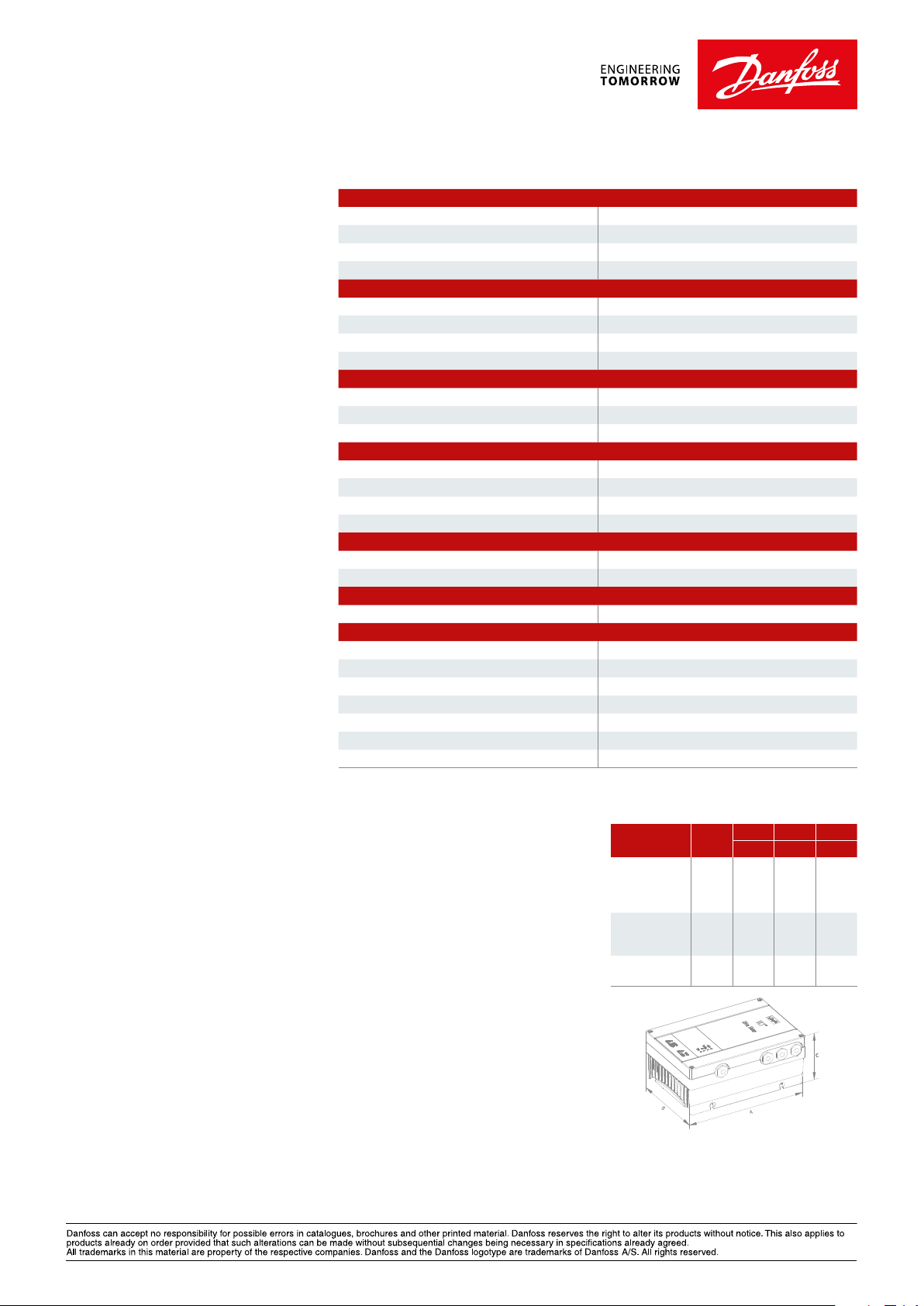

Dimensions

Dimensions

[mm]

MH1

MH2

MH3

Length Width Height

kW

A B C

0.55

0.75

231 162 107

1.1

1.5

2.2

34277 187 113

5.5

322 220 124

7.5

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, drives.danfoss.com, E-mail: info@danfoss.com

DKDD.PFP.703.B1.02 © Copyright Danfoss Drives | 2016.03

Loading...

Loading...