FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Table of Contents

Chapter 1 SafetyChapter 1 Safety

Chapter 1 SafetyChapter 1 Safety

Chapter 1 Safety

....................................................................................................................................................................

....................................................................................................................................................................

..................................................................................page 1-1

■ Warnings............................................... page 1-2

■ Safety Precautions ................................ page 1-3

■ Warning Against Unintended Start ....... page 1-3

Chapter 2Chapter 2

Chapter 2Chapter 2

Chapter 2

General TGeneral T

General TGeneral T

General T

echnical Dataechnical Data

echnical Dataechnical Data

echnical Data

........................................................................................................

........................................................................................................

....................................................page 2-1

■ Specifications ........................................ page 2-2

■ General Technical Data ......................... page 2-2

Chapter 3Chapter 3

Chapter 3Chapter 3

Chapter 3

DimensionsDimensions

DimensionsDimensions

Dimensions

..............................................................................................................................................

..............................................................................................................................................

.......................................................................page 3-1

■ Product Dimensions.............................. page 3-2

Chapter 4Chapter 4

Chapter 4Chapter 4

Chapter 4

OrderingOrdering

OrderingOrdering

Ordering

....................................................................................................................................................................

....................................................................................................................................................................

.................................................................................. page 4-1

■ Ordering information ..............................page 4-2

■ Ordering form ........................................ page 4-7

Chapter 5Chapter 5

Chapter 5Chapter 5

Chapter 5

Product ConceptProduct Concept

Product ConceptProduct Concept

Product Concept

............................................................................................................................

............................................................................................................................

..............................................................page 5-1

■ Integrating an AFD and motor .............. page 5-2

Chapter 6Chapter 6

Chapter 6Chapter 6

Chapter 6

InstallationInstallation

InstallationInstallation

Installation

..................................................................................................................................................

..................................................................................................................................................

.........................................................................page 6-1

■ Mechanical installation .......................... page 6-2

■ Motor information..................................page 6-4

■ Terminal Scpecifications ........................ page 6-6

■ Electrical Installation .............................. page 6-8

Chapter 7Chapter 7

Chapter 7Chapter 7

Chapter 7

OperationOperation

OperationOperation

Operation

....................................................................................................................................................

....................................................................................................................................................

..........................................................................page 7-1

■ Start-up ................................................. page 7-2

■ Control Options .....................................page 7-2

■ Local Control Panel ...............................page 7-5

Chapter 8Chapter 8

Chapter 8Chapter 8

Chapter 8

Parameter Group 0: Operation & DisplayParameter Group 0: Operation & Display

Parameter Group 0: Operation & DisplayParameter Group 0: Operation & Display

Parameter Group 0: Operation & Display

..............................................................

..............................................................

............................... page 8-1

■ Parameters 001-019 ............................. page 8-2

Chapter 9Chapter 9

Chapter 9Chapter 9

Chapter 9

Parameter Group 1: Load & MotorParameter Group 1: Load & Motor

Parameter Group 1: Load & MotorParameter Group 1: Load & Motor

Parameter Group 1: Load & Motor

....................................................................

....................................................................

.................................. page 9-1

Instruction Manual

MG.03.B6.22 Document Version 2.0

Software version 2.1x

The software version number

is displayed in parameter 624

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

■ Parameters 100-139 ............................. page 9-2

Chapter 10Chapter 10

Chapter 10Chapter 10

Chapter 10

Parameter Group 2: References & LimitsParameter Group 2: References & Limits

Parameter Group 2: References & LimitsParameter Group 2: References & Limits

Parameter Group 2: References & Limits

..............................................................

..............................................................

...............................

page 10-1

■ Parameters 200-231 ............................. page 10-2

Chapter 11Chapter 11

Chapter 11Chapter 11

Chapter 11

Parameter Group 3: Inputs & OutputsParameter Group 3: Inputs & Outputs

Parameter Group 3: Inputs & OutputsParameter Group 3: Inputs & Outputs

Parameter Group 3: Inputs & Outputs

............................................................

............................................................

..............................page 11-1

■ Parameters 317-340 ............................. page 11-2

Chapter 12Chapter 12

Chapter 12Chapter 12

Chapter 12

Parameter Group 4: Special FunctionsParameter Group 4: Special Functions

Parameter Group 4: Special FunctionsParameter Group 4: Special Functions

Parameter Group 4: Special Functions

........................................................

........................................................

............................page 12-1

■ Parameters 400-446 ............................. page 12-2

Chapter 13Chapter 13

Chapter 13Chapter 13

Chapter 13

Parameter Group 5: Serial CommunicationParameter Group 5: Serial Communication

Parameter Group 5: Serial CommunicationParameter Group 5: Serial Communication

Parameter Group 5: Serial Communication

............................................................

............................................................

..............................page 13-1

■ Parameters 500-543 ............................. page 13-2

Chapter 14Chapter 14

Chapter 14Chapter 14

Chapter 14

Parameter GrParameter Gr

Parameter GrParameter Gr

Parameter Gr

oup 6: Toup 6: T

oup 6: Toup 6: T

oup 6: T

echnical Functionsechnical Functions

echnical Functionsechnical Functions

echnical Functions

..............................................................

..............................................................

...............................page 14-1

■ Parameters 600-635 ............................. page 14-2

Chapter 15Chapter 15

Chapter 15Chapter 15

Chapter 15

Serial CommunicationSerial Communication

Serial CommunicationSerial Communication

Serial Communication

............................................................................................................

............................................................................................................

......................................................page 15-1

■ Danfoss PC Software ............................ page 15-2

■ Serial bus ..............................................page 15-3

■ Telegram Communication ..................... page 15-3

■ Telegram Build-up ................................. page 15-3

■ Data Bytes ............................................ page 15-4

Chapter 16Chapter 16

Chapter 16Chapter 16

Chapter 16

MessagesMessages

MessagesMessages

Messages

..................................................................................................................................................

..................................................................................................................................................

.........................................................................page 16-1

■ List of Warnings and Alarms ................. page 16-2

■ What if the Motor Does Not Start? .......page 16-2

■ Warnings............................................... page 16-3

■ Warnings Words 1+2 and Alarm Word . page 16-5

Chapter 17Chapter 17

Chapter 17Chapter 17

Chapter 17

CE / EMCCE / EMC

CE / EMCCE / EMC

CE / EMC

..................................................................................................................................................

..................................................................................................................................................

.........................................................................page 17-1

Table of Contents

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

■ CE Labeling ........................................... page 17-2

■ The Machinery Directive (89/392/EEC) . page 17-2

■ The Low-Voltage Directive /73/23/EEC)page 17-2

■ The EMC Directive (89/336/EEC) ......... page 17-2

■ Compliance with EMC Directive (89/336/EEC) page 17-2

■ What is Covered? ................................. page 17-2

■ Danfoss VLT

®

DriveMotor & CE Labeling page 17-3

■ Galvanic Isolation (PELV ) ...................... page 17-3

■ Ground Leakage Current .....................page 17-4

■ Acoustic Noise ...................................... page 17-4

■ Balance................................................. page 17-4

■ Extreme Running Conditions ................page 17-4

■ EMC Standards .................................... page 17-5

■ Harsh Environments .............................. page 17-6

Chapter 18Chapter 18

Chapter 18Chapter 18

Chapter 18

Special ConditionsSpecial Conditions

Special ConditionsSpecial Conditions

Special Conditions

....................................................................................................................

....................................................................................................................

..........................................................page 18-1

■ Derating ................................................ page 18-2

■ Derating for Ambient Temperature and

for running at low speed ....................... page 18-2

■ Derating for Air Pressure.......................page 18-2

■ Derating for High Switching Frequency .page 18-3

■ Vibration and Shock ............................... page 18-3

■ Air Humidity ...........................................page 18-3

■ Efficiency............................................... page 18-3

■ Harmonics............................................. page 18-4

■ Power Factor ........................................ page 18-4

Chapter 19Chapter 19

Chapter 19Chapter 19

Chapter 19

ParametersParameters

ParametersParameters

Parameters

..............................................................................................................................................

..............................................................................................................................................

.......................................................................page 19-1

■ Factory Parameter Settings .................. page 19-2

Chapter 20Chapter 20

Chapter 20Chapter 20

Chapter 20

IndexIndex

IndexIndex

Index

..............................................................................................................................................................

..............................................................................................................................................................

............................................................................... ..page 20-1

■ Index ..................................................... page 20-2

Table of Contents

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Chapter 1Chapter 1

Chapter 1Chapter 1

Chapter 1 ■ Warnings............................................... page 1-2

■ Safety Precautions ................................ page 1-3

■ Warning Against Unintended Start ....... page 1-3

Safety

1-1

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

Safety

WARNINGWARNING

WARNINGWARNING

WARNING

WARNINGWARNING

WARNINGWARNING

WARNING

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

The FCM 300 Series unit contains dangerous voltages when connected to line voltage.

After disconnection from the line, wait at least 4 minutes before touching any electrical

components. Also make sure that other voltage inputs have been disconnected. Only a

competent electrician should carry out the electrical installation. Improper installation of

the FCM 300 Series unit may cause equipment failure, serious injury or death. Follow this

manual and the National Electrical Codes (NEC

®

) and local safety codes.

Electrostatic Precaution: Electrostatic discharge (ESD). Many electronic components are

sensitive to static electricity. Voltages so low that they can not be felt, seen or heard, can

reduce the life, affect performance, or completely destroy sensitive electronic.

When performing service, proper ESD equipment should be used to prevent possible

damage from occurring.

It is the reponsibility of the user or the person installing the FCM 300 to provide proper

grounding and branch circuit protection according to the National Electrical Code (NEC

®

)

and local codes.

Motor overload protection is internal to the unit.

1-2

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Safety

Safety Precautions

1. The FCM 300 unit must be disconnected from

the AC line if repair work is to be carried out.

After the AC supply has been disconnected, be

sure the necessary time (4 min.) has passed

before removing line terminal wires.

2. The "Stop/Reset" key on the optional local

control pad or local operating panel of the FCM

300 unit DOES NOT disconnect the equipment

from the AC line and is

NOT to be used as a

safety switch.

3. The installer must supply correct protective

grounding of the equipment and the user must

be protected against supply voltage in

accordance with the National Electrical Code

and local codes. Class 20 motor overload protection is provided internally.

4. The ground leakage currents are higher than 3.5

mA.

5. Use lifting points, if provided. Lift FCM 300 units

vertically only. Lifting points are provided to

support the weight of the FCM 300 only - do not

use lifting points when additional equipment is

attached.

6. Before installation, check unit for fan cover

damage, foot/mounting damage, shaft damage

and loose fasteners. Check nameplate data on

motor.

7. FCM 300 types 311-375 (over 44 lb/20 kg)

should be positioned by lifting machines only for your safety, do not attempt hand lifting. Refer

to "Handling the FCM 300" on page 6-5 for

actual weights.

8. Installation must be correctly fused and isolated

per CE directives.

Warning Against Unintended Start

1. The unit can be brought to a stop by means of

digital commands, bus commands, references or

a local stop, while the FCM 300 unit is

connected to the AC line.

These stop functions are

NOT sufficient to

ensure that no unintended start occurs and

should

NOT be used for personal safety

considerations.

2. While parameters are being changed, the motor

may start.

3. A FCM 300 unit that has been stopped may start

if faults occur int the electronics of the unit, or if a

temporary overload occurs or if there is an

interruption in the AC line supply.

1-3

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Chapter 2Chapter 2

Chapter 2Chapter 2

Chapter 2 ■ Specifications ........................................page 2-2

■ General Technical Data ......................... page 2-2

General Technical Data

2-1

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

General Technical Data

■ FCM 305-375 for 3 phases, 380-480 V

FCMFCM

FCMFCM

FCM

305305

305305

305

307307

307307

307

311311

311311

311

315 315

315 315

315

322322

322322

322

330330

330330

330

340340

340340

340

355355

355355

355

375375

375375

375

Motor output

[HP] 0.75 1.0 1.5 2.0 3.0 4.0 5.0 7.5 10.0

[kW] 0.55 0.75 1.1 1.5 2.2 3.0 4.0 5.5 7.5

Motor torque

2 pole [Nm] 1.8 2.4 3.5 4.8 7.0 9.5 12.6 17.5 24.0

4 pole [Nm] 3.5 4.8 7.0 9.6 14.0 19.1 25.4 35.0 48.0

Frame

size [mm] 56 56 143 145 182 182 184 213 215

Weight [kg] 11 13 17 20 26 28 37 56 61

Input current

380 V

2 p 1.4 1.6 2.2 2.8 4.1 5.3 7.0 9.3 13.0

4p 1.4 1.7 2.5 3.3 4.7 6.4 7.9 11.1 15.3

480 V

2 p 1.2 1.3 1.8 2.3 3.3 4.2 5.6 7.4 10.2

4 p 1.1 1.4 2.0 2.6 3.7 5.1 6.4 8.8 11.9

Power

terminals

[AWG] 10 10 10 10 10 10 10 6 6

[mm2] 44444441010

Gland sizes 3XPG16* 3XPG16* 3XPG16* 3XPG16* 3XPG16* 3XPG16* 3XPG16* 1XPG21/ 1XPG21/

3XPG16* 3XPG16*

Max. prefuse

UL

1)

[A] 10 10 10 10 10 15 15 25 25

IEC1) [A] 25 25 25 25 25 25 25 25 25

* PG to NPT adapters can be ordered separately. See page 4-5.

1)

Type gG prefuses must be used. If you wish to observe UL/cUL, KTS-R 500 V pre-fuses or equivalent must

be used. The fuses must provide protection in a circuit capable of supplying max. 100,000 amps rms

(symmetrical), 500 V maximum.

AC line supply, TT, TN and IT* (L1, L2, L3):

- Supply voltage 380-480 V units ......................................................... 3 x 380/400/415/440/460/480 V ±10%

- Supply frequency ...............................................................................................................................50/60 Hz

- Max. imbalance of supply voltage....................................................................... ±2% of rated supply voltage

- Power factor / cos ϕ ....................................................................................................... max. 0.9/1.0 at rated load

- Switching on supply input L1, L2, L3 ............................................................................. approx. 1 time/2 min

See chapter 18, "Special conditions".

*) Not valid for RFI class 1B units

Torque characteristics:

- Starting torque/overload torque ..............................................................................................160 % for 1 min

- Continuous torque .................................................................................................................... see page 18-2

■ General technical data

2-2

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

General Technical Data

Control card, analog inputs:

- No. of programmable analog voltage inputs ................................................................................................. 1

- Terminal nos. ......................................................................................................................................... X101-2

- Voltage level .................................................................................................................. 0 - 10 V DC (scalable)

- Input resistance, R

i

................................................................................................................... approx. 10 kΩ

- No. of programmable analog current inputs ...................................................................................................1

- Terminal no. .......................................................................................................................................... X101-1

- Current range ................................................................................................................... 0 - 20 mA (scalable)

- Input resistance, R

i

................................................................................................................... approx. 300 Ω

- Resolution .................................................................................................................................................. 9 bit

- Accuracy on input................................................................................................... Max. error 1% of full scale

- Scanning time ................................................................................................................................... 20 msec.

Control card, digital/pulse and analog outputs:

- No. of programmable digital and analog outputs ......................................................................................... 1

- Terminal nos. ......................................................................................................................................... X101-9

- Voltage level at digital output/load .................................................................................... 0 - 24 V DC/25 mA

- Current at analog output ................................................................................................................. 0 - 20 mA

- Maximum load to frame (terminal 8) at analog output ............................................................... R

LOAD

≤ 500 Ω

- Accuracy of analog output ................................................................................ Max. error: 1.5% of full scale

- Resolution on analog output. .....................................................................................................................8 bit

Control card, RS 485 serial communication:

- Terminal nos. ................................................................................................................................... X100-1, -2

Control characteristics (adjustable frequency drive):

- Frequency range ..............................................................................................................................0 - 132 Hz

- Resolution on output frequency ............................................................................................................. 0.1 %

- System response time ............................................................................................................ Max. 40 msec.

Control card, digital/pulse inputs:

- Number of programmable digital inputs ..........................................................................................................4

- Terminal nos. ........................................................................................................................X101-2, -3, -4, -5

- Voltage level ................................................................................................... 0-24 V DC (PNP positive logics)

- Voltage level, logic ´0´ ........................................................................................................................ < 5 V DC

- Voltage level, logic ´1´ ...................................................................................................................... > 10 V DC

- Maximum voltage on input ................................................................................................................. 28 V DC

- Input resistance, R

i

..................................................................................................................... approx. 2 kΩ

- Scanning time ................................................................................................................................... 20 msec

Control card, pulse input:

- No. of programmable pulse inputs ................................................................................................................ 1

- Terminal nos. ......................................................................................................................................... X101-3

- Max. frequency on terminal 3, open collector/push pull 24 V ................................................... 8 kHz/70 kHz

- Resolution ................................................................................................................................................ 10 bit

- Accuracy (0.1-1 kHz), terminal 3 ...................................................................... Max. error: 0.5% of full scale

- Accuracy (1-12 kHz), terminal 3 ........................................................................ Max. error: 0.1% of full scale

2-3

Externals:

- Enclosure ............................................................................................................................. IP 55 (IP56, IP66)

- Vibration test ........................................................................................................ (IEC 68 see page 18-3) 1 g

- Max. relative humidity ...................................................93 % +2 %, -3 % (IEC 68-2-3) for storage/transport

- Ambient temperature .......................................................................Max. 40°C (24-hour average max. 35°C)

Derating for high ambient temperature, see chapter 18.

- Min. ambient temperature in full operation .................................................................................................0°C

- Min. ambient temperature at reduced performance .............................................................................. -10°C

- Temperature during storage/transport .....................................................................................-25 - +65/70°C

- Max. altitude above sea level ................................................................................................ 3,300 ft./1000 m

Derating for air pressure, see chapter 18.

- EMC standards applied, Emission................................... EN 50081-1/2, EN 61800-3, EN 55011, EN 55014

Immunity ................... EN 50082-2, EN 61000-4-2, IEC 1000-4-3, EN 61000-4-4

EN 61000-4-5, ENV 50140, ENV 50141

- Safety standards applied, ............................................................................EN 60146, EN 50178, EN 60204

UL508

Protection:

••

••

• Thermal overload protection of motor and electronics.

••

••

• Monitoring of the intermediate circuit voltage ensures that the inverter cuts out if the intermediate circuit

voltage gets too high or too low.

••

••

• If an AC line phase is missing, the inverter will cut out when a load is placed on the motor.

••

••

• Overcurrent, and voltage transients protection.

2-4

MG.03.B6.22 - VL T is a r egistered Danfoss trademark

General Technical Data

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Chapter 3Chapter 3

Chapter 3Chapter 3

Chapter 3 ■

DimensionsDimensions

DimensionsDimensions

Dimensions

....................................................................................

....................................................................................

..........................................page 3-2

Dimensions

3-1

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

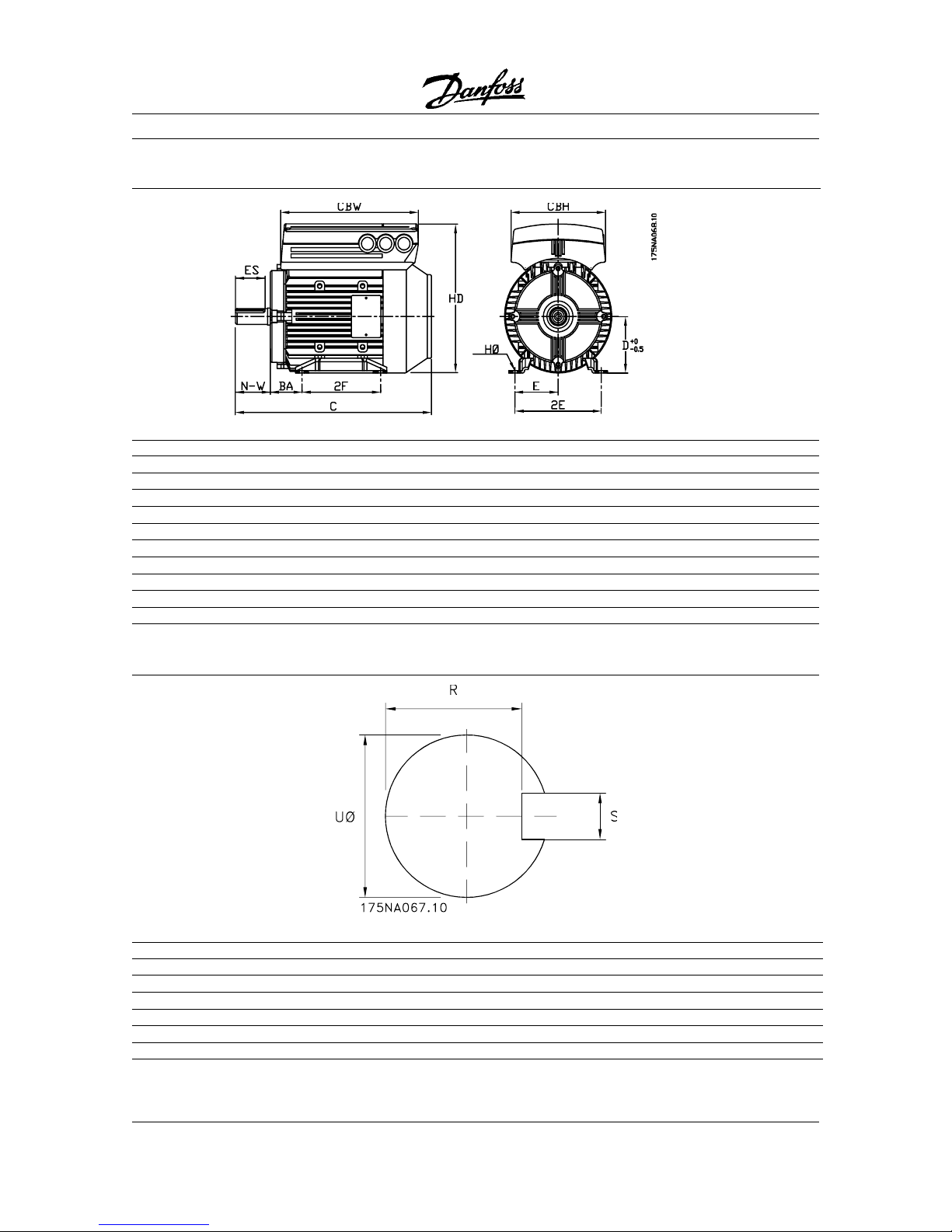

Dimensions

FCMFCM

FCMFCM

FCM

305305

305305

305

307307

307307

307

311311

311311

311

315315

315315

315

322322

322322

322

330330

330330

330

340340

340340

340

355355

355355

355

375375

375375

375

Frame sizeFrame size

Frame sizeFrame size

Frame size

5656

5656

56

5656

5656

56

143T143T

143T143T

143T

145T145T

145T145T

145T

182¨T182¨T

182¨T182¨T

182¨T

182T182T

182T182T

182T

184T184T

184T184T

184T

213T213T

213T213T

213T

215T215T

215T215T

215T

HPHP

HPHP

HP

0.750.75

0.750.75

0.75

1.01.0

1.01.0

1.0

1.51.5

1.51.5

1.5

2.02.0

2.02.0

2.0

3.03.0

3.03.0

3.0

4.04.0

4.04.0

4.0

5.55.5

5.55.5

5.5

7.57.5

7.57.5

7.5

10.010.0

10.010.0

10.0

UØ [in] 0.625 0.625 0.875 0.875 1.125 1.125 1.125 1.375 1.375

N-W [in] 1.875 1.875 2.25 2.25 2.75 2.75 2.75 3.25 5.575

ES [in] 1.375 1.375 1.406 1.406 1.75 1.75 1.75 2.375 2.375

S [in] 0.188 0.188 0.188 0.188 0.25 0.25 0.25 0.313 0.313

R [in] 0.517 0.517 0.771 0.771 0.986 0.986 0.986 1.201 1.201

Foot mounting - B3Foot mounting - B3

Foot mounting - B3Foot mounting - B3

Foot mounting - B3

GeneralGeneral

GeneralGeneral

General

FCMFCM

FCMFCM

FCM

305305

305305

305

307307

307307

307

311311

311311

311

315315

315315

315

322322

322322

322

330330

330330

330

340340

340340

340

355355

355355

355

375375

375375

375

Frame sizeFrame size

Frame sizeFrame size

Frame size

5656

5656

56

5656

5656

56

143T143T

143T143T

143T

145T145T

145T145T

145T

NANA

NANA

NA

NANA

NANA

NA

184T184T

184T184T

184T

213T213T

213T213T

213T

215T215T

215T215T

215T

HPHP

HPHP

HP

0.750.75

0.750.75

0.75

1.01.0

1.01.0

1.0

1.51.5

1.51.5

1.5

2.02.0

2.02.0

2.0

--

--

-

--

--

-

5.55.5

5.55.5

5.5

7.57.5

7.57.5

7.5

10.010.0

10.010.0

10.0

2E [in] 4.875 4.875 5.5 5.5 - - 7.5 8.5 8.5

BA [in] 2.75 2.75 2.25 2.25 - - 2.75 3.5 3.5

D [in] 3.5 3.5 3.5 3.5 - - 4.5 5.25 5.25

HØ [in] 0.344 0.344 0.344 0.344 - - 0.5 0.5 0.5

2F [in] 3 3 4 5 - - 4 5.5 7

C [in] 12.25 12.25 13 13 - - 15.78 17.781 17.781

CBW [in] 8.11 8.11 9.06 9.06 - - 11.26 13.38 13.38

CBH [in] 5.55 5.55 6.22 6.22 - - 7.76 9.25 9.25

HD [in] 8,98 8,98 9,31 9,31 11,50 13,14 13,14

Shaft Drive EndShaft Drive End

Shaft Drive EndShaft Drive End

Shaft Drive End

■ Dimensions

3-2

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

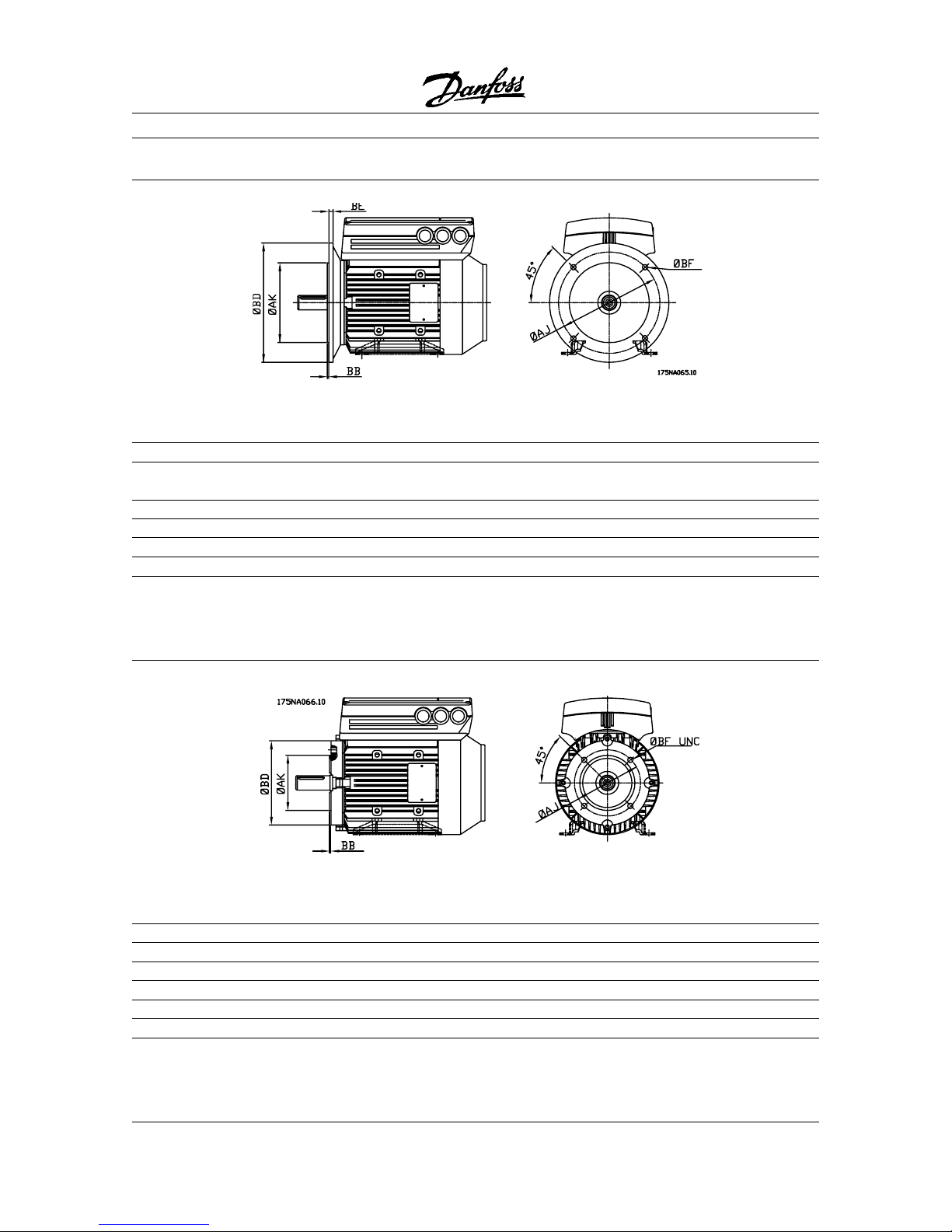

B14B14

B14B14

B14

FCMFCM

FCMFCM

FCM

305305

305305

305

307307

307307

307

311311

311311

311

315315

315315

315

322322

322322

322

330330

330330

330

340340

340340

340

355355

355355

355

375375

375375

375

Frame sizeFrame size

Frame sizeFrame size

Frame size

5656

5656

56

5656

5656

56

143143

143143

143

145145

145145

145

182182

182182

182

182182

182182

182

184184

184184

184

213213

213213

213

215215

215215

215

HPHP

HPHP

HP

0.750.75

0.750.75

0.75

1.01.0

1.01.0

1.0

1.51.5

1.51.5

1.5

2.02.0

2.02.0

2.0

3.03.0

3.03.0

3.0

4.04.0

4.04.0

4.0

5.55.5

5.55.5

5.5

7.57.5

7.57.5

7.5

10.010.0

10.010.0

10.0

ØAJ [in] 5.575 5.875 8.575 5.875 5.875 7.25 7.25 7.25 7.25

ØAK [in] 4.5 4.5 4.5 4.5 4.5 8.5 8.5 8.5 8.5

ØBD [in] 6.5 6.5 6.5 6.5 6.5 9 9 9 9

ØBF UNC [in] 0.375 0.375 0.375 0.375 0.375 0.5 0.5 0.5 0.5

BB [in] 0.125 0.125 0.125 0.125 0.156 0.156 0.25 0.25 0.25

Flange mounting - B5, B35 (B3+B5)Flange mounting - B5, B35 (B3+B5)

Flange mounting - B5, B35 (B3+B5)Flange mounting - B5, B35 (B3+B5)

Flange mounting - B5, B35 (B3+B5)

B5B5

B5B5

B5

FCMFCM

FCMFCM

FCM

305305

305305

305

307307

307307

307

311311

311311

311

315315

315315

315

322322

322322

322

330330

330330

330

340340

340340

340

355355

355355

355

375375

375375

375

Frame sizeFrame size

Frame sizeFrame size

Frame size

NANA

NANA

NA

NANA

NANA

NA

143143

143143

143

145145

145145

145

182182

182182

182

182182

182182

182

184184

184184

184

213213

213213

213

215 215

215 215

215

HPHP

HPHP

HP

--

--

-

--

--

-

1.51.5

1.51.5

1.5

2.02.0

2.02.0

2.0

3.03.0

3.03.0

3.0

4.04.0

4.04.0

4.0

5.55.5

5.55.5

5.5

7.57.5

7.57.5

7.5

10.010.0

10.010.0

10.0

ØAJ [in] - - 10 10 10 10 10 10 10

ØAK[in] - - 9 999999

ØBD[in] - - 11 11 11 11 11 11 11

ØBF [in] - - 0.531 0.531 0.531 0.531 0.531 0.531 0.531

BB [in] - - 0.25 0.25 0.25 0.25 0.25 0.25 0.25

BE [in] - - 0.5 0.5 0.50 0.50 0.5 0.5 0.5

Face mounting - B14, B34 (B3+B14)Face mounting - B14, B34 (B3+B14)

Face mounting - B14, B34 (B3+B14)Face mounting - B14, B34 (B3+B14)

Face mounting - B14, B34 (B3+B14)

Dimensions

3-3

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Ordering

Chapter 4Chapter 4

Chapter 4Chapter 4

Chapter 4 ■ Ordering information overview .................... page 4-2

■ Product range VLT

®

DriveMotor

FCM 300 Series

..................................... page 4-4

■ Ordering information for

frames and flanges ................................ page 4-6

4-1

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

Ordering Information Overview

■■

■■

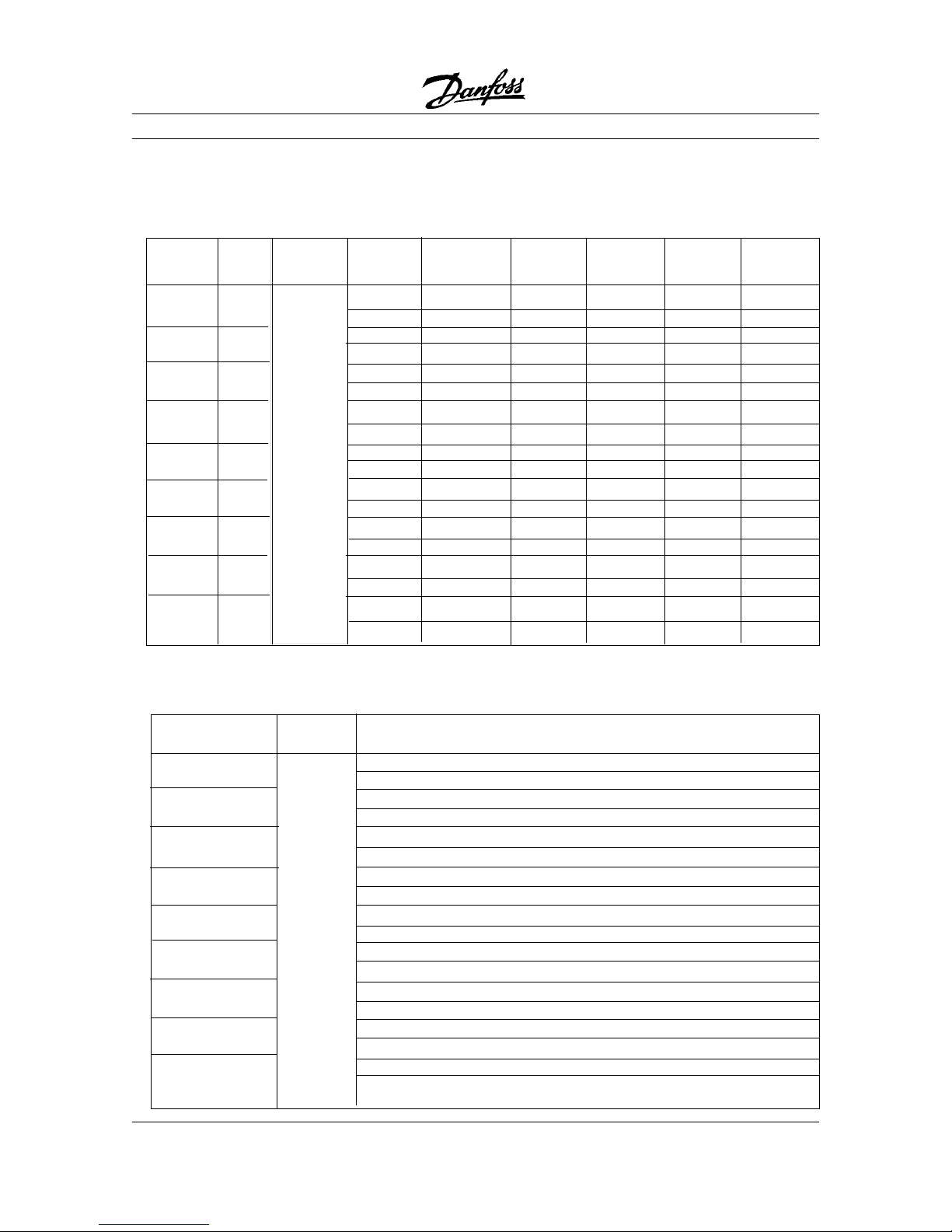

■ Code Numbers for 2 Pole Motors with HVAC Parameter Setting H

Type HP Phases Hardw. Foot D Flange C Face Foot & Foot &

Nema Ref Voltage Variant D Flange C Fac

e

FCM305 0.75 ST 176H1578 NA 176H1579 NA 176H1580

56 SP 176H1581 NA 176H1582 N A 176H1583

FCM307 1.0 ST 176H1584 N A 176H1585 NA 176H1586

56 T4 SP 176H1587 NA 176H1588 NA 176H1589

FCM311 1.5 3 phase ST 176H1590 176H1591 176H1592 176H1593 176H1594

143 380-480 V SP 176H1595 176H1596 176H1597 176H1598 176H1599

FCM315 2.0 ST 176H1600 176H1601 176H1602 176H1603 176H1604

145 SP 176H1605 176H1606 176H1607 176H1608 176H1609

FCM322 3.0 ST NA 176H1610 176H1611 NA NA

182 SP NA 176H1612 176H1613 N A NA

FCM330 4.0 ST NA 176H1614 176h1615 NA NA

182 SP NA 176H1616 176H1617 N A NA

FCM340 5.5 ST 176H1618 176H1619 176H1620 176H1621 176H1622

184 SP 176H1623 176H1624 176H1625 176H1626 176H1627

■ Code Numbers for 2 Pole Motors with HVAC Parameter Setting H

4-2

SP 176H1643 176H1644 176H1645 176H1646 176H1647

FCM350 7.5 ST 176H1628 176H1629 176H1630 176H1631 176H1632

213 SP 176H1633 176H1634 176H1635 176H1636 176H1637

FCM375 10.0 ST

215

176H1638 176H1639 176H1640 176H1641 176H1642

Type HP Phases Hardw. Foot D FLange C Face Foot & Foot &

Nema Ref Voltage Variant D Flange C Face

FCM305 0.75 ST 176H1648 NA 176H1649 N A 176H1650

56 SP 176H1651 NA 176H1652 NA 176H1653

FCM311 1.5 T4 ST 176H1660 176H1661 176H1662 176H1663 176H1664

143 3 phase SP 176H1665 176H1666 176H1667 176H1668 176H1669

FCM315 2.0 380-480 V ST 176H1670 176H1671 176H1672 176H1673 176H1674

145 SP 176H1675 176H1676 176H1677 176H1678 176H1679

FCM322 3.0 ST NA 176H1680 176H1681 NA NA

182 SP NA 176H1682 176H1683 NA NA

FCM330 4.0 ST NA 176H1684 176H1685 NA NA

182 SP NA 176H1686 176H167 N A N A

FCM340 5.5 ST 176H1688 176H1689 176H1690 176H1691 176H1692

184 SP 176H1693 176H1694 176H1695 176H1696 176H1697

FCM350 7.5 ST 176H1698 176H1699 176J1700 176H701 176H1702

213 SP 176H1703 176H1704 176H1705 176H1706 176H1707

FCM375 10.0 ST 176H1708 176H1709 176H1710 176H1711 176H1712

215 SP 176H1713 176H1714 176H1715 176H1716 176H1717

FCM307 1.0 ST 176H1654 N A 176H1655 NA 176H1656

56 SP 176H1657 NA 176H1658 NA 176H1659

Ordering

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

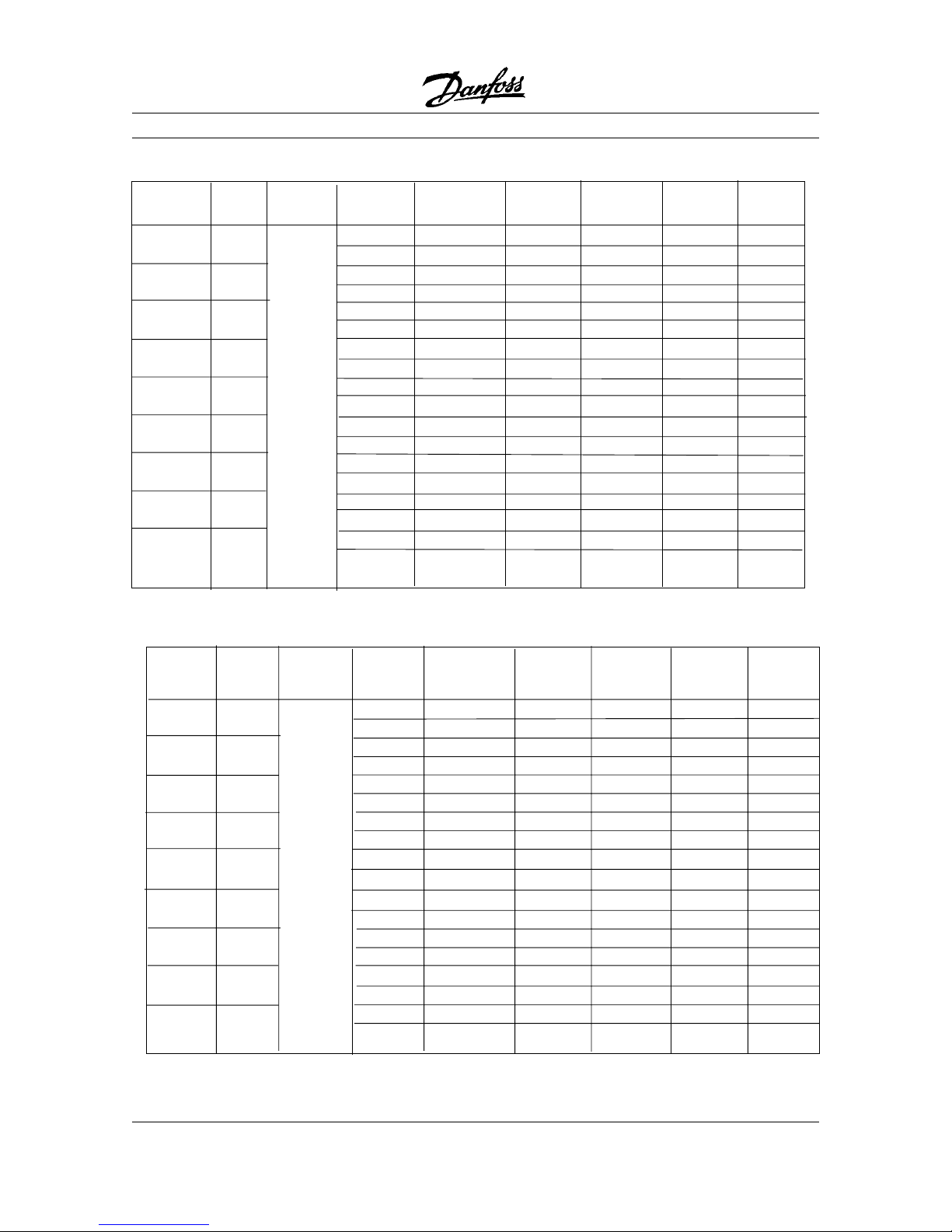

■■

■■

■ Code Numbers for 2 Pole Motors with Industrial Parameter Setting I

Type H P Phases Hardw. Foot D Flange C Face Foot & Foot &

Nema Ref Voltage Variant D Flange C Face

FCM305 0.75 ST 176H1864 NA 176H1865 N A 176H1866

56 SP 176H1867 NA 176H1868 NA 176H1869

FCM307 1.0 ST 176H1870 N A 176H1871 NA 176H1872

56 SP 176H1873 NA 176H1874 NA 176H1875

FCM311 1.5 T4 ST 176H1876 176H1877 176H1878 176H1879 176H1880

143 3 phase S P 176H1881 176H1882 176H1883 176H1884 176J1885

FCM315 2.0 380-180V ST 176H1886 176H1887 176H1888 176H1889 176H1890

145 SP 176H1891 176H1892 176H1893 176H1894 176H1895

FCM322 3.0 ST NA 176H1896 176H1897 NA NA

182 SP NA 176H1898 176H1899 NA NA

FCM330 4.0 ST NA 176H1900 176H1901 NA NA

182 SP NA 176H1902 176H1903 NA NA

FCM340 5.5 ST 176H1904 176H1905 176H1906 176H1907 176H1908

184 SP 176H1909 176H1910 176H1911 176H1912 176H1913

FCM350 7.5 ST 176H1914 176H1915 176H1916 176H1917 176H1918

213 SP 176H1919 176H1920 176H1921 176H1922 176H1923

FCM375 10.0 ST 176H1924 176H1925 176H1926 176H1927 176H1928

215 SP 176H1929 176H1930 176H1931 176H1932 176H1933

4-3

Type HP Phases Hardw. Foot D Flange C Face Foot & Foot &

Nema Ref Voltage Variant D Flange C Face

FCM305 0.75 ST 176H1934 NA 176H1935 NA 176H1936

56 SP 176H1937 NA 176H1938 N A 176H1939

FCM307 1.0 ST 176H1940 N A 176H1941 NA 176H1942

56 SP 176H1943 NA 176H1944 N A 176H1945

FCM311 1.5 T4 ST 176H1946 176H1947 176H1948 176H1949 176H1950

143 3 phase S P 176H1951 176H1952 176H1953 176H1954 176H1955

FCM315 2.0 380-480 V S T 176H1956 176H1957 176H1958 176H1959 176H1960

145 SP 176H1961 176H1962 176H1963 176H1964 176H1965

FCM322 3.0 ST NA 176H1966 176H1967 NA NA

182 SP NA 176H1968 176H1969 N A NA

FCM330 4.0 ST NA 176H1970 176H1971 NA NA

182 SP NA 176H1972 176H1973 N A NA

FCM 340 5.5 ST 176H1974 176H1975 176H1976 176H1977 176H1978

184 SP 176H1979 176H1980 176H1981 176H1982 176H1983

FCM350 7.5 ST 176H1984 176H1985 176H1986 176H1987 176H1988

213 SP 176H1989 176H1990 176H1991 176H1992 176H1993

FCM375 10.0 ST 176H1994 176H1995 176H1996 176H1997 176H1998

215 SP 176H1999 176H2000 176H2001 176H2002 176H2003

■■

■■

■ Code Numbers for 4 Pole Motors with Industrial Parameter Setting I

Ordering

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

■ Product range VLT® DriveMotor FCM 300 Series,

2/4 poled motors

FCM 355-P-T4-ST-S55-R2-0213T-4-1-B03-213-T-00

This means that the ordered FCM300 is an

FCM355 7,5 HP, three-phase mains voltage of

380 - 480V +/- 10%,

T4 and for process

application

P. The inverter is a standard version

for remote control

ST in a NEMA 12/IP55

enclosure

S55 with integrated RFI filter, class B1

R2. The motor frame size and version is 213T

which is a foot mounted motor

0213T. The motor

has 4 poles

4 and is cooled by the shaft-mounted

fan

1. The motor is a foot mounted motor B03

and the frame is 213. The inverter box is

mounted on the top of the motor

T and no drain

hole is placed

00.

As an example the above motor with D flange,

inverter on the right side, drain hole position

between feet

FCM355-P-T4-ST-S55-R2-0213T-4-1-B05-213R-D1

If you wish to place your order by using the type

code directly, please use the codes given in

parenthesis on the left-hand side of the ordering

forms. The code sequence in the type code is

stated at the top of each part of the form

(character number).

The ordering form for the basic unit must always

be completed. When the type code is written,

always state the characters of the basic string (1-

30).

Together with the order confirmation the

customer receives an 8-figure code number to be

used when reordering.

Type

Motor

Mains supply

output

FCM 305FCM 305

FCM 305FCM 305

FCM 305 0.75 HP

FCM 307FCM 307

FCM 307FCM 307

FCM 307 1.0 HP

FCM 311FCM 311

FCM 311FCM 311

FCM 311 1.5 HP

FCM 315FCM 315

FCM 315FCM 315

FCM 315 2.0 HP

FCM 322FCM 322

FCM 322FCM 322

FCM 322 3.0 HP

3 phase 380-480 V

FCFC

FCFC

FC

M 330M 330

M 330M 330

M 330 4.0 HP

FCM 340FCM 340

FCM 340FCM 340

FCM 340 5.0 HP

FCM 35FCM 35

FCM 35FCM 35

FCM 35

55

55

5 7.5 HP

FCM 37FCM 37

FCM 37FCM 37

FCM 37

55

55

5 10.0 HP

Each type in the product range is available in

different versions.

Inverter versions

Drive control:

-ST: Standard version

- SP: Version for PROFIBUS

RFI filter:

Inverter with integrated RFI filter, class A1 (industrial)

or class B1 (domestic).

Cooling:

- TEFV: Motor cooled by a shaft mounted fan (IC

411)

- FV: Motor cooled by an independent fan (IC 416)

(Not UL)

Mounting versions

- Foot mounting (B3)

- Flange mounting (B5)

- Face mounting (B14)

- Foot + flange mounting (B35)

- Foot + face mounting (B34)

See chapter 6.

Inverter box position: Top, right side or left side.

Drainhole (+ position): None, between feet, opposite

feet, vertical drive end, vertical non-drive end, 90°

right of feet, 90° left of feet.

■■

■■

■ NEMA Ordering

Take a copy of the ordering forms on page 4-8. Fill

in and post or fax your order to the nearest branch

office of the Danfoss sales organisation. On the

basis of your order, the FCM 300 Series motor is

given a type code, which may look as follows:

4-4

Ordering

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Danfoss PC software for serial communication

All FCM 300 Series units come standard with an RS

485 port to communicate with a PC using Danofss

VLT

®

Dialog Software (see page 7-3).

Ordering numbers, VLT® Software Dialog

VLT® Software Dialog 175Z0953

Incl Basic, Logging, Template, Guided tour modules in 6

languages (Danish, English, German, Italian, Spanish and

French)

Accessories for the FC motor

A Local Operation Pad (LOP) for local set point and

start/stop is available for the FC motor. The LOP is

IP 66 enclosed. A Local Control Panel (LCP 2) which

makes up a complete interface for operation,

programming and monitoring of the FC motor is also

available.

Ordering numbers, accessories

Local Operation Pad (LOP) 175N0128

Local Control Panel (LCP 2) 175N0131

Remote mounting kit (LCP 2) 175N0160

Plug kit (LCP 2) 175N0161

Cable for plug kit (LCP 2) 175N0162

Cable (direct mounting) (LCP 2) 175N0165

Service plug kit (LCP 2) 175N0166

4-5

Ordering

PG 16 to ½" NPT adapter 176H9207

PG 21 to 3/4" NPT adapter 176H9208

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

Frame sizes and the corresponding flange sizes for different mounting versions

T ype Frame size version Motor flange size

Foot Flange Face 2 and 4 pole motors

FCM305 00056 NA 0056C 056

FCM307 00056 NA 0056C 056

FCM311 0143T 143TD 143TC 143

FCM315 0145T 145TD 145TC 145

FCM322 NA 182TD 182TC 182

FCM330 NA 182TD 182TC 182

FCM340 0184T 184TD 184TC 184

FCM355 0213T 213TD 213TC 213

FCM375 0215T 215TD 215TC 215

■ NEMA Ordering info for Flange, Face and Foot Versions

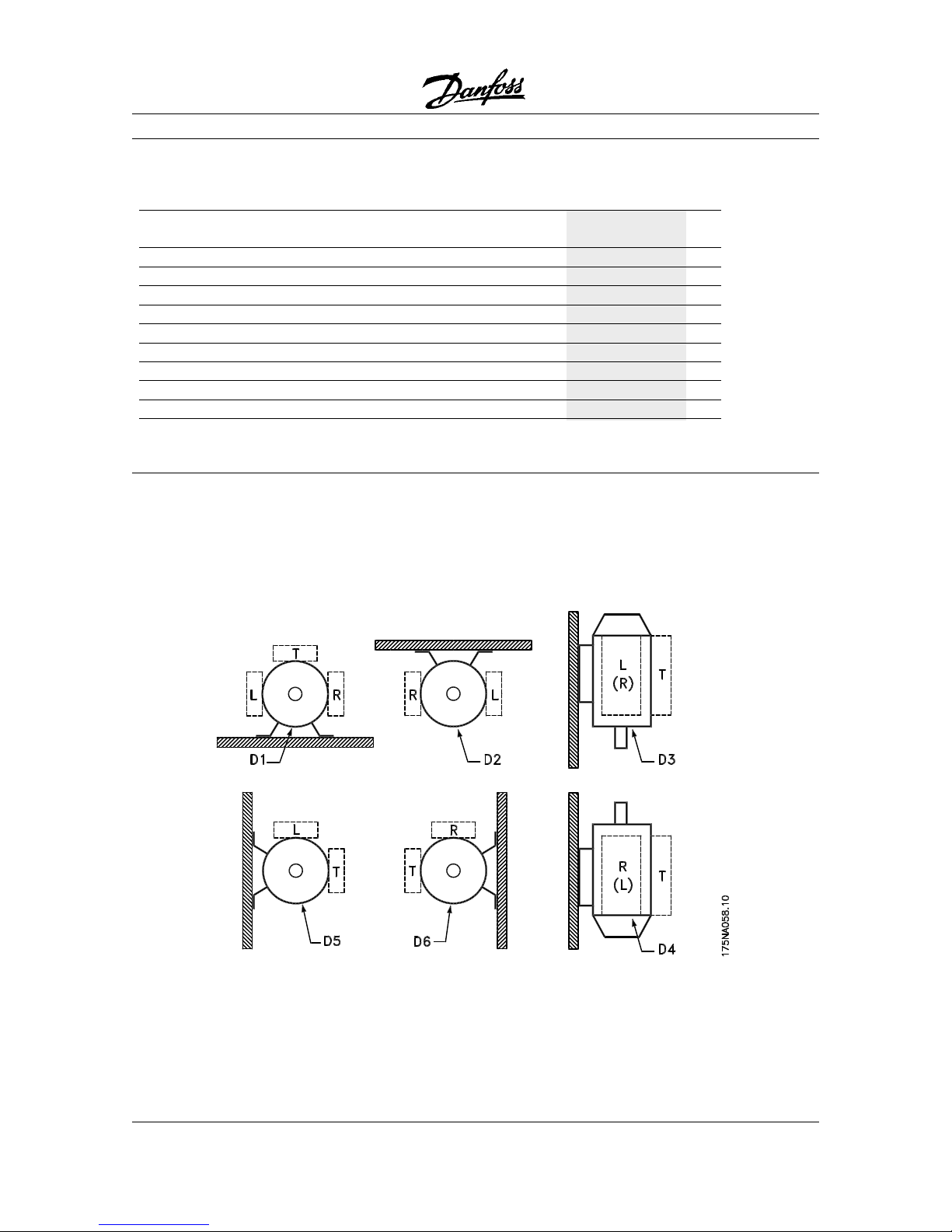

■ Ordering info for inverter box position and drain hole position seen from drice end side.

4-6

Ordering

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

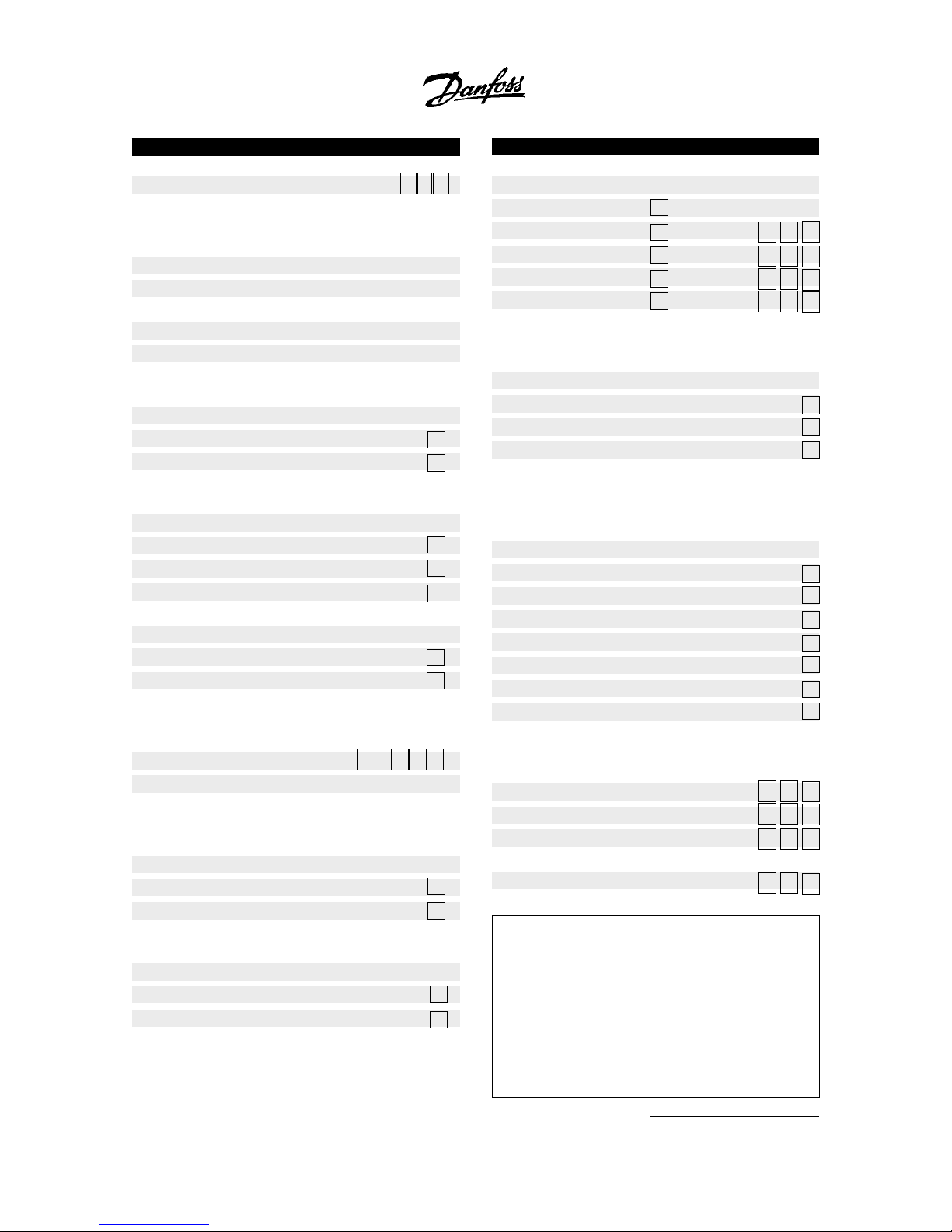

Ordering form FCM 300 Series

Mounting vs. and flange size (char. nos. 24-29)

(B03) Foot 0 0 0

(B05) Flange flange size

(B35) Foot & flange flange size

(B14) Face flange size

(B34) Foot & face flange size

Tick off as appropriate and select flange size from

the table on page 4-7.

Inverter box position (char. no. 30)

(T) Top

(R) Right side

(L) Left side

Tick off as appropriate.

Inverter box position is seen from drive end.

(See drawing on page 4-7).

Drain hole position (char. nos. 31-32)

(00) None

(D1) Between feet

(D2) Opposite feet

(D3) Vertical drive end

(D4) Vertical non-drive end

(D5) 90

° °

° °

° right of feet

(D6) 90

° °

° °

° left of feet

Tick off as appropriate.

(See drawing on page 4-7).

Other options (contact Danfoss for code)

Number of FCM 300 Series ordered

Ordered by:

Ordering form FCM 300 Series

FCM type (character nos. 1-6)

Select the required FCM type from the product

range on the previous page and fill in the squares.

Application range (char. no. 7)

(P) Process

Mains voltage (char. nos. 8-9)

(T4) 3-phase 380-480 V AC

Tick off as appropriate.

Inverter vs. (char. nos. 10-11)

(ST) Standard

(SP) PROFIBUS

Tick off as appropriate.

Enclosure (char. no. 12-14)

(S55) NEMA 12 IP55

(S56) IP56

(S66) IP66

RFI filter (char. nos. 15-16)

(R1) W/ integrated filter, class A1

(R2) W/integrated filter, class B1

Tick off as appropriate.

Frame size and version

(char. nos. 17-21)

Fill in the squares with the appropriate value from

column 2 and 3 in the table on page 4-7.

Polarity (char. no. 22)

(4) 4 poles

(2) 2 poles

Tick off as appropriate.

Cooling (char. no. 23)

(1) (IC 411) Shaft mounted fan

(6) (IC 416) (not UL) Forced ventilation unit

Tick off as appropriate.

Date:

4-7

Ordering

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Chapter 5Chapter 5

Chapter 5Chapter 5

Chapter 5 ■

Product ConceptProduct Concept

Product ConceptProduct Concept

Product Concept

..................................................................

..................................................................

.................................page 5-2

Product Concept

5-1

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

Product Concept

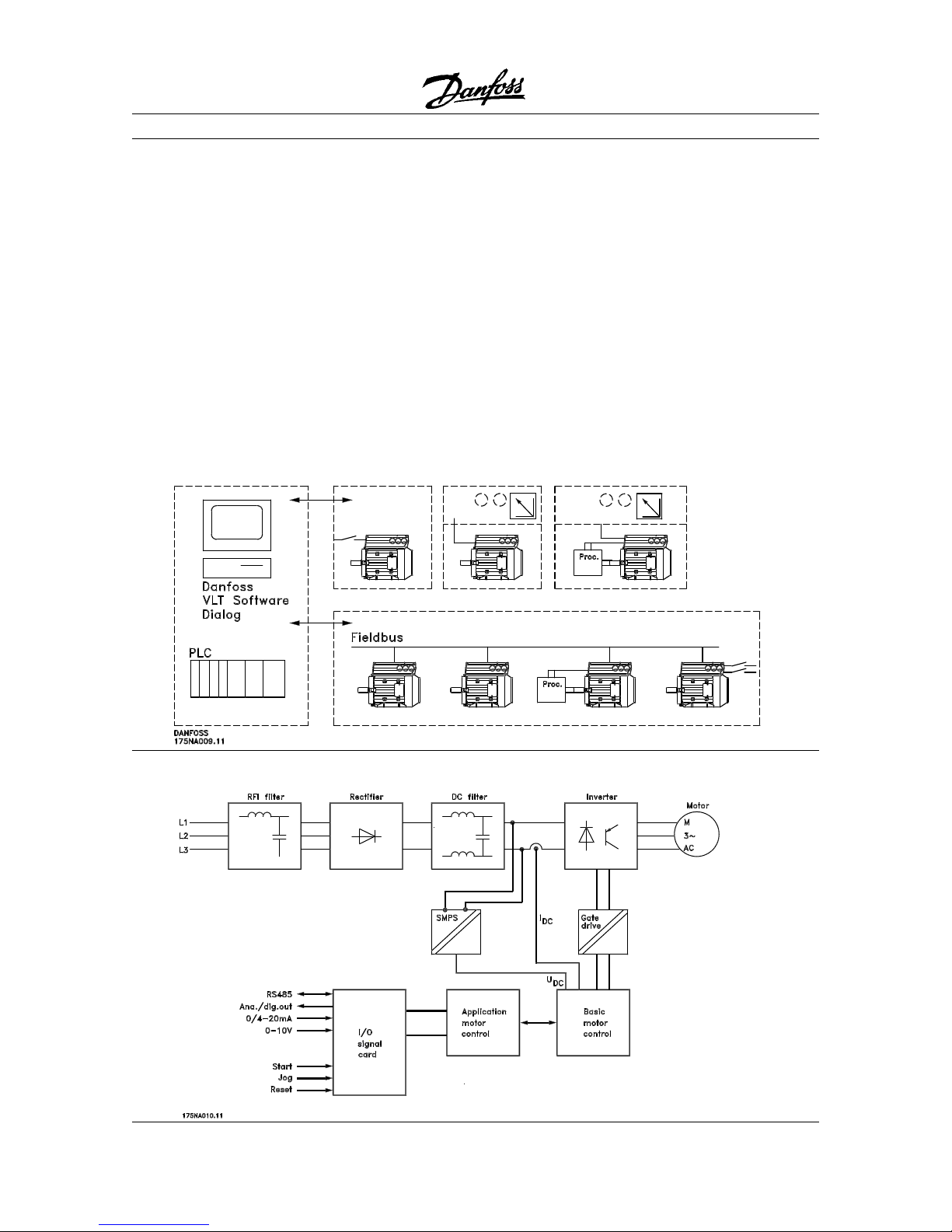

■ Integration of adjustable frequency drive and

motor

The Danfoss VLT

®

adjustable frequency drive

integrated onto the asynchronous motor gives

infinite speed control in one unit.

The VLT

®

FCM 300 Series is a very compact

alternative to the traditional solution with a VLT

adjustable frequency drive and motor as separate

units. The adjustable frequency drive is attached in

place of the motor terminal box, and it is no higher

than the standard terminal box, nor wider or longer

than the motor (see page 3-2).

Installation is made extremely easy. Panel space is

not a problem. There is no need for special details

on wiring to meet the EMC directive, since motor

cables are not necessary. The only connections are

the AC line and control connections.

Factory-set adaption between theadjustable

frequency drive and motor gives precise and energy

efficient control in addition to reducing installation

time.

The FCM 300 can be used in stand alone systems

with traditional control signals, such as start/stop

signals, speed references and closed loop process

control or in multiple drive systems with control

signals distributed by a fieldbus.

Combination of fieldbus and traditional control signals

and closed loop PID control is possible. Also possible is a combination fieldbus and traditional control

signals and closed loop PID control.

Control structures

■ Block diagram for FCM 300 Series

■

5-2

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Chapter 6Chapter 6

Chapter 6Chapter 6

Chapter 6 ■

Mechanical InstallationMechanical Installation

Mechanical InstallationMechanical Installation

Mechanical Installation

Mounting Clearances ............................ page 6-2

Alignment .............................................. page 6-2

Maximum axial and radial loads

Standard Ball Bearings ................... page 6-2

Angular Contact Bearings ............... page 6-3

Bolt Torques .......................................... page 6-3

Maintenance......................................... page 6-3

■ Motor information

Motor Description .................................. page 6-4

Handling the FCM 300..........................page 6-5

Bearings................................................ page 6-5

Output Shaf ts ....................................... page 6-5

■ Terminal Scpecifications ........................ page 6-6

Terminal and Switch Locations ............. page 6-6

Connection Diagram ............................. page 6-6

Tightening Torques ................................page 6-7

Maximum Cable Cross Section ............page 6-7

Screw Sizes .......................................... page 6-7

■ Electrical Installation .............................. page 6-8

AC line fuses .........................................page 6-8

Installation

6-1

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

Installation

When the application calls for direct coupling,

the shafts must be correctly aligned in all three

planes. Bad alignment can be a major source of

noise and vibration.

Allowance must be made for shaft endfloat and

thermal expansion in both axial and vertical planes.

It is preferable to use flexible drive couplings.

■ Alignment

Maximum permissible external axial and radial loads in N (1N = 0.225 lbf) standard ball bearings

Horizontal shaft Vertical shaft

Load towards Load away Shaft up Shaft down

Frame motor from motor load load lo ad load

size Poles Up Down Up Down Max. radial

2

80 2 275 441 481 245 294 432 638

4 373 549 569 343 392 520 785

90 2 412 638 598 294 373 520 824

4 540 765 716 402 471 628 903

100 2 85 3 853 932 9 32 814 814 1207

4 1010 1010 1118 1118 961 961 1393

112 2 85 3 853 932 9 32 814 814 1207

4 1010 1010 1118 1118 961 961 1393

132S 2 1059 1403 1570 95 2 1216 1305 1785

4 1265 1609 1825 1138 1472 1481 1972

132M 4 1256 1609 1854 1109 1501 1462 2040

1

All figures are based on Lna bearing life of 20,000 hours.

Lna = adjusted L10 life rating taking account of:-Reliability -Material improvements -Lubrication conditions

2

Max. permissible radial load at end of shaft (horizontal mounting).

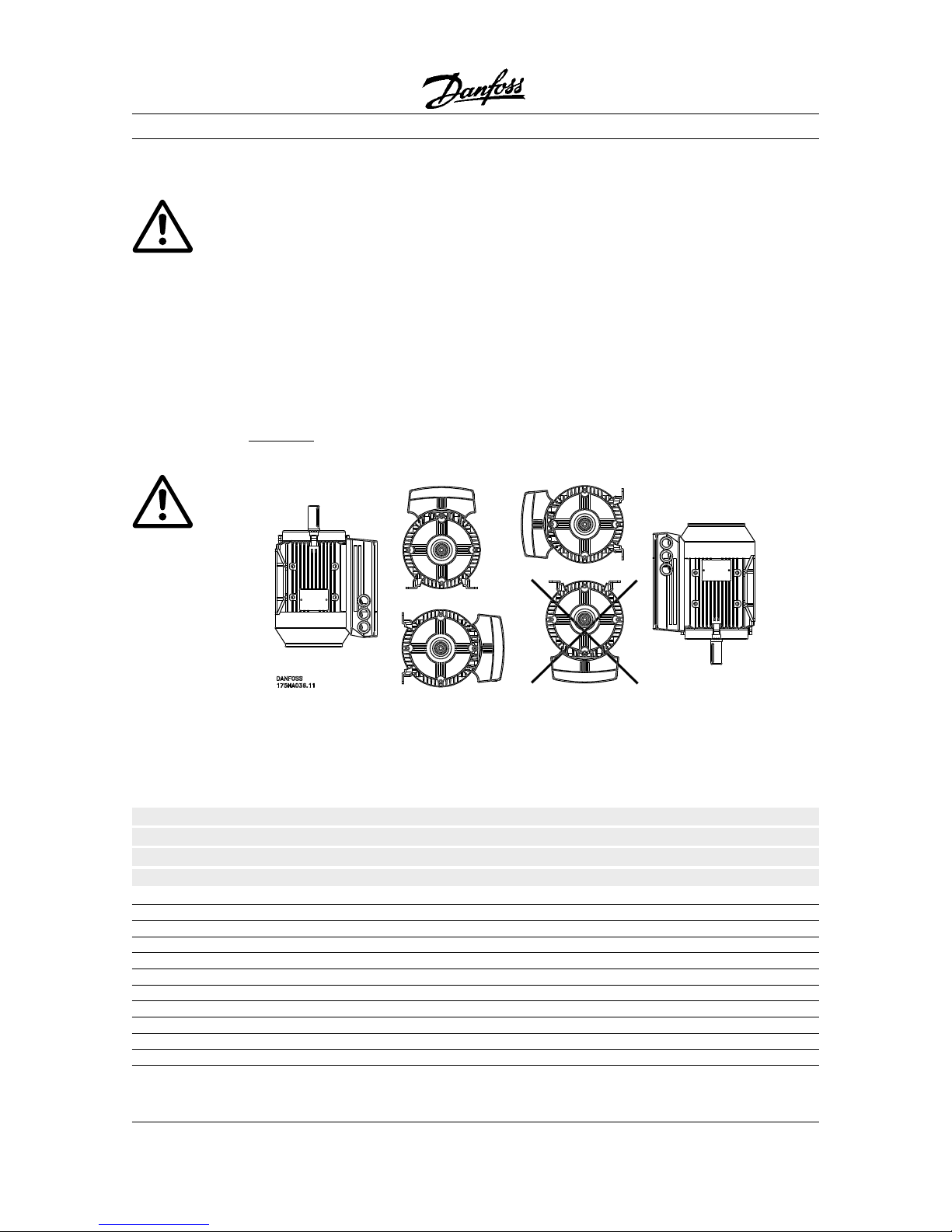

■ Mechanical Installation of the FCM 300

Do not force fittings couplings, pulleys,

etc. onto the FCM 300 motor shaft, as

this will cause bearing damage,

increasing bearing noise and

significantly reducing bearing life.

To avoid overheating, the ambient temperature

should not exceed 104

o

F/40 oC. The average 24-

hour temperature is not to exceed 95

o

F/35 oC. For

more information, see "Derating".

Before installation, check unit for fan cover damage,

foot/mounting damage, shaft damage and loose

fasteners. Check nameplate data on motor.

The FCM 300 unit

should not be mounted such that

the inverter portion of the unit (regardless of feet

position) is upside down.

Mounting Clearances

FCM 300 units must be installed with adequate

access for routine maintenance.

Minimum clearance = 29.5 in (0.75 m) on all sides

Minimum clearance at fan inlet = 2 in. (50 mm)

Where several units are installed in close proximity,

care must be taken to ensure warm air from units is

not recirculated.

FCM 300 units must be mounted on rigid, level

surfaces.

Fitting Pinions, Pulleys and Coupling

These should be sized to fit FCM 300 standard

dimensions.

■

■

6-2

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Maximum permissible external axial and radial loads in N (1N = 0.225 lbf) angular contact bearings

Horizontal shaft Vertical shaft

Load towards Load away Shaft up Shaft down

Frame motor from motor load load lo ad load

size Poles Up Down Up Down Max. radial

2

80 2 1375 2205 2405 1225 1470 2160 3190

4 1865 2745 2845 1715 1960 2600 3925

90 2 2060 3190 2990 1470 1865 2600 4120

4 2700 3825 3580 2010 2355 3140 4515

100 2 4265 4265 4660 4660 4070 4070 6035

4 5050 5050 5590 5590 4805 4805 6965

112 2 4265 4265 4660 4660 4070 4070 6035

4 5050 5050 5590 5590 4805 4805 6965

132S 2 5295 7015 7850 4760 6080 6525 8925

4 6325 8045 9125 5690 7360 7405 9860

132M 4 6280 8045 9270 5545 7505 7310 10200

1

All figures are based on Lna bearing life of 20,000 hours.

Lna = adjusted L10 life rating taking account of:-Reliability -Material improvements -Lubrication conditions

2

Max. permissible radial load at end of shaft (horizontal mounting).

Installation

■ Foot Mounting Bolt Torques

Face/Flange, feet and lid should be secured with the

bolt sizes and torque's detailed in the table below.

Foot mounting bolt torques

FCM Type Frame size Bolt diameter Torque

Nm.

305-307 80 M8 (taptite) 24-25

311-315 90 M8 (taptite) 24-25

322-330 100 M8 (taptite) 32-35

340 112 M8 (taptite) 32-35

355-375 132 M8 (taptite) 32-35

Face/Flange bolt torques

FCM Type Frame size Bolt diameter Torque

Nm

305-307 80 M5 5

311-315 90 M5 5

322-330 100 M6 (taptite) 8-10

340 112 M6 (taptite) 8-10

355-375 132 M6 (taptite) 8-10

LID screws torque: 2.2 - 2.4 Nm, Plastic plug (cable entrance) torque: 2.0 Nm

1 Nm = 1.196 lb-ft

■■

■■

■

Maintenance

Routine cleaning of the FCM 300Routine cleaning of the FCM 300

Routine cleaning of the FCM 300Routine cleaning of the FCM 300

Routine cleaning of the FCM 300

Remove the fan cover and ensure that all air inlet

holes are completely clear. Clean any dirt and

obstructions from behind the fan and along the ribs of

the frame, and between the motor and inverter.

Periodic maintenance of motorPeriodic maintenance of motor

Periodic maintenance of motorPeriodic maintenance of motor

Periodic maintenance of motor

..

..

.

a) Remove the inverter , the fan cover and the

fan which is keyed to the shaft extension.

Loosen and remove bearing cover screws and

endshield bolts/studs.The endshields should then

be eased off their spigots.

(b) The rotor can now be carefully withdrawn from

the stator, taking care not to damage the stator

bore and both stator and rotor windings.

(c) Having dismantled the motor, maintenance can

be carried out to remove all dirt. For this

purpose, the use of an air line supplying dry

compressed air under comparatively low

pressure is best, as a high velocity air-stream

can force dirt into the spaces between the

windings and insulation, etc. Grease-removing

solvents can cause damage to impregnating

varnish or insulation

(d) The FCM 300 should be re-assembled in the

reverse order from dismantling, remembering to

ease endshields onto bearings and spigots.

DO NOT USE FORCE.

(e) Before starting, check that the rotor spins

freely . Ensur e that the electrical connections ar e

correct.

(f) Refit any pulley, coupling, spr ocket etc. which

has been removed, being particularly careful to

ensure correct alignment with the driven part,

as misalignment will lead to ultimate bearing

trouble and shaft breakage.

(g) When replacing screws and bolts, care should

be taken to use only those with the grade

recommended by

the manufacturer. These must also be of

identical thread form and screw/bolt length

(see the table above).

6-3

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

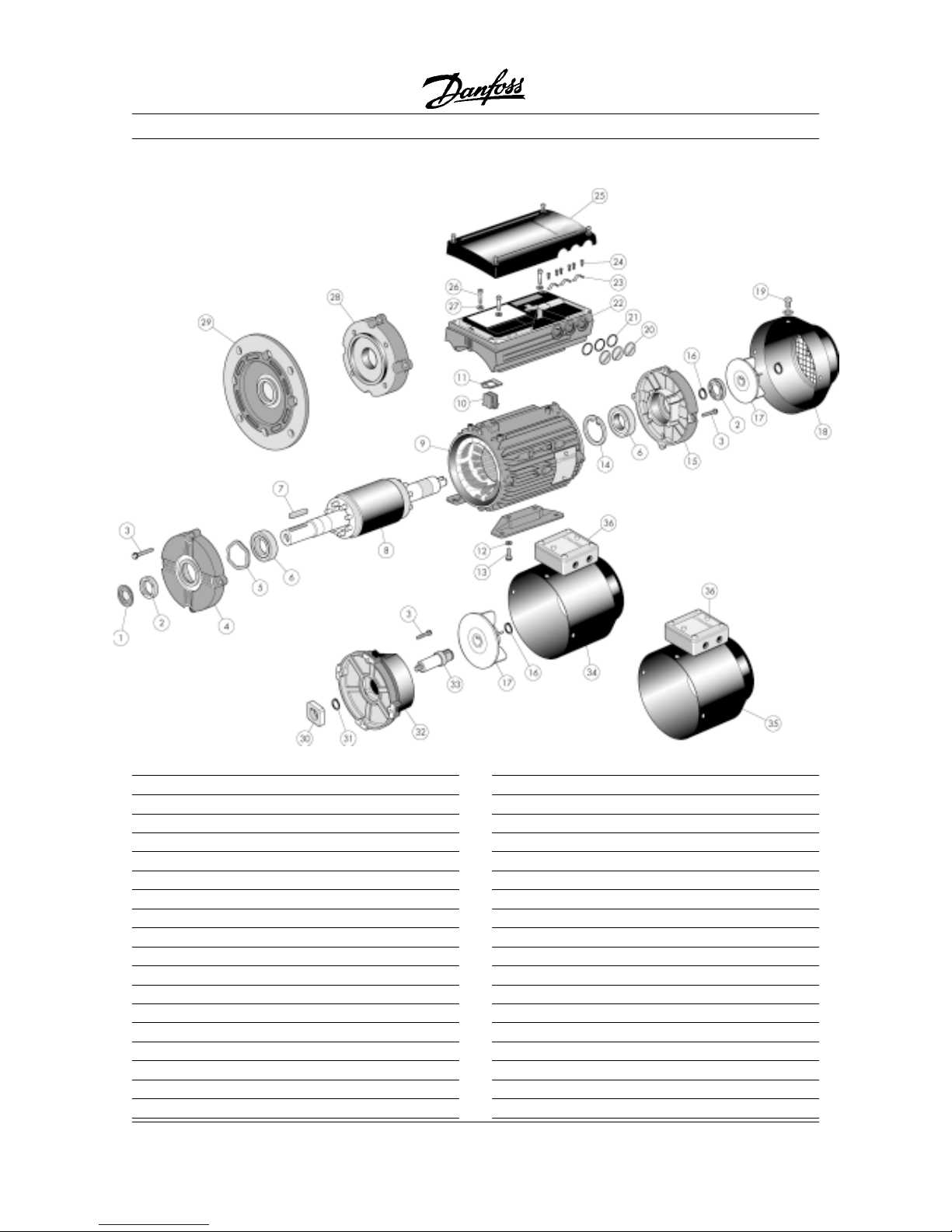

Installation

ItemItem

ItemItem

Item

DescriptionDescription

DescriptionDescription

Description

1 Slinger (when fitted)

2 Drive end oilseal

3 Endshield fixing bolt

4 Drive end endshield

5 Preload washer

6 Bearing

7 Shaft key

8 Rotor assembly

9 Stator assembly with or without feet

10 Connector block

11 Gasket

12 Detachable feet

13 Foot mounting bolt and washer

14 Bearing retention circlip

15 Non-drive endshield

16 Bearing circlip

17 Fan

18 Fan cover

ItemItem

ItemItem

Item

DescriptionDescription

DescriptionDescription

Description

19 Fan cover screw and washer

20 Plastic cable entrance plugs

21 O‘ ring

22 ISM box

23 Cable strap

24 Cable strap screws

25 ISM box lid

26 Torx screw

27 Washer

28 Face endshield

29 Flange endshield

30 Brake hub

31 Brake hub retention circlip

32 Brake and adaptor plate

33 Stub shaft

34 Brake fan cover

35 Force vent fan cover

36 Terminal box

■ Motor Information

The FCM 300 consists of the following parts:

6-4

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Handling and lifting of VLT® DriveMotors (FCM 300

units) must only be undertaken by qualified personnel.

Full product documentation and operating instructions

must be available together with tools and equipment

necessary for safe working practice. Eyebolts and/or

lifting points supplied with the FCM 300 are designed

to support only the weight of the FCM 300, not the

weight of the FCM 300 and any auxiliary equipment

attached to it. Be absolutely sure that cranes, jacks,

slings and lifting beams are capable of carrying the

weight of equipment to be lifted.

Where an eyebolt is provided with the motor,

■ Handling the FCM 300

this should be screwed down until its shoulder is

firmly against seated the face of the stator frame to be

lifted.

FCM type approx. weight (kg.) lbs

FCM 305 11 24,3

FCM 307 13 28,7

FCM 311 17 37,5

FCM 315 20 44,1

FCM 322 26 57,3

FCM 330 28 61,7

FCM 340 37 81,6

FCM 355 56 123,5

FCM 375 61 134,5

■■

■■

■

Bearings

To avoid static indention, the storage area should be

vibration free. Where exposure to some vibration is

unavoidable, the shaft should be locked. Bearings

may be fitted with a shaft locking device which

should be kept in place during storage.

Shafts should be rotated by hand, one quarter of a

revolution, at weekly intervals.

Lubrication

FCM Lubrication Temperature

type range

305 - 375 Esso unirex N3 -10 + 140oC/

-14 + 284oF

Bearing life

Maximum hours bearing life (Lna) expected at 80

o

C/176oF bearing temp. x 103 hours.

FCM 3600 rpm 3000 rpm 1800 rpm 1500 rpm

Hori z. Vert . H ori z. Ve rt. Hori z. Ve rt. Horiz.Vert.

305-315 20 20 22 22 30 30 32 32

322-340 22 22 26 26 33 33 35 35

355-375 22 22 26 26 33 33 35 35

Lna bearing life is the adjusted, L10 life rating, taking account of: -Reliability -Material improvement -Lubrication conditions.

Standard Bearing references and oil seals

FCM Mounting Poles (2/4) Bearings Oil seals - Bore x O/D x width in mm

Drive end Non-drive end Drive end Non-drive end

305-307 All All 6204 2Z 6202 2Z 20 x 30 x 7 15 x 24 x 5

311-315 All All 6205 2Z 6203 2Z 25 x 35 x 7 17 x 28 x 6

322-330 All All 6206 2Z 6205 2Z 30 x 42 x 7 25 x 37 x 7

340 All All 6206 2Z 6205 2Z 30 x 42 x 7 25 x 37 x 7

355-375 All All 6208 2Z 6305 2Z 40 x 52 x 7 25 x 37 x 7

■■

■■

■

Output shafts

Output shafts are produced from 35/40 Ton

(460/540 MN/m

2

) tensile steel. Drive end shafts are

provided with a tapped hole to DIN 332 Form D and

a closed profile keyway as standard.

Balance

All motors are dynamically balanced, to ISO 2373

with key convention to IEC 34-14.

InertiaInertia

InertiaInertia

Inertia

FCM J [kgm2]*

2 pole 4 pole

305 0.0015 0.0019

307 0.0015 0.0027

311 0.0024 0.0035

315 0.0024 0.0047

322 0.006 0.009

330 0.007 0.010

340 0.008 0.016

355 0.017 0.027

375 0.020 0.032

Installation

* 1 kgm2 = 23.73036 lbft

2

NOTE!

Ball and roller bearings are shipped from the factory

fully charged with grease. Sealed bearings have

sufficient grease for at least two years of continuous

operation in normal ambient temperatures (see

General Specifications).

6-5

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

Terminal Specifications

To access terminals, remove the inverter top cover,

which is held in place by 4 screws.

Terminal blocks X100 and X101 should be removed

to make the AC Line terminals more accessible.

Lift the corner of the protective black plastic to

expose the AC Line terminals (L1, L2 and L3).

DODO

DODO

DO

NOTNOT

NOTNOT

NOT remove the plastic cover!

Remove necessary

PG plastic plugs to insert AC

Line cable and control cables. Use as many

openings as necessary.

PG to NPT adapters are

sold separately.

Terminal and Switch Locations

X101: Terminal block for analog/digital control signals

Terminal No. Function Example

1 Analog input (0-20 mA) Feedback signal

2 Analog (0-10 V)/digital input 2 Speed reference

3 Digital input (or pulse) 3 Reset

4 Digital input (or precise stop) 4 Start

5 Digital input (other) 5 Jog (fixed speed)

6 24 V DC supply for digital inputs (max. 150 mA)

7 10 V DC supply for potentiometer (max. 15 mA)

8 0 V for terminals 1-7 and 9

9 Analog (0-20 mA)/digital output Fault indication

X100: Terminal block for data communication

Terminal No. Function

1 P RS 485 for connection to

2 N RS 485 bus or PC

3 5 V DC

Supply for RS 485 bus

4 0 V DC

For PROFIBUS versions please refer to the manual

MG90AXYY.

LED 300-304

LED 300 (red): Fault trip

LED 301 (yellow): Warning

LED 302 (green): Power on

LED 303-304: Communication

Reset (pushbutton)

Start

Jog

Speed reference

- Reset to be closed short time for

resetting fault trips

- Start to be closed for changing

to run mode

- Jog will run at fixed speed

while closed (10 Hz)

- Speed reference (0-10 V)

determines speed while in run mode

Connection diagram - factory setting

Screen

For terminating an RS 485 serial communication

interface, units at both ends of the bus must have

their RS 485 switch turned to ON.

The RS 485 connector interfaces with the service

plug kit (part#176N0166) when both serial

communication and the LCP-2 are to be used

simultaneously.

Installation

■

■

■

■

6-6

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Installation

Tightening Torques

Cover (lid) screws: 19.5 - 21.2 lb-in (2.2 - 2.4 Nm)

Plastic cable entrance plugs: 19.5 lb-in (2.2 Nm)

L1, L2, L3 (AC Line) screws (FCM 305-340): 5 - 7 lb-in (0.5 - 0.6 Nm)

L1, L2, L3 (AC Line) screws (FCM 355-375): 15 lb-in (1.2 - 1.5 Nm)

Earth Ground: 30.1 lb-in (3.4 Nm)

Terminal screws require a max 2.5 mm flat-blade screwdriver.

AC Line screws require a 8mm flat-blade screwdriver.

Earth ground and cable clamp screws all require T-20 Torx or flat-blade screwdriver.

Lid screws require Philips screwdriver.

Maximum Cable Cross Section

Note:

Use

o

60 C copper wire or better

AWG mm

2

Max size AC Line cable (FCM 305-340): 10 4.0

Max size AC Line cable (FCM 355-375): 6 10

Max size control cable: 16 1.5

Max size serial communication cable: 16 1.5

Earth Ground: 6 10

Screw Sizes

Cover (lid) screws: M5

Earth Ground and Cable Clamp screws (FCM 305-340): M4

Earth Ground and Cable Clamp screws (FCM 355-375): M5

■

■

■

6-7

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

Installation

The FCM 300 Series unit contains

dangerous voltages when connected

to line voltage. After disconnecting

from the line, wait at least 4 minutes before

touching any electrical components. Also make sure

that other voltage inputs have been disconnected.

Only competent electricians should carry out the

electrical installation. Improper installattion of the

FCM 300 Series unit may cause equipment failure,

serious injury or death. Follow this manual and

National Electrical Codes (NEC

®

) and local safety

codes and guidelines.

To avoid potential shock hazard when servicing the

unit, remove all power to all units that share any

conduit to be worked on.

In general, a conduit should not contain unshielded

power conductors for more than three (3) FCM 300

units.

NOTE:

It is the user's or installer's responsibility to ensure

correct grounding and branch circuit protection in

accordance with national and local codes.

The ground leakage currents are higher than 3.5

mA. This means the FCM 300 requires a fixed,

permant installation, as well as reinforced protective

grounding.

To meet EMC specifications, control cables must be

shielded. Connect the shielded cable to ground at

both ends and use cable clamps.

Before wiring the unit, make sure your supply

voltage corresponds with the voltage requirement of

the FCM 300 unit, TT, IT and TN lines.

Type B RCD's (ELCB relays) or multiple protective

grounding can be used as extra protection of 3

phase equipment with a bridge rectifier and for a

brief discharge on power-up. If RCD's are used,

local regulations must be observed.

Be sure the installation is fused correctly.

Connect the three AC line phases to terminals L1,

L2 and L3 and the ground to the separate earth

ground terminal provided. When power is applied,

the green LED (LED 302) should be lit to indicate

the power is on. In units with built-in Profibus, LED

303 will flash. For further information on Profibus,

pleae see the Profibus manual.

For start-up instructions, please see "Operation" on

page 7-2.

AC Line Fuses

External fuses must be installed in the AC line supply

to the FCM 300 unit.

FCM Type AC Line Voltage Bussmann KTS-R or

JJS Type:

305 380-480 VAC 10 A

307 380-480 VAC 10 A

311 380-480 VAC 10 A

315 380-480 VAC 10 A

322 380-480 VAC 10 A

330 380-480 VAC 15 A

340 380-480 VAC 15 A

355 380-480 VAC 25 A

375 380-480 VAC 25 A

Suitable for use on a circuit capable of delivering not

more than 100,000 rms Symmetrical Amperes, 500

Volts Maximum, when protected by the above

fuses.

■

Electrical Installation

CAUTION!

■

6-8

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Chapter 7Chapter 7

Chapter 7Chapter 7

Chapter 7 ■ Start-up ................................................. page 7-2

■ Control Options .....................................page 7-2

Serial Communication ........................... page 7-2

VLT Dialog and PC ................................ page 7-3

Local Control Panel (LCP-2) .................page 7-3

Local Operation Pad (LOP)................... page 7-4

■ Local Control Panel ...............................page 7-5

Display ................................................... page 7-5

Control Keys ......................................... page 7-6

Control Keys Functions ......................... page 7-6

Display Read-out State ........................ page 7-7

Display Mode ........................................ page 7-7

Quick Menu Mode vs. Menu Mode ...... page 7-8

Parameter Selection ............................. page 7-8

Menu Mode .......................................... page 7-9

Parameter Groups ................................ page 7-9

Change Data ........................................page 7-9

Menu Structure ..................................... page 7-11

Operation

7-1

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

Operation

Start-up

After AC line connections have been made, check

to see that the LED 302 (green) is lit. For Profibus

versions, LED 303 will flash. For more Profibus

information, see the Profibus manual.

For out-of-the-box use without an LOP, LCP-2,

serial communications or PC (see "Control

Options"), simple on/off and speed control is

accomplished as follows:

1. Run cable from terminals 4 and 6 to a start/stop

contact or switch. See diagram below.

2. Wire potentiometer to terminals 2, 7 and 8. See

diagram below.

NOTE

:

Pre-programmed factory parameter settings are

suitable for basic on/off and speed operation as

depicted in the following diagram.

Reset (pushbutton)

Start

Jog

Speed reference

- Reset to be closed short time for

resetting fault trips

- Start to be closed (maintained) for

changing to run mode

- Jog will run at fixed speed

while closed (10 Hz)

- Speed reference (0-10 V)

determines speed while in run mode

Connection diagram - factory setting

NOTE:

Be sure the lid screws are tightened down

sufficiently (19.5 - 21.2 lb-in) to seal lid.

NOTE:

The rotional direction of the motor can not be

changed by switching phases. The default direction

is clockwise. Changing the motor direction must be

programmed in parameter 200.

Control Options

The FCM 300 can be programmed

and operated

with:

1. Serial communication using the RS 485

connection

2. VLT Dialog software and a PC using the RS 485

connection

3. Local Control Panel (LCP-2)

The FCM 300 can be operated, b

ut not

programmed with:

1. Local Operation Pad (LOP) wired to the control

terminals

Serial Communication

Terminal block X100, terminals 1-4 are available for

connecting an RS 485 bus.

■

■

Operation

■

7-2

FCM 300 Series

MG.03.B6.2G - VL T is a register ed Danfoss trademark

Serial Communication (continued...)

For installations that require both serial

communication and use of an LCP-2, the service

plug kit (part #176NO166) and cable (part

#175NO162) provides the necessary interface.

The LCP-2 is attached to the cable and the RS 485

bus is connected to the X100 terminal strip.

Software only: part #175ZO953

Software RS 232/485 converter and cables: part #176F1705

Connect cables from PC to X 100 terminals.

Remote mounting kit

A remote mounting kit (part #175NO160) is available to

mount the LCP-2 on a wall or in a panel.

■

■

VLT Dialog software and PC

VLT Dialog is a powerful drive software tool that allows

set-up, start-up and control of the FCM 300 and other

Danfoss units.

■

Local Control Panel (LCP-2)

The LCP-2 (part #175N0131) is used for programming

and commissioning the FCM 300 units. Use the plug

kit (part #175NO161) and cable (part #175NO162).

The plug kit wires to the X100 terminals. See "Local

Control" on page 7-5 for more information on the LCP-

2.

When serial communication and the LCP-2 are to be

used simultaneously, the service plug kit and cable

provide an alternative connection for the LCP-2. For

more information, see "Serial Communication" on this

page.

NOTE:

The LCP-2 and VLT Dialog can not be used in

conjunction with one another.

Terminal X100/

yellow

green

red

blue

1

4

3

2

D-sub pin

8

3

2

9

Color of wire/

Operation

■

7-3

FCM 300 Series

MG.03.B6.2G - VLT is a r egistered Danfoss trademark

LCP-2