MAKING MODERN LIVING POSSIBLE

Design Guide

FCM 300

ATB Motors

Contents

VLT® FCM Series

Introduction

Software version 4

Safety regulations 5

Warning against unintended start 5

Introduction 6

Integration of frequency converter and motor 7

Ordering form 8

Product range 9

Ordering 10

PC Software tools 10

Ordering info for Frames and Flanges 11

Ordering info for inverter box position and drain hole position 11

Installation

FCM 305-375 for 3 phases, 380-480 V 12

General technical data 12

Tightening Torques 16

Maximum Cable Cross Section 16

Screw Sizes 16

Protection: 16

Description of the motor 17

Handling the FC motor 18

Bearings 18

Output shafts 19

Dimensions 19

Installation of the FC motor 22

Alignment 22

Bolt torques 23

Maintenance 23

Forced ventilation (FV) units 23

Voltage range for forced ventilation (FV) unit 24

FCM 300 Thermal Protection 24

Service plug kit (175N2546) 25

Plug kit (175N2545) 25

Remote mounting kit (175N0160) 25

Potentiometer option (177N0011) 26

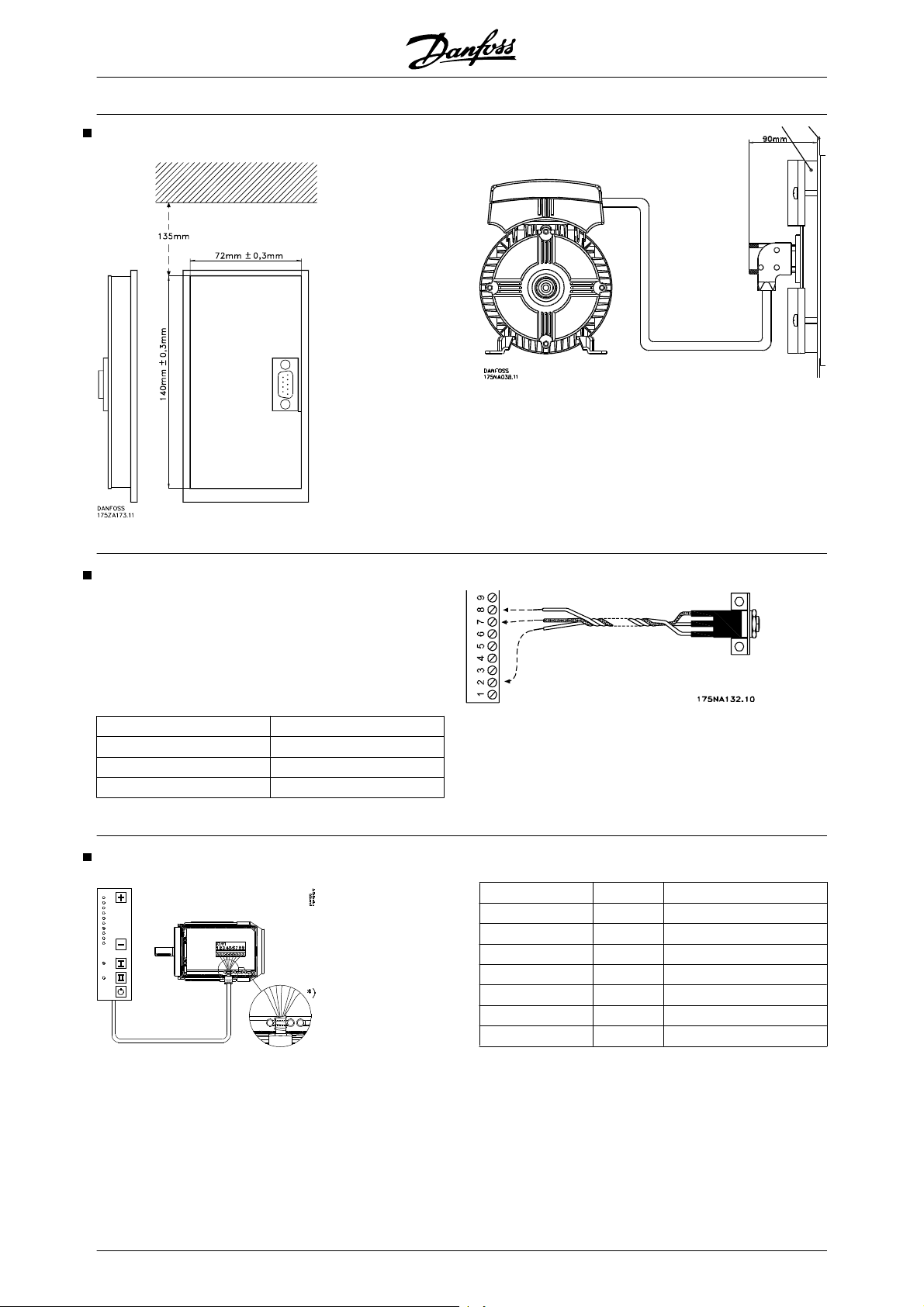

Local Operation Pad (LOP) (175N0128) IP65 26

4

12

Programming

Control panel (175NO131) 28

LCP installation 28

LCP functions 28

Display 28

LEDs 29

Control keys 29

Control key functions 29

Display read-out state 30

MG.03.H6.02 - VLT® is a registered Danfoss trademark 1

28

VLT® FCM Series

Display mode 30

Display mode - selection of read-out state 30

Quick menu mode versus Menu mode 31

Quick Setup via Quick menu 31

Parameter selection 31

Menu mode 32

Parameter groups 32

Changing data 32

Changing a text value 32

Infinitely variable change of numeric data value 32

Menu structure 33

Parameter Group 0-** Operation/Display 34

Parameter Group 1-** Load/Motor 40

Serial bus 68

Telegram communication 68

Telegram build-up 68

Databytes 69

Control word according to Fieldbus Profile Standard 71

Parameter Group 5-** Serial Communication 77

Parameter Group 6-** Technical Functions 84

All about FCM 300

Galvanic isolation (PELV) 88

Earth leakage current 88

Extreme running conditions 88

Acoustic noise 89

Balance 89

Thermal Protection and Derating 89

Derating for ambient temperature 89

Derating for air pressure 90

Derating for running at low speed 90

Derating for high switching frequency 90

Vibration and shock 91

Air humidity 91

UL standard 91

Efficiency 91

Mains supply interference/harmonics 91

Power factor 92

What is CE labelling? 92

The machinery directive(98/37/EEC) 92

The low-voltage directive (73/23/EEC) 92

The EMC directive(89/336/EEC) 92

What is covered? 92

Danfoss FCM 300 Series motor and CE labelling 92

Compliance with EMC directive 89/336/EEC 93

EMC standards 93

Aggressive environments 94

List of warnings and alarms 95

What if the motor does not start? 95

88

2 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

Warnings 96

Warning word, extended Status word and Alarm word 97

List of parameters 99

Index

104

MG.03.H6.02 - VLT® is a registered Danfoss trademark 3

VLT® FCM Series

FCM 300 Series

Design Guide

Software version: 3.1x

This Design Guide can be used for all FCM 300 Series frequency converters with software version 3.1x.

The software version number can be seen from parameter 624 Software version no.

Disposal Instruction

Equipment containing electrical components may not be disposed of together with domestic waste.

It must be separately collected with electrical and electronic waste according to local and currently

valid legislation.

When reading through this Design Guide, you will

come across various symbols that require special attention.

The symbols used are the following:

This symbol indicates a general warning.

NB!

This symbol indicates something to be noted by the reader.

This symbol indicates a high-voltage

warning.

4 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

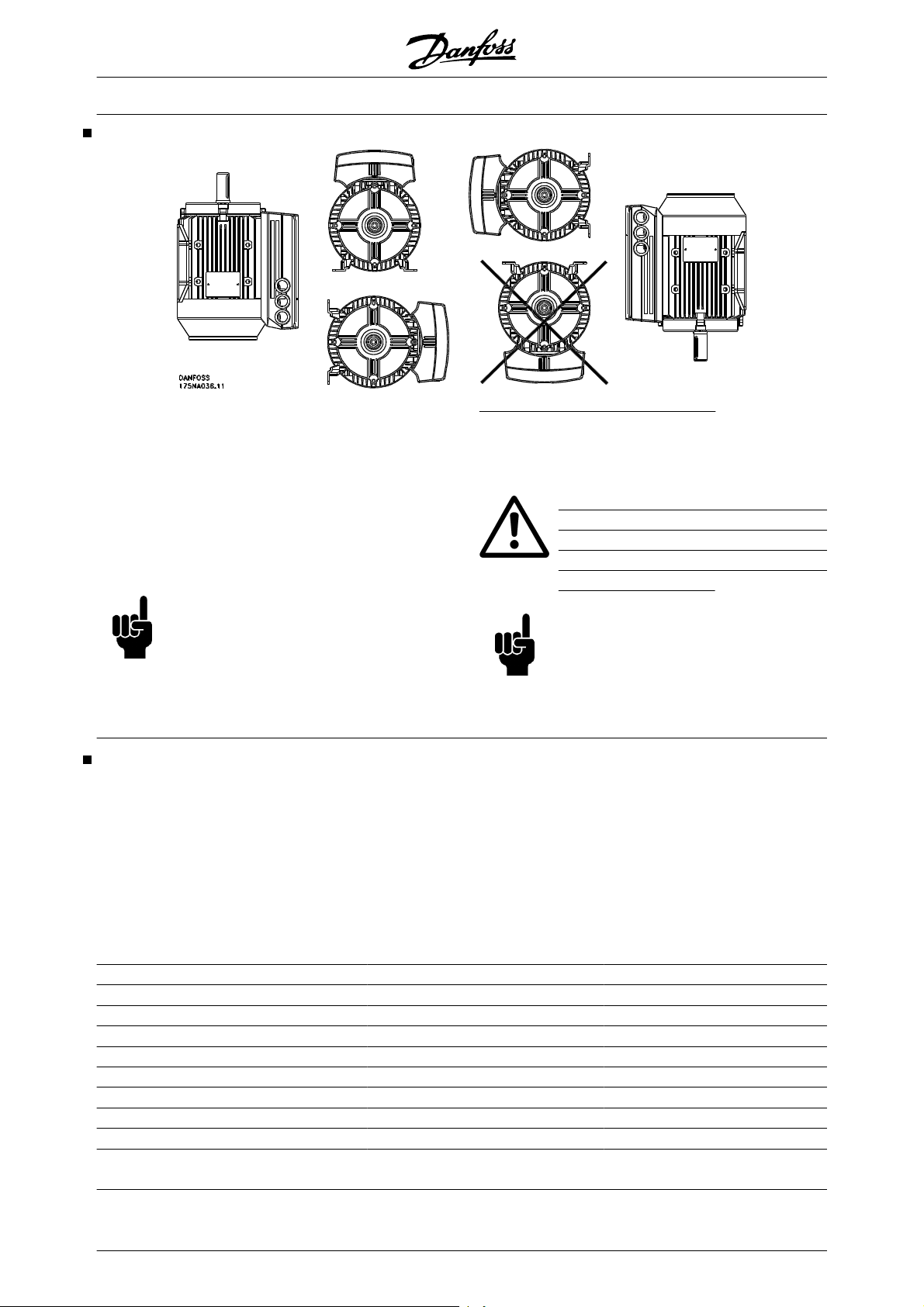

All operations must be carried out by appropriately trained personel.

Use all lifting facilities provided e.g. both

lifting points if fitted or single lifting point if

fitted*.

Vertical lifting - Prevent uncontrolled rotation.

Lift machine - Do not lift other equipment

with motor lifting points only.

Before installation check for fan cover

damage, shaft damage, foot/mounting

damage, and loose fasteners. Check

nameplate details.

Ensure level mounting surface, balanced

mounting, not misaligned.

Gaskets, and/or sealants, and guards

must be correctly fitted.

Correct belt tension.

Please observe derating rules, see "Special condi-

tions".

*Note: maximum hand lift is 20 kg below shoulder, but

above ground level. Max. gross weights:

Frame size 80: 15 kg

-

Frame size 90 & 100: 30 kg

-

Frame size 112: 45 kg

-

Frame size 132: 80 kg

-

The voltage on the FC motor is dangerous

when the motor is connected to mains. Incorrect installation of the FC motor may

lead to material damage or serious injury,

or it may be fatal.

Consequently, the instructions in this

manual as well as national and local rules

and safety regulations must be complied

with.

Touching the electrical parts may be fatal,

even after the mains supply has been disconnected. Wait at least 4 minutes.

- Installation must be fused and isolated

correctly.

- Covers and cable entries must be fitted.

NB!

It is the user's or certified electrician's responsibility to ensure correct earthing and

protection in accordance with applicable

national and local requirements and

standards.

Safety regulations

1. The VLT DriveMotor (FC motor) must be disconnected from mains if repair work is to be

carried out.

Check that the mains supply has been disconnected and that the necessary time has

passed (4 minutes).

2. Correct protective earthing of the equipment

must be established, the user must be protected against supply voltage, and the motor

must be protected against overload in accordance with applicable national and local

regulations.

Use of RCD's (ELCB relays) is described in

chapter 10.

3. The earth leakage currents are higher than

3.5 mA. This means that the FC motor requires a fixed, permanent installation as well

as reinforced protective earthing.

Warning against unintended start

1. The motor can be brought to a stop by means

of digital commands, bus commands, or references, while the frequency converter is

connected to mains.

If personal safety considerations make it necessary to ensure that no unintended start

occurs,

cient .

2. While parameters are being changed, the

motor may start.

3. A motor that has been stopped may start if

faults occur in the electronics of the FC motor, or if a temporary overload or a fault in the

mains supply ceases.

these stop functions are not suffi-

By altitudes above 2 km, please contact

Danfoss Drives regarding PELV.

MG.03.H6.02 - VLT® is a registered Danfoss trademark 5

VLT® FCM Series

Introduction

Design Guide:

Gives all required information for design purposes, and gives a good insight

Specific technical publications on the FCM 300 series:

into the product concept, product range, technical data, control, programming, etc.

Quick Setup:

Helps the users to quickly get their FCM 300 Series motor unit installed and

running.

The Quick Setup is always delivered with the unit.

If you have any questions concerning FCM 300 Series,

please call us. We have drive specialists all over the

world ready to advise you on applications, program-

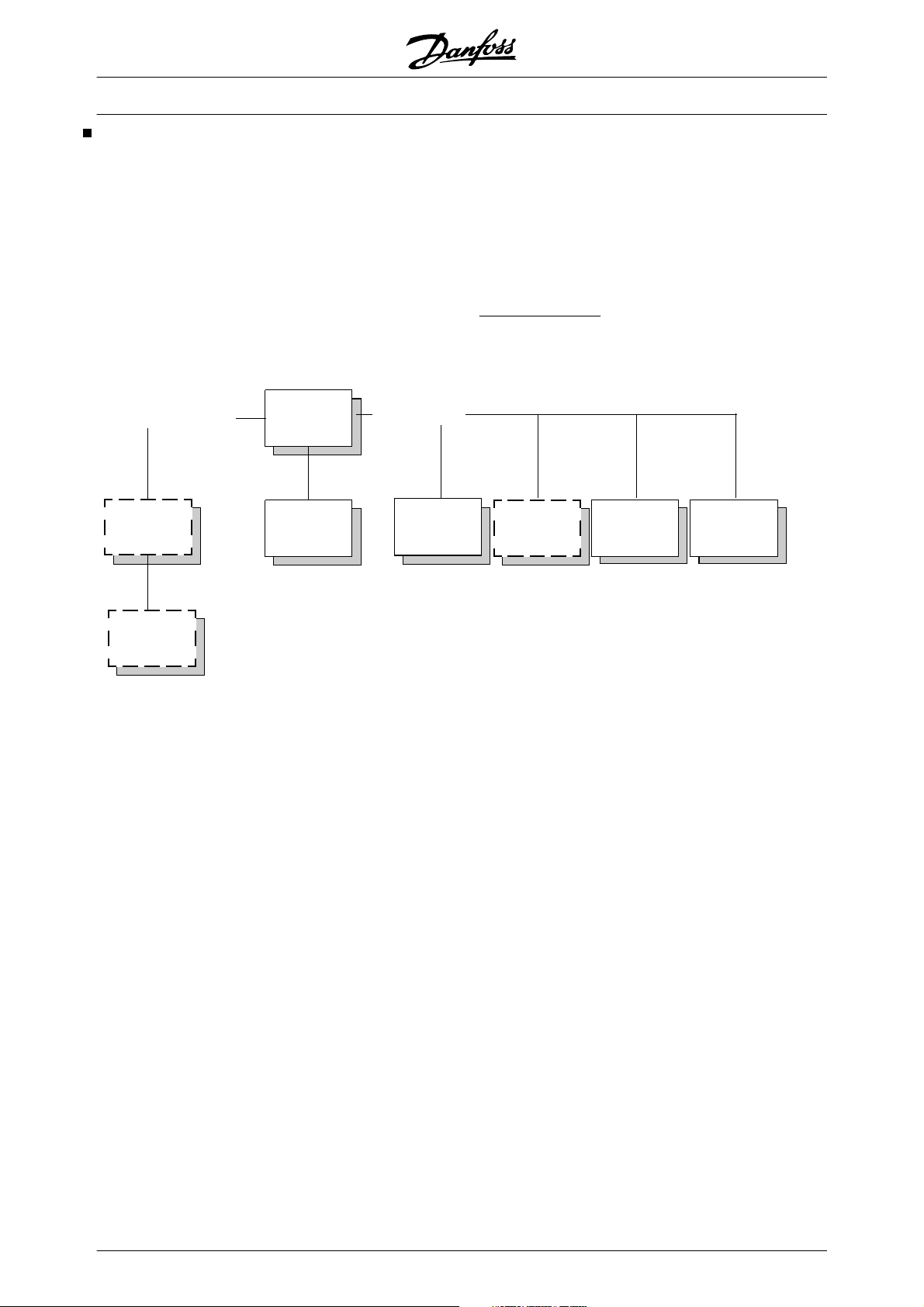

Available literature

The chart below gives an overview of the literature

available for the FCM 300 Series.

ming, training and service.

Promotion

Brochure

MB.03.CX.YY

All

users

Quick Setup

MG.03.FX.YY

Misc.

Design

Guide

MG.03.HX.YY

MCT 10 Setup

Software Manual

MG.10.RX.YY

PROFIBUS-

Manual

MG.03.EX.YY

1

16.1

175NA1

Data sheet

MD.03.AX.YY

Articles

MZ.03.AX.YY

X = version number

YY = language

6 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

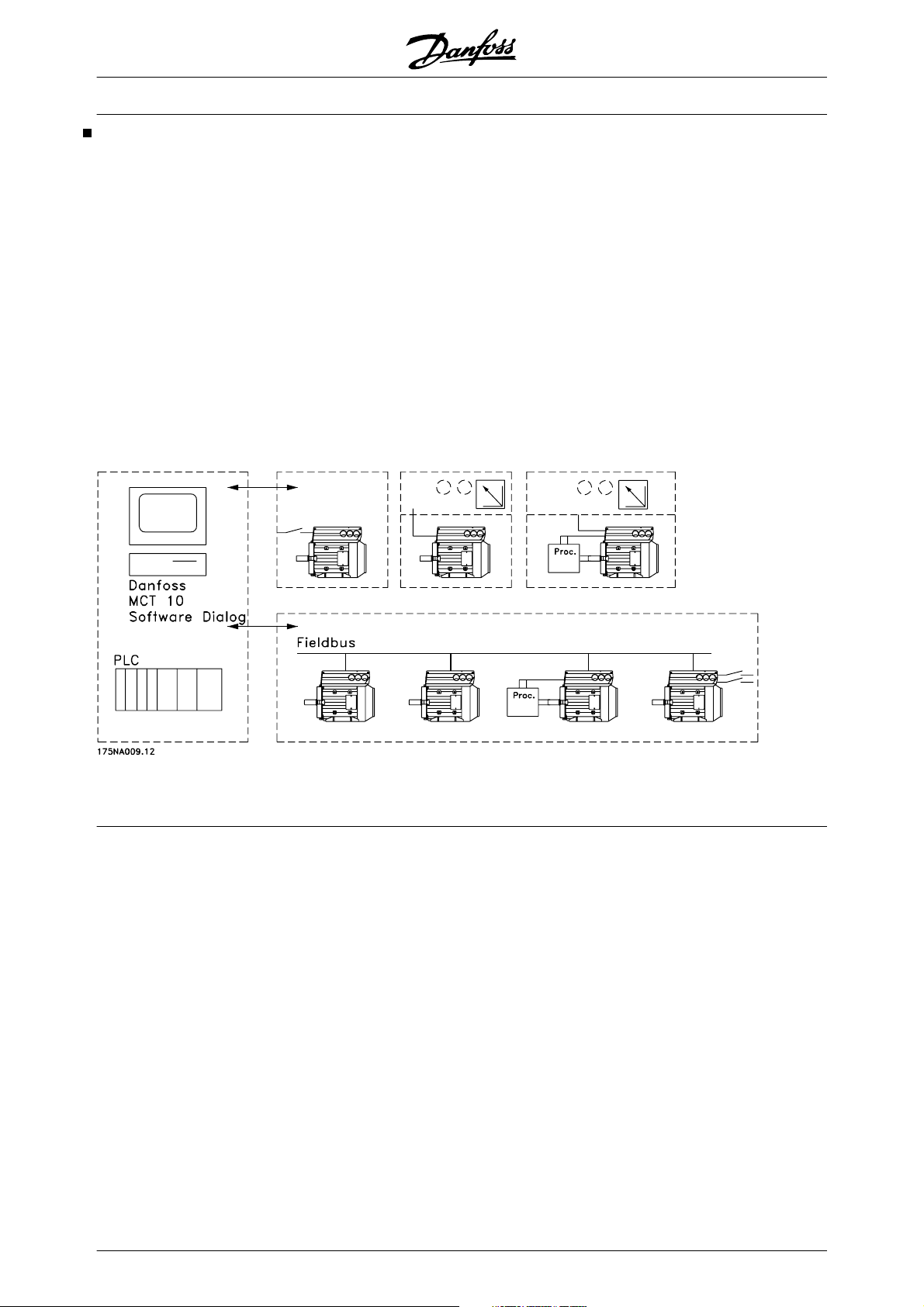

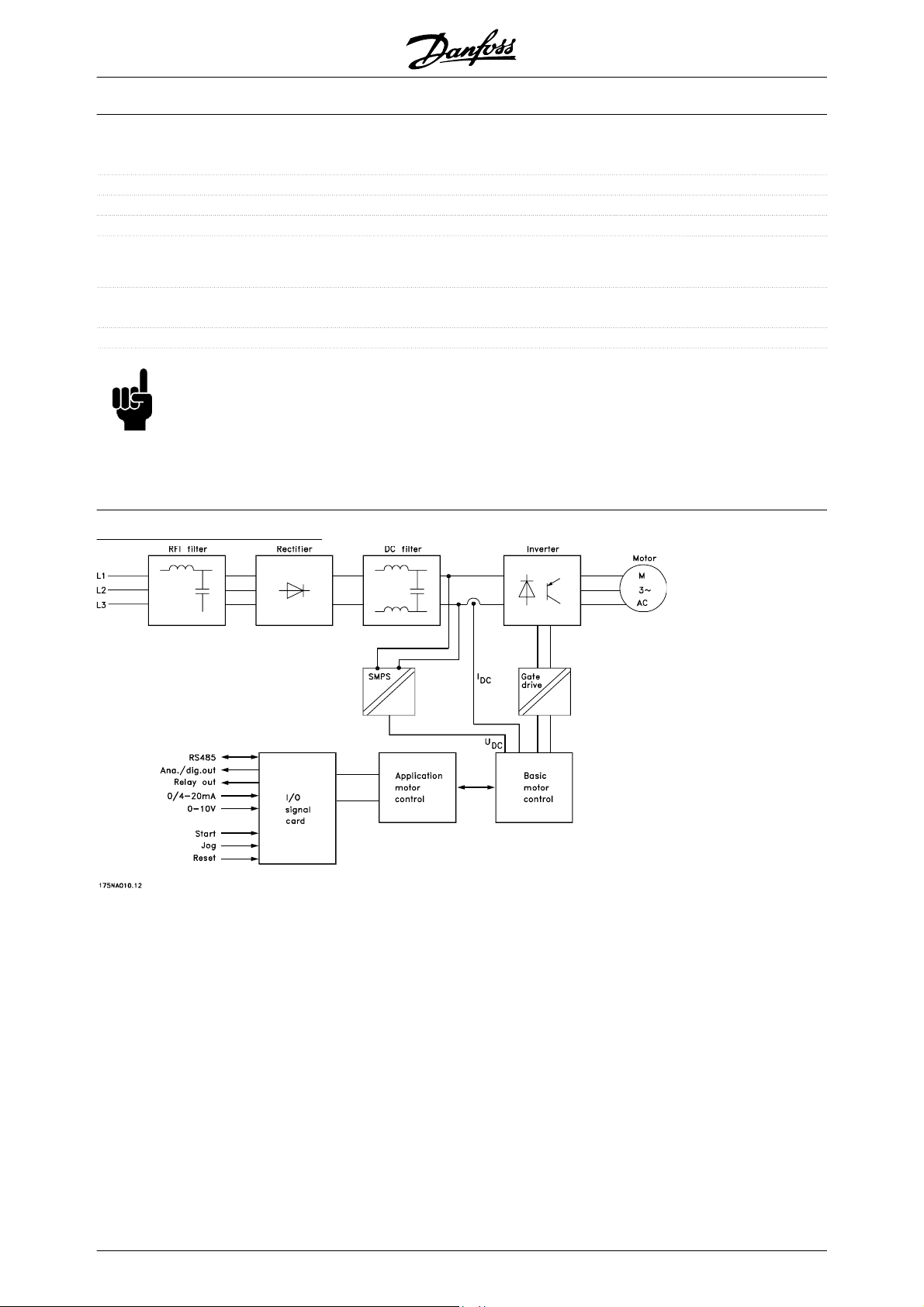

Integration of frequency converter and motor

The Danfoss VLT frequency converter integrated onto

the asynchronous motor gives infinite speed control in

one unit.

The VLT DriveMotor FCM 300 Series is a very compact alternative to the ordinary solution with VLT frequency converter and motor as separate units. The

frequency converter is attached instead of the motor

terminal box, and it is no higher than the standard terminal box, nor wider or longer than the motor (see

chapter 6).

Installation is made extremely easy. Panel space is not

a problem. There is no need for special details on wiring to meet the EMC directive, since motor cables are

not necessary. The only connections are mains and

control connections.

Factory-set adaption between frequency converter

and motor gives precise and energy efficient control in

addition to eliminating pre-setting on site.

The FC motor can be used in stand alone SYSTEMs

with traditional control signals, such as start/stop signals, speed references and closed loop process control or in multiple drive SYSTEMs with control signals

distributed by a field bus.

Combination of fieldbus and traditional control signals

and closed loop PID control is possible.

Control structures

MG.03.H6.02 - VLT® is a registered Danfoss trademark 7

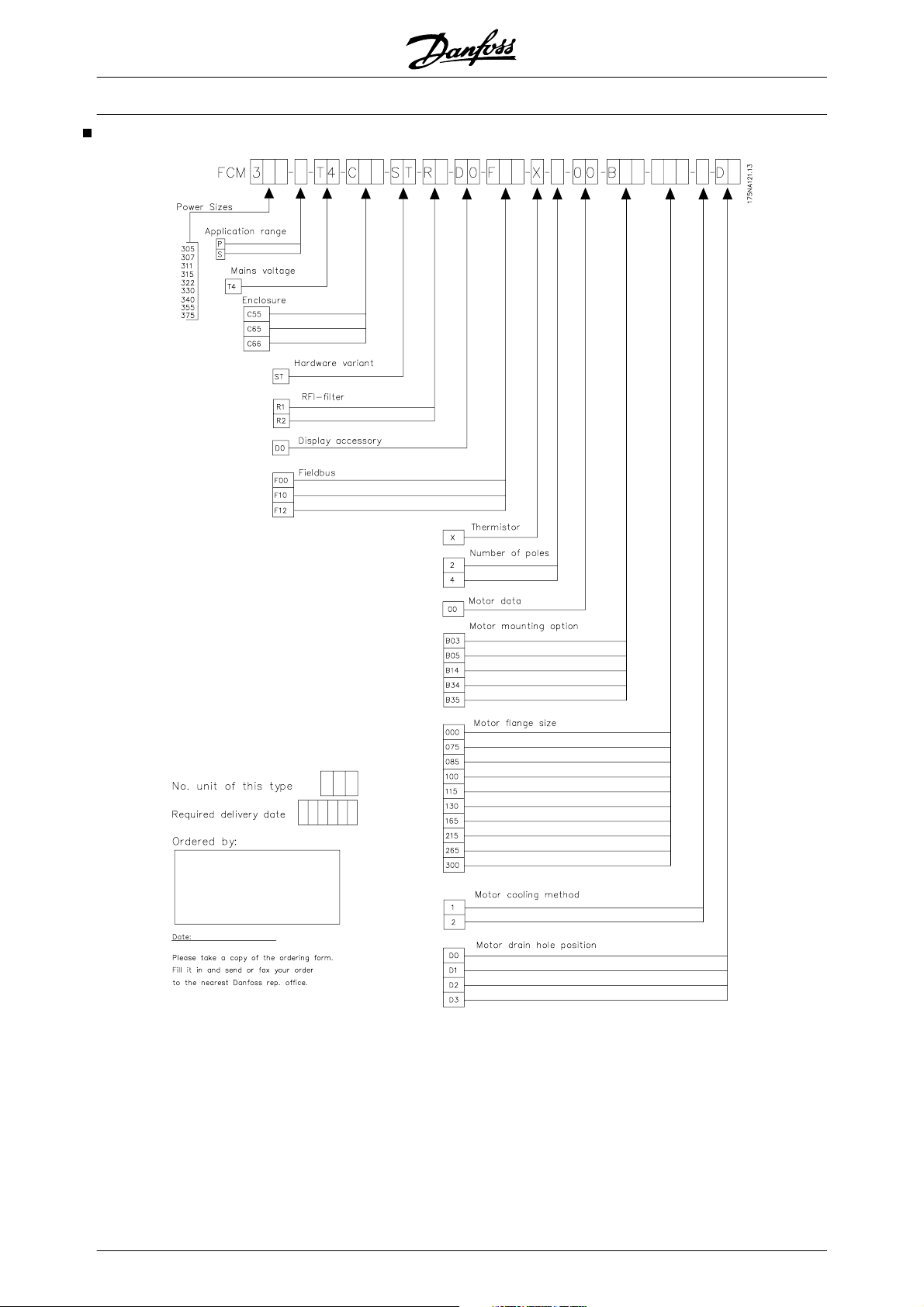

Ordering form

VLT® FCM Series

8 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

Product range

VLT DriveMotor FCM 300 Series, 2/4 poled motors

Type

FCM 305 0.55 kW

FCM 307 0.75 kW

FCM 311 1.1 kW

FCM 315 1.5 kW

FCM 322 2.2 kW

FCM 330 3.0 kW

FCM 340 4.0 kW

FCM 355 5.5 kW

FCM 375 7.5 kW

Each type in the product range is available in different

versions:

Inverter versions

Power size:

(See power size table)

Application

• P: Process

• S: Sensorless (special pump OEM)

Mains voltage:

• T4: 380-480 V three phase supply

Enclosure

• C55: IP55

• C65: IP65

• C66: IP66

Hardware variant:

• ST: Standard

RFI filter

• R1: Compliance with class 1A

• R2: Compliance with class 1B

Display connector

Motor output Mains supply

3 phase 380-480 V

Motor data

• 00: ATB motor

Motor mounting option

• B03: Foot mounting

• B05: B5 flange

• B14: B14 face

• B34: Foot and B14 face

• B35: Foot and B5 flange

Motor flange code

(Regarding standard flange size and available flange

sizes, see table, IEC-FFxxx, Dimension M).

• 000: Foot mounting only

• 085: 85 mm

• 100: 100 mm

• 115: 115 mm

• 130: 130 mm

• 165: 165 mm

• 215: 215 mm

• 265: 265 mm

• 300: 300 mm

Motor cooling method

• 1: Shaft mounted fan

• 2: Forced ventilation

Motor drain hole position

(see drawing)

• D0: No drain hole

• D1: Opposite inverter box both ends (drive/

non drive)

• D2: 90 (deg) inverter box right

• D3: 90 (deg) inverter box left

• D0: No display plug able connector

Fieldbus

• F00: No fieldbus

• F10: Profibus DPV1 3 MB

• F12: Profibus DPV1 12 MB

Motor thermistor

• X: No motor thermistor

Number of poles

• 2: 2 pole motor

• 4: 4 pole motor

MG.03.H6.02 - VLT® is a registered Danfoss trademark 9

VLT® FCM Series

Ordering

Take a copy of the ordering form, see section Ordering

form. Fill in and post or fax your order to the nearest

branch office of the Danfoss sales organisation. On the

basis of your order, the FCM 300 Series motor is given

a type code.

The ordering form for the basic unit must always be

completed. When the type code is written, always state

the characters of the basic string (1-34). Together with

the order confirmation the customer receives an 8-figure code number to be used when reordering.

Danfoss PC software for serial communication, MCT

10

All FCM 300 Series units have an RS 485 port as

standard, which enables them to communicate e.g.

with a PC. A programme entitled MCT 10 is available

for this purpose (see section PC Software tools).

Ordering numbers, MCT 10

Please order your CD containing MCT 10 Set-up Software using code number 130B1000.

Accessories for the FC motor

A Local Operation Pad (LOP) for local set point and

start/stop is available for the FC motor. The LOP is IP

65 enclosed. A Local Control Panel (LCP 2) which

makes up a complete interface for operation, programming and monitoring of the FC motor is also available.

• Commissioning frequency converters on line

• Saving settings for all frequency converters

• Replacing a drive in a network

• Expanding an existing network

• Future developed drives will be supported

The MCT 10 Set-up Software Modules

The following modules are included in the software

package:

MCT 10 Set-up Software

Setting parameters

Copy to and from frequency converters

Documentation and print out of parameter settings incl. diagrams

Ordering number:

Please order your CD containing MCT 10 Set-up Software using code number 130B1000.

SyncPos

Creating SyncPos programme

Ordering numbers, accessories

Local Operation Pad incl. cable(LOP) 175N0128

Local Control Panel (LCP 2) 175N0131

Remote mounting kit (LCP 2) 175N0160

Plug kit (LCP 2) 175N2545

Cable for plug kit (LCP 2) 175N0162

Cable (direct mounting) (LCP 2) 175N0165

Service plug kit (LCP 2) 175N2546

Potentiometer option 177N0011

PC Software tools

PC Software - MCT 10

All drives are equipped with a serial communication

port. We provide a PC tool for communication between

PC and frequency converter, VLT Motion Control Tool

MCT 10 Set-up Software.

MCT 10 Set-up Software

MCT 10 has been designed as an easy to use interactive tool for setting parameters in our frequency

converters.

The MCT 10 Set-up Software will be useful for:

• Planning a communication network off-line.

MCT 10 contains a complete frequency converter database

10 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

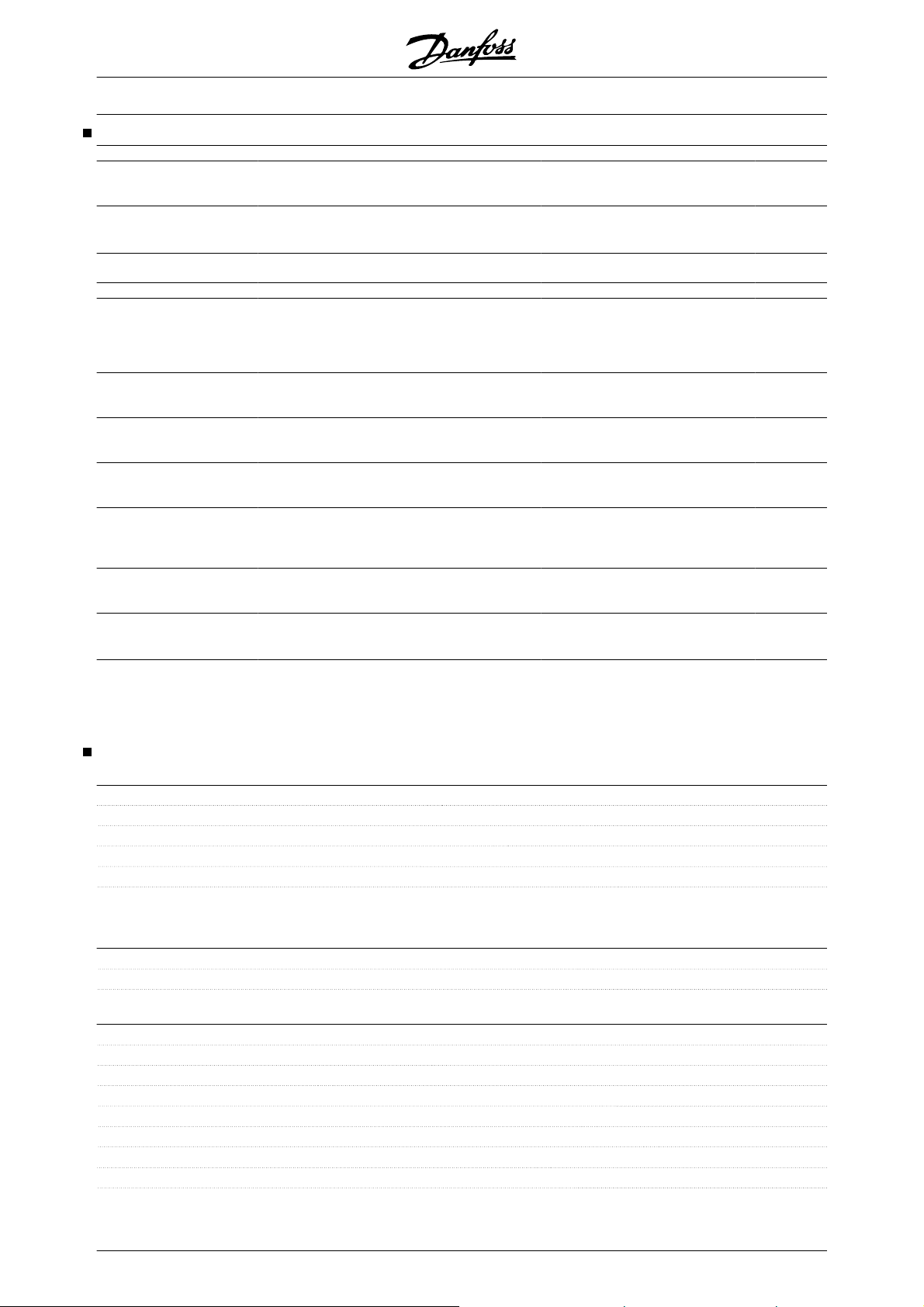

Ordering info for Frames and Flanges

Frame sizes and the corresponding flange sizes for different mounting versions

Type

Motor frame size Mounting version Flange code, standard

(S) [mm]

FCM 305 80

FCM 307 80

FCM 311 90

FCM 315 90

FCM 322 100

FCM 330 100

FCM 340 112

FCM 355 132

FCM 375 132

B5/B35 165 100/115/130/215

B14/B34 100 85/115/130

B5/B35 165 100/115/130/215

B14/B34 100 85/115/130

B5/B35 165 130/215

B14/B34 115 100/130

B5/B35 165 130/215

B14/B34 115 100/130

B5/B35 215 165/265

B14/B34 130 115/165

B5/B35 215 165/265

B14/B34 130 115/165

B5/B35 215 165/265

B14/B34 130 165

B5/B35 265 215/300

B14/B34 165 130

B5/B35 265 215/300

B14/B34 165 130

Flange size according to IEC ref. FFxxx (Dimension M), see section Dimensions

S: Available as standard shaft

*

No changes regarding shaft dimensions

Flange code, alterna-

*

tives

[mm]

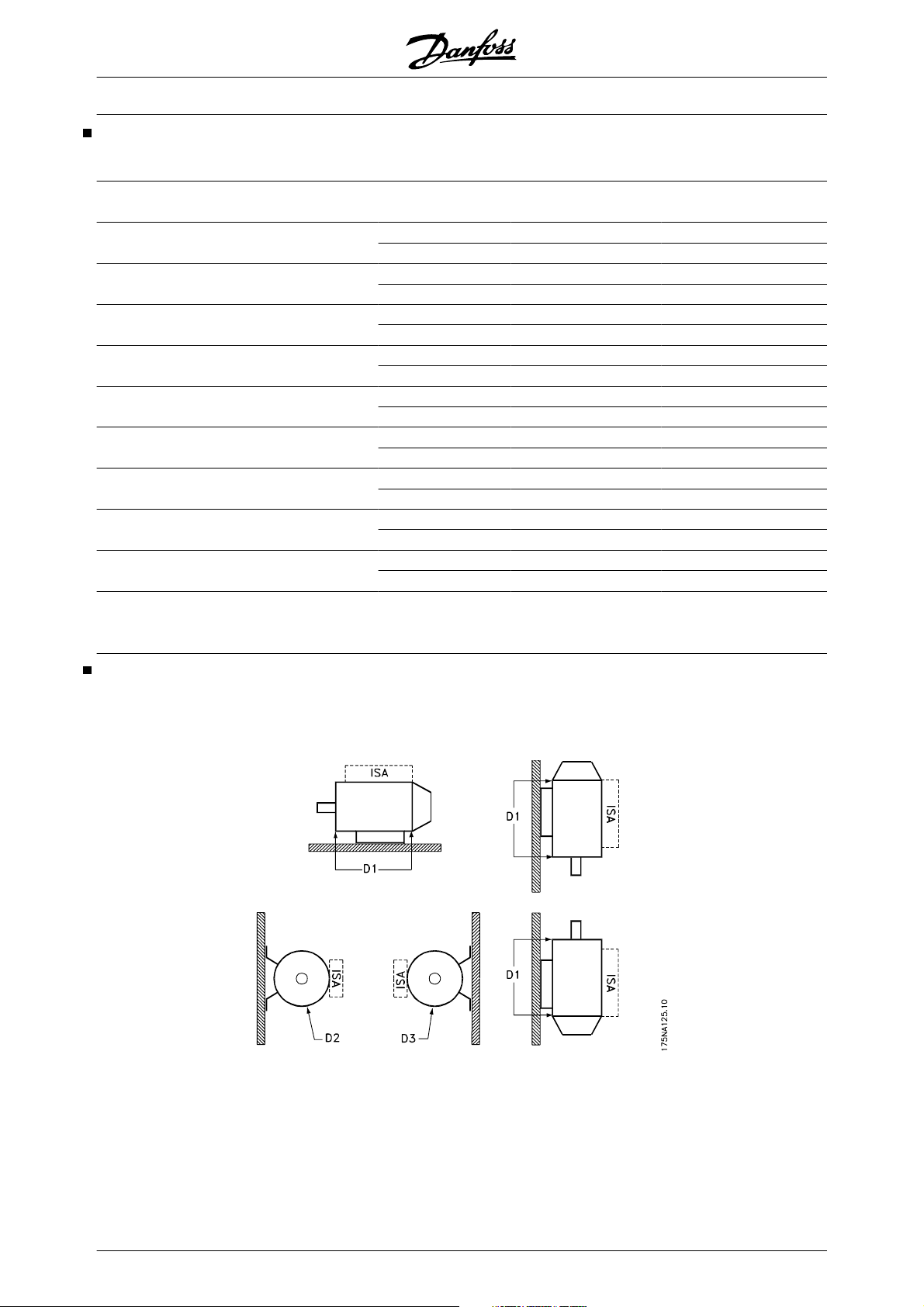

Ordering info for inverter box position and drain

hole position

Inverter box position, always top mounted.

All drain holes are mounted with screw and washer, IP 66 if not opened.

D1: Drain holes opposite inverter side, both drive end and non drive end.

D2/D3: Drain holes 90° to inverter, both drive end and non drive end.

MG.03.H6.02 - VLT® is a registered Danfoss trademark 11

VLT® FCM Series

FCM 305-375 for 3 phases, 380-480 V

FCM 305 307 311 315 322 330 340 355 375

Motor output

[HP] 0.75 1.0 1.5 2.0 3.0 4.0 5.0 7.5 10.0

[kW]

Motor torque

2 pole [Nm]

4 pole [Nm]

Frame

size [mm]

Weight [kg] 11 13 17 20 26 28 37 56 61

Input current

[A]

380 V

2 p 1.5 1.8 2.3 3.4 4.5 5.0 8.0 12.0 15.0

4 p

480 V

2 p 1.2 1.4 1.8 2.7 3.6 4.0 6.3 9.5 11.9

4 p

Efficiency at

nom. speed

(4 pole) %

Efficiency at

nom. speed

(2 pole) %

Power terminals

[AWG] 10101010101010 6 6

[mm2]

Gland sizes 3xM20x1.5 3xM20x1.5 3xM20x1.5 3xM20x1.5 3xM20x1.5 3xM20x1.5 3xM20x1.5 1xM25x1.5

Max. prefuse

3)

UL

IEC

At 400 V 3000 r/min

1)

At 400 V 1500 r/min

2)

Type gG prefuses must be used. If you want to maintain UL/cUL you must use prefuses of the type Bussmann KTS-R 500 V or

3)

Ferraz Shawmut, ATMR Class C (max. 30A). The fuses must be placed for protection in a circuit that is capable of supplying a maximum

of 100,000 amps RMS (symmetrical), 500 V maximum.

3)

1)

2)

[A]

[A]

General technical data

Mains supply, TT, TN and IT* (L1, L2, L3):

- Supply voltage 380-480 V units 3 x 380/400/415/440/460/480 V ±10%

- Supply frequency 50/60 Hz

- Max. imbalance of supply voltage ±2% of rated supply voltage

- Power factor / cos max. 0.9/1.0 at rated load

- No. of switching operations on supply input L1, L2, L3 approx. 1 time/2 min

0.55 0.75 1.1 1.5 2.2 3.0 4.0 5.5 7.5

1.8 2.4 3.5 4.8 7.0 9.5 12.6 17.5 24.0

3.5 4.8 7.0 9.6 14.0 19.1 25.4 35.0 48.0

80 80 90 90 100 100 112 132 132

1.4 1.7 2.5 3.3 4.7 6.4 8.0 11.0 15.5

1.1 1.3 2.0 2.6 3.7 5.1 6.3 8.7 12.3

66 71 74 80 80 81 80 84 84

61 64 76 75 76 85 82 83 91

4 4 4 4 4 4 4 10 10

2xM20x1.5

10 10 10 10 10 15 15 25 25

25 25 25 25 25 25 25 25 25

1xM25x1.5/

/

2xM20x1.5

*) Not valid for RFI class 1B units

Torque characteristics:

- Starting torque/overload torque 160 % for 1 min

- Continuous torque see above

Control card, digital/pulse inputs:

- Number of programmable digital inputs 4

- Terminal nos. X101-2, -3, -4, -5

- Voltage level 0-24 V DC (PNP positive logics)

- Voltage level, logic 0 < 5 V DC

- Voltage level, logic 1 > 10 V DC

- Maximum voltage on input 28 V DC

- Input resistance, R

i

approx. 2 kΩ

- Scanning time 20 msec

12 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

Control card, pulse input:

- No. of programmable pulse inputs 1

- Terminal nos. X101-3

- Max. frequency on terminal 3, open collector/push pull 24 V 8 kHz/70 kHz

- Resolution 10 bit

- Accuracy (0.1-1 kHz), terminal 3 Max. error: 0.5% of full scale

- Accuracy (1-12 kHz), terminal 3 Max. error: 0.1% of full scale

Control card, analogue inputs:

- No. of programmable analogue voltage inputs 1

- Terminal nos. X101-2

- Voltage level 0 - 10 V DC (scalable)

- Input resistance, R

i

- No. of programmable analogue current inputs 1

- Terminal no. X101-1

- Current range 0 - 20 mA (scalable)

- Input resistance, R

i

- Resolution 9 bit

- Accuracy on input Max. error 1% of full scale

- Scanning time 20 msec.

approx. 10 kΩ

approx. 300 Ω

Control card, digital/pulse and analogue outputs:

- No. of programmable digital and analogue outputs 1

- Terminal nos. X101-9

- Voltage level at digital output/load 0 - 24 V DC/25 mA

- Current at analoque output 0 - 20 mA

R

- Maximum load to frame (terminal 8) at analogue output

LOAD

500 Ω

- Accuracy of analogue output Max. error: 1.5% of full scale

- Resolution on analogue output. 8 bit

Relay output:

- No. of programmable relay outputs 1

- Terminal number (resistive and inductive load) 1-3 (break), 1-2 (make)

- Max. terminal load (AC1) on 1-3, 1-2 250 V AC, 2A, 500 VA

- Max. terminal load (DC1) (IEC 947) on 1-3, 1-2 25 V DC, 3A / 50 V DC, 1.5 A , 75 W

- Min. terminal load (AC/DC) on 1-3, 1-2 control card 24 V DC, 10 mA/ 24 V AC, 100 mA

Rated values for up to 300,000 operations (at inductive loads the number of operations is reduced by 50%)

Control card, RS 485 serial communication:

- Terminal nos. X100-1, -2

Control characteristics (frequency converter):

0 - 132 Hz

- Frequency range

Please see special conditions for frequency range for IP 66 motors at the end of this section.

- Resolution on output frequency 0.1 %

- System response time Max. 40 msec.

- Speed accuracy (open loop, CT mode, 4 P motor driven in speed range 150-1500 rPm) +/- 15 rpm

Externals:

IP 55 (IP65, IP66)

- Enclosure

Please see special conditions for frequency range for IP 66 motors at the end of this section.

- Vibration test 1 g

- Max. relative humidity 95 % for storage/transport/operation

- Ambient temperature Max. 40°C (24-hour average max. 35°C)

MG.03.H6.02 - VLT® is a registered Danfoss trademark 13

VLT® FCM Series

see Derating for high ambient temperature

- Min. ambient temperature in full operation

- Min. ambient temperature at reduced performance -10°C

- Temperature during storage/transport -25 - +65/70°C

- Max. altitude above sea level 1000 m

see Derating for air pressure

- EMC standards applied, Emission

EN 61000-6-2, EN 61000-4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-5,

- EMC standards applied, Immunity

- Safety standards applied, EN 60146, EN 50178, EN 60204, UL508

NB!

Please note that the normal IP 66 solution

is only intended for speed up to maximum

3000 rpm. If higher speed is needed,

please give notification when ordering.

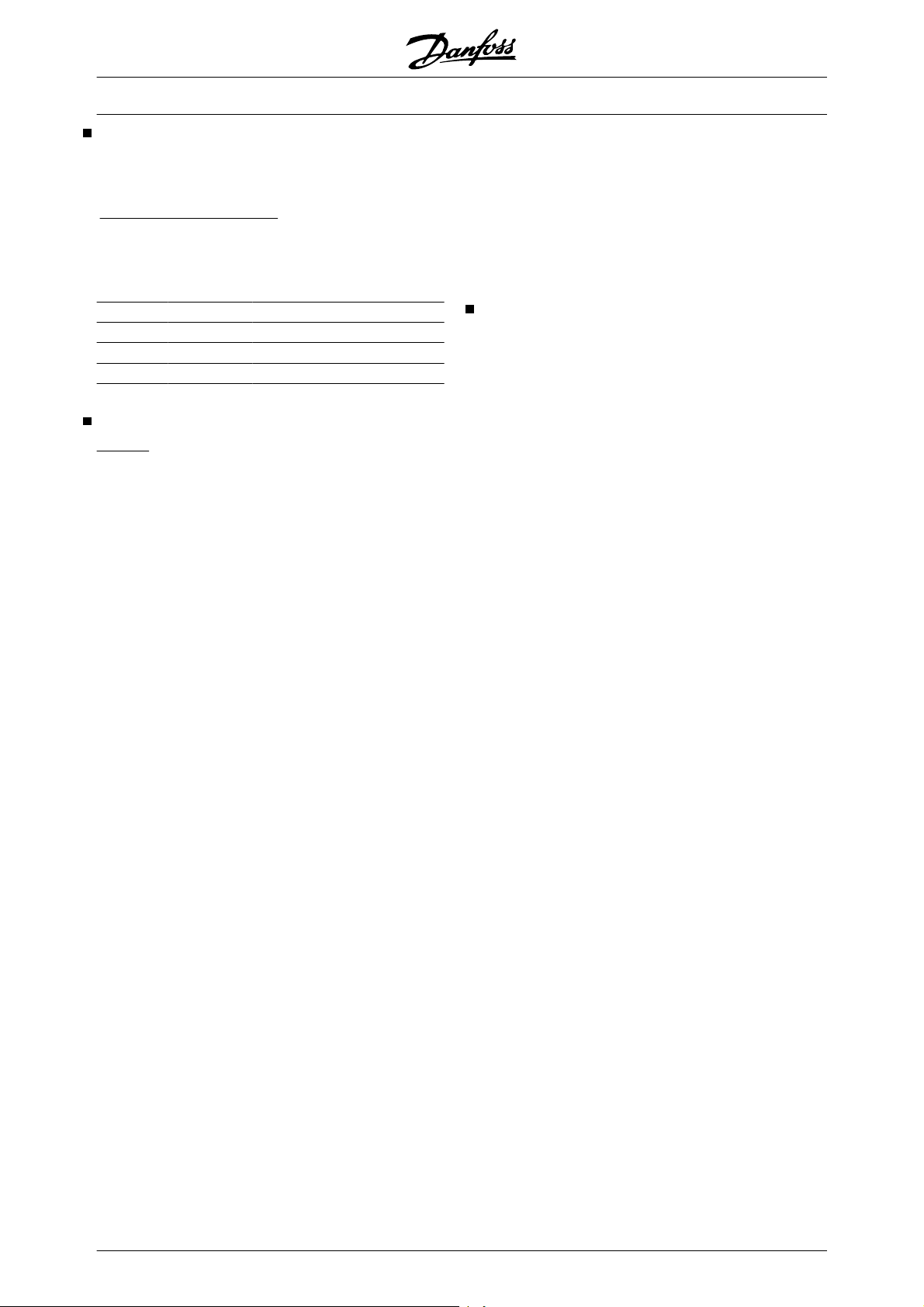

Key diagram for FCM 300 Series

EN 61000-6-3/EN 6100-6-4, EN 61800-3, EN 55011, EN 55014

EN 61000-4-6, ENV 50204

0°C

14 MG.03.H6.02 - VLT® is a registered Danfoss trademark

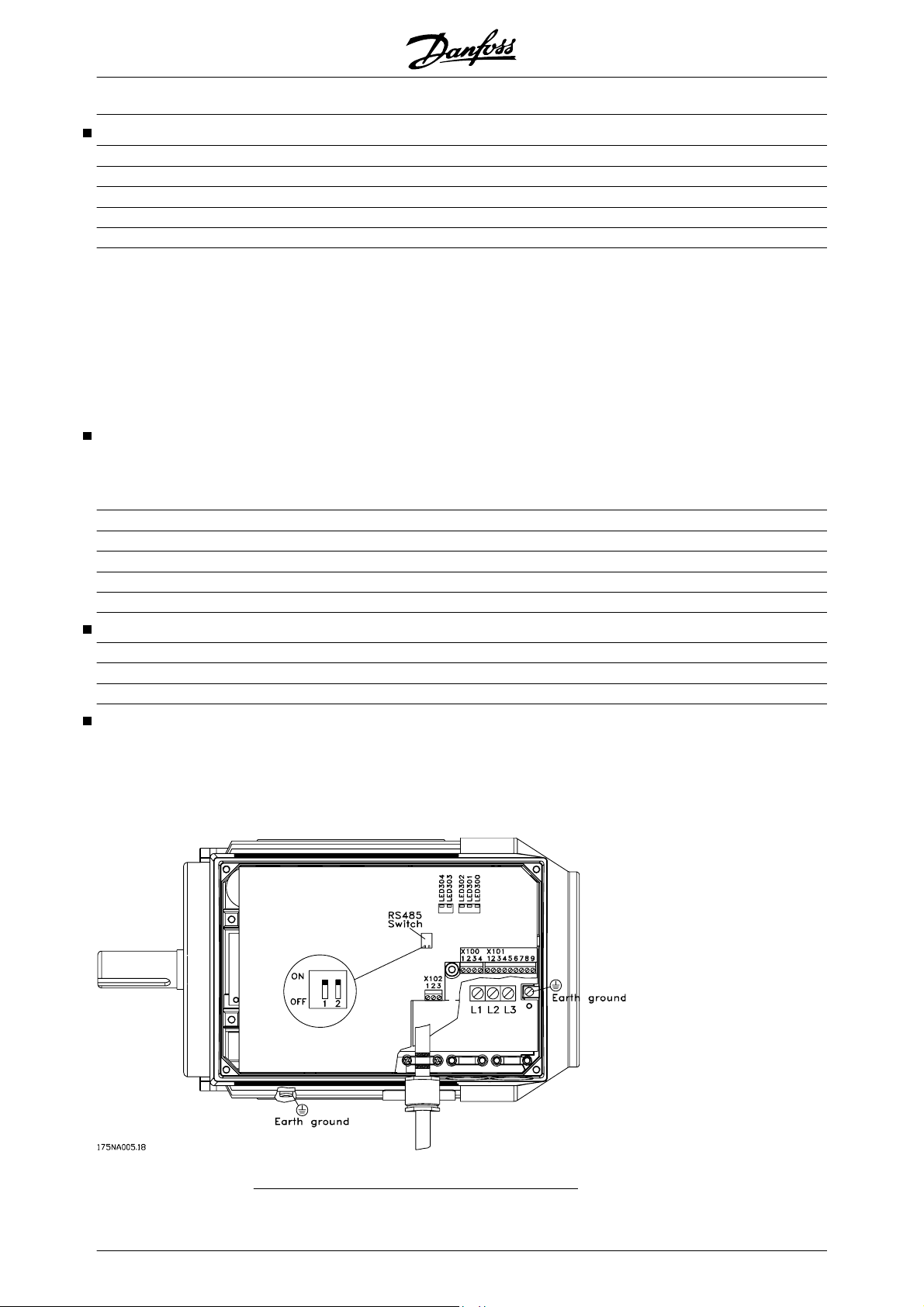

X101: Terminal block for analogue/digital control signals

Terminal No.

1 Analogue input (0-20 mA) Feedback signal

2 Analogue (0-10 V)/digital input 2 Speed reference

3 Digital input (or pulse) 3 Reset

4 Digital input (or precise stop) 4 Start

5 Digital input (other) 5 Jog (fixed speed)

6 24 V DC supply for digital inputs (max. 150 mA)

7 10 V DC supply for potentiometer (max. 15 mA)

8 0 V for terminals 1-7 and 9

9 Analogue (0-20 mA)/digital output Fault indication

Connection diagram - factory setting

Function Example

VLT® FCM Series

-

Reset to be closed short time for resetting fault trips

- Start to be closed for changing to run mode

- Jog will run at fixed speed while closed (10 Hz)

- Speed reference (0-10 V) determines speed while in

run mode

X102: Terminal block for relay output

Terminal No. Function

1-2 Make (normally open)

1-3 Brake (normally closed)

See parameter 323 (relay output) for programming of

relay output.

X100: Terminal block for data communication

Terminal No.

1 P RS 485 for connection to

2 N RS 485

3 5 V DC Supply for RS

4 0 V DC

Function

bus or PC

485 bus

LED 300-304

LED 300 (red): Fault trip

LED 301 (yellow): Warning

LED 302 (green): Power on

LED 303-304: Communication

For PROFIBUS versions please refer to the manual

MG.90.AX.YY.

MG.03.H6.02 - VLT® is a registered Danfoss trademark 15

VLT® FCM Series

Tightening Torques

Cover (lid) screws:

Plastic cable entrance plugs: 19.5 lb-in (2.2 Nm)

L1, L2, L3 (AC Line) screws (FCM 305-340): 5 - 7 lb-in (0.5 - 0.6 Nm)

L1, L2, L3 (AC Line) screws (FCM 355-375): 15 lb-in (1.2 - 1.5 Nm)

Earth Ground: 30.1 lb-in (3.4 Nm)

Terminal screws require a max 2.5 mm flat-blade

screwdriver.

AC Line screws require a 8mm flat-blade screwdriver.

Lid screws , earth ground and cable clamp screws all

require T-20 Torx or flat-blade screwdriver (max. tightening speed 300 RPM).

Maximum Cable Cross Section

Note:

Use °60 C copper wire or better

Max size AC Line cable (FCM 305-340): 10 4.0

Max size AC Line cable (FCM 355-375): 6 10

Max size control cable: 16 1.5

Max size serial communication cable: 16 1.5

Earth Ground: 6 10

25.6 - 31lb-in (3 - 3.5 Nm)

AWG

mm

2

Screw Sizes

Cover (lid) screws:

M5

Earth Ground and Cable Clamp screws (FCM 305-340): M4

Earth Ground and Cable Clamp screws (FCM 355-375): M5

Protection:

• Thermal overload protection of motor and

electronics.

• Monitoring of the intermediate circuit voltage

mediate circuit voltage gets too high or too

low.

• If a mains phase is missing, the inverter will

cut out when a load is placed on the motor.

ensures that the inverter cuts out if the inter-

Terminal arrangement (for installation see quick setup, MG.03.AX.62)

16 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

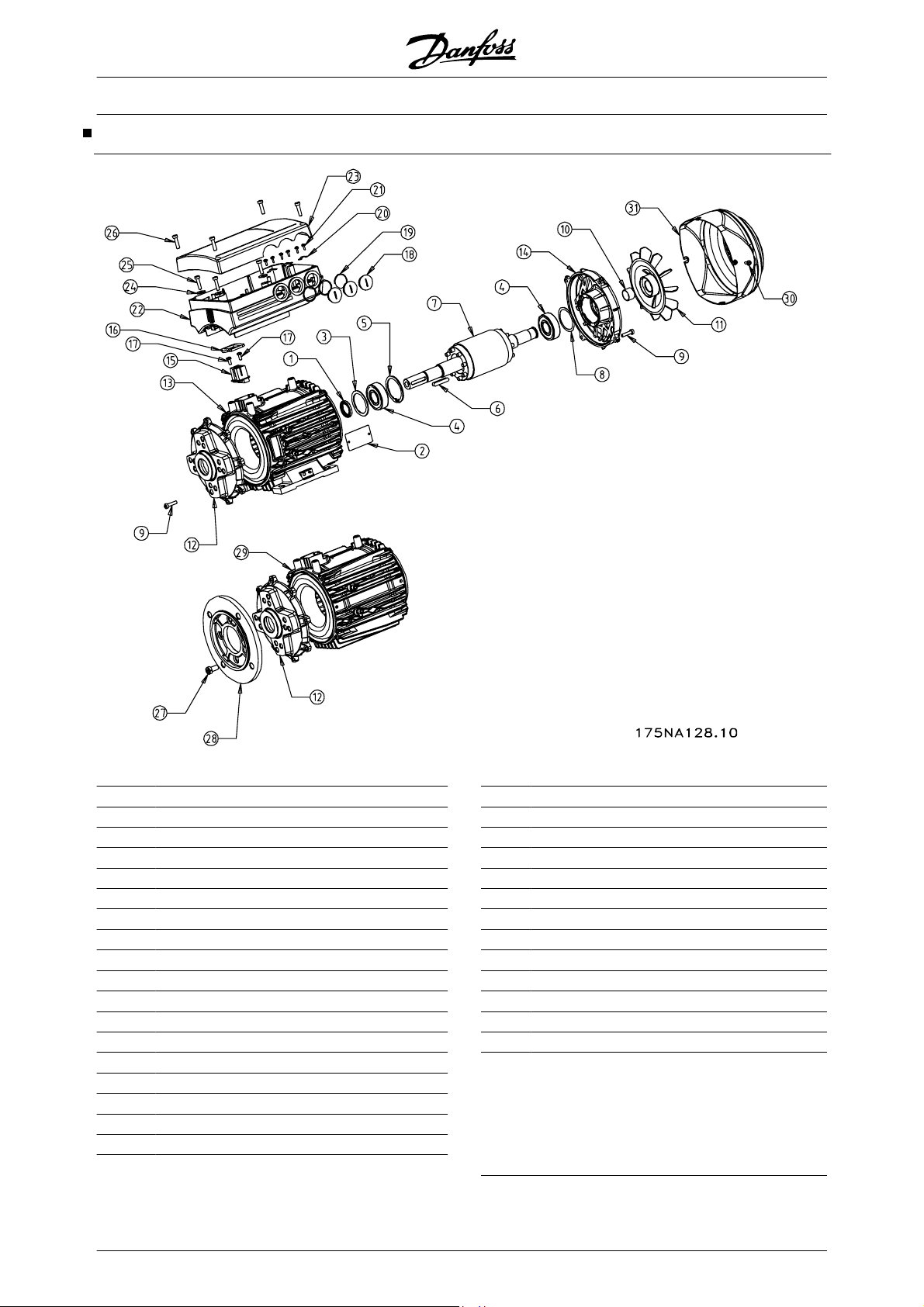

Description of the motor

The FC motor consists of the following parts:

Item Description Item Description

1 Gasket

2 Name plate

3 Shim ring

4 Ball bearing

5 Circlip for drive-end bearing

6 Key

7 Rotor

8 Shim ring for bearing

9 Tension screws

10 Tolerance ring for air blower

11 Air blower

12 Endshield drive end

13 Stator

14 Endshield non drive end

15 Connector block

16

17

18

Gasket

Screws for connector block

Metric blind plugs

19

20

21

22

23

24

25

26

27

28

29

30

31

Gaskets for cable glands

Cable Clamps

Screws for cable clamps

Frequency inverter

Lid for frequency inverter

Gasket

Torx-screws for inverter monting

Screws for lid

Mounting screws for flange ring

Flange ring

Stator

Mounting screws for air blower hood

Air blower hood

MG.03.H6.02 - VLT® is a registered Danfoss trademark 17

VLT® FCM Series

Handling the FC motor

Handling and lifting of VLT DriveMotors (FC motors)

must only be undertaken by qualified personnel. Full

product documentation and operating instructions

must be available together with tools and equipment

necessary for safe working practice. Eyebolts and/or

lifting trunnions supplied with the FC motor are designed to support only the weight of the FC motor, not

the weight of the FC motor and any auxcillary equipment attached to it. Be absolutely sure that cranes,

jacks, slings and lifting beams are capable of carrying

the weight of equipment to be lifted. Where an eyebolt

is provided with the motor, this should be screwed

Bearings

The standard solution is fixed bearing in the drive side

of the motor (shaft output side).

To avoid static indention, the storage area should be

vibration free. Where exposure to some vibration is

unavoidable, the shaft should be locked. Bearings may

be fitted with a shaft locking device which should be

kept in place during storage. Shafts should be rotated

down until its shoulder is firmly against the face of the

stator frame to be lifted.

FCM type approx. weight (kg.)

FCM 305

11

FCM 307 13

FCM 307 17

FCM 315 20

FCM 322 26

FCM 330 28

FCM 340 37

FCM 355 56

FCM 375 61

by hand, one quarter of a revolution, at weekly intervals. Bearings are despatched from the works fully

charged with lithium based grease.

Lubrication

Frame size Lubrication type Temperatur range

80-132 Esso unirex N3 -10 to + 1400°C

Bearing life

3

Maximum hours bearing life (Lna) expected at 80° C bearing temp. x 10

FCM

3000 min

-1

hours.

1500 min

-1

Horiz. Vert. Horiz. Vert.

305-315

22 22 30 30

322-340 26 26 30 30

355-375 26 26 30 30

Lna bearing life is the adjusted, L10 life rating, taking account of: -Reliability -Material improvement -Lubrication

conditions.

Standard Bearing references and oil seals

FCM Mounting Poles (2/4) Bearings Oil seals - Bore x O/D x width in mm

Drive end Non-drive end

305-307

All All 6204 2Z-C3 6204 2RS-C3 20 x 30 x 7

311-315 All All 6205 2Z-C3 6205 2RS-C3 25 x 35 x 7

322-330 All All 6206 2Z-C3 6206 2RS-C3 30 x 42 x 7

340 All All 6206 2Z-C3 6206 2RS-C3 30 x 42 x 7

355-375 All All 6208 2Z-C3 6208 2RS-C3 40 x 52 x 7

18 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

Output shafts

Balance

All motors are dynamically balanced, to ISO 8821with

key convention to IEC 60034-14.

Dimensions

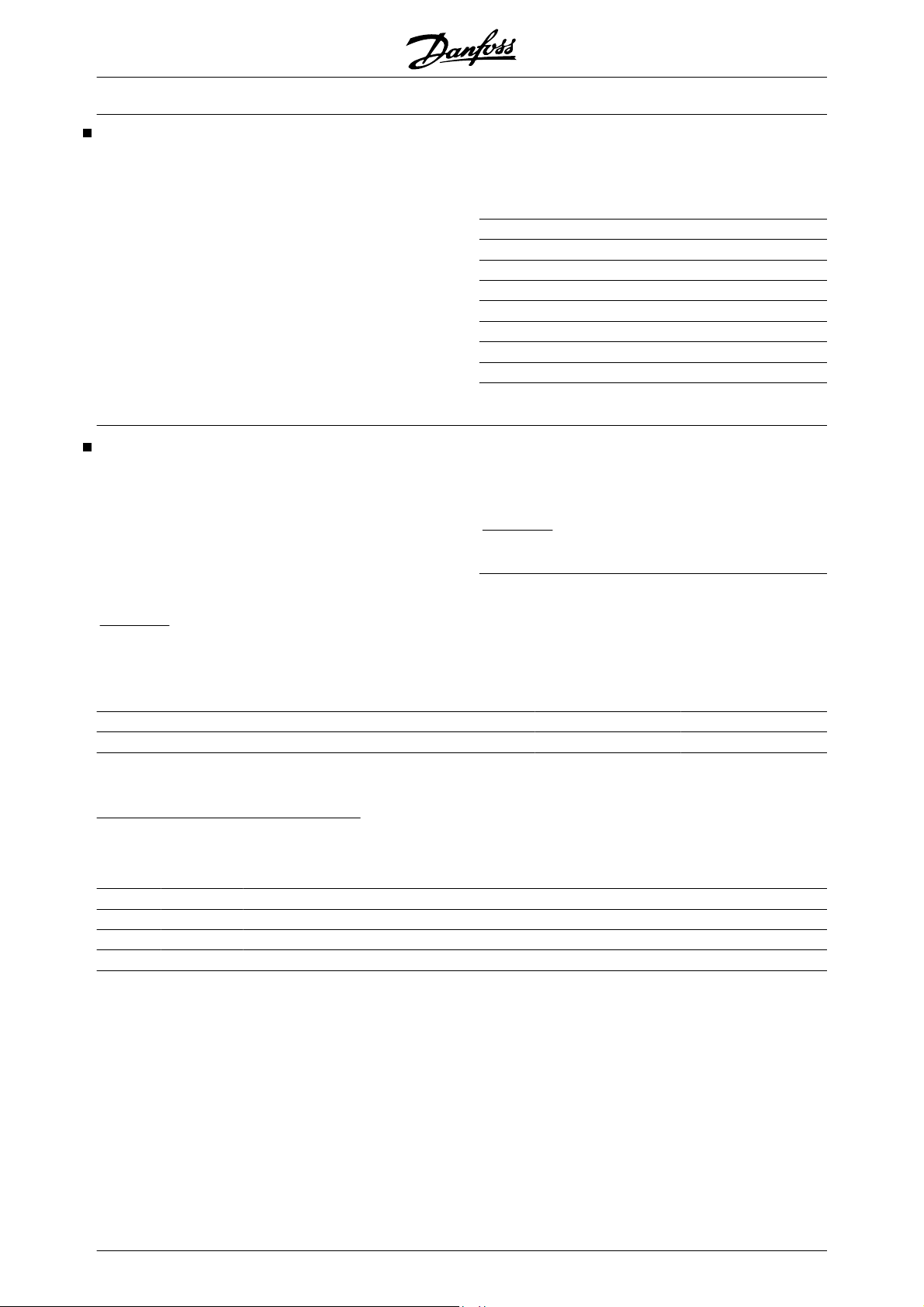

Foot mounting - B3

Inertia J [kgm2]

FCM 2 pole 4 pole

305

307 0.00082 0.0027

311 0.00090 0.0022

315 0.0011 0.0030

322 0.0024 0.0042

330 0.0028 0.0050

340 0.0053 0.0091

355 0.0072 0.0143

375 0.0097 0.0190

0.00082 0.0019

General

FCM

Frame size 80 80 90 90 100 100 112 132 132

A [mm] 125 125 140 140 160 160 190 216 216

B [mm] 100 100 125 125 140 140 140 178 178

C [mm] 50 50 56 56 63 63 70 89 89

H [mm] 80 80 90 90 100 100 112 132 132

K [mm] 9 9 9 9 12 12 12 12 12

EB [mm] 4 4 5 5 5 5 5 5 5

AA [mm] 33.5 33.5 35 35 38 38 44 55 55

AB [mm] 153 153 170 170 195 195 225 256 256

BB [mm] 125 125 155 155 176 176 176 218 218

L [mm] 293 293 319 319 363 363 380 485 485

AC [mm] 159 159 176 176 196 196 220 246 246

HD [mm] 228.5 228.5 241 241 267 267 296 344 344

FCL [mm] 206 206 230 230 256 256 286 340 340

FCW [mm] 142 142 158 158 176 176 197 235 235

305 307 311 315 322 330 340 355 375

MG.03.H6.02 - VLT® is a registered Danfoss trademark 19

VLT® FCM Series

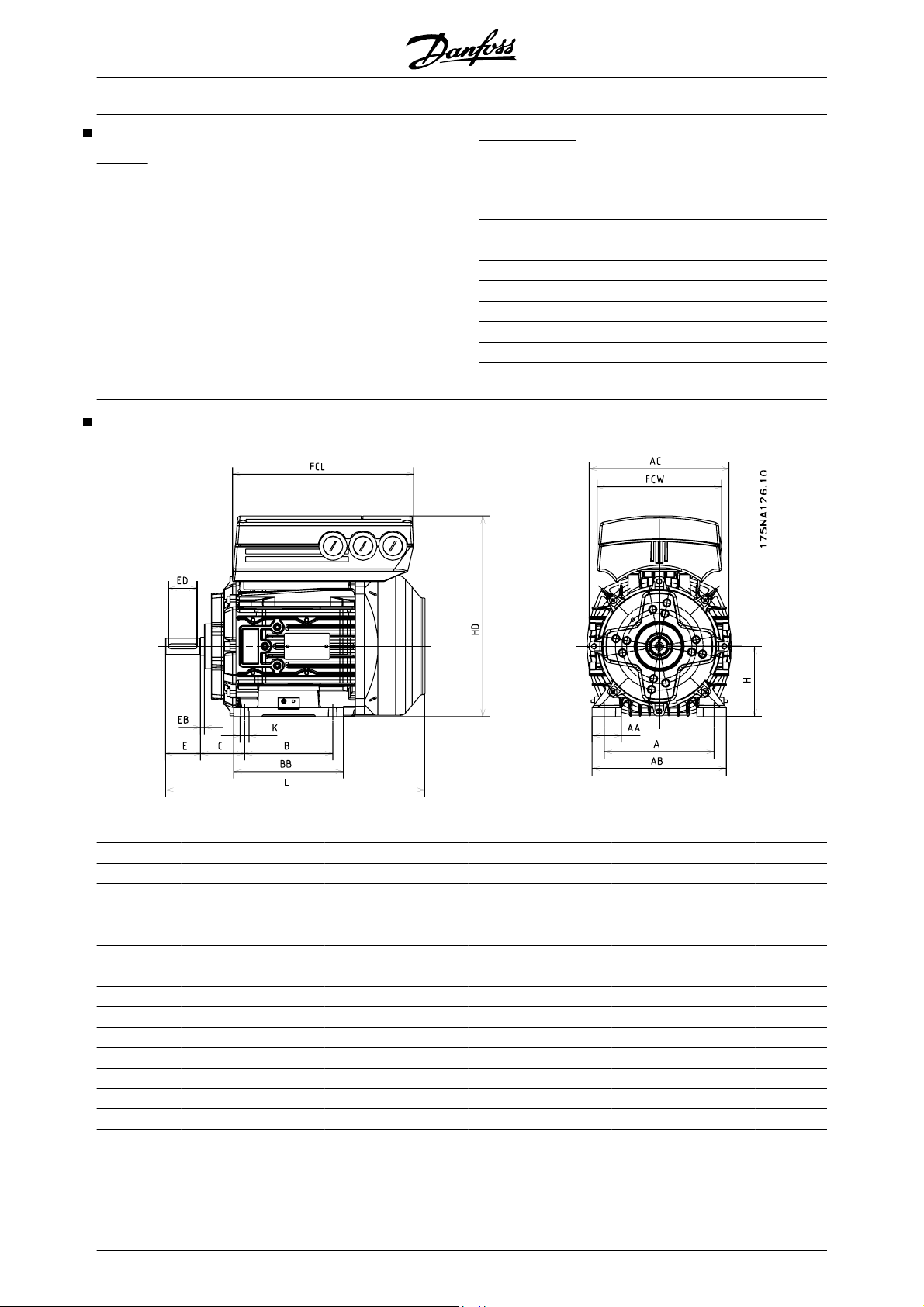

Flange mounting - B5, B35 (B3+B5)

B5

FCM

Frame size 80 80 90 90 100 100 112 132 132

IEC Ref. FF165 FF165 FF165 FF165 FF215 FF215 FF215 FF265 FF265

DIN Ref. A200 A200 A200 A200 A250 A250 A250 A300 A300

M [mm] 165 165 165 165 215 215 215 265 265

N [mm] 130 130 130 130 180 180 180 250 230

P [mm] 200 200 200 200 250 250 250 300 300

S [mm] 12 12 11.5 11.5 14 14 14 14 14

T [mm] 3.5 3.5 3.5 3.5 4 4 4 4 4

LA [mm] 10 10 10 10 11 11 11 12 12

305 307 311 315 322 330 340 355 375

Face mounting - B14, B34 (B3+B14)

B14

FCM

Frame size 80 80 90 90 100 100 112 132 132

IEC Ref. FT100 FT100 FT115 FT115 FT130 FT130 FT130 FT165 FT165

DIN Ref. C120 C120 C140 C140 C160 C160 C160 C200 C200

M [mm] 100 100 115 115 130 130 130 165 165

N [mm] 80 80 95 95 110 110 110 130 130

P [mm] 120 120 140 140 160 160 160 200 200

S [mm] M6 M6 M8 M8 M8 M8 M8 M10 M10

T [mm] 3 3 3 3 3.5 3.5 3.5 3.5 3.5

LA [mm] 12 12 10 10 10 10 10 12 12

305 307 311 315 322 330 340 355 375

20 MG.03.H6.02 - VLT® is a registered Danfoss trademark

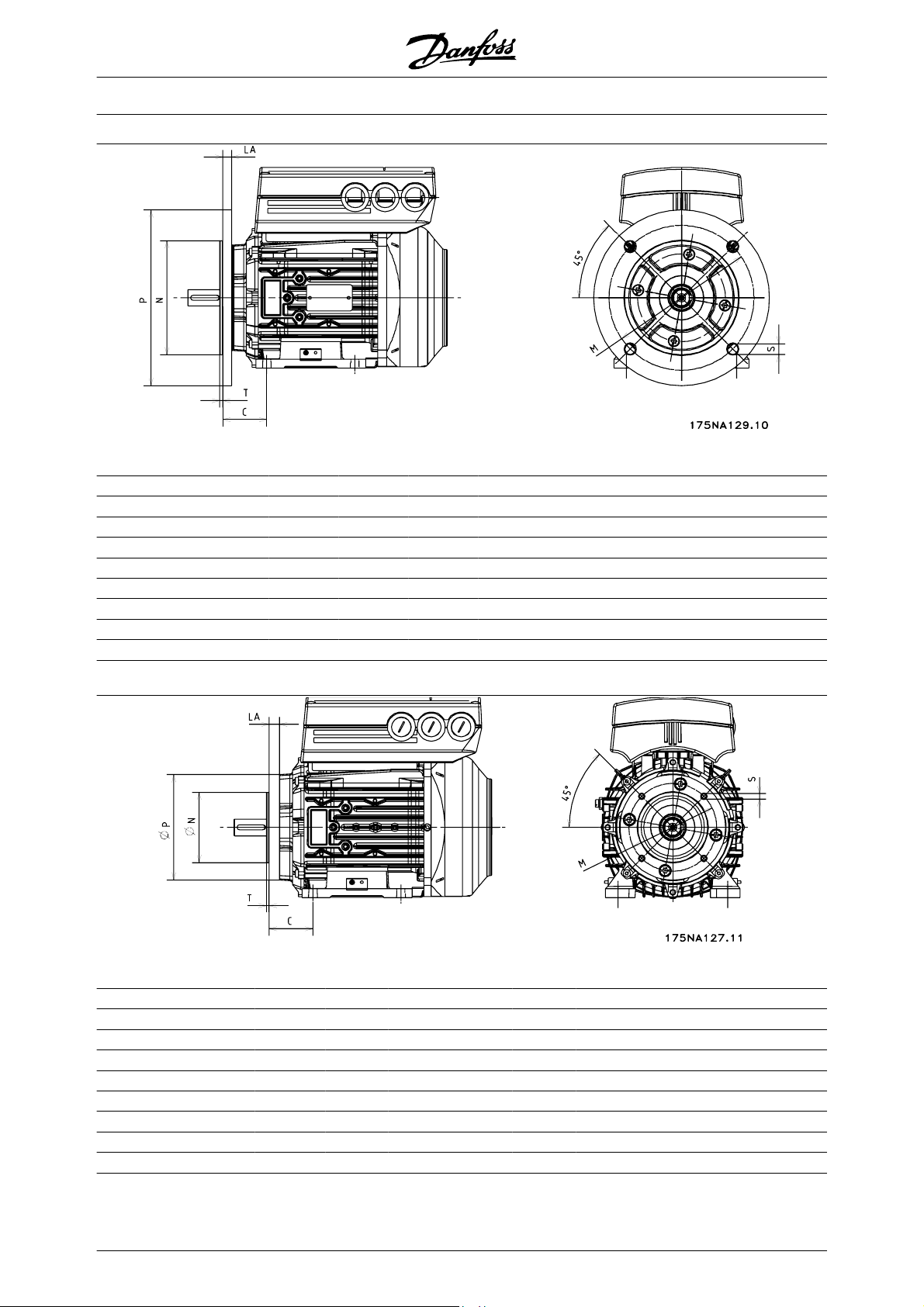

Shaft Drive End

VLT® FCM Series

Shaft tapped

DH x deep to

DIN 332 Form DR

Closed profile keyway

FCM 305 307 311 315 322 330 340 355 375

Frame size 80 80 90 90 100 100 112 132 132

∅D [mm]

E [mm] 40 40 50 50 60 60 60 80 80

ED [mm] 32 32 40 40 50 50 50 70 70

DH [mm] M6x16 M6x16 M8x19 M8x19 M10x22 M10x22 M10x22 M12x28 M12x28

F [mm] 6 6 8 8 8 8 8 10 10

GA [mm] 21.5 21.5 27 27 31 31 31 41 41

19 19 24 24 28 28 28 38 38

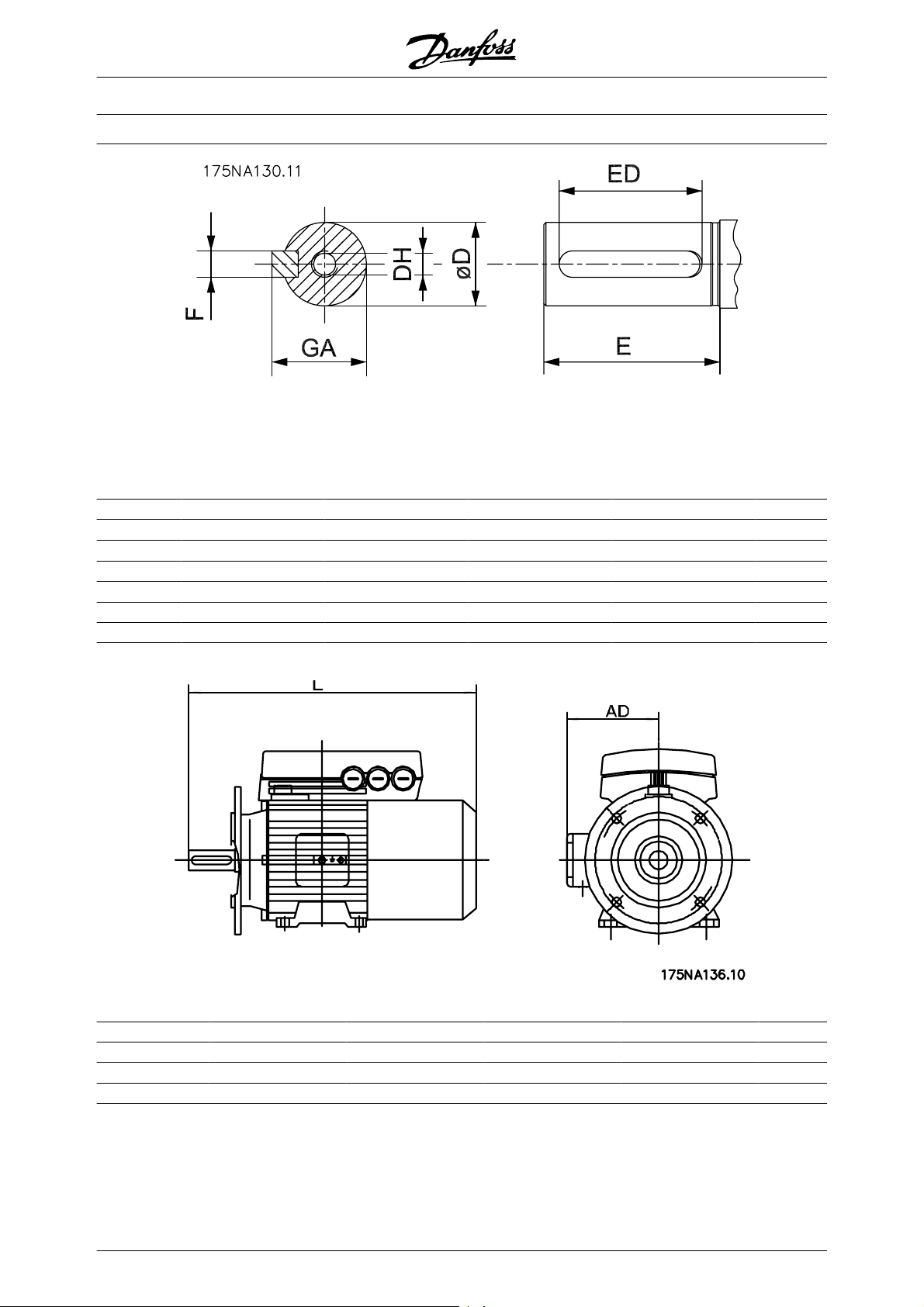

Forced ventilation

FCM

Frame size 80 80 90 90 100 100 112 132 132

AD [mm] 132 132 160 160 170 170 182 195 195

L [mm] 386 386 427,5 427,5 440 440 482 616 616

MG.03.H6.02 - VLT® is a registered Danfoss trademark 21

305 307 311 315 322 330 340 355 375

Installation of the FC motor

VLT® FCM Series

FC motors must be installed with adequate access for

routine maintenance. A minimum of 0.75m of working

space around the motor is recommended. Adequate

space around the motor, particularly at the fan inlet (50

mm), is also necessary to facilitate airflow.

Where several FC motors are installed in close proximity, care must be taken to ensure that there is no

recirculation of exhausted warm air. Foundations must

be solid, rigid and level.

NB!

Electrical installation

Do not remove the top foil inside the inverter part, as this is a part of the protective arrangements.

Alignment

When the application calls for direct coupling, the

shafts must be correctly aligned in all three planes.

Bad alignment can be a major source of noise and vibration.

Fitting pinions, pulleys and couplings.

These should be bored to our standard limits and fitted

on the shaft with a screwing motion. Attention must be

paid to correct guarding of all moving parts.

Tapping of fitments onto the FC motor

shaft, with a hammer or mallet, causes

bearing damage. This results in an increase in bearing noise and a significant

reduction in bearing life.

NB!

Max. length of mounting bolts penetrating

the B14 flange, see section Dimensions in

this chapter.

Allowance must be made for shaft endfloat and thermal expansion in both axial and vertical planes. It is

preferable to use flexible drive couplings.

Maximum permissible axial and radial loads in N

Frame size Poles Axial load in [N]

Horizontal shaft

80

80 4 760 770

90 2 600 650

90 4 810 820

100 2 830 890

100 4 1120 1160

112 2 820 890

112 4 1100 1110

132 2 1300 1440

132 4 1710 1780

All figures are based on L10 bearing life of 20,000 hours, standrad bearings.

Reinforced bearings available.

22 MG.03.H6.02 - VLT® is a registered Danfoss trademark

2 570 610

Radial load in [N] at 0.5 X shaft

length

VLT® FCM Series

Bolt torques

Endshields and lid should be secured with the bolt

sizes and torque's detailed in the table below.

Endshield fixing bolt torques

FCM

Type

Nm.

305-307

311-315 90 M5 5

322-330 100 M6 (taptite) 8-10

340 112 M6 (taptite) 8-10

355-375 132 M8 (taptite) 29

LID screws torque: 2.2 - 2.4 Nm

Maintenance

Routine cleaning of the FC motor

Remove the fan cover and ensure that all air inlet holes

are completely free. Clean any dirt and obstructions

from behind the fan and along the ribs of the frame,

and between the motor and inverter part.

Periodic maintenance of motor part.

a. Remove the inverter part, the fan cover and

Frame size Bolt diameter Torque

80 M5 5

the fan which is keyed to the shaft extension.

Loosen and remove bearing cover screws

and endshield bolts/studs.The endshields

should then be eased off their spigots.

driven part, as misalignment will lead to ultimate bearing trouble and shaft breakage.

g. When replacing screws and bolts, care

should be taken to use only those with the

requisite quality and tensile strength recommended by the manufacturer. These must

also be of identical thread form and screw/

bolt length (see the table above).

Forced ventilation (FV) units

In some applications the fan built on to the motor shaft

do not give sufficient cooling for operation at low

speed. That problem is solved by mounting a FV unit.

Typical applications are for example conveyors, spindles and other constant torque (CT) applications

where the customer wants a wide control range without reduction in torque down to low speed.

The VLT Drive Motor yields full continuous torque

down to low speed with FV built on. The forced vent

enclosure is IP 66. Approved according to UL.

b. The rotor can now be carefully withdrawn

from the stator, taking care not to damage the

stator bore and both stator and rotor windings.

c. Having dismantled the motor, maintenance

can be carried out to remove all dirt. For this

purpose, the use of an air line supplying dry

compressed air under comparatively low

pressure is best, as a high velocity air-stream

can force dirt into the spaces between the

windings and insulation, etc. Grease-removing solvents can cause damage to impregnating varnish or insulation

d. The FC-motor should be re-assembled in the

reverse order from dismantling, remembering to ease endshields onto bearings and

spigots. DO NOT USE FORCE.

e. Before starting, check that the rotor revolves

freely. Ensure that the electrical connections

are correct.

f. Refit any pulley, coupling, sprocket etc.

which has been removed, being particularly

careful to ensure correct alignment with the

MG.03.H6.02 - VLT® is a registered Danfoss trademark 23

VLT® FCM Series

Voltage range for forced ventilation (FV) unit

The FVU can be supplied with a wide range of voltages

depending on the way the terminals are connected.

Standard is three phase 380-500 V (50 Hz), 380-575

FCM 300 Thermal Protection

The thermal protection of FC and motor is covered in

the following way:

1. Overload situations are handled by the cal-

2

culated electrical load (I

X t).

2. Missing ventillation and high ambient temperature is handled by the temperature

measurement. The derating for low speed

(due to missing ventillation) is not incoporated in the electrical load calculaton but taken

care of by the temperature measurement.

Forced ventillation is thus automaticly covered.

Electrical load

The current is measured in the DC link and the estimated load is calculated. The level of the electrical

load is set at an output torque of 105%. Above that

level a counter is increased, below the level it is decreased. The counter starts at zero. When the counter

reaches 100, the unit trips. At 98 the warning indication

goes on (LED and status word).

V (60 Hz) with the possibility to connect three phase

220-290 V (50 Hz), 220-332 V (60 Hz) or single phase

230-277 V (50/60 Hz). The capacitor for single phase

is mounted inside the terminal box.

Trip level => Immediate trip and alarm indication (LED

and status word).

The value can be read in parameter 537 (LCP: Heat

sink temp.).

The temperature levels seem to be high, but due to a

local heating of the sensor the practical levels of the

inside air temperature are approx. 10 deg C lower.

Load Time from 0 to 100 Time from 100 to 0

0% - 60 sec

20% - 100 sec

40% - 150 sec

60% - 200 sec

80% - 250 sec

105% 900 sec (if over 105%) 300 sec (if under 105%)

120% 550 sec 140% 210 sec 160% 60 sec >165% 20 sec -

At full AC brake (parameter 400) a load > 165% is simulated => 20 sec to trip.

The value can be read in parameter 527. (LCP:FC

thermal)..

Temperature measurement

The temperature measurement is sensing the temperature within the electronics box.'

At warning level => Warning indication goes on (LED

and status word) and the unit might trip if the temperature doesn't sink back below warning level within 15

minutes. If the function TEMP.DEP.SW is activated in

parameter 412, the switching frequency is decreased

gradually down to 2 kHz attempting to decrease the

temperature.

24 MG.03.H6.02 - VLT® is a registered Danfoss trademark

Service plug kit (175N2546)

Purpose:

To run LCP2 and PROFIBUS at the same time. The

service plug can be used with FCM 300 of serial number 03Gxxx and software version as from 2.03. Used

together with cable for plug kit 175N0162.

Plug kit (175N2545)

Purpose

To make a plugable connection between LCP 2 and

FCM 300.

Used together with cable for plug kit 175N0162.

VLT® FCM Series

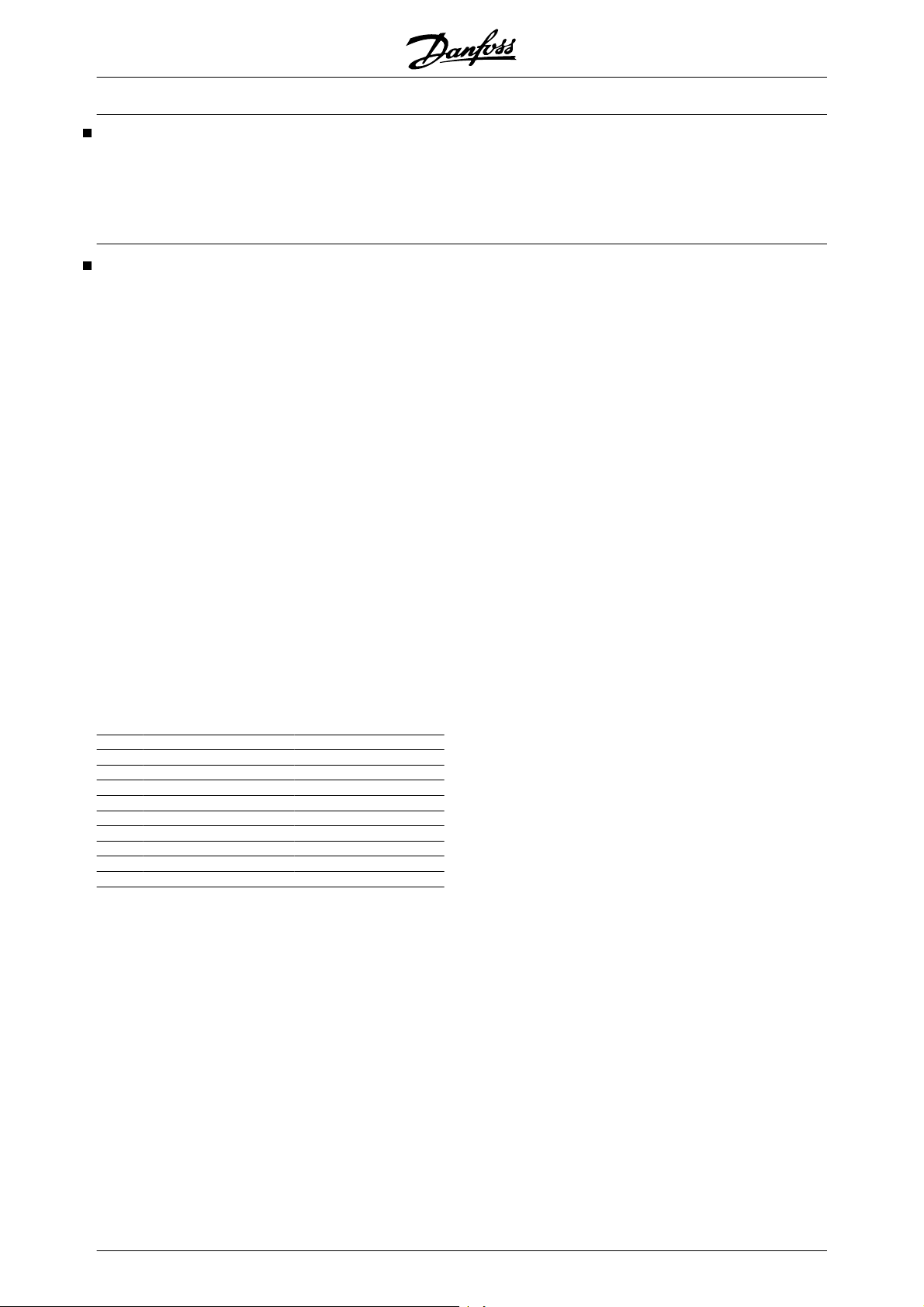

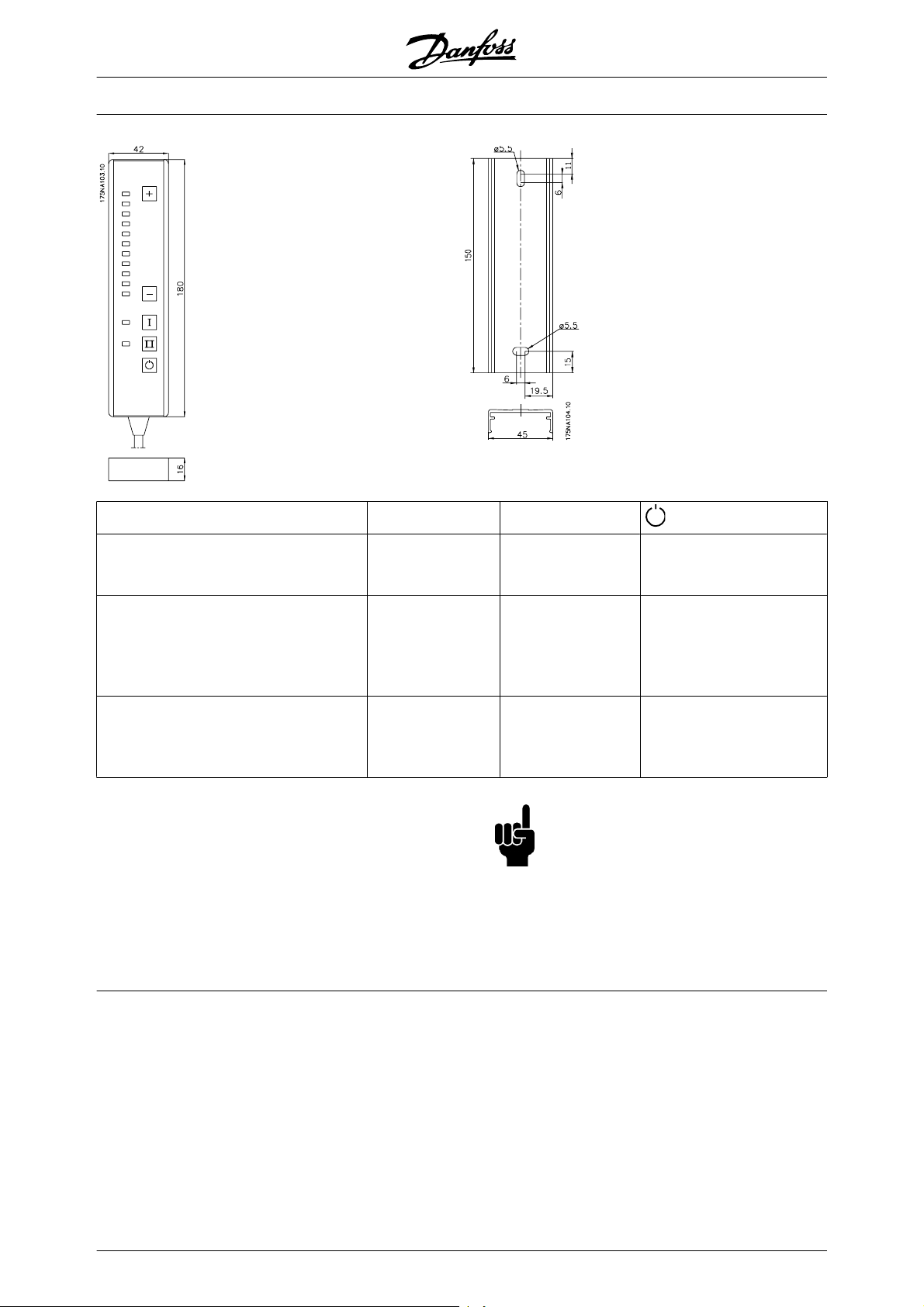

Remote mounting kit (175N0160)

Connections

Colour of wire/ Terminal X100/ D-sub pin

yellow 1 8

green 2 9

red 3 2

blue 4 3

MG.03.H6.02 - VLT® is a registered Danfoss trademark 25

Remote mounting kit cont.

VLT® FCM Series

Potentiometer option (177N0011)

Option to control the reference by means of a potentiometer. The option is mounted instead of a cable bracket. The potentiometer is operated by removing the blind

plug to set the desired reference, and then mount the

blind plug again.

Colour of wire Terminal on X101

White 2 (analog input)

Red 8 (0 V)

Black 7 (+10 V)

Local Operation Pad (LOP) (175N0128) IP65

Wiring

Colour of wire

White 2 Reference

Brown 3 Reset

Purple * or Grey 4 See table under button

Green 5 See table under button

Red 6 +24V

Yellow 7 +10V

Blue 8 Ground

Terminal Function

* Can be orange in some cables

26 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

Local Operation Panel (LOP) 175N0128 IP 65 Fixture for LOP 175N2717 (included in 175N0128)

Functions/settings Key I (Start) Key II (Start)

Default - Dual speed operation (connect

purple wire):

No changes to factory setting.

Function 2 - Dual mode operation (connect purple wire)

Select desired modes of operation in Setups 1 and 2 (use para. 4-6) Parameter

335 = 18 (select Setup)

Function 3 - Dual direction operation

(connect grey wire)

Parameter 335 = 10 (start reversing) Parameter 200 = 1 (both directions)

*If no reset is required, do not connect the brown

wire**or set parameter 213

Use the +/- keys to set reference

At power up the unit will always be in stop mode. Set

reference will be stored during power down. If permanent start mode is desired, connect terminal 6 to terminal 4 and do not connect purple/grey wire to terminal

4. This means the stop function on LOP is disabled.

Run on set reference (+/-)

Run with Setup 1 Run with Setup 2 Stop (and reset* - if trip)

Run forward Run reverse Stop (and reset* - if trip)

Run on 10 Hz** jog

speed

NB!

After fitting, cut off or isolate excess wire.

Key (Stop)

Stop (and reset* - if trip)

MG.03.H6.02 - VLT® is a registered Danfoss trademark 27

VLT® FCM Series

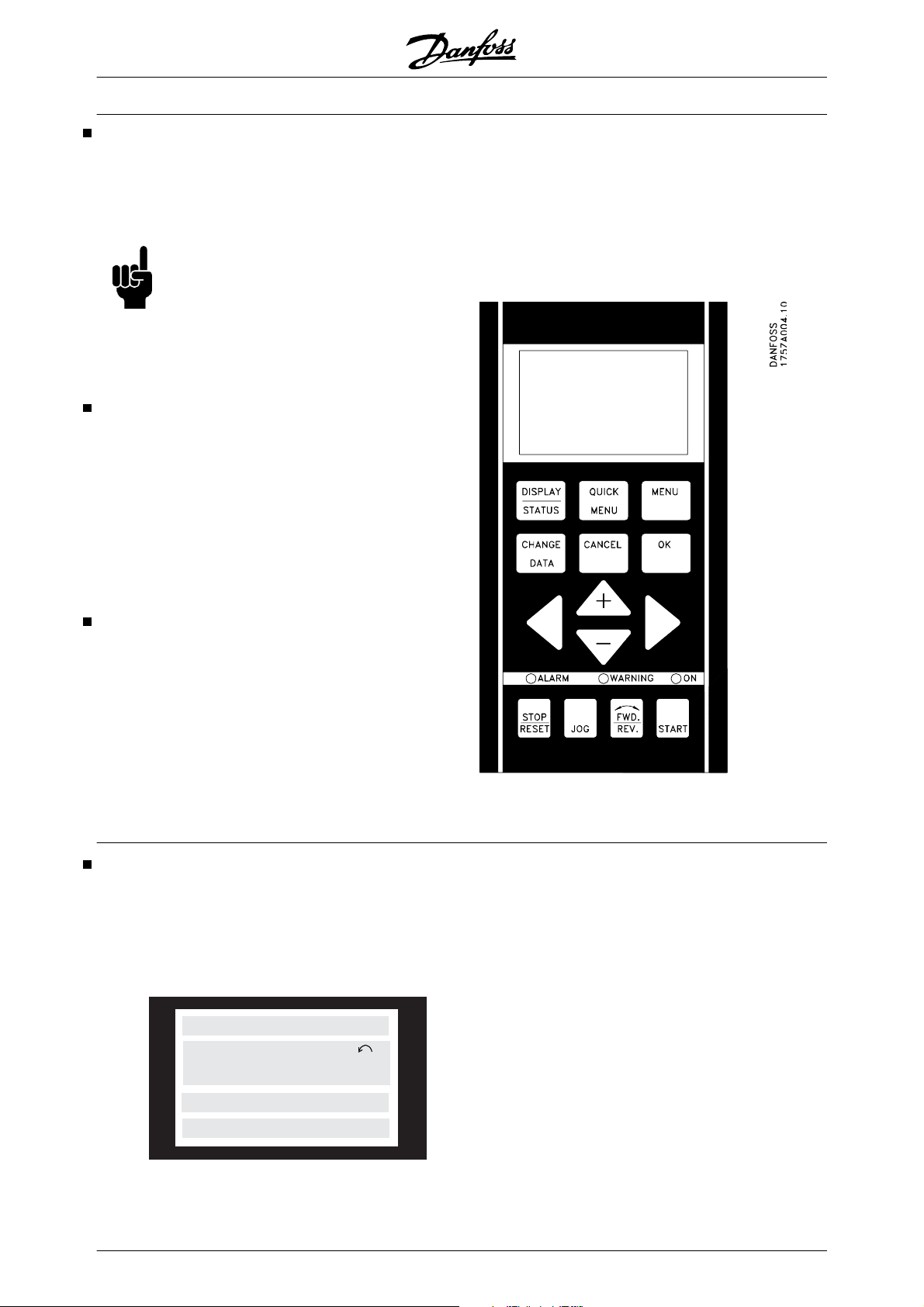

Control panel (175NO131)

The FC motor optionally features a Local Control Panel- LCP 2 which makes up a complete interface for

operation and monitoring of the FC motor.

IP 65 on front.

NB!

The LCP from the VLT 5000 Series (code

number 175Z0401) cannot be used for the

FC motor. However, the general LCP 2

(code number 175N0131) can be used for

both the FCM 300, VLT 2800 and the VLT

5000 Series.

LCP installation

The LCP 2 is connected to the terminal X100, 1-4 (see

separate instruction MI.03.AX.YY).

1. Service Plug Kit (175N2546) (see section

Service plug kit) and cabel 175N0162

2.

Plug kit (175N2545) (see section Plug kit) and

cabel 175N0162

3. Remote mounting kit (175N0160) (see section Remote mounting kit)

4 measurements and 3 operating conditions continuously. During programming, all the information required for quick, effective parameter Setup of the FC

motor will be displayed. As a supplement to the display, there are three LEDs for voltage, warning and

alarm. All program parameters of the FC motor can be

changed immediately from the control panel, unless

this function has been blocked via parameter 018.

LCP functions

The functions of the control panel can be divided into

three groups:

•display

• keys for changing program parameters

• keys for local operation

All data are indicated by means of a 4-line alphanumeric display, which in normal operation is able show

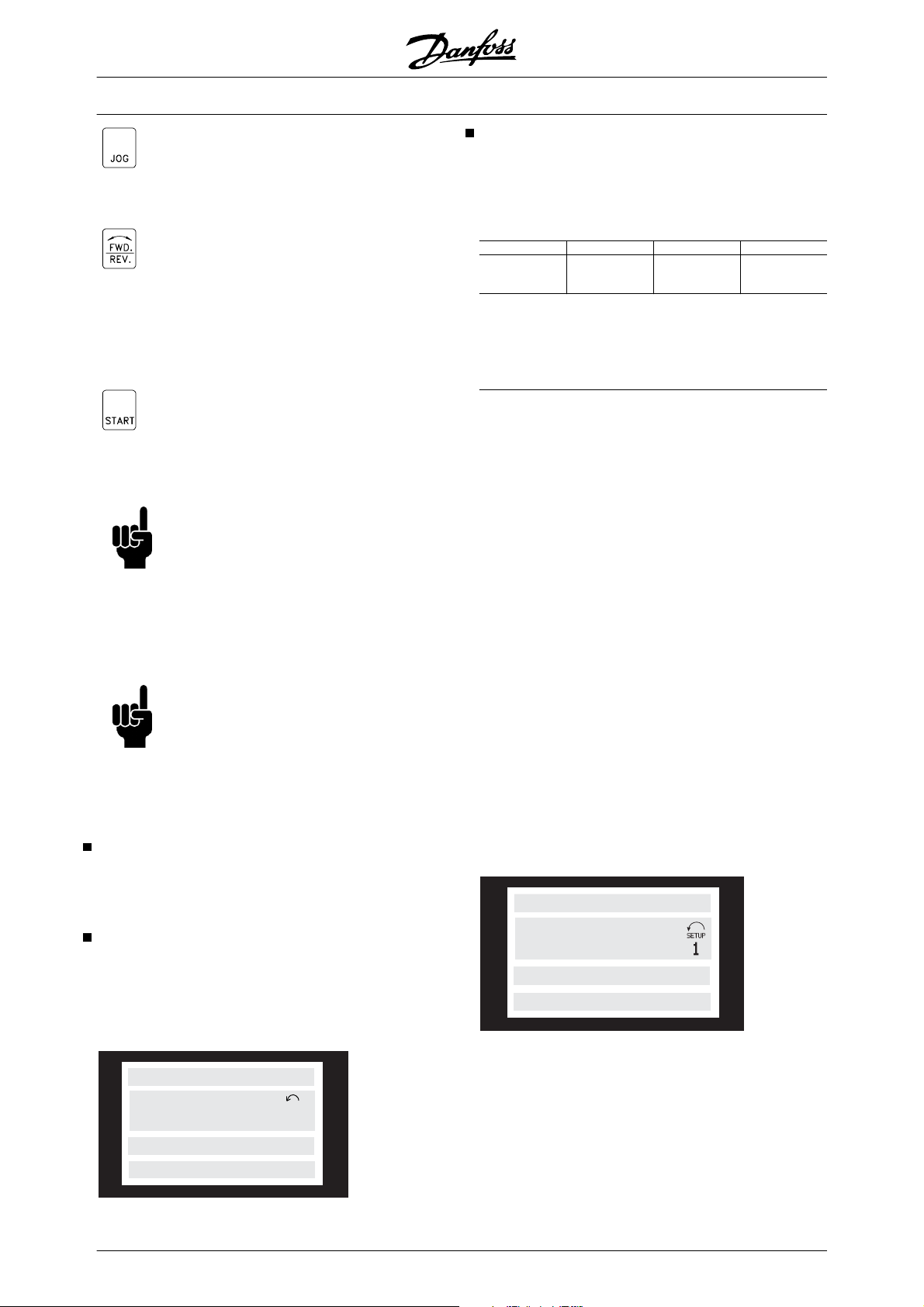

Display

The LCD-displayhas rear lighting and a total of 4 alpha-numeric lines together with a box that shows the

direction of rotation (arrow) and the chosen Setup as

well as the Setup in which programming is taking place

if that is the case.

1st line

2nd line

3rd line

4th line

12345678901234567890

SETUP

12345678

1

12345678901234567890

12345678901234567890

1st line shows up to 3 measurements continuously in

normal operating status or a text which explains the

2nd line.

2nd line shows a measurement with related unit continuously, regardless of status (except in the case of

alarm/warning).

175ZA443.10

3rd line is normally blank and is used in the menu

mode to show the selected parameter number or parameter group number and name.

4th line is used in operating status for showing a status

text or in data change mode for showing the value of

the selected parameter.

28 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

An arrow indicates the direction of rotation

of the motor. Furthermore, the Setup which

has been selected as the Active Setup in

parameter 004 is shown. When programming another Setup than the Active Setup,

the number of the Setup which is being programmed will appear to the right. This second Setup number will flash.

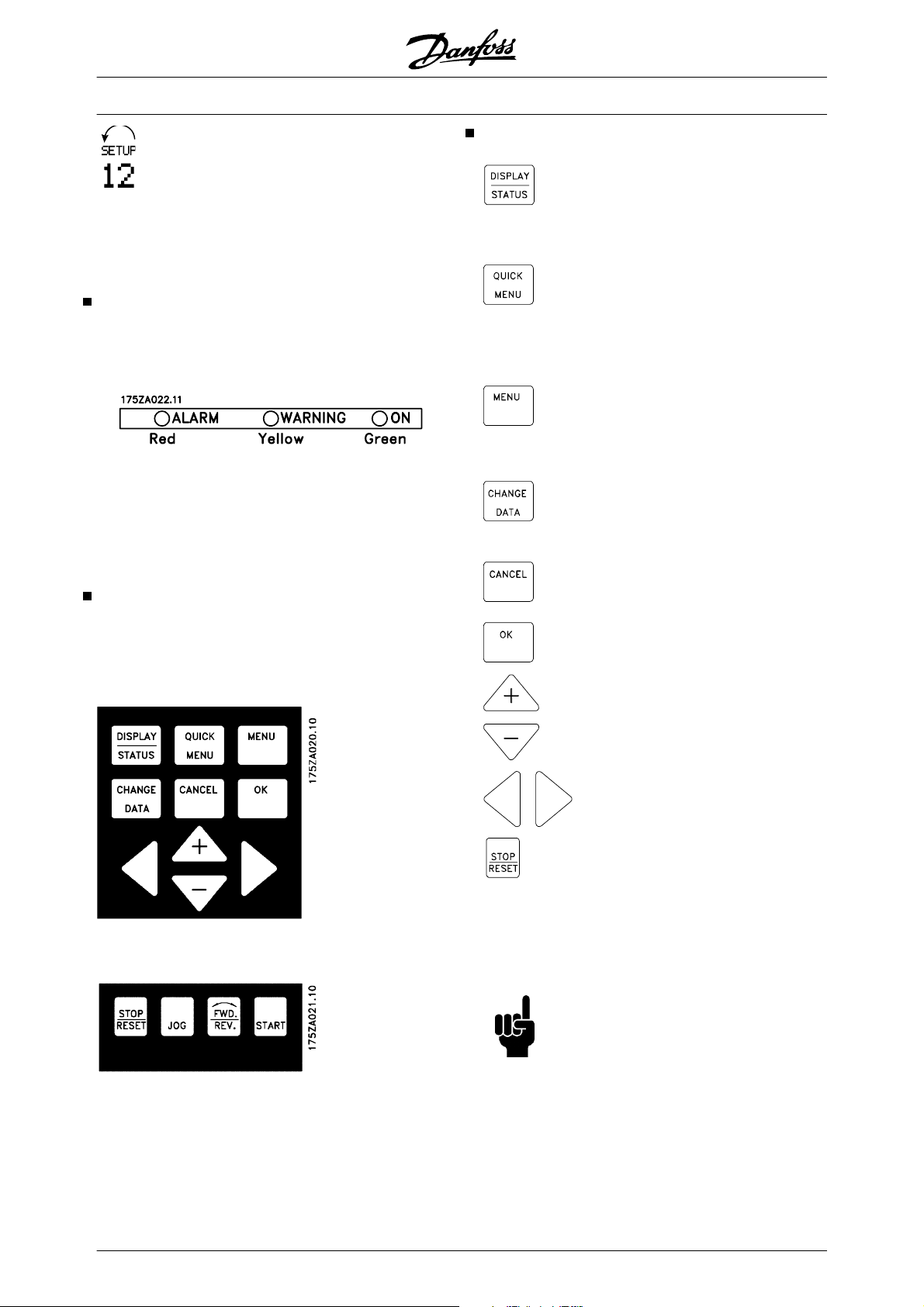

LEDs

At the bottom of the control panel is a red alarm

LEDand a yellow warning LED, as well as a green

voltage LED.

If certain threshold values are exceeded, the alarm

and/or warning lamp lights up together with a status

and alarm text on the control panel.

The voltage LED is activated when the FC motor receives voltage; at the same time the rear lighting of the

display will be on.

Control keys

The control keys are divided into functions. This

means that the keys between display and indicator

LEDs are used for parameter Setup, including choice

of display indication during normal operation.

Control key functions

[DISPLAY / STATUS] is used for

selecting the mode of display or for

changing back to Display mode

from either the Quick menu mode

or the Menu mode.

[QUICK MENU] is used for programming the parameters that belong under the Quick menu mode.

It is possible to switch directly between Quick menu mode and

Menu mode.

[MENU] is used for programming

all parameters. It is possible to

switch directly between Menu

mode and Quick menu mode.

[CHANGE DATA] is used for

changing the parameter selected

either in the Menu mode or the

Quick menu mode.

[CANCEL] is used if a change of

the selected parameter is not to be

carried out.

[OK] is used for confirming a

change of the parameter selected.

[+/-] is used for selecting parameter and for changing the chosen

parameter or for changing the read

out in line 2.

Keys for local control are found under the indicator

LEDs.

[<>] is used for selecting group

and to move the cursor when

changing numerical parameters.

[STOP / RESET] is used for stopping or for resetting the FC motor

after a drop-out (trip). Can be selected via parameter 014 to be active or inactive. If stop is activated,

line 2 will flash, and [START] must

be activated.

NB!

Pressing [STOP/RESET] will prevent motor from running also with disconnected

LCP 2. Restarting is only possible via the

LCP 2 [START] key.

MG.03.H6.02 - VLT® is a registered Danfoss trademark 29

195NA113

10

VLT® FCM Series

[JOG] overrides the output frequency to a preset frequency while

the key is kept down. Can be selected via parameter 015 to be active or inactive.

[FWD / REV] changes the direction of rotation of the motor, which

is indicated by means of the arrow

on the display although only in Local. Can be selected via parameter

016 to be active or inactive (parameter 013 must be set to [1] or

[3] and parameter 200 set to [1].

[START] is used for starting the FC

motor after stop via the [Stop] key.

Is always active, but cannot override a stop command given via the

terminal strip.

NB!

If the keys for local control have been selected as active, they will remain active

both when the frequency has been set for

Local Control and for Remote Control via

parameter 002, although with the exception of [FWD/REV], which is only active in

Local operation.

NB!

If no external stop function has been selected and the [STOP] key has been selected as inactive via parameter 014, the

FC motor can be started and can only be

stopped by disconnecting the voltage to

the motor.

Display mode - selection of read-out state

There are three options in connection with the choice

of read-out state in the Display mode - I, II and III. The

choice of read-out state determines the number of operating variables read out.

Read-out state: I: II: III:

Line 1 Description for

operating variable in line 2

Data value for 3

operating variables in line 1

Description for 3

operating variables in line 1

The table below gives the units linked to the variables

in the first and second line of the display (see parameter 009).

Operating variable: Unit:

Reference [%]

Reference [unit]*

Feedback [unit]*

Frequency [Hz]

Frequency x scaling [-]

Motor current [A]

Torque [%]

Power [kW]

Power [HP]

Motor voltage [V]

DC-link voltage [V]

FC thermal [%]

Hours run [Hours]

Input status, dig. Input [Binary code]

External reference [%]

Status word [Hex]

Heat sink temp. [ºC]

Alarm word [Hex]

Control word [Hex]

Warning word 1 [Hex]

Warning word 2 [Hex]

Analog input 1 [mA]

Analog input 2 [V]

*) Select in parameter 416. The unit is shown in readout state 1 line 1

otherwise 'U' is shown.

Operating variables 1,1 and 1,2 and 1,3 in the first line,

and operating variable 2 in the second line are selected via parameter 009, 010, 011 and 012.

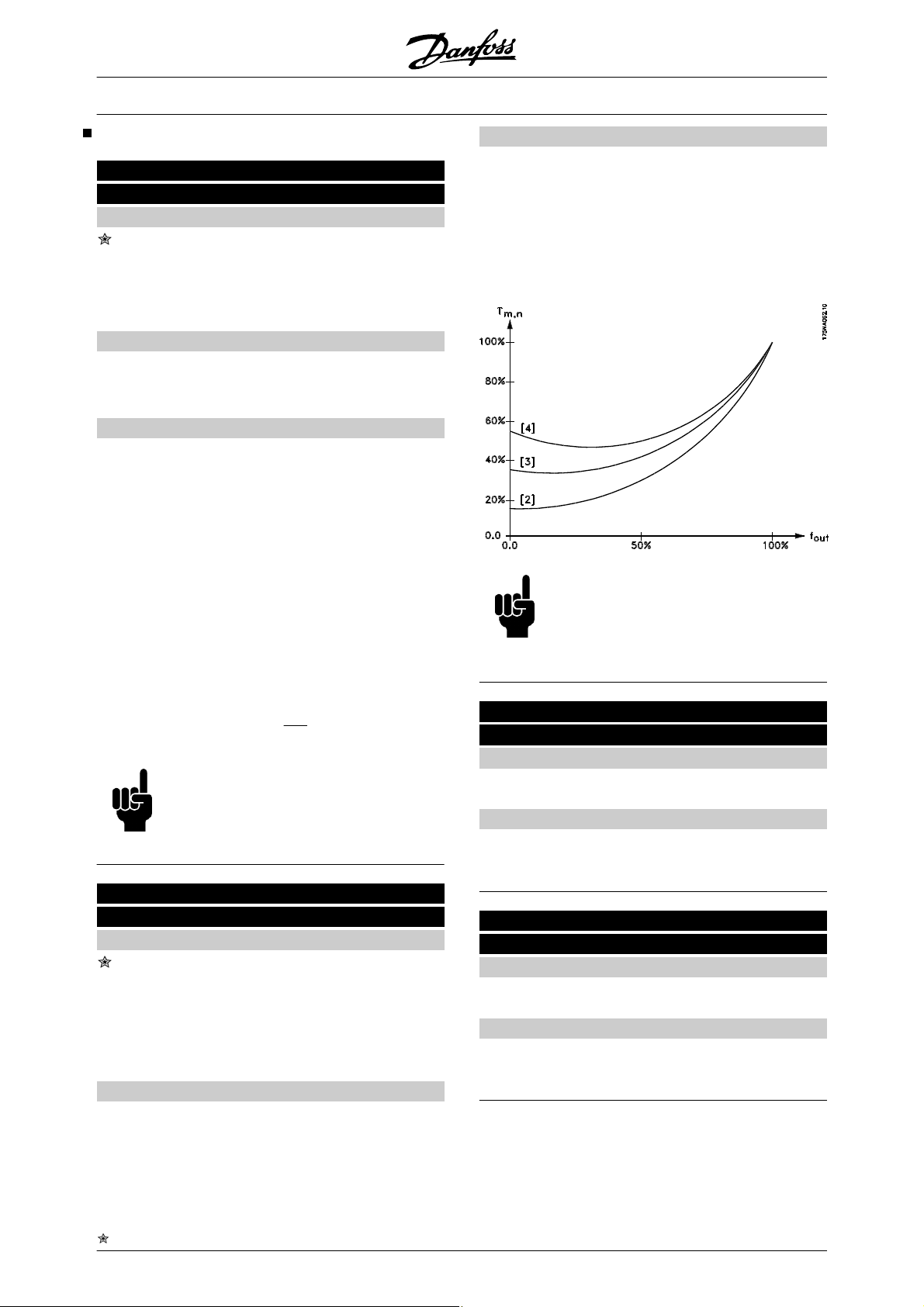

• Read-out state I:

Display read-out state

The display read-out state can be varied - see the list

This read-out state is standard after starting up or after

initialisation.

on page 32 - depending on whether the FC motor is in

normal operation or is being programmed.

Display mode

In normal operation, up to 4 different operating varia-

FREQUENCY

50.0 Hz

bles can be indicated continuously: 1,1 and 1,2 and 1,3

and 2, and in line 4 the present operating status or

MOTOR IS RUNNING

alarms and warnings that have arisen.

Line 2 gives the data value of an operating variable

VAR 1.1 VAR 1.2 VAR 1.3

.

VAR 2

SETUP

1

STATUS

30 MG.03.H6.02 - VLT® is a registered Danfoss trademark

with related unit, and line 1 provides a text which explains line 2, cf. table. In the example, Frequency has

been selected as variable via parameter 009. During

normal operation another variable can immediately be

read out by using the [+/-] keys.

• Read-out state II:

VLT® FCM Series

Switching between read-out states I and II is effected

by pressing the [DISPLAY / STATUS] key.

24.3% 30.2% 13.8A

50.0 Hz

MOTOR IS RUNNING

In this state, data values for four operating values are

shown at the same time, giving the related unit, cf. table. In the example, Reference, Torque, Current and

Frequency are selected as variables in the first and

second line.

• Read-out state III:

This read-out state can be held as long as the [DISPLAY/STATUS] key is pressed. When the key is released, the system switches back to Read-out state II,

unless the key is pressed for less than approx. 1 sec.

REF% TORQUE CURR A

In addition to having a name, each parameter is linked

up with a number which is the same regardless of the

programming mode. In the Menu mode, the parameters are divided into groups, with the first digit of the

parameter number (from the left) indicating the group

number of the parameter in question.

Regardless of the mode of programming, a change of

a parameter will take effect and be visible both in the

Menu mode and in the Quick menumode.

Quick Setup via Quick menu

The Quick Setup starts with pressing the [QUICK

MENU] key, which brings out the following read-out on

the display:

QUICK MENU X OF Y

50.0 Hz

SETUP

1

001 LANGUAGE

ENGLISH

SETUP

50.0 Hz

1

MOTOR IS RUNNING

This is where parameter names and units for operating

variables in the first line are given - operating variable

2 remains unchanged.

Quick menu mode versus Menu mode

The FC motor series can be used for practically all assignments, which is why the number of parameters is

quite large. Also, this series offers a choice between

two programming modes - a Menu mode and a Quick

menu mode.

• The Quick menu takes the user through a

number of parameters that may be enough to

get the motor to run nearly optimally, if the

factory setting for the other parameters takes

the desired control functions into account, as

well as the configuration of signal inputs/outputs (control terminals).

At the bottom of the display, the parameter number

and name are given together with the status/value of

the first parameter under Quick Setup. The first time

the [Quick Menu] key is pressed after the unit has been

switched on, the read-outs will always start at pos. 1 see table below.

Parameter selection

The selection of parameter is effected by means of the

[+/-] keys. The following parameters are accessible:

Pos.: No.: Parameter: Unit:

1 001 Language

2 200 Direction of rotation

3 101 Torque characteristic

4 204 Min. reference [Hz]

5 205 Max. reference [Hz]

6 207 Ramp up time [sec.]

7 208 Ramp down time [sec.]

8 002 Local/remote control

9 003 Local reference

10 500 Bus address

• The Menu mode makes it possible to select

and change all parameters at the user's option. However, some parameters will be

"missing", depending on the choice of configuration (parameter 100), e.g. open loop

hides all the PID parameters.

MG.03.H6.02 - VLT® is a registered Danfoss trademark 31

VLT® FCM Series

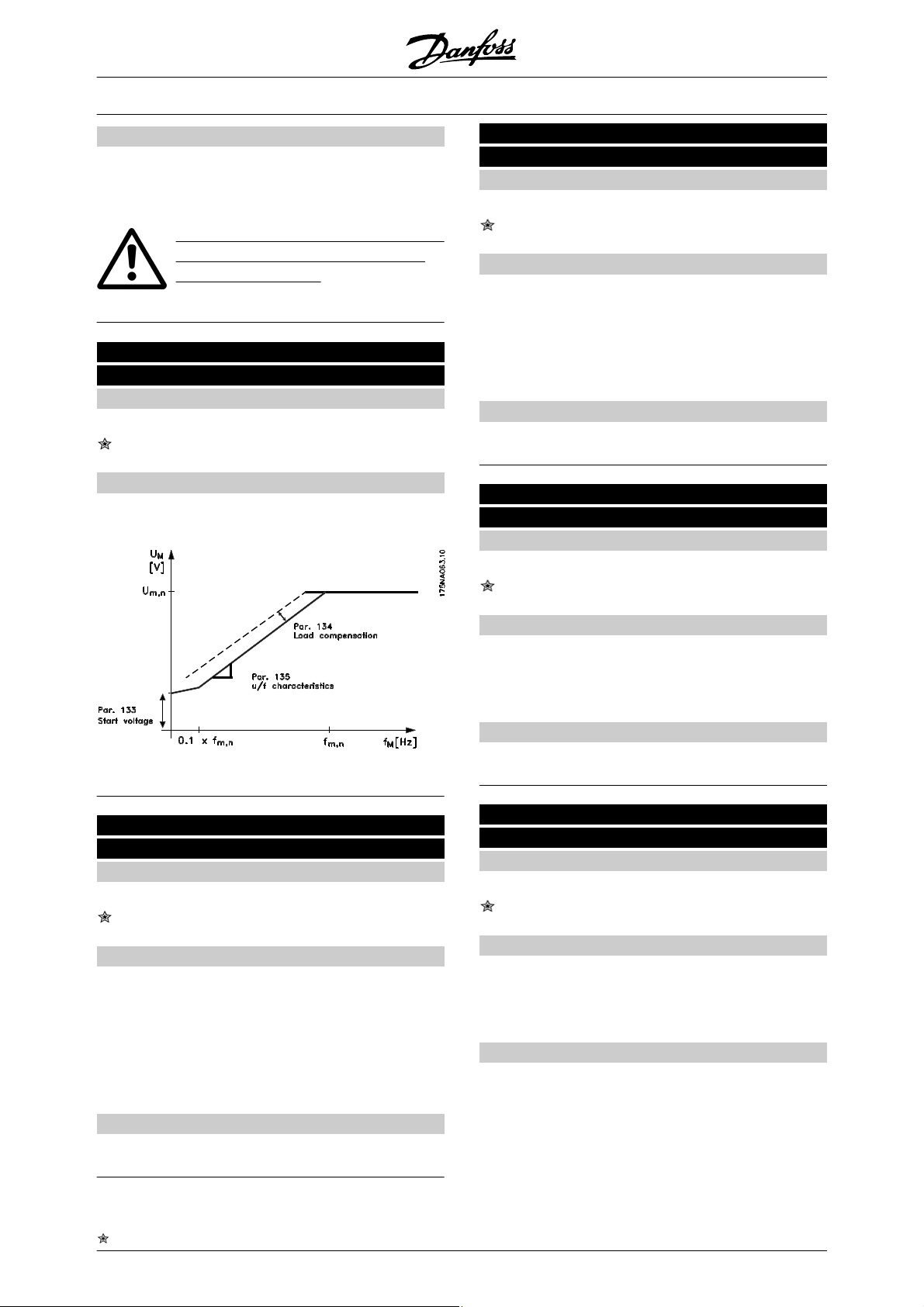

Menu mode

The Menu mode is started by pressing the [MENU]

key, which produces the following read-out on the display:

FREQUENCY

50.0 Hz

0 KEYB.&DISPLAY

Line 3 on the display shows the parameter group number and name.

Parameter groups

In the Menu mode the parameters are divided into

groups. Selection of parameter group is effected by

means of the [<>] keys.

The following parameter groups are accessible:

Group no.

0 Operation & Display

1 Load & Motor

2 References & Limits

3 Inputs & Outputs

4 Special functions

5 Serial communication

6 Technical functions

*For information on parameter group 800 and 900 for

PROFIBUS, please see the FCM Profibus manual

MG.03.EX.YY.

When the desired parameter group has been selected,

each parameter can be chosen by means of the [+/-]

keys:

Parameter group:

line 4 will flash on the display. The procedure for

changing data depends on whether the selected parameter represents a numerical data value or a text

value.

Changing a text value

If the selected parameter is a text value, the text value

is changed by means of the [+/-] keys.

FREQUENCY

50.0 Hz

001 LANGUAGE

ENGLISH

The bottom display line shows the text value that will

be entered (saved) when acknowledgement is given

[OK].

Infinitely variable change of numeric data value

If the chosen parameter represents a numeric data

value, a digit is first selected by means of the [<>] keys.

FREQUENCY

50.0 Hz

130 START FREQUENCY

09.0 HZ

Then the chosen digit is changed infinitely variably by

means of the [+/-] keys:

SETUP

1

FREQUENCY

FREQUENCY

50.0 Hz

50.0 Hz

001 LANGUAGE

ENGLISH

The 3rd line of the display shows the parameter number and name, while the status/value of the selected

parameter is shown in line 4.

Changing data

Regardless of whether a parameter has been selected

under the Quick menu or the Menu mode, the procedure for changing data is the same. Pressing the

[CHANGE DATA] key gives access to changing the

selected parameter, following which the underlining in

32 MG.03.H6.02 - VLT® is a registered Danfoss trademark

130 START FREQUENCY

10.0 HZ

The chosen digit is indicated by the digit flashing. The

bottom display line shows the data value that will be

entered (saved) when signing off with [OK].

SETUP

1

Menu structure

DISPLAY MODE

VAR 1.1 VAR 1.2 VAR 1.3

▲

VAR 2

STATUS

VLT® FCM Series

▲

▲

MENU MODE

FREQUENCY

50.0 HZ

0 KEYB.&DISPLAY

Choice of

parameter

DATA MODE

FREQUENCY

50.0 HZ

001 LANGUAGE

ENGLISH

▲

Choice of

group

▲

QUICK MENU MODE

QUICK MENU 1 OF 13

▲

▲

▲

50.0 HZ

001 LANGUAGE

ENGLISH

▲

DATA CHANGE MODE

FREQUENCY

50.0 HZ

001 LANGUAGE

ENGLISH

175ZA446.11

MG.03.H6.02 - VLT® is a registered Danfoss trademark 33

Choice of

data value

DATA CHANGE MODE

QUICK MENU 1 OF 13

50.0 HZ

001 LANGUAGE

ENGLISH

VLT® FCM Series

Parameter Group 0-** Operation/Display

001 Language

(LANGUAGE)

Value:

English (ENGLISH) [0]

German (DEUTSCH) [1]

French (FRANCAIS) [2]

Danish (DANSK) [3]

Spanish (ESPAÑOL) [4]

Italian (ITALIANO) [5]

State when delivered may vary from factory setting.

Function:

The choice in this parameter defines the language to

be used on the display.

Description of choice:

There is a choice of English [0], German[1], French [2],

Danish [3], Spanish [4] and Italian [5].

002 Local/remote control

(OPERATION SITE)

Value:

Remote control (REMOTE) [0]

Local control (LOCAL) [1]

Function:

There is a choice of two methods of controlling the FC

motor: Remote control [0] and Local control [1].

Description of choice:

If Remote control [0] is selected, the FC motor can be

controlled via:

1. The control terminals or the serial communication port .

2. The [START] key. However, this cannot overrule Stop commands (also start-disable) entered via the digital inputs or the serial

communication port.

3. The [STOP], [JOG] and [RESET] keys, provided that these are active (see parameters

014, 015 and 017).

If Local control [1] is selected, the FC motor can be

controlled via:

1. The [START] key. However, this cannot override Stop commands on the digital terminals

(if [2] or [4] has been selected in parameter

013).

2. The [STOP], [JOG] and [RESET] keys, provided that these are active (see parameters

014, 015 and 017).

3. The [FWD/REV] key, provided that this has

been activated in parameter 016 and that in

parameter 013 a choice of [1] or [3] has been

made.

4. Via parameter 003 the local referencecan be

controlled by means of the "Arrow up" and

"Arrow down" keys.

003 Local reference

(LOCAL REFERENCE)

Value:

Par 013 set for [1] or [2]:

0 - f

MAX

000.000

Par 013 set for [3] or [4] and par. 203

= [0] set for:

Ref

MIN

- Ref

MAX

000.000

Par 013 set for [3] or [4] and par. 203

= [1] set for:

MAX

- + Ref

MAX

000.000

-Ref

Function:

This parameter allows manual setting of the desired

reference value (speed or reference for the selected

configuration, depending on the choice made in parameter 013).

The unit follows the configuration selected in parameter 100, provided that Process regulation, closed loop

[3] has been selected.

Description of choice:

Local [1] must be selected in parameter 002 for this

parameter to be used.

The set value is saved in the case of a voltage dropout,

see parameter 019.

In this parameter Data Change Mode is not exited automatically (after time out).

Local reference cannot be set via the serial communication port.

Warning: Since the value set is remembered after the power has been cut, the

motor may start without warning when the

power is reinstated; if parameter 019 is

changed to Auto restart, use saved ref.

[0].

= factory setting, () = display text, [] = value for use in communication via serial communication port

34 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

004 Active Setup

(ACTIVE SETUP)

Value:

Factory Setup (FACTORY SETUP) [0]

Setup 1 (SETUP 1) [1]

Setup 2 (SETUP 2) [2]

Multi Setup (MULTI SETUP) [5]

Function:

The choice in this parameter defines the Setup number

you want to control the functions of the FC motor.

All parameters can be programmed in two individual

parameter Setups, Setup 1 and Setup 2. In addition,

there is a pre-programmed Setup, called Factory Setup, that cannot be modified.

Description of choice:

Factory Setup [0] contains the factory data. Can be

used as a data source if the other Setups are to be

returned to a known state.

Parameters 005 and 006 allow copying from one Setup to the other.

Setups 1 [1] and 2 [2] are two individual Setups that

can be selected as required.

Multi-Setup [5] is used if remote-mounting switching

between Setups is desired. Terminals 2, 3, 4, and 5 as

well as the serial communication port can be used for

switching between Setups.

Setups 1 [1] and 2 [2] are individual Setups which can

be used as required. They can be programmed freely,

regardless of the Setup selected as the Active Setup

and thus controlling the functions of the FC motor.

NB!

If a general change of data or a copying to

the Active Setup is effected, this immediately affects the functioning of the unit.

006 Copying of Setups

(SETUP COPY)

Value:

No copying (NO COPY) [0]

Copy to Setup 1 from # (COPY TO SETUP 1) [1]

Copy to Setup 2 from # (COPY TO SETUP 2) [2]

Copy to Setup all from # (COPY TO ALL) [5]

# = the Setup selected in parameter 005

Function:

A copy is made from the Setup selected in parameter

005 to one of the other Setups or to all the other Setups

simultaneously.

NB!

Copying is only possible in Stop Mode

(motor stopped on a Stop command).

Copying will take max. 3 seconds and has

ended when parameter 006 has returned

to value 0.

005 Programming Setup

(EDIT SETUP)

Value:

Factory Setup (FACTORY SETUP) [0]

Setup 1 (SETUP 1) [1]

Setup 2 (SETUP 2) [2]

Active Setup (ACTIVE SETUP) [5]

Function:

The choice is of the Setup in which programming

(change of data) is to occur during operation. It is possible to programme the two Setups independently of

the Setup selected as the Active Setup (selected in

parameter 004).

Description of choice:

The Factory Setup [0] contains the factory data and can

be used as a data source if the other Setups are to be

returned to a known state.

= factory setting, () = display text, [] = value for use in communication via serial communication port

MG.03.H6.02 - VLT® is a registered Danfoss trademark 35

007 LCP copy

(LCP COPY)

Value:

No copying (NO COPY) [0]

Upload all parameters (UPLOAD ALL PAR-

AM) [1]

Download all parameters (DOWNLOAD ALL) [2]

Download power-independent par.

(DOWNLOAD SIZE INDEP.) [3]

Function:

Parameter 007 is used if it is desired to use the integrated copying function of the control panel. You can

therefore easily copy parameter value(s) from one FC

motor to another.

VLT® FCM Series

Description of choice:

Select Upload all parameters [1] if all parameter values

are to be transmitted to the control panel. Select

Download all parameters [2] if all transmitted parameter

values are to be copied to the FC motor on which the

control panel has been mounted. Select Download

power-independent par. [3] if only the power-independent parameters are to be downloaded. This is used if

downloading to a FC motor that has a different rated

power than the one from where the parameter Setup

originates.

NB!

Uploading/Downloading can only be carried out in the Stop mode and only between units with the same

major database version (see par. 626 value

major.minor)

008 Display scaling of motor frequency

(FREQUENCY SCALE)

Value:

0.01 - 100.00 [1 - 10000]

1.00 [100]

Function:

This parameter chooses the factor to be multiplied by

the motor frequency, f

, for presentation in the display,

M

when parameters 009-012 have been set for Frequency x Scaling [5].

Description of choice:

Set the desired scaling factor.

Power [HP] (POWER [hp] [US]) [9]

Motor voltage [V] (MOTOR VOLTAGE [V]) [11]

DC link voltage [V] (DC LINK VOLTAGE [V]) [12]

Thermal load, FC [%] (FC THERMAL [%]) [14]

Hours run [Hours] (RUNNING HOURS) [15]

Digital input [Binary code] (DIGITAL INPUT

[BIN]) [16]

External reference [%] (EXTERNAL REF

[%]) [21]

Status word [Hex] (STATUS WORD [HEX]) [22]

Heat sink temp. [°C] (HEATSINK TEMP [°C]) [25]

Alarm word [Hex] (ALARM WORD [HEX]) [26]

Control word [Hex] (CONTROL WORD

[HEX]) [27]

Warning word 1 [Hex]

(WARNING WORD 1 [HEX]) [28]

Warning word 2 [Hex]

(EXTENDED STATUS WORD [HEX]) [29]

Analog input 1 [mA] (ANALOG INPUT 1

[mA]) [30]

Analog input 2 [V] (ANALOG INPUT 2 [V]) [31]

Function:

This parameter allows a choice of the data value to be

displayed in line 2 of the display.

Parameters 010-012 enable the use of three additional

data values to be displayed in line 1.

For display read-outs, press the [DISPLAY/STATUS]

button, see also page 31.

NB!

In parameter 009, "none" [0] cannot be

selected.

009 Display line 2

(DISPLAY LINE 2)

Value:

None [0]

Reference [%] (REFERENCE [%]) [1]

Reference [unit] (REFERENCE [UNIT]) [2]

Feedback [unit] (FEEDBACK [UNIT]) [3]

Frequency [Hz] (FREQUENCY [Hz]) [4]

Frequency x Scaling [-] (FREQUENCY X

SCALE) [5]

Motor current [A] (MOTOR CURRENT [A]) [6]

Torque [%] (TORQUE [%]) [7]

Power [kW] (POWER [kW]) [8]

= factory setting, () = display text, [] = value for use in communication via serial communication port

36 MG.03.H6.02 - VLT® is a registered Danfoss trademark

Description of choice:

Reference [%] corresponds to the total reference (sum

of digital/analogue/preset/bus/freeze ref./ catch-up

and slow-down).

Reference [unit] gives the sum of the references using

the unit stated on the basis of configuration in parameter 100 (Hz, Hz and rpm).

Feedback [unit] gives the status value of terminal 1 and

2 using the unit/scale selected in parameter 414, 415

and 416.

Frequency [Hz] gives the motor frequency, i.e. the output frequency to the motor.

Frequency x Scaling [-] corresponds to the present motor frequency f

multiplied by a factor (scaling) set in

M

parameter 008.

VLT® FCM Series

Motor current [A] states the phase current of the motor

measured as effective value.

Torque [%] gives the current motor load in relation to

the rated motor torque.

Power [kW] states the actual power consumed by the

motor in kW.

Power [HP] states the actual power consumed by the

motor in HP.

Motor voltage [V] states the voltage supplied to the

motor.

DC link voltage [V] states the intermediate circuit voltage in the FC motor.

Thermal load, FC [%] states the calculated/ estimated

thermal load on the FC motor. 100% is the cut-out limit.

Hours run [Hours] states the number of hours that the

motor has run since the latest reset in parameter 619.

Digital input [Binary code] states the signal states from

the 4 digital terminals (2, 3, 4 and 5). Input 5 corresponds to the bit at the far left. '0' = no signal, '1' =

connected signal.

External reference [%] gives the sum of the external

reference as a percentage (the sum of analogue/

pulse/bus).

Status word [Hex] gives the status word sent via the

serial communication port in Hex code from the FC

motor.

Heat sink temp. [°C] states the present heat sink temperature of the FC motor. The cut-out limit is 90 ± 5°C;

cutting back in occurs at 60 ± 5°C.

Alarm word [Hex] indicates one or several alarms in a

Hex code. See page 74.

Control word [Hex] indicates the control word for the

FC motor. See Serial communication.

Warning word 1 [Hex] indicates one or more warnings

in a Hex code. See page 74 for further information.

Extended status word [Hex] indicates one or more status states in a Hex code. See page 74 for further

information.

Analog input 1 [mA] states the signal value on terminal

1.

Analog input 2[V] states the signal value on terminal 2.

Function:

This parameter enables a choice of the first of three

data values to be shown on the display, line 1, position

1.

Description of choice:

There is a choice of 24 different data values, see parameter 009.

011 Display line 1.2

(DISPLAY LINE 1.2)

Value:

Motor current [A] [1]

See parameter 009

Function:

This parameter enables a choice of the second of the

three data values to be shown on the display, line 1,

position 2.

For Display read-outs, press the [DISPLAY/STATUS]

button, see also page 31.

Description of choice:

There is a choice of 24 different data values, see parameter 009.

012 Display line 1.3

(DISPLAY LINE 1.3)

Value:

Power [kW] [8]

See parameter 009

Function:

This parameter enables a choice of the third of the

three data values to be shown on the display, line 1,

position 3.

Display read-outs are made by pressing the [DISPLAY/STATUS] button, see also page 31.

010 Display line 1.1

(DISPLAY LINE 1.1)

Value:

Reference [%] [1]

See parameter 009.

= factory setting, () = display text, [] = value for use in communication via serial communication port

MG.03.H6.02 - VLT® is a registered Danfoss trademark 37

Description of choice:

There is a choice of 24 different data values, see parameter 009.

VLT® FCM Series

013

Local Control/Configuration as parameter 100

(LOCAL CTRL/CONFIG.)

Value:

Local not active (DISABLE) [0]

LCP control and open loop.

(LCP CTRL/OPEN LOOP) [1]

LCP digital control and open loop.

(LCP+DIG CTRL/OP.LOOP) [2]

LCP control/as parameter 100.

(LCP CTRL/AS P100) [3]

LCP digital control/as parameter 100.

(LCP+DIG CTRL/AS P100) [4]

Function:

This is where the desired function is to be selected if

Local control has been chosen in parameter 002. See

also the description of parameter 100.

Description of choice:

If Local not active [0] is selected, a possible setting of

Local reference via parameter 003 is blocked. It is only

possible to change to Local not active [0] from one of

the other setting options in parameter 013, when the

FC motor has been set to Remote control [0] in parameter 002.

LCP control and open loop [1] is used when the speed

is to be adjustable (in Hz) via parameter 003, when the

FC motor has been set to Local control [1] in parameter

002.

If parameter 100 has not been set to Speed regulation

open loop [0], switch to Speed regulation open loop [0].

LCP digital control and open loop [2] functions as LCP

control and open loop [1], the only difference being that

when parameter 002 has been set to Local operation

[1], the motor is controlled via the digital inputs.

does not correspond to the reversing signal (negative

reference), the motor frequency f

will be set at 0 Hz.

M

Shift from LCP digital control and open loop to Remote

control:

The selected configuration (parameter 100) will be active. Shifts are effected without any abrupt movement.

Shift from Remote control to LCP control/as parameter

100 or LCP digital control/as parameter 100.

The present reference will be maintained. If the reference signal is negative, the local reference will be set

at 0.

Shift from LCP control/as parameter 100 or LCP re-

mote control as parameter 100 to Remote control.

The reference will be replaced by the active reference

signal from the remote control..

014 Local stop

(LOCAL STOP)

Value:

Not possible (DISABLE) [0]

Possible (ENABLE) [1]

Function:

This parameter disables/enables the local stop function in question from the control panel. This key is used

when parameter 002 has been set for Remote control

[0] or Local [1].

Description of choice:

If Disable [0] is selected in this parameter, the [STOP]

key will be inactive.

NB!

If Enable is selected, the [STOP] key overrules all Start commands.

LCP control/as parameter 100 [3] is selected if the reference is to be set via parameter 003.

LCP digital control/as parameter 100 [4] functions as

LCP control/as parameter 100 [3], although, when pa-

rameter 002 has been set to Local operation [1], the

motor may be controlled via the digital inputs.

NB!

Shift from Remote control to LCP digital

control and open loop:

015 Local jog

(LOCAL JOGGING)

Value:

Not possible (DISABLE) [0]

Possible (ENABLE) [1]

Function:

In this parameter, the jog function can be enabled/ disabled on the control panel.

The present motor frequency and direction of rotation

must be maintained. If the present direction of rotation

= factory setting, () = display text, [] = value for use in communication via serial communication port

38 MG.03.H6.02 - VLT® is a registered Danfoss trademark

VLT® FCM Series

Description of choice:

If Disable [0] is selected in this parameter, the [JOG]

key will be inactive.

016 Local reversing

(LOCAL REVERSING)

Value:

Not possible (DISABLE) [0]

Possible (ENABLE) [1]

Function:

In this parameter, the reversing function can be enabled/disabled on the control panel. This key can only

be used if parameter 002 has been set to Local oper-

ation [1] and parameter 013 to LCP control with open

loop [1] or LCP control as parameter 100 [3].