Page 1

ENGINEERING TOMORROW

Design Guide

VLT® Decentral Drive FCD 302

www.DanfossDrives.com

Page 2

Page 3

Contents Design Guide

Contents

1 Introduction

1.1 How to Read the Design Guide

1.1.1 Additional Resources 6

1.2 Document and Software Version

1.3 Denitions

1.3.1 Frequency Converter 6

1.3.2 Input 7

1.3.3 Motor 7

1.3.4 References 7

1.3.5 Miscellaneous 8

1.4 Safety Precautions

1.5 CE Labeling

1.5.1 Conformity 11

1.5.2 What Is Covered? 12

1.6 Compliance with EMC Directive 2004/1087EC

1.7 Approvals

1.8 Disposal

6

6

6

6

10

11

12

12

12

2 Product Overview and Functions

2.1 Galvanic Isolation (PELV)

2.1.1 PELV - Protective Extra Low Voltage 13

2.1.2 Ground Leakage Current 14

2.2 Control

2.2.1 Control Principle 15

2.2.2 Internal Current Control in VVC+ Mode 16

2.3 Control Structures

2.3.1 Control Structure in VVC+ Advanced Vector Control 16

2.3.2 Control Structure in Flux Sensorless 17

2.3.3 Control Structure in Flux with Motor Feedback 18

2.3.4 Local [Hand On] and Remote [Auto On] Control 19

2.3.5 Programming of Torque Limit and Stop 20

2.4 PID Control

2.4.1 Speed PID Control 21

2.4.2 Parameters Relevant for Speed Control 21

2.4.3 Tuning PID Speed Control 24

13

13

14

16

21

2.4.4 Process PID Control 24

2.4.5 Process Control Relevant Parameters 26

MG04H322 Danfoss A/S © 05/2018 All rights reserved.

Page 4

Contents

VLT® Decentral Drive FCD 302

2.4.6 Example of Process PID Control 27

2.4.7 Programming Order 28

2.4.8 Process Controller Optimization 30

2.4.9 Ziegler Nichols Tuning Method 30

2.5 Control Cables and Terminals

2.5.1 Control Cable Routing 31

2.5.2 DIP Switches 31

2.5.3 Basic Wiring Example 31

2.5.4 Electrical Installation, Control Cables 32

2.5.5 Relay Output 33

2.6 Handling of Reference

2.6.1 Reference Limits 35

2.6.2 Scaling of Preset References and Bus References 36

2.6.3 Scaling of Analog and Pulse References and Feedback 36

2.6.4 Dead Band Around Zero 37

2.7 Brake Functions

2.7.1 Mechanical Brake 41

2.7.1.1 Mechanical Brake Selection Guide and Electrical Circuit Description 42

2.7.1.2 Mechanical Brake Control 43

2.7.1.3 Mechanical Brake Cabling 45

2.7.1.4 Hoist Mechanical Brake 45

31

34

41

2.7.2 Dynamic Brake 45

2.7.2.1 Brake Resistors 45

2.7.2.2 Selection of Brake Resistor 45

2.7.2.3 Brake Resistors 10 W 46

2.7.2.4 Brake Resistor 40% 46

2.7.2.5 Control with Brake Function 47

2.7.2.6 Brake Resistor Cabling 47

2.8 Safe Torque O

2.9 EMC

2.9.1 General Aspects of EMC Emissions 47

2.9.2 Emission Requirements 49

2.9.3 Immunity Requirements 50

2.9.4 EMC 51

2.9.4.1 EMC-correct Installation 51

2.9.4.2 Use of EMC-correct Cables 53

2.9.4.3 Grounding of Shielded Control Cables 54

2.9.4.4 RFI Switch 55

47

47

Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 5

Contents Design Guide

2.9.5 Mains Supply Interference/Harmonics 55

2.9.5.1 Eect of Harmonics in a Power Distribution System 56

2.9.5.2 Harmonic Limitation Standards and Requirements 56

2.9.5.3 Harmonic Mitigation 57

2.9.5.4 Harmonic Calculation 57

2.9.6 Residual Current Device 57

2.9.7 EMC Test Results 57

3 System Integration

3.1 Ambient Conditions

3.1.1 Air Humidity 58

3.1.2 Aggressive Environments 58

3.1.3 Vibration and Shock 58

3.1.4 Acoustic Noise 58

3.2 Mounting Positions

3.2.1 Mounting Positions for Hygienic Installation 59

3.3 Electrical Input: Mains-side Dynamics

3.3.1 Connections 60

3.3.1.1 Cables General 60

3.3.1.2 Connection to Mains and Grounding 60

3.3.1.3 Relay Connection 61

3.3.2 Fuses and Circuit Breakers 61

3.3.2.1 Fuses 61

3.3.2.2 Recommendations 61

3.3.2.3 CE Compliance 61

58

58

58

60

3.3.2.4 UL Compliance 61

3.4 Electrical Output: Motor-side Dynamics

3.4.1 Motor Connection 61

3.4.2 Mains Disconnectors 64

3.4.3 Additional Motor Information 64

3.4.3.1 Motor Cable 64

3.4.3.2 Motor Thermal Protection 64

3.4.3.3 Parallel Connection of Motors 65

3.4.3.4 Motor Insulation 65

3.4.3.5 Motor Bearing Currents 65

3.4.4 Extreme Running Conditions 66

3.4.4.1 Motor Thermal Protection 66

3.5 Final Test and Set-up

3.5.1 High-voltage Test 67

MG04H322 Danfoss A/S © 05/2018 All rights reserved.

61

67

Page 6

Contents

VLT® Decentral Drive FCD 302

3.5.2 Grounding 67

3.5.3 Safety Grounding Connection 67

3.5.4 Final Set-up Check 68

4 Application Examples

4.1 Overview

4.2 AMA

4.2.1 AMA with T27 Connected 69

4.2.2 AMA without T27 Connected 69

4.3 Analog Speed Reference

4.3.1 Voltage Analog Speed Reference 69

4.3.2 Current Analog Speed Reference 70

4.3.3 Speed Reference (Using a Manual Potentiometer) 70

4.3.4 Speed Up/Speed Down 70

4.4 Start/Stop Applications

4.4.1 Start/Stop Command with Safe Torque O 71

4.4.2 Pulse Start/Stop 71

4.4.3 Start/Stop with Reversing and 4 Preset Speeds 72

4.5 Bus and Relay Connection

4.5.1 External Alarm Reset 72

4.5.2 RS485 Network Connection 73

69

69

69

69

71

72

4.5.3 Motor Thermistor 73

4.5.4 Using SLC to Set a Relay 74

4.6 Brake Application

4.6.1 Mechanical Brake Control 74

4.6.2 Hoist Mechanical Brake 75

4.7 Encoder

4.7.1 Encoder Direction 77

4.8 Closed-loop Drive System

4.9 Smart Logic Control

5 Special Conditions

5.1 Manual Derating

5.1.1 Derating for Low Air Pressure 81

5.1.2 Derating for Running at Low Speed 81

5.1.3 Ambient Temperature 82

5.1.3.1 Power Size 0.37–0.75 kW 82

5.1.3.2 Power Size 1.1–1.5 kW 82

5.1.3.3 Power Size 2.2–3.0 kW 83

74

77

77

79

81

81

Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 7

Contents Design Guide

5.2 Automatic Derating

5.2.1 Sine-Wave Filter Fixed Mode 85

5.2.2 Overview Table 86

5.2.3 High Motor Load 86

5.2.4 High Voltage on the DC link 87

5.2.5 Low Motor Speed 87

5.2.6 High Internal 87

5.2.7 Current 88

5.3 Derating for Running at Low Speed

6 Type Code and Selection Guide

6.1 Type Code Description

6.2 Ordering Numbers

6.2.1 Ordering Numbers: Accessories 90

6.2.2 Ordering Numbers: Spare Parts 91

6.3 Options and Accessories

6.3.1 Fieldbus Options 92

6.3.2 VLT® Encoder Input MCB 102 92

83

88

89

89

90

92

6.3.3 VLT® Resolver Input MCB 103 94

7 Specications

7.1 Mechanical Dimensions

7.2 Electrical Data and Wire Sizes

7.2.1 Overview 98

7.2.2 UL/cUL Approved Pre-fuses 99

7.2.3 VLT® Decentral Drive FCD 302 DC Voltage Levels 99

7.3 General Specications

7.4 Eciency

7.5 dU/dt Conditions

Index

97

97

98

100

105

105

107

MG04H322 Danfoss A/S © 05/2018 All rights reserved.

Page 8

Introduction

VLT® Decentral Drive FCD 302

11

1 Introduction

1.1 How to Read the Design Guide

The design guide provides information required for

integration of the frequency converter in a diversity of

applications.

1.1.1 Additional Resources

®

Decentral Drive FCD 302 Operating Guide, for

VLT

•

information required to install and commission

the frequency converter.

VLT® AutomationDrive FC 301/302 Programming

•

Guide, for information about how to program the

unit, including complete parameter descriptions.

Modbus RTU Operating Instructions, for the

•

information required for controlling, monitoring,

and programming the frequency converter via

the built-in Modbus eldbus.

VLT® PROFIBUS Converter MCA 114 Operating

•

Instructions, VLT

Guide, and VLT® PROFINET MCA 120 Installation

Guide, for information required for controlling,

monitoring, and programming the frequency

converter via a eldbus.

VLT® Encoder Option MCB 102 Installation

•

Instructions.

®

VLT

•

•

•

•

•

Technical literature and approvals are available online at

www.danfoss.com/en/search/?lter=type%3Adocumentation

%2Csegment%3Adds.

The following symbols are used in this manual:

AutomationDrive FC 300, Resolver Option MCB

103 Installation Instructions.

VLT® AutomationDrive FC 300, Safe PLC Interface

Option MCB 108 Installation Instructions.

VLT® Brake Resistor MCE 101 Design Guide.

VLT® Frequency Converters Safe Torque O

Operating Guide.

Approvals.

®

EtherNet/IP MCA 121 Installation

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE!

Indicates important information, including situations that

may result in damage to equipment or property.

The following conventions are used in this manual:

Numbered lists indicate procedures.

•

Bullet lists indicate other information and

•

description of illustrations.

Italicized text indicates:

•

- Cross-reference.

- Link.

- Footnote.

- Parameter name.

- Parameter group name.

- Parameter option.

All dimensions in drawings are in mm (inch).

•

Document and Software Version

1.2

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding software

version.

Edition Remarks Software version

MG04H3xx EMC-correct Installation has been

updated.

Table 1.1 Document and Software Version

Denitions

1.3

1.3.1 Frequency Converter

I

VLT,MAX

Maximum output current.

I

VLT,N

Rated output current supplied by the frequency converter.

U

VLT,MAX

Maximum output voltage.

7.5x

6 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 9

175ZA078.10

Pull-out

RPM

Torque

Introduction Design Guide

1.3.2 Input

Control command

Start and stop the connected motor with LCP and digital

inputs.

Functions are divided into 2 groups.

Functions in group 1 have higher priority than functions in

group 2.

Group 1 Reset, coast stop, reset and coast stop, quick stop,

DC brake, stop, the [OFF] key.

Group 2 Start, pulse start, reversing, start reversing, jog,

freeze output.

Table 1.2 Function Groups

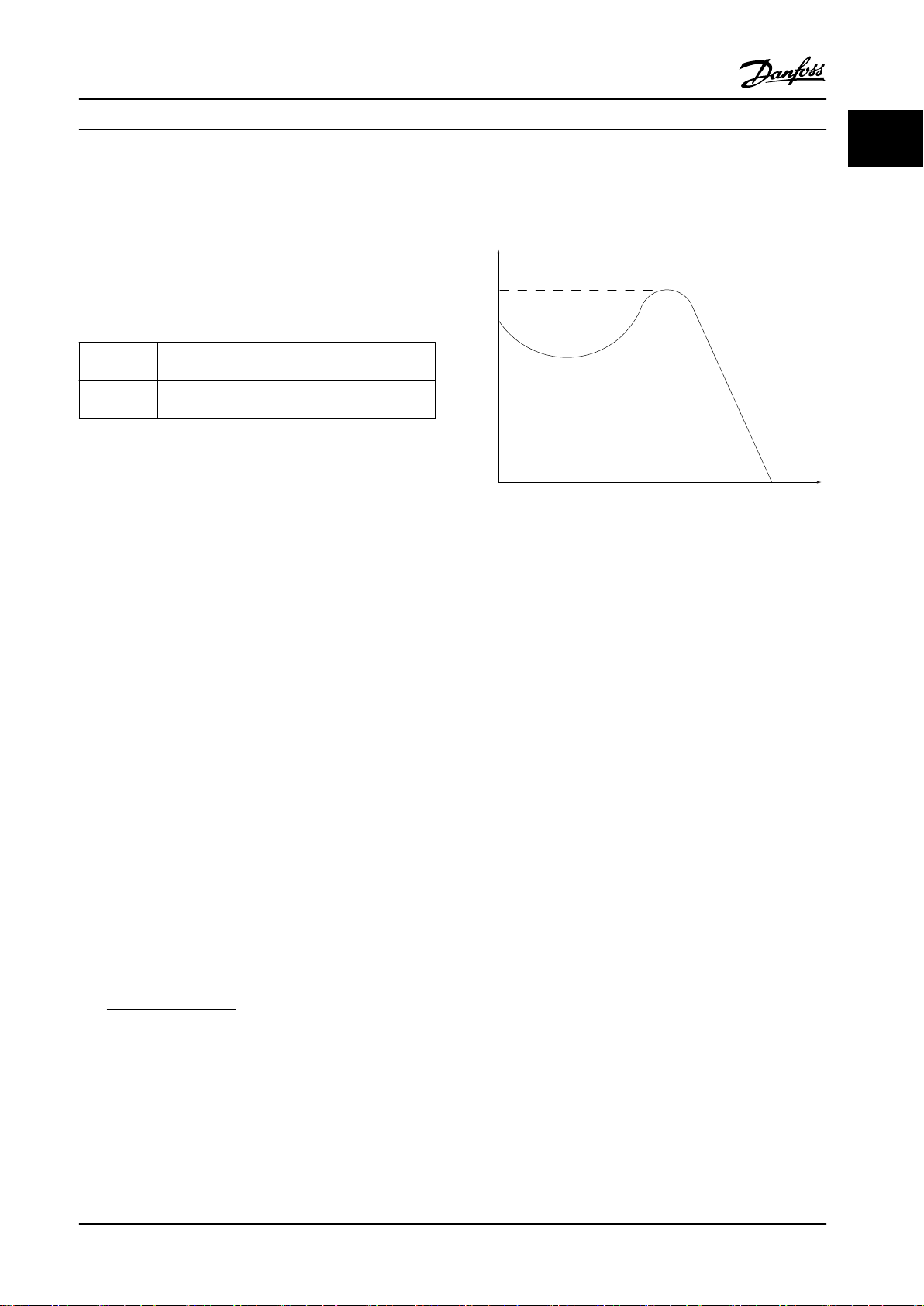

1.3.3 Motor

U

M,N

Rated motor voltage (nameplate data).

Break-away torque

1 1

Motor running

Torque generated on output shaft and speed from 0 RPM

to maximum speed on motor.

f

JOG

Motor frequency when the jog function is activated (via

digital terminals).

f

M

Motor frequency.

f

MAX

Maximum motor frequency.

f

MIN

Minimum motor frequency.

f

M,N

Rated motor frequency (nameplate data).

I

M

Motor current (actual).

I

M,N

Rated motor current (nameplate data).

n

M,N

Nominal motor speed (nameplate data).

n

s

Synchronous motor speed.

2 × par . 1 − 23 × 60s

ns=

n

slip

par . 1 − 39

Motor slip.

P

M,N

Rated motor power (nameplate data in kW or hp).

T

M,N

Rated torque (motor).

U

M

Instant motor voltage.

Figure 1.1 Break-away Torque

η

VLT

The eciency of the frequency converter is dened as the

ratio between the power output and the power input.

Start-disable command

A stop command belonging to Group 1 control commands

- see Table 1.2.

Stop command

A stop command belonging to Group 1 control commands

- see Table 1.2.

1.3.4 References

Analog reference

A signal transmitted to the analog inputs 53 or 54 (voltage

or current).

Binary reference

A signal transmitted to the serial communication port.

Preset reference

A dened preset reference to be set from -100% to +100%

of the reference range. Selection of 8 preset references via

the digital terminals.

Pulse reference

A pulse frequency signal transmitted to the digital inputs

(terminal 29 or 33).

Ref

MAX

Determines the relationship between the reference input at

100% full scale value (typically 10 V, 20 mA) and the

resulting reference. The maximum reference value is set in

parameter 3-03 Maximum Reference.

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 7

Page 10

Introduction

VLT® Decentral Drive FCD 302

11

Ref

MIN

Determines the relationship between the reference input at

0% value (typically 0 V, 0 mA, 4 mA) and the resulting

reference. The minimum reference value is set in

parameter 3-02 Minimum Reference.

1.3.5 Miscellaneous

Analog inputs

The analog inputs are used for controlling various

functions of the frequency converter.

There are 2 types of analog inputs:

Current input, 0–20 mA, and 4–20 mA

Voltage input, -10 V DC to +10 V DC.

Analog outputs

The analog outputs can supply a signal of 0–20 mA, 4–

20 mA.

Automatic motor adaptation, AMA

AMA algorithm determines the electrical parameters for

the connected motor at standstill.

Brake resistor

The brake resistor is a module capable of absorbing the

brake power generated in regenerative braking. This

regenerative brake power increases the DC-link voltage

and a brake chopper ensures that the power is transmitted

to the brake resistor.

CT characteristics

Constant torque characteristics used for all applications

such as conveyor belts, displacement pumps, and cranes.

Digital inputs

The digital inputs can be used for controlling various

functions of the frequency converter.

Digital outputs

The frequency converter features 2 solid-state outputs that

can supply a 24 V DC (maximum 40 mA) signal.

DSP

Digital signal processor.

ETR

Electronic thermal relay is a thermal load calculation based

on present load and time. Its purpose is to estimate the

motor temperature.

Hiperface

Hiperface® is a registered trademark by Stegmann.

Initializing

If initializing is carried out (parameter 14-22 Operation

Mode), the frequency converter returns to the default

setting.

®

Intermittent duty cycle

An intermittent duty rating refers to a sequence of duty

cycles. Each cycle consists of an on-load and an o-load

period. The operation can be either periodic duty or nonperiodic duty.

LCP

The local control panel makes up a complete interface for

control and programming of the frequency converter. The

control panel is detachable and can be installed up to 3 m

(10 ft) from the frequency converter, that is, in a front

panel with the installation kit option.

lsb

Least signicant bit.

msb

Most signicant bit.

MCM

Short for mille circular mil, an American measuring unit for

cable cross-section. 1 MCM=0.5067 mm2.

Online/oine parameters

Changes to online parameters are activated immediately

after the data value is changed. Press [OK] to activate

changes to o-line parameters.

Process PID

The PID control maintains the required speed, pressure,

temperature, and so on, by adjusting the output frequency

to match the varying load.

PCD

Process control data.

Power cycle

Switch o the mains until display (LCP) is dark, then turn

power on again.

Pulse input/incremental encoder

An external, digital pulse transmitter used for feeding back

information on motor speed. The encoder is used in

applications where great accuracy in speed control is

required.

RCD

Residual current device.

Set-up

Save parameter settings in 4 set-ups. Change between the

4 parameter set-ups and edit 1 set-up, while another setup is active.

SFAVM

Switching pattern called stator ux-oriented asynchronous

vector modulation (parameter 14-00 Switching Pattern).

Slip compensation

The frequency converter compensates for the motor slip by

giving the frequency a supplement that follows the

measured motor load keeping the motor speed almost

constant.

8 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 11

Introduction Design Guide

1 1

SLC

The SLC (smart logic control) is a sequence of user-dened

actions executed when the associated user-dened events

are evaluated as true by the SLC. (See chapter 4.9.1 Smart

Logic Controller).

STW

Status word.

FC standard bus

Includes RS485 bus with FC protocol or MC protocol. See

parameter 8-30 Protocol.

THD

Total harmonic distortion states the total contribution of

harmonic.

Thermistor

A temperature-dependent resistor placed on the frequency

converter or the motor.

Trip

A state entered in fault situations, for example if the

frequency converter is subject to an overtemperature or

when the frequency converter is protecting the motor,

process, or mechanism. The frequency converter prevents a

restart until the cause of the fault has disappeared. To

cancel the trip state, restart the frequency converter. Do

not use the trip state for personal safety.

Trip lock

The frequency converter enters this state in fault situations

to protect itself. The frequency converter requires physical

intervention, for example when there is a short circuit on

the output. A trip lock can only be canceled by disconnecting mains, removing the cause of the fault, and

reconnecting the frequency converter. Restart is prevented

until the trip state is canceled by activating reset or,

sometimes, by being programmed to reset automatically.

Do not use the trip lock state for personal safety.

VT characteristics

Variable torque characteristics used for pumps and fans.

+

VVC

If compared with standard voltage/frequency ratio control,

voltage vector control (VVC+) improves the dynamics and

the stability, both when the speed reference is changed

and in relation to the load torque.

60° AVM

60° asynchronous vector modulation

(parameter 14-00 Switching Pattern).

Power factor

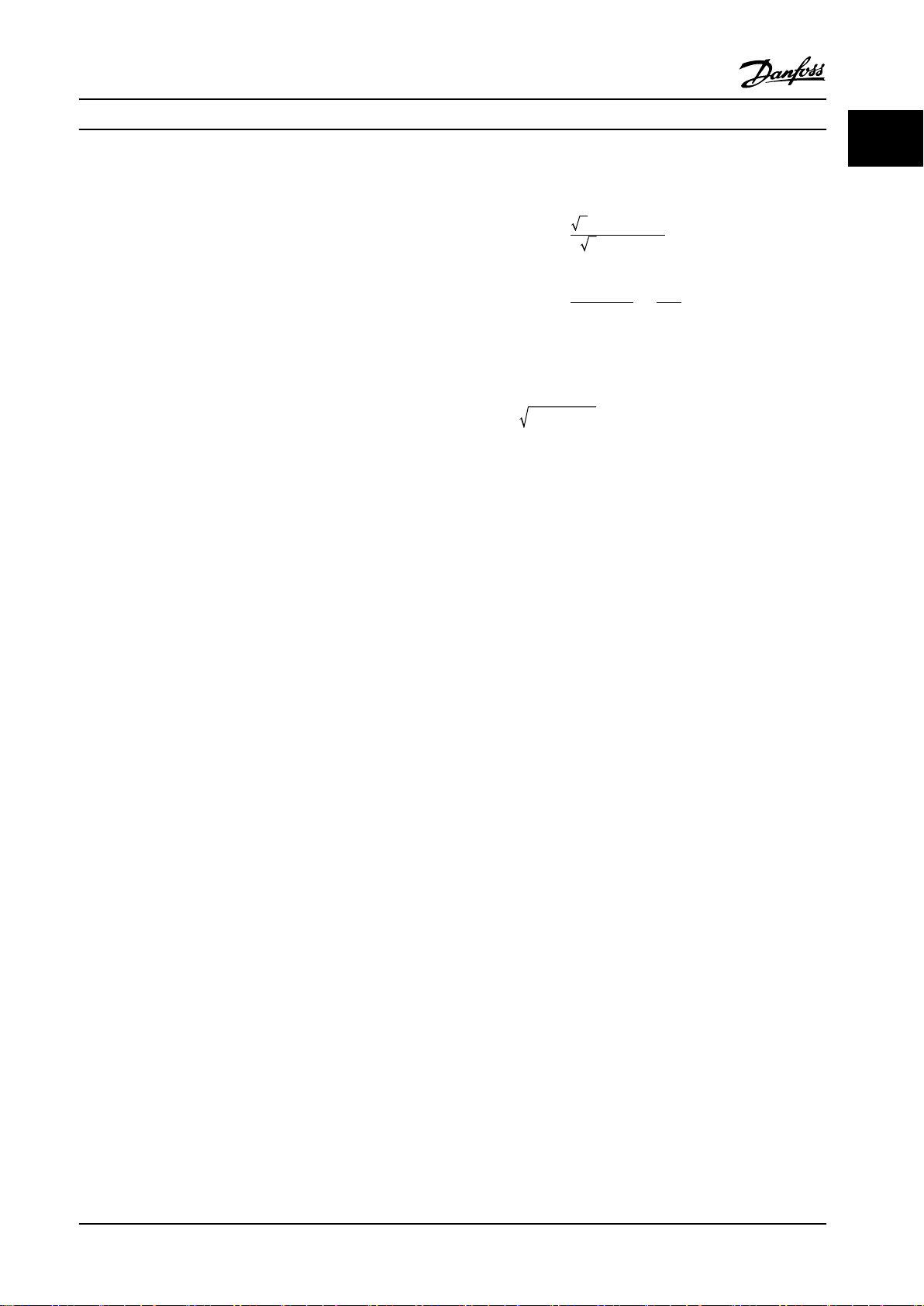

The power factor is the relation between I1 and I

Power factor =

3xUxI1cosϕ

3xUxI

RMS

RMS

.

The power factor for 3-phase control:

Power factor =

I1xcosϕ1

I

RMS

=

I

1

sincecosϕ1 = 1

I

RMS

The power factor indicates to which extent the frequency

converter imposes a load on the mains supply.

The lower the power factor, the higher the I

RMS

for the

same kW performance.

I

RMS

=

I

+ I

1

5

+ I

2

+ .. + I

7

2

n

2

2

In addition, a high-power factor indicates that the dierent

harmonic currents are low.

The DC coils in the frequency converters produce a highpower factor, which minimizes the imposed load on the

mains supply.

Target position

The nal target position specied by positioning

commands. The prole generator uses this position to

calculate the speed prole.

Commanded position

The actual position reference calculated by the prole

generator. The frequency converter uses the commanded

position as setpoint for position PI.

Actual position

The actual position from an encoder, or a value that the

motor control calculates in open loop. The frequency

converter uses the actual position as feedback for position

PI.

Position error

Position error is the dierence between the actual position

and the commanded position. The position error is the

input for the position PI controller.

Position unit

The physical unit for position values.

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 9

Page 12

Introduction

VLT® Decentral Drive FCD 302

11

1.4 Safety Precautions

WARNING

The voltage of the frequency converter is dangerous

whenever connected to mains. Correct planning of the

installation of the motor, frequency converter, and

eldbus are necessary. Follow the instructions in this

manual, and the national and local rules and safety

regulations. Failure to follow design recommendations

could result in death, serious personal injury, or damage

to the equipment once in operation.

WARNING

HIGH VOLTAGE

Touching the electrical parts may be fatal - even after

the equipment has been disconnected from mains.

In planning, ensure that other voltage inputs can be

disconnected, such as external 24 V DC, load sharing

(linkage of DC intermediate circuit), and the motor

connection for kinetic back-up.

Systems where frequency converters are installed must, if

necessary, be equipped with additional monitoring and

protective devices according to the valid safety

regulations, for example law on mechanical tools,

regulations for the prevention of accidents, and so on.

Modications on the frequency converters by means of

the operating software are allowed.

Failure to follow design recommendations, could result in

death or serious injury once the equipment is in

operation.

NOTICE!

Hazardous situations have to be identied by the

machine builder/integrator who is responsible for taking

necessary preventive means into consideration.

Additional monitoring and protective devices may be

included, always according to valid national safety

regulations, for example, law on mechanical tools,

regulations for the prevention of accidents.

NOTICE!

Crane, lifts, and hoists:

The controlling of external brakes must always be

designed with a redundant system. The frequency

converter can in no circumstances be the primary safety

circuit. Comply with relevant standards, for example.

Hoists and cranes: IEC 60204-32

Lifts: EN 81

Protection mode

Once a hardware limit on motor current or DC-link voltage

is exceeded, the frequency converter enters protection

mode. Protection mode means a change of the PWM

modulation strategy and a low switching frequency to

minimize losses. This continues 10 s after the last fault and

increases the reliability and the robustness of the

frequency converter while re-establishing full control of the

motor.

In hoist applications, protection mode is not usable

because the frequency converter is usually unable to leave

this mode again and therefore it extends the time before

activating the brake – which is not recommended.

The protection mode can be disabled by setting

parameter 14-26 Trip Delay at Inverter Fault to 0 which

means that the frequency converter trips immediately if 1

of the hardware limits is exceeded.

NOTICE!

Disable protection mode in hoisting applications

(parameter 14-26 Trip Delay at Inverter Fault=0).

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors,

which can remain charged even when the frequency

converter is not powered. High voltage can be present

even when the warning LED indicator lights are o.

Failure to wait the specied time after power has been

removed before performing service or repair work can

result in death or serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

•

minimum waiting time is specied in Table 1.3

and is also visible on the product label on top

of the frequency converter.

Before performing any service or repair work,

•

use an appropriate voltage measuring device to

make sure that the capacitors are fully

discharged.

10 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 13

Introduction Design Guide

1 1

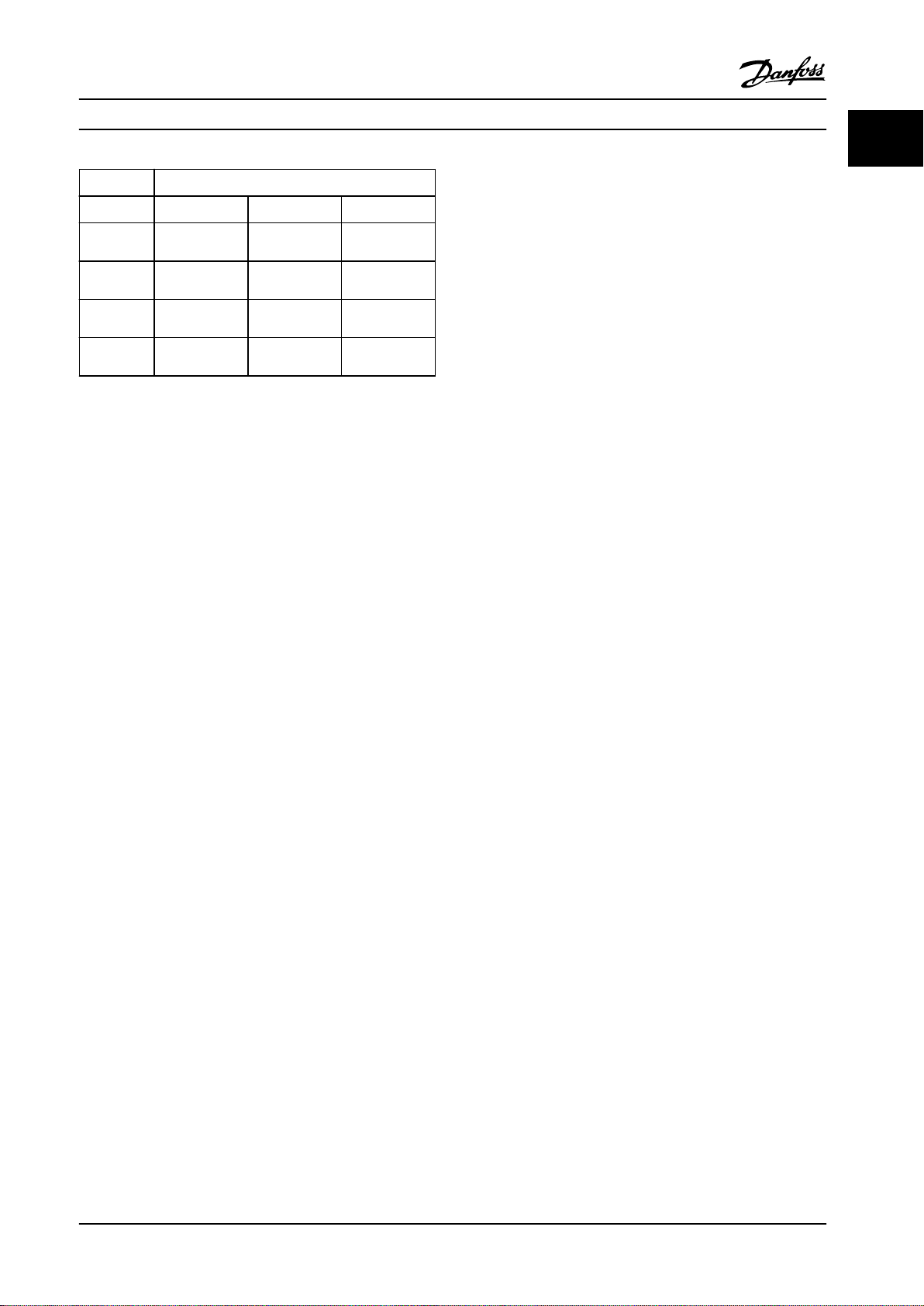

Voltage [V] Minimum waiting time (minutes)

4 7 15

200–240 0.25–3.7 kW

(0.34–5 hp)

380–500 0.25–7.5 kW

(0.34–10 hp)

525–600 0.75–7.5 kW

(1–10 hp)

525–690 – 1.5–7.5 kW

Table 1.3 Discharge Time

– 5.5–37 kW

(7.5–50 hp)

– 11–75 kW

(15–100 hp)

– 11–75 kW

(15–100 hp)

(2–10 hp)

(15–100 hp)

11–75 kW

1.5 CE Labeling

CE labeling is a positive feature when used for its original

purpose, that is, to facilitate trade within the EU and EFTA.

However, CE labeling may cover many

cations. Check what a given CE label specically covers.

The specications can vary greatly. A CE label may

therefore give the installer a false sense of security when

using a frequency converter as a component in a system

or an appliance.

Danfoss CE labels the frequency converters in accordance

with the Low Voltage Directive. This means that if the

frequency converter is installed correctly, compliance with

the Low Voltage Directive is achieved. Danfoss issues a

declaration of conformity that conrms CE labeling in

accordance with the Low Voltage Directive.

The CE label also applies to the EMC directive, if the

instructions for EMC-correct installation and

followed. On this basis, a declaration of conformity in

accordance with the EMC directive is issued.

dierent speci-

ltering are

What is CE conformity and labeling?

The purpose of CE labeling is to avoid technical trade

obstacles within EFTA and the EU. The EU has introduced

the CE label as a simple way of showing whether a

product complies with the relevant EU directives. The CE

label says nothing about the specications or quality of

the product. Frequency converters are regulated by 2 EU

directives:

The Low Voltage Directive (2014/35/EU)

Frequency converters must be CE-labeled in accordance

with the Low Voltage Directive of January 1, 2014. The Low

Voltage Directive applies to all electrical equipment in the

50–1000 V AC and the 75–1500 V DC voltage ranges.

The aim of the directive is to ensure personal safety and

avoid property damage when operating electrical

equipment that is installed, maintained, and used as

intended.

The EMC Directive (2014/30/EU)

The purpose of the EMC (electromagnetic compatibility)

Directive is to reduce electromagnetic interference and

enhance immunity of electrical equipment and installations. The basic protection requirement of the EMC

Directive is that devices that generate electromagnetic

interference (EMI), or whose operation could be aected

by EMI, must be designed to limit the generation of

electromagnetic interference. The devices must have a

suitable degree of immunity to EMI when properly

installed, maintained, and used as intended.

Electrical equipment devices used alone or as part of a

system must bear the CE mark. Systems do not require the

CE mark, but must comply with the basic protection

requirements of the EMC Directive.

The frequency converter is most often used by professionals of the trade as a complex component forming part

of a larger appliance, system, or installation.

The design guide oers detailed instructions for installation

to ensure EMC-correct installation.

1.5.1 Conformity

The Machinery Directive (2006/42/EC)

Frequency converters do not fall under the machinery

directive. However, if a frequency converter is supplied for

use in a machine, Danfoss provides information on safety

aspects relating to the frequency converter.

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 11

Page 14

Introduction

VLT® Decentral Drive FCD 302

11

1.5.2 What Is Covered?

The EU EMC Directive 2014/30/EU outline 3 typical

situations of using a frequency converter. See below for

EMC coverage and CE labeling.

The frequency converter is sold directly to the

•

end user. The frequency converter is for example

sold to a do-it-yourself market. The end user is a

layman, installing the frequency converter for use

with a hobby machine, a kitchen appliance, and

so on. For such applications, the frequency

converter must be CE labeled in accordance with

the EMC directive.

The frequency converter is sold for installation in

•

a plant. The plant is built up by professionals of

the trade. It could be a production plant or a

heating/ventilation plant designed and installed

by professionals of the trade. The frequency

converter and the nished plant do not have to

be CE labeled under the EMC directive. However,

the unit must comply with the basic EMC

requirements of the directive. This is ensured by

using components, appliances, and systems that

are CE labeled under the EMC directive.

The frequency converter is sold as part of a

•

complete system. The system is marketed as

complete, for example an air-conditioning system.

The complete system must be CE labeled in

accordance with the EMC directive. The

manufacturer can ensure CE labeling under the

EMC directive either by using CE labeled

components or by testing the EMC of the system.

If only CE labeled components are used, it is

unnecessary to test the entire system.

Approvals

1.7

Table 1.4 FCD 302 Approvals

The frequency converter complies with UL 508C thermal

memory retention requirements. For more information,

refer to chapter 3.4.3.2 Motor Thermal Protection.

1.8 Disposal

Equipment containing electrical

components may not be disposed of

together with domestic waste.

It must be separately collected with

electrical and electronic waste according

to local and currently valid legislation.

Table 1.5 Disposal Instruction

Compliance with EMC Directive

1.6

2004/1087EC

The frequency converter is mostly used by professionals of

the trade as a complex component forming part of a larger

appliance, system, or installation.

NOTICE!

The responsibility for the nal EMC properties of the

appliance, system, or installation rests with the installer.

As an aid to the installer, Danfoss has prepared EMC installation guidelines for the power drive system. The standards

and test levels stated for power drive systems are complied

with, if the EMC-correct instructions for installation are

followed, see chapter 2.9.4 EMC.

12 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 15

130BC963.10

130BC964.10

130BC968.11

1325 4

6

9

8

M

7

Product Overview and Functi... Design Guide

2 Product Overview and Functions

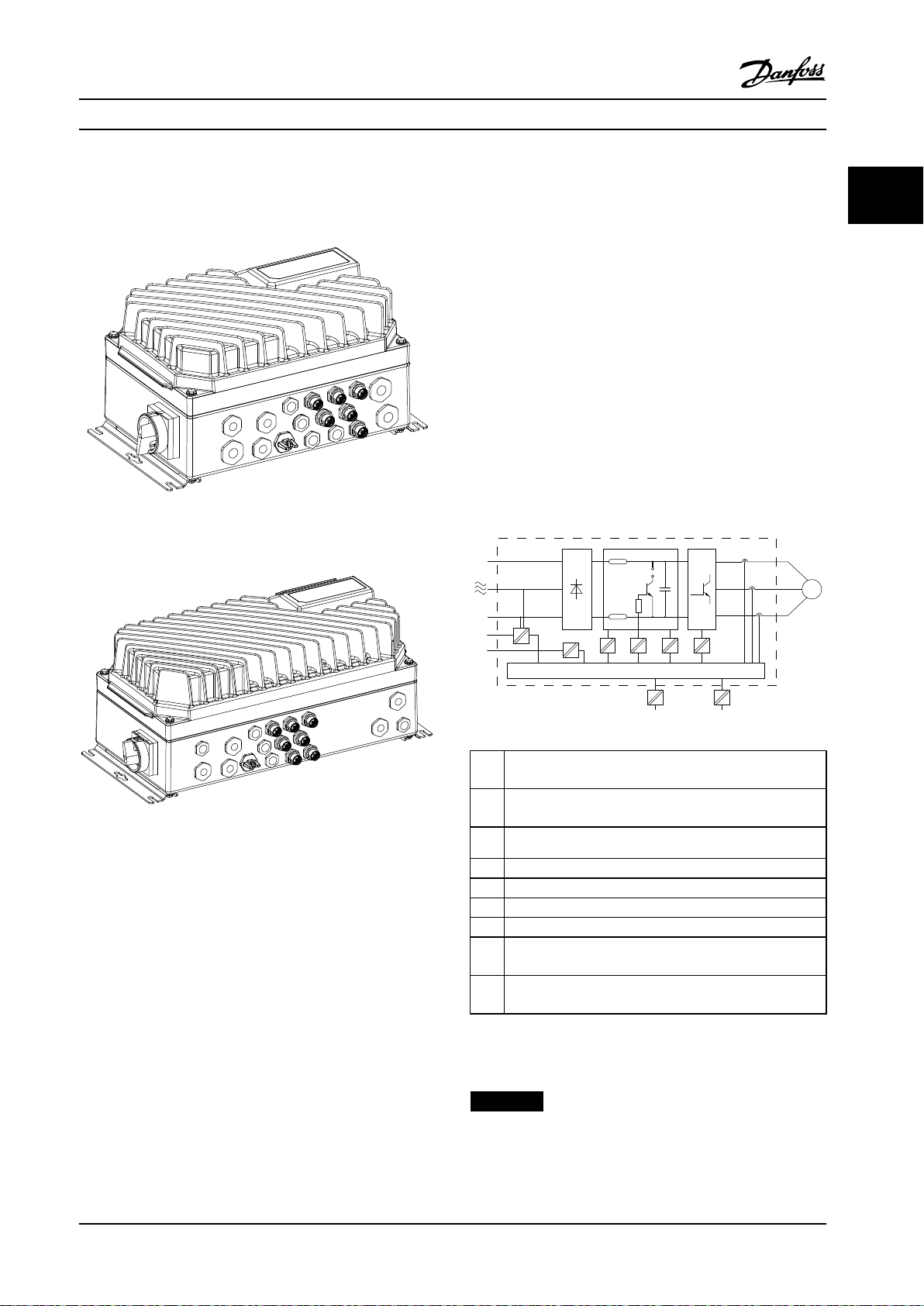

Figure 2.1 Small Unit

2 2

relevant creepage/clearance distances. These requirements

are described in the EN 61800-5-1 standard.

The components that make up the electrical isolation, as

described in Figure 2.3, also comply with the requirements

for higher isolation and the relevant test as described in

EN 61800-5-1.

The PELV galvanic isolation can be shown in 6 locations

(see Figure 2.3).

To maintain PELV, all connections made to the control

terminals must be PELV, for example, thermistor must be

reinforced/double insulated.

1 Power supply (SMPS) including signal isolation of UDC,

indicating the voltage of intermediate DC Link circuit.

2 Gate drive that runs the IGBTs (trigger transformers/opto-

Figure 2.2 Large Unit

2.1 Galvanic Isolation (PELV)

2.1.1 PELV - Protective Extra Low Voltage

PELV oers protection by way of extra low voltage.

Protection against electric shock is ensured when the

electrical supply is of the PELV type and the installation is

couplers).

3 Current transducers.

4 Opto-coupler, brake module.

5 Internal inrush, RFI, and temperature measurement circuits.

6 Custom relays.

7 Mechanical brake.

8 Functional galvanic isolation for the 24 V back-up option

and for the RS485 standard bus interface.

9 Functional galvanic isolation for the 24 V back-up option

and for the RS485 standard bus interface.

made as described in local/national regulations on PELV

supplies.

Figure 2.3 Galvanic Isolation

All control terminals and relay terminals 01–03/04–06

comply with PELV (protective extra low voltage), except for

grounded delta leg above 400 V.

Galvanic (ensured) isolation is obtained by fullling

NOTICE!

Installation at high altitude:

380–500 V: At altitudes above 2000 m (6561 ft), contact

Danfoss regarding PELV.

requirements for higher isolation and by providing the

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 13

Page 16

130BB957.11

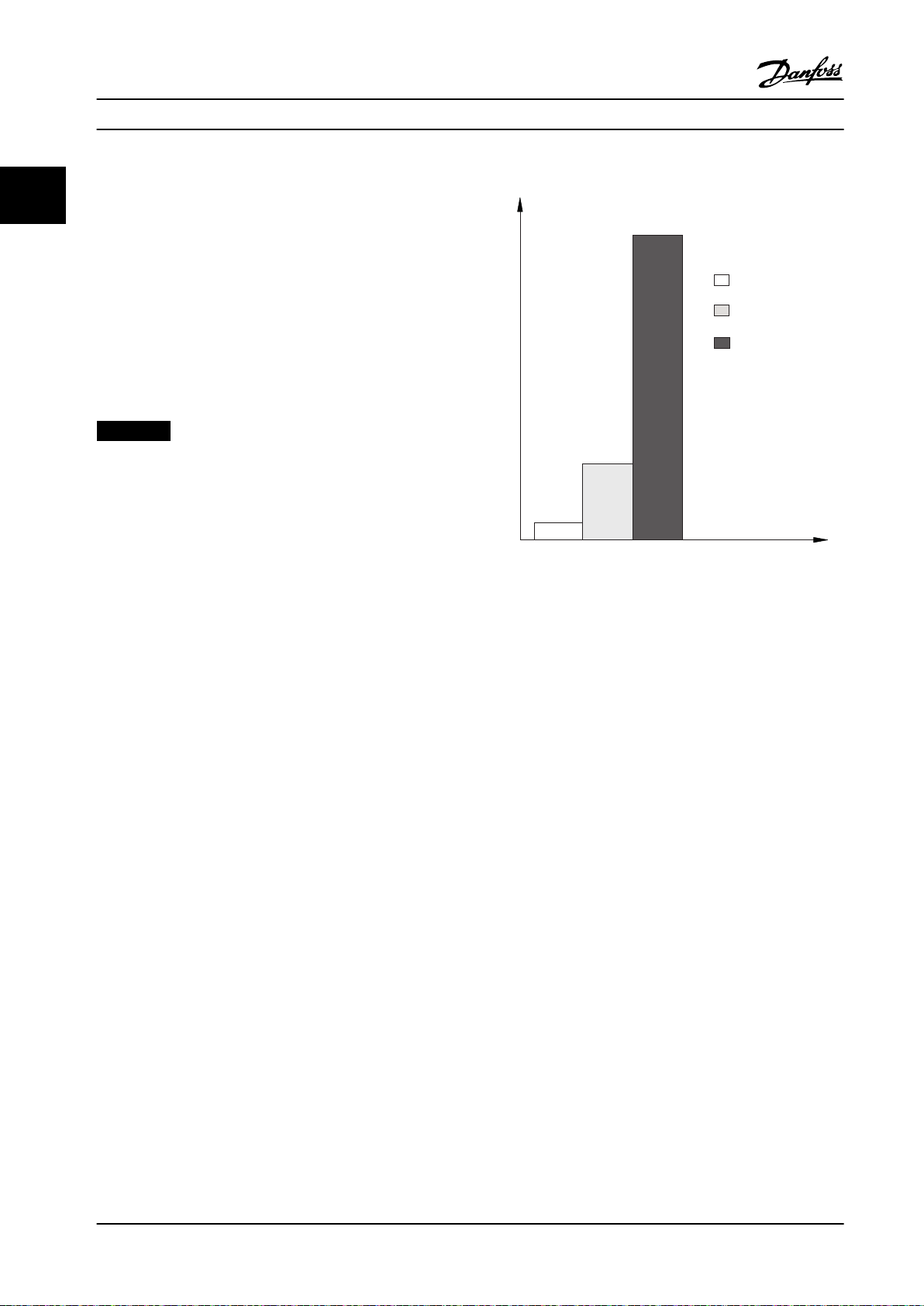

Leakage current [mA]

100 Hz

2 kHz

100 kHz

Product Overview and Functi...

VLT® Decentral Drive FCD 302

2.1.2 Ground Leakage Current

22

Follow national and local codes regarding protective

grounding of equipment with a leakage current >3.5 mA.

Frequency converter technology implies high frequency

switching at high power. This generates a leakage current

in the ground connection. A fault current in the frequency

converter at the output power terminals might contain a

DC component which can charge the lter capacitors and

cause a transient ground current.

The leakage current also depends on the line distortion.

NOTICE!

When a lter is used, turn o parameter 14-50 RFI Filter

when charging the lter, to avoid that a high leakage

current makes the RCD switch.

EN/IEC61800-5-1 (power drive system product standard)

requires special care if the leakage current exceeds 3.5 mA.

Grounding must be reinforced in 1 of the following ways:

Figure 2.4 Inuence of Cut-o Frequency of the RCD

Ground wire (terminal 95) of at least 10 mm

•

(7 AWG). This requires a PE adapter (available as

an option).

Two separate ground wires both complying with

•

the dimensioning rules.

See EN/IEC61800-5-1 and EN 50178 for further information.

Using RCDs

Where residual current devices (RCDs), also known as

ground leakage circuit breakers (CLCBs), are used, comply

with the following:

Use RCDs of type B, which are capable of

•

detecting AC and DC currents.

Use RCDs with an inrush delay to prevent faults

•

due to transient ground currents.

Dimension RCDs according to the system

•

ration and environmental considerations.

2

congu-

See also RCD Application Note.

Control

2.2

A frequency converter recties AC voltage from mains into

DC voltage. This DC voltage is converted into an AC

current with a variable amplitude and frequency.

The motor is supplied with variable voltage, current, and

frequency, which enables innitely variable speed control

of 3-phased, standard AC motors and permanent magnet

synchronous motors.

The VLT® Decentral Drive FCD 302 frequency converter is

designed for installations of multiple smaller frequency

converters, especially on conveyor applications, for

example, in the food and beverage industries and materials

handling. In installations where multiple motors are spread

around a facility such as bottling plants, food preparation,

packaging plants, and airport baggage handling installations, there may be dozens, perhaps hundreds, of

frequency converters, working together but spread over a

large physical area. In these cases, cabling costs alone

outweigh the cost of the individual frequency converters

and it makes sense to get the control closer to the motors.

The frequency converter can control either the speed or

the torque on the motor shaft.

14 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 17

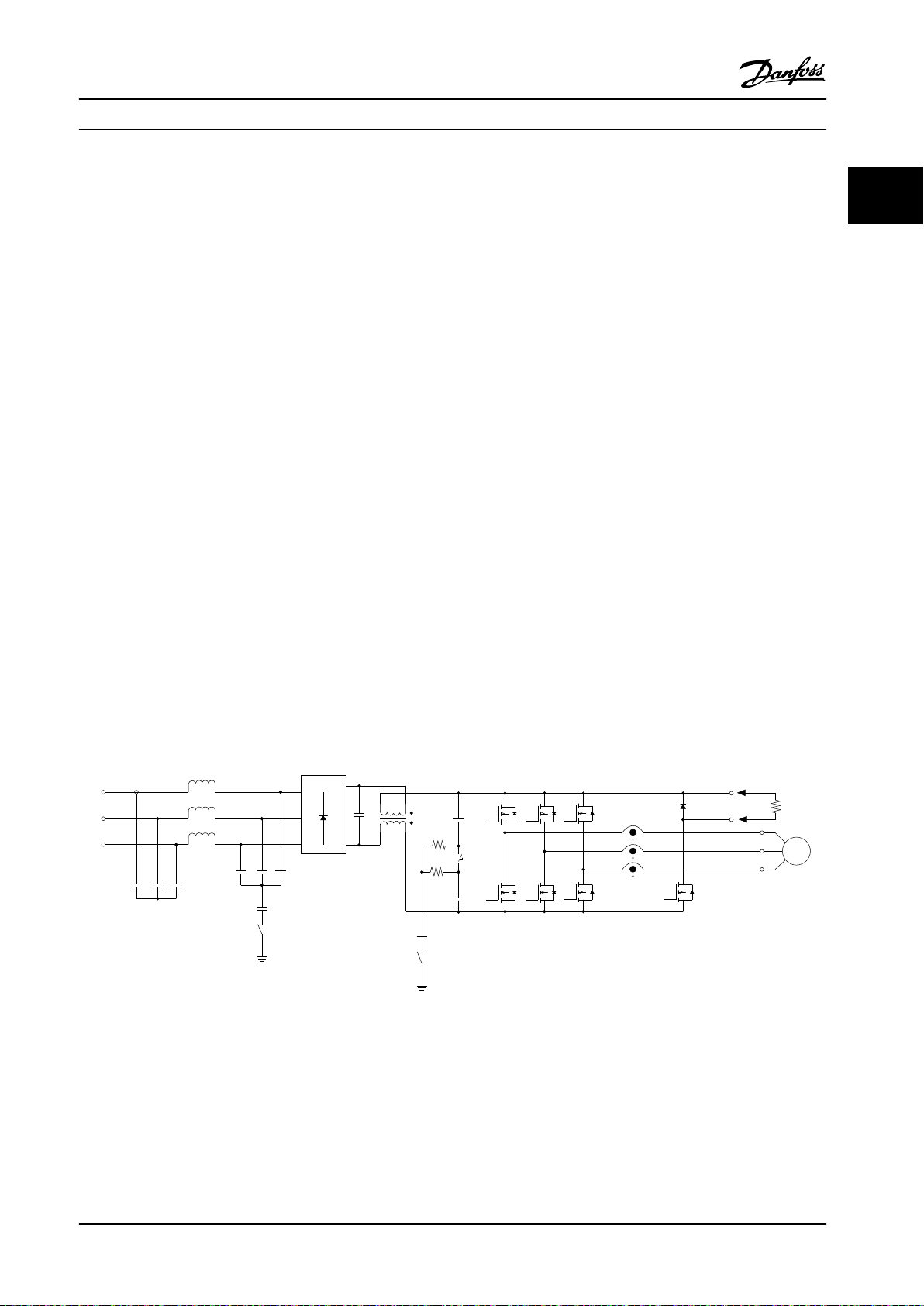

R+

82

R81

Brake

Resistor

U 96

V 97

W 98

InrushR inr

P 14-50

L1 91

L2 92

L3 93

M

130BC965.10

Product Overview and Functi... Design Guide

Speed control

Two types of speed control:

Speed open-loop control, which does not require

•

any feedback from the motor (sensorless).

Speed closed-loop PID control, which requires a

•

speed feedback to an input. A properly optimized

speed closed-loop control is more accurate than a

speed open-loop control.

Torque control

The torque control function is used in applications where

the torque on motor output shaft controls the application

as tension control.

Closed loop in ux mode with encoder feedback

•

comprises motor control based on feedback

signals from the system. It improves performance

in all 4 quadrants and at all motor speeds.

Open loop in VVC+ mode. The function is used in

•

mechanical robust applications, but the accuracy

is limited. Open-loop torque function works only

in 1 speed direction. The torque is calculated on

basis of current measurement internal in the

frequency converter. See application example

chapter 2.3.1 Control Structure in VVC+ Advanced

Vector Control.

Speed/torque reference

The reference to these controls can either be a single

reference or be the sum of various references including

relatively scaled references. The handling of references is

explained in detail in chapter 2.6 Handling of Reference.

2 2

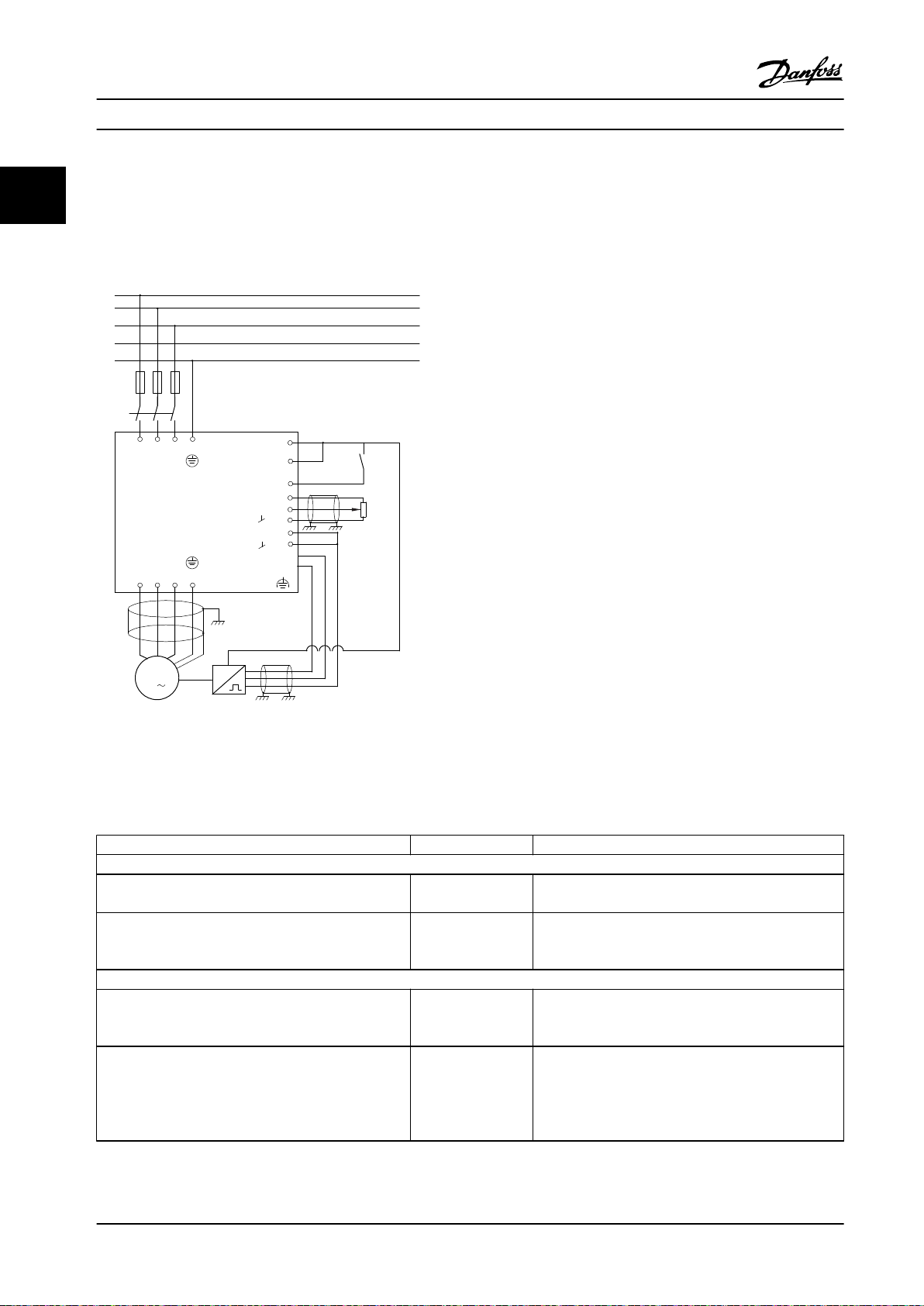

2.2.1 Control Principle

The frequency converter is compatible with various motor control principles such as U/f special motor mode, VVC+, or ux

vector motor control.

In addition, the frequency converter is operable with permanent magnet synchronous motors (brushless servo motors) and

normal squirrel lift cabin asynchronous motors.

The short circuit behavior depends on the 3 current transducers in the motor phases and the desaturation protection with

feedback from the brake.

Figure 2.5 Control Principle

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 15

Page 18

+

_

+

_

Cong. mode

Ref.

Process

P 1-00

High

+f max.

Low

-f max.

P 4-11

Motor speed

low limit (RPM)

P 4-12

Motor speed

low limit (Hz)

P 4-13

Motor speed

high limit (RPM)

P 4-14

Motor speed

high limit (Hz)

Motor

controller

Ramp

Speed

PID

P 7-20 Process feedback

1 source

P 7-22 Process feedback

2 source

P 7-00 Speed PID

feedback source

P 1-00

Cong. mode

P 4-19

Max. output freq.

-f max.

Motor

controller

P 4-19

Max. output freq.

+f max.

P 3-**

P 7-0*

130BA055.10

Product Overview and Functi...

2.2.2

Internal Current Control in VVC+ Mode

VLT® Decentral Drive FCD 302

22

The frequency converter features an integral current limit control which is activated when the motor current, and thus the

torque, is higher than the torque limits set in parameter 4-16 Torque Limit Motor Mode, parameter 4-17 Torque Limit Generator

Mode, and parameter 4-18 Current Limit.

When the frequency converter is at the current limit during motor operation or regenerative operation, it reduces torque to

below the preset torque limits as quickly as possible without losing control of the motor.

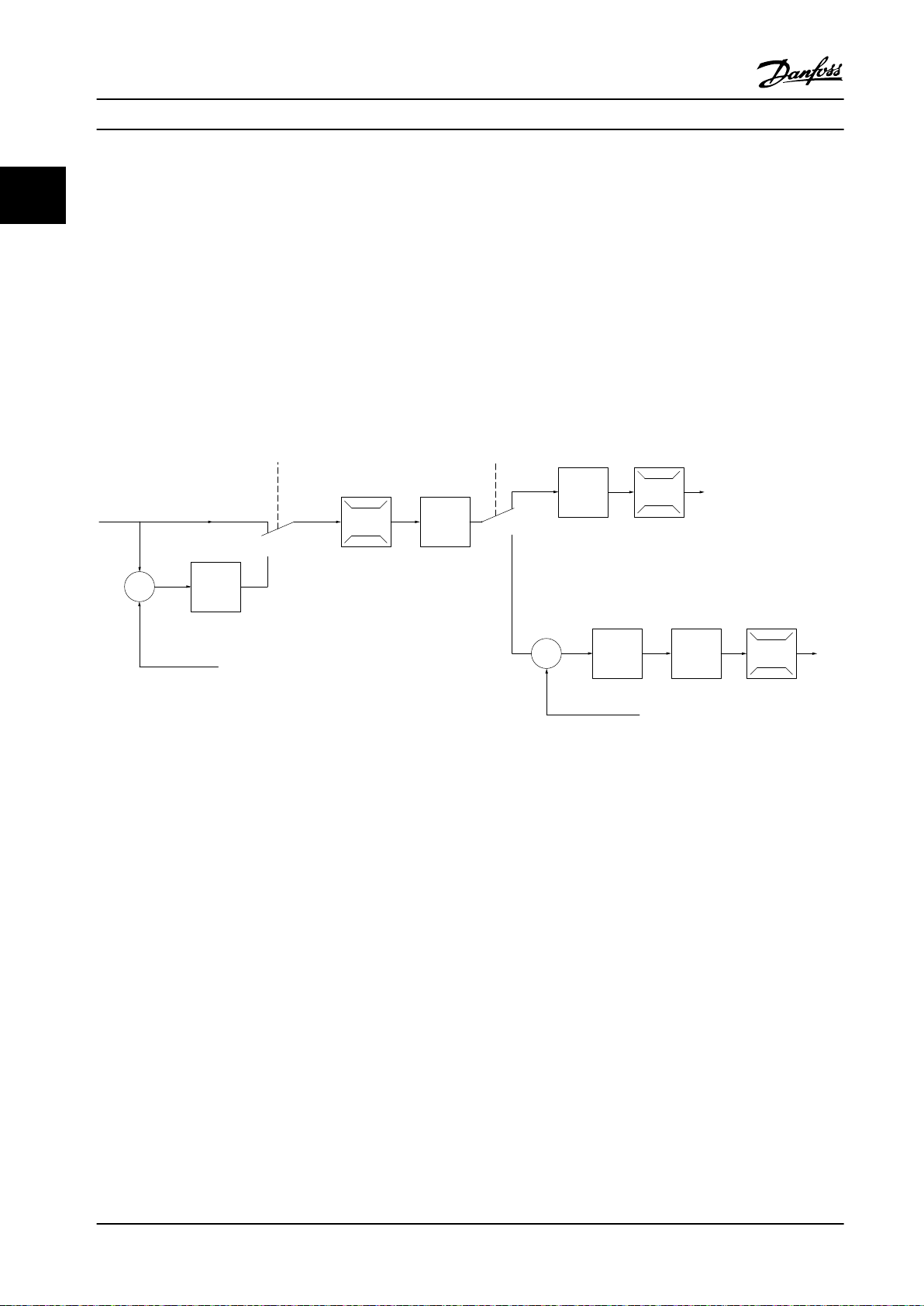

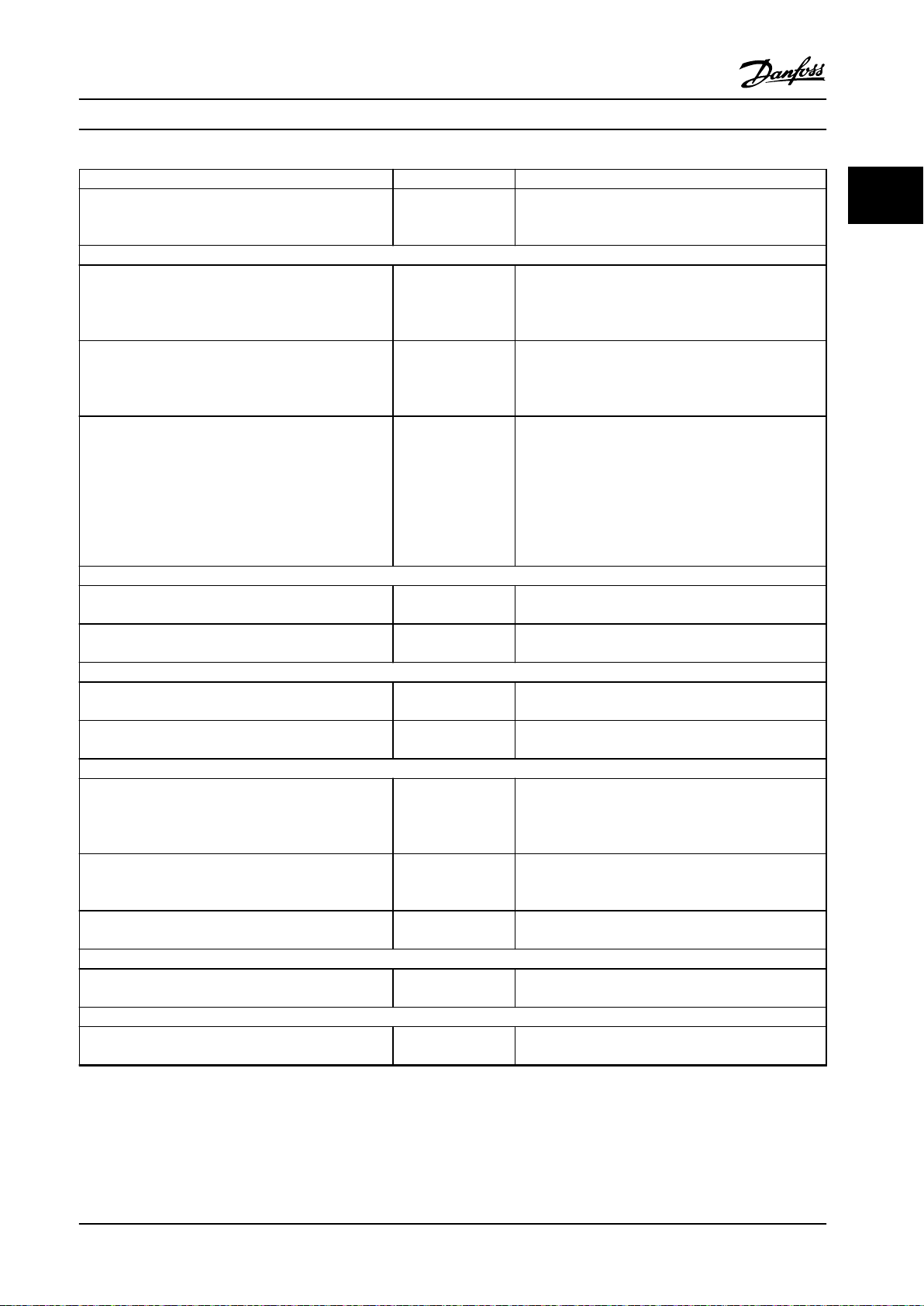

2.3 Control Structures

2.3.1

Control Structure in VVC+ Advanced Vector Control

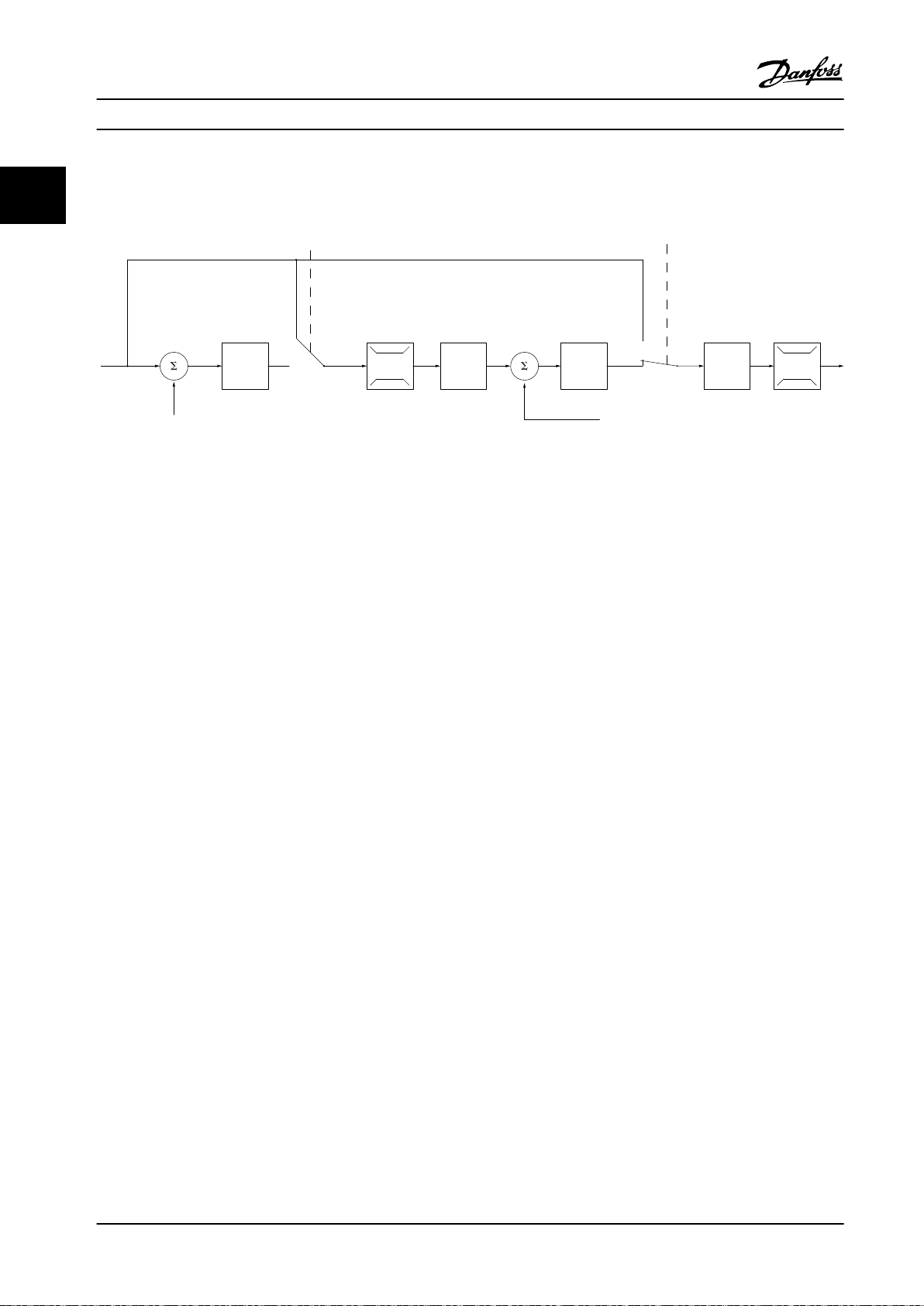

Figure 2.6 Control Structure in VVC+ Open-loop and Closed-loop Congurations

In the conguration shown in Figure 2.6, parameter 1-01 Motor Control Principle is set to [1] VVC+ and parameter 1-00 Congu-

ration Mode is set to [0] Speed open loop. The resulting reference from the reference handling system is received and fed

through the ramp limitation and speed limitation before being sent to the motor control. The output of the motor control is

then limited by the maximum frequency limit.

If parameter 1-00

and speed limitation into a speed PID control. The speed PID control parameters are in the parameter group 7-0* Speed PID

Ctrl. The resulting reference from the speed PID control is sent to the motor control limited by the frequency limit.

Select [3] Process in parameter 1-00 Conguration Mode to use the process PID control for closed-loop control of, for example,

speed or pressure in the controlled application. The process PID parameters are in parameter group 7-2* Process Ctrl. Feedb

and parameter group 7-3* Process PID Ctrl.

16 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Conguration Mode is set to [1] Speed closed loop, the resulting reference passes from the ramp limitation

Page 19

+

_

+

_

130BA053.11

Ref.

Cong. mode

P 1-00

P 7-20 Process feedback

1 source

P 7-22 Process feedback

2 source

Process

PID

P 4-11 Motor speed

low limit [RPM]

P 4-12 Motor speed

low limit [Hz]

P 4-14 Motor speed

high limit [Hz]

P 4-13 Motor speed

high limit [RPM]

Low

High

Ramp

P 3-**

+f max.

P 4-19

Max. output

freq.

Motor

controller

-f max.

Speed

PID

P 7-0*

Product Overview and Functi... Design Guide

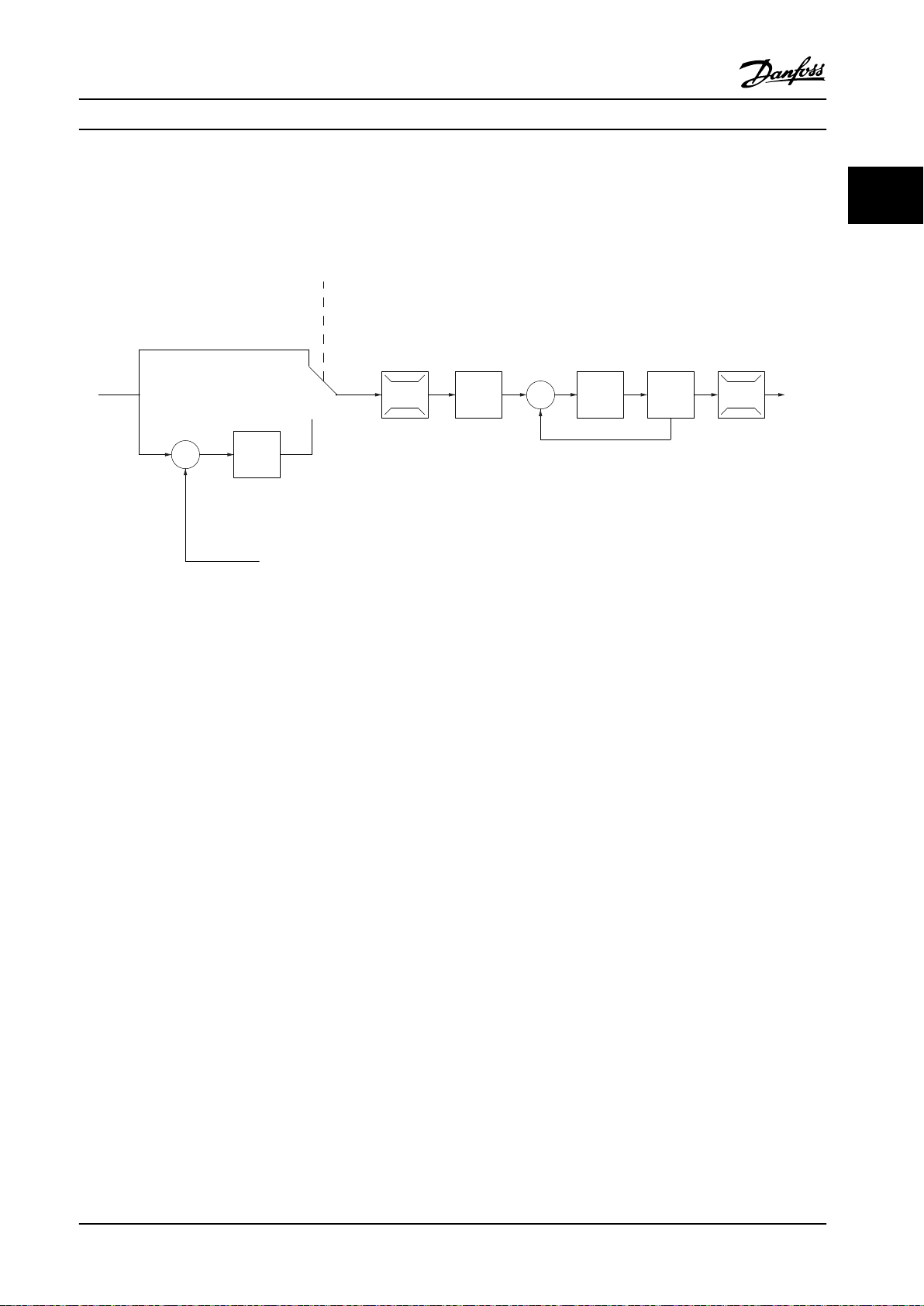

2.3.2 Control Structure in Flux Sensorless

Control structure in ux sensorless open-loop and closed-loop congurations.

2 2

Figure 2.7 Control Structure in Flux Sensorless

In the conguration shown, parameter 1-01 Motor Control Principle is set to [2] Flux Sensorless and parameter 1-00 Congu-

ration Mode is set to [0] Speed open loop. The resulting reference from the reference handling system is fed through the

ramp and speed limitations as determined by the parameter settings indicated.

An estimated speed feedback is generated to the speed PID to control the output frequency.

The speed PID must be set with its P, I, and D parameters (parameter group 7-0* Speed PID Ctrl.).

Select [3] Process in parameter 1-00 Conguration Mode to use the process PID control for closed-loop control of speed or

pressure in the controlled application. The process PID parameters are in parameter group 7-2* Process Ctrl. Feedb. and

parameter group7-3* Process PID Ctrl.

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 17

Page 20

130BA054.11

P 3-** P 7-0*P 7-2*

+

_

+

_

P 7-20 Process feedback

1 source

P 7-22 Process feedback

2 source

P 4-11 Motor speed

low limit (RPM)

P 4-12 Motor speed

low limit (Hz)

P 4-13 Motor speed

high limit (RPM)

P 4-14 Motor speed

high limit (Hz)

High

Low

Ref.

Process

PID

Speed

PID

Ramp

P 7-00

PID source

Motor

controller

-f max.

+f max.

P 4-19

Max. output

freq.

P 1-00

Cong. mode

P 1-00

Cong. mode

Torque

Product Overview and Functi...

VLT® Decentral Drive FCD 302

2.3.3 Control Structure in Flux with Motor Feedback

22

Figure 2.8 Control Structure in Flux with Motor Feedback

In the conguration shown, parameter 1-01 Motor Control Principle is set to [3] Flux w motor feedb and parameter 1-00 Cong-

uration Mode is set to [1] Speed closed loop.

The motor control in this conguration relies on a feedback signal from an encoder mounted directly on the motor (set in

parameter 1-02 Flux Motor Feedback Source).

Select [1] Speed closed loop in parameter 1-00 Conguration Mode to use the resulting reference as an input for the speed

PID control. The speed PID control parameters are located in parameter group 7-0* Speed PID Ctrl.

Select [2] Torque in parameter 1-00 Conguration Mode to use the resulting reference directly as a torque reference. Torque

control can only be selected in the [3] Flux with motor feedback (parameter 1-01 Motor Control Principle) conguration. When

this mode has been selected, the reference uses the Nm unit. It requires no torque feedback, since the actual torque is

calculated based on the current measurement of the frequency converter.

Select [3] Process in parameter 1-00

Conguration Mode to use the process PID control for closed-loop control of a process

variable (for example, speed) in the controlled application.

18 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 21

130BP046.10

Hand

on

O

Auto

on

Reset

Remote

reference

Local

reference

(Auto On)

(Hand On)

Linked to hand/auto

Local

Remote

Reference

130BA245.12

LCP keys:

(Hand On), (O),

and (Auto On)

P 3-13 Reference Site

Product Overview and Functi... Design Guide

2.3.4 Local [Hand On] and Remote [Auto

On] Control

The frequency converter can be operated manually via the

local control panel (LCP) or remotely via analog and digital

inputs and eldbus. If allowed in parameter 0-40 [Hand on]

Key on LCP, parameter 0-41 [O] Key on LCP,

parameter 0-42 [Auto on] Key on LCP, and

parameter 0-43 [Reset] Key on LCP, it is possible to start and

stop the frequency converter via the LCP using the [Hand

On] and [O] keys. Alarms can be reset via the [Reset] key.

After pressing the [Hand On] key, the frequency converter

goes into hand-on mode and follows (as default) the local

reference that can be set using the navigation keys on the

LCP.

After pressing the [Auto On] key, the frequency converter

goes into auto-on mode and follows (as default) the

remote reference. In this mode, it is possible to control the

frequency converter via the digital inputs and various serial

interfaces (RS485, USB, or an optional

about starting, stopping, changing ramps, parameter setups, and so on, in parameter group 5-1* Digital Inputs or

parameter group 8-5* Digital/Bus.

eldbus). See more

Active reference and conguration mode

The active reference can be either the local reference or

the remote reference.

In parameter 3-13 Reference Site, the local reference can be

permanently selected by selecting [2] Local.

For permanent setting of the remote reference, select [1]

Remote. By selecting [0] Linked to Hand/Auto (default), the

reference site links to the active mode (hand-on mode or

auto-on Mode).

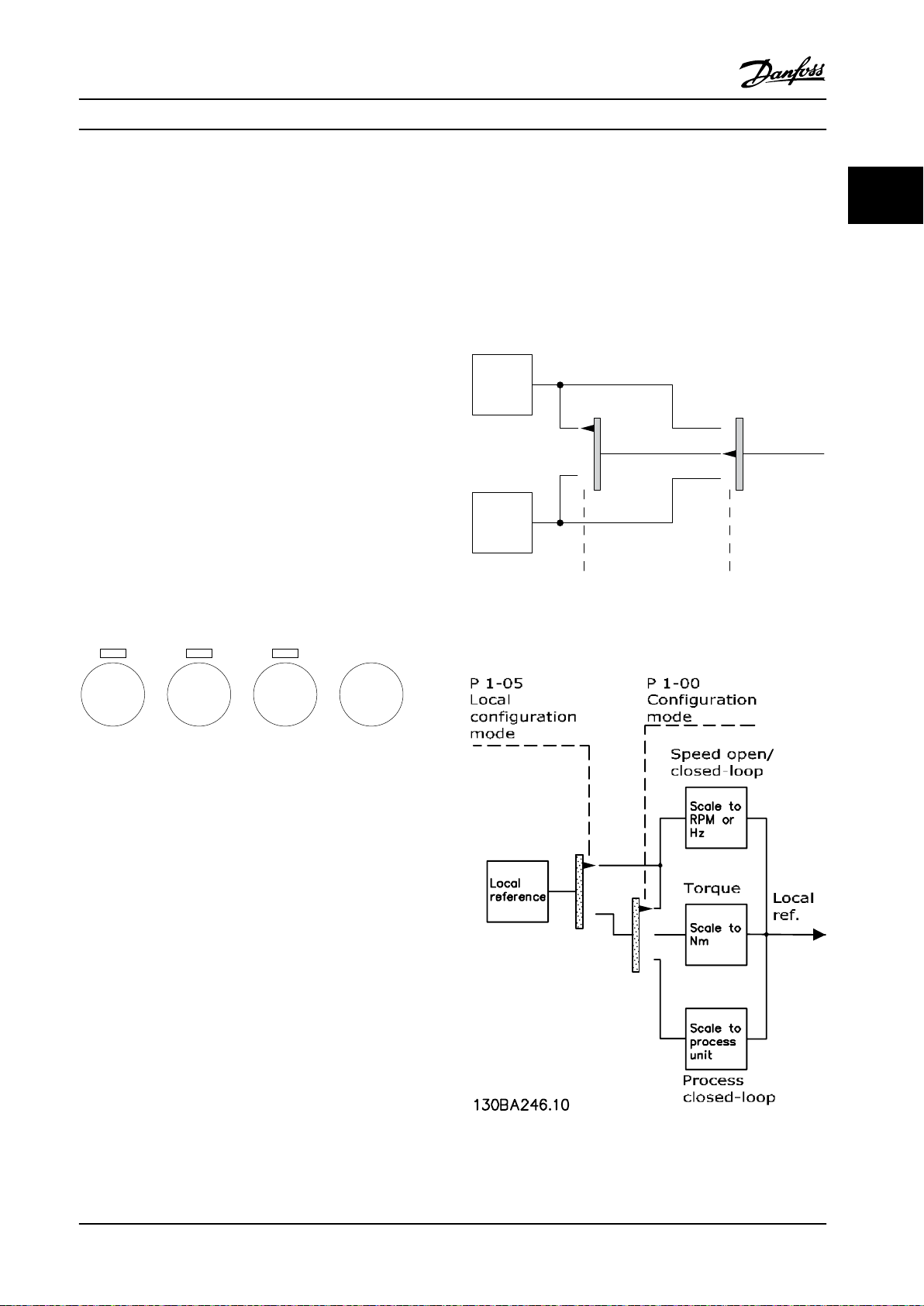

Figure 2.10 Local Handling of Reference

2 2

Figure 2.9 LCP Keys

Figure 2.11 Remote Handling of Reference

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 19

Page 22

130BC997.10

P 5-40 [0] [32]

-

+

01 02 03

24 VDC

I max

0.1 Amp

2 3

1

Product Overview and Functi...

VLT® Decentral Drive FCD 302

LCP keys Parameter 3-13 Reference Site Active reference

22

Hand Linked to Hand/Auto Local

Hand⇒O

Auto Linked to Hand/Auto Remote

Auto⇒O Linked to Hand/Auto Remote

All keys Local Local

All keys Remote Remote

Table 2.1 Conditions for Local/Remote Handling of Reference

Parameter 1-00

Linked to Hand/Auto Local

Conguration Mode determines what type

Parameter 5-02 Terminal 29 Mode [1] Terminal 29

Mode Output

Parameter 5-31 Terminal 29 digital Output [27]

Torque Limit & Stop

[0] Relay output (relay 1)

•

Parameter 5-40 Function Relay [32] Mechanical

Brake Control

of application control principle (that is, speed, torque, or

process control) is used when the remote reference is

active. Parameter 1-05 Local Mode Conguration determines

the type of application control principle that is used when

the local reference is active. One of them is always active,

but both cannot be active at the same time.

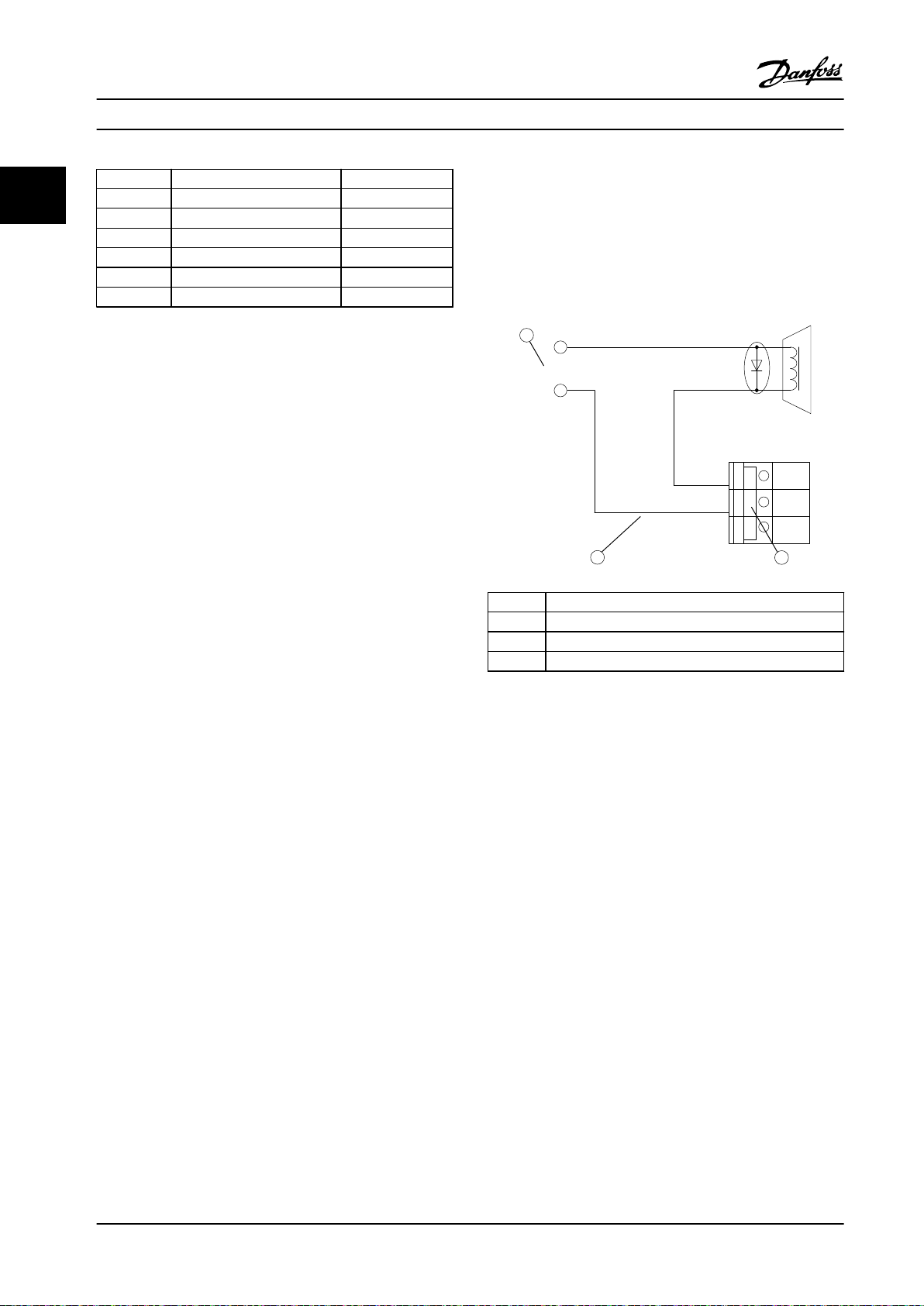

2.3.5 Programming of Torque Limit and

Stop

In applications with an external electro-mechanical brake,

such as hoisting applications, it is possible to stop the

frequency converter via a standard stop command and

simultaneously activate the external electro-mechanical

brake.

The example given below, illustrates the programming of

the frequency converter connections.

The external brake can be connected to relay 1 or 2.

Program parameter 5-01 Terminal 27 Mode to [2] Coast,

inverse or [3] Coast and Reset, inverse, and program

parameter 5-02 Terminal 29 Mode to [1] Output and [27]

Torque limit & stop.

Item Description

1 External 24 V DC

2 Mechanical brake connection

3 Relay 1

Figure 2.12 Mechanical Brake Control

Description

If a stop command is active via terminal 18, and the

frequency converter is not at the torque limit, the motor

ramps down to 0 Hz.

If the frequency converter is at the torque limit and a stop

command is activated, parameter 5-31 Terminal 29 digital

Output (programmed to [27] torque limit and stop) is

activated. The signal to terminal 27 changes from logic 1

to logic 0, and the motor starts to coast. The coast ensures

that the hoist stops even if the frequency converter itself

cannot handle the required torque (that is, due to

excessive overload).

Start/stop via terminal 18

•

•

•

20 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Parameter 5-10 Terminal 18 Digital Input [8] Start

Quick stop via terminal 27

Parameter 5-12 Terminal 27 Digital Input [2] Coast

Stop, inverse

Terminal 29 output

Page 23

Product Overview and Functi... Design Guide

2.4 PID Control

2.4.1 Speed PID Control

2 2

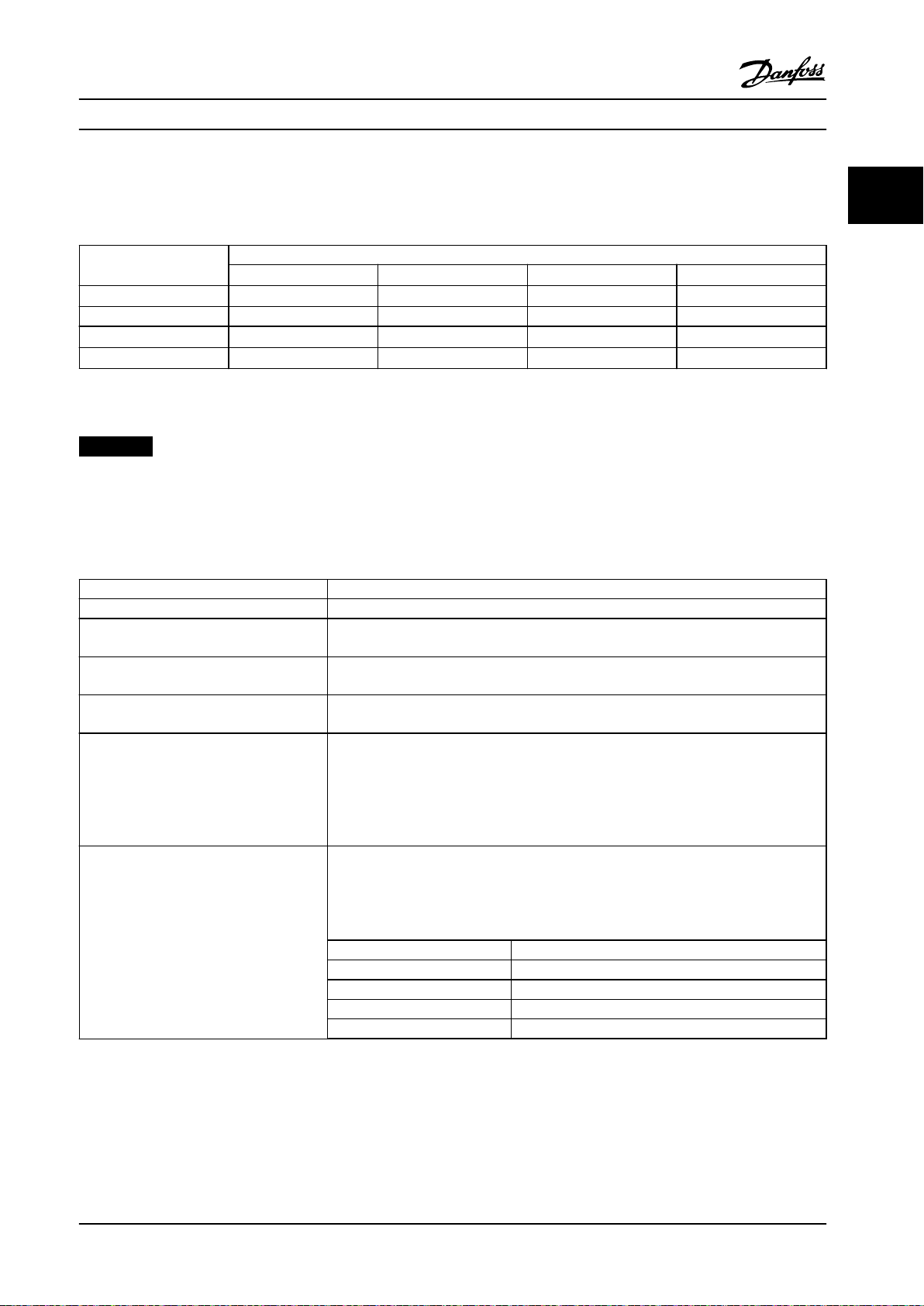

Parameter 1-00 Congu-

ration Mode

[0] Speed open loop

[1] Speed closed loop – Active – Active

[2] Torque – – –

[3] Process –

Table 2.2 Control Congurations where the Speed Control is Active

1) “Not active” means that the specic mode is available, but the speed control is not active in that mode.

Parameter 1-01 Motor Control Principle

U/f

Not active

1)

+

VVC

Not active

Not active

Flux sensorless Flux w/ encoder feedback

1)

1)

Active –

Not active

Active Active

1)

NOTICE!

The speed PID control works under the default parameter setting, but tuning the parameters is highly recommended to

optimize the motor control performance. The 2 ux motor control principles are particularly dependent on proper

tuning to yield their full potential.

2.4.2 Parameters Relevant for Speed Control

Parameter Description of function

Parameter 7-00 Speed PID Feedback Source Select from which input the speed PID should get its feedback.

Parameter 30-83 Speed PID Proportional Gain The higher the value - the quicker the control. However, too high value may lead to

oscillations.

Parameter 7-03 Speed PID Integral Time Eliminates steady state speed error. Lower value means quick reaction. However, too low

value may lead to oscillations.

Parameter 7-04 Speed PID Dierentiation Time Provides a gain proportional to the rate of change of the feedback. A setting of 0 disables

the dierentiator.

Parameter 7-05 Speed PID Di. Gain Limit If there are quick changes in reference or feedback in a given application, which means

that the error changes swiftly, the dierentiator may soon become too dominant. This is

because it reacts to changes in the error. The quicker the error changes, the stronger the

dierentiator gain is. The dierentiator gain can thus be limited to allow setting of the

reasonable dierentiation time for slow changes and a suitably quick gain for quick

changes.

Parameter 7-06 Speed PID Lowpass Filter Time A low-pass lter that dampens oscillations on the feedback signal and improves steady

state performance. However, too large lter time deteriorates the dynamic performance of

the speed PID control.

Practical settings of parameter 7-06 Speed PID Lowpass Filter Time taken from the number of

pulses per revolution from encoder (PPR):

Encoder PPR Parameter 7-06 Speed PID Lowpass Filter Time

512 10 ms

1024 5 ms

2048 2 ms

4096 1 ms

Table 2.3 Parameters Relevant for Speed Control

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 21

Page 24

M

3

96 97 9998

91 92 93 95

50

12

L1 L2L1PEL3

W PEVU

F1

L2

L3

N

PE

18

53

37

55

20

32

33

39

24 Vdc

130BA174.10

Product Overview and Functi...

VLT® Decentral Drive FCD 302

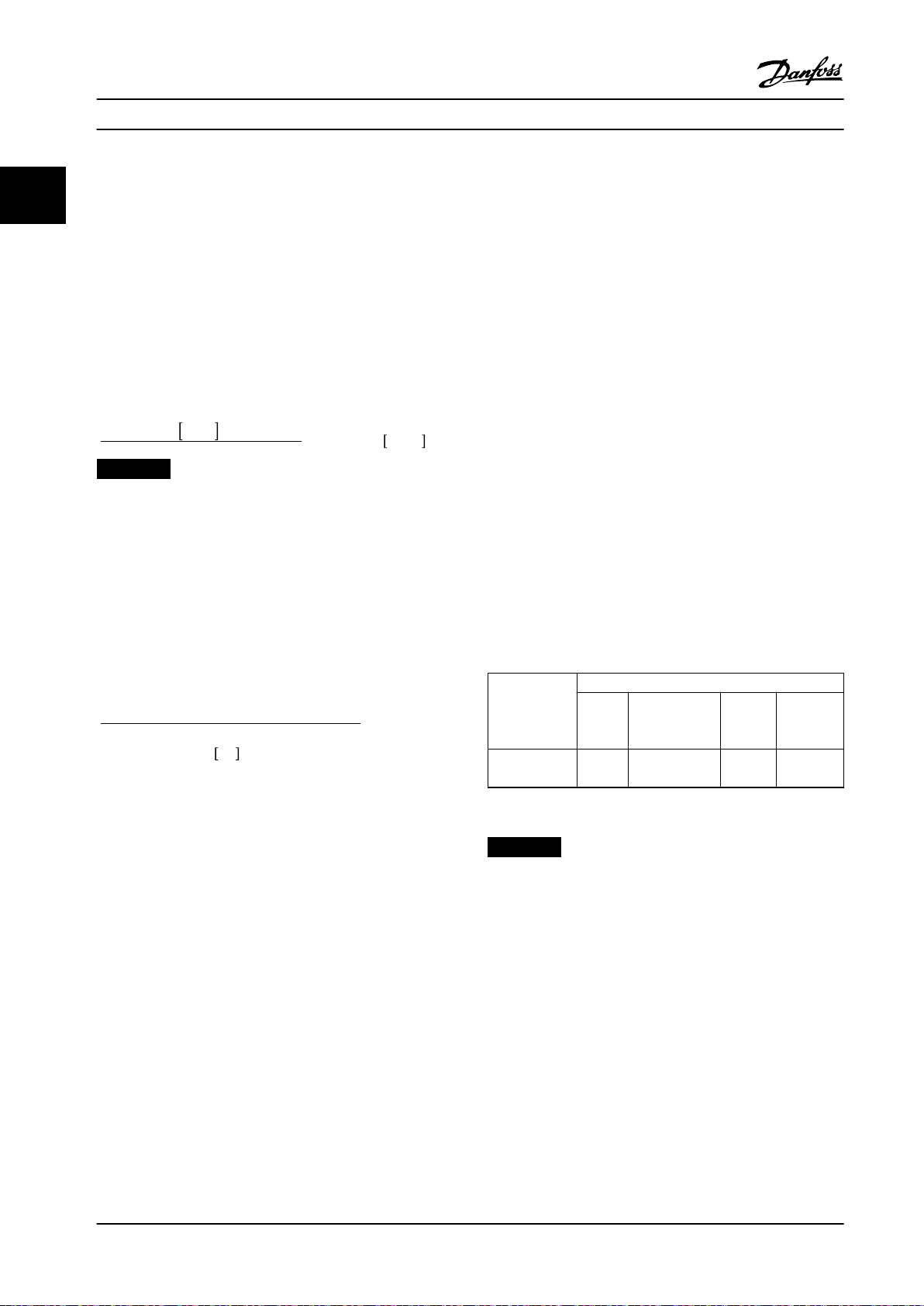

Example of how to program the speed control

22

In this case, the speed PID control is used to maintain a constant motor speed regardless of the changing load on the

motor. The required motor speed is set via a potentiometer connected to terminal 53. The speed range is 0–1500 RPM

corresponding to 0–10 V over the potentiometer. Starting and stopping is controlled by a switch connected to terminal 18.

The speed PID monitors the actual RPM of the motor by using a 24 V (HTL) incremental encoder as feedback. The feedback

sensor is an encoder (1024 pulses per revolution) connected to terminals 32 and 33.

Figure 2.13 Example - Speed Control Connections

The following must be programmed in the order shown (see explanation of settings in the

301/FC 302 Programming Guide)

In the list, it is assumed that all other parameters and switches remain at their default setting.

Function Parameter Setting

1) Make sure that the motor runs properly. Do the following:

Set the motor parameters using nameplate data. Parameter group 1-2*

Motor Data

Perform an automatic motor adaptation. Parameter 1-29 Auto

matic Motor

Adaptation (AMA)

2) Check that the motor is running and that the encoder is attached properly. Do the following:

Press the [Hand On] LCP key. Check that the motor is

– Set a positive reference.

running and note in which direction it is turning

(referred to as the positive direction).

Go to parameter 16-20 Motor Angle. Turn the motor

slowly in the positive direction. It must be turned so

slowly (only a few RPM) that it can be determined if the

value in parameter 16-20 Motor Angle is increasing or

decreasing.

Parameter 16-20 Moto

r Angle

As specied on motor nameplate.

[1] Enable complete AMA.

(Read-only parameter) Note: An increasing value

overows at 65535 and starts again at 0.

VLT® AutomationDrive FC

22 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 25

Product Overview and Functi... Design Guide

Function Parameter Setting

If parameter 16-20 Motor Angle is decreasing, then

change the encoder direction in parameter 5-71 Term

32/33 Encoder Direction.

3) Make sure that the frequency converter limits are set to safe values.

Set acceptable limits for the references. Parameter 3-02 Minim

Check that the ramp settings are within frequency

converter capabilities and allowed application operating

specications.

Set acceptable limits for the motor speed and frequency. Parameter 4-11 Motor

4) Congure the speed control and select the motor control principle.

Activation of speed control. Parameter 1-00 Cong

Selection of motor control principle. Parameter 1-01 Motor

5) Congure and scale the reference to the speed control.

Set up analog input 53 as a reference source. Parameter 3-15 Refere

Scale analog input 53 from 0 RPM (0 V ) to 1500 RPM

(10 V).

6) Congure the 24 V HTL encoder signal as feedback for the motor control and the speed control.

Set up digital input 32 and 33 as encoder inputs. Parameter 5-14 Termi

Select terminal 32/33 as motor feedback. Parameter 1-02 Flux

Select terminal 32/33 as speed PID feedback. Parameter 7-00 Speed

7) Tune the speed control PID parameters.

Use the tuning guidelines when relevant or tune

manually.

8) Finished.

Save the parameter setting to the LCP for safe keeping. Parameter 0-50 LCP

Parameter 5-71 Term

32/33 Encoder

Direction

um Reference

Parameter 3-03 Maxi

mum Reference

Parameter 3-41 Ramp

1 Ramp-up Time

Parameter 3-42 Ramp

1 Ramp-down Time

Speed Low Limit

[RPM]

Parameter 4-13 Motor

Speed High Limit

[RPM]

Parameter 4-19 Max

Output Frequency

uration Mode

Control Principle

nce Resource 1

Parameter group 6-1*

Analog Input 1

nal 32 Digital Input

Parameter 5-15 Termi

nal 33 Digital Input

Motor Feedback

Source

PID Feedback Source

Parameter group 7-0*

Speed PID Ctrl.

Copy

[1] Counterclockwise (if parameter 16-20 Motor Angle is

decreasing).

0 RPM (default).

1500 RPM (default).

Default setting.

Default setting.

0 RPM (default).

1500 RPM (default).

60 Hz (default 132 Hz).

[1] Speed closed loop.

[3] Flux w motor feedb.

Not necessary (default).

Not necessary (default).

[0] No operation (default).

Not necessary (default).

Not necessary (default).

See the guidelines in chapter 2.4.3 Tuning PID Speed

Control.

[1] All to LCP.

2 2

Table 2.4 Speed Control Settings

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 23

Page 26

Product Overview and Functi...

VLT® Decentral Drive FCD 302

2.4.3 Tuning PID Speed Control

22

The following tuning guidelines are relevant when using 1

of the ux motor control principles in applications where

the load is mainly inertial (with a low amount of friction).

The value of parameter 30-83 Speed PID Proportional Gain

depends on the combined inertia of the motor and load,

and the selected bandwidth can be calculated using the

following formula:

Par . 7 − 02 =

Totalinertia k gm2xpar . 1 − 25

Par . 1 − 20x 9550

xBandwidth

NOTICE!

Parameter 1-20 Motor Power [kW] is the motor power in

[kW] (that is, enter 4 kW instead of 4000 W in the

formula).

A practical value for the bandwidth is 20 rad/s. Check the

result of the Parameter 30-83 Speed PID Proportional Gain

calculation against the following formula (not required

when using high-resolution feedback such as a SinCos

feedback):

rad/ s

other factors in the application might limit the

parameter 30-83 Speed PID Proportional Gain to a lower

value.

To minimize the overshoot, parameter 7-03 Speed PID

Integral Time could be set to approximately 2.5 s (varies

with the application).

Parameter 7-04 Speed PID

to 0 until everything else is tuned. If necessary, nish the

tuning by experimenting with small increments of this

setting.

Dierentiation Time should be set

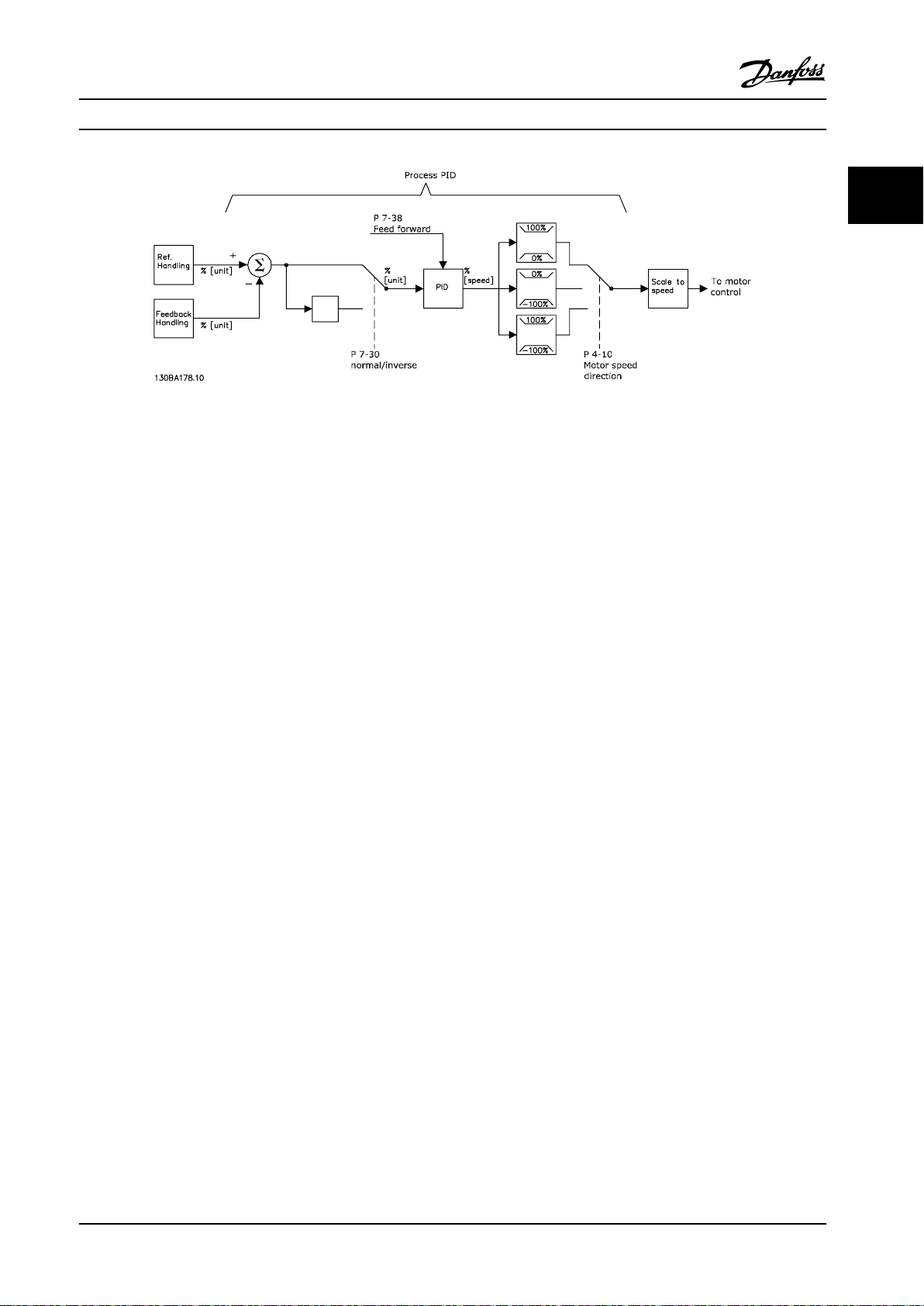

2.4.4 Process PID Control

The process PID Control can be used to control application

parameters that can be measured by a sensor (that is,

pressure, temperature, ow) and be aected by the

connected motor through a pump, fan, or otherwise.

Table 2.5 shows the control congurations where the

process control is possible. When a ux vector motor

control principle is used, take care also to tune the speed

control PID parameters. To see where the speed control is

active, refer to chapter 2.3 Control Structures.

Par . 7 − 02

0 . 01x4xEncoderResolutionxPar . 7 − 06

xMaxtorqueripple %

A good start value for parameter 7-06 Speed PID Lowpass

Filter Time is 5 ms (lower encoder resolution calls for a

higher lter value). Typically, a maximum torque ripple of

3% is acceptable. For incremental encoders, the encoder

resolution is found in either parameter 5-70 Term 32/33

Pulses per Revolution (24 V HTL on standard frequency

converter) or parameter 17-11 Resolution (PPR) (5 V TTL on

VLT® Encoder Input MCB 102 option).

Generally, the practical maximum limit of

parameter 30-83 Speed PID Proportional Gain is determined

by the encoder resolution and the feedback lter time. But

MAX

=

2xπ

Parameter 1-00

Conguration

Mode

[3] Process – Process Process

Table 2.5 Process PID Control Settings

Parameter 1-01 Motor Control Principle

U/f

VVC

+

Flux

sensorles

s

& speed

Flux with

encoder

feedback

Process &

speed

NOTICE!

The process PID control works under the default

parameter setting, but tuning the parameters is highly

recommended to optimize the application control

performance. The 2 ux motor control principles are

specially dependent on proper speed control PID tuning

(before tuning the process control PID) to yield their full

potential.

24 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 27

Product Overview and Functi... Design Guide

Figure 2.14 Process PID Control Diagram

2 2

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 25

Page 28

Product Overview and Functi...

VLT® Decentral Drive FCD 302

2.4.5 Process Control Relevant Parameters

22

Parameter Description of function

Parameter 7-20 Process CL Feedback 1 Resource Select from which source (that is, analog or pulse input) the process PID should get its

feedback.

Parameter 7-22 Process CL Feedback 2 Resource Optional: Determine if (and from where) the process PID should get an additional

feedback signal. If an additional feedback source is selected, the 2 feedback signals are

added before being used in the process PID control.

Parameter 7-30 Process PID Normal/Inverse

Control

Parameter 7-31 Process PID Anti Windup The anti-wind-up function ensures that when either a frequency limit or a torque limit is

Parameter 7-32 Process PID Controller Start

Value

Parameter 7-33 Process PID Proportional Gain The higher the value - the quicker the control. However, too large value may lead to

Parameter 7-34 Process PID Integral Time Eliminates steady state speed error. Lower value means quick reaction. However, too small

Parameter 7-35 Process PID Dierentiation Time Provides a gain proportional to the rate of change of the feedback. A setting of 0 disables

Parameter 7-36 Process PID Dierentiation Gain

Limit

Parameter 7-38 Process PID Feed Forward

Factor

Parameter 5-54 Pulse Filter Time Constant #29

(Pulse term. 29), parameter 5-59 Pulse Filter

Time Constant #33 (Pulse term. 33),

parameter 6-16 Terminal 53 Filter Time

Constant (Analog term 53),

parameter 6-26 Terminal 54 Filter Time

Constant (Analog term. 54)

Under [0] Normal operation, the process control responds with an increase of the motor

speed if the feedback is getting lower than the reference. In the same situation, but under

[1] Inverse operation, the process control responds with a decreasing motor speed instead.

reached, the integrator is set to a gain that corresponds to the actual frequency. This

avoids integrating on an error that cannot in any case be compensated for with a speed

change. This function can be disabled by selecting [0] O.

In some applications, reaching the required speed/set point can take long time. In such

applications, it might be an advantage to set a xed motor speed from the frequency

converter before the process control is activated. This is done by setting a process PID

start value (speed) in parameter 7-32 Process PID Controller Start Value.

oscillations.

value may lead to oscillations.

the dierentiator.

If there are quick changes in reference or feedback in a given application - which means

that the error changes swiftly - the dierentiator may soon become too dominant. This is

because it reacts to changes in the error. The quicker the error changes, the stronger the

dierentiator gain is. The dierentiator gain can thus be limited to allow setting of the

reasonable dierentiation time for slow changes.

In applications where there is a good (and approximately linear) correlation between the

process reference and the motor speed necessary for obtaining that reference, the feed

forward factor can be used to achieve better dynamic performance of the process PID

control.

If there are oscillations of the current/voltage feedback signal, these can be dampened

with a low-pass lter. This time constant shows the speed limit of the ripples occurring on

the feedback signal.

Example: If the low-pass lter has been set to 0.1 s, the limit speed is 10 RAD/s (the

reciprocal of 0.1 s), corresponding to (10/(2 x π))=1.6 Hz. This means that all currents/

voltages that vary by more than 1.6 oscillations per second are dampened by the lter.

The control is only carried out on a feedback signal that varies by a frequency (speed) of

less than 1.6 Hz.

The low-pass lter improves steady state performance but selecting a too large lter time

deteriorates the dynamic performance of the process PID control.

Table 2.6 Parameters are Relevant for the Process Control

26 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 29

130BC966.10

5

6

1

100kW

n °CW

2

3

4

ON

WARNING

ALARM

Bus MS NS2NS1

Product Overview and Functi... Design Guide

2.4.6 Example of Process PID Control

Figure 2.15 is an example of a process PID control used in a

ventilation system.

Item Description

1 Cold air

2 Heat generating process

3 Temperature transmitter

4 Temperature

5 Fan speed

6 Heat

2 2

Figure 2.16 Two-wire Transmitter

Figure 2.15 Process PID Control in Ventilation System

1. Start/stop via a switch connected to terminal 18.

In a ventilation system, the temperature is to be settable

from -5 to +35 °C (23–95 °F) with a potentiometer of 0–

10 V. The task of the process control is to maintain

temperature at a constant preset level.

2. Temperature reference via potentiometer (-5 to

35 °C (23–95 °F), 0–10 V DC) connected to

terminal 53.

3. Temperature feedback via transmitter (-10 to

40 °C (14–104 °F), 4–20 mA) connected to

The control is of the inverse type, which means that when

the temperature increases, the ventilation speed is

terminal 54. Switch S202 set to ON (current

input).

increased as well, to generate more air. When the

temperature drops, the speed is reduced. The transmitter

used is a temperature sensor with a working range of -10

to +40 °C (14–104 °F), 4–20 mA. Minimum/maximum

speed 300/1500 RPM.

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 27

Page 30

Product Overview and Functi...

VLT® Decentral Drive FCD 302

2.4.7 Programming Order

22

Function Parameter Setting

Initialize the frequency converter. Parameter 14-22

Operation Mode

1) Set motor parameters.

Set the motor parameters according to nameplate

data.

Perform a full AMA. Parameter 1-29 Au

2) Check that motor is running in the right direction.

When the motor is connected to the frequency converter with straight forward phase order as U - U; V- V; W - W, the motor shaft usually

turns clockwise seen into shaft end.

Press [Hand On] LCP key. Check shaft direction by applying a manual reference.

If the motor turns opposite of the required

direction:

1. Change motor direction in

parameter 4-10 Motor Speed Direction.

2. Turn o mains - wait for DC link to discharge -

switch 2 of the motor phases.

Set conguration mode. Parameter 1-00 Co

Set local mode conguration Parameter 1-05 Lo

3) Set reference conguration, that is, the range for handling of reference. Set scaling of analog input in parameter group 6-** Analog

In/Out.

Set reference/feedback units.

•

Set minimum reference (10 °C (50 °F)).

•

Set maximum reference (80 °C (176 °F)).

•

If set value is determined from a preset value

(array parameter), set other reference sources to

no function.

4) Adjust limits for the frequency converter:

Set ramp times to an appropriate value as 20 s. Parameter 3-41 Ra

Parameter group

1-2* Motor Data

tomatic Motor

Adaptation (AMA)

Parameter 4-10 M

otor Speed

Direction

nguration Mode

cal Mode Congu-

ration

Parameter 3-01 Re

ference/Feedback

Unit

Parameter 3-02 Mi

nimum Reference

Parameter 3-03 M

aximum Reference

Parameter 3-10 Pr

eset Reference

mp 1 Ramp-up

Time

Parameter 3-42 Ra

mp 1 Ramp- down

Time

[2] Initialization - make a power-cycle - press reset.

As stated on motor nameplate.

[1] Enable complete AMA.

Select correct motor shaft direction.

[3] Process.

[0] Speed Open Loop.

[60] °C Unit shown on display.

-5 °C.

35 °C.

[0] 35%.

Par . 3 − 10

Ref =

Parameter 3-14 Preset Relative Reference to parameter 3-18 Relative

Scaling Reference Resource, [0] = No function

20 s.

20 s.

100

0

× Par . 3 − 03 − par . 3 − 02 = 24, 5°C

28 Danfoss A/S © 05/2018 All rights reserved. MG04H322

Page 31

Product Overview and Functi... Design Guide

Function Parameter Setting

Set minimum speed limits.

•

Set motor speed maximum limit.

•

Set maximum output frequency.

•

Set S201 or S202 to wanted analog input function (Voltage (V) or milliamps (I))

Parameter 4-11 M

otor Speed Low

Limit [RPM]

Parameter 4-13 M

otor Speed High

Limit [RPM]

Parameter 4-19 M

ax Output

Frequency

300 RPM.

1500 RPM.

60 Hz.

NOTICE!

Switches are sensitive - Make a power-cycle keeping the default setting of V.

5) Scale analog inputs used for reference and feedback.

Set terminal 53 low voltage.

•

Set terminal 53 high voltage.

•

Set terminal 54 low feedback value.

•

Set terminal 54 high feedback value.

•

Set feedback source.

•

6) Basic PID settings.

Process PID normal/inverse. Parameter 7-30 Pr

Process PID anti-wind-up. Parameter 7-31 Pr

Process PID start speed. Parameter 7-32 Pr

Save parameters to LCP. Parameter 0-50 LC

Parameter 6-10 Te

rminal 53 Low

Voltage

Parameter 6-11 Te

rminal 53 High

Voltage

Parameter 6-24 Te

rminal 54 Low

Ref./Feedb. Value

Parameter 6-25 Te

rminal 54 High

Ref./Feedb. Value

Parameter 7-20 Pr

ocess CL Feedback

1 Resource

ocess PID Normal/

Inverse Control

ocess PID Anti

Windup

ocess PID

Controller Start

Value

P Copy

0 V.

10 V.

-5 °C.

35 °C.

[2] Analog input 54.

[0] Normal.

[1] On.

300 RPM.

[1] All to LCP.

2 2

Table 2.7 Example of Process PID Control Set-up

MG04H322 Danfoss A/S © 05/2018 All rights reserved. 29

Page 32

130BA183.10

y(t)

t

P

u

Product Overview and Functi...

VLT® Decentral Drive FCD 302

2.4.8 Process Controller Optimization

2.4.9 Ziegler Nichols Tuning Method

22

The basic settings have now been made. All that needs to

be done is to optimize the proportional gain, the

integration time, and the dierentiation time

(parameter 7-33 Process PID Proportional Gain,

parameter 7-34 Process PID Integral Time,

parameter 7-35 Process PID Dierentiation Time). In most

processes, this can be done by following these guidelines:

1. Start the motor.

2. Set parameter 7-33 Process PID Proportional Gain

to 0.3 and increase it until the feedback signal

again begins to vary continuously. Then reduce

the value until the feedback signal has stabilized.

Now lower the proportional gain by 40–60%.

3. Set parameter 7-34 Process PID Integral Time to

20 s and reduce the value until the feedback

signal again begins to vary continuously. Increase

the integration time until the feedback signal

stabilizes, followed by an increase of 15–50%.

4. Only use parameter 7-35 Process PID

Time for very fast-acting systems only (dieren-

tiation time). The typical value is 4 times the set

integration time. The dierentiator should only be

used when the setting of the proportional gain

and the integration time has been fully

optimized. Make sure that oscillations on the

feedback signal are suciently dampened by the

lowpass lter on the feedback signal.

Dierentiation

NOTICE!

If necessary, start/stop can be activated several times to

provoke a variation of the feedback signal.

To tune the PID controls of the frequency converter,

Danfoss recommends the Ziegler Nichols tuning method.

NOTICE!

Do not use the Ziegler Nichols Tuning method in

applications that could be damaged by the oscillations

created by marginally stable control settings.

The criteria for adjusting the parameters are based on

evaluating the system at the limit of stability rather than

on taking a step response. Increase the proportional gain

until observing continuous oscillations (as measured on

the feedback), that is, until the system becomes marginally

stable. The corresponding gain (Ku) is called the ultimate

gain and is the gain, at which the oscillation is obtained.

The period of the oscillation (Pu) (called the ultimate

period) is determined as shown in Figure 2.17 and should

be measured when the amplitude of oscillation is small.

1. Select only proportional control, meaning that

the integral time is set to the maximum value,

while the dierentiation time is set to 0.

2. Increase the value of the proportional gain until

the point of instability is reached (sustained

oscillations) and the critical value of gain, Ku, is

reached.

3. Measure the period of oscillation to obtain the

critical time constant, Pu.

4. Use Table 2.8 to calculate the necessary PID