Page 1

VLT® Decentral Drive FCD 302

The VLT® Decentral Drive FCD 302 is the new generation of the VLT® Decentral Drive FCD 300, based on the

VLT® AutomationDrive FC 302 platform. Combining the key features of both products in a completely

re-designed enclosure, the drive is made for the best t for direct machine mounting.

IP 66

enclosure for conveyor

applications, installations

in wash-down areas

or widely distributed

applications with a large

number of drives

Designed for simplicity and robustness the new VLT® Decentral Drive

FCD 302 is a user-friendly product

with high performance and strong

protection degree.

Decentral drives are meant for

decentral mounting, eliminating the

need for space-consuming control

cabinets. With the drives placed near

the motor, there is no need for long

screened motor cables.

One-box concept

All options are built into the unit,

reducing the number of boxes

Feature Benet

Reliable Maximum uptime

Pluggable twin-part design

(installation box and electronic part)

Integrated lockable service switch available Local disconnection possible

User-friendly Saves commissioning and operation cost

Smooth surface Easy cleaning; no dirt trap

Adapts to any brand of motor and

geared motor, induction as well as

permanent magnet motors

Integrated power and eldbus

looping terminals

Visible LEDs Quick status check

Set-up and control through pluggable control

panel, eldbus communication and set-up

software VLT® Motion Control Tool MCT 10

Awarded control panel with on-board manual

(accessory)

Screwless spring-loaded terminals Easy and fast connection

Integrated USB port Direct connection to PC

Intelligent Built-in feature

Smart Logic Control Reduces need for PLC capacity

Safe Torque O (Safe Stop) as standard Reduces the need for extra components

Intelligent warning systems Warning before controlled stop

to be mounted, connections and

terminations in the installation. Consequently labor costs for mounting

and risk of failures are dramatically

reduced.

Power range

0.37 – 3 kW, 3 x 380 – 480 V

Enclosure

n IP 66 standard black

n IP 66 standard white

n IP 66 hygienic white

(all enclosures are rated as NEMA 4X)

Easy and fast service

Easy and exible installation

Cable savings

Easy commissioning

Easy operation

Facts about our products

Page 2

Integrated 24 V supply

24 V DC control supply is provided

by the drive. Separate supply terminals have been made for remote I/Os

distribution.

Power looping

The new FCD 302 facilitates internal

power looping. Terminals for 6 mm

2

(big box) or 4 mm2 (small box) power

cable inside the enclosure allows

connection of multiple units in the

same branch.

Ethernet switch

Integrated Ethernet switch/ hub with

the two RJ-45 ports are available in

the drive for easy daisy-chaining of

Ethernet communication. Fieldbuses

are routed easily, without adding

commissioning time, by connecting

Ethernet or Probus based eldbuses

to a M12 pluggable interface.

Safety

The VLT® Decentral Drive FCD 302

is delivered as standard with the

Safe Torque O (Safe Stop) function

in compliance with EN ISO 13849-1

Category 3 PL d and SIL 2 according

to IEC 61508 low demand and high

demand mode.

Fieldbus options

(integrated into the control card)

n PROFIBUS DP

n PROFINET

n EtherNet/IP

n Et h erC AT

n POWERLINK

Application options

n VLT® Encoder Input MCB 102

n VLT® Resolver Input MCB 103

n VLT® Safe PLC I/O MCB 108

Specications

Mains supply (L1, L2, L3)

Supply voltage 380 – 480 V ±10%

Supply frequency 50/60 Hz

True Power Factor (λ) 0.92 nominal at rated load

Displacement Power Factor (cos ф) (>0.98)

Switching on input supply 2 times/min.

Output data (U, V, W)

Output voltage 0 – 100% of supply

Output frequency

Switching on output Unlimited

Ramp times 0.01 – 3600 sec.

Digital inputs

Programmable digital inputs 4 (6)

Logic PNP or NPN

Voltage level 0 – 24 V DC

Note: One/two digital inputs can be programmed as digital output

Analogue inputs

Number of analogue inputs 2

Modes Voltage or current

Voltage level -10 to +10 V (scaleable)

Current level 0/4 – 20 mA (scaleable)

Pulse/encoder inputs

Programmable pulse/encoder inputs 2

Voltage level 0 – 24 V DC (PNP positive logic)

Digital output

Programmable digital/pulse outputs 2

Voltage level at digital/frequency output 0 – 24 V

Analogue output

Programmable analogue outputs 1

Current range 0/4 – 20 mA

Relay outputs

Programmable relay outputs 2

Integrated 24 V supply

Max. load 600 mA

0 – 590 Hz

0 – 300 Hz (Flux mode)

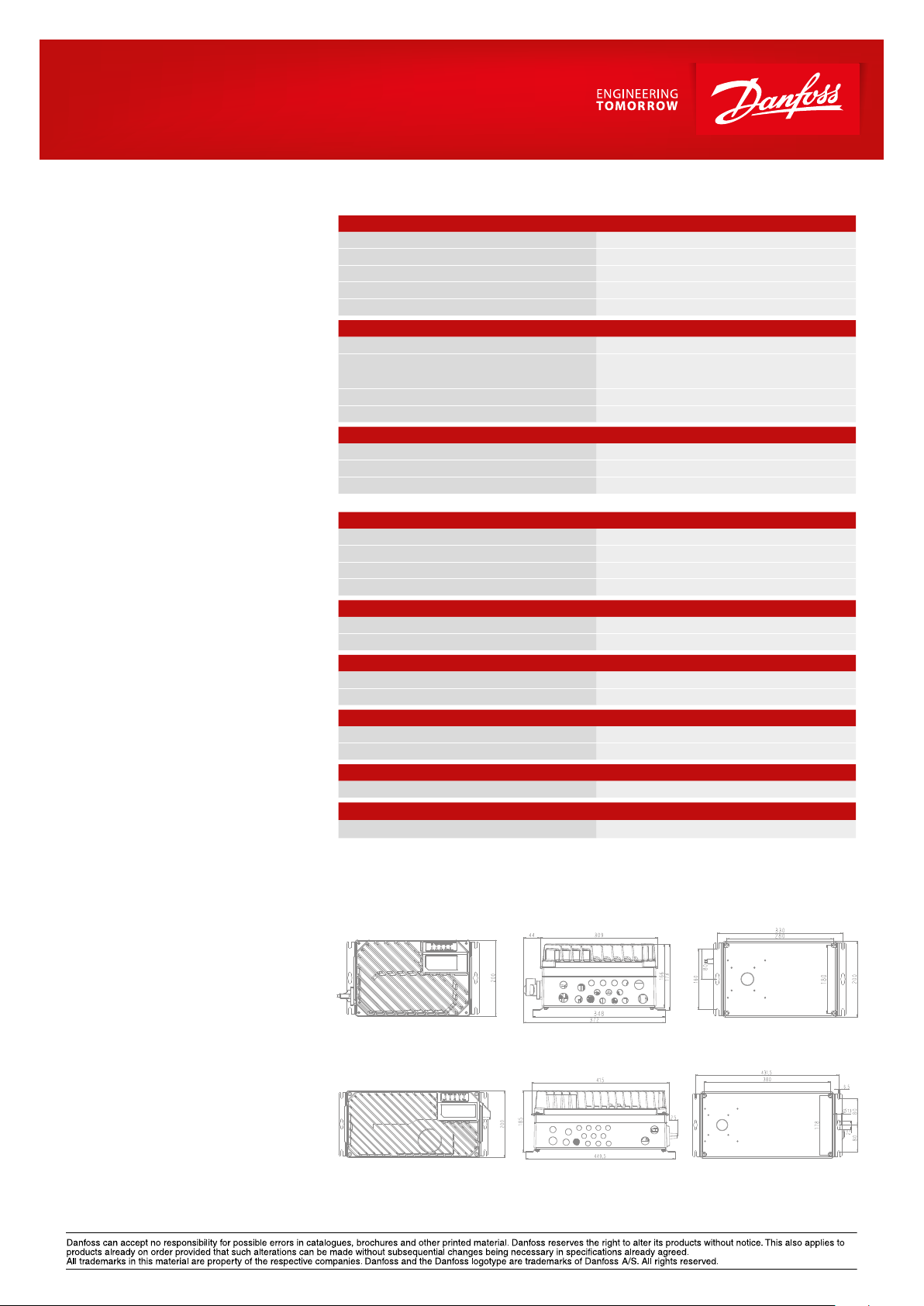

Dimensions

Small frame

(0.37 – 2.2 kW/0.5 – 3.0 HP)

Hardware options

n Mounting brackets

n Service switch

n Internal circuit breaker

n M12 sensor plugs

n 24 V DC input for control supply

n Brake chopper

n Electromechanical brake control

Large frame

(0.37 – 3 kW/0.5 – 4.0 HP)

and supply

n Fieldbus plugs

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80

www.danfoss.com/drives • E-mail: info@danfoss.com

DKDD.PFP.750.A4.02 VLT® is a trademark of Danfoss A/S Produced by PE-MMSC 2014.09

All measurements are in mm

Loading...

Loading...