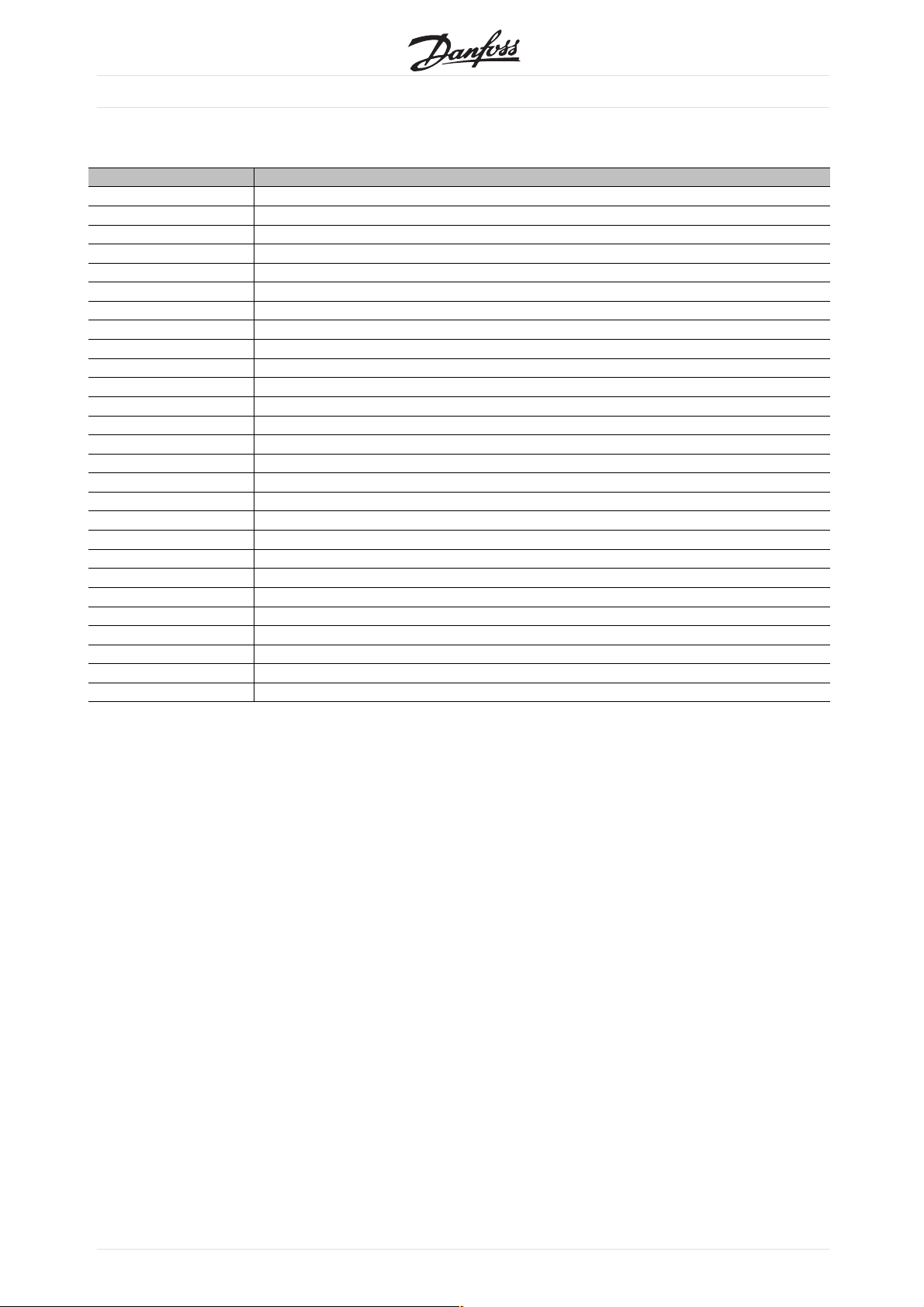

Contents

■

VLT®2800 / FCD 300 DeviceNet

Introd

Technical Data

uction

About this manual .................................................................................................. 3

Assumptions .......................................................................................................... 3

What yo

Available literature .................................................................................................. 4

Supplied with the unit ............................................................................................ 4

Produc

Network ................................................................................................................. 5

User Profile ............................................................................................................ 5

Interfa

Data Communication Interface ............................................................................... 5

Overall Function ..................................................................................................... 5

Control

Cable Le

Topology ................................................................................................................ 6

Cable Specifications ............................................................................................... 6

Network

Cable Cross Section .............................................................................................. 6

EMC Precautions ................................................................................................... 7

VLT Respo

u should already know .............................................................................. 3

t and Environment ...................................................................................... 5

ce to DeviceNet Network ............................................................................. 5

Card Self-test ............................................................................................ 5

ngths ........................................................................................................ 6

Power Supply ......................................................................................... 6

....................................................................................................... 3

.................................................................................................. 6

nse Time ............................................................................................... 8

Electrical Installation

VLT 2800 C

VLT 2800 Earth Connection ................................................................................... 10

VLT 2800 DeviceNet Connection ........................................................................... 10

FCD 300 El

User Interface ......................................................................................................... 12

Quick Setup ........................................................................................................... 13

onnection of the Cable Screen ........................................................... 9

ectrical connection ............................................................................... 11

Master-Slave configuration

Drive Pro

I/O Assembly Instances ......................................................................................... 15

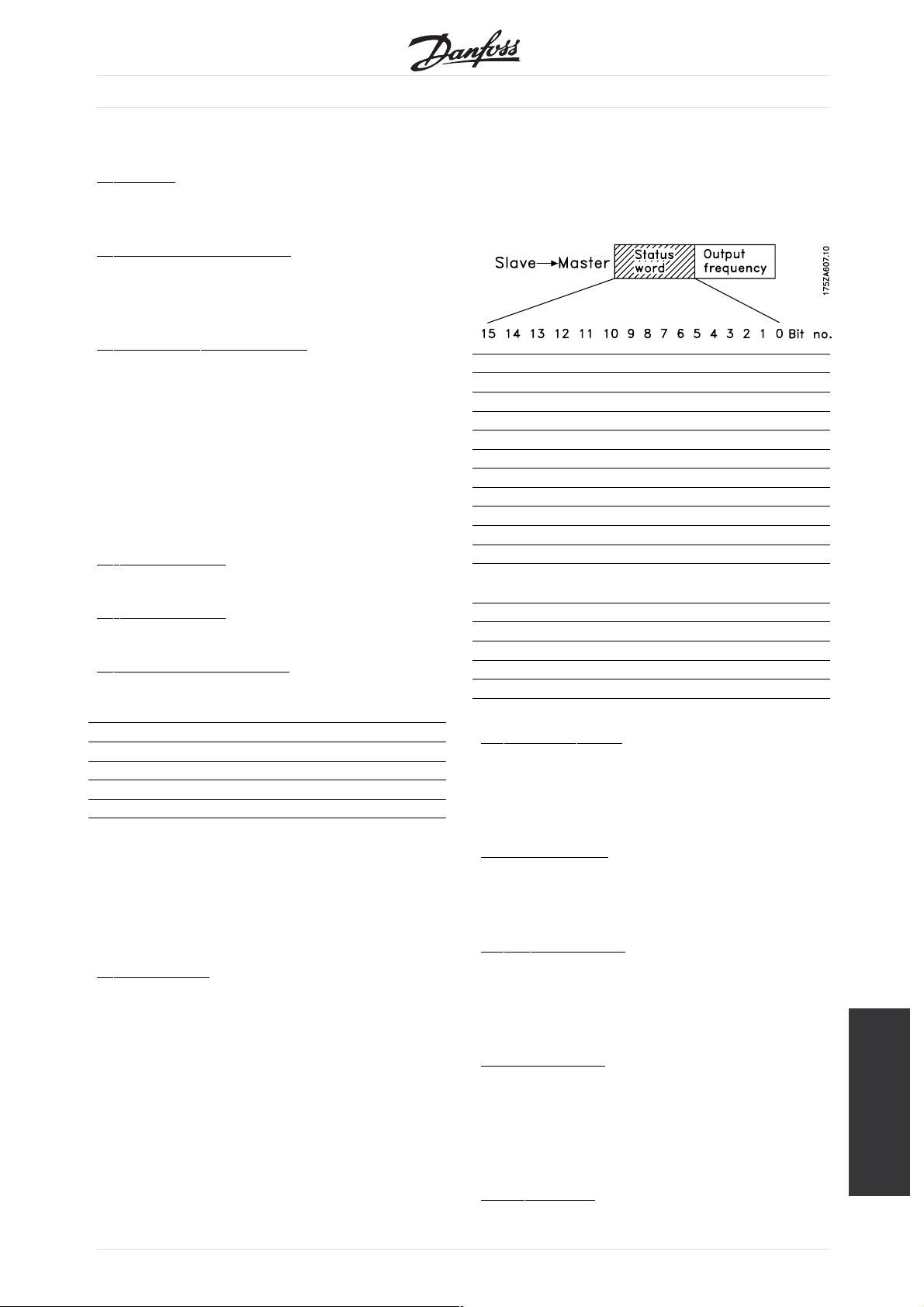

Control Word and Status Word under

Instance

Control Word and Status Word

under Instance 21/71 ............................................................................................. 17

Bus speed r

Actual output speed, under Instance 20/70

and 21/71 ............................................................................................................. 19

Control Wo

Bus reference value ............................................................................................... 23

Actual output frequency ......................................................................................... 23

Process Da

file

....................................................................................................... 15

20/70 ....................................................................................................... 16

eference value, under Instance 20/70 and 21/71 ............................... 19

rd and Status Word under Instance 100/150 and 101/151 ................. 20

ta, PCD ................................................................................................ 24

.................................................................................... 9

....................................................................... 14

DeviceNet object classes

Class Code

MG.90.B2.02 - VLT is a registered Danfoss trade mark

0x01 ................................................................................................... 25

........................................................................... 25

1

VLT®2800 / FCD 300 DeviceNet

Class Code 0x02 ................................................................................................... 25

Class Code 0x03 ................................................................................................... 25

Class C

Class Code 0x05 ................................................................................................... 26

Class Code 0x28 ................................................................................................... 30

Class Co

Class Code 0x2A ................................................................................................... 32

Danfoss Classes .................................................................................................... 33

ode 0x04 ................................................................................................... 26

de 0x29 ................................................................................................... 31

DeviceNet Operation Mode

Bit Strobe ............................................................................................................... 34

Polling

Change of State, COS ........................................................................................... 35

EDS File

VLT 2800 US version with DeviceNet .................................................................... 36

VLT 2800 European version with DeviceNet .......................................................... 36

FCD 300 E

Programming

Special

Warning and Alarm Messages ............................................................................... 45

Abbreviations ......................................................................................................... 46

Factory s

Factory settings - FCD 300 .................................................................................... 55

Addition

.................................................................................................................... 35

s

............................................................................................................. 36

uropean version with DeviceNet ........................................................... 37

.................................................................................................... 38

Attention .................................................................................................... 38

ettings - VLT 2800 .................................................................................. 47

al control features for VLT 2800

........................................................................ 34

............................................ 62

2

MG.90.B2.02-VLTisaregisteredDanfosstrademark

Introduction

■

About this manual

■

This manual is intended to be used both as an

instructional and as a reference manual. It only

briefly touches on the basics of the DeviceNet

protocol. Whenever it is necessary for gaining

an understanding of the AC Drive Profile, please

refer to the ODVA version 2.0.

The manual is also intended to serve as a

guideline when you specify and optimize your

communication system.

Even if you are an experienced DeviceNet programmer,

we suggest that you read this manual in its entirety

before you start programming, since important

information can be found in all chapters.

Assumptions

■

This manual assumes that you are using a DANFOSS

VLT 2800 or FCD 300 unit with DeviceNet. It is

also assumed that you are using a PLC or PC, as a

master, that is equipped with a serial communication

card supporting all the DeviceNet communication

services required by your application. Further more

it is assumed that all requirements stipulated in the

DeviceNet standard as well as those set up in the

AC Drive Profile and those pertaining to the VLT

Variable Speed Drive are strictly observed as well

as all limitations therein fully respected.

VLT®2800 / FCD 300 DeviceNet

Introduction

What you should already know

■

The DANFOSS DeviceNet is designed to communicate

with any master abiding by the DeviceNet standard.

It is therefore assumed that you have full knowledge

of the PC or PLC you intend to use as a master

in your system. Any questions pertaining to

hardware or software produced by any other

manufacturer is beyond the scope of this manual

and is of no concern to DANFOSS.

If you have questions about how to set up master

- master communication or communication to

a non-Danfoss slave, the appropriate manuals

should be consulted.

MG.90.B2.02 - VLT is a registered Danfoss trade mark

3

VLT®2800 / FCD 300 DeviceNet

Available literature

■

Supplied with the unit

■

Below is a list of the literature available for VLT 2800

and FCD 300. It must be noted that there may be

deviations from one country to the next.

Supplied with the unit:

Operating instructions ....................................................................................................................... MG.28.AX.YY

Quick setup ....................................................................................................................................... MG.28.AX.62

Parameter list ................................................................................................................................... MG.28.DX.YY

Various literature:

Design Guide for VLT 2800 .............................................................................................................. MG.28.EX.YY

Data sheet for VLT 2800 .................................................................................................................. MD.28.AX.YY

Design Guide for FCD 300 ............................................................................................................... MG.04.AX.YY

Data sheet for FCD 300 ................................................................................................................... MD.04.AX.YY

Instructions for VLT 2800:

Assembly/disassembly ....................................................................................................................... MI.28.A1.02

LCP remote-mounting kit ................................................................................................................... MI.56.AX.51

Filter instruction .................................................................................................................................. MI.28.B1.02

Communication with VLT 2800 and FCD 300:

Profibus manual ................................................................................................................................ MG.90.AX.YY

VLT 2800 DeviceNet manual ............................................................................................................ MG.90.BX.YY

X = version number

YY = language version

4

MG.90.B2.02-VLTisaregisteredDanfosstrademark

Product and Environment

■

DeviceNet is a distributed control network. The

Net protocol is embedded in the control card

Device

and is a communication protocol conforming to the

Open DeviceNet Vendor Association (ODVA) standard.

The control card allows DeviceNet compatible

controllers, sensors, and network management

tools to control, monitor, and supervise the

VLT frequency converter. The control card is

designed to the DeviceNet System Protocol for

Vendors as a slave device.

Network

■

The VLT frequency converter will function as a slave

on the DeviceNet network. All addressing and linking

to nodes is done at installation time by a network

manager tool. The network installer and the network

management master have a significant influence on

how the node functions on the network. A DeviceNet

network can support up to 64 nodes.

User Profile

■

The end-user is a network manager programmer

or a controller who see the DeviceNet control

card as a transparent bridge to the VLT frequency

converter. Control and supervision of the VLT

frequency converter will still be possible through

the standard parameter set.

VLT®2800 / FCD 300 DeviceNet

LCP2 or Dialog can be used on the Sub D

plug while using DeviceNet.

Overall Function

■

DeviceNet is a low-level network that standardizes

communications between industrial devices (sensors,

limit switches) and high level devices (controllers).

The communication network can be peer to peer or

master/slave. DeviceNet uses CAN technology for

Media Access Control and Physical Signaling and it

supports up to 64 nodes. DeviceNet also defines

device profiles for devices belonging to specific

classes. For other devices, a custom class must be

defined in order to make it DeviceNet compatible.

This further enhances the interchangeability and

interoperability of the network. Each node on the

network has its own unique media access control

identifier (MAC ID) to distinguish it on the network.

Control Card Self-test

■

Please refer to parameter 620 in the

Programming chapter.

Introduction

Interface to DeviceNet Network

■

The Interface connection to the DeviceNet network is

implemented through a CAN chip. Four different I/O

Assembly is available in the VLT frequency converter

DeviceNet interface, which can be configured by

the user. The I/O assembly can handle Polled

mode, Bit Strobe, Change of state (COS) and

Cyclic. For explicit messages, the interface has two

Unconnected Messages Manager (UCMM) available.

This allows two nodes on the DeviceNet to directly

access parameters in the VLT frequency converter

without involving a pre-configured master.

Data Communication Interface

■

No direct data communication interface (e.g. via a

serial port) other than the DeviceNet interface and the

VLT frequency converter interface is considered.

MG.90.B2.02 - VLT is a registered Danfoss trade mark

5

Technical Data

■

Cable Lengths

■

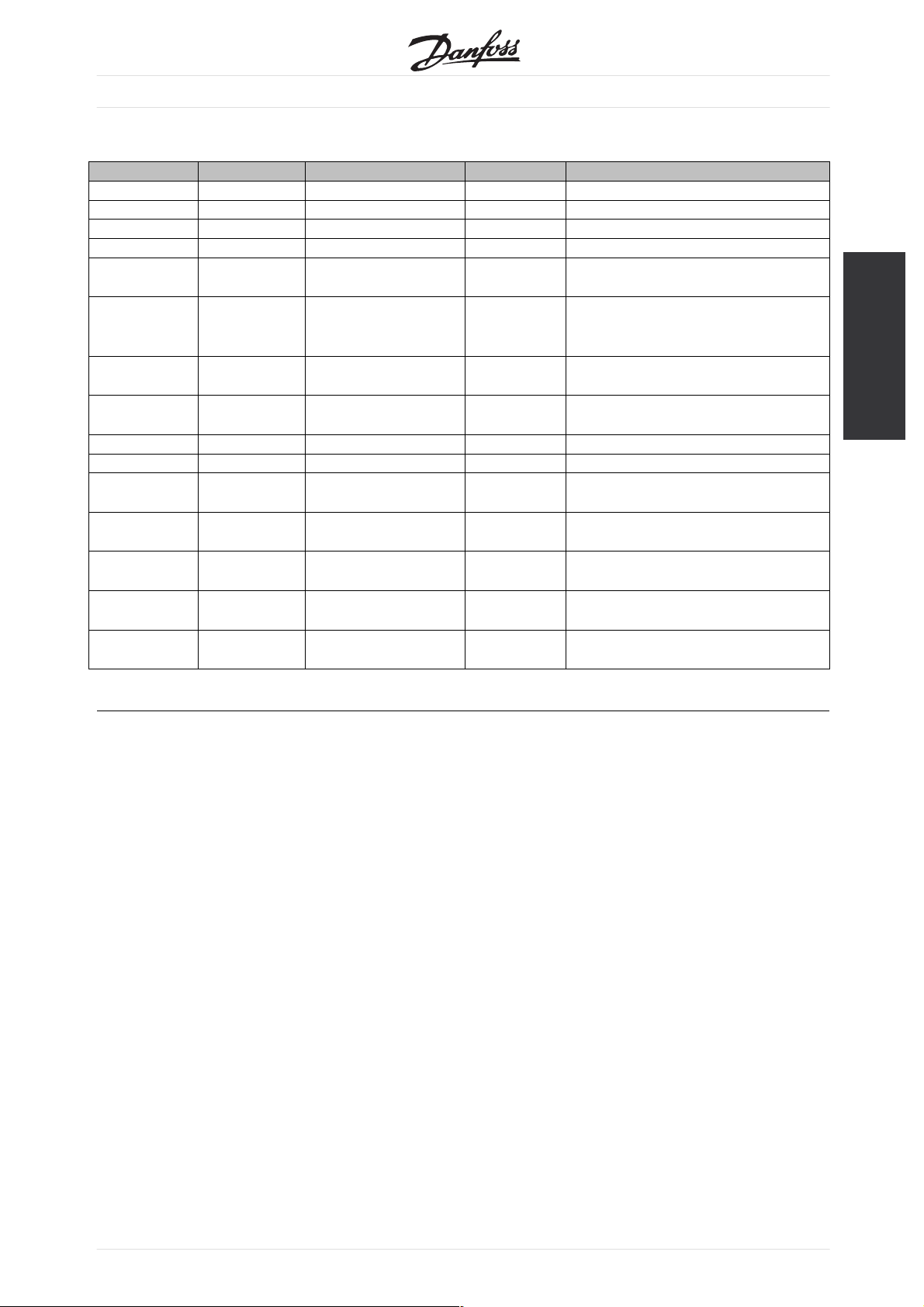

125k baud 500 meters (1640 ft.) 156meters(512ft.)

250k baud 250 meters (820 ft.) 78 meters (256 ft.)

500k baud 100 meters (328 ft.)

Topology

■

VLT®2800 / FCD 300 DeviceNet

Drop LengthBaud Rate Max. total cable length [m]

Maximum Cumulative

6 meters (20 ft.)

for one drop

39 meters (128 ft.)

Cable Specifications

■

The cable is to be used according to ODVA

specifications.

Network Power Supply

■

The DeviceNet option is an optically isolated node,

where transceiver power is provided by the network.

External network power supply requirements are:

11 - 25 VDC

10 mA draw per VLT frequency converter node.

Cable Cross Section

■

6

MG.90.B2.02-VLTisaregisteredDanfosstrademark

VLT®2800 / FCD 300 DeviceNet

EMC Precautions

■

The following EMC precautions are recommended to

interference free operation of the DeviceNet

obtain

network. Additional information on EMC can be

found in the FCD 300 and in the VLT 2800 Series

ting Instructions and Design Guide.

Opera

NB!:

Relevant national and local regulations,

for example regarding protective earth

connection, must be observed

The De

kept away from motor and brake resistor cables

viceNet communication cable must be

to avoid coupling of high frequency noise from

one cable to the other. Normally a distance of

200 mm (

recommended to keep the greatest possible distance

between the cables, especially where cables are

runni

If the DeviceNet cable has to cross a motor

and brake resistor cable they must cross each

other at an angle of 90

8 inches) is sufficient, but it is generally

ng in parallel over long distances.

.

Technical Data

Example: VLT 2800 panel mounting

MG.90.B2.02 - VLT is a registered Danfoss trade mark

7

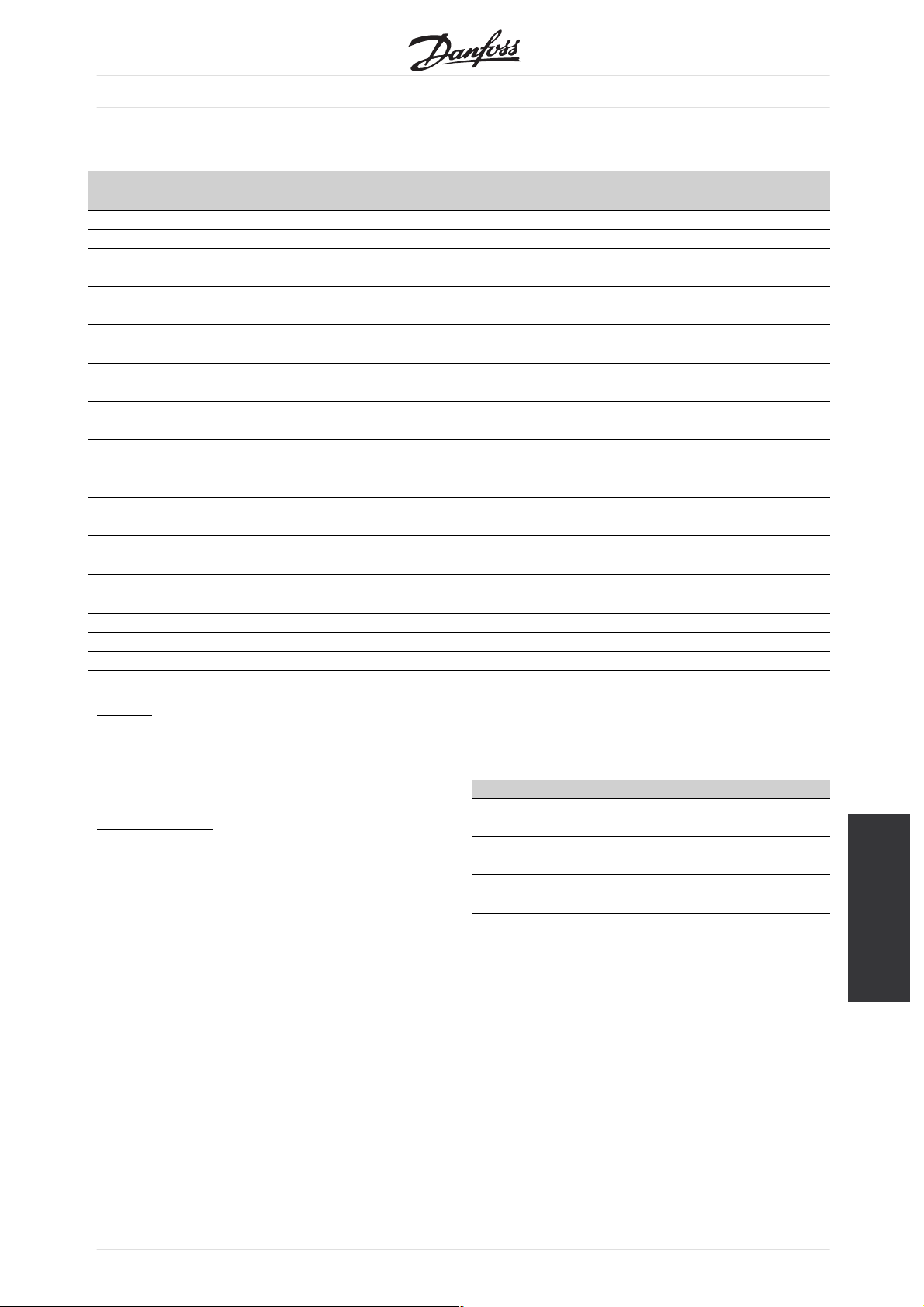

VLT Response Time

■

The update time via the DeviceNet connection

can be d

1. The communication time, which is the time it

2. The internal update time, which is the time it

ivided into two parts:

takes to transmit data from the master to the

slave (VLT with DeviceNet option).

takes to transmit data between the VLT frequency

converter control card and the DeviceNet interface.

VLT®2800 / FCD 300 DeviceNet

Communication time (t

mission speed (baudrate) and the type of master

trans

in use. More slaves or lower transmission speed

will increase the communication time.

) depends on the actual

com

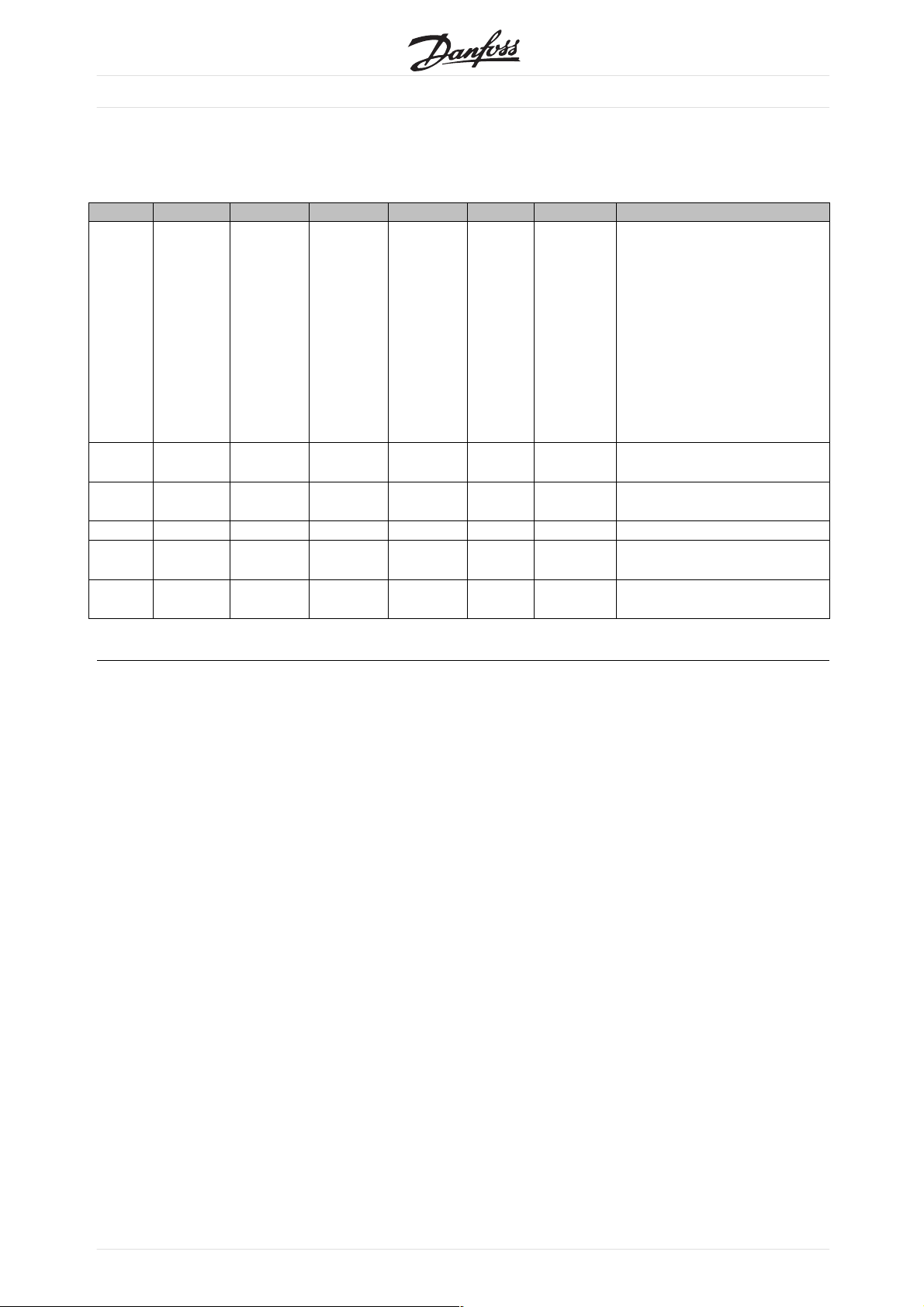

Data Update

time, t

int

Control word via I/O instances 14 msec

Main actual value via I/O instances 44 msec

Status word via I/O instances 14 msec

Reference via I/O instances 44 msec

Control via Class Code 0x29 14 msec

ReferenceviaClassCode0x2A 44msec

Change of parameter via Explicit

94 msec

message and Danfoss Object

Read of parameter via Explicit message

14 msec

and Danfoss Object

8

MG.90.B2.02-VLTisaregisteredDanfosstrademark

Electrical Installation

■

VLT®2800 / FCD 300 DeviceNet

VLT 2800 Connection of the Cable Screen

■

Danfoss recommends that the screen of the DeviceNet

cable be connected to ground at both ends of

the cable at every DeviceNet station (see Danfoss

recommendation for further details).

It is very important to have a low impedance ground

connection of the screen, also at high frequencies.

This can be obtained by connecting the surface

of the screen to ground, for example by means of

a cable clamp or a conductive cable gland. VLT

frequency converter Series are provided with different

clamps and brackets to enable a proper ground

connection of the DeviceNet cable screen. The

screen connection is shown in the drawing.

For fulfilling the CE and EMC compliance.

VLT 2800 ODVA recommendation

Screen must be connected to ground at only

one point on the network.

NB!:

Please note, that this recommendation conflicts

with the EMC correct installation.

Electrical Installation

MG.90.B2.02 - VLT is a registered Danfoss trade mark

9

VLT 2800 Earth Connection

■

portant that all stations connected to the

It is im

DeviceNet network are connected to the same earth

potential. The earth connection must have a low HF

requency) impedance. This can be achieved

(high f

by connecting a large surface area of the cabinet to

ground, for example by mounting the VLT frequency

rter on a conductive rear plate. Especially

conve

when having long distances between the stations

in a DeviceNet network it can be necessary to use

ional potential equalizing cables, connecting the

addit

individual stations to the same earth potential.

VLT 2800 DeviceNet Connection

■

It is essential that the bus line be terminated properly.

match of impedance may result in reflections

Amis

on the line that will corrupt data transmission.

VLT®2800 / FCD 300 DeviceNet

The DeviceNet control card is provided with

a pluggable connector.

By using a pluggable connector as a splice between

trunk lines, removal of devices will not sever the

two

network. Strain relief, if required, must be provided by

the developer. In current installations of this type of

nector, the strain relief is attached to the product.

con

NB!:

Wires should not be installed while the

network is active. This will prevent problems

such as shorting the network supply or

disrupting communications.

VLT 2800 Drop cable

An alternative to splicing two trunk lines in the

nnector on the control card, is using a DeviceNet

co

connection box or a T-connector. For this kind of

installation a drop cable is available as an option.

Drop cable ordering number: 195N3113

NB!:

Please note, that terminal 46 has been removed

from the DeviceNet card, meaning that

parameter 341-342 are not having any function.

10

MG.90.B2.02-VLTisaregisteredDanfosstrademark

FCD 300 Electrical connection

■

The DeviceNet bus connection can be performed

h a plug, that is to be mounted in the

throug

FCD 300 housing (M16 gland hole) and wired

to the inside terminal strip.

Wiring list

VLT®2800 / FCD 300 DeviceNet

M12 Circular connector

Terminal strip Colour Function

4 68 White Can high

5 69 Blue Can low

2 67 Red +24V

3 70 Black GND

1 D Green Drain

DeviceNet plug 175N2279

Electrical Installation

MG.90.B2.02 - VLT is a registered Danfoss trade mark

11

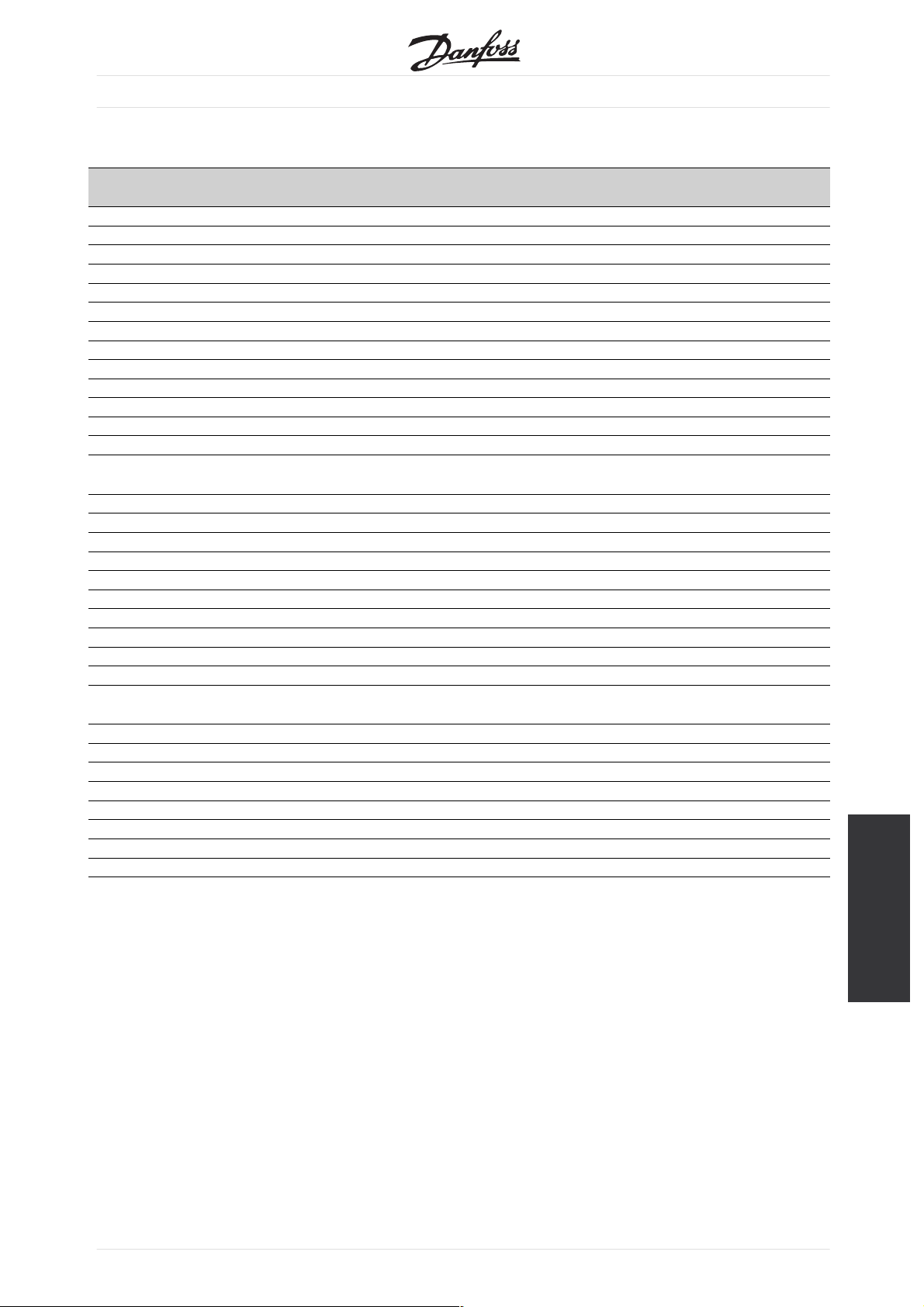

User Interface

■

The DeviceNet control card contains two

or (green/red) LED’s for each connector

bi-col

hookup port, to indicate the state of the device

and network, respectively.

Module LED:

VLT®2800 / FCD 300 DeviceNet

LD1 on VLT 2800 Dual colour

(Green/Red)

Yellow FCD 300 STATUS LED

when selected as DeviceNet in

VLT status

parameter 26

OFF OFF Device is OFF

GREEN YELLOW Device is operational

Flashing GREEN Flashing YELLOW Device is in standby

Flashing RED OFF Device detects a recoverable fault

RED OFF Device detects an unrecoverable

fault

Flashing GREEN/RED Flashing YELLOW Device is self testing

WORK LED:

NET

VLT status LD2 on VLT 2800 Dual

lour (Green/Red)

co

Network is non-

OFF OFF Network is non-

powered/not on-line

twork is on-line but

Ne

ashing GREEN

Fl

not connected

Network is on-line and

nnected

co

Network has a

GREEN GREEN Network is on-line and

Flashing RED OFF Network has a

connection timeout

etwork has a critical

N

ED

R

link failure

Green BUS LED on

D 300

FC

ashing GREEN

Fl

FF

O

VLT status

powered/not on-line

twork is on-line but

Ne

not connected

nnected

co

connection timeout

etwork has a critical

N

link failure

12

MG.90.B2.02-VLTisaregisteredDanfosstrademark

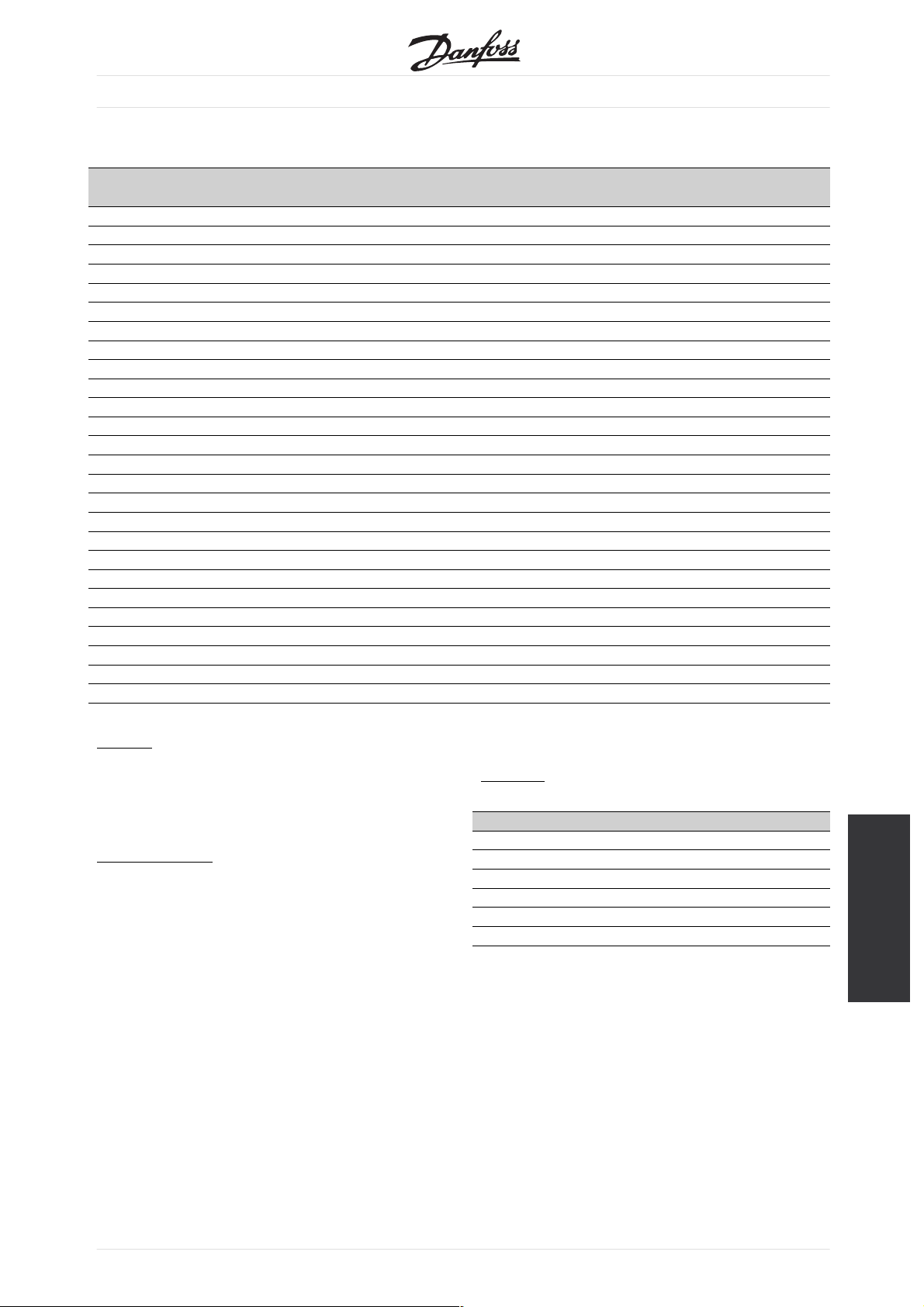

Quick Setup

■

Parameter 800 = "Fieldbus selection".

Parameter 833 = "Fieldbus enable".

Parameter 918 = "Select Bus address".

Parameter 801 = "Select Baudrate".

Parameter 904 = "Choose I/O instances".

Parameter 502 = "Coasting select".

VLT®2800 / FCD 300 DeviceNet

Electrical Installation

MG.90.B2.02 - VLT is a registered Danfoss trade mark

13

Master-Slave configuration

■

System configuration

■

The system configuration of a DeviceNet master and a

VLT 2800/FCD 300 can be split up into two parts.

The first part is the setting of DeviceNet communication

related parameters. These are the baud rate and

station address/MAC ID.

By VLT 2800/FCD 300 these parameters can

be set by the LCP or access via a DeviceNet

configuration tool. None of these parameters

can be set by mechanical switches.

After the baud rate and station address/MAC ID

are set a connection to a DeviceNet DeviceNet

configuration tool can be established.

The second and larger area of a system configuration

is the setting of application related parameters.

EDS files are easy to create and it is strongly

recommended to generate an EDS for each VLT

2800/FCD 300. This can be done by uploading the

EDS file from each drive by a DeviceNet configuration

tool. In the VLT 2800/FCD 300 EDS file it is possible to

configured the drive and read or write to parameters.

The language of the EDS file is depending of the

actual setting of parameter 001 Language.

In parameter 838 EDS Data type it is possible to

choose between two dataformat for uploading EDS

files. Before uploading the EDS file please check if

the master support Errata 1 or Errata 2.

For Off-line configuration Danfoss can provide

you with english EDS files, see section EDS

files for the EDS file name. Contact your local

Danfoss supplier for the EDS files.

VLT®2800 / FCD 300 DeviceNet

Another important configuration parameter is the

selection of communication mechanisms that enable

an efficient and responsive I/O system. By VLT

2800/FCD 300 it is possible to choose between the

following communication mechanisms:

•

Poll I/O

•

Bit Strobe I/O

•

Change-of-state (COS) / Cyclic I/O

•

Explicit Messaging

See DeviceNet Operation Mode in this manual

for further information.

The last configuration parameter is the choice of

Instance type in parameter 904 PPO selection. Here is

it possible to select beween a Danfoss Specific profile

(Instance 100/150 or 101/151) or a ODVA Specific

AC Drive profile (Instance 20/70 or 21/71).

14

MG.90.B2.02-VLTisaregisteredDanfosstrademark

Drive Profile

■

I/O Assembly Instances

■

The I/O Assembly Instance definitions in this section

define the format of the "data" attribute (attribute 3)

for I/O Assembly Instances. I/O Assemblies support

a hierarchy of motor control devices. The device

hierarchy includes motor starters, soft starters, AC

and DC drives, and servo drives. Assembly Instances

are numbered within the hierarchy so that each

device type is assigned a range of Assembly Instance

numbers, with higher functionality devices supporting

VLT®2800 / FCD 300 DeviceNet

higher instance numbers. Devices in the hierarchy

can choose to support instance numbers that are

lower than theirs in the hierarchy. For example an AC

drive may choose to support some I/O Assemblies

in the starter profile to make it easier to interchange

starters and drives within the system.

MG.90.B2.02 - VLT is a registered Danfoss trade mark

Drive Profile

15

Control Word and Status Word under

■

Instance 20/70

Set par

Instance 20/70 [12].

The control word in Instance 20 is defined as

follow

ameter 904 PPO type to select

ing:

Bit Bit = 0 Bit =1

00 Stop Run Fwd.

01 Reserved for future

use

Reserved for future

use

02 No function Fault reset

03 -15Reserved for future

use

Bit 0, Run Fwd:

Bit 0 = "0" means that the VLT frequency

converter has a stop command.

Bit 0 = "1" leads to a start command and the VLT

frequency converter will start to run the motor.

it 2, Fault Reset

B

Bit 0 = "0" means that there is no reset of a trip.

Bit 0 = "1" means that a trip is reset.

Reserved for future

use

VLT®2800 / FCD 300 DeviceNet

and 21/71.

ThestatuswordinInstance70isdefinedasfollowing:

Bit Bit = 0 Bit =1

00 No fault Trip

01 Reserved for future

use

02 Not running Running

03 -15Reserved for future

use

Bit 0,Fault:

Bit 0 = "0" means that there is no fault on

the VLT frequency converter.

Bit 0 = "1" means that there is a fault on the

VLT frequency converter.

B

it 2, Running

Bit 0 = "0" means that there is no active start command.

Bit 0 = "1" means that there is an active start command.

Regarding the Actual output speed, see section

Actual output speed, under Instance 20/70 and 21/71.

Reserved for future

use

Reserved for future

use

Regarding the Speed reference, see section Bus

speed reference value, under Instance 20/70

16

MG.90.B2.02-VLTisaregisteredDanfosstrademark

Control Word and Status Word

■

under Instance 21/71

Set par

Instance 21/71 [13].

The control word in Instance 21 is defined as

followi

ameter 904 PPO type 1 to select

ng:

Bit Bit = 0 Bit =1

00 Stop Run Fwd

01 Stop Run Rev

02 No function Fault reset

03

04

05 Net Ctrl

06 Net Ref

07 15

Bit 0, Run Fwd:

Bit 0 = "0" means that the VLT frequency

converter has a stop command.

Bit 0 = "1" leads to a start command and

the VLT frequency converter will start to run

the motor clockwise.

it 1, Run Rev:

B

Bit 0 = "0" leads to a stop of the motor.

Bit 0 = "1" leads to a start of the motor.

it 2, Fault Reset:

B

Bit 0 = "0" means that there is no reset of a trip.

Bit 0 = "1" means that a trip is reset.

it 5, Net Ref:

B

NB!:

Please note, that a change will have an

effect on parameter 502 - 506.

it 6, Net Crtl:

B

VLT®2800 / FCD 300 DeviceNet

ThestatuswordinInstance71isdefinedasfollowing:

Bit Bit = 0 Bit =1

00 Trip

01 Warning

02 Running 1 Fwd

03 Running 2 Rev.

04 Ready

05 Crtl from Net

06 Ref from Net

07 At reference

08 -15State Attribute

Bit 0,Fault:

Bit 0 = "0" means that there is no fault on

the VLT frequency converter.

Bit 0 = "1" means that there is a fault on the

VLT frequency converter.

B

it 1, Warning:

Bit 0 = "0" means that there is no unusual situation.

Bit 0 = "1" means that an abnormal condition

has arisen .

B

it 2, Running 1:

Bit2="0"meansthatthedriveisnotinoneof

these states or that Run 1 is not set.

Bit 2 = "1" means that the drive state attribute is

enabled or stopping , or that Fault-Stop and bit 0

(Run 1) of the CTW is set at the same time.

B

it 3, Running 2:

Bit 3 = "0" means means, that the drive is not in

one of these states or that Run 2 is not set.

Bit 3 = "1" means that the drive state attribute is

enabled or stopping , or that fault-stop and bit 0

(Run 2) of the CTW is set at the same time.

NB!:

Please note, that a change will have an effect

on parameter 214, 305, 307, 308 and 314.

Regarding the Speed reference, see section Bus

speed reference value, under Instance 20/70

and 21/71.

MG.90.B2.02 - VLT is a registered Danfoss trade mark

it 4, Ready:

B

Bit 4 = "0" means that the state attribute

is in another state.

Bit 4 = "1" means that the state attribute is

ready or enabled or stopping.

Drive Profile

17

Bit 5, Control from net:

Bit5="0"meansthatthedriveiscontrolled

from th

Bit 5 = "1" means that Devicenet has the control

(start, stop, reverse) of the drive.

B

Bit 6 = "0" means that the reference comes

from the drive’s inputs.

Bit 6 = "1" means that the reference is

coming from Devicenet.

B

Bit 7 = "0" means that the motor is running, but

that the present speed is different from the preset

speed

ramped up/down during start/stop.

Bit 7 = "1" means that the drive’s speed

equal

B

Represents the state attribute of the drive, as

indicated in the following table:

e standard inputs.

it 6, Ref from Net:

At reference:

it 7,

reference, i.e. while the speed is being

s the reference.

it 8 - 15, State attribute:

VLT®2800 / FCD 300 DeviceNet

Number Meaning

0 (Vendor specific)

1 Startup

2 Not ready

3 Ready

4 Enabled

5 Stopping

6 Fault stop

7 Faulted

Regarding the Actual output speed, see section Actual

output speed, under Instance 20/70 and 21/71

18

MG.90.B2.02-VLTisaregisteredDanfosstrademark

Bus speed reference value, under Instance

■

20/70 and 21/71

The speed reference value is transmitted to the VLT

frequency converter in the form of a 16-bit word. The

value is transmitted as a whole number. (Negative

figures are formatted by means of 2’s complement.)

us speed reference has the following format:

The b

Parameter 203 = "0" ["ref

00 Hex) [RPM] ⇒ + 32767 (7FFF Hex) [RPM]

0(00

Parameter 203 = "1" [- ref

67 (8000 Hex ) ⇒ +32767 [RPM] (7FFF Hex)

-327

MIN

MAX

⇒ ref

⇒ +ref

MAX

"]

MAX

]

VLT®2800 / FCD 300 DeviceNet

Actual output speed, under Instance 20/70

■

and 21/71

The value of the actual speed of the motor, is

transmitted in the form of a 16-bit word.

The value is transmitted as a whole number. (Negative

figures are formed by means of 2’s complement.)

The actual speed value has the following format:

-32767 (8000 Hex) [RPM] ⇒ +32767 [RPM]

(7FFF Hex) [RPM]

The actual reference [Ref. %] in the VLT depends

on the settings, in the following parameters:

104 Motor frequency

106 Motor Nom. speed

Max. Reference

205

Note that, If the bus speed reference is negative,

and the control word contains a run reverse

signal, the drive runs clockwise.

MG.90.B2.02 - VLT is a registered Danfoss trade mark

Drive Profile

19

Control Word and Status Word under Instance

■

100/150 and 101/151

Set par

Instance 100/150.

The control word in Instance 100/101 is defined as

follow

ameter 904 PPO type 1 [10] to select

ing:

Bit Bit = 0 Bit =1

00 Preset ref. lsb

01 Preset ref. msb

02 DC braking

03 Coasting stop

04 Quick stop

05 Freeze outp. freq.

06 Ramp stop Start

07 Reset

08 Jog

09 Ramp 1 Ramp 2

10 Data not valid Data valid

11 No function

12 No function

13 Select Setup, lsb

14 Select Setup, msb

15 Reversing

Bit 00/01:

Bit 00/01 is used to select between the two

pre-programmed references (parameters 215-218

Preset reference)accordingtothefollowingtable:

Preset ref. Parameter Bit 01 Bit 00

121500

221601

321710

421811

NB!:

In parameter 508 Selection of preset

reference a selection is made to define how

Bit 00/01 gates with the corresponding

function on the digital inputs.

VLT®2800 / FCD 300 DeviceNet

B

it 02, DC brake:

Bit 02 =

voltage and duration are preset in parameters 132

DC brake voltage and parameter 126 DC braking

time.N

is made to define how Bit 02 gates with the

corresponding function on a digital input.

it 03, Coasting stop:

B

Bit 03 =’0’causes the frequency converter to

immediately "let go" of the motor (the output transistors

are "shut off"), so that it coasts to a standstill.

Bit 03 =’1’causes the frequency converter to be able

start the motor if the other starting conditions have

been fulfilled. Note: In parameter 502 Coasting stop

a selection is made to define how Bit 03 gates with

the corresponding function on a digital input.

B

it 04, Quick stop:

Bit 04 =’0’causes a stop, in which the motor’s

disrampeddowntostopviaparameter

spee

212 Quick stop ramp-down time.

B

it 05, Freeze output frequency:

Bit 05 =’0’causes the present output frequency

(in Hz) to freeze. The frozen output frequency can

now only be changed by means of the digital inputs

programmed to Speed up and Speed down.

n only be stopped by the following:

ca

•

Bit03Coastingstop

•

Bit 02 DC braking

•

Dig

stop or Reset and coasting stop.

B

it 06, Ramp stop/start:

Bit 06 =’0’causes a stop, in which the motor’s

speed is ramped down to stop via the selected

ramp down parameter.

Bit 06 =’1’causes the frequency converter to be able

to start the motor, if the other starting conditions have

been fulfilled. Note: In parameter 505 Start a selection

is made to define how Bit 06 Ramp stop/start gates

with the corresponding function on a digital input.

causes DC braking and stop. Brake

’0’

ote: In parameter 504 DC brake a selection

NB!:

reeze output is active, the frequency

If F

converter cannot be stopped via Bit 06 Start

or via a digital input. The frequency converter

ital input programmed to DC braking, Coasting

20

t 07, Reset:

B

i

Bit 07 =’0’does not cause a reset.

Bit 07 =’1’causes the reset of a trip. Reset is

tivated on the signal’s leading edge, i.e. when

ac

changing from logic’0’to logic’1’.

MG.90.B2.02-VLTisaregisteredDanfosstrademark

VLT®2800 / FCD 300 DeviceNet

Bit 08, Jog:

Bit 08 =’1’causes the output frequency to be

determined by parameter 213 Jog frequency.

it 09, Selection of ramp 1/2:

B

Bit 09 = "0" means that ramp 1 is active (parameters

207/208). Bit 09 = "1" means that ramp 2

(parameters 209/210) is active.

B

it 10, Data not valid/Data valid:

Is used to tell the frequency converter whether the

controlwordistobeusedorignored. Bit10=

causes the control word to be ignored, Bit 10

’0’

=’1’causes the control word to be used. This

function is relevant, because the control word is

always contained in the telegram, regardless of which

type of telegram is used, i.e. it is possible to turn

off the control word if you do not wish to use it in

connection with updating or reading parameters.

B

it 11, No function:

Bit 11 has no function.

it 12, No function:

B

Bit 12 has no function.

it 13/14, Selection of Setup:

B

Bits 13 and 14 are used to choose from the four

menu Setups according to the following table:

The Status Word in Instance 150/151 is

defined as following:

Bit Bit = 0 Bit =1

00 Control ready

01 Drive ready

02 Coasting stop

03 No trip Trip

04 Not used

05 Not used

06 Not used

07 No warning Warning

08 Speed ≠ ref. Speed = ref.

09 Local control Ser. communi.

10 Outside

frequency range

Frequency limit

OK

11 Motor running

12

13 Voltage warn.

14 Current limit

15 Thermal warn.

Setup Bit 14 Bit 13

100

201

310

411

ThefunctionisonlypossiblewhenMulti-Setups is

selected in parameter 004 Active Setup.

Note: I parameter 507 Selection of Setup a selection

is made to define how Bit 13/14 gates with the

corresponding function on the digital inputs.

it 15 Reversing:

B

Bit 15 =’0’causes no reversing.

Bit 15 =’1’causes reversing.

Note: In the factory setting reversing is set to

digital in parameter 506 Reversing. Bit 15 only

causes reversing when either Ser. communication,

Logic or or Logic and is selected.

Bit 00, Control ready:

Bit 00 =’1’. The frequency converter is

ready for operation.

Bit 00 =’0’. The frequency converter is

not ready for operation.

it 01, Drive ready:

B

Bit 01 =’1’. The frequency converter is ready for

operation, but there is an active coasting command

via the digital inputs or via serial communication.

B

it 02, Coasting stop:

Bit 02 =’0’. The frequency converter has

released the motor.

Bit 02 =’1’. The frequency converter can start the

motor when a start command is given.

B

it 03, No trip/trip:

Bit 03 =’0’means that the frequency converter

is not in fault mode.

Bit 03 =’1’means that the frequency converter

is tripped, and that it needs a reset signal for

operation to be reestablished.

Drive Profile

MG.90.B2.02 - VLT is a registered Danfoss trade mark

B

it 04, Not used:

Bit04isnotusedinthestatusword.

21

VLT®2800 / FCD 300 DeviceNet

Bit 05, Not used:

Bit 05 is not used in the status word.

B

it 06, Not used:

Bit 06 is not used in the status word.

it 07, No warning/warning:

B

Bit 07 =’0’means that there are no warnings.

Bit 07 =’1’means that a warning has occurred.

B

it 08, Speed≠ ref/speed = ref.:

Bit 08 =’0’means that the motor is running, but that

the present speed is different from the preset speed

reference. It might, for example, be the case while the

speed is being ramped up/down during start/stop.

Bit 08 =’1’means that the motor’s present speed

is the same as the preset speed reference.

B

it 09, Local operation/serial communication control:

Bit 09 =’0’means that [STOP/RESET] is activated

on the control unit, or that Local control in parameter

002 Local/remote operation is selected. It is

not possible to control the frequency converter

via serial communication.

Bit 09 =’1’means that it is possible to control the

frequency converter via serial communication.

Bit 15 =’1’means that the temperature limit has been

exceeded in either the motor, frequency converter or

from a t

hermistor that is connected to a digital input.

B

it 10, Outside frequency range:

Bit 10 =’0’, if the output frequency has reached

the value in parameter 201 Output frequency

low limit or parameter 202 Output frequency

high limit. Bit 10 = "1" means that the output

frequency is within the defined limits.

B

it 11, Running/not running:

Bit 11 =’0’meansthatthemotorisnotrunning.

Bit 11 =’1’means that the frequency converter

has a start signal or that the output frequency

is greater than 0 Hz.

B

it 13, Voltage warning high/low:

Bit 13 =’0’means that there are no voltage warnings.

Bit 13 =’1’means that the DC voltage in the frequency

converter’s intermediate circuit is too low or too high.

it 14, Current limit:

B

Bit 14 =’0’means that the output current is less than

the value in parameter 221 Current Limit I

LIM

.

Bit 14 =’1’means that the output current is

greater than the value in parameter 221 Current

LimitI

and that the frequency converter will

LIM

trip after a set period of time.

B

it 15, Thermal warning:

Bit 15 =’0’means that there is no thermal warning.

22

MG.90.B2.02-VLTisaregisteredDanfosstrademark

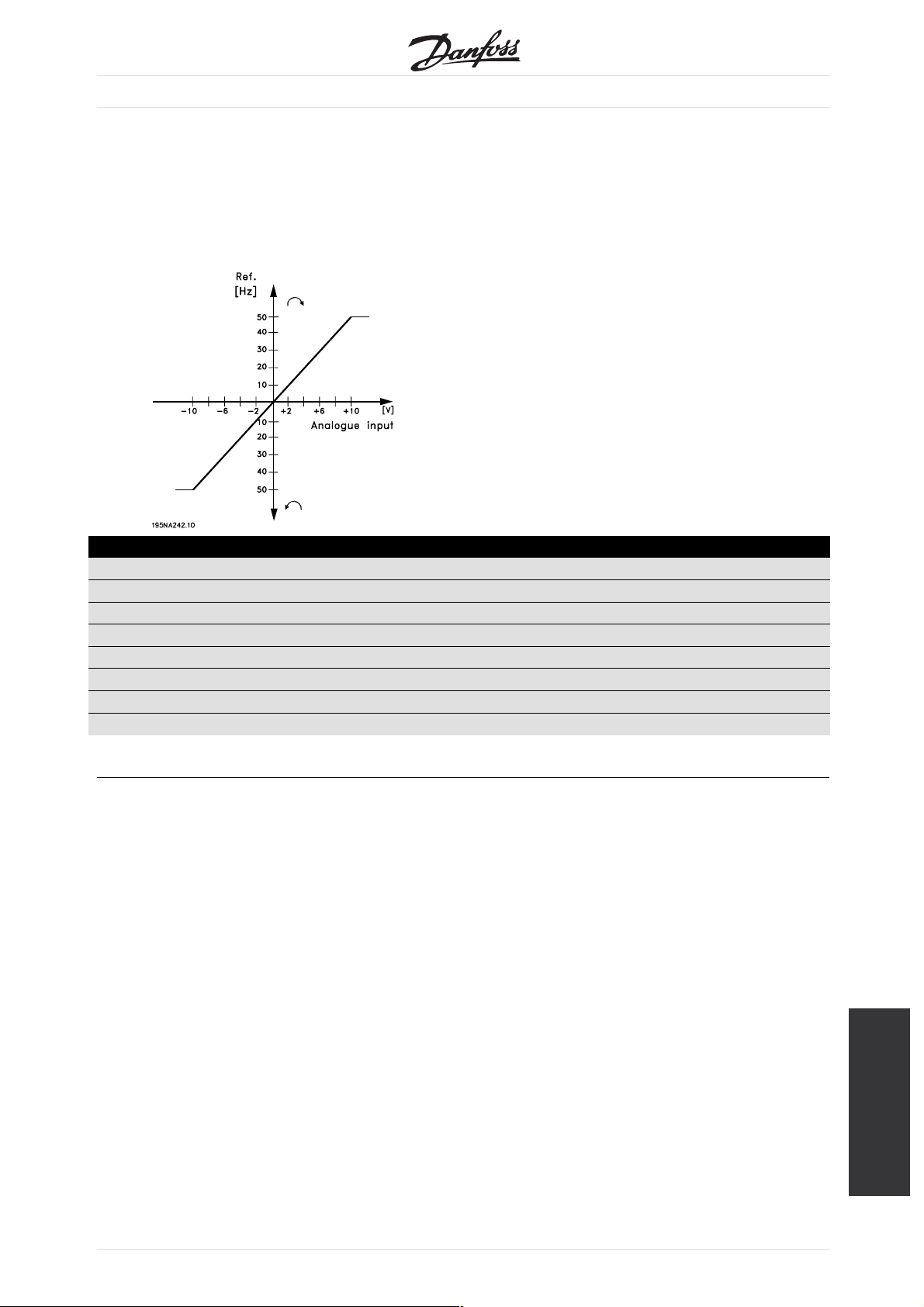

Bus reference value

■

The frequency reference value is transmitted to

the VLT frequency converter in the form of a

16-bit word. The value is transmitted as a whole

number (-32767 ⇒ 32767). (Negative figures are

formatted by means of 2’s complement.)

The bus reference has the following format:

Parameter 203 = "0" ["ref

MIN

⇒ ref

MAX

"]

0 ⇒ 16384 (4000 Hex) ~ 0 ⇒ 100% ~ "ref

Parameter 203 = "1" [- ref

MAX

⇒ +ref

MAX

- 16384 (C000 Hex) ⇒ + 16384 (4000 Hex) ~

-100%⇒ + 100% ~ - ref

MAX

⇒ +ref

MAX

MIN

]

⇒ ref

MAX

VLT®2800 / FCD 300 DeviceNet

Actual output frequency

■

The value of the actual output frequency of the VLT

frequency converter, is transmitted in the form of a

16-bit word. The value is transmitted as a whole

number (-32767 ⇒ 32767) (Negative figures are

formed by means of 2’s complement).

The actual output frequency has the following format:

-32767 ⇒ +32767.

-16384 (C000 Hex) corresponds to -100%, and

16384 (4000 Hex) corresponds to 100%.

MG.90.B2.02 - VLT is a registered Danfoss trade mark

Drive Profile

23

VLT®2800 / FCD 300 DeviceNet

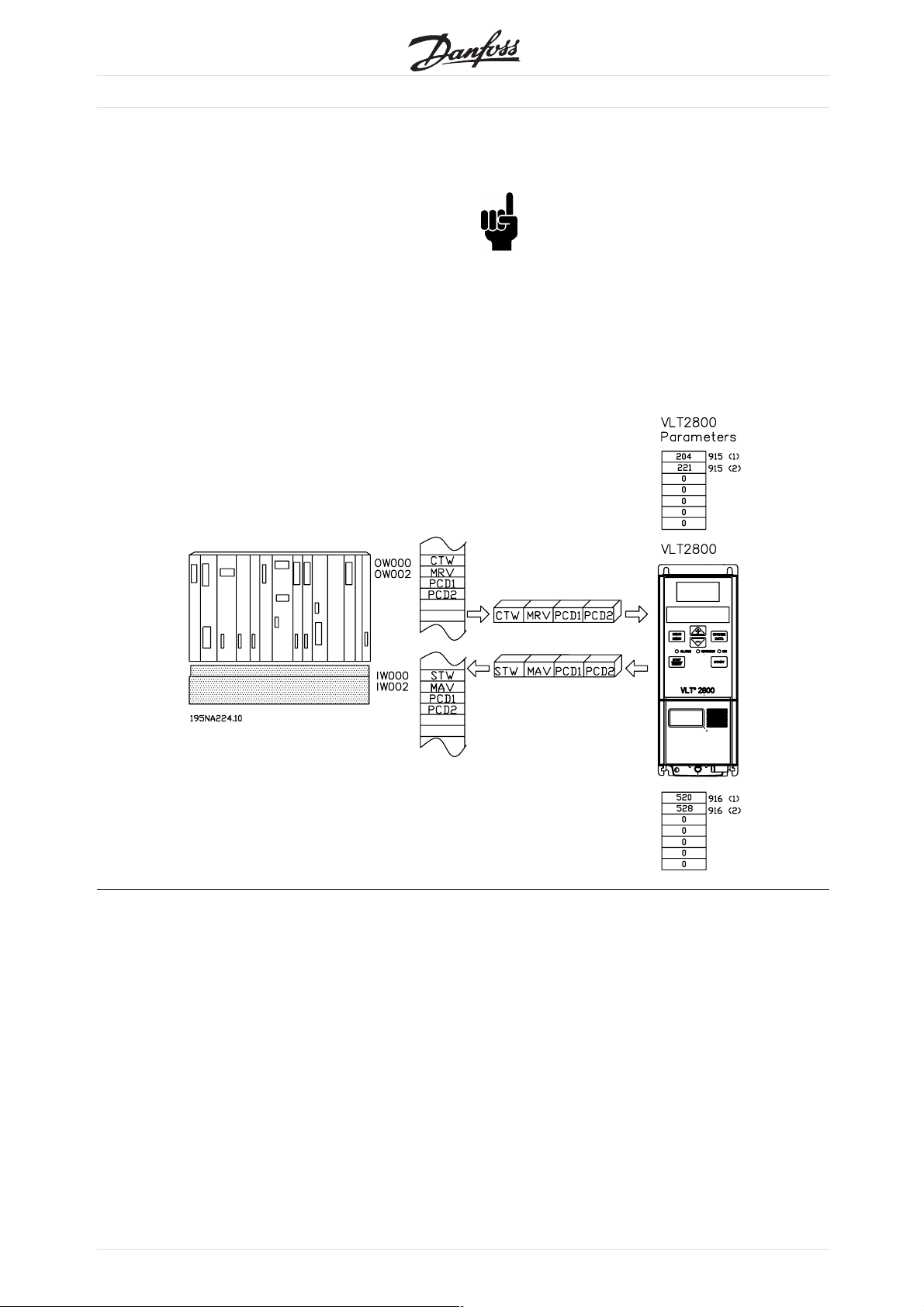

Process Data, PCD

■

The VLT 2800/FCD 300 DeviceNet offers a flexible

way for

Data (I/O words) and the functionality of each word.

To activate the user definable Process data the

user h

parameter 904 PPO selection. This will change

the I/O size to four words in the input and output

area.

profile for the Control-/Status word as well for the

Main Reference Value/Main Actual Value.

The first two words are fixed on the VLT 2800/FCD

300 DeviceNet, whereas the input and output PCD1

the user to customize the number of Process

as to select the I/O Instance 101/151 in

This selection uses the Danfoss specific

and PCD2 can be selected by the user. The number

of PCDs active in a system is fixed to 2 words.

NB!:

The changing of Parameter 904 PPO selection

is first active at the next powerup, and it may

change the mapping of the Masters (PC/PLC).

To enable the use of PCD data of the VLT

FCD 300 DeviceNet the contents of each

2800/

single PCD word has to be configured in Parameter

915 PCD write configuration and 916 PCD read

iguration. Changing Parameter 915/916 has

conf

immediately effect on the PCD data.

24

MG.90.B2.02-VLTisaregisteredDanfosstrademark

VLT®2800 / FCD 300 DeviceNet

DeviceNet object classes

■

Class Code 0x01

■

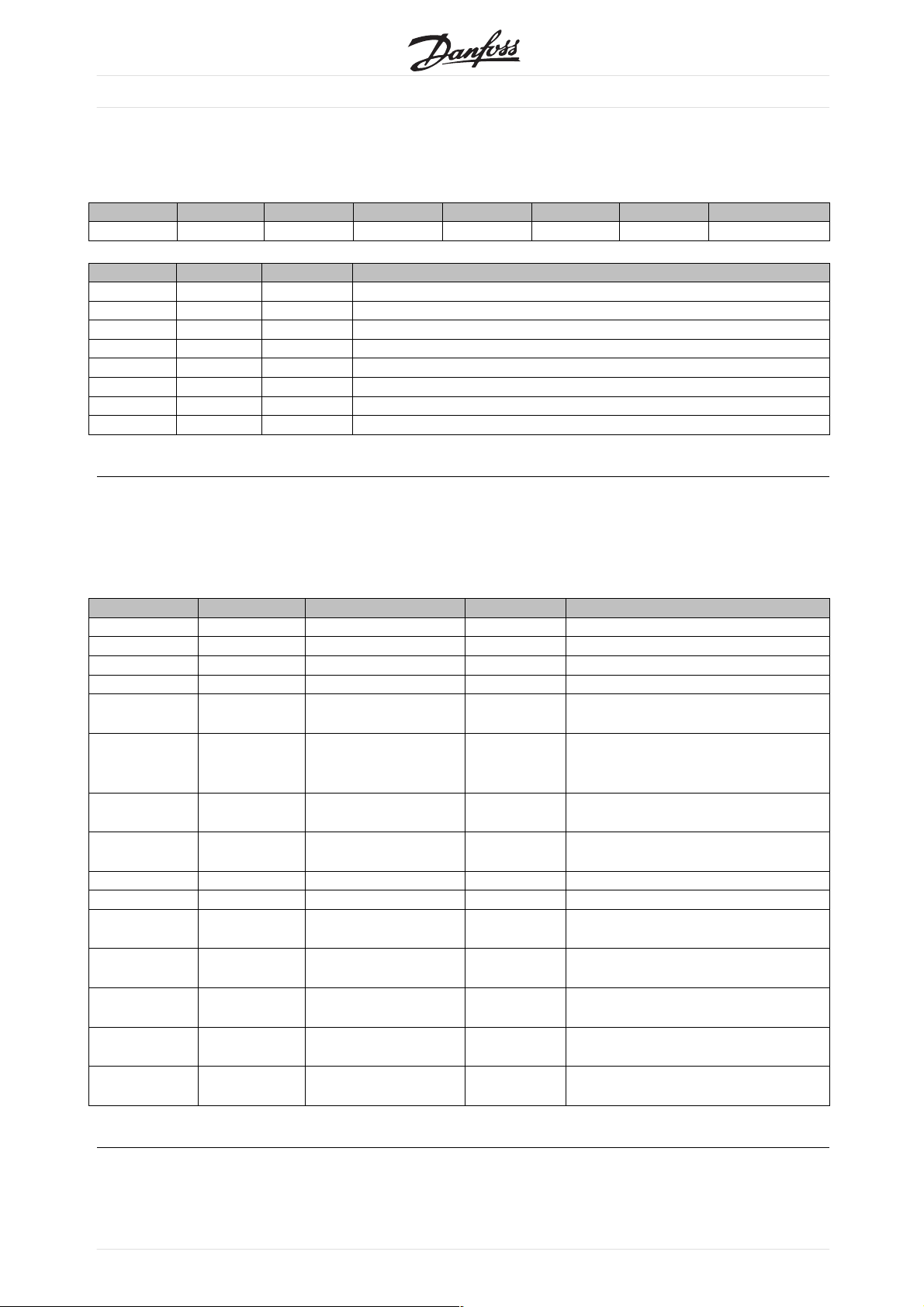

For Class Code 0x01, the following Identity Instance

Attributes have been implemented:

Attribute Access Name Datatype Min/Max Units Default Description

1 Get Vendor USINT 97 Danfoss Drives

Vendor Code

2 Get Device Type UINT 2 AC/DC Motor

3 Get Product Code UINT 200 - 399 VLT 2800

400 - 499 FCD 300

4 Get Revision UINT Software version on

5 Get Status UINT

6 Get Serial number UDINT From VLT 2800/FCD

7 Get Product Name String VLT 2800/FCD 300

10 Get/Set Heartbeat

Interval

USINT

See EDS File section

VLT 2800/FCD 300

300

classes

DeviceNet object

Class Code 0x02

■

For Class Code 0x02, the following Message Router

Instance Attributes have been implemented:

Attribute Access Name Datatype Min/Max Units Default Description

1 Get Number of

Class Code 0x03

■

classes

USINT

For Class Code 0x03, the following DeviceNet

Objects have been implemented:

Attribute Access Name Datatype Min/Max Units Default Description

1 Get/Set MAC ID USINT 0-63 63 Node adress

2 Get/Set Baud Rate USINT 0-2 0 0=125

1=250

2=500

3 Get/Set BOI BOOL Bus-Off Interrupt

5 Get Allocate

Information

6 Get MAC ID Switch

changed

7 Get Baud Rate

switched from

last power up

BOOL 0-1 0 The Node adress

BOOL 0-1 0 Tha Baud Rate Switch

Only required

if predefined

Master/Slave is

implemented

Switch has changed

since the last

power-up/reset

has changed since the

last power-up/reset

MG.90.B2.02 - VLT is a registered Danfoss trade mark

25

VLT®2800 / FCD 300 DeviceNet

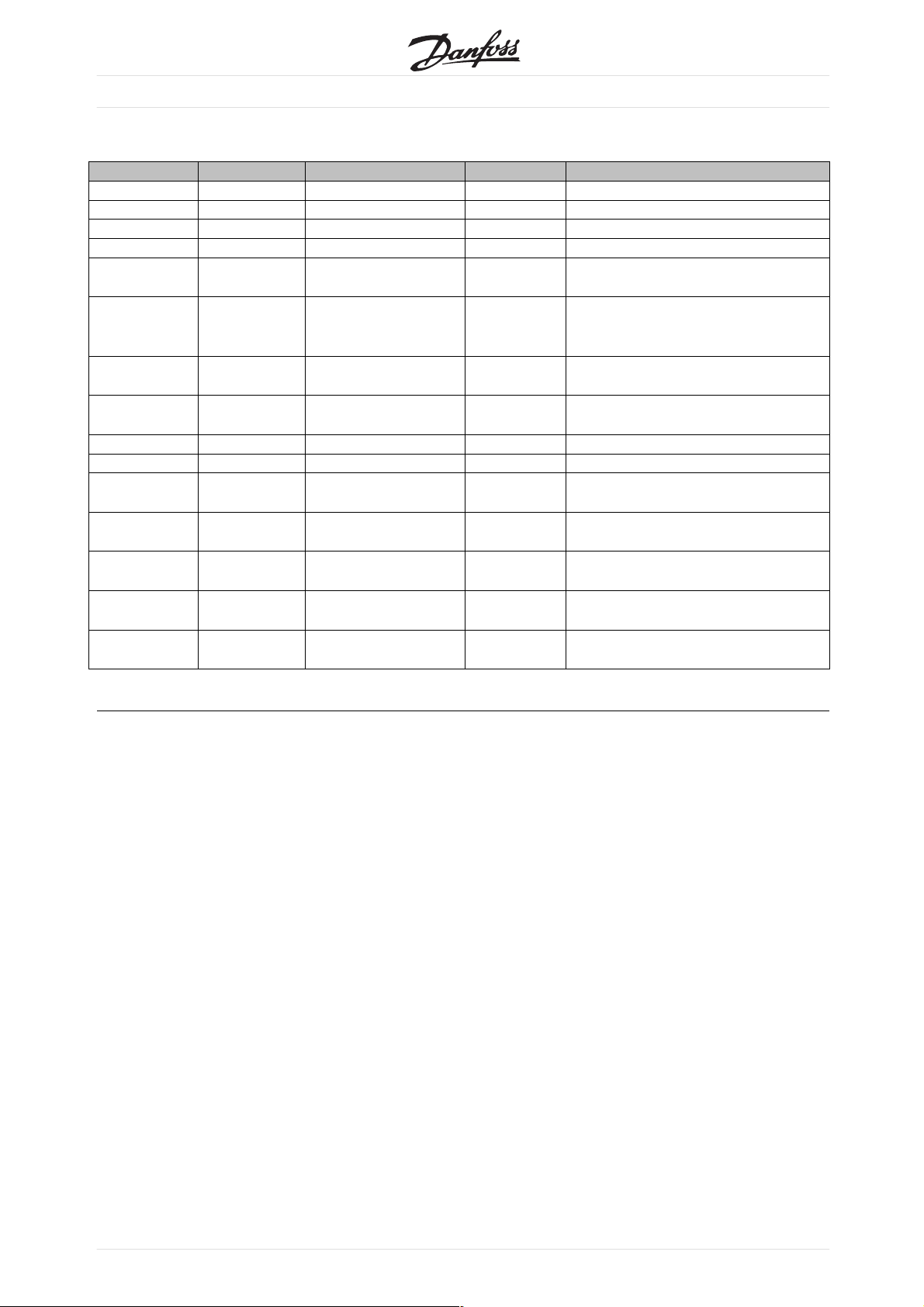

Class Code 0x04

■

For Class Code 0x04, the following Assembly Object

ces have been implemented:

Instan

Attribute Access Name Datatype Min/Max Units Default Description

3 Set Data ARRA

Attribute Access Datasize Description

20 Set 2Words DeviceNet AC/DC Profile

21 Set 2Words DeviceNet AC/DC Profile

70 Get 2Words DeviceNet AC/DC Profile

71 Get 2Words DeviceNet AC/DC Profile

100 Set 2Words Danfoss specific, no PCD Words

101 Set 4Words Danfoss specific, 2 PCD Words

150 Get 2Words Danfoss specific, no PCD Words

151 Get 4Words Danfoss specific, 2 PCD Words

Class Code 0x05

■

For Class Code 0x05, the following Connection

Object Attributes have been implemented:

Y

Instance 1 Attributes: Explicit Message Instance

Attribute Access Name Datatype Description

1 Get State USINT State of the object

2 Get Instance Type USINT Indicates either I/O or Messages Connection

3 Get Transport Class Trigger USINT Defines behaviour of the Connection

4 Get Produced Connection ID UINT CAN Identifier Field when the Connection transmits

5 Get Consumed Connection ID UINT AN Identifier Field value that denotes message to

be received

6 Get Initial Communication

Characteristics

7 Get Produced Connection size UINT Maximum number of bytes transmitted across this

8 Get Consumed Connection size UINT Maximum number of bytes received across this

9 Get/Set Expected Package UINT Defines timming associated w ith this Connection

12 Get Watchdog timeout action USINT Defines how to handle Inactivity/Watchdog timeout

13 Get Produced Connection Path

Length

14 Get Produced Connection Path Array of USINT Specifies the Application Object(s) whose data is to

15 Get Consumed Connection Path

Length

16 Get Consumed Connection Path Array of USINT Specifies the Application object(s) that are to receive

17 Get Production Inhibit Time UINT Defines minimum time between new data production.

USINT Defines the message group(s) across which

productions and consumptions associated with this

Connection occur

Connection

Connection

UINT Number of Bytes in the produced connection path

attribute

be produced by these Connection Objects

UINT Number of bytes in the consumed connection path

attribute

the data consumed by this Connection object

This attribute is required for I/O Client connection

26

MG.90.B2.02-VLTisaregisteredDanfosstrademark

VLT®2800 / FCD 300 DeviceNet

Instance 2 Attributes: Polled I/O

Attribute Access Name Datatype Description

1 Get State USINT State of the object

2 Get Instance Type USINT Indicates either I/O or Messages Connection

3 Get Transport Class Trigger USINT Defines behaviour of the Connection

4 Get Produced Connection ID UINT CAN Identifier Field when the Connection transmits

5 Get Consumed Connection ID UINT AN Identifier Field value that denotes message to

be received

6 Get Initial

7 Get Produced Connection size UINT Maximum number of bytes transmitted across this

8 Get Consume

9 Get/Set Expected Package UINT Defines timming associated w ith this Connection

12 Get Watchdog timeout action USINT Defines how to handle Inactivity/Watchdog timeout

13 Get Produced Connection Path

14 Get Produced Connection Path Array of USINT Specifies the Application Object(s) whose data is to

15 Get Consumed Connection Path

16 Get Consumed Connection Path Array of USINT Specifies the Application object(s) that are to receive

17 Get Production Inhibit Time UINT Defines minimum time between new data production.

Communication

Characteristics

d Connection size

Length

Length

USINT Defines

UINT Maximum

UINT Number of Bytes in the produced connection path

UINT Number of bytes in the consumed connection path

the message group(s) across which

productions and consumptions associated with this

Connection occur

Connection

number of bytes received across this

Connection

attribute

ced by these Connection Objects

be produ

attribute

the data consumed by this Connection object

This attribute is required for I/O Client connection

classes

DeviceNet object

MG.90.B2.02 - VLT is a registered Danfoss trade mark

27

VLT®2800 / FCD 300 DeviceNet

Instance 3: Bit Strobe

Attribute Access Name Datatype Description

1 Get State USINT State of the object

2 Get Instance Type USINT Indicates either I/O or Messages Connection

3 Get Transport Class Trigger USINT Defines behaviour of the Connection

4 Get Produced Connection ID UINT CAN Identifier Field when the Connection transmits

5 Get Consumed Connection ID UiNT AN Identifier Field value that denotes message to

be received

6 Get Initial

7 Get Produced Connection size UINT Maximum number of bytes transmitted across this

8 Get Consume

9 Get/Set Expected Package UINT Defines timming associated w ith this Connection

12 Get Watchdog timeout action USINT Defines how to handle Inactivity/Watchdog timeout

13 Get Produced Connection Path

14 Get Produced Connection Path Array of USINT Specifies the Application Object(s) whose data is to

15 Get Consumed Connection Path

16 Get Consumed Connection Path Array of USINT Specifies the Application object(s) that are to receive

17 Get Production Inhibit Time UINT Defines minimum time between new data production.

Communication

Characteristics

d Connection size

Length

Length

USINT Defines

UINT Maximum

UINT Number of Bytes in the produced connection path

UINT Number of bytes in the consumed connection path

the message group(s) across which

productions and consumptions associated with this

Connection occur

Connection

number of bytes received across this

Connection

attribute

ced by these Connection Objects

be produ

attribute

the data consumed by this Connection object

This attribute is required for I/O Client connection

28

MG.90.B2.02-VLTisaregisteredDanfosstrademark

VLT®2800 / FCD 300 DeviceNet

Instance 4: Change of State/Cycle

Attribute Access Name Datatype Description

1 Get State USINT State of the object

2 Get Instance Type USINT Indicates either I/O or Messages Connection

3 Get Transport Class Trigger USINT Defines behaviour of the Connection

4 Get Produced Connection ID UINT CAN Identifier Field when the Connection transmits

5 Get Consumed Connection ID UiNT AN Identifier Field value that denotes message to

be received

6 Get Initial

7 Get Produced Connection size UINT Maximum number of bytes transmitted across this

8 Get Consume

9 Get/Set Expected Package UINT Defines timming associated w ith this Connection

12 Get Watchdog timeout action USINT Defines how to handle Inactivity/Watchdog timeout

13 Get Produced Connection Path

14 Get Produced Connection Path Array of USINT Specifies the Application Object(s) whose data is to

15 Get Consumed Connection Path

16 Get Consumed Connection Path Array of USINT Specifies the Application object(s) that are to receive

17 Get Production Inhibit Time UINT Defines minimum time between new data production.

Communication

Characteristics

d Connection size

Length

Length

USINT Defines

UINT Maximum

UINT Number of Bytes in the produced connection path

UINT Number of bytes in the consumed connection path

the message group(s) across which

productions and consumptions associated with this

Connection occur

Connection

number of bytes received across this

Connection

attribute

ced by these Connection Objects

be produ

attribute

the data consumed by this Connection object

This attribute is required for I/O Client connection

classes

DeviceNet object

MG.90.B2.02 - VLT is a registered Danfoss trade mark

29

VLT®2800 / FCD 300 DeviceNet

Class Code 0x28

■

For Class Code 0x28, the following Motor Data

ce Attributes have been implemented:

Instan

Attribute Access Name Datatype Min/Max Units Default Description

3 Get/

6 Get/Set Rated

7 Get/Set Rated

8 Get/Set Rated power UDINT 0-18500 Watt Drive depend Rated Power at Rated Frequency

9 Get/Set Rated

15 Get/Set Base Speed UNIT 100-60000 RPM Drive depend Nominal Motor speed

Set

rType

Moto

Current

e

Voltag

Frequency

T

USIN

UNIT 0-100.00 100 mA Drive depend Rates Stator Current

UNIT 200-500 Volt Drive depend Rated Base Voltage

UNIT 1-1000 Hz Drive de

0-10 7 0=No

pend

nStandardMotor

1=PMDCMotor

2=FCDCMotor

3=PMS

4 = FC Synchronous Motor

5 = Switched Reluctance Motor

6=Wou

7 = Squirrel Cage Induction Motor

8 = Stepper Motor

9=Sinu

10 = Trapezoidal PM BL Motor

(from Motor nameplate)

(from M

Rated El

(from Motor nameplate)

(from Motor nameplate)

ynchronous Motor

nd Rotor Induction Motor

soidal PM BL Motor

otor nameplate)

ec. Frequency

30

MG.90.B2.02-VLTisaregisteredDanfosstrademark

VLT®2800 / FCD 300 DeviceNet

Class Code 0x29

■

For Class Code 0x29, the following Control Supervisory

ce Attributes have been implemented:

Instan

Attribute Access Name Datatype Min/Max Default Description

3 Get/

4 Get/Set Run 2 Bool 0-1 Run rev, see note below

5 Get/S

6 Get State USINT 0-7 0 = Vendor Specific

7 Get Running 1 Bool 0-1 0 0 = Other State

8 Get Running 2 Bool 0-1 0 0 = Other State

Set

Run 1 Bool 0-1 Run F

et

NetCt

rl

Bool 0-1 1 0=Loc

wd, see note below

al Control

1 = Control from Network

1=Startup

2 = Not ready

3 = Ready

4=Enabled

5=Stopping

6=FaultStop

7 = Fault

ble and Run 1) or

1=(Ena

(Stopping and Running 1 ) or

(Fault stop and Running 1)

1=(EnableandRun2)or

(Stopping and Running 2) or

(Fault stop and Running 2)

classes

DeviceNet object

9 Get Ready Bool 0-1 0 = Other State

1 = Ready or Enabled or Stopping

10 Get Fault Bool 0-1 0=NoFaultsPresent

1 = Fault Occured (latched)

12 Get/Set Fault Rst Bool 0-1 0 0=NoAction

0 →1=ResetFault

13 Get Fault Code UINT

15 Get Crt From Net Bool 0-1 1 0 = Control is local

1 = Control is from Network

16 Get/Set DN Fault Mode USINT 0-2 1 Action on loss of DeviceNet

0=Fault+Stop

1 = Ignore (Warning Optional)

2=Danfossspecific

AC drive profile is only available if selecting

Instance 20/70 or 21/71

MG.90.B2.02 - VLT is a registered Danfoss trade mark

31

VLT®2800 / FCD 300 DeviceNet

Class Code 0x2A

■

For Class Code 0x2A, the following AC/DC Drive

ce Attributes have been implemented:

Instan

Attribute Access Name Datatype Min/Max Default Description

3 Get At Re

4 Get/Set Net Ref Bool 0-1 1 0 = Set reference not DN Control

6 Get/Set Drive Mode USINT 0-5 1 0 = Vendor specific mode

7 Get Speed Actual INT RPM / 2

8 Get/Set Speed Ref INT RPM / 2

22 Get/Set Speed Scale SINT -128 - 127 Speed scaling factor

ference

Bool 0-1 0=Dr

Speed Scale

Speed Scale

ive not at reference

1 = Drive actual at reference

1 = Set Reference at DN Control

n loop speed (Frequency)

1=Ope

2 = Closed loop speed control

3 = Torque control

ess control (e.g. PI)

4=Proc

5=Positioncontrol

Actual drive speed (best approximation)

Speed Reference

29 Get Ref from Net Bool 0-1 0 = Local speed reference

1 = DeviceNet speed reference

32

MG.90.B2.02-VLTisaregisteredDanfosstrademark

Danfoss Classes

■

VLT®2800 / FCD 300 DeviceNet

Parameter 001 - 099 Class 100

Parameter 101 - 199 Class 101

Parameter 200 - 299 Class 102

Parameter 300 - 399 Class 103

Parameter 400 - 499 Class 104

Parameter 500 - 599 Class 105

Parameter 600 - 699 Class 106

Parameter 700 - 799 Class 107

Parameter 800 - 899 Class 108

Parameter 900 - 999 Class 109

Index Pointer Class 120

Instance Description:

The Danfoss VLT 2800/FCD 300 DeviceNet only use

Instance 1, so always leave this at the value of 1.

Attribute Description:

The attributes for the VLT 2800/FCD 300 parameter

are the last 2 (two) digits of the parameter + 100.

Example:

The parameter 529 (Analog input, terminal

53) will have the following:

Class 105

Instance 1

Attribute 129

Reading/writing to parameters with index:

Parameters of type indexed (e.g. 915 & 916)

need special handling since DeviceNet does

not support indexed addressing.

The way to handle this in the VLT 2800/FCD 300, is

by using the the Danfoss Class 120. which serves

as an index pointer. The pointer has to be set up

before e

Example:

Write 518 in index 2 in parameter 916 PCD Read:

very read/write of an indexed parameter.

NB!:

If two masters are accessing this feature at

the same ime, wrong data may occur.

classes

DeviceNet object

First setup the index pointer in class 120.

In this example index 2:

Class Instance Attribute Variable

120 Dec 1Dec 100 Dec 2Dec

78 Hex 1Hex 64 Hex 2hex

Next step is to write the data (in this example

518) to parameter 916 PCD Read

Class Instance Attribute Variable

109 Dec 1Dec 116 Dec 518 Dec

6D Hex 1Hex 74 Hex 206 hex

MG.90.B2.02 - VLT is a registered Danfoss trade mark

33

DeviceNet Operation Mode

■

Bit Strobe

■

Bit strobe provides the ability of a slave to react to

a special command of the master in a defined way.

Master sends the Bit strobe command to many

devices at a time, only one bit of the message is

assigned to a single slave at a time, what means, that

only the state "TRUE" or "FALSE" can be transmitted.

This parameter may be used for synchronizing drives.

Executing the Bit-Strobe command with a value of

"1" (TRUE) leads the addressed drive to ignore the

input values of the control word and the reference

transmitted via the Assembly Instances , the Control

Supervisor and the AC/DC Drive Object. If the

Bit-Strobe command is executed with a value of "0"

VLT®2800 / FCD 300 DeviceNet

(FALSE), the drive reacts according to the input values

again. This means, that the value of the Bit-Strobe

command is stored internally and the drive reacts

according the value of the Bit-Strobe command.

The master can transmit the new reference when

the Bit-Strobe value is "1", it must be valid after

the execution of the Bit-Strobe command with the

value "0" [10]. After a Bit-Strobe command has

been executed, the device must answer with the

according I/O telegram and ignore any CTW, MAV

and PCDs transmitted by the master.

34

MG.90.B2.02-VLTisaregisteredDanfosstrademark

Polling

■

This is the standard Devicenet operation mode,

g that data can be acquired by the master via

meanin

polling using the Devicenet or Danfoss objects.

Change of State, COS

■

This operation modus can be used in order to

minimize network traffic. Messages are only sent to

the consumer, if a defined state or value has changed.

In order to signalize, that the connection has not been

crashed or is powered off, a Heartbeat Message is

transmitted within a specified time (Heartbeat Interval).

This time is defined in attribute heartbeat time of the

connection object class code 0x05. To prevent the

device from producing heavy network traffic, if a value

often changes, the Production Inhibit Time (attribute of

connection object) is defined. This parameter defines

the minimum delay between 2 c-o-s messages.

The Attribute Expected Package Rate defines

the maximum time between two Cos messages

even though the value has not changed. Cos

operation modus can only be used on I/O

instances defined in parameter 904.

VLT®2800 / FCD 300 DeviceNet

Mode

DeviceNet Operation

Parameters 834 through 837 can be used for filtering

ut undesired events for Cos. If a filter bit is set

o

to 0, the corresponding I/0 instance bit will not

be able to produce a Cos message.

MG.90.B2.02 - VLT is a registered Danfoss trade mark

35

EDS Files

■

VLT®2800 / FCD 300 DeviceNet

Note that the EDS files can be uploaded from the

VLT frequency converters via RS Networx. Before

uploading the EDS file you must check the version

of RS Networx in Help and About RS Networx. RS

Networx version 3.11.00 supports the format Errata 2

and no changes must be made to the VLT frequency

converter. RS Networx version 3.00.00 supports

Errata 1 and parameter 838 EDS Data type must be

set to Errata 1 and power must be re-cycle.

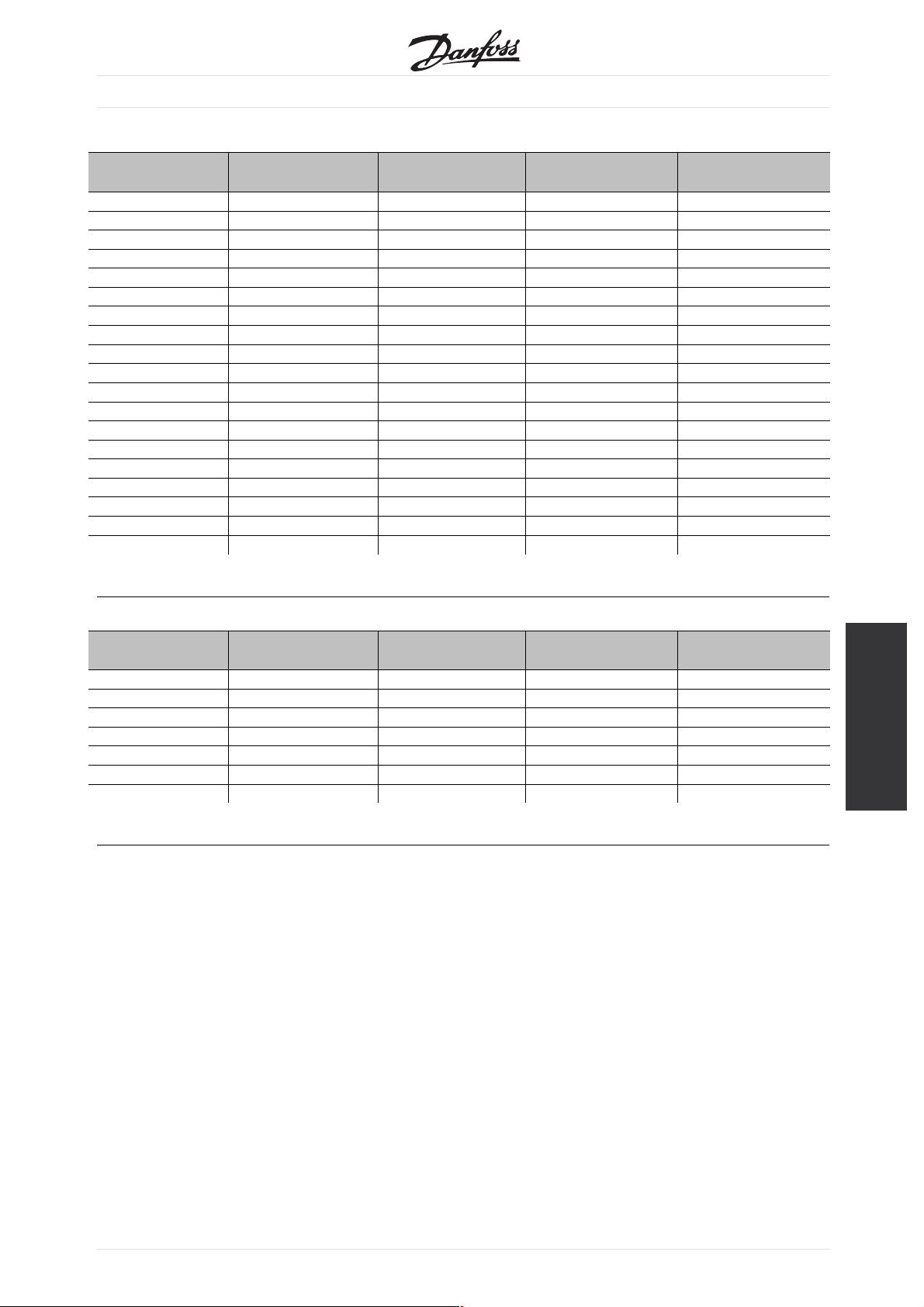

VLT 2800 US version with DeviceNet

Product Code Drive Model Drive Rating

232 VLT 2803 0.37 (0.50) 200 - 240 V

233 VLT 2805 0.55 (0.75) 200 - 240 V

234 VLT 2807 0.75 (1.00) 200 - 240 V

235 VLT 2811 1.10 (1.50) 200 - 240 V

236 VLT 2815 1.50 (2.00) 200 - 240 V

237 VLT 2822 2.20 (3.00) 200 - 240 V

238 VLT 2830 3.70 (5.00) 200 - 240 V

283 VLT 2805 0.55 (0.75) 380 - 480 V

284 VLT 2807 0.75 (1.00) 380 - 480 V

285 VLT 2811 1.10 (1.50) 380 - 480 V

286 VLT 2815 1.50 (2.00) 380 - 480 V

287 VLT 2822 2.20 (3.00) 380 - 480 V

288 VLT 2830 3.00 (4.00) 380 - 480 V

289 VLT 2840 4.00 (5.00) 380 - 480 V

290 VLT 2855 5.50 (7.50) 380 - 480 V

291 VLT 2875 7.50 (10.00) 380 - 480 V

292 VLT 2880 11.0 (15.00) 380 - 480 V

293 VLT 2881 15.0 (20.00) 380 - 480 V

294 VLT 2882 18.5 (25.00) 380 - 480 V

Start RS Networx and go online and the VLT

2800/FCD 300 will be shown as a grey box as

unregistered device. Click on the VLT 2800/FCD

300 and go to Tools and choose EDS Wizard. Click

on next by the EDS wizard and choose Create an

EDS file. RS Networx will now start to create an

EDS file from the VLT frequency converter.

To upload EDS files please visit www.DanfossDrives.com

Vol tage EDS File Name

kW (HP)

36

MG.90.B2.02-VLTisaregisteredDanfosstrademark

VLT 2800 European version with DeviceNet

Product Code Drive Model Drive Rating

332 VLT 2803 0.37 (0.50) 200 - 240 V

333 VLT 2805 0.55 (0.75) 200 - 240 V

334 VLT 2807 0.75 (1.00) 200 - 240 V

335 VLT 2811 1.10 (1.50) 200 - 240 V

336 VLT 2815 1.50 (2.00) 200 - 240 V

337 VLT 2822 2.20 (3.00) 200 - 240 V

338 VLT 2830 3.70 (5.00) 200 - 240 V

383 VLT 2805 0.55 (0.75) 380 - 480 V

384 VLT 2807 0.75 (1.00) 380 - 480 V

385 VLT 2811 1.10 (1.50) 380 - 480 V

386 VLT 2815 1.50 (2.00) 380 - 480 V

387 VLT 2822 2.20 (3.00) 380 - 480 V

388 VLT 2830 3.00 (4.00) 380 - 480 V

389 VLT 2840 4.00 (5.00) 380 - 480 V

390 VLT 2855 5.50 (7.50) 380 - 480 V

391 VLT 2875 7.50 (10.00) 380 - 480 V

392 VLT 2880 11.0 (15.00) 380 - 480 V

393 VLT 2881 15.0 (20.00) 380 - 480 V

394 VLT 2882 18.5 (25.00) 380 - 480 V

VLT®2800 / FCD 300 DeviceNet

Vol tage EDS File Name

kW (HP

FCD 300 European version with DeviceNet

Product Code Drive Model Drive Rating

480 FCD 303 0.37 (0.50) 380 - 480 V

481 FCD 305 0.55 (0.75) 380 - 480 V

482 FCD 307 0.75 (1.00) 380 - 480 V

483 FCD 311 1.10 (1.50) 380 - 480 V

484 FCD 315 1.50 (2.00) 380 - 480 V

485 FCD 322 2.20 (3.00) 380 - 480 V

486 FCD 330 3.00 (4.00) 380 - 480 V

kW (HP

Vol tage EDS File Name

EDS

Files

MG.90.B2.02 - VLT is a registered Danfoss trade mark

37

VLT®2800 / FCD 300 DeviceNet

Special Attention

■

NB!:

Please note, that terminal 46 has been

removed from the VLT 2800 DeviceNet

card, meaning that parameter 341 - 342

are not having any function.

•

002:

If operation site = Local, then control via

DeviceNet is not possible.

•

502-508:

tion of how to gate DeviceNet control

Selec

commands with control commands on the digital

inputs of the control card.

•

515-538:

Data read out parameters that can be used to read

various actual data from the VLT, as for example

actual status on the analog and digital inputs of the

control card thus using these as inputs to the master.

•

Select DeviceNet in this parameter.

800 P

rotocol Select

Description of choice:

For FCD 300 connections see FCD 300 Design

Guide MG.04.AX.YY par. 620.

Normal function [0] is used for normal

operation of the motor.

Control card test [2] is selected if you wish to check

the control card’s analog/digital input, analog/digital

outputs, relay outputs and 10 V and 24 V voltages.

The test is performed as follows:

18, 27, 33 are connected to relay terminal 03.

19, 29, V+ are connected to relay terminal 02.

50 - 53 are connected.

42 - 60 are connected.

55 - V- are connected.

12 is connected to relay terminal 01.

•

801 Baud rate select

Selection of DeviceNet transmission speed.

•

833 Fieldbus enable

le the DeviceNet communication. The

Enab

default setting is disable.

•

904 PPO selection

Selection of Instance type.

•

918 Station address / MAC ID

he Station address / MAC ID in this parameter.

Set t

620 Operation Mode

(OPERATION MODE)

Val ue:

✭Normal operation (NORMAL OPERATION)

Control card test (CONTROL CARD TEST)

Initialize (INITIALIZE)

Function:

In addition to its normal function, this parameter

can be used to test the control card.

There is also the opportunity to perform an

initialisation at the factory setting for all parameters

in all Setups, with the exception of parameters

500 Address, 501 Baudrate, 600-605 Operating

data and 615-617 Fault log.

✭

= factory setting. () = display text [] = value for use in communication via serial communication port

[0]

[2]

[3]

Use the following procedure for the control card test:

1. Select control card test.

2. Disconnect the mains voltage and wait until the

light in the display has disappeared.

3. Mount according to drawing and description.

4. Connect the mains voltage.

5. The frequency converter automatically undertakes

a test of the control card.

If the frequency converter displays a fault code from

37-45, the control card test has failed. Replace the

control card to start up the frequency converter.

If the frequency converter comes into Display mode,

the test is OK. Remove the test connector and

the frequency converter is ready for operation.

Parameter 620 Operating mode is automatically

set to Normal operation [0].

Initialisation [3] is selected if you wish to use

the unit’s factory setting.

Procedure for initialisation:

1. Select Initialisation [3].

2. Disconnect the mains voltage and wait until the

light in the display has disappeared.

3. Connect the mains voltage.

4. An initialisation is performed in all parameters

in all Setups, with the exception of parameters

38

MG.90.B2.02-VLTisaregisteredDanfosstrademark

VLT®2800 / FCD 300 DeviceNet

500 Address, 501 Baudrate, 600-605 Operating

data, 615-617 Fault log, 833 Fieldbus enable

and 904

800 Pr

Val ue:

✭DeviceNet (DEVICENET)

Function:

This parameter is read only.

801 Baud Rate Select

Val ue:

✭125 kbps (125 KBPS)

250 kbps (250 KBPS)

500 kbps (500 KBPS)

Function:

Selection of the DeviceNet transmission speed. It

must correspond to the transmission speed of the

master and the other DeviceNet nodes.

Description of choice:

Select the baud rate.

PPO selection.

otocol Select

(PROTOCOL SELECT)

(BAUD RATE SELECT)

[2]

[20]

[21]

[22]

804 Bus time out function

(TIME OUT FUNCT.)

Val ue:

✭OFF (OFF)

Freeze output frequency (FREEZE OUTPUT)

Stop with auto restart (STOP)

Output = jog frequency (JOGGING)

Output = max speed (MAX SPEED)

Stop with trip (STOP AND TRIP)

Select Setup 2 (SELECT SETUP 2)

Function:

The timeout counter is activated at the first receipt

of a valid control word, i.e. bit 10 = OK.

Description of choice:

The VLT remains in the timeout status until one

of the following four conditions occurs.

1. A valid con

and control via DeviceNet is resumed with the

current control word. If the timeout function Stop

with trip

or control panel is necessary.

2. Parameter 002 = Local operation => local control

through c

3. Parameter 804 = Off => control via DeviceNet

is resumed, with the control word used

last bein

trol word (bit 10 = OK) is received

is selected a reset via bus, terminals

ontrol panel is active.

g taken.

[0]

[1]

[2]

[3]

[4]

[5]

[8]

NB!:

Note that a change of this parameter is

first executed at next power up.

803 Bus time out

(BUS TIME OUT)

Val ue:

1 - 99 sec

Function:

If the VLT frequency converter doesn’t receive a

control word for a period longer than the time set in

this parameter, the function selected in parameter

804 Response after bus errror will be activated.

Description of choice:

Set the desired time.

Please note, that when the drive is running Cyclic or

COS mode, the Bus time out has to be set higher

than Heartbeat Rate. If not, the VLT will time out.

✭ 1 sec

805 Bit 10 function

(BIT 10 FUNCTION)

Function:

This parameter is read only.

832 Bus Off Interrupt Behavior

(BUS OFF INT. BEH)

Val ue:

✭Hold the device in bus-off state (HOLD CAN)

Reset the device and continue communicating

(RESET CAN)

Function:

This param

behavior if a bus-off interrupt is detected.

Description of choice:

If this parameter is set to Hold the device in bus-off

state [0] and a bus-off event is detected, the VLT

2800/FCD 300 will go into reset/bus-off state.

eter defines the VLT 2800/FCD 300

[0]

[1]

Programming

✭

= factory setting. () = display text [] = value for use in communication via serial communication port

MG.90.B2.02 - VLT is a registered Danfoss trade mark

39

VLT®2800 / FCD 300 DeviceNet

If this parameter is set to Reset the device and continue

communicating [1] and a bus-off event is detected the

VLT 2800/FCD 300 will try to reset and re-initialise

the CAN chip and to continue communication.

833 Fieldbus enable

(FIELDBUS ENABLE)

Val ue:

✭Disabled (DISABLE)

Enabled (ENABLE)

Function:

This parameter allows to disable the

communication interface.

Description of choice:

Select Enable [1] to start the DeviceNet communication.