VLT® Decentral FCD 300

The VLT® Decentral FCD 300 is a complete frequency converter designed for decentral mounting.

It can be mounted on the machine or a wall close to the motor, or directly on the motor.

Perfect

match for:

– Material handling in Food

& Beverage Industry

– Installations in wash-down

areas

– Widely distributed

applications

The VLT® Decentral FCD 300 comes in

very robust enclosure, with a special

painting treatment to withstand harsh

environments and typical cleaning

agents used in wash-down areas.

Its design oers a smooth cleaningfriendly surface.

The decentral design reduces the

need for central control panels and

eliminates the need for space-consuming motor control cabinets.

Feature Benet

Reliable Maximum uptime

Special surface treatment as protection against

aggressive environments

Twin part design (installation box and

electronic part)

Integrated lockable service switch available Local disconnection possible

Full protection is oered Protects the motor and drive

User-friendly Saves commissioning and operating cost

Adapts to any brand of motor and

geared motor

Designed for power and eldbus looping Cable savings

Visible LEDs Quick status check

Set-up and controlled through a remote control

panel or eldbus communication and dedicated

MCT 10 set-up software

The need for long screened motor

cables is signicantly reduced.

Power range

0.37 – 3.3 kW, 3 x 380 – 480 V

Enclosure

IP 66/Type 4X (indoor)

Easy cleaning; no dirt trap

Easy and fast service

Easy and exible installation

Easy commissioning

Facts about our products

Plug-and-drive

The bottom section contains maintenance-free Cage Clamp connectors

and looping facilities for power and

eldbus cables. Once installed,

commissioning and upgrading can

be performed in no time by plugging

in another control lid.

Flexible installation

The FCD 300 series facilitates internal

power line and eldbus looping.

Terminals for 4 mm2 power cables

inside the enclosure allows connection of up to 10+ units.

Available options

Service switch

n

n

M12 connectors for external

sensors

n

Han 10E motor connector

n

Brake chopper and resistor

n

24 V external back up of control

and communication

n External electromechanical

brake control and supply

Specications

Mains supply (L1, L2, L3)

Supply voltage 3 x 380/40 0/415/440/48 0 V ±10%

Supply frequency 50/60 Hz

Max. imbalance on supply voltage ±2.0% of rated supply voltage

Switching on input supply 2 times/min.

Power Factor (cos φ) 0.9 /1.0 at rated load

Output data (U, V, W)

Output voltage 0–100% of supply

Overload torque 160% for 60 sec.

Switching on output Unlimited

Ramp times 0.02 – 3600 sec.

Output frequency 0.2 – 132 Hz, 1– 590 Hz

Digital inputs

Programmable digital inputs 5

Voltage level 0–24 V DC (PNP positive logic)

Analog inputs

Analog inputs 2 (1 voltage, 1 current)

Voltage level/Current level 0– ±10 V DC / 0/4–20 mA (scaleables)

Pulse inputs

Programmable pulse inputs 2 (24 V DC)

Max. frequency 110 kHz (push-pull) / 5 kHz (open collector)

Analog output

Programmable analog output 1

Current range 0/4–20 mA

Digital output

Programmable digital/frequency output 1

Voltage/frequency level 24 V DC/10 kHz (max.)

Relay output

Programmable relay output 1

Max. terminal load 250 V AC, 2 A, 500 VA

Fieldbus communication

FC Protocol, Modbus RTU, Metasys N2 Built-in

Probus DP, DeviceNet, AS-interface Optional (integrated)

Externals

Vibration test 1.0 g (IEC 60068)

Max. relative humidity 95 % (IEC 60068-2-3)

Ambient temperature Max. 40˚C (24 hour average max. 35˚C)

Min. ambient temperature in full operation 0˚C

Min. ambient temperature at reduced

performance

Approvals CE, UL, C-tick, ATEX*

* Contact Danfoss for details

-10˚C

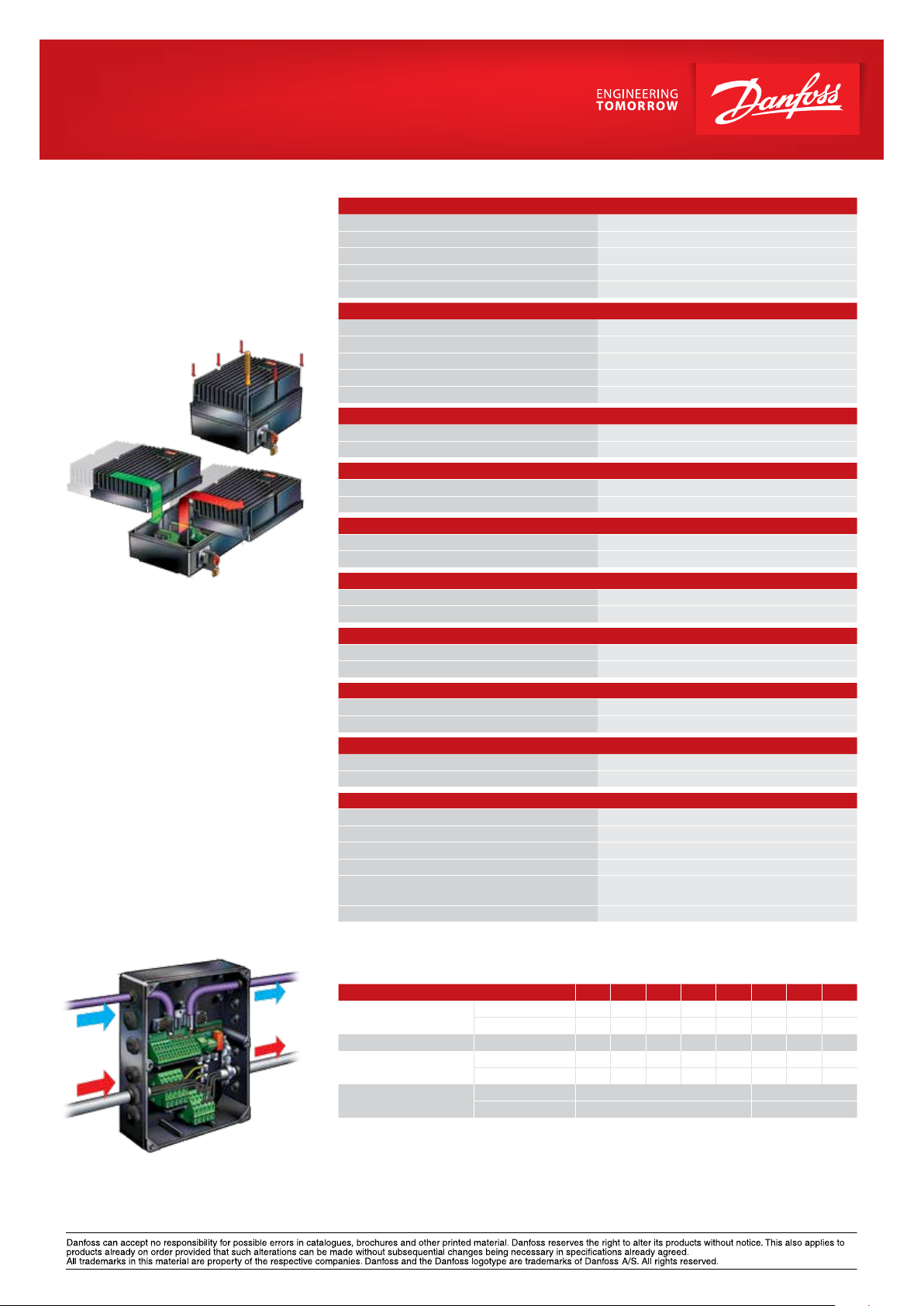

Technical data

VLT® Decentral FCD 303 305 307 311 315 322 330 335*

[A] 1.4 1.8 2.2 3.0 3.7 5.2 7.0 7.6

I

Output current

(3 x 380 – 480 V)

Output power (400 V) S

Typical shaft output

Mechanical dimensions

H x W x D (mm)

max. 35˚ C

* t

amb

DKDD.PFP.751.A1.02 VLT® is a trademark of Danfoss A/S Produced by PE-MMSC 2012.09

INV (60s)

[A] 2.2 2.9 3.5 4.8 5.9 8.3 11.2 11.4

I

MAX (60s)

INV

[K VA] 1.0 1.2 1.5 2.0 2.6 3.6 4.8 5.3

[kW] 0.37 0.55 0.75 1.1 1.5 2.2 3.0 3.3

P

M,N

[HP] 0.5 0.75 1.0 1.5 2.0 3.0 4.0 5.0

P

M,N

Motor mounting 244 x 192 x 142 300 x 258 x 151

Stand alone 300 x 192 x 145 367 x 258 x 154

Loading...

Loading...