Page 1

ENGINEERING TOMORROW

Quick Guide • Kurzanleitung • Guide rapide •

Guíarápida • Guia Rápido • Краткое руководство

VLT® Micro Drive FC 51

vlt-drives.danfoss.com

Page 2

Page 3

Page 4

Page 5

Contents

Contents

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1 Quick Guide

1.1 Introduction

1.1.1 Purpose of the Manual 6

1.1.2 Additional Resources 6

1.1.3 IT Mains 6

1.1.4 Avoid Unintended Start 6

1.2 Safety

1.3 Installation

1.3.1 Side-by-side Installation 8

1.3.2 Mechanical Dimensions 9

1.3.3 Connecting to Mains and Motor 12

1.3.4 Control Terminals 12

1.3.5 Power Circuit - Overview 14

1.3.6 Load Sharing/Brake 15

1.4 Programming

1.4.1 Programming on Automatic Motor Adaptation (AMA) 15

1.4.2 Programming on Automatic Motor Tuning (AMT) 15

6

6

7

8

15

1.5 Parameter Overview

1.6 Troubleshooting

1.7 Specications

1.8 General Technical Data

1.9 Special Conditions

1.9.1 Derating for Ambient Temperature 30

1.9.2 Derating for Low Air Pressure 30

1.9.3 Derating for Running at Low Speeds 30

1.10 Options and Spare Parts

2 Kurzanleitung

2.1 Einführung

2.1.1 Zielsetzung des Handbuchs 32

2.1.2 Zusätzliche Materialien 32

2.1.3 IT-Netz 32

2.1.4 Unerwarteten Anlauf vermeiden 32

2.2 Sicherheit

2.3 Installation

17

21

23

27

30

31

32

32

33

34

2.3.1 Seite-an-Seite-Installation 34

2.3.2 Mechanische Abmessungen 35

2.3.3 Netz- und Motoranschluss 37

2.3.4 Steuerklemmen 38

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 1

Page 6

Contents

VLT® Micro Drive FC 51

2.3.5 Elektrische Installation - Übersicht 40

2.3.6 Zwischenkreiskopplung/Bremse 41

2.4 Programmieren

2.4.1 Programmieren einer automatischen Motoranpassung (AMA) 41

2.4.2 Programmieren des Automatic Motor Tuning (AMT) 42

2.5 Parameterübersicht

2.6 Fehlersuche und -behebung

2.7 Technische Daten

2.8 Allgemeine technische Daten

2.9 Besondere Betriebsbedingungen

2.9.1 Leistungsreduzierung wegen erhöhter Umgebungstemperatur 56

2.9.2 Leistungsreduzierung wegen niedrigem Luftdruck 56

2.9.3 Leistungsreduzierung beim Betrieb mit niedriger Drehzahl 56

2.10 Optionen und Ersatzteile

3 Guide rapide

3.1 Introduction

3.1.1 Objet de ce manuel 58

3.1.2 Ressources supplémentaires 58

3.1.3 Secteur IT 58

41

43

47

49

53

56

57

58

58

3.1.4 Éviter les démarrages imprévus 58

3.2 Sécurité

3.3 Installation

3.3.1 Montage côte à côte 60

3.3.2 Encombrement 61

3.3.3 Raccordement au secteur et au moteur 64

3.3.4 Bornes de commande 64

3.3.5 Circuit d'alimentation - Vue d'ensemble 66

3.3.6 Répartition de la charge/frein 67

3.4 Programmation

3.4.1 Programmation de l'adaptation automatique au moteur (AMA) 67

3.4.2 Programmation sur Réglage auto. du moteur (AMT) 68

3.5 Vue d'ensemble des paramètres

3.6 Dépannage

3.7 Spécications

3.8 Caractéristiques techniques générales

3.9 Exigences particulières

59

60

67

69

73

75

79

82

3.9.1 Déclassement pour température ambiante 82

3.9.2 Déclassement pour basse pression atmosphérique 82

3.9.3 Déclassement pour fonctionnement à faible vitesse 82

3.10 Options et pièces détachées

2 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

83

Page 7

Contents

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

4 Guía rápida

4.1 Introducción

4.1.1 Objetivo de este manual 84

4.1.2 Recursos adicionales 84

4.1.3 Alimentación aislada de tierra (IT) 84

4.1.4 Evite los arranques accidentales 84

4.2 Seguridad

4.3 Instalación

4.3.1 Montaje lado a lado 86

4.3.2 Dimensiones mecánicas 87

4.3.3 Conexión a la alimentación y al motor 90

4.3.4 Terminales de control 90

4.3.5 Circuito de potencia - Presentación 92

4.3.6 Carga compartida / freno 93

4.4 Programación

4.4.1 Programación de la adaptación automática del motor (AMA) 93

4.4.2 Programación del ajuste automático del motor (AMT) 94

84

84

85

86

93

4.5 Resumen de parámetros

4.6 Resolución del problema

4.7 Especicaciones

4.8 Especicaciones técnicas generales

4.9 Condiciones especiales

4.9.1 Reducción de potencia en función de la temperatura ambiente 111

4.9.2 Reducción de potencia debido a la baja presión atmosférica 111

4.9.3 Reducción de potencia en función del funcionamiento a bajas vueltas 111

4.10 Opciones y repuestos

5 Guia Rápido

5.1 Introdução

5.1.1 Objetivo do manual 113

5.1.2 Recursos adicionais 113

5.1.3 Rede Elétrica IT 113

5.1.4 Evite partida acidental 113

5.2 Segurança

5.3 Instalação

95

102

104

108

111

112

113

113

114

115

5.3.1 Instalação lado a lado 115

5.3.2 Dimensões mecânicas 116

5.3.3 Conexão na Rede Elétrica e Motor 119

5.3.4 Terminais de Controle 119

5.3.5 Circuito de Alimentação - Visão Geral 121

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 3

Page 8

Contents

VLT® Micro Drive FC 51

5.3.6 Load Sharing/Freio 122

5.4 Programação

5.4.1 Programação na Adaptação Automática do Motor (AMA) 122

5.4.2 Programação na adaptação automática do motor (AMT) 122

5.5 Visão Geral dos Parâmetros

5.6 Resolução de Problemas

5.7 Especicações

5.8 Dados Técnicos Gerais

5.9 Condições Especiais

5.9.1 Derating para temperatura ambiente 138

5.9.2 Derating para pressão do ar baixa 138

5.9.3 Derating devido a funcionamento em baixas velocidades 138

5.10 Opcionais e Peças de Reposição

6 Краткое руководство

6.1 Введение

6.1.1 Цель этого руководства 140

6.1.2 Дополнительные ресурсы 140

6.1.3 Сеть IT 140

122

124

129

131

135

138

139

140

140

6.1.4 Предотвращение непреднамеренного пуска 140

6.2 Техника безопасности

6.3 Монтаж

6.3.1 Монтаж рядом вплотную 142

6.3.2 Габаритные и присоединительные размеры 143

6.3.3 Подключение к сети и к двигателю 146

6.3.4 Клеммы управления 146

6.3.5 Краткое описание силовой цепи 148

6.3.6 Распределение нагрузки/тормоз 149

6.4 Программирование

6.4.1 Программирование с помощью автоматической адаптации двигателя (ААД) 149

6.4.2 Программирование с помощью автоматической настройки двигателя (AMT) 150

6.5 Обзор параметров

6.6 Устранение неисправностей

6.7 Технические характеристики

6.8 Общие технические данные

6.9 Особые условия

141

142

149

151

158

160

164

167

6.9.1 Снижение номинальных характеристик в зависимости от температуры

окружающей среды 167

6.9.2 Снижение номинальных параметров в случае низкого атмосферного

давления 167

6.9.3 Снижение номинальных параметров при работе на низких скоростях 167

4 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 9

Contents

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

6.10 Дополнительные устройства и запасные части

Index

168

169

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 5

Page 10

089

Quick Guide

VLT® Micro Drive FC 51

11

1 Quick Guide

1.1 Introduction

1.1.1 Purpose of the Manual

This quick guide provides information for safe installation

and commissioning of the VLT® Micro Drive FC 51

frequency converter.

The frequency converter complies with UL 508C thermal

memory retention requirements. For more information,

refer to the section Motor Thermal Protection in the

product-specic design guide.

1.1.3 IT Mains

NOTICE

The quick guide is intended for use by

To use the frequency converter safely and professionally,

read and follow the operating instructions. Pay particular

attention to the safety instructions and general warnings.

Always keep this quick guide with the frequency converter.

VLT® is a registered trademark.

1.1.2 Additional Resources

Additional resources are available to understand advanced

frequency converter functions and programming:

The VLT® Micro Drive FC 51 Programming Guide

•

provides greater detail on working with

parameters and many application examples.

The VLT® Micro Drive FC 51 Design Guide provides

•

detailed information about capabilities and

functionality to design motor control systems.

Instructions for operation with optional

•

equipment and replacement of components.

Supplementary publications and manuals are available at:

drives.danfoss.com/downloads/portal/#/

qualied personnel.

IT MAINS

Installation on isolated mains source, that is IT mains.

Maximum supply voltage allowed when connected to

mains: 440 V.

As an option, Danfoss oers recommended line lters for

improved harmonics performance. See Table 1.11.

1.1.4 Avoid Unintended Start

While the frequency converter is connected to mains, the

motor can be started/stopped using digital commands, bus

commands, references, or via the LCP (local control panel).

To avoid unintended start:

Disconnect the frequency converter from mains

•

for personal safety considerations.

Always press [O/Reset] before changing

•

parameters.

Equipment containing electrical components

must not be disposed of together with domestic

waste.

It must be separately collected with electrical

and electronic waste according to local and

currently valid legislation.

6 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 11

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1.2 Safety

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input, DC supply, or load sharing.

Failure to perform installation, start-up, and maintenance

by qualied personnel can result in death or serious

injury.

Only qualied personnel must perform instal-

•

lation, start-up, and maintenance.

Before performing any service or repair work,

•

use an appropriate voltage measuring device to

make sure that there is no remaining voltage on

the drive.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

the motor may start at any time, causing risk of death,

serious injury, equipment, or property damage. The

motor can start by means of an external switch, a

eldbus command, an input reference signal from the

LCP or LOP, or after a cleared fault condition.

Disconnect the frequency converter from mains

•

whenever personal safety considerations make

it necessary to avoid unintended motor start.

Press [O/Reset] on the LCP before

•

programming parameters.

The frequency converter, motor, and any driven

•

equipment must be in operational readiness

when the frequency converter is connected to

AC mains.

NOTICE

The [O/Reset] key is not a safety switch. It does not

disconnect the frequency converter from mains.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors,

which can remain charged even when the frequency

converter is not powered. High voltage can be present

even when the warning LED indicator lights are o.

Failure to wait the specied time after power has been

removed before performing service or repair work can

result in death or serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

•

minimum duration of waiting time is specied

in Table 1.1.

Before performing any service or repair work,

•

use an appropriate voltage measuring device to

make sure that the capacitors are fully

discharged.

Size Minimum waiting time (minutes)

M1, M2, and M3 4

M4 and M5 15

Table 1.1 Discharge Time

Leakage current (>3.5 mA)

Follow national and local codes regarding protective

earthing of equipment with a leakage current >3,5 mA.

Frequency converter technology implies high frequency

switching at high power. This generates a leakage current

in the ground connection. A fault current in the frequency

converter at the output power terminals might contain a

DC component, which can charge the lter capacitors and

cause a transient ground current. The ground leakage

current depends on various system congurations

including RFI ltering, screened motor cables, and

frequency converter power.

EN/IEC61800-5-1 (Power Drive System Product Standard)

requires special care if the leakage current exceeds 3.5 mA.

Reinforce Grounding in 1 of the following ways:

1 1

Grounding wire of at least 10 mm2 (8 AWG).

•

2 separate ground wires both complying with the

•

dimensioning rules.

See EN 60364-5-54 § 543.7 for further information.

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 7

Page 12

Quick Guide

VLT® Micro Drive FC 51

11

Using RCDs

Where residual current devices (RCDs), also known as earth

leakage circuit breakers (ELCBs), are used, comply with the

following:

Use RCDs of type B that can detect AC and DC

•

currents.

Use RCDs with an inrush delay to prevent faults

•

due to transient ground currents.

Dimension RCDs according to the system congu-

•

ration and environmental considerations.

Motor thermal protection

Motor overload protection is possible by setting parameter

1-90 Motor Thermal Protection to [4] ETR trip. For the North

American market: Implemented ETR function provides class

20 motor overload protection, in accordance with NEC.

Installation at high altitudes

For altitudes above 2000 m (6562 ft), contact Danfoss

regarding PELV.

1.3.1 Side-by-side Installation

The frequency converter can be mounted side by side for

IP20 rating units and requires 100 mm (3.9 in) clearance

above and below for cooling. Refer to chapter 1.7 Speci-

cations for details on environmental ratings of the

frequency converter.

1.2.1 Safety Instructions

Make sure that the frequency converter is

•

properly grounded.

Do not remove mains connections, motor

•

connections, or other power connections while

the frequency converter is connected to power.

Protect users against supply voltage.

•

Protect the motor against overloading according

•

to national and local regulations.

The ground leakage current exceeds 3.5 mA.

•

Ground the frequency converter properly.

The [O/Reset] key is not a safety switch. It does

•

not disconnect the frequency converter from

mains.

Installation

1.3

1.

Disconnect the VLT® Micro Drive FC 51 from

mains (and external DC supply, if present).

2. Wait for 4 minutes (M1, M2, and M3) and 15

minutes (M4 and M5) for discharge of the DC-link.

See Table 1.1.

3. Disconnect the DC bus terminals and the brake

terminals (if present).

4. Remove the motor cable.

8 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 13

B

a A

a A

a A

a A

a A

C

C

C C C

b

B

b

B

b

B

b

B

b

Ø 7mm

M5

M4

M3

M2

M1

Ø 7mm Ø 5.5mm Ø 4.5mm

130BB321.11

Ø 4.5mm

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

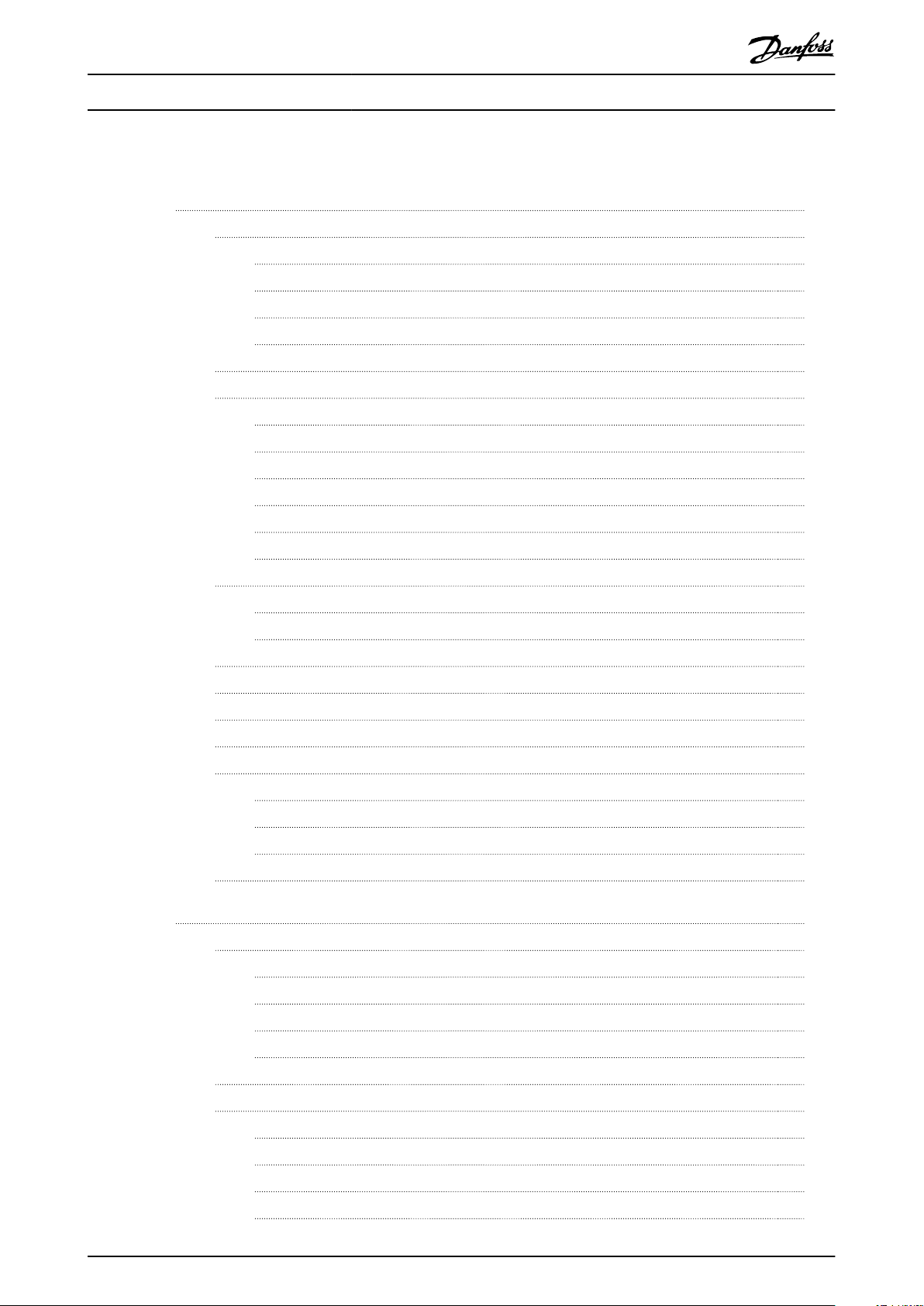

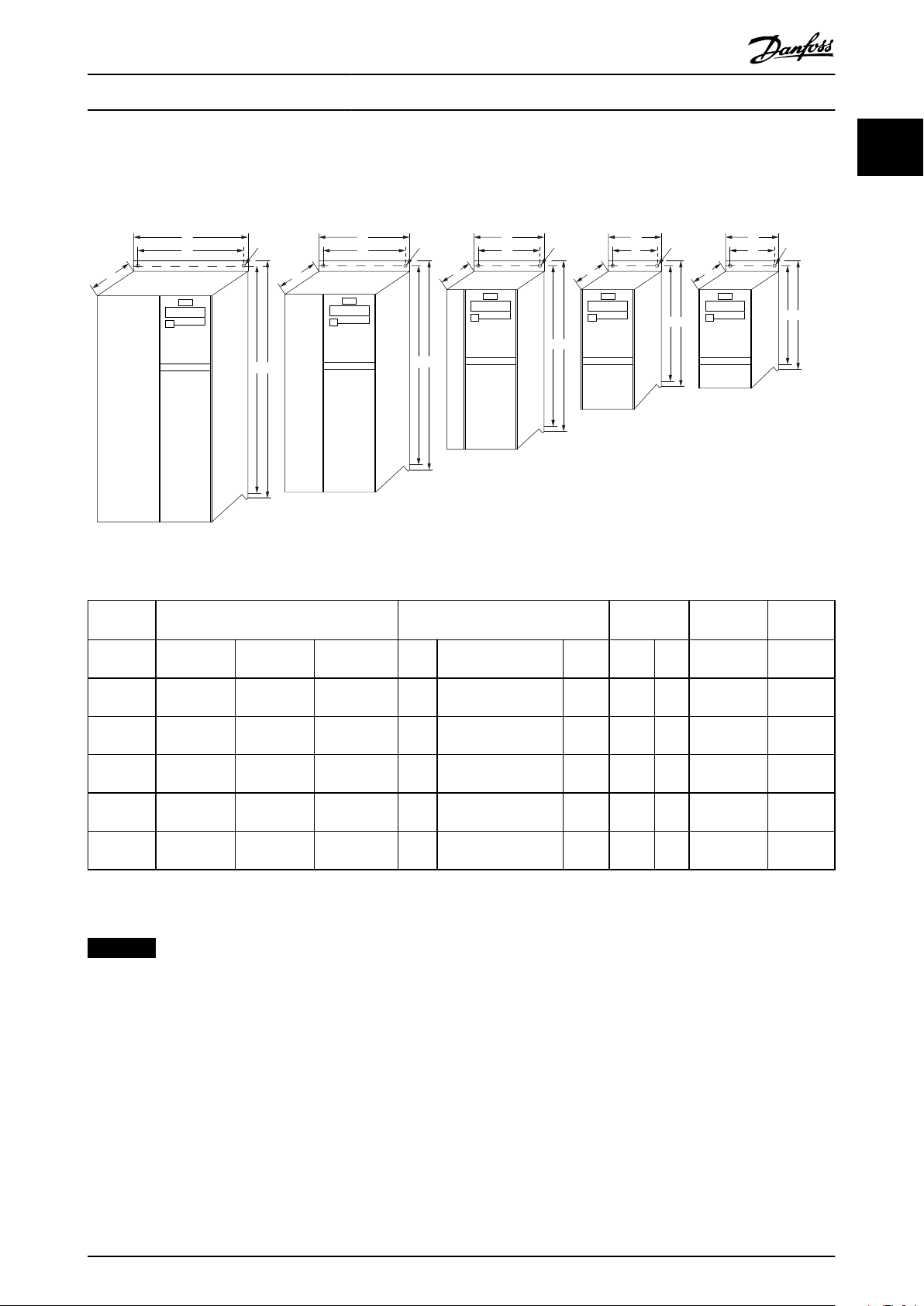

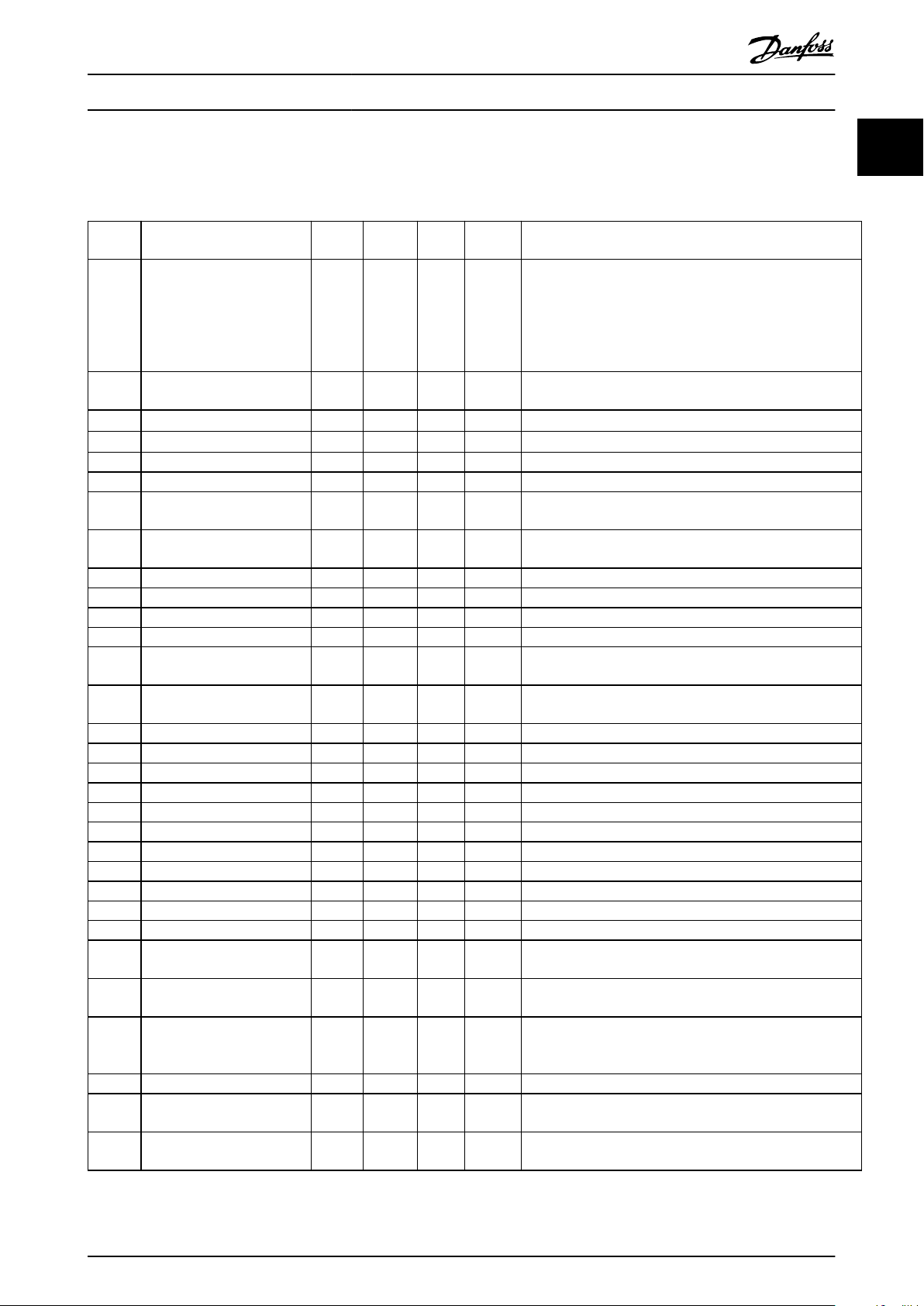

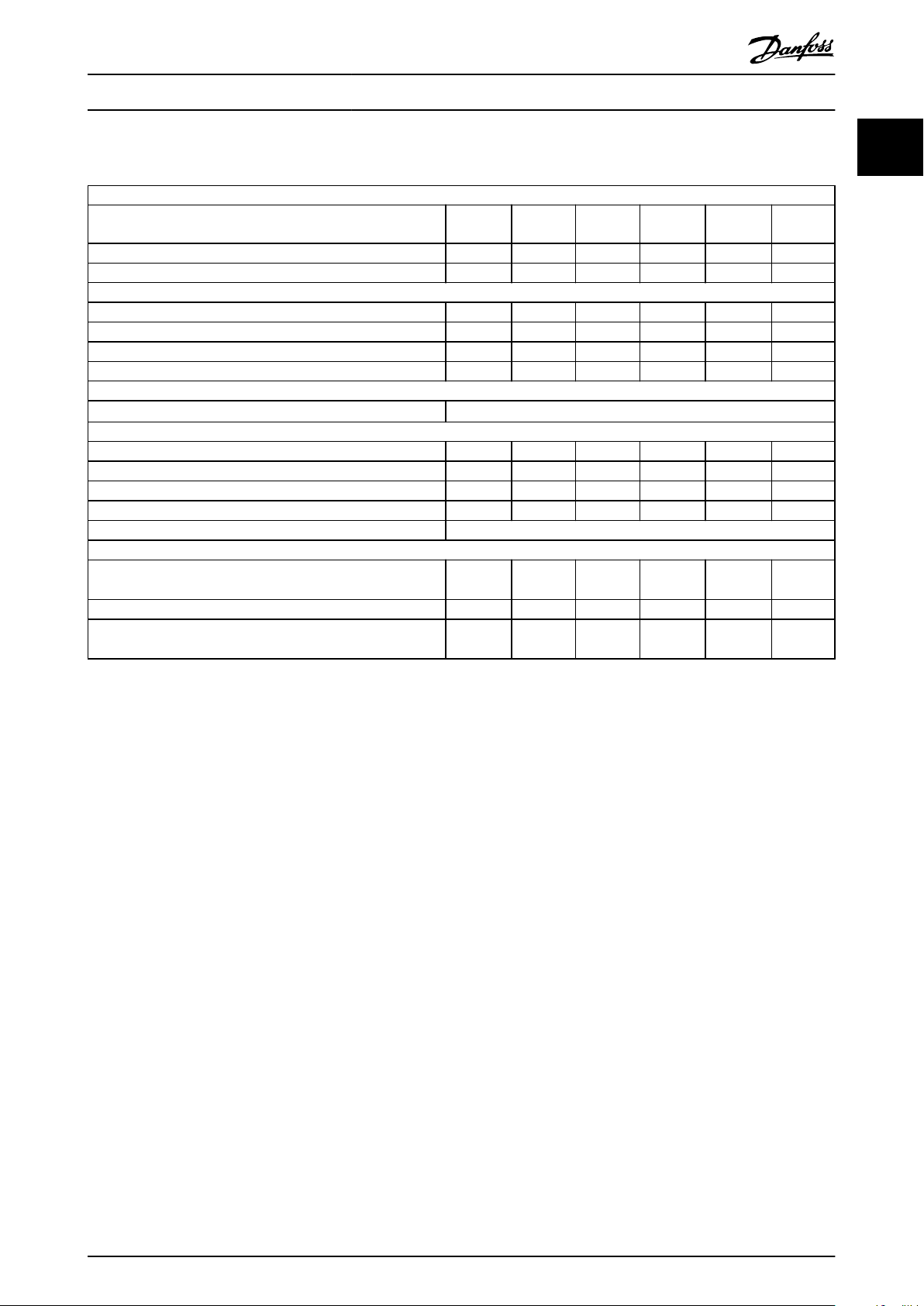

1.3.2 Mechanical Dimensions

A template for drilling is found on the ap of the packaging.

Illustration 1.1 Mechanical Dimensions

1 1

Power [kW (hp)] Height [mm (in)]

Enclosure 1x200–240 V 3x200–240 V 3x380–480 V A

M1

0.18–0.75

(0.24–1.0)

M2 1.5 (2.0) 1.5 (2.0)

M3 2.2 (3.0)

M4 – –

M5 – –

0.25–0.75

(0.34–1.0)

2.2–3.7

(3.0–5.0)

0.37–0.75

(0.5–1.0)

1.5–2.2

(2.0–3.0)

3.0–7.5

(4.0–10)

11.0–15.0

(15–20)

18.5–22.0

(25–30)

150

(5.9)

176

(6.9)

239

(9.4)

292

(11.5)

335

(13.2)

A (including

decoupling plate)

205 (8.1)

230 (9.1)

294 (11.6)

347.5 (13.7)

387.5 (15.3)

Width

[mm (in)]

a B b C [kg]

140.4

(5.5)70(2.8)55(2.2)

166.4

(6.6)75(3.0)59(2.3)

226

(8.9)90(3.5)69(2.7)

272.4

(10.7)

(12.4)

315

125

(4.9)97(3.8)

165

140

(6.5)

(5.5)

1)

Depth

[mm (in)]

Maximum

weight

148 (5.8) 1.1

168 (6.6) 1.6

194 (7.6) 3.0

241 (9.5) 6.0

248 (9.8) 9.5

Table 1.2 Mechanical Dimensions

1) For LCP with potentiometer, add 7.6 mm (0.3 in).

NOTICE

All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Copper

conductors required, 60–75 °C (140–167 °F) recommended.

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 9

Page 14

Quick Guide

VLT® Micro Drive FC 51

11

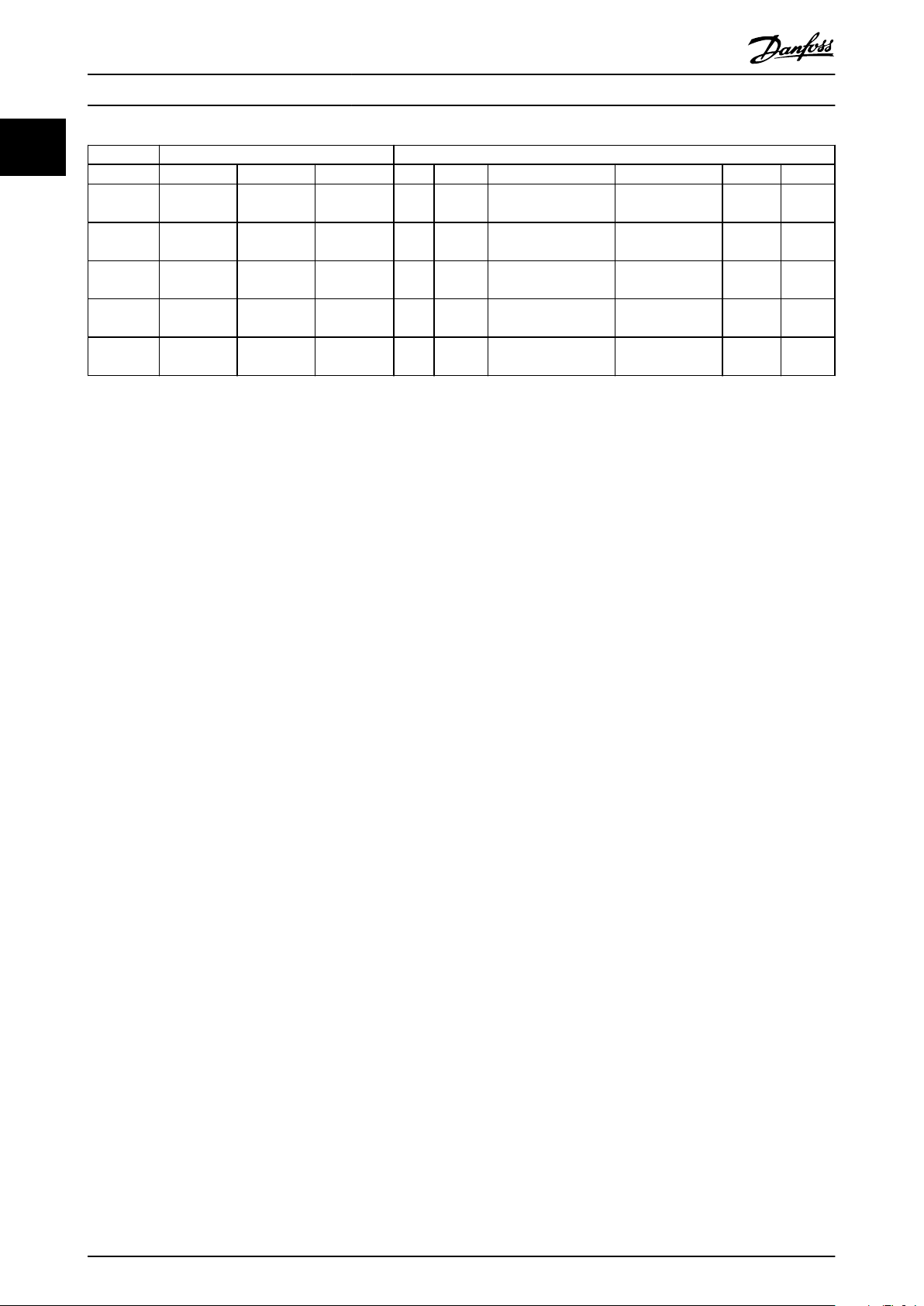

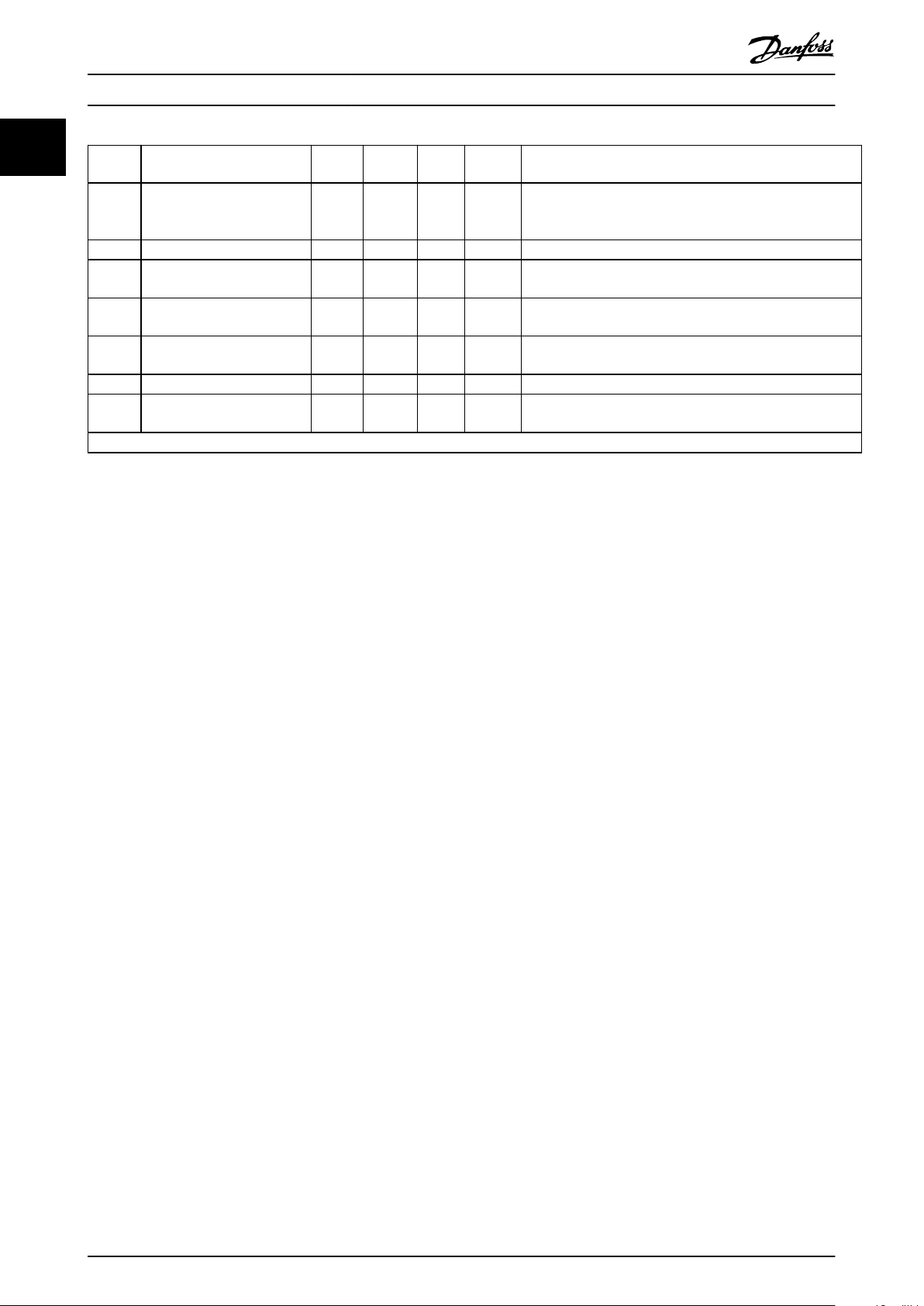

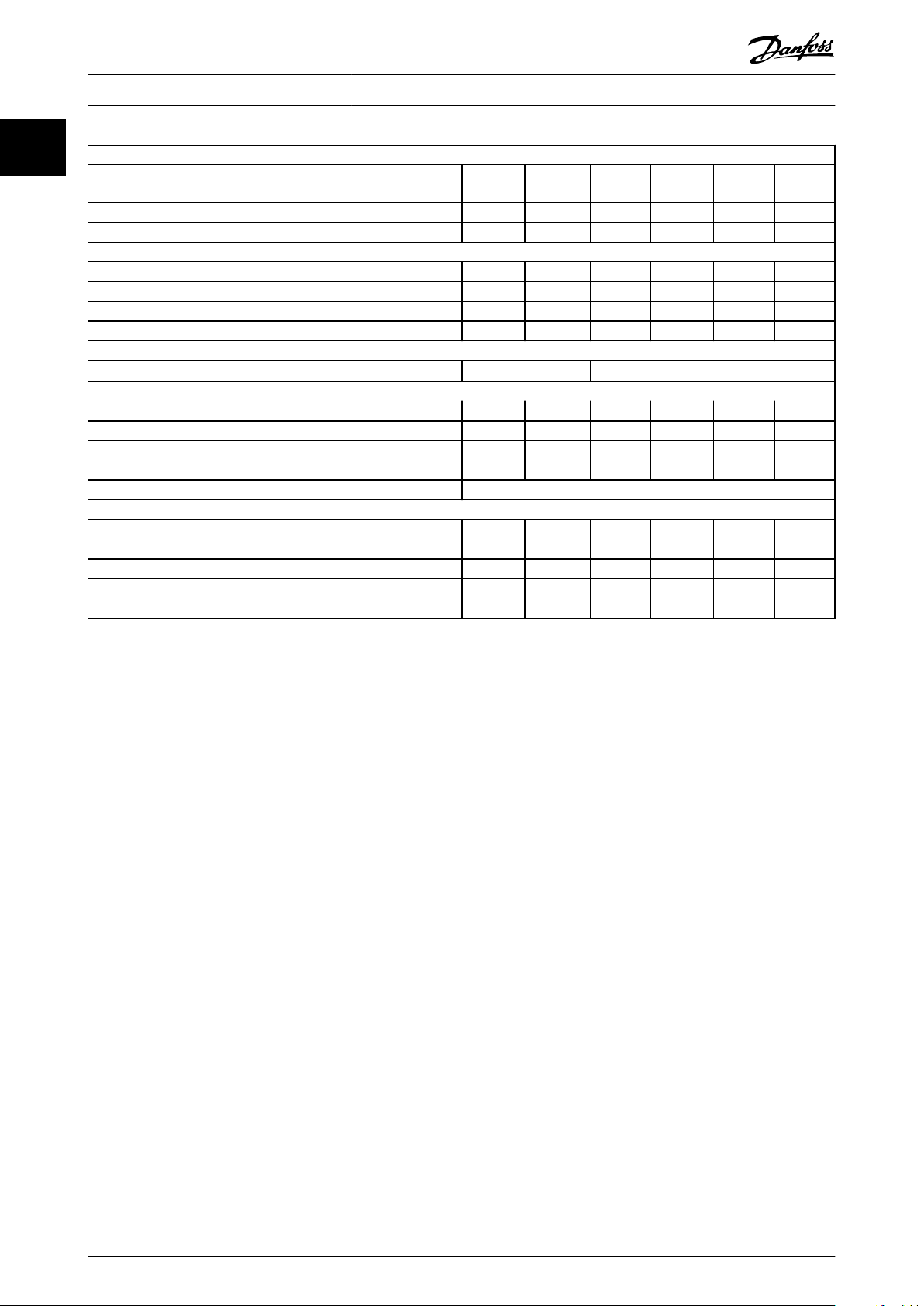

Power [kW (hp)] Torque [Nm (in-lb)]

Enclosure 1x200–240 V 3x200–240 V 3x380–480 V Line Motor DC connection/brake Control terminals Ground Relay

M1

M2 1.5 (2.0) 1.5 (2.0)

M3 2.2 (3.0)

M4 – –

M5 – –

Table 1.3 Tightening of Terminals

1) Spade connectors (6.3 mm (0.25 in) Faston plugs).

0.18–0.75

(0.24–1.0)

0.25–0.75

(0.34–1.0)

2.2–3.7

(3.0–5.0)

0.37–0.75

(0.5–1.0)

1.5–2.2

(2.0–3.0)

3.0–7.5

(4.0–10)

11.0–15.0

(15–20)

18.5–22.0

(25–30)

0.8

(7.1)

0.8

(7.1)

0.8

(7.1)

1.3

(11.5)

1.3

(11.5)

0.7

(6.2)

0.7

(6.2)

0.7

(6.2)

1.3

(11.5)

1.3

(11.5)

1)

Spade

1)

Spade

1)

Spade

1.3 (11.5) 0.15 (1.3) 3 (26.6)

1.3 (11.5) 0.15 (1.3) 3 (26.6)

0.15 (1.3) 3 (26.6)

0.15 (1.3) 3 (26.6)

0.15 (1.3) 3 (26.6)

0.5

(4.4)

0.5

(4.4)

0.5

(4.4)

0.5

(4.4)

0.5

(4.4)

10 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 15

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

Branch circuit protection

To protect the installation against electrical and re

hazards, protect all branch circuits in an installation, switch

gear, machines, and so on, against short circuits and

overcurrent according to national/international regulations.

Short-circuit protection

Use the fuses mentioned in Table 1.4 to protect service

personnel or other equipment if there is an internal failure

in the unit or short circuit on DC-link. If there is a short

circuit on the motor or brake output, the frequency

converter provides full short-circuit protection.

Overcurrent protection

To avoid overheating of the cables in the installation,

provide overload protection. Always carry out overcurrent

protection according to national regulations. Fuses must be

designed for protection in a circuit capable of supplying a

maximum of 100000 A

(symmetrical), 480 V maximum.

rms

Non-UL compliance

If UL/cUL is not to be complied with, use the fuses

mentioned in Table 1.4, which ensure compliance with

EN50178/IEC61800-5-1:

If there is a malfunction, not following the fuse recommendation may result in damage to the frequency converter

and the installation.

Maximum fuses UL

FC 51

Bussmann Bussmann Bussmann Littelfuse

1x200–240 V

kW Type RK1 Type J Type T Type RK1 Type CC Type RK1 Type gG

0K18–0K37 KTN-R15 JKS-15 JJN-15 KLN-R15 ATM-R15 A2K-15R 16A

0K75 KTN-R25 JKS-25 JJN-25 KLN-R25 ATM-R25 A2K-25R 25A

1K5 KTN-R35 JKS-35 JJN-35 KLN-R35 – A2K-35R 35A

2K2 KTN-R50 JKS-50 JJN-50 KLN-R50 – A2K-50R 50A

3x200–240 V

0K25 KTN-R10 JKS-10 JJN-10 KLN-R10 ATM-R10 A2K-10R 10A

0K37 KTN-R15 JKS-15 JJN-15 KLN-R15 ATM-R15 A2K-15R 16A

0K75 KTN-R20 JKS-20 JJN-20 KLN-R20 ATM-R20 A2K-20R 20A

1K5 KTN-R25 JKS-25 JJN-25 KLN-R25 ATM-R25 A2K-25R 25A

2K2 KTN-R40 JKS-40 JJN-40 KLN-R40 ATM-R40 A2K-40R 40A

3K7 KTN-R40 JKS-40 JJN-40 KLN-R40 – A2K-40R 40A

3x380–480 V

0K37–0K75 KTS-R10 JKS-10 JJS-10 KLS-R10 ATM-R10 A6K-10R 10A

1K5 KTS-R15 JKS-15 JJS-15 KLS-R15 ATM-R15 A2K-15R 16A

2K2 KTS-R20 JKS-20 JJS-20 KLS-R20 ATM-R20 A6K-20R 20A

3K0 KTS-R40 JKS-40 JJS-40 KLS-R40 ATM-R40 A6K-40R 40A

4K0 KTS-R40 JKS-40 JJS-40 KLS-R40 ATM-R40 A6K-40R 40A

5K5 KTS-R40 JKS-40 JJS-40 KLS-R40 – A6K-40R 40A

7K5 KTS-R40 JKS-40 JJS-40 KLS-R40 – A6K-40R 40A

11K0 KTS-R60 JKS-60 JJS-60 KLS-R60 – A6K-60R 63A

15K0 KTS-R60 JKS-60 JJS-60 KLS-R60 – A6K-60R 63A

18K5 KTS-R60 JKS-60 JJS-60 KLS-R60 – A6K-60R 80A

22K0 KTS-R60 JKS-60 JJS-60 KLS-R60 – A6K-60R 80A

Ferraz

Shawmut

Ferraz Shawmut

Maximum fuses

non–UL

1 1

Table 1.4 Fuses

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 11

Page 16

Quick Guide

VLT® Micro Drive FC 51

11

1.3.3 Connecting to Mains and Motor

The frequency converter is designed to operate all

standard 3-phased asynchronous motors.

The frequency converter is designed to accept mains/

motor cables with a maximum cross-section of 4 mm2/10

AWG (M1, M2 and M3), and a maximum cross-section of 16

mm2/6 AWG (M4 and M5).

Use a shielded/armored motor cable to comply

•

with EMC emission specications, and connect

this cable to both the decoupling plate and the

motor metal.

Keep motor cable as short as possible to reduce

•

the noise level and leakage currents.

For further details on mounting of the decoupling

•

plate, see VLT® Micro Drive FC 51 Decoupling

Mounting Plate Instructions.

Also see the chapter EMC-correct Electrical Instal-

•

lation in the VLT® Micro Drive FC 51 Design Guide.

1. Mount the ground wires to PE terminal.

2. Connect motor to terminals U, V, and W.

3. Mount mains supply to terminals L1/L, L2, and

L3/N (3-phase) or L1/L and L3/N (single-phase)

and tighten.

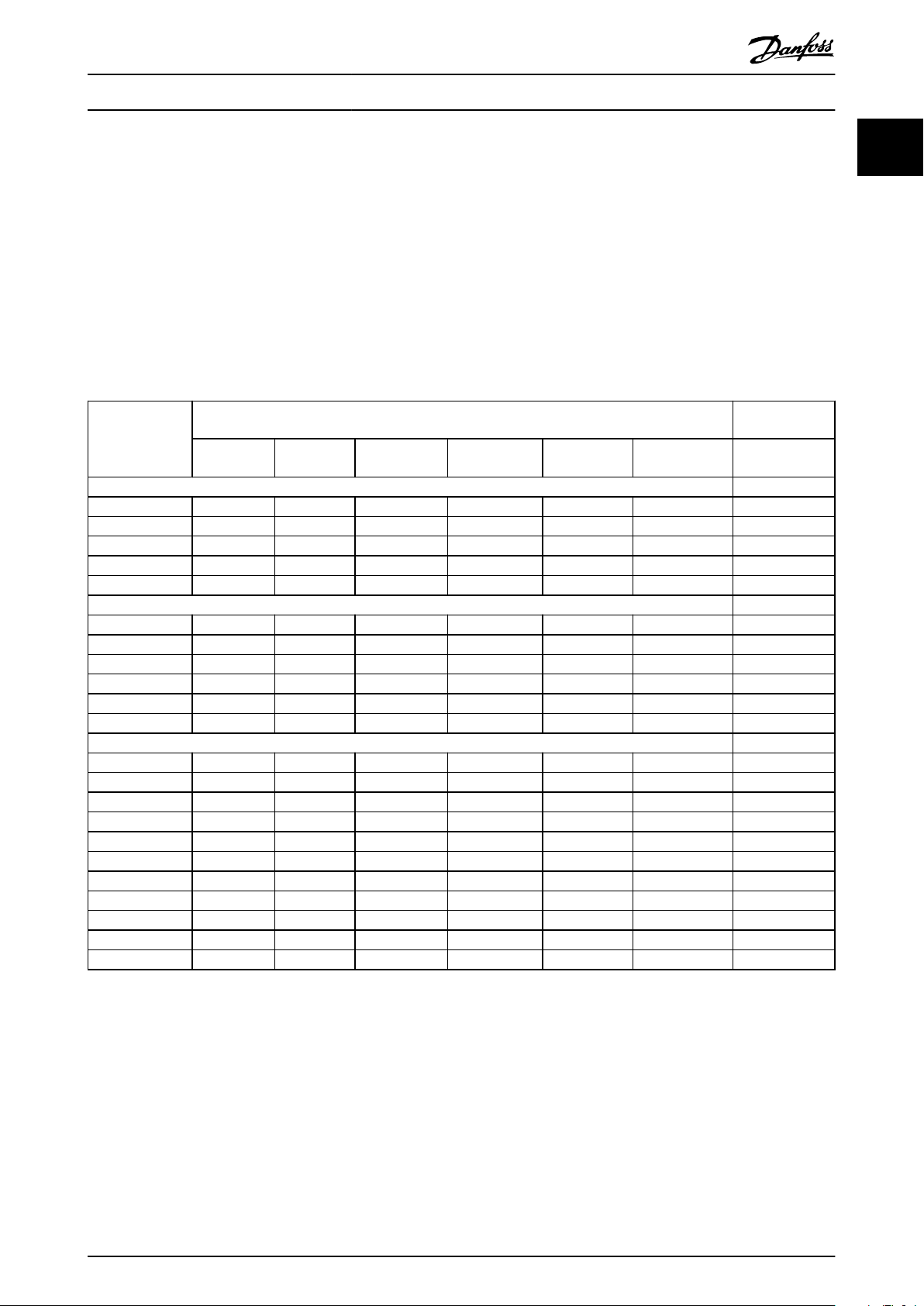

Illustration 1.3 Removing Terminal Cover

Switch 1

Switch 2

Switch 3 No function

Switch 4

1)=default setting

O=PNP terminals 29

On=NPN terminals 29

O=PNP terminal 18, 19, 27 and 33

On=NPN terminal 18, 19, 27 and 33

O=Terminal 53 0–10 V

On=Terminal 53 0/4-20 mA

1)

1)

1)

Illustration 1.2 Mounting of Ground Cable, Mains, and Motor

Wires

1.3.4 Control Terminals

All control cable terminals are located underneath the

terminal cover in front of the frequency converter. Remove

the terminal cover using a screwdriver.

NOTICE

See the back of the terminal cover for outlines of control

terminals and switches.

Do not operate switches with power on the frequency

converter.

Set parameter 6-19 Terminal 53 Mode according to Switch

4 position.

Table 1.5 Settings for S200 Switches 1–4

Illustration 1.4 S200 Switches 1–4

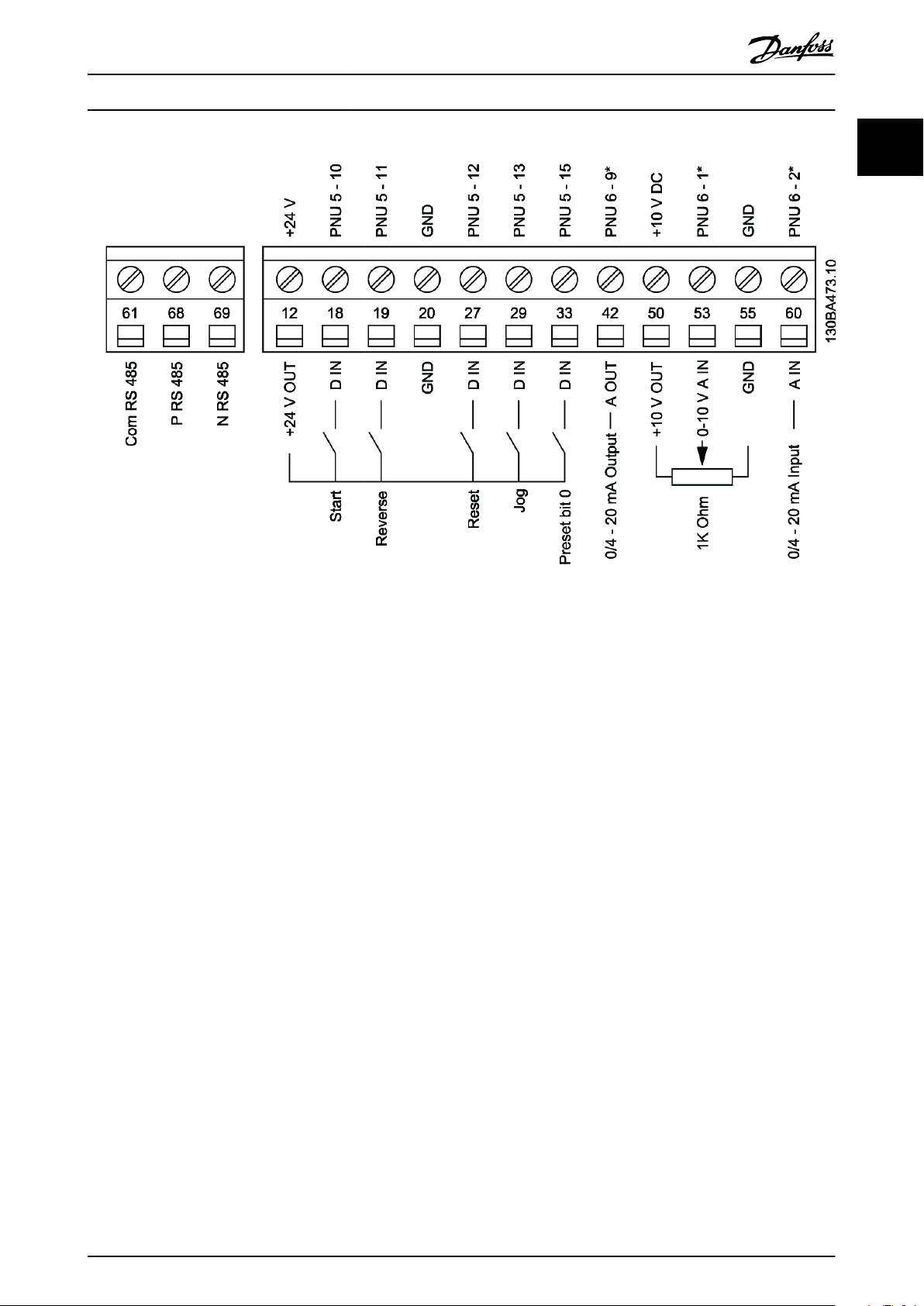

Illustration 1.5 shows all control terminals of the frequency

converter. Applying start (terminal 18) and an analog

reference (terminal 53 or 60) make the frequency converter

run.

12 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 17

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1 1

Illustration 1.5 Overview of Control Terminals in PNP-conguration with Factory Setting

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 13

Page 18

130BA242.17

1)

Quick Guide

VLT® Micro Drive FC 51

11

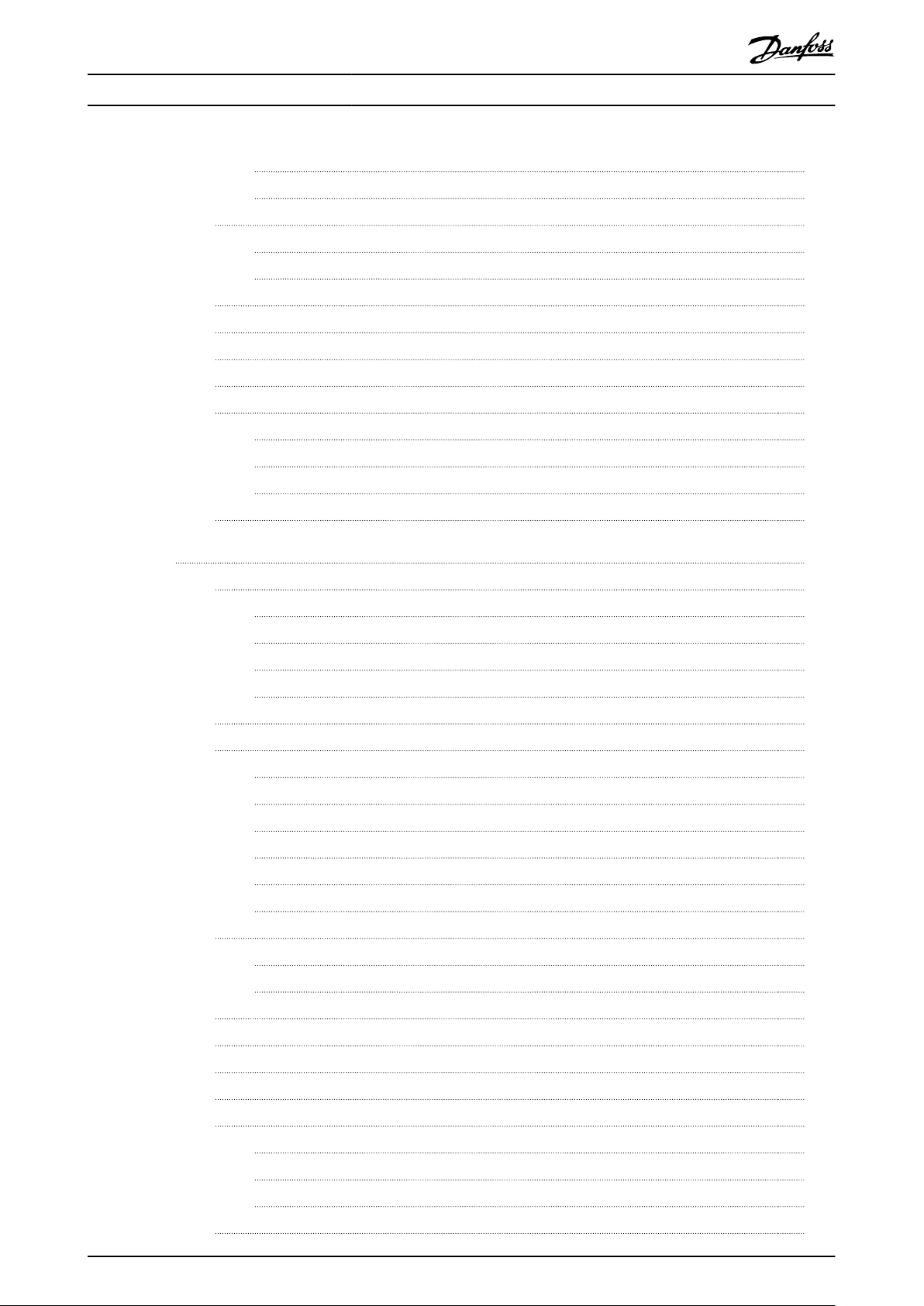

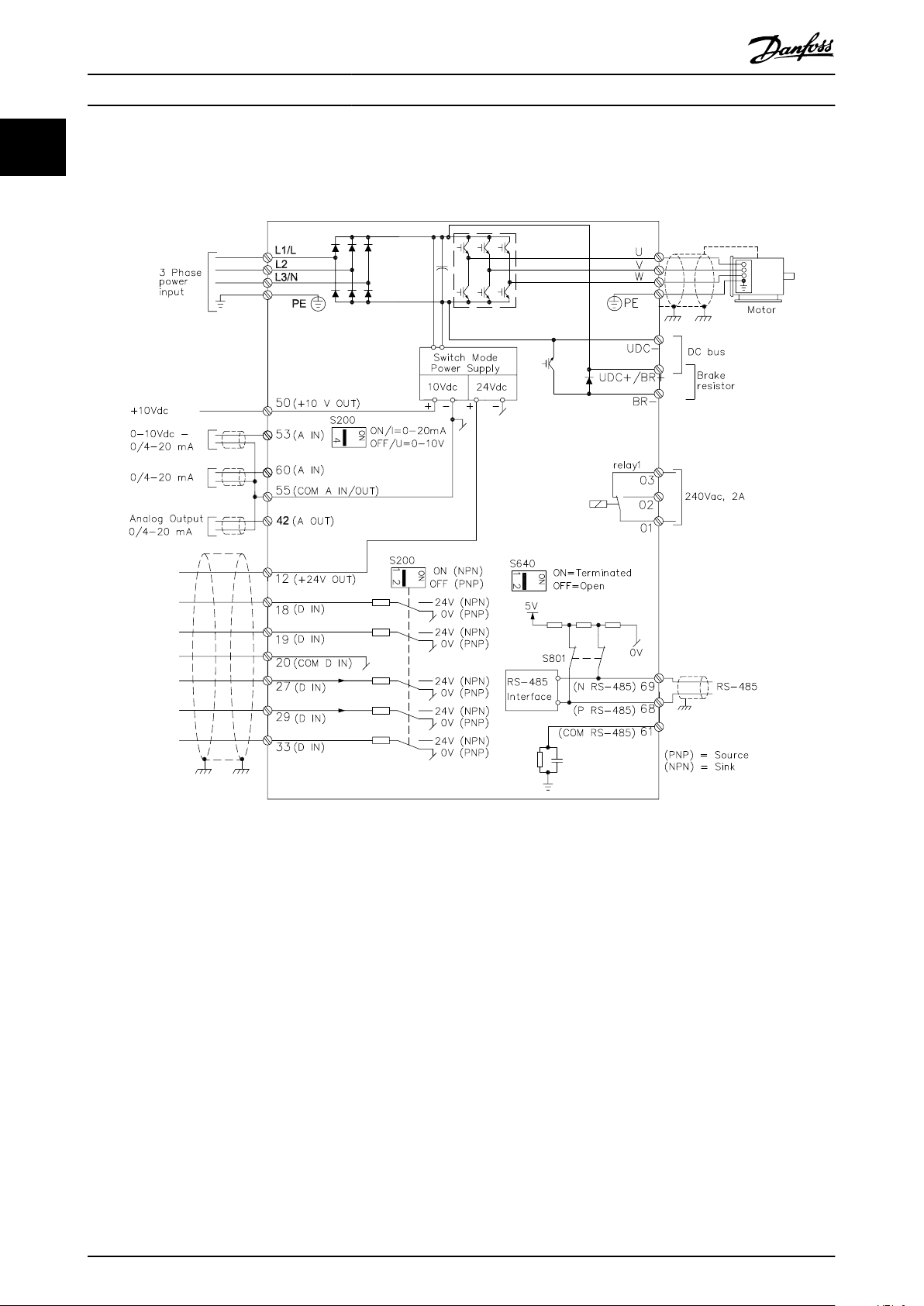

1.3.5 Power Circuit - Overview

Illustration 1.6 Diagram Showing all Electrical Terminals

1) Brakes (BR+ and BR-) are not applicable for enclosure size M1.

For information about brake resistors, see VLT® Brake Resistor MCE 101 Design Guide.

Improved power factor and EMC performance can be achieved by installing optional Danfoss line lters.

Danfoss power lters can also be used for load sharing. For more information about load sharing, see VLT® FC 51 Micro Drive

Load Sharing application note.

14 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 19

130BA605.13

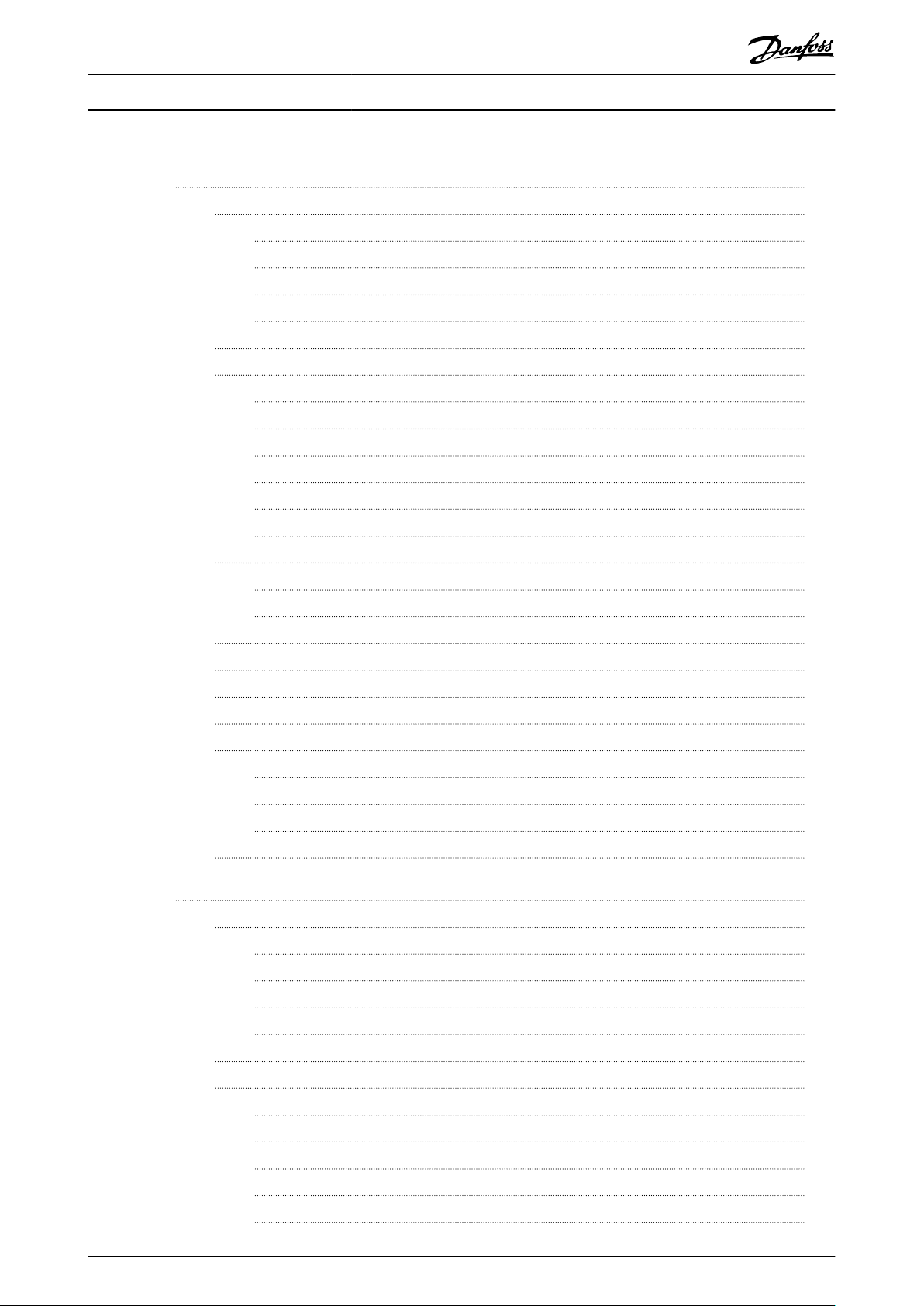

Set-up

number

Parameter

number

Motor

direction

Menu

key

Indicator

lights

Value

Numeric

display

Unit

Selected

menu

Navigation

keys

Potentiometer

(LCP 12)

Operation keys

and leds

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1.3.6 Load Sharing/Brake

Use 6.3 mm (0.25 in) insulated Faston plugs designed for

high voltage for DC (load sharing and brake).

Contact Danfoss or see Load sharing instruction VLT® 5000

for load sharing and VLT® 2800/5000/5000 FLUX/FCD 300

Brake for brake.

Load sharing

Connect terminals -UDC and +UDC/+BR.

Brake

Connect terminals -BR and +UDC/+BR (not applicable for

enclosure size M1).

NOTICE

Voltage levels of up to 850 V DC may occur between

terminals +UDC/+BR and -UDC. Not short circuit

protected.

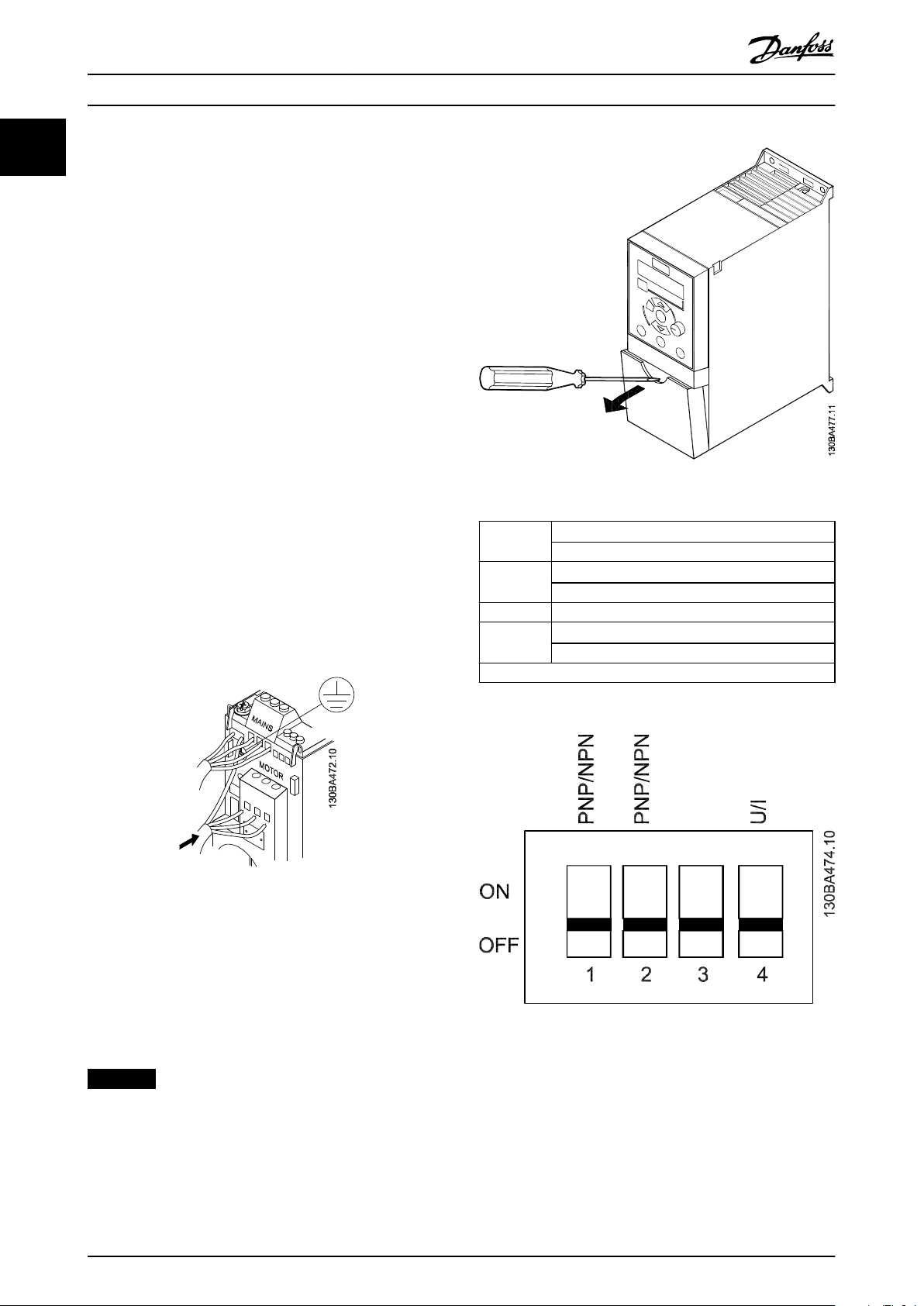

1.4 Programming

1.4.1 Programming on Automatic Motor

Adaptation (AMA)

For detailed information on programming, see VLT® Micro

Drive FC 51 Programming Guide.

NOTICE

The frequency converter can also be programmed from a

PC via RS485 com-port by installing the MCT 10 Set-up

Software.

This software can either be ordered using code number

130B1000 or downloaded from the Danfoss web site:

www.danfoss.com/BusinessAreas/DrivesSolutions/softwaredownload

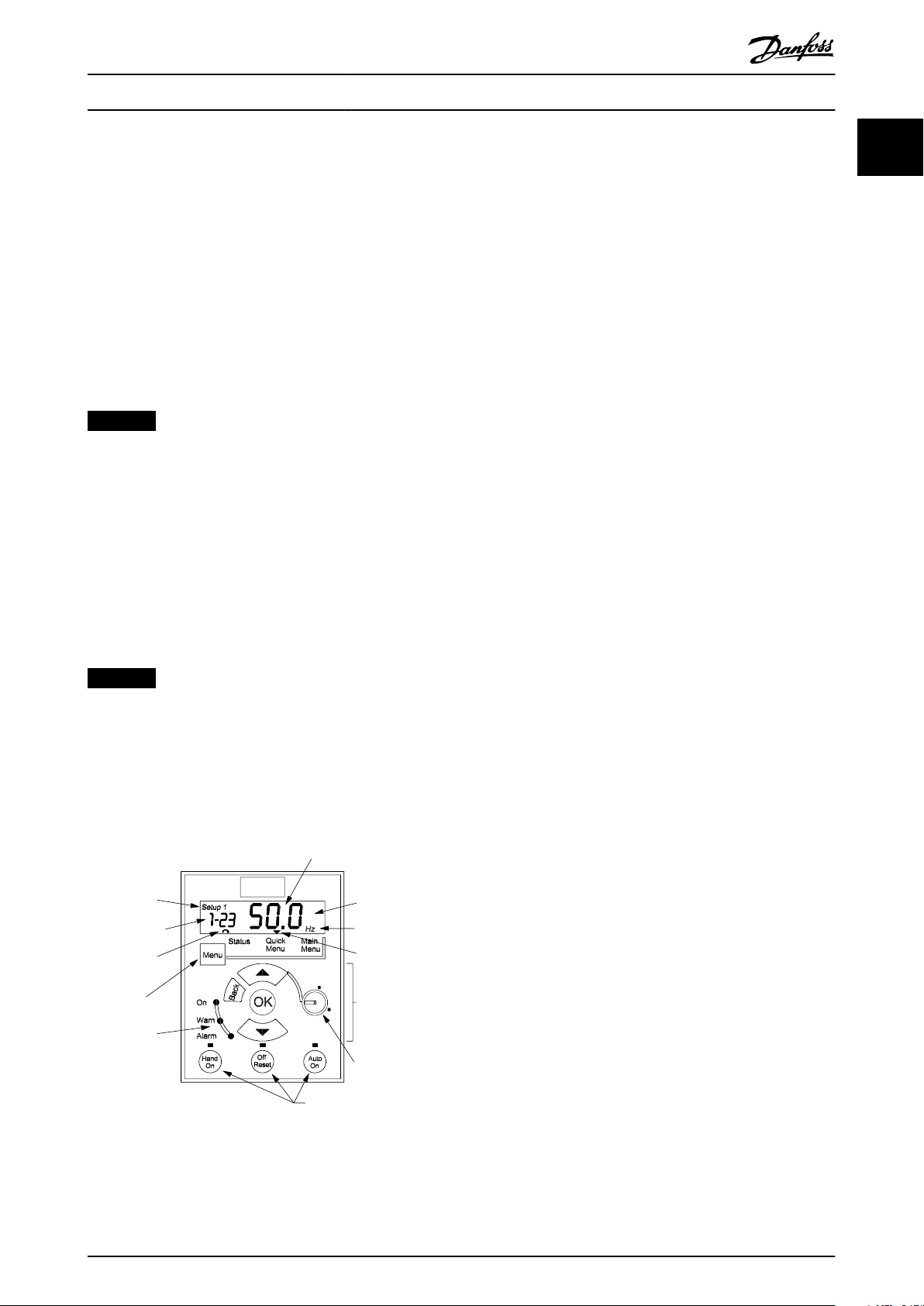

Press [Menu] to select 1 of the following menus:

Status

For readouts only.

Quick Menu

For access to Quick Menus 1 and 2.

Main Menu

For access to all parameters.

Navigation keys

[Back]: For moving to the previous step or layer in the

navigation structure.

[▲] [▼]: For manoeuvring between parameter groups,

parameters and within parameters.

[OK]: For selecting a parameter and for accepting changes

to parameter settings.

Pressing [OK] for more than 1 s enters Adjust mode. In

Adjust mode, it is possible to make fast adjustment by

pressing [▲] [▼] combined with [OK].

Press [▲] [▼] to change value. Press [OK] to shift between

digits quickly.

To exit Adjust mode, press [OK] more than 1 s again with

changes saving or press [Back] without changes saving.

Operation keys

A yellow indicator light above the operation keys indicates

the active key.

[Hand On]: Starts the motor and enables control of the

frequency converter via the LCP.

[O/Reset]: The motor stops. If in alarm mode, the motor

resets.

[Auto On]: The frequency converter is controlled either via

control terminals or serial communication.

[Potentiometer] (LCP12): The potentiometer works in 2

ways depending on the mode in which the frequency

converter is running.

In auto-on mode, the potentiometer acts as an extra

programmable analog input.

In hand-on mode, the potentiometer controls local

reference.

1 1

1.4.2 Programming on Automatic Motor

Tuning (AMT)

Run AMT to optimise compatibility between the frequency

converter and the motor in VVC+ mode.

Illustration 1.7 Description of LCP Keys and Display

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 15

The frequency converter builds a mathematical

•

model of the motor for regulating output motor

current thus enhancing motor performance.

Run this procedure on a cold motor for best

•

results. To run AMT, use the numeric LCP (NLCP).

There are 2 AMT modes for frequency converters.

Page 20

Quick Guide

VLT® Micro Drive FC 51

11

Mode 1

1. Enter the main menu.

2. Go to parameter group 1-** Load and Motor.

3. Press [OK].

4. Set motor parameters using nameplate data for

parameter group 1-2* Motor Data.

5. Go to parameter 1-29 Automatic Motor Tuning

(AMT).

6. Press [OK].

7. Select [2] Enable AMT.

8. Press [OK].

9. The test runs automatically and indicates when it

is complete.

Mode 2

1. Enter the main menu.

2. Go to parameter group 1-** Load and Motor.

3. Press [OK].

4. Set motor parameters using nameplate data for

parameter group 1-2* Motor Data.

5. Go to parameter 1-29 Automatic Motor Tuning

(AMT).

6. Press [OK].

7. Select [3] Complete AMT with Rotating motor.

8. Press [OK].

9. The test runs automatically and indicates when it

is complete.

NOTICE

In mode 2, the rotor rotates during the AMT progress.

Do not add any load on motor in this AMT progress.

16 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 21

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1.5 Parameter Overview

0-** Operation/Display

0-0* Basic Settings

0-03 Regional Settings

*[0] International

[1] US

0-04 Oper. State at Power-up

(Hand)

[0] Resume

*[1] Forced stop, ref=old

[2] Forced stop, ref=0

0-1* Set-up Handling

0-10 Active Set-up

*[1] Set-up 1

[2] Set-up 2

[9] Multi Set-up

0-11 Edit Set-up

*[1] Set-up 1

[2] Set-up 2

[9] Active Set-up

0-12 Link Set-ups

[0] Not Linked

*[20] Linked

0-31 Custom Readout Min Scale

0.00–9999.00 * 0.00

0-32 Custom Readout Max Scale

0.00–9999.00 * 100.0

0-4* LCP Keypad

0-40 [Hand on] Key on LCP

[0] Disabled

*[1] Enabled

0-41 [O / Reset] Key on LCP

[0] Disable All

*[1] Enable All

[2] Enable Reset Only

0-42 [Auto on] Key on LCP

[0] Disabled

*[1] Enabled

0-5* Copy/Save

0-50 LCP Copy

*[0] No copy

[1] All to LCP

[2] All from LCP

[3] Size indep. from LCP

0-51 Set-up Copy

*[0] No copy

[1] Copy from set-up 1

[2] Copy from set-up 2

[9] Copy from Factory set-up

0-6* Password

0-60 (Main) Menu Password

0–999 *0

1) M4 and M5 only

0-61 Access to Main/Quick Menu

w/o Password

*[0] Full access

[1] LCP:Read Only

[2] LCP:No Access

1-** Load/Motor

1-0* General Settings

1-00 Conguration Mode

*[0] Speed open loop

[3] Process

1-01 Motor Control Principle

[0] U/f

*[1] VVC+

1-03 Torque Characteristics

*[0] Constant torque

[2] Automatic Energy Optim.

1-05 Local Mode Conguration

[0] Speed Open Loop

*[2] As cong in par. 1-00

1-2* Motor Data

1-20 Motor Power [kW] [hp]

[1] 0.09 kW/0.12 hp

[2] 0.12 kW/0.16 hp

[3] 0.18 kW/0.25 hp

[4] 0.25 kW/0.33 hp

[5] 0.37 kW/0.50 hp

[6] 0.55 kW/0.75 hp

[7] 0.75 kW/1.00 hp

[8] 1.10 kW/1.50 hp

[9] 1.50 kW/2.00 hp

[10] 2.20 kW/3.00 hp

[11] 3.00 kW/4.00 hp

[12] 3.70 kW/5.00 hp

[13] 4.00 kW/5.40 hp

[14] 5.50 kW/7.50 hp

[15] 7.50 kW/10.00 hp

[16] 11.00 kW/15.00 hp

[17] 15.00 kW/20.00 hp

[18] 18.50 kW/25.00 hp

[19] 22.00 kW/29.50 hp

[20] 30.00 kW/40.00 hp

1-22 Motor Voltage

50-999 V *230–400 V

1-23 Motor Frequency

20–400 Hz *50 Hz

1-24 Motor Current

0.01–100.00 A *Motortype dep.

1-25 Motor Nominal Speed

100–9999 rpm *Motortype dep.

1-29 Automatic Motor Tuning

(AMT)

*[0] O

[2] Enable AMT

[3] Complete AMT with Rotating

motor

1-3* Adv. Motor Data

1-30 Stator Resistance (Rs)

[Ohm] * Dep. on motor data

1-33 Stator Leakage Reactance

(X1)

[Ohm] * Dep. on motor data

1-35 Main Reactance (Xh)

[Ohm] * Dep. on motor data

1-5* Load Indep. Setting

1-50 Motor Magnetisation at 0

Speed

0–300% *100%

1-52 Min Speed Norm. Magnet.

[Hz]

0.0–10.0 Hz *0.0Hz

1-55 U/f Characteristic - U

0-999.9 V

1-56 U/f Characteristic - F

0-400 Hz

1-6* Load Depen. Setting

1-60 Low Speed Load Compensation

0–199% *100%

1-61 High Speed Load Compensation

0–199% *100%

1-62 Slip Compensation

-400–399% *100%

1-63 Slip Compensation Time

Constant

0.05–5.00 s *0.10 s

1-7* Start Adjustments

1-71 Start Delay

0.0–10.0 s *0.0 s

1-72 Start Function

[0] DC hold/delay time

[1] DC brake/delay time

*[2] Coast/delay time

1-73 Flying Start

*[0] Disabled

[1] Enabled

1-8* Stop Adjustments

1-80 Function at Stop

*[0] Coast

[1] DC hold

1 1

1-82 Min Speed for Funct. at

Stop [Hz]

0.0–20.0 Hz *0.0 Hz

1-9*Motor Temperature

1-90 Motor Thermal Protection

*[0] No protection

[1] Thermistor warning

[2] Thermistor trip

[3] Etr warning

[4] Etr trip

1-93 Thermistor Resource

*[0] None

[1] Analog input 53

[6] Digital input 29

2-** Brakes

2-0* DC-Brake

2-00 DC Hold Current

0–150% *50%

2-01 DC Brake Current

0–150% *50%

2-02 DC Braking Time

0.0–60.0 s *10.0 s

2-04 DC Brake Cut In Speed

0.0–400.0 Hz *0.0Hz

2-1* Brake Energy Funct.

2-10 Brake Function

*[0] O

[1] Resistor brake

[2] AC brake

2-11 Brake Resistor (ohm)

Min/Max/default: Powersize dep.

2-14 Brake Voltage reduce

0 - Powersize dep.* 0

2-16 AC Brake, Max current

0-150% *100%

2-17 Overvoltage Control

*[0] Disabled

[1] Enabled (not at stop)

[2] Enabled

2-2* Mechanical Brake

2-20 Release Brake Current

0.00–100.0 A *0.00 A

2-22 Activate Brake Speed [Hz]

0.0–400.0 Hz *0.0 Hz

3-** Reference / Ramps

3-0* Reference Limits

3-00 Reference Range

*[0] Min - Max

[1] -Max - +Max

3-02 Minimum Reference

-4999–4999 *0.000

3-03 Maximum Reference

-4999–4999 *50.00

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 17

Page 22

Quick Guide

VLT® Micro Drive FC 51

11

3-1* References

3-10 Preset Reference

-100.0–100.0% *0.00% 3-11 Jog

Speed [Hz]

0.0–400.0 Hz *5.0 Hz

3-12 Catch up/slow Down Value

0.00–100.0% * 0.00%

3-14 Preset Relative Reference

-100.0–100.0% *0.00%

3-15 Reference Resource 1

[0] No function

*[1] Analog Input 53

[2] Analog input 60

[8] Pulse input 33

[11] Local bus ref

[21] LCP Potentiometer

3-16 Reference Resource 2

[0] No function

[1] Analog in 53

*[2] Analog in 60

[8] Pulse input 33

*[11] Local bus reference

[21] LCP Potentiometer

3-17 Reference Resource 3

[0] No function

[1] Analog Input 53

[2] Analog input 60

[8] Pulse input 33

*[11] Local bus ref

[21] LCP Potentiometer

3-18 Relative Scaling Ref.

Resource

*[0] No function

[1] Analog Input 53

[2] Analog input 60

[8] Pulse input 33

[11] Local bus ref

[21] LCP Potentiometer

3-4* Ramp 1

3-40 Ramp 1 Type

*[0] Linear

[2] Sine2 ramp

3-41 Ramp 1 Ramp up Time

0.05–3600 s *3.00 s (10.00 s1))

3-42 Ramp 1 Ramp Down Time

0.05–3600 s *3.00s (10.00s1))

3-5* Ramp 2

3-50 Ramp 2 Type

*[0] Linear

[2] Sine2 ramp

3-51 Ramp 2 Ramp up Time

0.05–3600 s *3.00 s (10.00 s1))

3-52 Ramp 2 Ramp down Time

0.05–3600 s *3.00 s (10.00 s1))

3-8* Other Ramps

3-80 Jog Ramp Time

0.05–3600 s *3.00 s (10.00s1))

1) M4 and M5 only

3-81 Quick Stop Ramp Time

0.05–3600 s *3.00 s (10.00s1))

4-** Limits/Warnings

4-1* Motor Limits 4-10 Motor

Speed Direction

*[0] Clockwise If Par. 1-00 is set

to close loop control

[1] CounterClockwise

*[2] Both if Par. 1-00 is set to

open loop control

4-12 Motor Speed Low Limit

[Hz]

0.0–400.0 Hz *0.0 Hz

4-14 Motor Speed High Limit

[Hz]

0.1–400.0 Hz *65.0 Hz

4-16 Torque Limit Motor Mode

0–400% *150%

4-17 Torque Limit Generator

Mode

0–400% *100%

4-4* Adj. Warnings 2

4-40 Warning Frequency Low

0.00–Value of 4-41 Hz *0.0 Hz

4-41 Warning Frequency High

Value of 4-40–400.0 Hz *400.00

Hz

4-5* Adj. Warnings

4-50 Warning Current Low

0.00–100.00 A *0.00 A

4-51 Warning Current High

0.0–100.00 A *100.00 A

4-54 Warning Reference Low

-4999.000–Value of 4-55

* -4999.000

4-55 Warning Reference High

Value of 4-54–4999.000

*4999.000

4-56 Warning Feedback Low

-4999.000–Value of 4-57

* -4999.000

4-57 Warning Feedback High

Value of 4-56–4999.000 *4999.000

4-58 Missing Motor Phase

Function

[0] O

*[1] On

4-6* Speed Bypass

4-61 Bypass Speed From [Hz]

0.0–400.0 Hz *0.0 Hz

4-63 Bypass Speed To [Hz]

0.0–400.0 Hz *0.0 Hz

5-1* Digital Inputs5-10 Terminal

18 Digital Input

[0] No function

[1] Reset

[2] Coast inverse

[3] Coast and reset inv.

[4] Quick stop inverse

[5] DC-brake inv.

[6] Stop inv

*[8] Start

[9] Latched start

[10] Reversing

[11] Start reversing

[12] Enable start forward

[13] Enable start reverse

[14] Jog

[16-18] Preset ref bit 0-2

[19] Freeze reference5-10

Terminal 18 Digital Input

[20] Freeze output

[21] Speed up

[22] Speed down

[23] Set-up select bit 0

[28] Catch up

[29] Slow down

[34] Ramp bit 0

[60] Counter A (up)

[61] Counter A (down)

[62] Reset counter A

[63] Counter B (up)

[64] Counter B (down)

[65] Reset counter B

5-11 Terminal 19 Digital Input

See par. 5-10. * [10] Reversing

5-12 Terminal 27 Digital Input

See par. 5-10. * [1] Reset

5-13 Terminal 29 Digital Input

See par. 5-10. * [14] Jog

5-15 Terminal 33 Digital Input

See par. 5-10. * [16] Preset ref bit

0

[26] Precise Stop Inverse

[27] Start, Precise Stop

[32] Pulse Input

5-3* Digital Outputs

5-34 On Delay, Terminal 42

Digital Output

0.00–600.00 s * 0.01 s

5-35 O Delay, Terminal 42

Digital Output

0.00–600.00 s * 0.01 s

5-4* Relays

5-40 Function Relay

[52] Remote ref. active

[53] No alarm

[54] Start cmd active

[55] Running reverse

[56] Drive in hand mode

[57] Drive in auto mode

[60-63] Comparator 0-3

[70-73] Logic rule 0-3

[81] SL digital output B

5-41 On Delay, Relay

0.00–600.00 s *0.01 s

5-42 O Delay, Relay

0.00–600.00 s *0.01 s

5-5* Pulse Input

5-55 Terminal 33 Low Frequency

20–4999 Hz *20 Hz

5-56 Terminal 33 High

Frequency

21–5000 Hz *5000 Hz

5-57 Term. 33 Low Ref./Feedb.

Value

-4999–4999 *0.000

5-58 Term. 33 High Ref./Feedb.

Value

-4999–4999 *50.000

6-** Analog In/Out

6-0* Analog I/O Mode

6-00 Live Zero Timeout Time

1-99 s *10 s

6-01 Live Zero TimeoutFunction

*[0] O

[1] Freeze output

[2] Stop

[3] Jogging

[4] Max speed

[5] Stop and trip

6-1* Analog Input 1

6-10 Terminal 53 Low Voltage

0.00–9.99 V *0.07 V

6-11 Terminal 53 High Voltage

0.01–10.00 V *10.00 V

6-12 Terminal 53 Low Current

0.00–19.99 mA *0.14 mA

6-13 Terminal 53 High Current

0.01–20.00 mA *20.00 mA

6-14 Term. 53 Low Ref./Feedb.

Value

-4999-4999 *0.000

6-15 Term. 53 High Ref./Feedb.

Value

-4999-4999 *50.000

6-16 Terminal 53 Filter Time

Constant

0.01–10.00 s *0.01 s

18 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 23

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

6-19 Terminal 53 mode

*[0] Voltage mode

[1] Current mode 4

6-2* Analog Input 2

6-22 Terminal 60 Low Current

0.00–19.99 mA *0.14 mA

6-23 Terminal 60 High Current

0.01–20.00 mA *20.00 mA

6-24 Term. 60 Low Ref./Feedb.

Value

-4999-4999 *0.000

6-25 Term. 60 High Ref./Feedb.

Value

-4999–4999 *50.00

6-26 Terminal 60 Filter Time

Constant

0.01–10.00 s *0.01 s

6-8* LCP Potentiometer

6-80 LCP Potmeter Enable

[0] Disabled

*[1] Enable

6-81 LCP potm. Low Reference

-4999–4999 *0.000

6-82 LCP potm. High Reference

-4999–4999 *50.00

6-9* Analog Output xx

6-90 Terminal 42 Mode

*[0] 0-20 mA

[1] 4-20 mA

[2] Digital Output

6-91 Terminal 42 Analog Output

*[0] No operation

[10] Output Frequency

[11] Reference

[12] Feedback

[13] Motor Current

[16] Power

[19] DC Link Voltage

[20] Bus Reference

6-92 Terminal 42 Digital Output

See parameter 5-40

*[0] No Operation

[80] SL Digital Output A

6-93 Terminal 42 Output Min

Scale

0.00-200.0% *0.00%

6-94 Terminal 42 Output Max

Scale

0.00-200.0% *100.0%

7-** Controllers

7-2* Process Ctrl. Feedb

7-20 Process CL Feedback 1

Resource

*[0] NoFunction

[1] Analog Input 53

[2] Analog input 60

[8] PulseInput33

[11] LocalBusRef

7-3* Process PI

Ctrl. 7-30 Process PI Normal/

Inverse Ctrl

*[0] Normal

[1] Inverse

7-31 Process PI Anti Windup

[0] Disable

*[1] Enable

7-32 Process PI Start Speed

0.0–200.0 Hz *0.0 Hz

7-33 Process PI Proportional

Gain

0.00–10.00 *0.01

7-34 Process PI Integral Time

0.10–9999 s *9999 s

7-38 Process PI Feed Forward

Factor

0–400% *0%

7-39 On Reference Bandwidth

0–200% *5%

8-** omm. and Options

8-0* General Settings

8-01 Control Site

*[0] Digital and ControlWord

[1] Digital only

[2] ControlWord only

8-02 Control Word Source

[0] None

*[1] FC RS485

8-03 Control Word Timeout

Time

0.1–6500 s *1.0 s

8-04 Control Word Timeout

Function

*[0] O

[1] Freeze Output

[2] Stop

[3] Jogging

[4] Max. Speed

[5] Stop and trip

8-06 Reset Control Word

Timeout

*[0] No Function

[1] Do reset

8-3* FC Port Settings

8-30 Protocol

*[0] FC

[2] Modbus

8-31 Address

1-247 *1

8-32 FC Port Baud Rate

[0] 2400 Baud

[1] 4800 Baud

*[2] 9600 Baud For choose FC

Bus in 8-30

*[3] 19200 Baud For choose

Modbus in 8-30

[4] 38400 Baud

8-33 FC Port Parity

*[0] Even Parity, 1 Stop Bit

[1] Odd Parity, 1 Stop Bit

[2] No Parity, 1 Stop Bit

[3] No Parity, 2 Stop Bits

8-35 Minimum Response Delay

0.001–0.5 *0.010 s

8-36 Max Response Delay

0.100–10.00 s *5.000 s

8-4* FC MC protocol set

8-43 FC Port PCD Read Congu-

ration

*[0] None Expressionlimit

[1] [1500] Operation Hours

[2] [1501] Running Hours

[3] [1502] kWh Counter

[4] [1600] Control Word

[5] [1601] Reference [Unit]

[6] [1602] Reference %

[7] [1603] Status Word

[8] [1605] Main Actual Value [%]

[9] [1609] Custom Readout

[10] [1610] Power [kW]

[11] [1611] Power [hp]

[12] [1612] Motor Voltage

[13] [1613] Frequency

[14] [1614] Motor Current

[15] [1615] Frequency [%]

[16] [1618] Motor Thermal

[17] [1630] DC Link Voltage

[18] [1634] Heatsink Temp.

[19] [1635] Inverter Thermal

[20] [1638] SL Controller State

[21] [1650] External Reference

[22] [1651] Pulse Reference

[23] [1652] Feedback [Unit]

[24] [1660] Digital Input

18,19,27,33

[25] [1661] Digtial Input 29

[26] [1662] Analog Input 53 (V)

[27] [1663] Analog Input 53 (mA)

[28] [1664] Analog Input 60

[29] [1665] Analog Output 42

[mA]

[30] [1668] Freq. Input 33 [Hz]

[31] [1671] Relay Output [bin]

[32] [1672] Counter A

[33] [1673] Counter B

[34] [1690] Alarm Word

[35] [1692] Warning Word

[36] [1694] Ext. Status Word

8-5* Digital/Bus

8-50 Coasting Select

[0] DigitalInput

[1] Bus

[2] LogicAnd

*[3] LogicOr

8-51 Quick Stop Select

See par. 8-50 * [3] LogicOr

8-52 DC Brake Select

See par. 8-50 *[3] LogicOr

8-53 Start Select

See par. 8-50 *[3] LogicOr

8-54 Reversing Select

See par. 8-50 *[3] LogicOr

8-55 Set-up Select

See par. 8-50 *[3] LogicOr

8-56 Preset Reference Select

See parameter 8-50 * [3] LogicOr

8-8* Bus communication

Diagnostics

8-80 Bus Message Count

0-0 N/A *0 N/A

8-81 Bus Error Count

0-0 N/A *0 N/A

8-82 Slave Messages Rcvd

0-0 N/A *0 N/A

8-83 Slave Error Count

0-0 N/A *0 N/A

8-9* Bus Jog / Feedback

8-94 Bus feedback 1

0x8000-0x7FFF *0

13-** Smart Logic

13-0* SLC Settings

13-00 SL Controller Mode

*[0] O

[1] On

13-01 Start Event

[0] False

[1] True

[2] Running

[3] InRange

[4] OnReference

[7] OutOfCurrentRange

[8] BelowILow

[9] AboveIHigh

[16] ThermalWarning

[17] MainOutOfRange

[18] Reversing

[19] Warning

[20] Alarm_Trip

[21] Alarm_TripLock

[22-25] Comparator 0-3

[26-29] LogicRule0-3

[33] DigitalInput_18

[34] DigitalInput_19

[35] DigitalInput_27

[36] DigitalInput_29

[38] DigitalInput_33

*[39] StartCommand

[40] DriveStopped

13-02 Stop Event

See parameter 13-01 * [40]

DriveStopped

13-03 Reset SLC

*[0] Do not reset

[1] Reset SLC

1 1

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 19

Page 24

Quick Guide

VLT® Micro Drive FC 51

11

13-1* Comparators

13-10 Comparator Operand

*[0] Disabled

[1] Reference

[2] Feedback

[3] MotorSpeed

[4] MotorCurrent

[6] MotorPower

[7] MotorVoltage

[8] DCLinkVoltage

[12] AnalogInput53

[13] AnalogInput60

[18] PulseInput33

[20] AlarmNumber

[30] CounterA

[31] CounterB

13-11 Comparator Operator

[0] Less Than

*[1] Approximately equals

[2] Greater Than

13-12 Comparator Value

-9999–9999 *0.0

13-2* Timers

13-20 SL Controller Timer

0.0–3600 s *0.0 s

13-4* Logic Rules

13-40 Logic Rule Boolean 1

See par. 13-01 *[0] False

[30] - [32] SL Time-out 0-2

13-41 Logic Rule Operator 1

*[0] Disabled

[1] And

[2] Or

[3] And not

[4] Or not

[5] Not and

[6] Not or

[7] Not and not

[8] Not or not

13-42 Logic Rule Boolean 2

See par. 13-40 * [0] False

13-43 Logic Rule Operator 2

See par. 13-41 *[0] Disabled

13-44 Logic Rule Boolean 3

See par. 13-40 * [0] False

13-5* States

13-51 SL Controller Event

See par. 13-40 *[0] False

13-52 SL Controller Action

*[0] Disabled

[1] NoAction

[2] SelectSetup1

[3] SelectSetup2

[10-17] SelectPresetRef0-7

[18] SelectRamp1

[19] SelectRamp2

[22] Run

[23] RunReverse

[24] Stop

[25] Qstop

[26] DCstop

[27] Coast

[28] FreezeOutput

[29] StartTimer0

[30] StartTimer1

[31] StartTimer2

[32] Set Digital Output A Low

[33] Set Digital Output B Low

[38] Set Digital Output A High

[39] Set Digital Output B High

[60] ResetCounterA

[61] ResetCounterB

14-** Special Functions

14-0* Inverter Switching

14-01 Switching Frequency

[0] 2 kHz

*[1] 4 kHz

[2] 8 kHz

[4] 16 kHz not available for M5

14-03 Overmodulation

[0] O

*[1] On

14-1* Mains monitoring

14-12 Function at mains

imbalance

*[0] Trip

[1] Warning

[2] Disabled

14-2* Trip Reset

14-20 Reset Mode

*[0] Manual reset

[1-9] AutoReset 1-9

[10] AutoReset 10

[11] AutoReset 15

[12] AutoReset 20

[13] Innite auto reset

[14] Reset at power up

14-21 Automatic Restart Time

0–600s * 10s

14-22 Operation Mode

*[0] Normal Operation

[2] Initialisation 14-26 Action At

Inverter Fault

*[0] Trip

[1] Warning 14-4* Energy

Optimising

14-41 AEO Minimum Magnetisation

40–75 %*66 %

14-9* Fault Settings

14-90 Fault level[3] Trip Lock

[4] Trip with delayed reset

15-** Drive Information

15-0* Operating Data

15-00 Operating Days

15-01 Running Hours

15-02 kWh Counter

15-03 Power Ups

15-04 Over Temps

15-05 Over Volts

15-06 Reset kWh Counter

*[0] Do not reset

[1] Reset counter

15-07 Reset Running Hours

Counter

*[0] Do not reset

[1] Reset counter

15-3* Fault Log

15-30 Fault Log: Error Code

15-4* Drive Identication

15-40 FC Type

15-41 Power Section

15-42 Voltage

15-43 Software Version

15-46 Frequency Converter

Order. No

15-48 LCP Id No

15-51 Frequency Converter

Serial No

16-** Data Readouts 16-0*

General Status

16-00 Control Word

0-0XFFFF

16-01 Reference [Unit]

-4999–4999 *0.000

16-02 Reference %

-200.0–200.0% *0.0%

16-03 Status Word

0–0XFFFF

16-05 Main Actual Value [%]

-200.0–200.0% *0.0%

16-09 Custom Readout

Dep. on par. 0-31, 0-32

16-1* Motor Status

16-10 Power [kW]

16-11 Power [hp]

16-12 Motor Voltage [V]

16-13 Frequency [Hz]

16-14 Motor Current [A]

16-15 Frequency [%]

16-18 Motor Thermal [%]

16-3* Drive Status

16-30 DC Link Voltage

16-34 Heat sink Temp.

16-35 Inverter Thermal

16-36 Inv.Nom. Current

16-37 Inv. Max. Current

16-38 SL Controller State

16-5* Ref./Feedb.

16-50 External Reference

16-51 Pulse Reference

16-52 Feedback [Unit]

16-6* Inputs/Outputs

16-60 Digital Input 18,19,27,33

0-1111

16-61 Digital Input 29

0-1

16-62 Analog Input 53 (volt)

16-63 Analog Input 53 (current)

16-64 Analog Input 60

16-65 Analog Output 42 [mA]

16-68 Pulse Input [Hz]

16-71 Relay Output [bin]

16-72 Counter A

16-73 Counter B

16-8* Fieldbus/FC Port

16-86 FC Port REF 1

0x8000-0x7FFFF

16-9* Diagnosis Readouts

16-90 Alarm Word

0-0XFFFFFFFF

16-92 Warning Word

0-0XFFFFFFFF

16-94 Ext. Status Word

0-0XFFFFFFFF

18-** Extended Motor Data

18-8* Motor Resistors

18-80 Stator Resistance (High

resolution)

0.000–99.990 ohm *0.000 ohm

18-81 Stator Leakage

Reactance(High resolution)

0.000–99.990 ohm *0.000 ohm

20 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 25

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1.6 Troubleshooting

1.6.1 Warnings and Alarms

Number Description WarningAlarm Trip

Lock

2 Live zero error X X Signal on terminal 53 or 60 is less than 50% of the value set

nom

nom

1)

1)

1)

and I

nom

X X X Missing phase on supply side, or too high voltage imbalance.

X X DC-link voltage exceeds the limit.

X X DC-link voltage drops below the voltage warning limit.

X X Thermistor or thermistor connection is disconnected.

X Wrong setting for motor voltage and/or motor current.

X Motor current is too low. Check settings.

X All parameter settings are initialized to default settings.

X No communication between LCP and frequency converter.

4

7

8

9 Inverter overloaded X X More than 100% load for too long.

10 Motor ETR overtemperature X X Motor is too hot. The load has exceeded 100% for too long.

11 Motor thermistor overtem-

12 Torque limit X Torque exceeds value set in either parameter 4-16 Torque Limit

13 Overcurrent X X X Inverter peak current limit is exceeded.

14 Ground fault X X X Discharge from output phases to ground.

16 Short circuit X X Short circuit in motor or on motor terminals.

17 Control word timeout X X No communication to frequency converter.

25 Brake resistor short-circuited X X Brake resistor is short-circuited, thus the brake function is

27 Brake chopper short-circuited X X Brake transistor is short-circuited, thus the brake function is

28 Brake check X Brake resistor is not connected/working.

29 Power board over temp X X X Heat sink cutout temperature has been reached.

30 Motor phase U missing X X Motor phase U is missing. Check the phase.

31 Motor phase V missing X X Motor phase V is missing. Check the phase.

32 Motor phase W missing X X Motor phase W is missing. Check the phase.

38 Internal fault X X Contact local Danfoss supplier.

44 Ground fault X X Discharge from output phases to ground.

47 Control voltage fault X X 24 V DC is overloaded.

51 AMA check U

52 AMA low I

59 Current limit X Frequency converter overload.

63 Mechanical brake low X Actual motor current has not exceeded the release brake-

80 Frequency converter initialized

84 The connection between

85 Key disabled X See parameter group 0-4* LCP.

86 Copy fail X An error occurred while copying from frequency converter to

87 LCP data invalid X Occurs when copying from LCP if the LCP contains erroneous

Mains phase loss

DC over voltage

DC under voltage

perature

to default value

frequency converter and LCP

is lost

Error Cause of problem

in:

Parameter 6-10 Terminal 53 Low Voltage.

•

Parameter 6-12 Terminal 53 Low Current.

•

Parameter 6-22 Terminal 54 Low Current.

•

Check supply voltage.

Motor Mode or parameter 4-17 Torque Limit Generator Mode.

disconnected.

disconnected.

current within the start delay-time window.

LCP, or from LCP to frequency converter.

data - or if no data was uploaded to the LCP.

1 1

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 21

Page 26

Quick Guide

VLT® Micro Drive FC 51

11

Number Description WarningAlarm Trip

Lock

88 LCP data not compatible X Occurs when copying from LCP if data are moved between

89 Parameter read only X Occurs when trying to write to a read-only parameter.

90 Parameter database busy X LCP and RS485 connection are trying to update parameters

91 Parameter value is not valid in

this mode

92 Parameter value exceeds the

minimum/maximum limits

nw run Not while running X Parameters can only be changed when the motor is stopped.

Err. A wrong password was

entered

1) These faults are caused by mains distortions. Install a Danfoss line lter to rectify this problem.

Table 1.6 Warnings and Alarms Code List

X Occurs when trying to write an illegal value to a parameter.

X Occurs when trying to set a value outside the range.

X Occurs when using a wrong password for changing a

Error Cause of problem

frequency converters with major dierences in software

versions.

simultaneously.

password-protected parameter.

22 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 27

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1.7 Specications

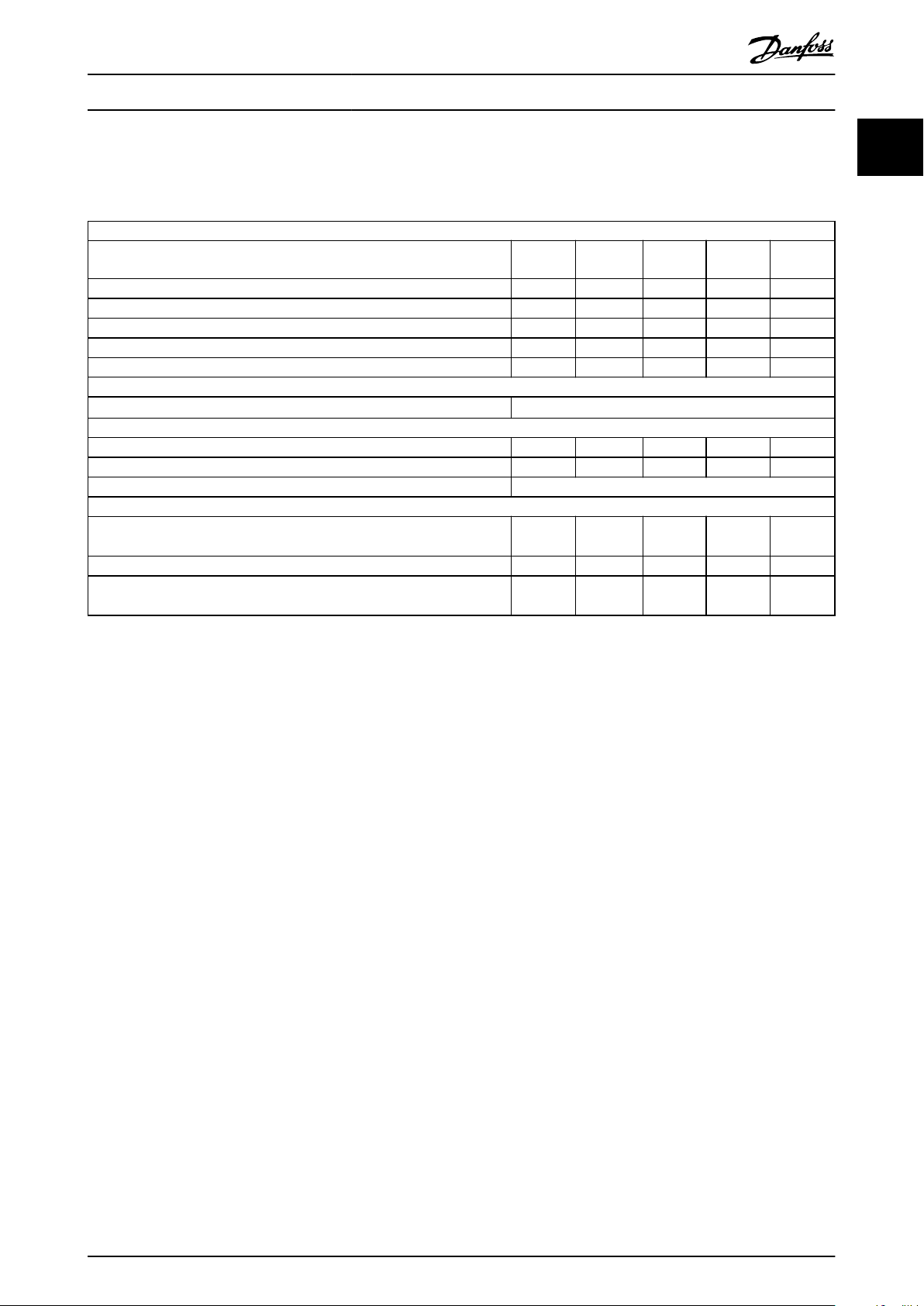

1.7.1 Mains Supply 1x200–240 V AC

Normal overload 150% for 1 minute

Frequency converter

Typical shaft output [kW]

Typical shaft output [hp] 0.25 0.5 1 2 3

Enclosure protection rating IP20 M1 M1 M1 M2 M3

Output current

Continuous (3x200–240 V AC) [A] 1.2 2.2 4.2 6.8 9.6

Intermittent (3x200–240 V AC) [A] 1.8 3.3 6.3 10.2 14.4

Maximum cable size:

(Mains, motor) [mm2/AWG]

Maximum input current

Continuous (1x200–240 V) [A] 3.3 6.1 11.6 18.7 26.4

Intermittent (1x200–240 V) [A] 4.5 8.3 15.6 26.4 37.0

Maximum mains fuses [A] See chapter 1.3.3 Fuses

Environment

Estimated power loss [W],

Best case/typical

Weight enclosure IP20 [kg] 1.1 1.1 1.1 1.6 3.0

Eciency [%],

Best case/typical

1)

2)

PK18

0.18

12.5/

15.5

95.6/

94.5

PK37

0.37

20.0/

25.0

96.5/

95.6

PK75

0.75

4/10

36.5/

44.0

96.6/

96.0

P1K5

1.5

61.0/

67.0

97.0/

96.7

P2K2

81.0/

85.1

96.9/

97.1

1 1

2.2

Table 1.7 Mains Supply 1x200–240 V AC

1) Applies for dimensioning of frequency converter cooling. If the switching frequency is higher than the default setting, the power losses may

increase. LCP and typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to

drives.danfoss.com/knowledge-center/energy-eciency-directive/#/.

2) Eciency measured at nominal current. For energy eciency class, see chapter 1.8.1 Surroundings. For part load losses, see drives.danfoss.com/

knowledge-center/energy-eciency-directive/#/.

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 23

Page 28

Quick Guide

VLT® Micro Drive FC 51

11

1.7.2 Mains Supply 3x200–240 V AC

Normal overload 150% for 1 minute

Frequency converter

Typical shaft output [kW]

Typical shaft output [hp] 0.33 0.5 1 2 3 5

Enclosure protection rating IP20 M1 M1 M1 M2 M3 M3

Output current

Continuous (3x200–240 V) [A] 1.5 2.2 4.2 6.8 9.6 15.2

Intermittent (3x200–240 V) [A] 2.3 3.3 6.3 10.2 14.4 22.8

Maximum cable size:

(Mains, motor) [mm2/AWG]

Maximum input current

Continuous (3x200–240 V) [A] 2.4 3.5 6.7 10.9 15.4 24.3

Intermittent (3x200–240 V) [A] 3.2 4.6 8.3 14.4 23.4 35.3

Maximum mains fuses [A] See chapter 1.3.3 Fuses

Environment

Estimated power loss [W]

Best case/typical

Weight enclosure IP20 [kg] 1.1 1.1 1.1 1.6 3.0 3.0

Eciency [%]

Best case/typical

1)

2)

PK25

0.25

14.0/

20.0

96.4/

94.9

PK37

0.37

19.0/

24.0

96.7/

95.8

PK75

0.75

31.5/

39.5

97.1/

96.3

4/10

P1K5

1.5

51.0/

57.0

97.4/

97.2

P2K2

2.2

72.0/

77.1

97.2/

97.4

P3K7

115.0/

122.8

97.3/

97.4

3.7

Table 1.8 Mains Supply 3x200–240 V AC

1) Applies for dimensioning of frequency converter cooling. If the switching frequency is higher than the default setting, the power losses may

increase. LCP and typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to

drives.danfoss.com/knowledge-center/energy-eciency-directive/#/.

2) Eciency measured at nominal current. For energy eciency class, see chapter 1.8.1 Surroundings. For part load losses, see drives.danfoss.com/

knowledge-center/energy-eciency-directive/#/.

24 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 29

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

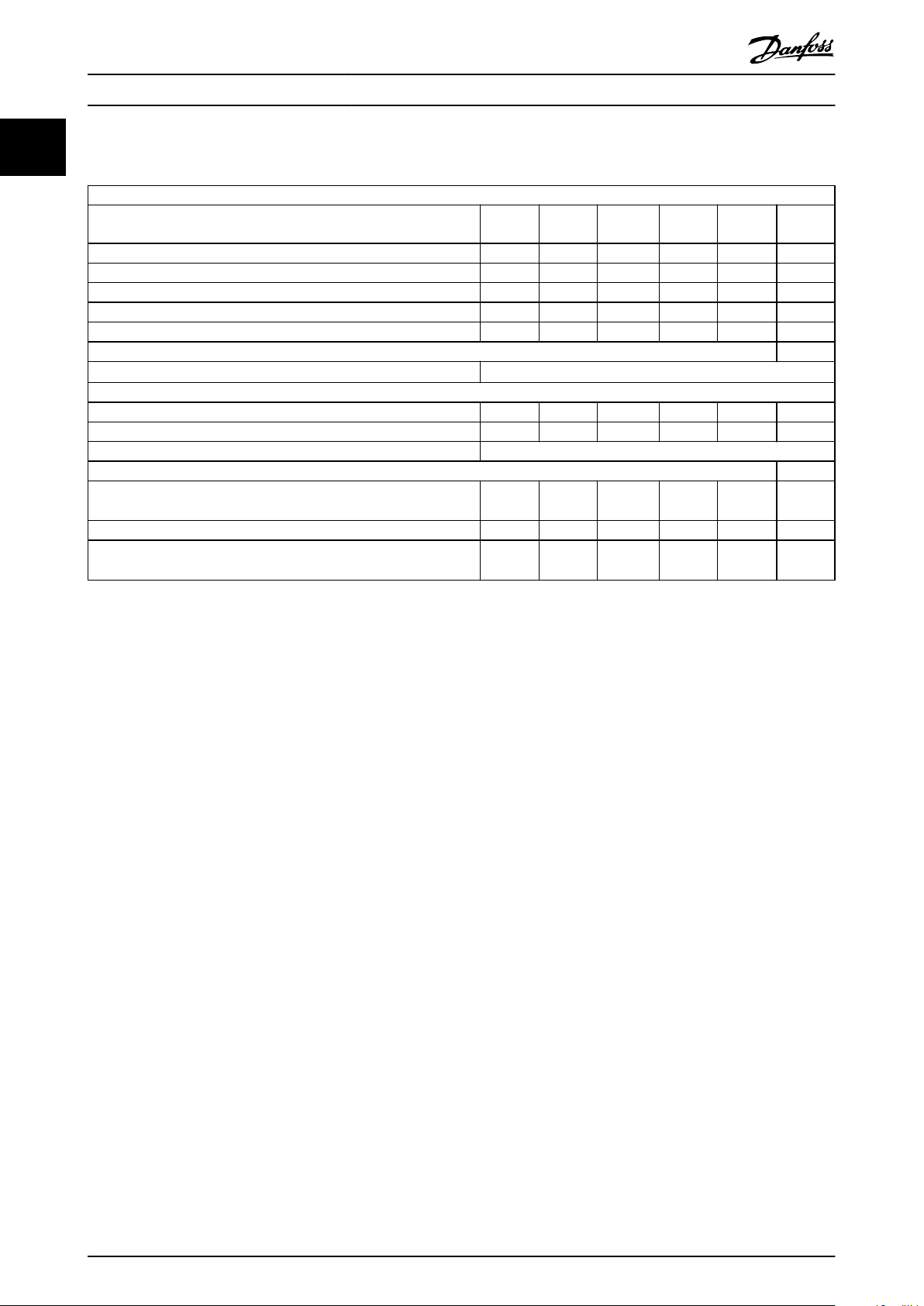

1.7.3 Mains Supply 3x380–480 V AC

Normal overload 150% for 1 minute

Frequency converter

Typical shaft output [kW]

Typical shaft output [hp] 0.5 1 2 3 4 5.5

Enclosure protection rating IP20 M1 M1 M2 M2 M3 M3

Output current

Continuous (3x380–440 V) [A] 1.2 2.2 3.7 5.3 7.2 9.0

Intermittent (3x380–440 V) [A] 1.8 3.3 5.6 8.0 10.8 13.7

Continuous (3x440–480 V) [A] 1.1 2.1 3.4 4.8 6.3 8.2

Intermittent (3x440–480 V) [A] 1.7 3.2 5.1 7.2 9.5 12.3

Maximum cable size:

(Mains, motor) [mm2/AWG]

Maximum input current

Continuous (3x380–440 V) [A] 1.9 3.5 5.9 8.5 11.5 14.4

Intermittent (3x380–440 V) [A] 2.6 4.7 8.7 12.6 16.8 20.2

Continuous (3x440–480 V) [A] 1.7 3.0 5.1 7.3 9.9 12.4

Intermittent (3x440–480 V) [A] 2.3 4.0 7.5 10.8 14.4 17.5

Maximum mains fuses [A] See chapter 1.3.3 Fuses

Environment

Estimated power loss [W]

Best case/typical

Weight enclosure IP20 [kg] 1.1 1.1 1.6 1.6 3.0 3.0

Eciency [%]

Best case/typical

1)

2)

PK37

0.37

18.5/

25.5

96.8/

95.5

PK75

0.75

28.5/

43.5

97.4/

96.0

P1K5

1.5

41.5/

56.5

98.0/

97.2

4/10

P2K2

2.2

57.5/

81.5

97.9/

97.1

P3K0

3.0

75.0/

101.6

98.0/

97.2

P4K0

98.5/

133.5

98.0/

97.3

1 1

4.0

Table 1.9 Mains Supply 3x380–480 V AC

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 25

Page 30

Quick Guide

VLT® Micro Drive FC 51

11

Normal overload 150% for 1 minute

Frequency converter

Typical shaft output [kW]

Typical shaft output [hp] 7.5 10 15 20 25 30

Enclosure protection rating IP20 M3 M3 M4 M4 M5 M5

Output current

Continuous (3x380–440 V) [A] 12.0 15.5 23.0 31.0 37.0 43.0

Intermittent (3x380–440 V) [A] 18.0 23.5 34.5 46.5 55.5 64.5

Continuous (3x440–480 V) [A] 11.0 14.0 21.0 27.0 34.0 40.0

Intermittent (3x440–480 V) [A] 16.5 21.3 31.5 40.5 51.0 60.0

Maximum cable size:

(Mains, motor) [mm2/AWG]

Maximum input current

Continuous (3x380–440 V) [A] 19.2 24.8 33.0 42.0 34.7 41.2

Intermittent (3x380–440 V) [A] 27.4 36.3 47.5 60.0 49.0 57.6

Continuous (3x440–480 V) [A] 16.6 21.4 29.0 36.0 31.5 37.5

Intermittent (3x440–480 V) [A] 23.6 30.1 41.0 52.0 44.0 53.0

Maximum mains fuses [A] See chapter 1.3.3 Fuses

Environment

Estimated power loss [W]

Best case/typical

Weight enclosure IP20 [kg] 3.0 3.0

Eciency [%]

Best case/typical

1)

2)

P5K5

5.5

131.0/

166.8

98.0/

97.5

P7K5

7.5

4/10 16/6

175.0/

217.5

98.0/

97.5

P11K

11

290.0/

342.0

97.8/

97.4

P15K

15

387.0/

454.0

97.7/

97.4

P18K

18.5

395.0/

428.0

98.1/

98.0

P22K

22

467.0/

520.0

98.1/

97.9

Table 1.10 Mains Supply 3x380–480 V AC

1) Applies for dimensioning of frequency converter cooling. If the switching frequency is higher than the default setting, the power losses may

increase. LCP and typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to

drives.danfoss.com/knowledge-center/energy-eciency-directive/#/.

2) Eciency measured at nominal current. For energy eciency class, see chapter 1.8.1 Surroundings. For part load losses, see drives.danfoss.com/

knowledge-center/energy-eciency-directive/#/.

26 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 31

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1.8 General Technical Data

Protection and features

Electronic motor thermal protection against overload.

•

Temperature monitoring of the heat sink ensures that the frequency converter trips if there is overtemperature.

•

The frequency converter is protected against short circuits between motor terminals U, V, W.

•

When a motor phase is missing, the frequency converter trips and issues an alarm.

•

When a mains phase is missing, the frequency converter trips or issues a warning (depending on the load).

•

Monitoring of the DC-link voltage ensures that the frequency converter trips when the DC-link voltage is too low

•

or too high.

The frequency converter is protected against ground faults on motor terminals U, V, W.

•

Mains supply (L1/L, L2, L3/N)

Supply voltage 200–240 V ±10%

Supply voltage 380–480 V ±10%

Supply frequency 50/60 Hz

Maximum imbalance temporary between mains phases 3.0% of rated supply voltage

True power factor ≥0.4 nominal at rated load

Displacement power factor (cosφ) near unity (>0.98)

Switching on input supply L1/L, L2, L3/N (power-ups) Maximum 2 times/minute

Environment according to EN60664-1 Overvoltage category III/pollution degree 2

The unit is suitable for use on a circuit capable of delivering not more than 100000 RMS symmetrical Amperes, 240/480 V

maximum.

1 1

Motor output (U, V, W)

Output voltage 0–100% of supply voltage

Output frequency 0–200 Hz (VVC+), 0–400 Hz (u/f)

Switching on output Unlimited

Ramp times 0.05–3600 s

Cable length and cross-section

Maximum motor cable length, shielded/armored (EMC-correct installation) 15 m (49 ft)

Maximum motor cable length, unshielded/unarmored 50 m (164 ft)

Maximum cross-section to motor, mains

Connection to load sharing/brake (M1, M2, M3) 6.3 mm insulated Faston plugs

Maximum cross-section to load sharing/brake (M4, M5) 16 mm2/6 AWG

Maximum cross-section to control terminals, rigid wire 1.5 mm2/16 AWG (2x0.75 mm2)

Maximum cross-section to control terminals, exible cable 1 mm2/18 AWG

Maximum cross-section to control terminals, cable with enclosed core 0.5 mm2/20 AWG

Minimum cross-section to control terminals 0.25 mm2 (24 AWG)

1) See chapter 1.7 Specications for more information.

1)

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 27

Page 32

Quick Guide

VLT® Micro Drive FC 51

11

Digital inputs (pulse/encoder inputs)

Programmable digital inputs (pulse/encoder) 5 (1)

Terminal number 18, 19, 27, 29, 33

Logic PNP or NPN

Voltage level 0–24 V DC

Voltage level, logic 0 PNP <5 V DC

Voltage level, logic 1 PNP >10 V DC

Voltage level, logic 0 NPN >19 V DC

Voltage level, logic 1 NPN <14 V DC

Maximum voltage on input 28 V DC

Input resistance, R

Maximum pulse frequency at terminal 33 5000 Hz

Minimum pulse frequency at terminal 33 20 Hz

Analog inputs

Number of analog inputs 2

Terminal number 53, 60

Voltage mode (terminal 53) Switch S200=OFF(U)

Current mode (terminal 53 and 60) Switch S200=ON(I)

Voltage level 0–10 V

Input resistance, R

Maximum voltage 20 V

Current level 0/4 to 20 mA (scaleable)

Input resistance, R

Maximum current 30 mA

i

i

i

Approximately 4000 Ω

Approximately 10000 Ω

Approximately 200 Ω

Analog output

Number of programmable analog outputs 1

Terminal number 42

Current range at analog output 0/4–20 mA

Maximum load to common at analog output 500 Ω

Maximum voltage at analog output 17 V

Accuracy on analog output Maximum error: 0.8% of full scale

Scan interval 4 ms

Resolution on analog output 8 bit

Scan interval 4 ms

Control card, RS485 serial communication

Terminal number 68 (P, TX+, RX+), 69 (N, TX-, RX-)

Terminal number 61 Common for terminals 68 and 69

Control card, 24 V DC output

Terminal number 12

Maximum load (M1 and M2) 100 mA

Maximum load (M3) 50 mA

Maximum load (M4 and M5) 80 mA

28 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 33

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

Relay output

Programmable relay output 1

Relay 01 terminal number 01–03 (break), 01–02 (make)

Maximum terminal load (AC-1)1) on 01–02 (NO) (Resistive load) 250 V AC, 2 A

Maximum terminal load (AC-15)1) on 01–02 (NO) (Inductive load @ cosφ 0.4) 250 V AC, 0.2 A

Maximum terminal load (DC-1)1) on 01–02 (NO) (Resistive load) 30 V DC, 2 A

Maximum terminal load (DC-13)1) on 01–02 (NO) (Inductive load) 24 V DC, 0.1 A

Maximum terminal load (AC-1)1) on 01–03 (NC) (Resistive load) 250 V AC, 2 A

Maximum terminal load (AC-15)1) on 01–03 (NC) (Inductive load @ cosφ 0.4) 250 V AC, 0.2 A

Maximum terminal load (DC-1)1) on 01–03 (NC) (Resistive load) 30 V DC, 2 A

Minimum terminal load on 01–03 (NC), 01–02 (NO) 24 V DC 10 mA, 24 V AC 20 mA

Environment according to EN 60664-1 Overvoltage category III/pollution degree 2

1) IEC 60947 part 4 and 5

Control card, 10 V DC output

Terminal number 50

Output voltage 10.5 V ±0.5 V

Maximum load 25 mA

NOTICE

All inputs, outputs, circuits, DC supplies, and relay contacts are galvanically isolated from the supply voltage (PELV) and

other high-voltage terminals.

Surroundings

Enclosure protection rating IP20

Enclosure kit available IP21, TYPE 1

Vibration test 1.0 g

Maximum relative humidity 5%–95 % (IEC 60721-3-3; Class 3K3 (non-condensing) during operation

Aggressive environment (IEC 60721-3-3), coated class 3C3

Test method according to IEC 60068-2-43 H2S (10 days)

Ambient temperature

Minimum ambient temperature during full-scale operation 0 °C (32 °F)

Minimum ambient temperature at reduced performance -10 °C (14 °F)

Temperature during storage/transport -25 to +65/70 °C (-13 to + 149/158 °F)

Maximum altitude above sea level without derating

Maximum altitude above sea level with derating

Safety standards EN/IEC 61800-5-1, UL 508C

EMC standards, Emission EN 61800-3, EN 61000-6-3/4, EN 55011, IEC 61800-3

EMC standards, Immunity

Energy eciency class IE2

1) Refer to chapter 1.9 Special Conditions for:

Derating for high ambient temperature.

•

Derating for high altitude.

•

2) Determined according to EN 50598-2 at:

Rated load.

•

90% rated frequency.

•

Switching frequency factory setting.

•

Switching pattern factory setting.

•

1)

1)

1)

EN 61800-3, EN 61000-6-1/2, EN 61000-4-2, EN 61000-4-3,

EN 61000-4-4, EN 61000-4-5, EN 61000-4-6

Maximum 40 °C (104 °F)

1000 m (3280 ft)

3000 m (9842 ft)

1 1

MG02BC4P Danfoss A/S © 10/2017 All rights reserved. 29

Page 34

Quick Guide

VLT® Micro Drive FC 51

11

1.9 Special Conditions

1.9.1 Derating for Ambient Temperature

The ambient temperature measured over 24 hours should

be at least 5 °C (41 °F) lower than the maximum ambient

temperature.

If the frequency converter is operated at high ambient

temperature, decrease the continuous output current.

The frequency converter has been designed for operation

at maximum 50 °C (122 °F) ambient temperature with 1

motor size smaller than nominal. Continuous operation at

full load at 50 °C (122 °F) ambient temperature reduces

the lifetime of the frequency converter.

Below 1000 m (3280 ft) altitude, no derating is necessary,

but above 1000 m (3280 ft), decrease the ambient

temperature or the maximum output current.

Decrease the output by 1% per 100 m (328 ft) altitude

above 1000 m (3280 ft), or reduce the maximum ambient

temperature by 1 °C (33.8 °F) per 200 m (656 ft).

1.9.3 Derating for Running at Low Speeds

When a motor is connected to a frequency converter,

check that the cooling of the motor is adequate.

A problem may occur at low speeds in constant torque

applications. Running continuously at low speeds – less

than half the nominal motor speed – may require extra air

cooling. Alternatively, select a larger motor (1 size up).

1.9.2 Derating for Low Air Pressure

The cooling capability of air is decreased at low air

pressure.

CAUTION

INSTALLATION AT HIGH ALTITUDE

For altitudes above 2000 m (6560 ft), contact Danfoss

regarding PELV.

30 Danfoss A/S © 10/2017 All rights reserved. MG02BC4P

Page 35

Quick Guide

Quick Guide•Kurzanleitung•Guide rapide•Guía rápida•Guia Rápido•Краткое

руководство

1.10 Options and Spare Parts

Ordering number Description

132B0100

132B0101

132B0102 LCP Remote Mounting Kit , w/3 m (10 ft) cable, IP55 with LCP 11, IP21 with LCP 12

132B0103 IP20 to NEMA Type 1 conversion kit, M1

132B0104 IP20 to NEMA Type 1 conversion kit, M2

132B0105 IP20 to NEMA Type 1 conversion kit, M3

132B0106 Decoupling plate mounting kit, M1 and M2

132B0107 Decoupling plate mounting kit, M3

132B0108 IP20 to IP21/Type1 conversion kit, M1

132B0109 IP20 to IP21/Type1 conversion kit, M2

132B0110 IP20 to IP21/Type1 conversion kit, M3

132B0111 DIN rail mounting kit, M1/M2

132B0120 IP20 to Nema 1 conversion kit, M4

132B0121 IP20 to Nema 1 conversion kit, M5

132B0122 Decoupling plate mounting kit, M4, M5

132B0126 Enclosure size M1 spare parts kits

132B0127 Enclosure size M2 spare parts kits

132B0128 Enclosure size M3 spare parts kits

132B0129 Enclosure size M4 spare parts kits

132B0130 Enclosure size M5 spare parts kits

132B0131 Blank cover

130B2522

130B2522

130B2533

130B2525

130B2530

130B2523

130B2523

130B2523

130B2526

130B2531

130B2527

130B2523

130B2523

130B2524

130B2526

130B2529

130B2531

130B2528

130B2527

VLT® Control Panel LCP 11 w/o potentiometer

VLT® Control Panel LCP 12 with potentiometer

VLT® Line Filter MCC 107 for 132F0001

VLT® Line Filter MCC 107 for 132F0002

VLT® Line Filter MCC 107 for 132F0003

VLT® Line Filter MCC 107 for 132F0005

VLT® Line Filter MCC 107 for 132F0007

VLT® Line Filter MCC 107 for 132F0008

VLT® Line Filter MCC 107 for 132F0009

VLT® Line Filter MCC 107 for 132F0010

VLT® Line Filter MCC 107 for 132F0012

VLT® Line Filter MCC 107 for 132F0014

VLT® Line Filter MCC 107 for 132F0016

VLT® Line Filter MCC 107 for 132F0017

VLT® Line Filter MCC 107 for 132F0018

VLT® Line Filter MCC 107 for 132F0020

VLT® Line Filter MCC 107 for 132F0022

VLT® Line Filter MCC 107 for 132F0024

VLT® Line Filter MCC 107 for 132F0026