Page 1

Installation Instructions

Mains, Motor and DC Link Terminals

®

VLT

AutomationDrive FC 360

The instructions provide information about the replacement of

the mains terminals, motor terminals, and DC link terminals in

®

the VLT

Only Danfoss-authorised, qualified personnel is allowed to

repair this equipment. The personnel must be familiar with the

instructions and safety measures described in the

VLT

AutomationDrive FC 360.

®

AutomationDrive FC 360 Service Manual.

Items Supplied

Items supplied depend on ordered code number and

enclosure type of the frequency converter.

Code number Items supplied

132b0297

132b0298

132b0299

132b0315

132b0316

132b0317

Mains terminal, enclosure type J6

•

Motor terminal, enclosure type J6

•

DC link terminal, enclosure type J6

•

Mains and motor terminal, enclosure type J7,

•

55 kW (3-phase block)

DC link terminal, enclosure type J7, 55 kW (2-

•

phase block)

Terminal for DC link, mains or motor,

•

enclosure type J7, 75 kW (1 single-phase

block supplied per order)

Safety Instructions

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which

can remain charged even when the frequency converter is

not powered. Failure to wait the specified time after power

has been removed before performing service or repair work,

could result in death or serious injury.

1. Stop the motor.

2. Disconnect AC mains, permanent magnet type

motors, and remote DC-link power supplies,

including battery back-ups, UPS, and DC-link

connections to other frequency converters.

3. Wait for the capacitors to discharge fully, before

performing any service or repair work. The duration

of waiting time is specified in Table 1.1.

Minimum waiting time (minutes)

Voltage [V]

415

380-480 0.37-7.5 kW 11-75 kW

High voltage may be present even when the warning LEDs are off!

Table 1.1 Discharge Time

Tools Required

Screwdrivers:

•

-

-

-

-

-

N8 socket wrench

•

N10 socket wrench

•

N5 Allen key

•

Flat-edged

T10

T20

T25

T30

Danfoss A/S © Rev. 2014-01-17 All rights reserved. MI06P102

Page 2

Installation Instructions

Mains, Motor and DC Link Terminals

®

VLT

AutomationDrive FC 360

Installation

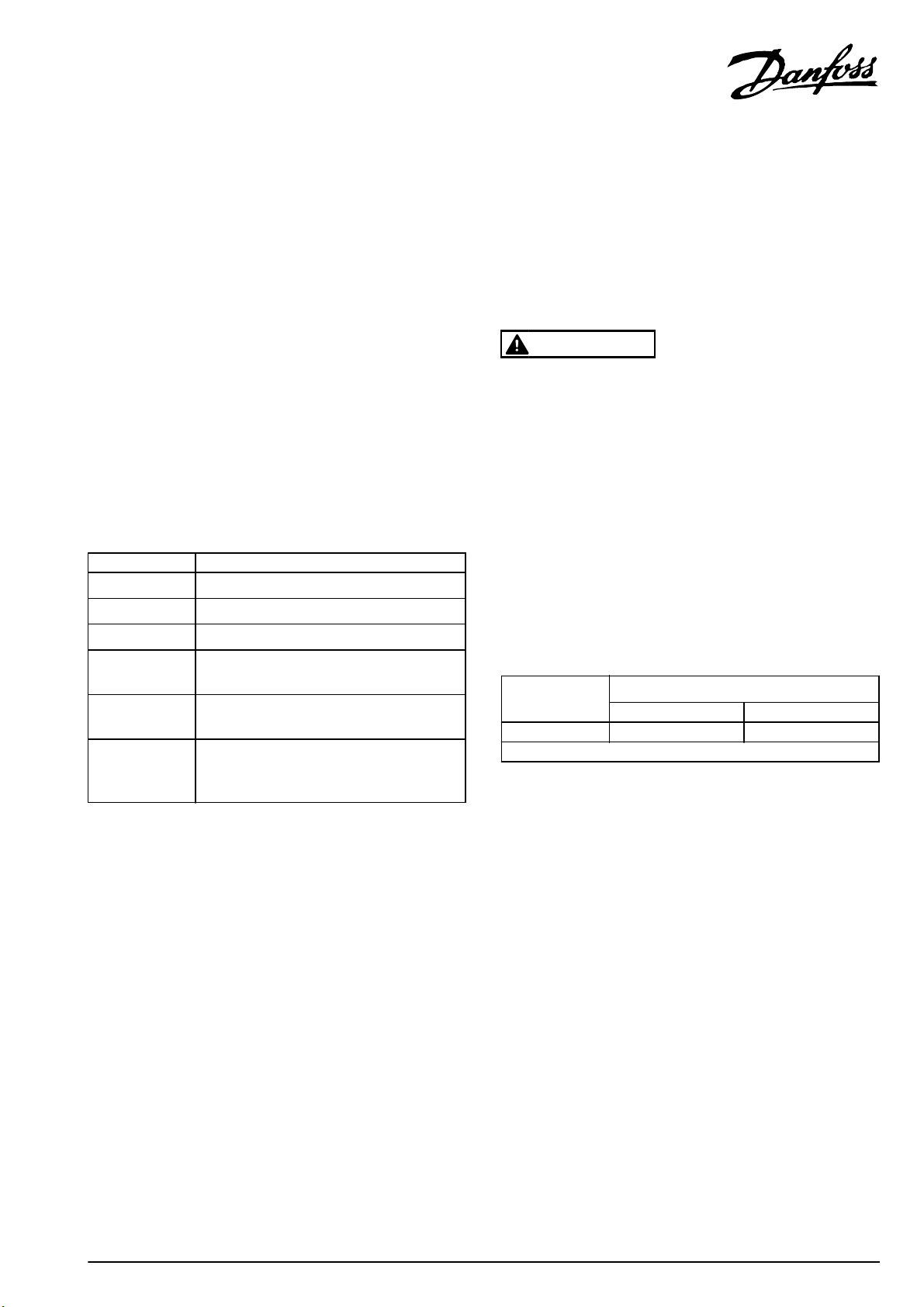

Replacing motor and DC link terminals for enclosure type

J6

1. Follow the instructions in

2. Unscrew the 3 M4x18 (T20) screws holding the

3. Unscrew the 2 M4x12 (T20) screws holding the DC

4. Install new motor or DC link terminals in reverse

®

AutomationDrive FC 360 Service Manual to

VLT

remove the power control card.

busbar to motor terminals, and remove the motor

terminals.

link terminal and remove the DC link terminal.

order.

1 Screws (T20, M4x18), holding the busbar to motor

terminal

2 Screws (T20, M4x12), holding the DC link terminal

Illustration 1.1 Motor Terminals and DC Link Terminals for J6

Replacing mains terminals for enclosure type J6

1. Follow the instructions in FC 360 Service Manual to

remove the power control card.

2. Follow the instructions in FC 360 Service Manual (see

the chapter on power card replacement) to remove:

RFI auxiliary card

•

Mains terminal (L1, L2, L3) screws (3xM4) on

•

rectifier module

Mains input cover

•

Mains input screen and cable

•

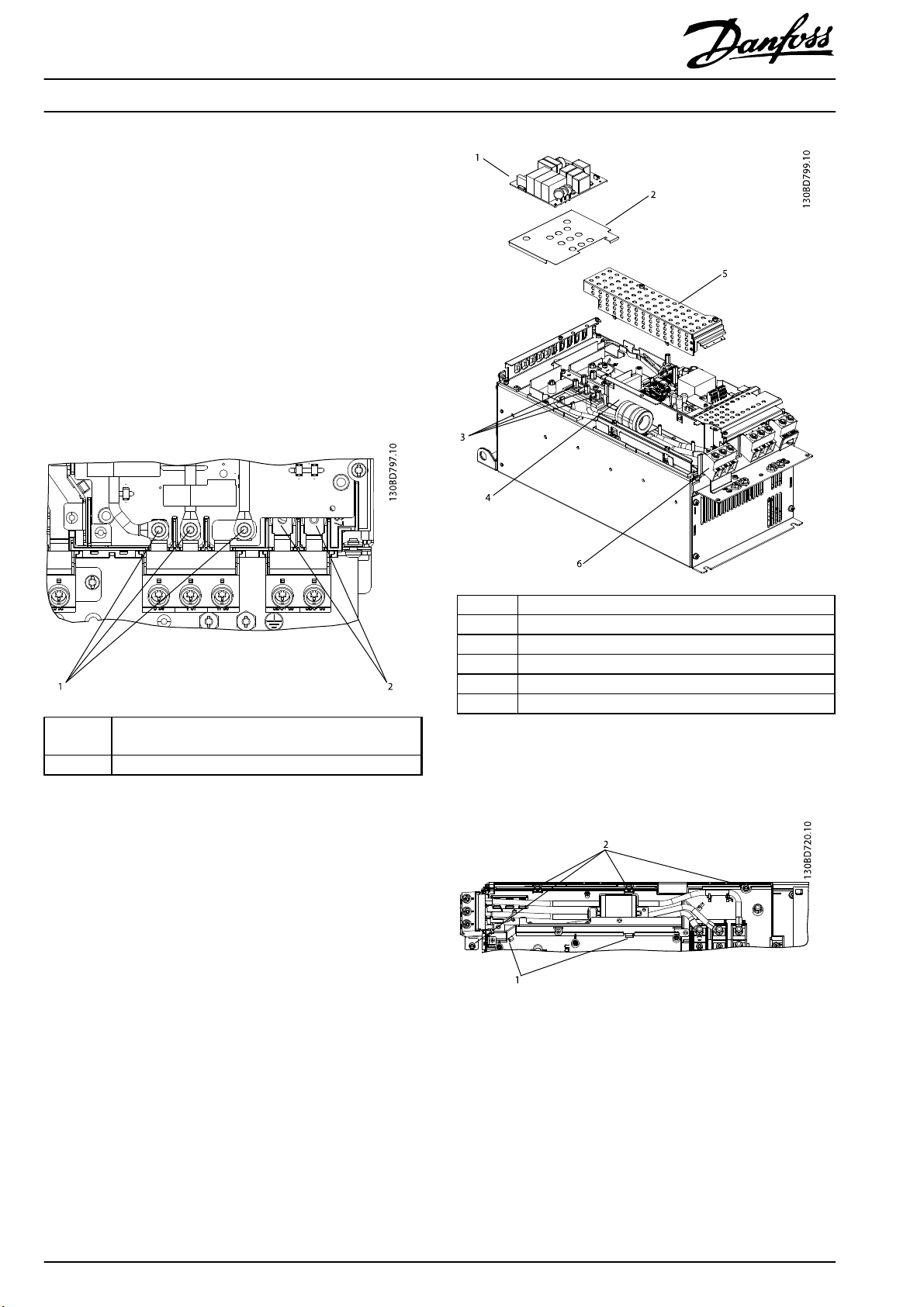

1RFI auxiliary card

2 Insulation foil

3 Mains terminal screws on rectifier module

4 Mains input screen and cable

5Mains input cover

6 Mains terminals

Illustration 1.2 Mains Terminals and Related Components for J6

3. Remove mains terminals and cables.

Illustration 1.3 Mains Terminals and Cables

4. Install new mains terminals in reverse order.

2

Danfoss A/S © Rev. 2014-01-17 All rights reserved. MI06P102

Page 3

Installation Instructions

Replacing mains terminals, motor terminals, and DC link

terminals for enclosure type J7

Mains, Motor and DC Link Terminals

®

VLT

AutomationDrive FC 360

NOTICE

55 kW terminals are supplied in 3-phase and 2-

•

phase blocks.

75 kW terminals are supplied in single-phase

•

blocks.

1. Follow the instructions in FC 360 Service Manual to

remove the power control card of the frequency

converter.

2. Follow the instructions in FC 360 Service Manual (see

chapter on power card replacement) to remove the

following components:

EMC screen plate

•

RFI filter assembly (only needed when

•

replacing a mains terminal).

1 RFI filter assembly

2 EMC screen plate

3 Motor terminals

4DC link terminals

5 Mains terminals

Illustration 1.4 J7 Terminal Overview

3. Unscrew the 2 M5x10 screws (T20) on the defective

terminal, and remove the terminal.

4. Install the new terminal in reverse order.

MI06P102 Danfoss A/S © Rev. 2014-01-17 All rights reserved.

3

Page 4

MI06P102132R0219 Rev. 2014-01-17

*MI06P102*

Loading...

Loading...